fuel pressure NISSAN PRIMERA 1999 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 221 of 2267

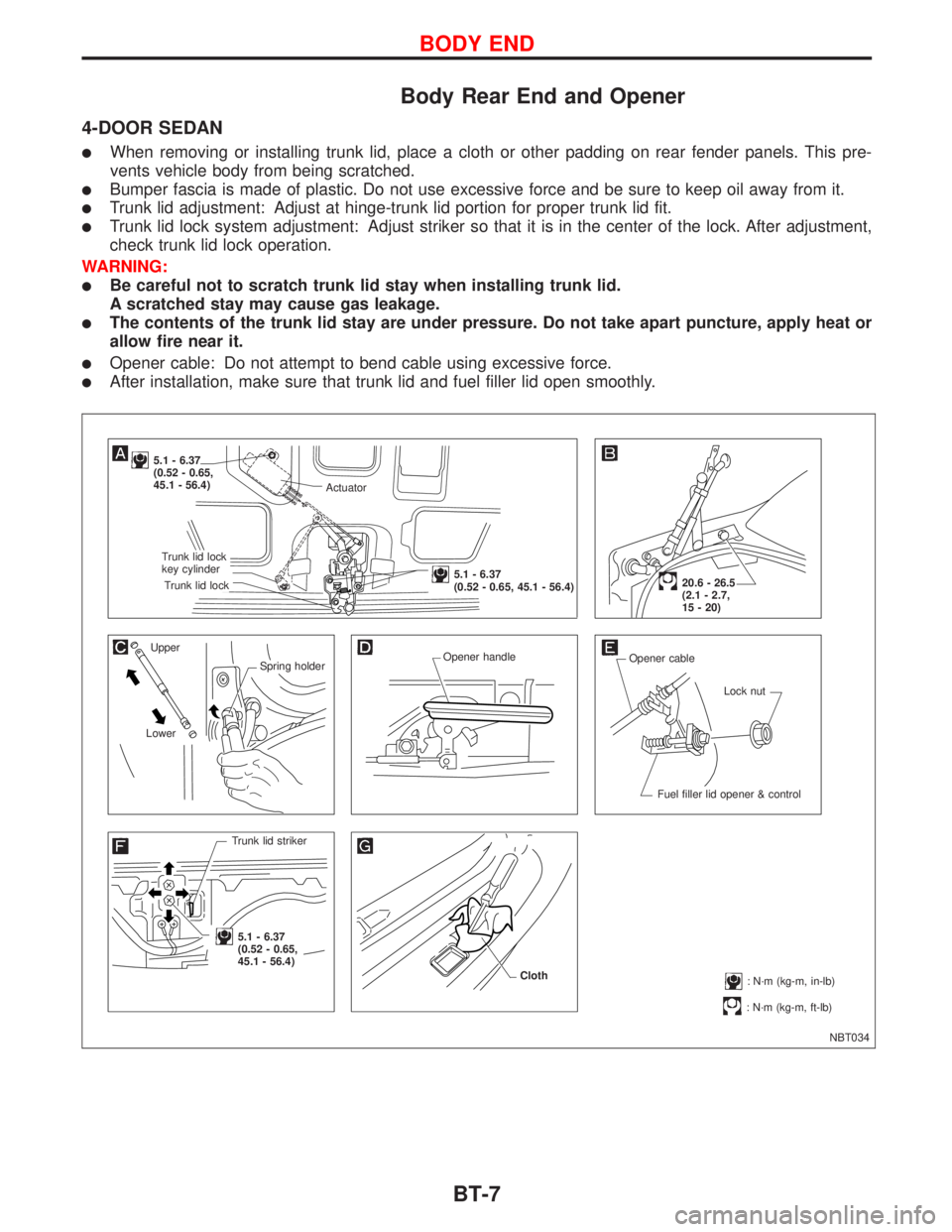

Body Rear End and Opener

4-DOOR SEDAN

lWhen removing or installing trunk lid, place a cloth or other padding on rear fender panels. This pre-

vents vehicle body from being scratched.

lBumper fascia is made of plastic. Do not use excessive force and be sure to keep oil away from it.

lTrunk lid adjustment: Adjust at hinge-trunk lid portion for proper trunk lid fit.

lTrunk lid lock system adjustment: Adjust striker so that it is in the center of the lock. After adjustment,

check trunk lid lock operation.

WARNING:

lBe careful not to scratch trunk lid stay when installing trunk lid.

A scratched stay may cause gas leakage.

lThe contents of the trunk lid stay are under pressure. Do not take apart puncture, apply heat or

allow fire near it.

lOpener cable: Do not attempt to bend cable using excessive force.

lAfter installation, make sure that trunk lid and fuel filler lid open smoothly.

NBT034

5.1 - 6.37

(0.52 - 0.65,

45.1 - 56.4)

Upper

Spring holder

LowerOpener handle

Opener cable

Lock nut

Fuel filler lid opener & control

Trunk lid striker

.5.1 - 6.37

(0.52 - 0.65,

45.1 - 56.4)

: N´m (kg-m, ft-lb)

20.6 - 26.5

(2.1 - 2.7,

15 - 20)

: N´m (kg-m, in-lb) Cloth

Actuator

.Trunk lid lock

key cylinder

.Trunk lid lock

.5.1 - 6.37

(0.52 - 0.65, 45.1 - 56.4)

