coolant NISSAN PULSAR 1987 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1987, Model line: PULSAR, Model: NISSAN PULSAR 1987Pages: 238, PDF Size: 28.91 MB

Page 70 of 238

70 Cooling and Heating Systems

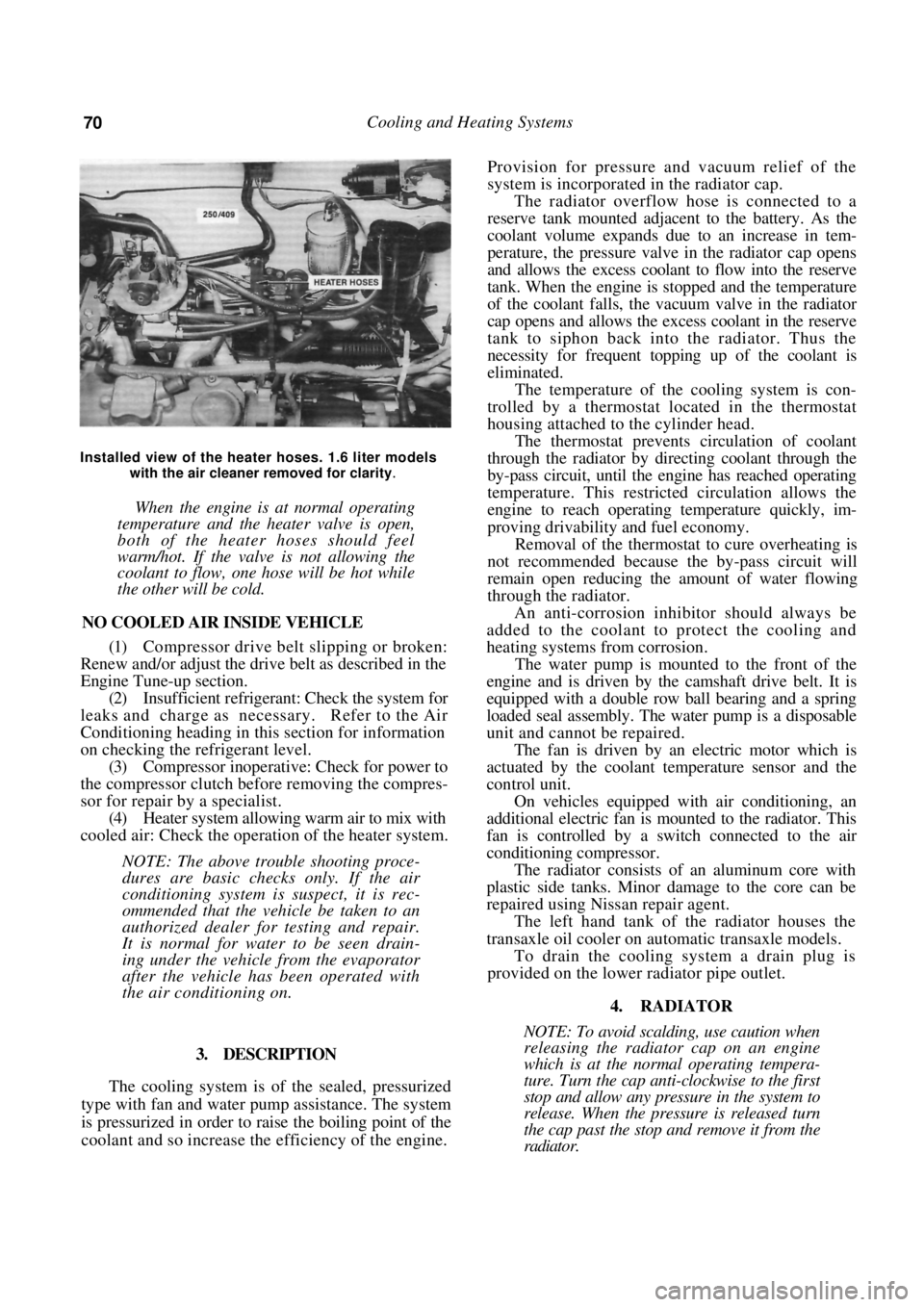

Installed view of the heater hoses. 1.6 liter models with the air cleaner removed for clarity

.

When the engine is at normal operating

temperature and the heater valve is open,

both of the heater hoses should feel

warm/hot. If the valve is not allowing the

coolant to flow, one hose will be hot while

the other will be cold.

NO COOLED AIR INSIDE VEHICLE

(1) Compressor drive belt slipping or broken:

Renew and/or adjust the drive belt as described in the

Engine Tune-up section.

(2) Insufficient refrigerant: Check the system for

leaks and charge as necessary. Refer to the Air

Conditioning heading in th is section for information

on checking the refrigerant level. (3) Compressor inoperative: Check for power to

the compressor clutch before removing the compres-

sor for repair by a specialist. (4) Heater system allowing warm air to mix with

cooled air: Check the operation of the heater system.

NOTE: The above trouble shooting proce-

dures are basic checks only. If the air

conditioning system is suspect, it is rec-

ommended that the vehicle be taken to an

authorized dealer for testing and repair.

It is normal for water to be seen drain-

ing under the vehicle from the evaporator

after the vehicle has been operated with

the air conditioning on.

3. DESCRIPTION

The cooling system is of the sealed, pressurized

type with fan and water pump assistance. The system

is pressurized in order to raise the boiling point of the

coolant and so increase the efficiency of the engine.

Provision for pressure a nd vacuum relief of the

system is incorporated in the radiator cap.

