control NISSAN PRIMERA 1999 Electronic Manual Online

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 226 of 2267

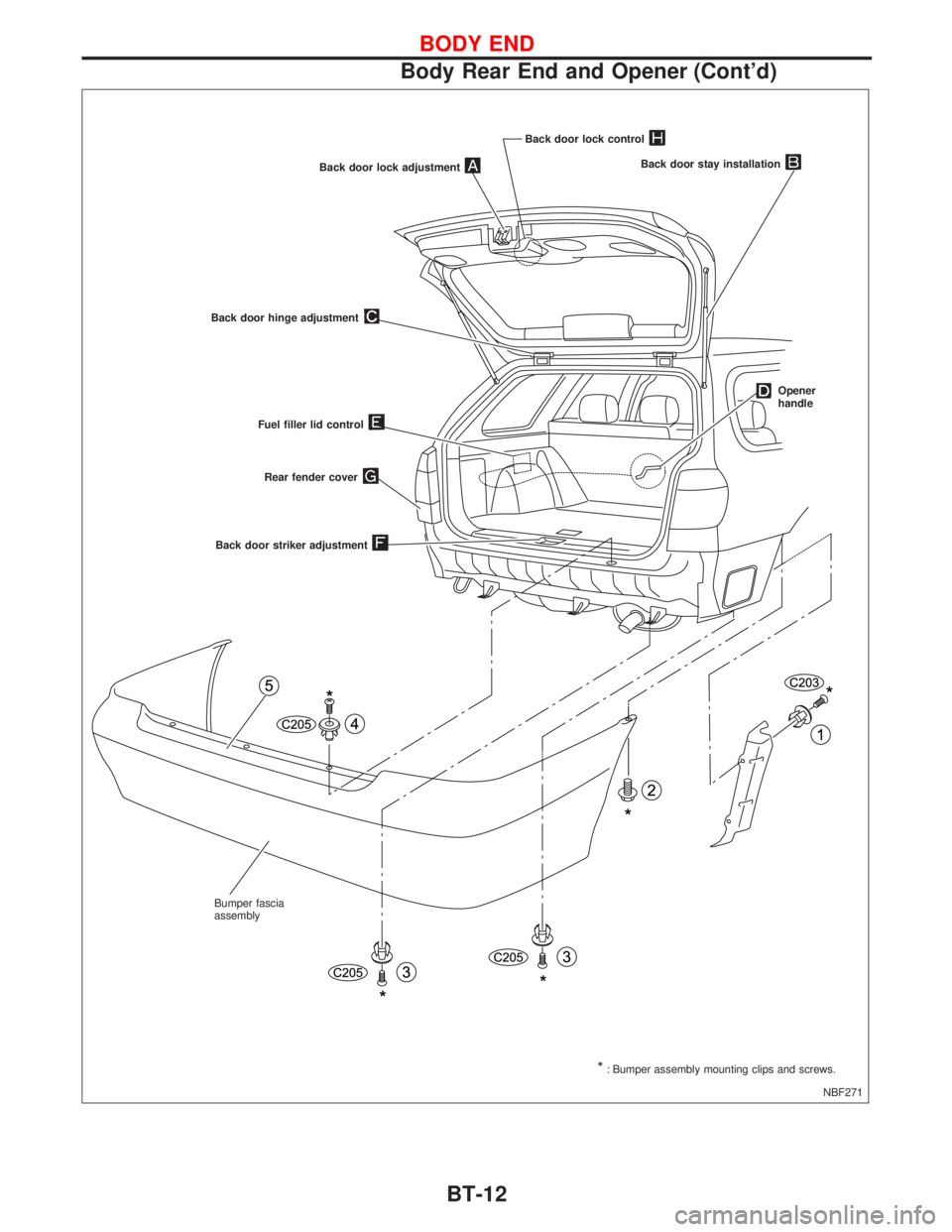

NBF271 Back door lock adjustment

Back door hinge adjustment

Back door stay installation

Opener

handle

Fuel filler lid control

Back door striker adjustment

*: Bumper assembly mounting clips and screws. Bumper fascia

assemblyRear fender cover

Back door lock control

BODY END

Body Rear End and Opener (Cont'd)