BODY END

BT-7

Page 223 of 2267

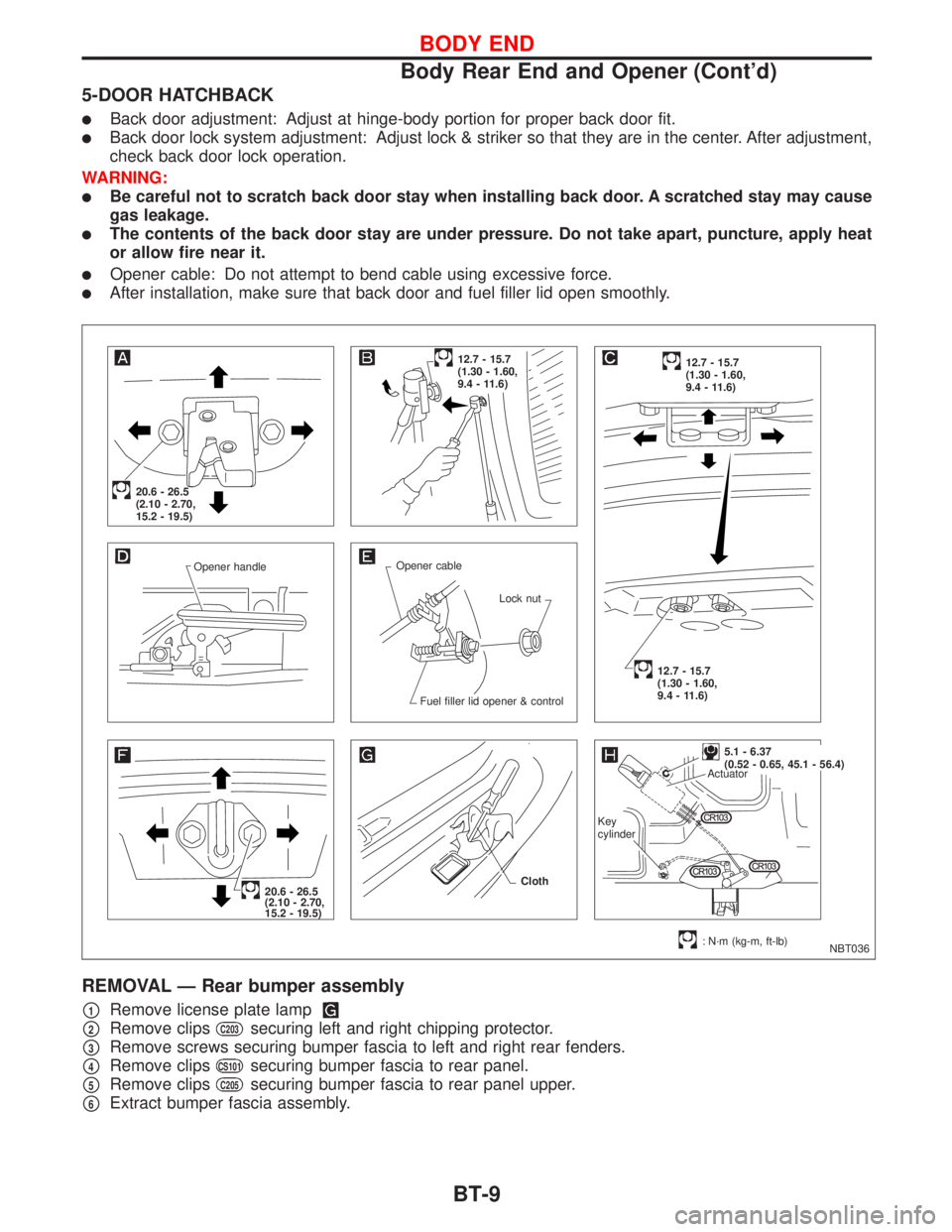

5-DOOR HATCHBACK

lBack door adjustment: Adjust at hinge-body portion for proper back door fit.

lBack door lock system adjustment: Adjust lock & striker so that they are in the center. After adjustment,

check back door lock operation.

WARNING:

lBe careful not to scratch back door stay when installing back door. A scratched stay may cause

gas leakage.

lThe contents of the back door stay are under pressure. Do not take apart, puncture, apply heat

or allow fire near it.

lOpener cable: Do not attempt to bend cable using excessive force.

lAfter installation, make sure that back door and fuel filler lid open smoothly.

REMOVAL Ð Rear bumper assembly

p1Remove license plate lamp

p2Remove clipsC203securing left and right chipping protector.

p3Remove screws securing bumper fascia to left and right rear fenders.

p4Remove clipsCS101securing bumper fascia to rear panel.

p5Remove clipsC205securing bumper fascia to rear panel upper.

p6Extract bumper fascia assembly.

NBT036 Opener handleOpener cable

Lock nut

Fuel filler lid opener & control

20.6 - 26.5

(2.10 - 2.70,

15.2 - 19.5)

12.7 - 15.7

(1.30 - 1.60,

9.4 - 11.6)12.7 - 15.7

(1.30 - 1.60,

9.4 - 11.6)

12.7 - 15.7

(1.30 - 1.60,

9.4 - 11.6)

20.6 - 26.5

(2.10 - 2.70,

15.2 - 19.5)

: N´m (kg-m, ft-lb) Cloth

.5.1 - 6.37

(0.52 - 0.65, 45.1 - 56.4)

Actuator

Key

cylinder

BODY END

Body Rear End and Opener (Cont'd)