The radiator overflow hose is connected to a

reserve tank mounted adjacent to the battery. As the

coolant volume expands due to an increase in tem-

perature, the pressure valve in the radiator cap opens

and allows the excess coolant to flow into the reserve

tank. When the engine is stopped and the temperature

of the coolant falls, the vacuum valve in the radiator

cap opens and allows the excess coolant in the reserve

tank to siphon back into the radiator. Thus the

necessity for frequent topping up of the coolant is

eliminated.

The temperature of the cooling system is con-

trolled by a thermostat located in the thermostat

housing attached to the cylinder head.

The thermostat prevents circulation of coolant

through the radiator by directing coolant through the

by-pass circuit, until the engine has reached operating

temperature. This restricted circulation allows the

engine to reach operating temperature quickly, im-

proving drivability and fuel economy.

Removal of the thermostat to cure overheating is

not recommended because th e by-pass circuit will

remain open reducing the amount of water flowing

through the radiator.

An anti-corrosion inhibitor should always be

added to the coolant to protect the cooling and

heating systems from corrosion.

The water pump is mounted to the front of the

engine and is driven by the camshaft drive belt. It is

equipped with a double row ball bearing and a spring

loaded seal assembly. The water pump is a disposable

unit and cannot be repaired.

The fan is driven by an electric motor which is

actuated by the coolant temperature sensor and the

control unit.

On vehicles equipped with air conditioning, an

additional electric fan is m ounted to the radiator. This

fan is controlled by a sw itch connected to the air

conditioning compressor.

The radiator consists of an aluminum core with

plastic side tanks. Minor damage to the core can be

repaired using Nissan repair agent.

The left hand tank of the radiator houses the

transaxle oil cooler on automatic transaxle models.

To drain the cooling system a drain plug is

provided on the lower radiator pipe outlet.

4. RADIATOR

NOTE: To avoid scalding, use caution when

releasing the radiator cap on an engine

which is at the normal operating tempera-

ture. Turn the cap anti-clockwise to the first

stop and allow any pressure in the system to

release. When the pressure is released turn

the cap past the stop and remove it from the

radiator.

Page 71 of 238

Cooling and Heating Systems 71

TO DRAIN AND REFILL

(1) Place a drain tin under the radiator drain

plug.

(2) Switch the heater controls to the maximum

heat position. (3) Remove the radiator cap and open the

radiator drain plug.

(4) Disconnect the reserve tank hose from the

radiator filler neck. (5) Lower the end of the hose and drain the

coolant from the reserve tank. (6) After all the coolant has drained from the

cooling system, install the radiator drain plug

ensuring

that the plug seal is in good condition. (7) Disconnect the wire from the temperature

sender switch and remove the switch using a suitable

spanner.

(8) Using a clean container, mix Nissan long life

coolant with clean soft water to the proportions

stipulated on the coolant container.

(9) Slowly pour the premixed coolant into the

radiator until the radiator is full and all air has

escaped through the temperat ure sender switch hole.

Install the radiator cap. (10) Fill the coolant reserve tank to the Maxi-

mum mark.

(11) Start the engine and allow it to idle.

(12) When coolant starts to flow through the

temperature sender switch hole, install the temperature

sender switch and tighten securely. (13) Continue idling the engine until the cooling

fan is activated.

(14) Switch the engine off and allow it to cool.

(15) Refill the radiator using coolant and install

the radiator cap.

Dismantled view of the radiator and associated components. Automatic transaxle model with

air conditioning.

Page 72 of 238

72 Cooling and Heating Systems

(16) After the vehicle has been driven several

kilometers check the coolant level in the reserve tank

and top up if necessary.

TO REMOVE

(1) Drain the cooling system as previously de-

scribed.

(2) Loosen the hose clamps and disconnect the

hoses from the radiator. (3) If applicable disconnect the automatic trans-

axle oil cooler hoses from the left hand side radiator

tank. Plug the hoses and fitt ings to prevent the entry

of dirt and the loss of fluid.

(4) Disconnect the hose from the reserve tank at

the top of the radiator. (5) On models with air conditioning, remove the

hoses and support bracket bolts and move the bracket

and hoses away from the top of the radiator. (6) Remove the radiator support bracket bolts

from the radiator support pa nel and lift the radiator

from the lower mountings and out of the vehicle.

NOTE: A radiator that has been in use for

some time should not be allowed to stand

empty for any length of time. The radiator

should be immersed in a tank of coolant or

otherwise kept full. If applicable, ensure that

no coolant is allowed to enter the automatic

transaxle oil cooler in the left hand side tank

of the radiator.

Failure to observe this precaution may

result in overheating when the engine is put

back into service. This is caused by internal

deposits in the radiator drying and flaking

and so obstructing the circulation of the

coolant in the system.