BT-12

Page 229 of 2267

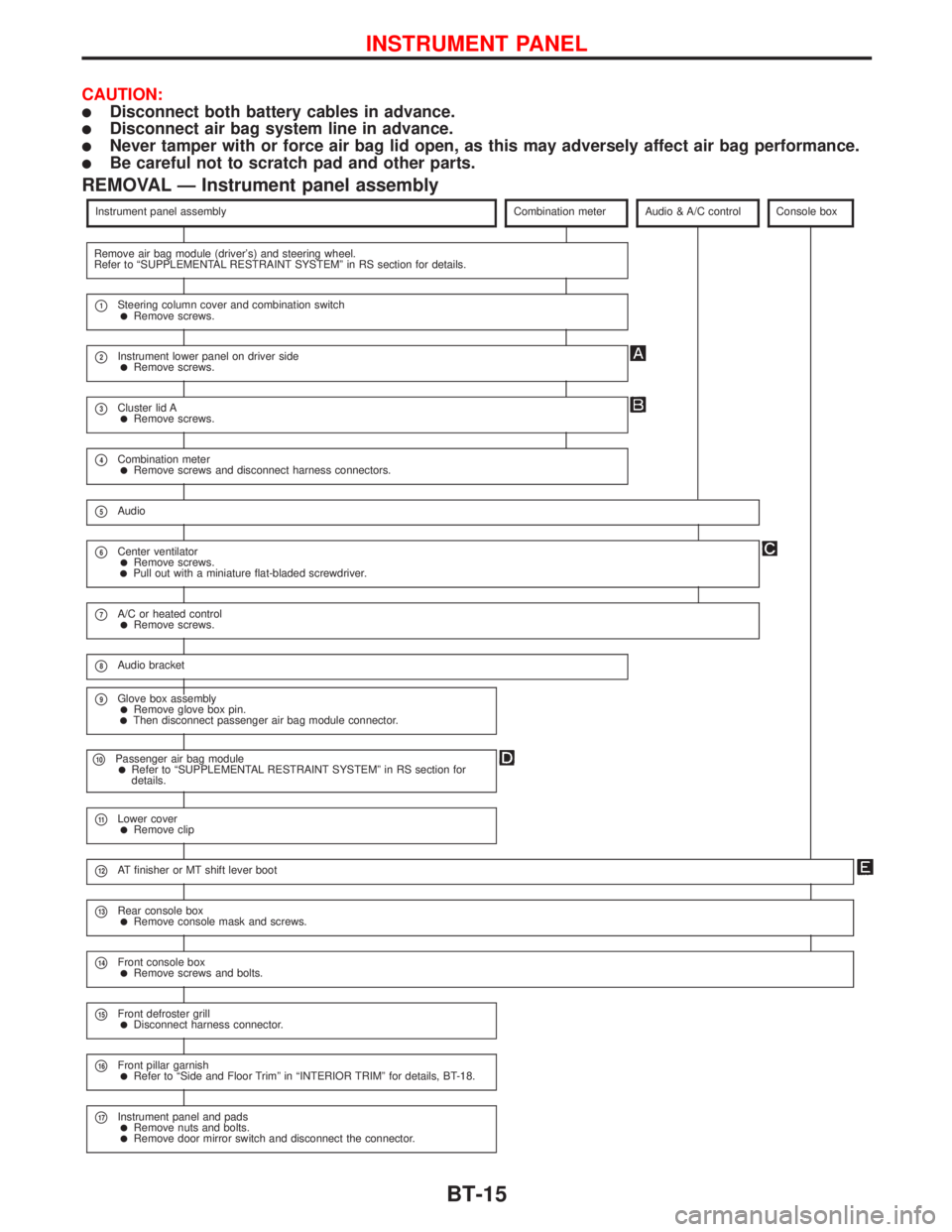

CAUTION:

lDisconnect both battery cables in advance.

lDisconnect air bag system line in advance.

lNever tamper with or force air bag lid open, as this may adversely affect air bag performance.

lBe careful not to scratch pad and other parts.

REMOVAL Ð Instrument panel assembly

Instrument panel assemblyCombination meterAudio & A/C controlConsole box

Remove air bag module (driver's) and steering wheel.

Refer to ªSUPPLEMENTAL RESTRAINT SYSTEMº in RS section for details.

p1Steering column cover and combination switchlRemove screws.

p2Instrument lower panel on driver sidelRemove screws.

p3Cluster lid AlRemove screws.

p4Combination meterlRemove screws and disconnect harness connectors.

p5Audio

p6Center ventilatorlRemove screws.lPull out with a miniature flat-bladed screwdriver.

p7A/C or heated controllRemove screws.

p8Audio bracket

p9Glove box assemblylRemove glove box pin.lThen disconnect passenger air bag module connector.

p10Passenger air bag modulelRefer to ªSUPPLEMENTAL RESTRAINT SYSTEMº in RS section for

details.

p11Lower coverlRemove clip

p12AT finisher or MT shift lever boot

p13Rear console boxlRemove console mask and screws.

p14Front console boxlRemove screws and bolts.

p15Front defroster grilllDisconnect harness connector.

p16Front pillar garnishlRefer to ªSide and Floor Trimº in ªINTERIOR TRIMº for details, BT-18.

p17Instrument panel and padslRemove nuts and bolts.lRemove door mirror switch and disconnect the connector.