BT-9

Page 225 of 2267

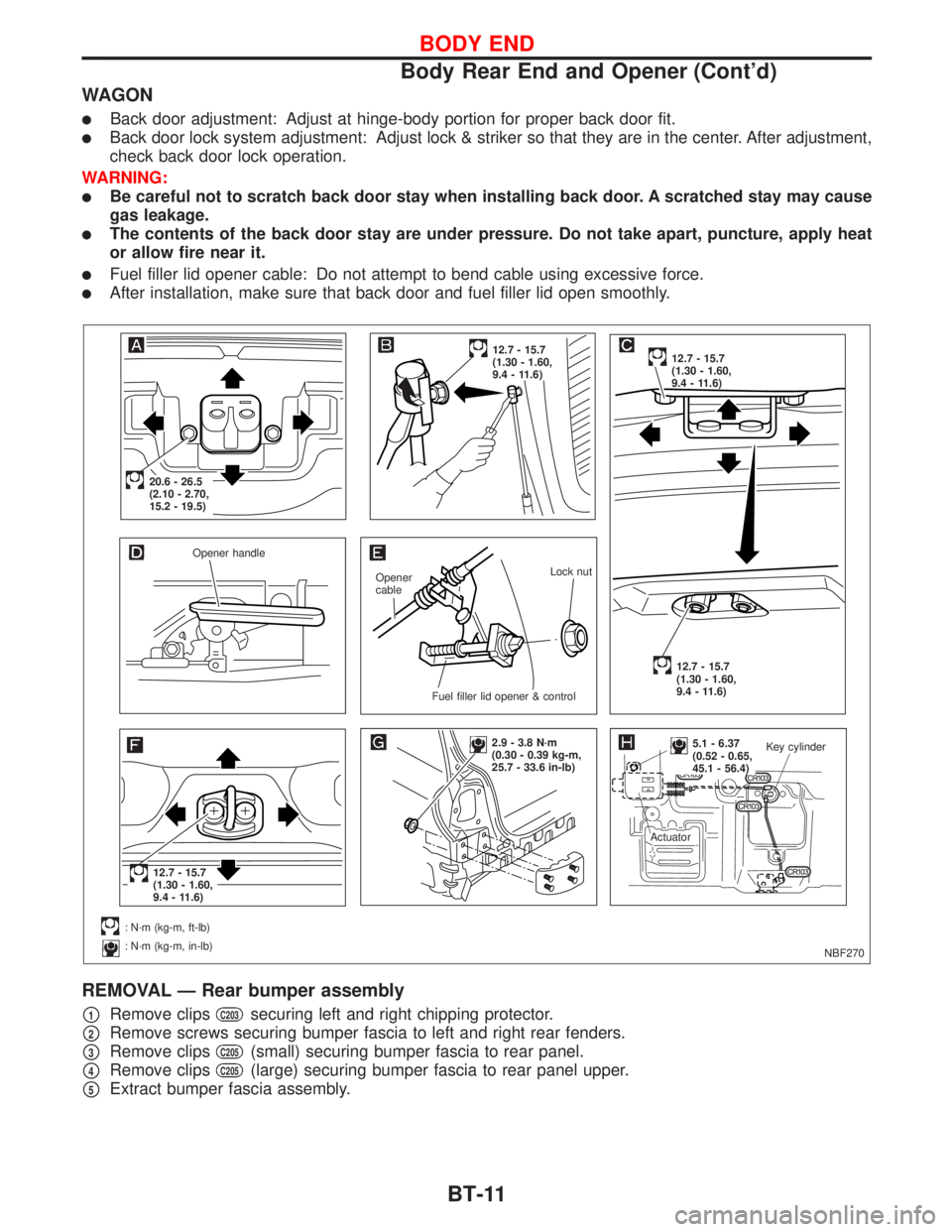

WAGON

lBack door adjustment: Adjust at hinge-body portion for proper back door fit.

lBack door lock system adjustment: Adjust lock & striker so that they are in the center. After adjustment,

check back door lock operation.

WARNING:

lBe careful not to scratch back door stay when installing back door. A scratched stay may cause

gas leakage.

lThe contents of the back door stay are under pressure. Do not take apart, puncture, apply heat

or allow fire near it.

lFuel filler lid opener cable: Do not attempt to bend cable using excessive force.

lAfter installation, make sure that back door and fuel filler lid open smoothly.

REMOVAL Ð Rear bumper assembly

p1Remove clipsC203securing left and right chipping protector.

p2Remove screws securing bumper fascia to left and right rear fenders.

p3Remove clipsC205(small) securing bumper fascia to rear panel.

p4Remove clipsC205(large) securing bumper fascia to rear panel upper.

p5Extract bumper fascia assembly.

NBF270 Opener handle

Opener

cableLock nut

.Fuel filler lid opener & control

.20.6 - 26.5

(2.10 - 2.70,

15.2 - 19.5)

12.7 - 15.7

(1.30 - 1.60,

9.4 - 11.6)12.7 - 15.7

(1.30 - 1.60,

9.4 - 11.6)

12.7 - 15.7

(1.30 - 1.60,

9.4 - 11.6)

.12.7 - 15.7

(1.30 - 1.60,

9.4 - 11.6)

: N´m (kg-m, ft-lb)

: N´m (kg-m, in-lb)

2.9 - 3.8 N´m

(0.30 - 0.39 kg-m,

25.7 - 33.6 in-lb)..5.1 - 6.37

(0.52 - 0.65,

45.1 - 56.4)Key cylinder

Actuator

BODY END

Body Rear End and Opener (Cont'd)

BT-11

Page 308 of 2267

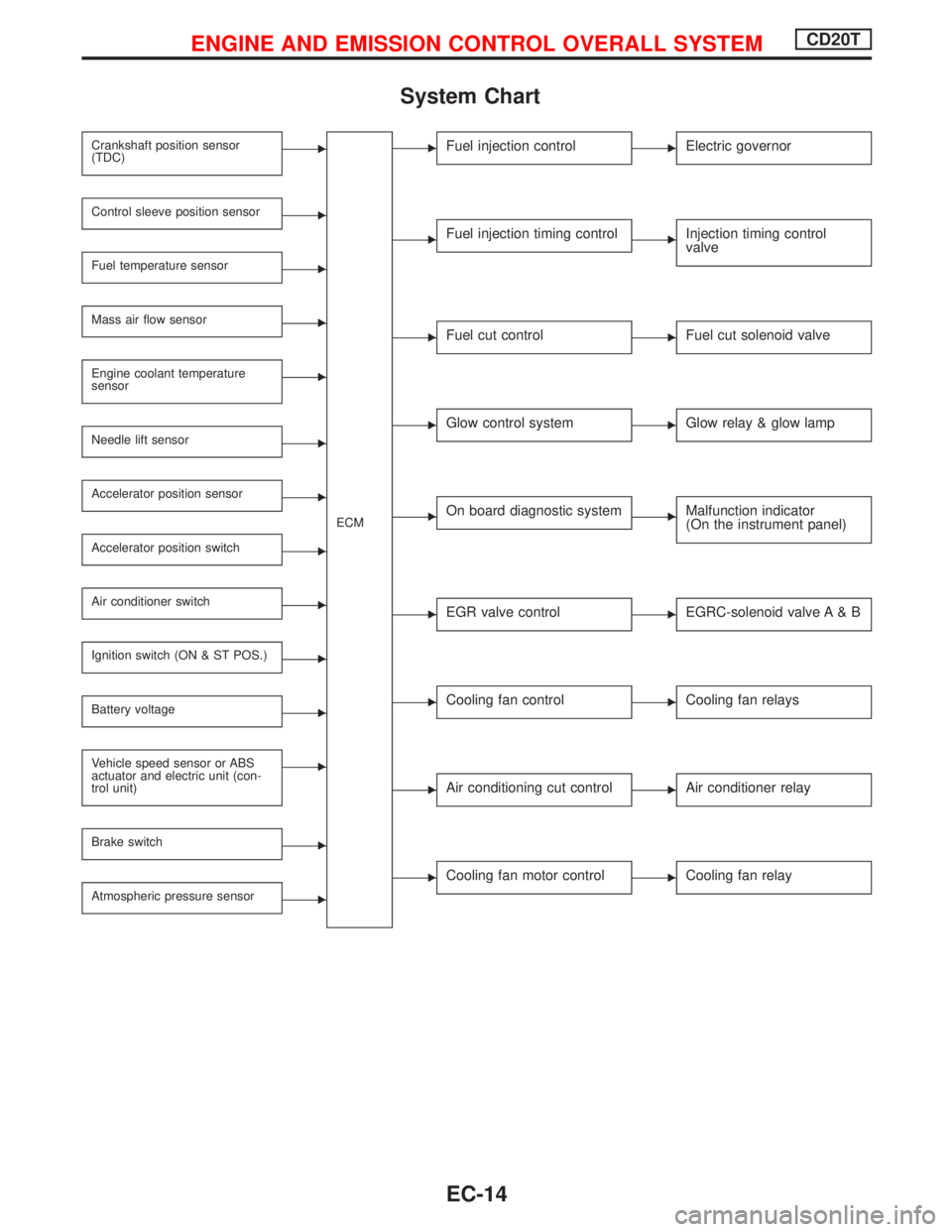

System Chart

Crankshaft position sensor

(TDC)E

ECM

Control sleeve position sensorE

Fuel temperature sensorE

Mass air flow sensorE

Engine coolant temperature

sensorE

Needle lift sensorE

Accelerator position sensorE

Accelerator position switchE

Air conditioner switchE

Ignition switch (ON & ST POS.)E

Battery voltageE

Vehicle speed sensor or ABS

actuator and electric unit (con-

trol unit)E

Brake switchE

Atmospheric pressure sensorE

EFuel injection controlEElectric governor

EFuel injection timing controlEInjection timing control

valve

EFuel cut controlEFuel cut solenoid valve

EGlow control systemEGlow relay & glow lamp

EOn board diagnostic systemEMalfunction indicator

(On the instrument panel)

