wiring NISSAN PULSAR 1987 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1987, Model line: PULSAR, Model: NISSAN PULSAR 1987Pages: 238, PDF Size: 28.91 MB

Page 66 of 238

66 Engine

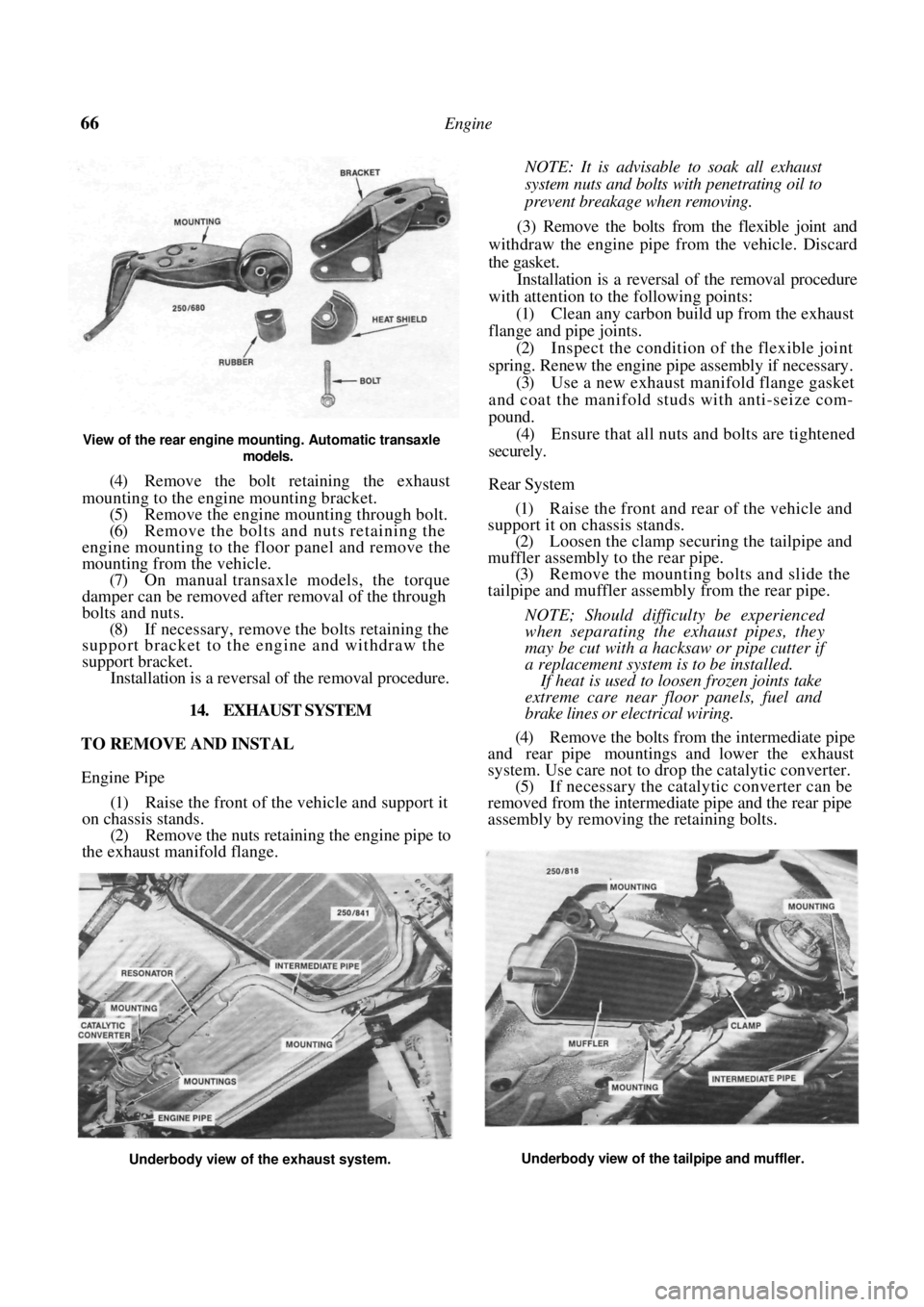

View of the rear engine mounting. Automatic transaxle models.

(4) Remove the bolt retaining the exhaust

mounting to the engine mounting bracket. (5) Remove the engine mounting through bolt.