INSTRUMENT PANEL

BT-15

Page 279 of 2267

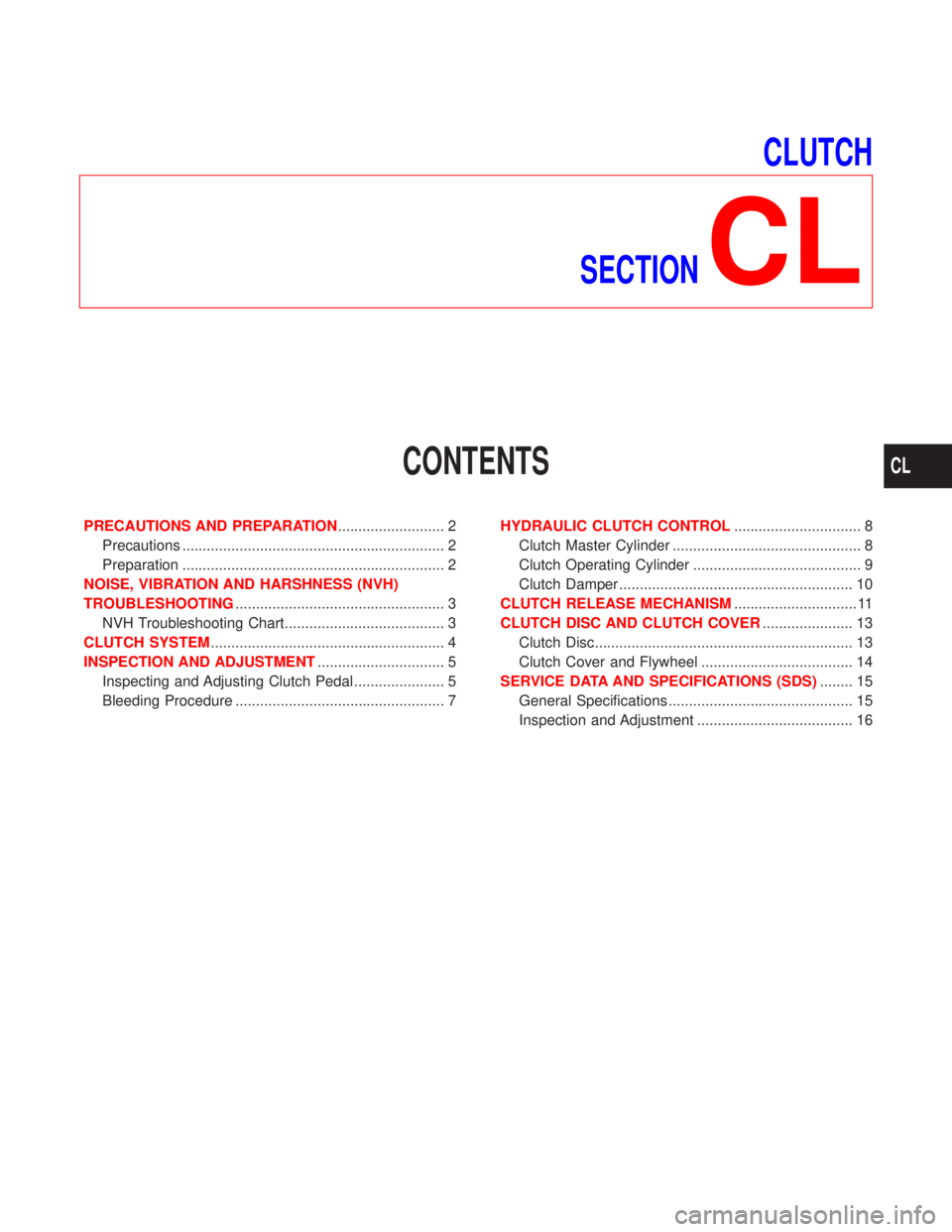

CLUTCH

SECTION

CL

CONTENTS

PRECAUTIONS AND PREPARATION.......................... 2

Precautions ................................................................ 2

Preparation ................................................................ 2

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING................................................... 3

NVH Troubleshooting Chart....................................... 3

CLUTCH SYSTEM......................................................... 4

INSPECTION AND ADJUSTMENT............................... 5

Inspecting and Adjusting Clutch Pedal ...................... 5

Bleeding Procedure ................................................... 7HYDRAULIC CLUTCH CONTROL............................... 8