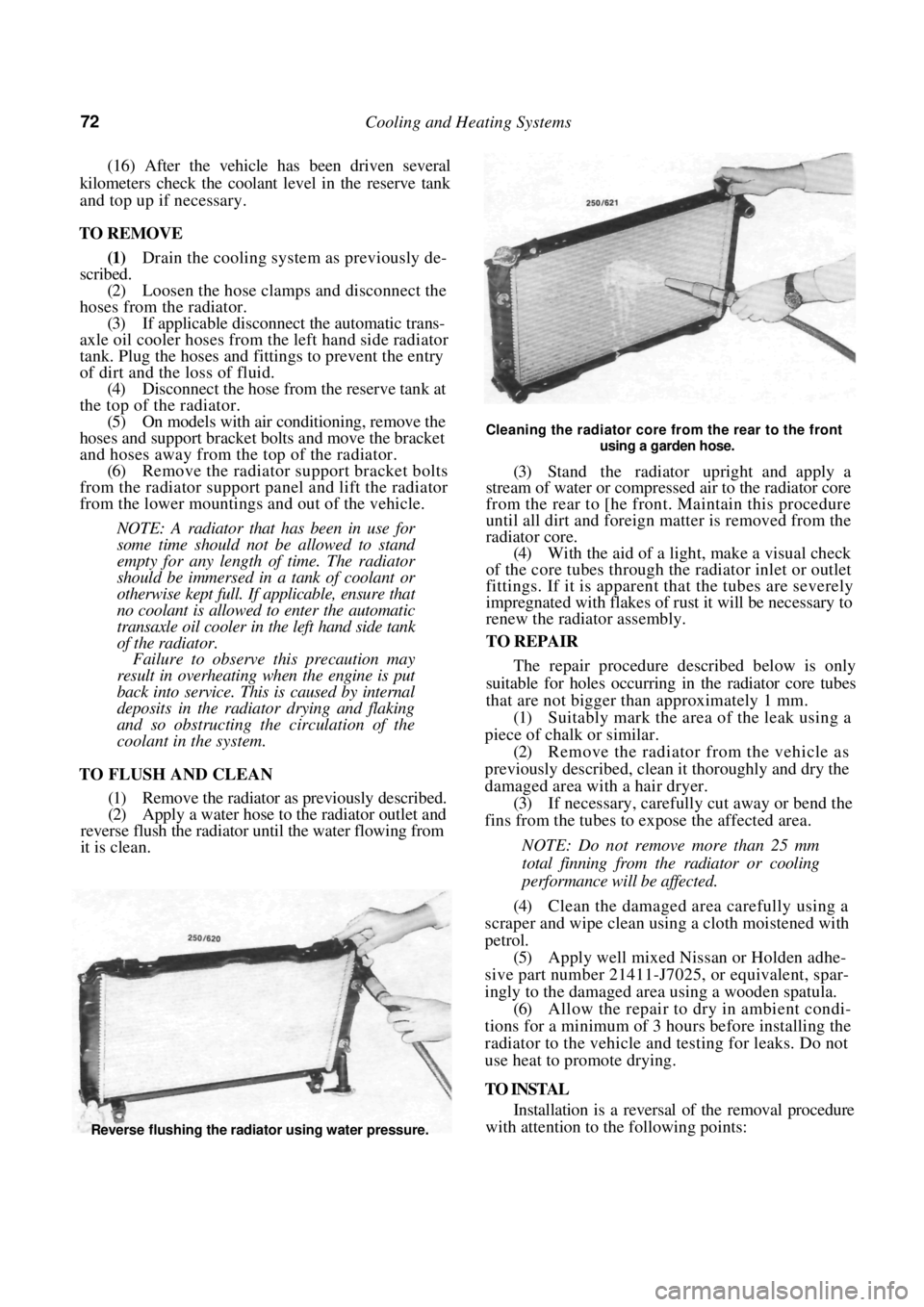

TO FLUSH AND CLEAN

(1) Remove the radiator as previously described.

(2) Apply a water hose to the radiator outlet and

reverse flush the radiator until the water flowing from

it is clean.

Cleaning the radiator core from the rear to the front

using a garden hose.

(3) Stand the radiator upright and apply a

stream of water or compressed air to the radiator core

from the rear to [he front. Maintain this procedure

until all dirt and foreign matter is removed from the

radiator core.

(4) With the aid of a light, make a visual check

of the core tubes through the radiator inlet or outlet

fittings. If it is apparent that the tubes are severely

impregnated with flakes of rust it will be necessary to

renew the radiator assembly.

TO REPAIR

The repair procedure described below is only

suitable for holes occurring in the radiator core tubes

that are not bigger than approximately 1 mm.

(1) Suitably mark the area of the leak using a

piece of chalk or similar. (2) Remove the radiator from the vehicle as

previously described, clean it thoroughly and dry the

damaged area with a hair dryer. (3) If necessary, carefully cut away or bend the

fins from the tubes to expose the affected area.

NOTE: Do not remove more than 25 mm

total finning from the radiator or cooling

performance will be affected.

(4) Clean the damaged area carefully using a

scraper and wipe clean using a cloth moistened with

petrol.

(5) Apply well mixed Nissan or Holden adhe-

sive part number 21411-J7025, or equivalent, spar-

ingly to the damaged area using a wooden spatula.

(6) Allow the repair to dry in ambient condi-

tions for a minimum of 3 hours before installing the

radiator to the vehicle and testing for leaks. Do not

use heat to promote drying.

TO INSTAL

Installation is a reversal of the removal procedure

with attention to the following points:

Reverse flushing the radiator using water pressure.

Page 73 of 238

Cooling and Heating Systems 73

(1) Renew all hoses that show signs of cracking

or perishing.

(2) Before finally tightening the hose clips, en-

sure that the hoses are push ed fully onto the radiator

and are not kinked. (3) On automatic transaxle models, ensure that

the oil cooler hoses are correctly installed to the

radiator and show no signs of leakage. Check and top

up the automatic transaxle fluid as necessary.

5. COOLING FAN

The radiator cooling fan is controlled by the

electronic control unit, and on vehicles with air

conditioning, the condenser fan relay. On vehicles

with air conditioning there are two cooling fans, one

is larger than the other. The large fan is for the

radiator and the smaller fan provides extra cooling

when the air conditioning is activated. Each fan is

controlled by a separate system.