(6) Remove the bolts and nuts retaining the

engine mounting to the floor panel and remove the

mounting from the vehicle.

(7) On manual transaxle models, the torque

damper can be removed after removal of the through

bolts and nuts. (8) If necessary, remove the bolts retaining the

support bracket to the engine and withdraw the

support bracket.

Installation is a reversal of the removal procedure.

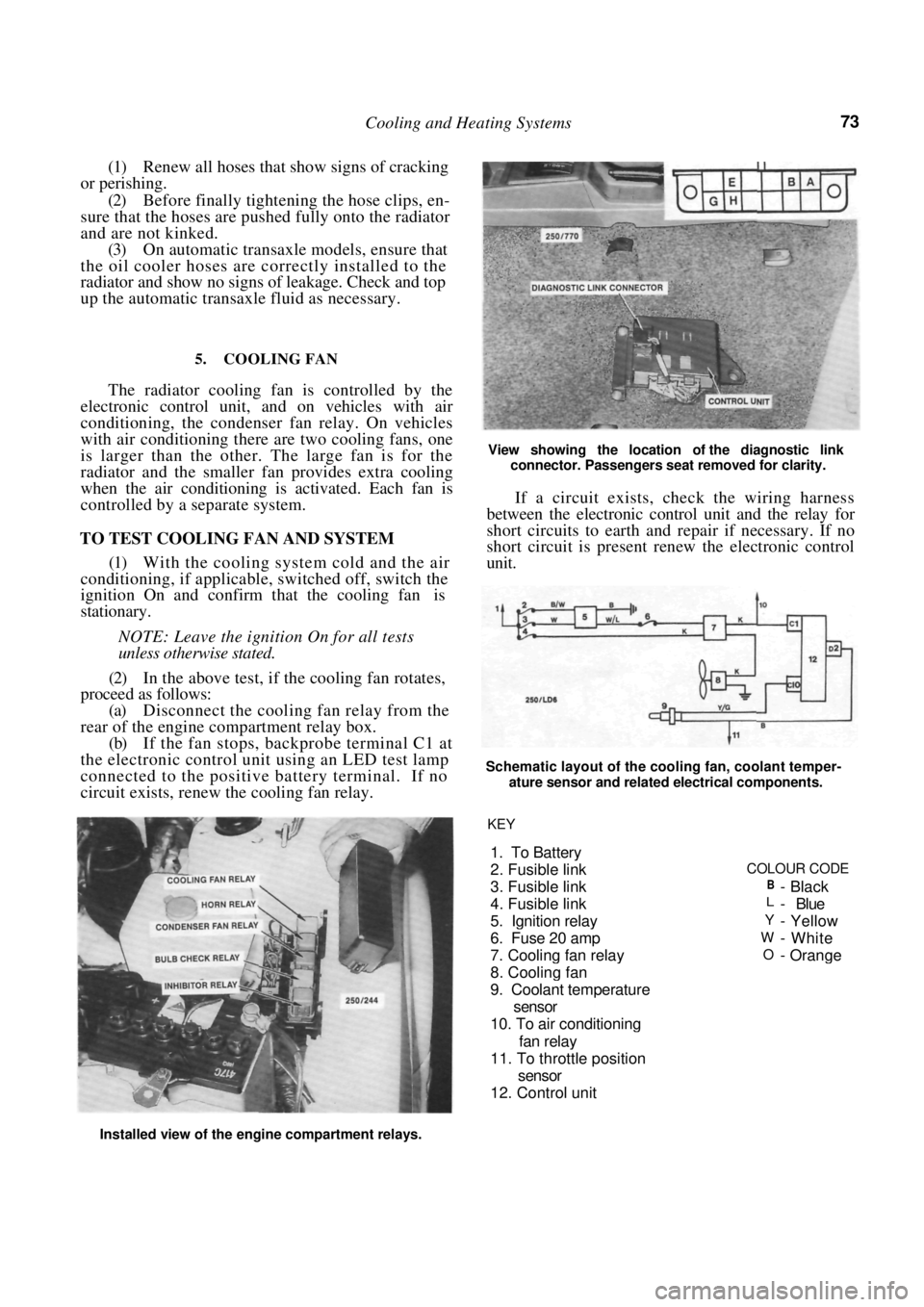

14. EXHAUST SYSTEM

TO REMOVE AND INSTAL

Engine Pipe

(1) Raise the front of the vehicle and support it

on chassis stands. (2) Remove the nuts retaining the engine pipe to

the exhaust manifold flange.