Clutch Master Cylinder .............................................. 8

Clutch Operating Cylinder ......................................... 9

Clutch Damper ......................................................... 10

CLUTCH RELEASE MECHANISM.............................. 11

CLUTCH DISC AND CLUTCH COVER...................... 13

Clutch Disc............................................................... 13

Clutch Cover and Flywheel ..................................... 14

SERVICE DATA AND SPECIFICATIONS (SDS)........ 15

General Specifications ............................................. 15

Inspection and Adjustment ...................................... 16

CL

Page 286 of 2267

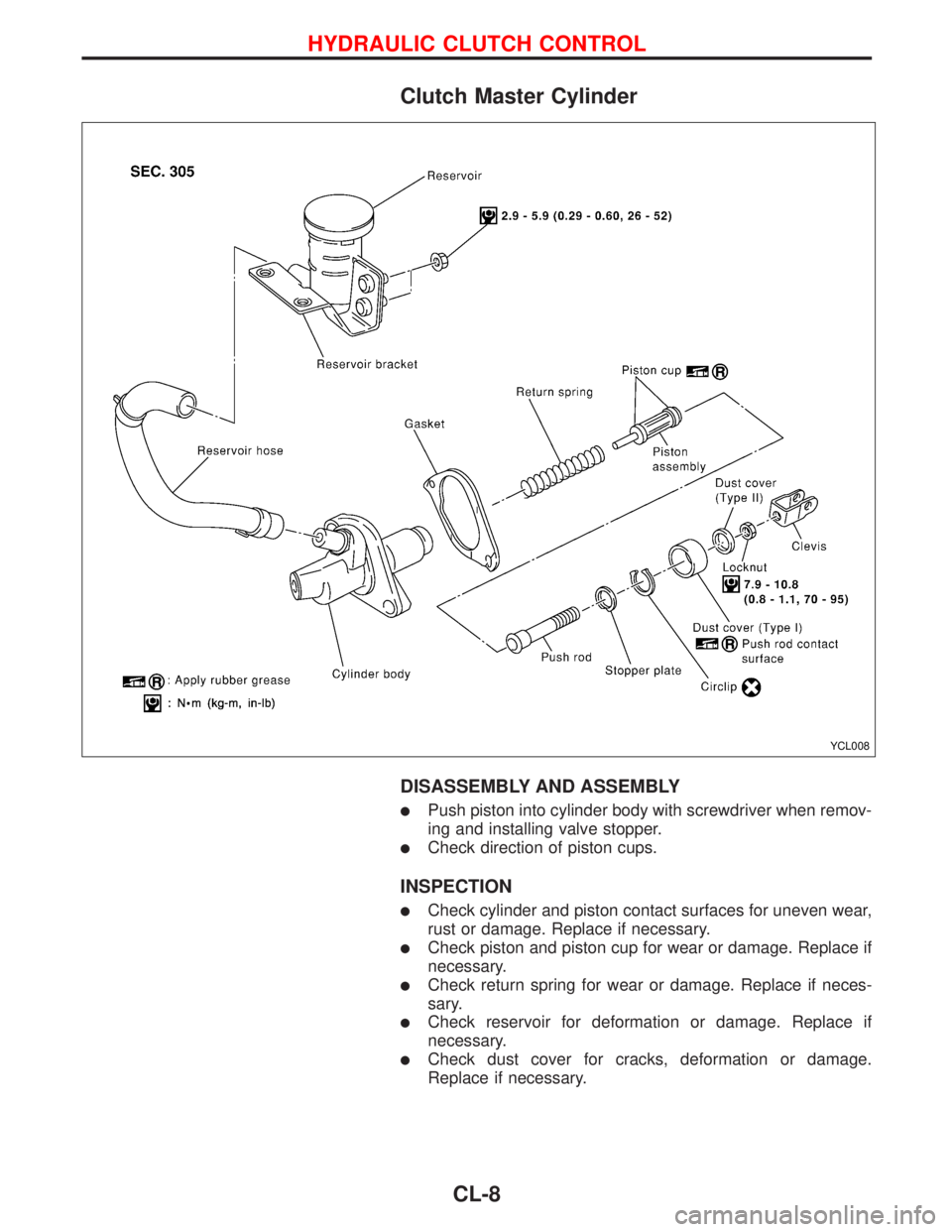

Clutch Master Cylinder

DISASSEMBLY AND ASSEMBLY

lPush piston into cylinder body with screwdriver when remov-

ing and installing valve stopper.

lCheck direction of piston cups.

INSPECTION

lCheck cylinder and piston contact surfaces for uneven wear,

rust or damage. Replace if necessary.

lCheck piston and piston cup for wear or damage. Replace if

necessary.

lCheck return spring for wear or damage. Replace if neces-

sary.

lCheck reservoir for deformation or damage. Replace if

necessary.

lCheck dust cover for cracks, deformation or damage.

Replace if necessary.

YCL008

HYDRAULIC CLUTCH CONTROL

CL-8

Page 287 of 2267

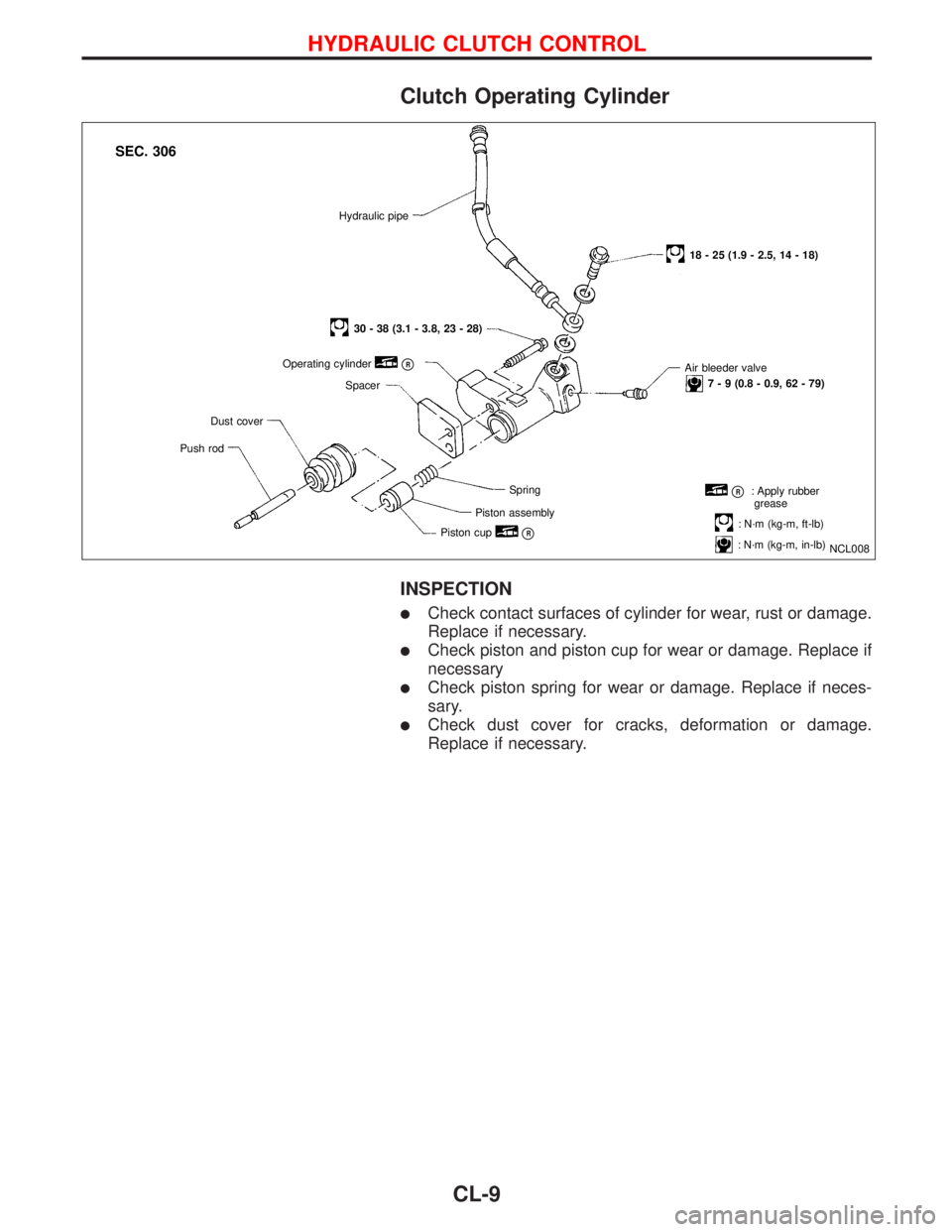

Clutch Operating Cylinder

INSPECTION

lCheck contact surfaces of cylinder for wear, rust or damage.