TO TEST COOLING FAN AND SYSTEM

(1) With the cooling system cold and the air

conditioning, if applicable, switched off, switch the

ignition On and confirm that the cooling fan is

stationary.

NOTE: Leave the ignition On for all tests

unless otherwise stated.

(2) In the above test, if the cooling fan rotates,

proceed as follows:

(a) Disconnect the cooling fan relay from the

rear of the engine compartment relay box.

(b) If the fan stops, backprobe terminal C1 at

the electronic control unit using an LED test lamp

connected to the positive battery terminal. If no

circuit exists, renew the cooling fan relay.

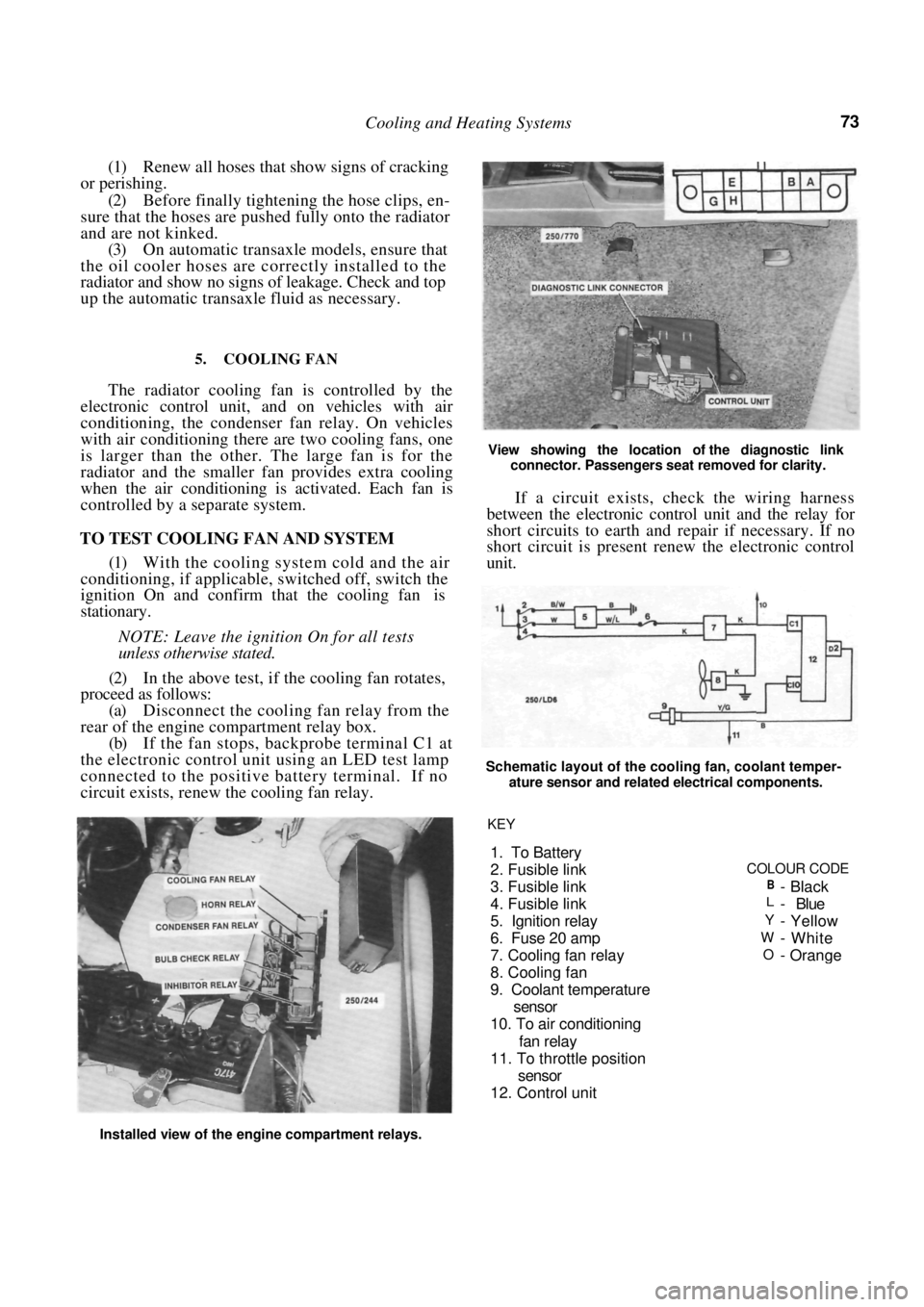

View showing the location of the diagnostic link

connector. Passengers seat removed for clarity.

If a circuit exists, check the wiring harness

between the electronic control unit and the relay for

short circuits to earth and repair if necessary. If no

short circuit is present renew the electronic control

unit.

Schematic layout of the cooling fan, coolant temper-

ature sensor and related electrical components.

Installed view of the engine compartment relays. KEY

1. To Battery

2. Fusible link

COLOUR CODE

3. Fusible link

B-Black

4. Fusible linkL- Blue

5. I

gnition relayY- Yellow

6. Fuse 20 am

pW-White

7. Coolin

g fan relayO-Orange

8. Coolin

g fan

9. Coolant tem

perature

sensor

10. To air conditionin

g

fan rela

y

11. To throttle

position

sensor

12. Control unit

Page 74 of 238

74 Cooling and Heating Systems

NOTE: Refer to the Fuel and Engine Man-

agement section for the correct procedure for

backprobing the control unit.