EEGR valve controlEEGRC-solenoid valve A & B

ECooling fan controlECooling fan relays

EAir conditioning cut controlEAir conditioner relay

ECooling fan motor controlECooling fan relay

ENGINE AND EMISSION CONTROL OVERALL SYSTEMCD20T

EC-14

Page 311 of 2267

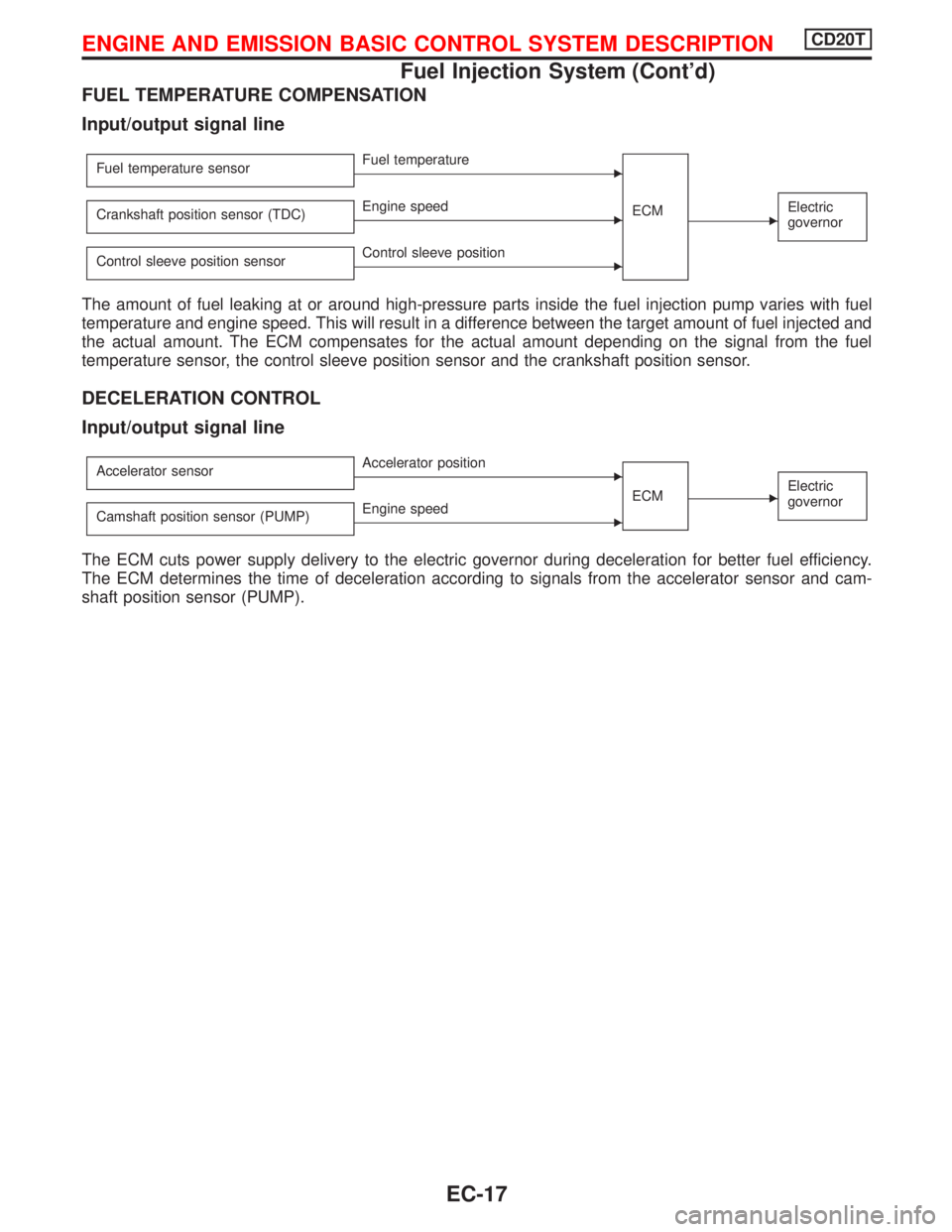

FUEL TEMPERATURE COMPENSATION

Input/output signal line

Fuel temperature sensorEFuel temperature

ECM

EElectric

governorCrankshaft position sensor (TDC)EEngine speed

Control sleeve position sensor

EControl sleeve position

The amount of fuel leaking at or around high-pressure parts inside the fuel injection pump varies with fuel

temperature and engine speed. This will result in a difference between the target amount of fuel injected and

the actual amount. The ECM compensates for the actual amount depending on the signal from the fuel

temperature sensor, the control sleeve position sensor and the crankshaft position sensor.

DECELERATION CONTROL

Input/output signal line

Accelerator sensorEAccelerator position

ECM

EElectric

governor

Camshaft position sensor (PUMP)EEngine speed

The ECM cuts power supply delivery to the electric governor during deceleration for better fuel efficiency.

The ECM determines the time of deceleration according to signals from the accelerator sensor and cam-

shaft position sensor (PUMP).

ENGINE AND EMISSION BASIC CONTROL SYSTEM DESCRIPTIONCD20T

Fuel Injection System (Cont'd)