Replace if necessary.

lCheck piston and piston cup for wear or damage. Replace if

necessary

lCheck piston spring for wear or damage. Replace if neces-

sary.

lCheck dust cover for cracks, deformation or damage.

Replace if necessary.

NCL008

18 - 25 (1.9 - 2.5, 14 - 18) Hydraulic pipe

Air bleeder valve

7 - 9 (0.8 - 0.9, 62 - 79)

30 - 38 (3.1 - 3.8, 23 - 28)

Operating cylinder

pR

Spacer

Dust cover

Push rod

Spring

Piston assembly

Piston cup

pR

pR: Apply rubber

grease

: N´m (kg-m, ft-lb)

: N´m (kg-m, in-lb)

SEC. 306

HYDRAULIC CLUTCH CONTROL

CL-9

Page 288 of 2267

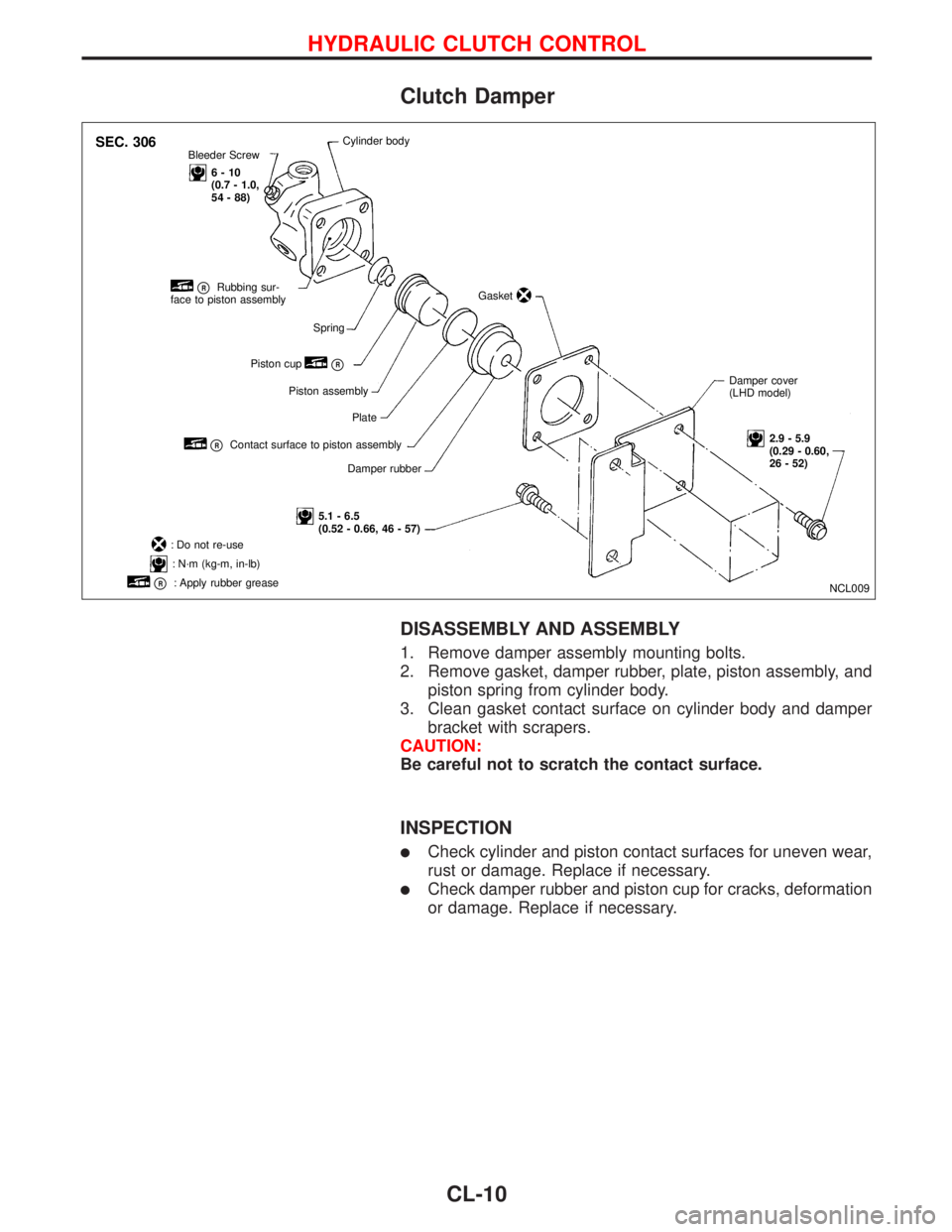

Clutch Damper

DISASSEMBLY AND ASSEMBLY

1. Remove damper assembly mounting bolts.

2. Remove gasket, damper rubber, plate, piston assembly, and

piston spring from cylinder body.

3. Clean gasket contact surface on cylinder body and damper

bracket with scrapers.

CAUTION:

Be careful not to scratch the contact surface.

INSPECTION

lCheck cylinder and piston contact surfaces for uneven wear,

rust or damage. Replace if necessary.

lCheck damper rubber and piston cup for cracks, deformation

or damage. Replace if necessary.