(3) In operation (1) if the cooling fan is station-

ary proceed as follows:

(a) Connect a jumper lead between the terminals

A and B of the diagnostic link connector. (b) if the fan runs, the fan circuit is satisfactory.

If the engine is overheating check the coolant temper-

ature sensor as described in the Fuel and Engine

Management section under the appropriate codes. (c) If the fan does not run, check the fuse (6) and

the fusible link (4) show n on the illustration.

(d) Backprobe terminal C1 at the electronic

control unit using an LED t est lamp connected to the

positive battery terminal. If no circuit exists, renew

the electronic control unit. (e) If the fuse and fusible links are serviceable,

ensure that power is available at the white and pink

wires from the fuse and fusible link of the cooling fan

relay. Repair any faults in the wiring to that point if

necessary. (f) Switch the ignition Off. disconnect the

cooling fan wiring connector at the radiator and

connect power to the fan. Renew the fan if it does not

run.

(4) On air conditioned models, remove the

jumper lead from the ALDL connector if still in-

stalled, start the engine and allow it to idle. Switch the

air conditioning on and ensu re that the cooling fan

runs.

If the cooling fan is opera ting as described above

but cooling system problems still exist, refer to the

Trouble Shooting heading at the start of this section.

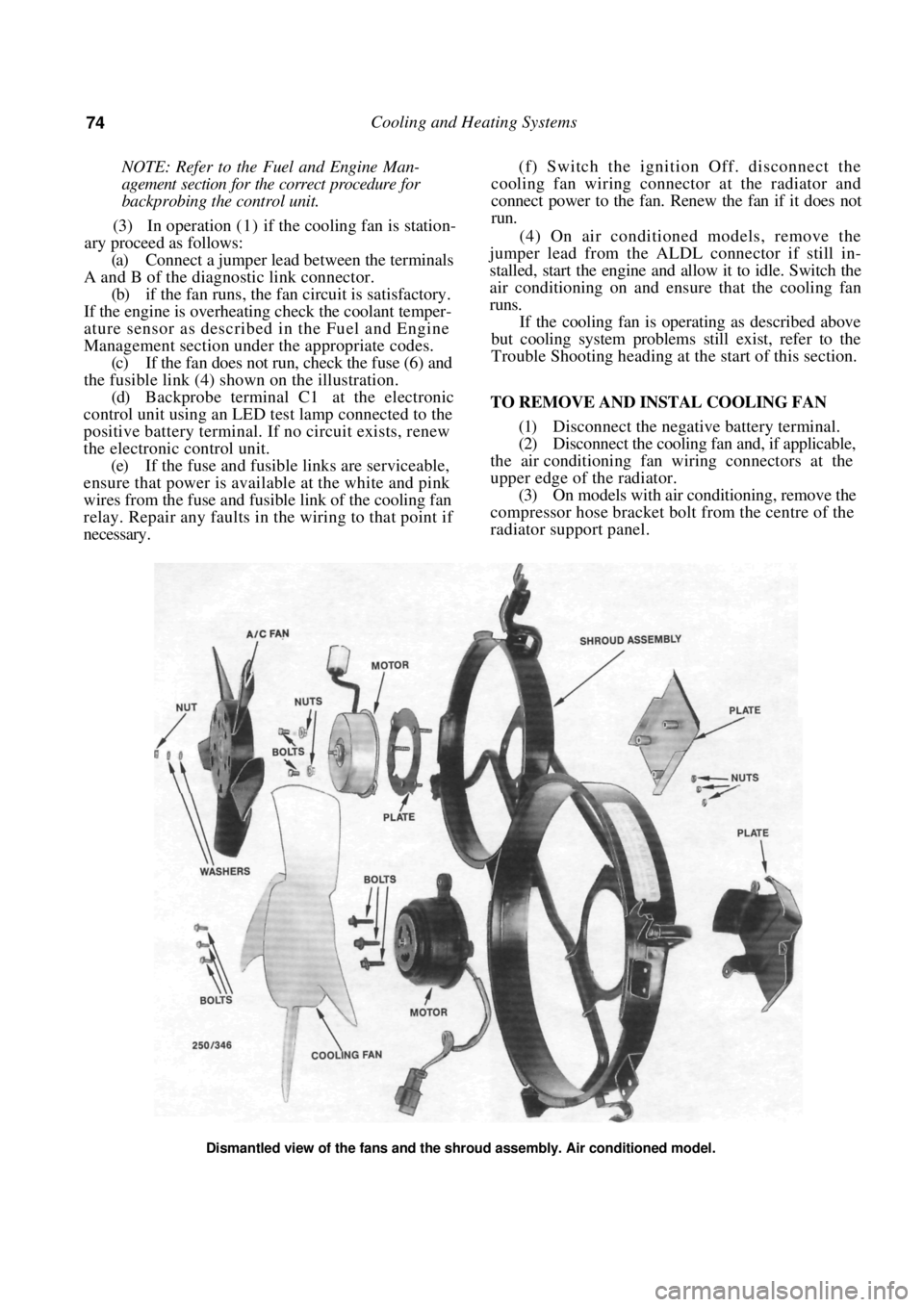

TO REMOVE AND INSTAL COOLING FAN

(1) Disconnect the negative battery terminal.

(2) Disconnect the cooling fa n and, if applicable,

the air conditioning fan wiring connectors at the

upper edge of the radiator. (3) On models with air conditioning, remove the

compressor hose bracket bolt from the centre of the

radiator support panel.