EC-17

Page 312 of 2267

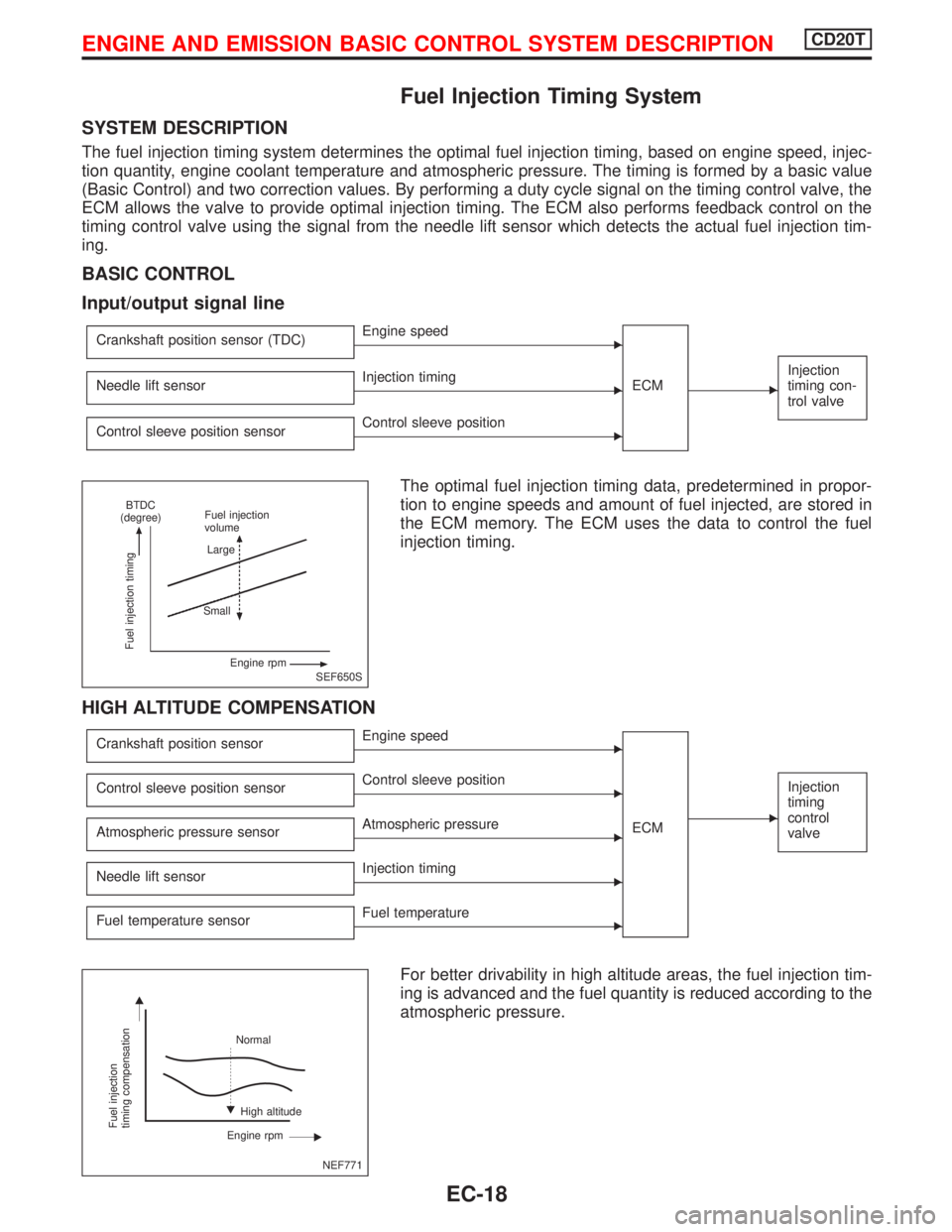

Fuel Injection Timing System

SYSTEM DESCRIPTION

The fuel injection timing system determines the optimal fuel injection timing, based on engine speed, injec-

tion quantity, engine coolant temperature and atmospheric pressure. The timing is formed by a basic value

(Basic Control) and two correction values. By performing a duty cycle signal on the timing control valve, the

ECM allows the valve to provide optimal injection timing. The ECM also performs feedback control on the

timing control valve using the signal from the needle lift sensor which detects the actual fuel injection tim-

ing.

BASIC CONTROL

Input/output signal line

Crankshaft position sensor (TDC)EEngine speed

ECM

E

Injection

timing con-

trol valveNeedle lift sensorEInjection timing

Control sleeve position sensor

EControl sleeve position

The optimal fuel injection timing data, predetermined in propor-

tion to engine speeds and amount of fuel injected, are stored in

the ECM memory. The ECM uses the data to control the fuel

injection timing.

HIGH ALTITUDE COMPENSATION

Crankshaft position sensorEEngine speed

ECM

E

Injection

timing

control

valveControl sleeve position sensorEControl sleeve position

Atmospheric pressure sensor

EAtmospheric pressure

Needle lift sensor

EInjection timing

Fuel temperature sensor

EFuel temperature

For better drivability in high altitude areas, the fuel injection tim-

ing is advanced and the fuel quantity is reduced according to the

atmospheric pressure.