NCL009 Bleeder Screw

6-10

(0.7 - 1.0,

54 - 88)Cylinder body

Gasket

Damper cover

(LHD model)

2.9 - 5.9

(0.29 - 0.60,

26 - 52)

5.1 - 6.5

(0.52 - 0.66, 46 - 57)Damper rubber

pRContact surface to piston assemblyPlate Piston assembly Piston cup

pR

pRRubbing sur-

face to piston assembly

Spring

: Do not re-use

: N´m (kg-m, in-lb)

pR: Apply rubber grease

SEC. 306

HYDRAULIC CLUTCH CONTROL

CL-10

Page 293 of 2267

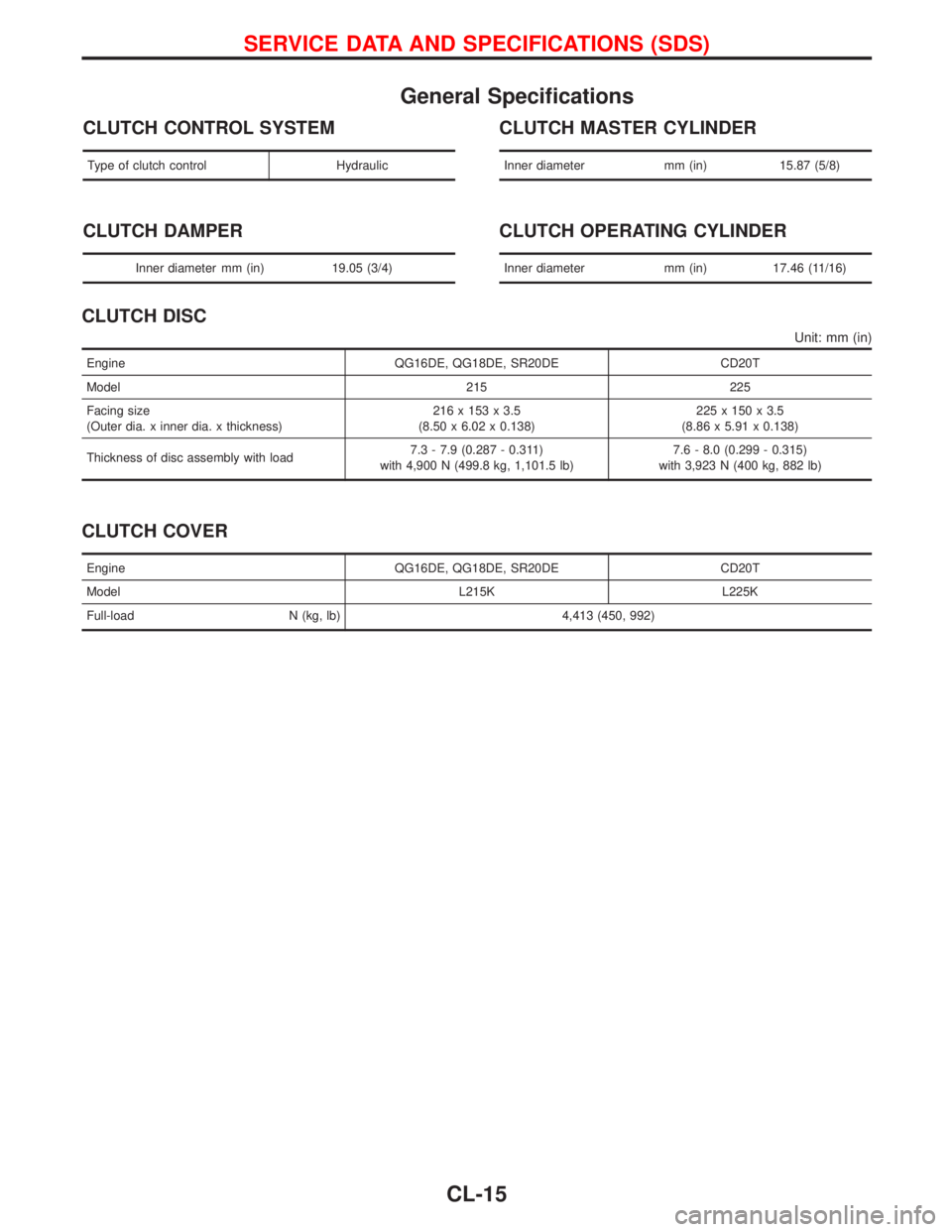

General Specifications

CLUTCH CONTROL SYSTEM

Type of clutch control Hydraulic

CLUTCH DAMPER

Inner diameter mm (in) 19.05 (3/4)

CLUTCH MASTER CYLINDER

Inner diameter mm (in) 15.87 (5/8)

CLUTCH OPERATING CYLINDER

Inner diameter mm (in) 17.46 (11/16)

CLUTCH DISC

Unit: mm (in)

Engine QG16DE, QG18DE, SR20DE CD20T

Model 215 225

Facing size

(Outer dia. x inner dia. x thickness)216 x 153 x 3.5

(8.50 x 6.02 x 0.138)225 x 150 x 3.5

(8.86 x 5.91 x 0.138)

Thickness of disc assembly with load7.3 - 7.9 (0.287 - 0.311)

with 4,900 N (499.8 kg, 1,101.5 lb)7.6 - 8.0 (0.299 - 0.315)

with 3,923 N (400 kg, 882 lb)

CLUTCH COVER

Engine QG16DE, QG18DE, SR20DE CD20T

Model L215K L225K

Full-load N (kg, lb) 4,413 (450, 992)

SERVICE DATA AND SPECIFICATIONS (SDS)

CL-15

Page 295 of 2267

ENGINE CONTROL SYSTEM

SECTION

EC

CONTENTS

CD20T

PRECAUTIONS AND PREPARATION.......................... 3

Special Service Tools ................................................ 3

Engine Fuel & Emission Control System .................. 5

Supplemental Restraint System (SRS)²AIR

BAG²and²SEAT BELT PRE-TENSIONER²............. 6

Precautions for On Board Diagnostic (OBD)