Dismantled view of the fans and the shroud assembly. Air conditioned model.

Page 75 of 238

Cooling and Heating Systems 75

(4) Remove the bolts retaining the fan shroud

assembly to the radiator and carefully move the

shroud assembly upwards and towards the engine to

release it from the lower mountings.

NOTE: On models with air conditioning, it

will be necessary to hold the air conditioning

compressor hoses toward s the engine to

allow clearance for removal of the shroud

assembly.

(5) If necessary, remove the fan from the fan

motor by removing the retaining bolts or on some

models the nut and washers.

(6) If necessary, remove the fan motor from the

shroud assembly by removing the retaining bolts or

nuts. Installation is a reversal of the removal procedure

with attention to the following points:

(1) Ensure all the fan motor and fan retaining

nuts and bolts are tightened securely. (2) Ensure that all the rubber mountings are in

good condition. Installation is a reversal of the removal procedure

with attention to the following points:

(1) Ensure that all sealing surfaces are clean.

(2) Renew the O ring on installation.

(3) Tighten the thermostat cover retaining bolts

securely.

(4) Fill the cooling system as previously de-

scribed ensuring that the heater control lever is in the

maximum heat position. Check for coolant leaks.

TO CHECK

NOTE: A visual examination of the thermo-

stat will often determine its serviceability

and make further testing unnecessary. For

instance, a thermostat with its valve fully-

open when removed from a cold engine is

obviously faulty and should be renewed.

Remove the thermostat from the thermostat

6. THERMOSTAT

Special Equipment Required:

To Check — Thermometer

TO REMOVE AND INSTAL

(1) Drain the cooling system as previously de-

scribed under the Radiator heading.

(2) On 1.6 liter models, remove the air cleaner

assembly. Refer to the Fuel and Engine Management

section if necessary. (3) Disconnect the top radiator hose from the

thermostat cover.

(4) Remove the bolts retaining the thermostat

cover to the thermostat housing. (5) Remove the thermostat cover, thermostat

and O ring from the thermostat housing.

NOTE: The thermostat and cover are ser-

viced as a unit and cannot be renewed

separately.

View of the thermostat removed from the vehicle and dismantled for testing. Line drawing showing the correct method to test the

thermostat.

(4) Progressively heat the mixture noting the

temperature reading on the thermometer as the ther-

mostat valve commences to open and when it is fully

open.

See the Specifications for opening and fully open

temperatures.

A thermostat which is not opening or is not open

at the specified temperatures should be renewed.

Page 76 of 238

Cooling and Heating Systems

7. THERMOSTAT HOUSING

Special Equipment Required:

To Adjust Camshaft Drive Belt — Adjusting tool

TO REMOVE AND INSTAL

(1) Disconnect the negative battery terminal.

(2) On 1.6 liter models, remove the air cleaner

assembly from the engine. Refer to the Fuel and

Engine Management section if necessary. (3) Drain the cooling system as previously de-

scribed. (4) Remove the camshaft drive belt as described

in the Engine section under the heading Camshaft

Drive Belt. (5) Remove the bolts retaining the camshaft

drive belt rear cover to the cylinder block and remove

the rear cover.

\ COOLANT TEMPERATURE SENSOR TEMPERATURE SENDER SWITCH

View of the thermostat housing and

components.

(6) Disconnect the top radi ator hose, the heater

hose and the inlet manifold heater hose from the

thermostat housing.

(7) Disconnect the wire from the temperature

sender switch and the coolant temperature sensor. (8) Remove the bolts retaining the thermostat

housing to the cylinder head and remove the thermo-

stat housing and the O ring from the cylinder head. Installation is a reversal of the removal procedure

with attention to the following points:

(1) Ensure that all mounting faces are clean.

(2) Renew the O ring on installation.

NOTE; Ensure that the O ring is not

twisted. Do not use sealant.

(3) Tighten the thermostat housing retaining

bolts to the specified torque. (4) Adjust the camshaft drive belt tension as

described in the Engine section under the heading

Camshaft Drive Belt. (5) Fill the cooling system as previously de-

scribed and check for coolant leaks. 8. WATER PUMP

Special Equipment Required:

To Adjust Camshaft Drive Belt — Adjusting tool

TO REMOVE AND INSTAL

NOTE: The water pump is non-repairable

and if faulty must be renewed as a complete

assembly.

(1)

Drain the cooling system as previously de-

scribed.

(2) Remove the camshaft drive belt as described

in the Engine section under the heading Camshaft

Drive Belt. (3) Remove the water pump retaining bolts and

remove the water pump and the O ring from the

engine. Installation is a reversal of the removal procedure

with attention to the following points:

View of the water pump and components removed

from the vehicle.

(1) Ensure that all mounting faces are clean.

(2) Use a new O ring and smear it with a liberal

amount of silicone grease.

(3) Install the water pump to the engine but

do

not tighten the retaining bolts until the camshaft drive

belt has been installed and tensioned correctly as

described in the Engine section under the heading

Camshaft Drive Belt.

(4) Fill the cooling system as previously de-

scribed in this section and check for coolant leaks.

9. WELCH PLUGS

To facilitate the casting of the cylinder block and

cylinder head passages and water jackets, a number of

openings had to be ma de at manufacture.

Page 77 of 238

Cooling and Heating Systems 77

These openings are plugged with welch plugs. The

plugs may have to be renewed when cleaning the

engine water jackets or when defective due to corro-

sion.