SEF650S

Fuel injection timing

BTDC

(degree)Fuel injection

volume

Large

Small

Engine rpm

NEF771

Fuel injection

timing compensation

Normal

High altitude

Engine rpm

ENGINE AND EMISSION BASIC CONTROL SYSTEM DESCRIPTIONCD20T

EC-18

Page 316 of 2267

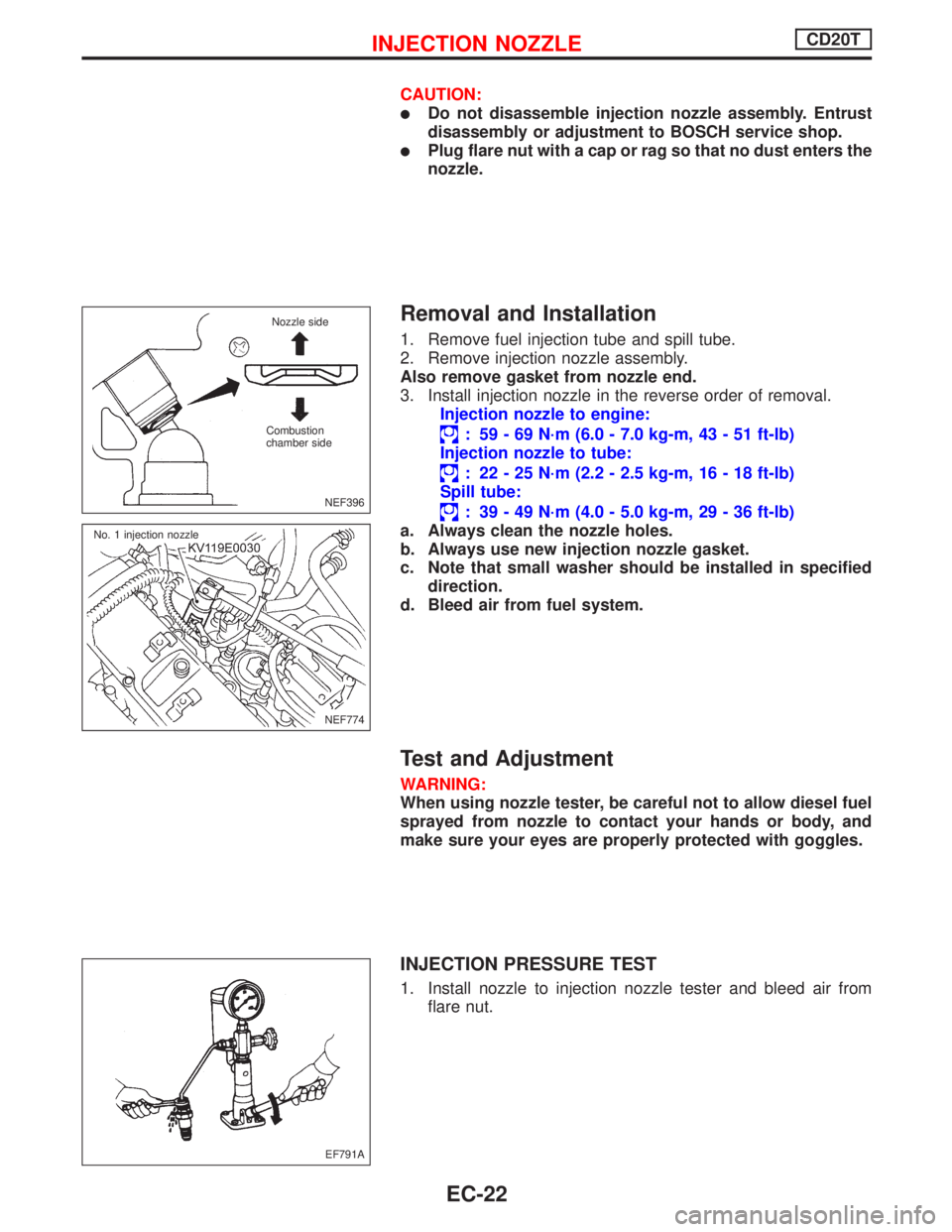

CAUTION:

lDo not disassemble injection nozzle assembly. Entrust

disassembly or adjustment to BOSCH service shop.

lPlug flare nut with a cap or rag so that no dust enters the

nozzle.

Removal and Installation

1. Remove fuel injection tube and spill tube.

2. Remove injection nozzle assembly.

Also remove gasket from nozzle end.

3. Install injection nozzle in the reverse order of removal.

Injection nozzle to engine:

: 59 - 69 N´m (6.0 - 7.0 kg-m, 43 - 51 ft-lb)

Injection nozzle to tube:

: 22 - 25 N´m (2.2 - 2.5 kg-m, 16 - 18 ft-lb)

Spill tube:

: 39 - 49 N´m (4.0 - 5.0 kg-m, 29 - 36 ft-lb)

a. Always clean the nozzle holes.

b. Always use new injection nozzle gasket.

c. Note that small washer should be installed in specified

direction.

d. Bleed air from fuel system.

Test and Adjustment

WARNING:

When using nozzle tester, be careful not to allow diesel fuel

sprayed from nozzle to contact your hands or body, and

make sure your eyes are properly protected with goggles.

INJECTION PRESSURE TEST

1. Install nozzle to injection nozzle tester and bleed air from

flare nut.

NEF396

Nozzle side

Combustion

chamber side

NEF774 No. 1 injection nozzle

EF791A

INJECTION NOZZLECD20T

EC-22

Page 341 of 2267

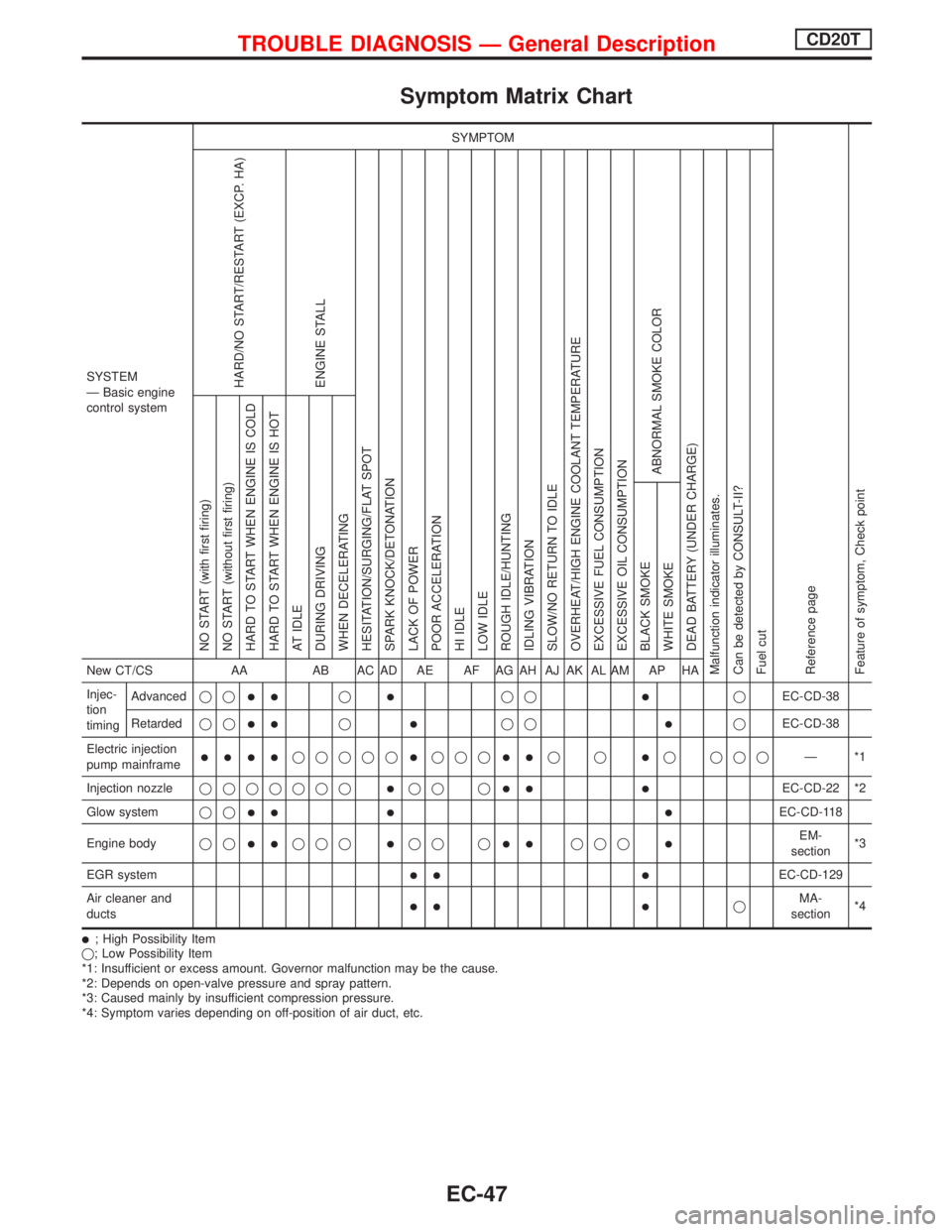

Symptom Matrix Chart

SYSTEM

Ð Basic engine

control systemSYMPTOM

Reference page

Feature of symptom, Check pointHARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER

POOR ACCELERATION

HI IDLE

LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEAT/HIGH ENGINE COOLANT TEMPERATURE

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

ABNORMAL SMOKE COLOR

DEAD BATTERY (UNDER CHARGE)

Malfunction indicator illuminates.