System of Engine ...................................................... 6

Precautions ................................................................ 7

ENGINE AND EMISSION CONTROL OVERALL

SYSTEM......................................................................... 9

Engine Control Module Component Parts

Location ..................................................................... 9

Circuit Diagram ......................................................... 11

System Diagram ...................................................... 12

Vacuum Hose Drawing ............................................ 13

System Chart ........................................................... 14

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTION............................................. 15

Glow Control System ............................................... 15

Fuel Injection System .............................................. 15

Fuel Injection Timing System .................................. 18

Air Conditioning Cut Control .................................... 20

Cooling Fan Control................................................. 20

CRANKCASE VENTILATION SYSTEM...................... 21

Description ............................................................... 21

Blow-by Control Valve ............................................. 21

Ventilation Hose ....................................................... 21

INJECTION NOZZLE................................................... 22

Removal and Installation ......................................... 22

Test and Adjustment ................................................ 22

ELECTRONIC FUEL INJECTION PUMP.................... 24

Removal ................................................................... 24

Installation ................................................................ 25Disassembly and Assembly ..................................... 26

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION............................................................. 27

CONSULT-II ............................................................. 27

TROUBLE DIAGNOSIS - INTRODUCTION................ 33

Introduction .............................................................. 33

Diagnostic Worksheet .............................................. 34

TROUBLE DIAGNOSIS - WORK FLOW.................... 35

Work Flow ................................................................ 35

Description for Work Flow ....................................... 36

TROUBLE DIAGNOSIS - BASIC INSPECTION......... 37

Basic Inspection....................................................... 37

TROUBLE DIAGNOSIS - GENERAL

DESCRIPTION............................................................. 39

Diagnostic Trouble Chart ......................................... 39

Symptom Matrix Chart ............................................. 47

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................ 50

Major Sensor Reference Graph in Data Monitor

Mode ........................................................................ 51

ECM Terminals and Reference Value ..................... 52

TROUBLE DIAGNOSIS FOR POWER SUPPLY........ 59

Main Power Supply and Ground Circuit .................. 59

TROUBLE DIAGNOSIS 1............................................ 62

Mass Air Flow Sensor (MAFS) ................................ 62

TROUBLE DIAGNOSIS 2............................................ 66

Engine Coolant Temperature (ECT) Sensor ........... 66

TROUBLE DIAGNOSIS 3............................................ 70

Vehicle Speed Sensor (VSS) .................................. 70

TROUBLE DIAGNOSIS 4............................................ 74

Control Sleeve Position Sensor (CSPS) ................. 74

TROUBLE DIAGNOSIS 5............................................ 78

Electric Governor ..................................................... 78

TROUBLE DIAGNOSIS 6............................................ 82

EC

Page 296 of 2267

Injection Timing Control Valve ................................. 82

TROUBLE DIAGNOSIS 7............................................ 86

Engine Control Module (ECM) ................................ 86

TROUBLE DIAGNOSIS 8............................................ 87

Cooling Fan (Overheat) ........................................... 87

TROUBLE DIAGNOSIS 9............................................ 97

Needle Lift Sensor (NLS) ........................................ 97

TROUBLE DIAGNOSIS 10........................................ 100

Fuel Cut Solenoid Valve ........................................ 100

TROUBLE DIAGNOSIS 11........................................ 104

Fuel Temperature Sensor (FTS)............................ 104

TROUBLE DIAGNOSIS 12........................................ 108

Accelerator Position Sensor & Switch ................... 108

TROUBLE DIAGNOSIS 13......................................... 114

Crankshaft Position Sensor (TDC) ......................... 114

TROUBLE DIAGNOSES 14....................................... 118

Glow Control System .............................................. 118TROUBLE DIAGNOSES 15...................................... 126

Air Conditioner Cut Control ................................... 126

TROUBLE DIAGNOSES 16...................................... 129

EGRC-Solenoid Valve ........................................... 129

TROUBLE DIAGNOSES 17...................................... 136

Brake Switch .......................................................... 136

TROUBLE DIAGNOSES 18...................................... 140

ECM Relay............................................................. 140

TROUBLE DIAGNOSES 19...................................... 141

MI & Data Link Connectors ................................... 141

TROUBLE DIAGNOSES 20...................................... 145

Start Signal ............................................................ 145

SERVICE DATA AND SPECIFICATIONS (SDS)...... 147

General Specifications ........................................... 147

Injection Nozzle ..................................................... 147

Inspection and Adjustment .................................... 147

When you read wiring diagrams:

lRead GI section, ªHOW TO READ WIRING DIAGRAMSº.

lSee EL section, ªPOWER SUPPLY ROUTINGº for power distribution circuit.

lSee EL section for NATS information and wiring diagram.

When you perform trouble diagnoses, read GI section, ªHOW TO FOLLOW FLOW CHART

IN TROUBLE DIAGNOSESº and ªHOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN

ELECTRICAL INCIDENTº.

For clarification of system component abbreviations and terminology read GI section

ªSAE J1930 TERMINOLOGY LISTº.