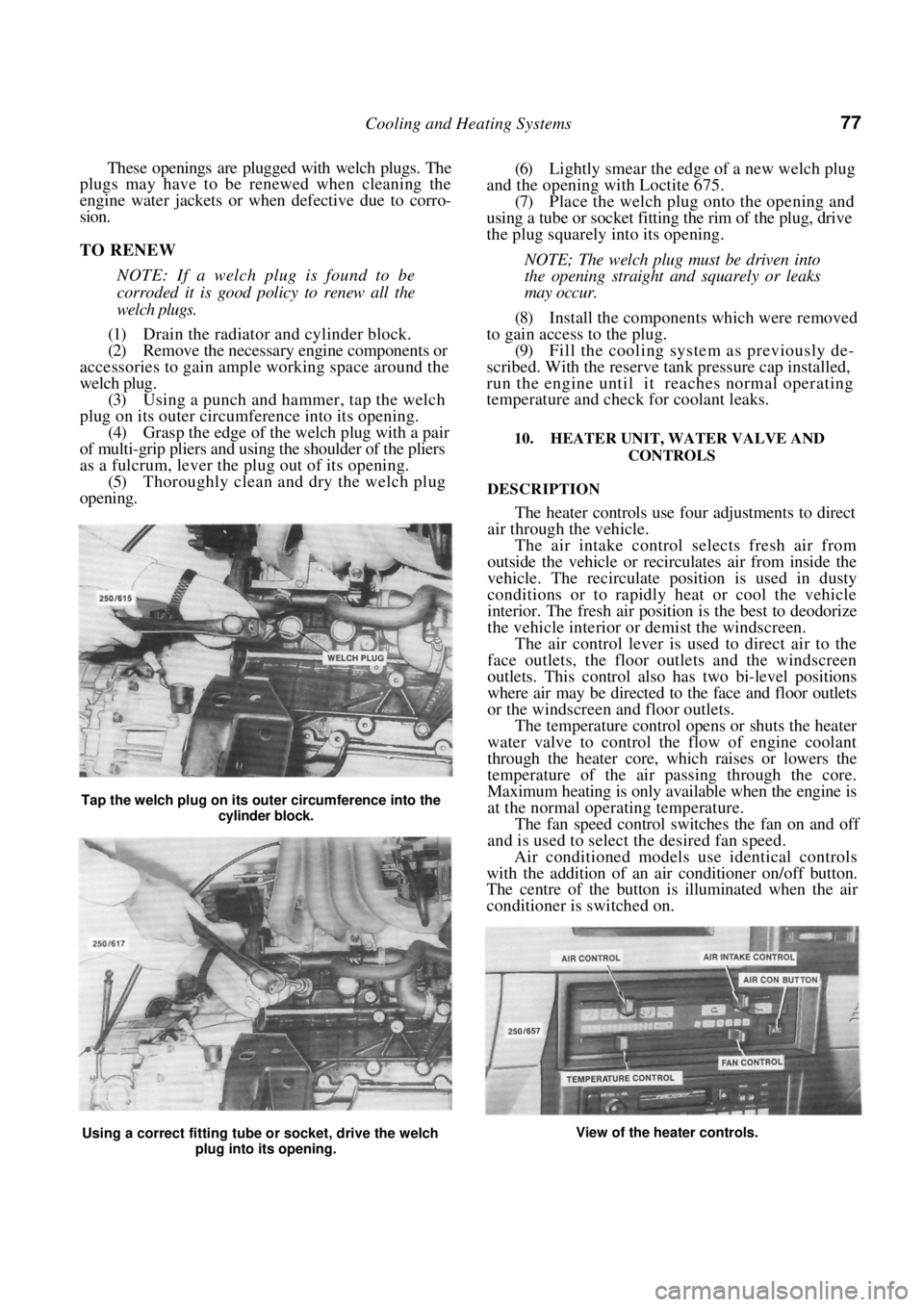

TO RENEW

NOTE: If a welch plug is found to be

corroded it is good policy to renew all the

welch plugs.

(1) Drain the radiator and cylinder block.

(2) Remove the necessary engine components or

accessories to gain ampl e working space around the

welch plug. (3) Using a punch and hammer, tap the welch

plug on its outer circumference into its opening. (4) Grasp the edge of the welch plug with a pair

of multi-grip pliers and using the shoulder of the pliers

as a fulcrum, lever the plug out of its opening. (5) Thoroughly clean and dry the welch plug

opening.

(6) Lightly smear the edge of a new welch plug

and the opening with Loctite 675. (7) Place the welch plug onto the opening and

using a tube or socket fitting the rim of the plug, drive

the plug squarely into its opening.

NOTE; The welch plug must be driven into

the opening straight and squarely or leaks

may occur.

(8) Install the components which were removed

to gain access to the plug. (9) Fill the cooling system as previously de-

scribed. With the reserve tank pressure cap installed,

run the engine until it reaches normal operating

temperature and check for coolant leaks.

10. HEATER UNIT, WATER VALVE AND

CONTROLS

DESCRIPTION

The heater controls use four adjustments to direct

air through the vehicle.

The air intake control selects fresh air from

outside the vehicle or recirculates air from inside the

vehicle. The recirculate position is used in dusty

conditions or to rapidly heat or cool the vehicle

interior. The fresh air positi on is the best to deodorize

the vehicle interior or demist the windscreen.

The air control lever is used to direct air to the

face outlets, the floor outle ts and the windscreen

outlets. This control also has two bi-level positions

where air may be directed to the face and floor outlets

or the windscreen and floor outlets.