Can be detected by CONSULT-II?

Fuel cutNO START (with first firing)

NO START (without first firing)

HARD TO START WHEN ENGINE IS COLD

HARD TO START WHEN ENGINE IS HOT

AT IDLE

DURING DRIVING

WHEN DECELERATING

BLACK SMOKE

WHITE SMOKENew CT/CS AA AB AC AD AE AF AG AH AJ AK AL AM AP HA

Injec-

tion

timingAdvancedqq

llqlqqlqEC-CD-38

Retardedqq

llqlqqlqEC-CD-38

Electric injection

pump mainframe

llllqqqqqlqqqllqqlq qqqÐ*1

Injection nozzleqqqqqqq

lqq qll lEC-CD-22 *2

Glow systemqq

ll l lEC-CD-118

Engine bodyqq

llqqqlqq qllqqqlEM-

section*3

EGR system

ll lEC-CD-129

Air cleaner and

ducts

ll lqMA-

section*4

l; High Possibility Item

q; Low Possibility Item

*1: Insufficient or excess amount. Governor malfunction may be the cause.

*2: Depends on open-valve pressure and spray pattern.

*3: Caused mainly by insufficient compression pressure.

*4: Symptom varies depending on off-position of air duct, etc.

TROUBLE DIAGNOSIS Ð General DescriptionCD20T

EC-47

Page 376 of 2267

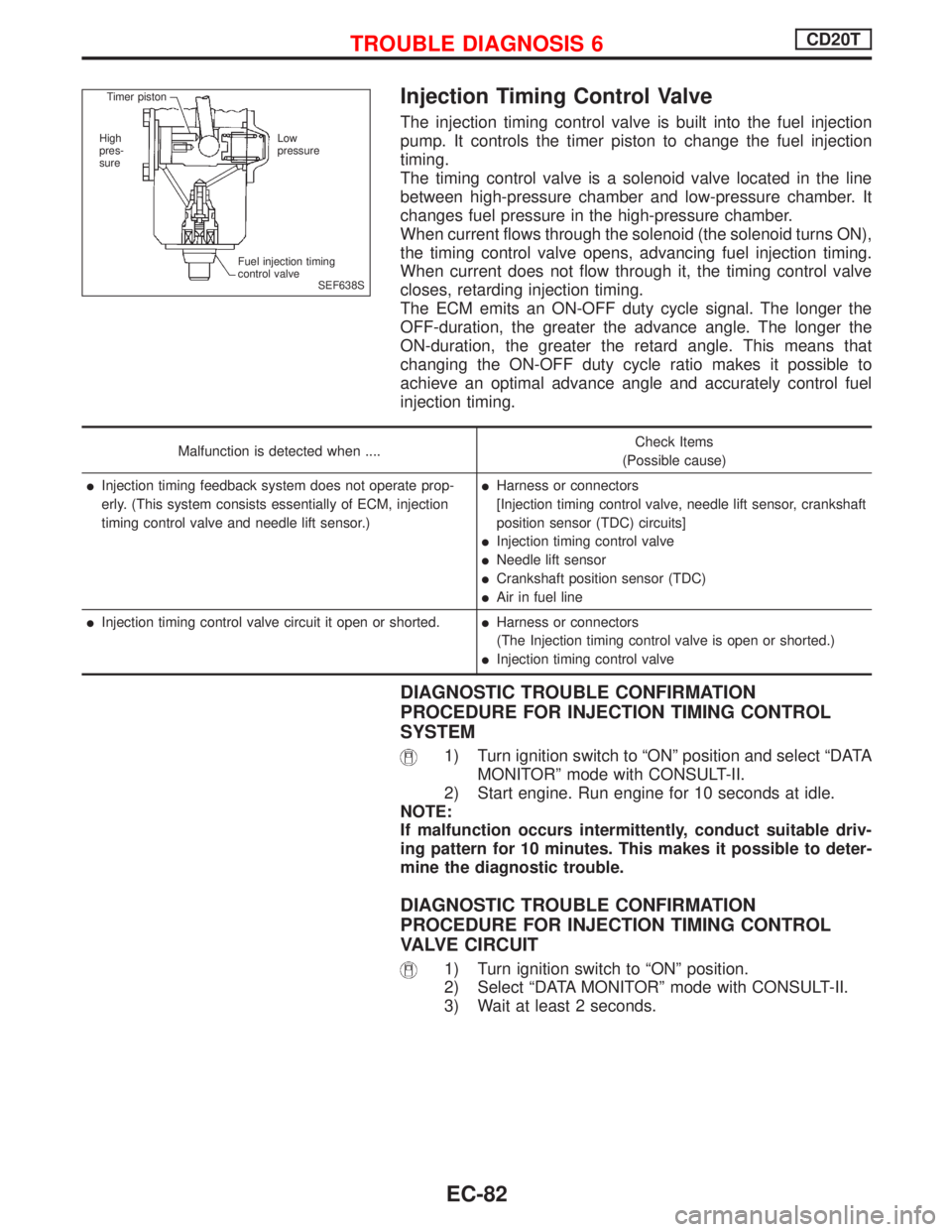

Injection Timing Control Valve

The injection timing control valve is built into the fuel injection

pump. It controls the timer piston to change the fuel injection

timing.

The timing control valve is a solenoid valve located in the line

between high-pressure chamber and low-pressure chamber. It

changes fuel pressure in the high-pressure chamber.

When current flows through the solenoid (the solenoid turns ON),

the timing control valve opens, advancing fuel injection timing.

When current does not flow through it, the timing control valve

closes, retarding injection timing.

The ECM emits an ON-OFF duty cycle signal. The longer the

OFF-duration, the greater the advance angle. The longer the

ON-duration, the greater the retard angle. This means that

changing the ON-OFF duty cycle ratio makes it possible to

achieve an optimal advance angle and accurately control fuel

injection timing.

Malfunction is detected when ....Check Items

(Possible cause)

lInjection timing feedback system does not operate prop-

erly. (This system consists essentially of ECM, injection

timing control valve and needle lift sensor.)lHarness or connectors

[Injection timing control valve, needle lift sensor, crankshaft

position sensor (TDC) circuits]

lInjection timing control valve

lNeedle lift sensor

lCrankshaft position sensor (TDC)

lAir in fuel line

lInjection timing control valve circuit it open or shorted.lHarness or connectors

(The Injection timing control valve is open or shorted.)

lInjection timing control valve

DIAGNOSTIC TROUBLE CONFIRMATION

PROCEDURE FOR INJECTION TIMING CONTROL

SYSTEM

1) Turn ignition switch to ªONº position and select ªDATA

MONITORº mode with CONSULT-II.