EC-2

Page 299 of 2267

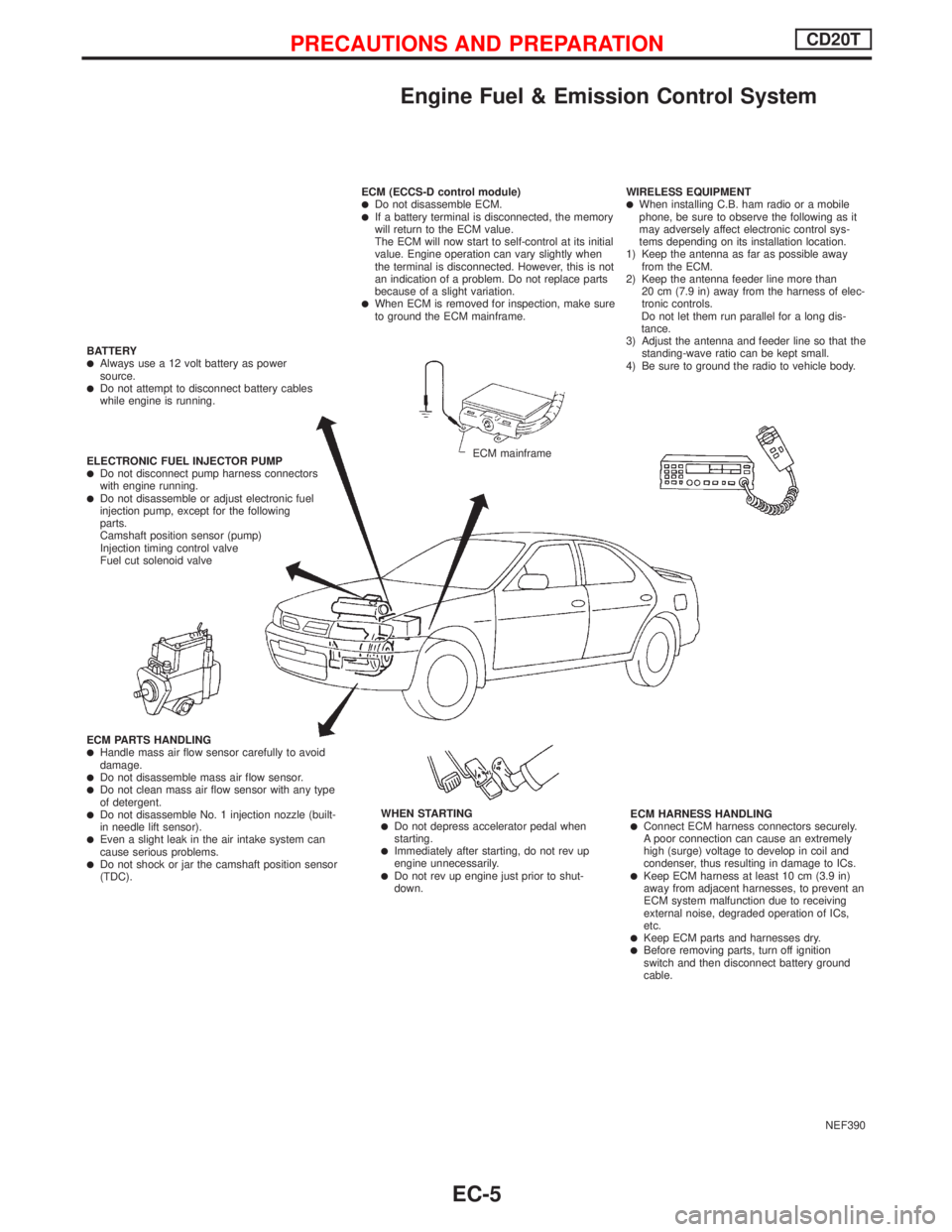

Engine Fuel & Emission Control System

NEF390 ECM (ECCS-D control module)

lDo not disassemble ECM.lIf a battery terminal is disconnected, the memory

will return to the ECM value.

The ECM will now start to self-control at its initial

value. Engine operation can vary slightly when

the terminal is disconnected. However, this is not

an indication of a problem. Do not replace parts

because of a slight variation.

lWhen ECM is removed for inspection, make sure

to ground the ECM mainframe.WIRELESS EQUIPMENT

lWhen installing C.B. ham radio or a mobile

phone, be sure to observe the following as it

may adversely affect electronic control sys-

tems depending on its installation location.

1) Keep the antenna as far as possible away

from the ECM.

2) Keep the antenna feeder line more than

20 cm (7.9 in) away from the harness of elec-

tronic controls.

Do not let them run parallel for a long dis-

tance.

3) Adjust the antenna and feeder line so that the

standing-wave ratio can be kept small.

4) Be sure to ground the radio to vehicle body.

ECM HARNESS HANDLING

lConnect ECM harness connectors securely.

A poor connection can cause an extremely

high (surge) voltage to develop in coil and

condenser, thus resulting in damage to ICs.

lKeep ECM harness at least 10 cm (3.9 in)

away from adjacent harnesses, to prevent an

ECM system malfunction due to receiving

external noise, degraded operation of ICs,

etc.

lKeep ECM parts and harnesses dry.lBefore removing parts, turn off ignition

switch and then disconnect battery ground

cable. WHEN STARTING

lDo not depress accelerator pedal when

starting.

lImmediately after starting, do not rev up

engine unnecessarily.

lDo not rev up engine just prior to shut-

down. ECM PARTS HANDLING

lHandle mass air flow sensor carefully to avoid

damage.

lDo not disassemble mass air flow sensor.lDo not clean mass air flow sensor with any type

of detergent.

lDo not disassemble No. 1 injection nozzle (built-

in needle lift sensor).

lEven a slight leak in the air intake system can

cause serious problems.

lDo not shock or jar the camshaft position sensor

(TDC). ELECTRONIC FUEL INJECTOR PUMP

lDo not disconnect pump harness connectors

with engine running.

lDo not disassemble or adjust electronic fuel

injection pump, except for the following

parts.

Camshaft position sensor (pump)

Injection timing control valve

Fuel cut solenoid valve BATTERY

lAlways use a 12 volt battery as power

source.

lDo not attempt to disconnect battery cables

while engine is running.

ECM mainframe

PRECAUTIONS AND PREPARATIONCD20T

EC-5