NOTE: It is advisable to soak all exhaust

system nuts and bolts wi th penetrating oil to

prevent breakage when removing.

(3) Remove the bolts from the flexible joint and

withdraw the engine pipe from the vehicle. Discard

the gasket.

Installation is a reversal of the removal procedure

with attention to the following points:

(1) Clean any carbon build up from the exhaust

flange and pipe joints. (2) Inspect the condition of the flexible joint

spring. Renew the engine pipe assembly if necessary. (3) Use a new exhaust manifold flange gasket

and coat the manifold studs with anti-seize com-

pound. (4) Ensure that all nuts and bolts are tightened

securely.

Rear System

(1) Raise the front and rear of the vehicle and

support it on chassis stands. (2) Loosen the clamp securing the tailpipe and

muffler assembly to the rear pipe. (3) Remove the mounting bolts and slide the

tailpipe and muffler assembly from the rear pipe.

NOTE; Should difficulty be experienced

when separating the exhaust pipes, they

may be cut with a hacksaw or pipe cutter if

a replacement system is to be installed.

If heat is used to loosen frozen joints take

extreme care near floor panels, fuel and

brake lines or electrical wiring.

(4) Remove the bolts from the intermediate pipe

and rear pipe mountings and lower the exhaust

system. Use care not to drop the catalytic converter.

(5) If necessary the cataly tic converter can be

removed from the intermediate pipe and the rear pipe

assembly by removing the retaining bolts.

Underbody view of the exhaust system. Underbody view of the tailpipe and muffler.

Page 73 of 238

Cooling and Heating Systems 73

(1) Renew all hoses that show signs of cracking

or perishing.

(2) Before finally tightening the hose clips, en-

sure that the hoses are push ed fully onto the radiator

and are not kinked. (3) On automatic transaxle models, ensure that

the oil cooler hoses are correctly installed to the

radiator and show no signs of leakage. Check and top

up the automatic transaxle fluid as necessary.

5. COOLING FAN

The radiator cooling fan is controlled by the

electronic control unit, and on vehicles with air

conditioning, the condenser fan relay. On vehicles

with air conditioning there are two cooling fans, one

is larger than the other. The large fan is for the

radiator and the smaller fan provides extra cooling

when the air conditioning is activated. Each fan is

controlled by a separate system.

TO TEST COOLING FAN AND SYSTEM

(1) With the cooling system cold and the air

conditioning, if applicable, switched off, switch the

ignition On and confirm that the cooling fan is

stationary.

NOTE: Leave the ignition On for all tests

unless otherwise stated.

(2) In the above test, if the cooling fan rotates,

proceed as follows:

(a) Disconnect the cooling fan relay from the

rear of the engine compartment relay box.

(b) If the fan stops, backprobe terminal C1 at

the electronic control unit using an LED test lamp

connected to the positive battery terminal. If no

circuit exists, renew the cooling fan relay.

View showing the location of the diagnostic link

connector. Passengers seat removed for clarity.

If a circuit exists, check the wiring harness

between the electronic control unit and the relay for

short circuits to earth and repair if necessary. If no

short circuit is present renew the electronic control

unit.