The temperature control opens or shuts the heater

water valve to control the flow of engine coolant

through the heater core, which raises or lowers the

temperature of the air passing through the core.

Maximum heating is only available when the engine is

at the normal operating temperature.

The fan speed control switches the fan on and off

and is used to select the desired fan speed.

Air conditioned models use identical controls

with the addition of an air conditioner on/off button.

The centre of the button is illuminated when the air

conditioner is switched on.

Tap the welch plug on its ou ter circumference into the

cylinder block.

Using a correct fitting tube or socket, drive the welch

plug into its opening. View of the heater controls.

Page 82 of 238

82

FUEL AND ENGINE MANAGEMENT

CAUTION: To prevent severe electrical shock, extreme care must be taken when

working on or near the electronic ignition system as dangerous high tension voltages

are produced in both the primary and secondary circuits. See the text fo\

r

precautionary notes.

SPECIFICATIONS

FUEL INJECTION

Type:

1.6 liter engine .................................. Single point

1.8 liter engine................................... Multi point

FUEL PUMP

Type ................................................................ Electric

Pressure at idle:

1.6 liter engine ..................................... 62-90 kPa

1.8 liter engine ................................ 190-230 kPa

FUEL FILTER

Type ................................................ Inline, disposable

AIR FILTER

Type ................................... Disposable paper element

DISTRIBUTOR

Make ........................................................ Delco Remy

Advance contro l .......................................... Electronic

Rotation of rotor .................................. Anti-clockwise

Firing order....................................................1 -3-4-2

ADJUSTMENTS

Base idle speed ..................................... 550-650 rpm

Ignition timing.......................................... 10° BTDC

TORQUE WRENCH SETTINGS

Throttle body nuts.......................................... 10 Nm

*Throttle body bolts ........................................ 12 Nm

*Fuel hose fittings............................................ 35 Nm

Fuel rail bolts ....................................................8 Nm

Fuel tank drain plug ........................................ 24 Nm

Coolant temperature sensor ............................ 12 Nm

Oxygen sensor .................................................. 40 Nm

MAT sensor..................................................... 14 Nm

*1.6 liter engine

l . 8 liter engine

1. FUEL AND ENGINE MANAGEMENT

TROUBLE SHOOTING

NOTE: The following Trouble Shooting pro-

cedures are basic checks only. If these pro-

cedures fail to locate the fault, refer to the

System Diagnosis and Adjustments heading

for more thorough testing.

Prior to performing any of the following

operations, refer to the Service Precautions

and Procedures heading.

ENGINE WILL NOT START OR HARD TO

START

(1) Water in the fuel: Dr ain the fuel from the

system and renew the fuel filter.

(2) Fault in the power supply: Check the battery,

fusible links and fuses. Check for clean, secure con-

nections, particularly the earth connections. Check the

EG1 and fuel pump relays.

NOTE: If the fuel pump relay fails, power

will be supplied to the fuel pump via the oil

pressure switch. When starting the engine,

Check that the MAP sensor hose is not blocked or split

and ensure that all electrical connections are clean and

secure.

Page 83 of 238

Fuel and Engine Management 83

the fuel pump will not operate until the oil

pressure is sufficient to extinguish the oil

pressure warning lamp. Therefore it will be

necessary to operate the starter motor for a

longer period than usual to start the engine.

(3) Faulty EFI component wiring connections:

Check that all component wiring connections are

clean and secure.

(4) Manifold absolute pressure (MAP) sensor

vacuum hose blocked or disconnected: Clear or recon-

nect the vacuum hose. (5) Fault in the ignition system: Check the

primary and secondary ignition circuits.

(6) Engine flooded: Fully depress the throttle

pedal until the engine starts. Check the coolant

temperature sensor. Check th e injector(s) for leakage.

ENGINE STARTS THEN STALLS

(1) Water in the fuel: Dr ain the fuel from the

system and renew the fuel filter.

(2) Air leakage at the inlet manifold: Check all

joints and hoses for air leaks. (3) Faulty EFI wiring connections: Check that

all component wiring connections are clean and

secure.

(4) Ignition timing incorrectly set: Check and

adjust the timing. (5) MAP sensor faulty or supply hose discon-

nected or blocked: Check the vacuum supply hose.

Check the operation of the MAP sensor.

ENGINE MISFIRES

(1) Faulty, dirty or incorrectly adjusted spark

plugs: Renew or clean and adjust the spark plugs.

(2) Condensation in the distributor cap: Dry and

examine the cap for cracks. (3) Faulty high tension leads: Check and renew

the high tension leads.

Testing the fuel system pressure using a pressure

gauge.

(4) Faulty ignition coil: Check and renew the

ignition coil.

(5) Fuel blockage: Check for blockage in the fuel

filter, lines and injector(s). (6) Low fuel pressure: Check the fuel pump and

fuel pressure regulator. (7) Water in the fuel: Dr ain the fuel from the

system and renew the fuel filter. (8) Loose fuel supply wiring connectors: Check

all connectors for tightness. (9) Faulty fuel injector: Check the connections

and test the condition of the fuel injectors.

ENGINE LACKS POWER

(1) Ignition timing incorrectly set: Check and

adjust the timing.

(2) Water in the fuel: Dr ain the fuel from the

system and renew the fuel filter.

(3) Incorrectly adjusted throttle cable: Adjust the

throttle cable.

Check the distributor cap for cracks or tracking be- tween the terminals. The air filter element should be renewed at 40 000 km

intervals. 1.8 liter engine.