2) Start engine. Run engine for 10 seconds at idle.

NOTE:

If malfunction occurs intermittently, conduct suitable driv-

ing pattern for 10 minutes. This makes it possible to deter-

mine the diagnostic trouble.

DIAGNOSTIC TROUBLE CONFIRMATION

PROCEDURE FOR INJECTION TIMING CONTROL

VALVE CIRCUIT

1) Turn ignition switch to ªONº position.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Wait at least 2 seconds.

SEF638S Timer piston

High

pres-

sureLow

pressure

Fuel injection timing

control valve

TROUBLE DIAGNOSIS 6CD20T

EC-82

Page 441 of 2267

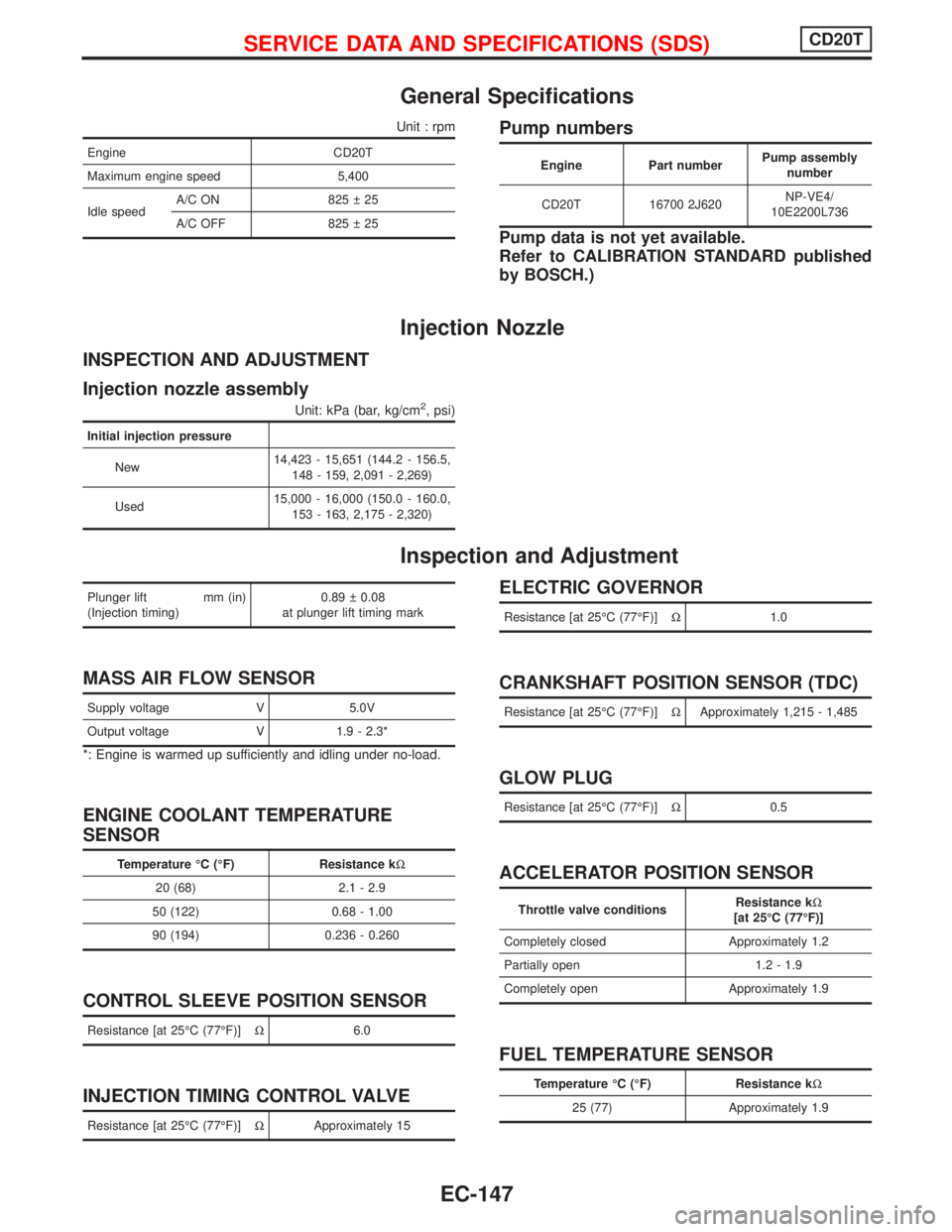

General Specifications

Unit : rpm

Engine CD20T

Maximum engine speed 5,400

Idle speedA/C ON 825 25

A/C OFF 825 25

Pump numbers

Engine Part numberPump assembly

number

CD20T 16700 2J620NP-VE4/

10E2200L736

Pump data is not yet available.

Refer to CALIBRATION STANDARD published

by BOSCH.)

Injection Nozzle

INSPECTION AND ADJUSTMENT

Injection nozzle assembly

Unit: kPa (bar, kg/cm2, psi)

Initial injection pressure

New14,423 - 15,651 (144.2 - 156.5,

148 - 159, 2,091 - 2,269)

Used15,000 - 16,000 (150.0 - 160.0,

153 - 163, 2,175 - 2,320)

Inspection and Adjustment

Plunger lift mm (in)

(Injection timing)0.89 0.08

at plunger lift timing mark

MASS AIR FLOW SENSOR

Supply voltage V 5.0V

Output voltage V 1.9 - 2.3*

*: Engine is warmed up sufficiently and idling under no-load.

ENGINE COOLANT TEMPERATURE

SENSOR

Temperature ÉC (ÉF) Resistance kW

20 (68) 2.1 - 2.9

50 (122) 0.68 - 1.00

90 (194) 0.236 - 0.260

CONTROL SLEEVE POSITION SENSOR

Resistance [at 25ÉC (77ÉF)]W6.0

INJECTION TIMING CONTROL VALVE

Resistance [at 25ÉC (77ÉF)]WApproximately 15

ELECTRIC GOVERNOR

Resistance [at 25ÉC (77ÉF)]W1.0

CRANKSHAFT POSITION SENSOR (TDC)

Resistance [at 25ÉC (77ÉF)]WApproximately 1,215 - 1,485

GLOW PLUG

Resistance [at 25ÉC (77ÉF)]W0.5

ACCELERATOR POSITION SENSOR

Throttle valve conditionsResistance kW

[at 25ÉC (77ÉF)]

Completely closed Approximately 1.2

Partially open 1.2 - 1.9

Completely open Approximately 1.9

FUEL TEMPERATURE SENSOR

Temperature ÉC (ÉF) Resistance kW

25 (77) Approximately 1.9

SERVICE DATA AND SPECIFICATIONS (SDS)CD20T

EC-147