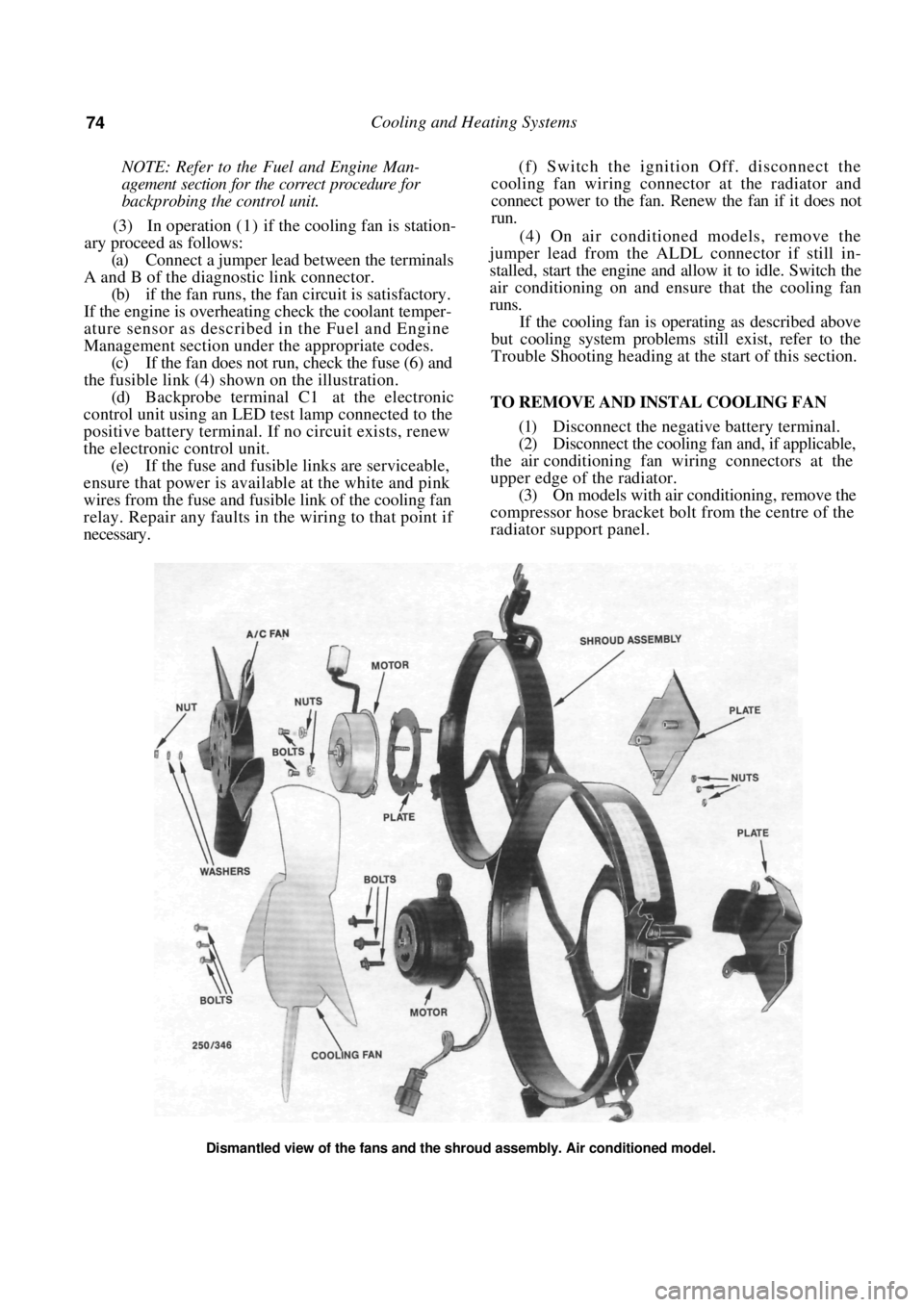

Schematic layout of the cooling fan, coolant temper-

ature sensor and related electrical components.

Installed view of the engine compartment relays. KEY

1. To Battery

2. Fusible link

COLOUR CODE

3. Fusible link

B-Black

4. Fusible linkL- Blue

5. I

gnition relayY- Yellow

6. Fuse 20 am

pW-White

7. Coolin

g fan relayO-Orange

8. Coolin

g fan

9. Coolant tem

perature

sensor

10. To air conditionin

g

fan rela

y

11. To throttle

position

sensor

12. Control unit

Page 74 of 238

74 Cooling and Heating Systems

NOTE: Refer to the Fuel and Engine Man-

agement section for the correct procedure for

backprobing the control unit.

(3) In operation (1) if the cooling fan is station-

ary proceed as follows:

(a) Connect a jumper lead between the terminals

A and B of the diagnostic link connector. (b) if the fan runs, the fan circuit is satisfactory.

If the engine is overheating check the coolant temper-

ature sensor as described in the Fuel and Engine

Management section under the appropriate codes. (c) If the fan does not run, check the fuse (6) and

the fusible link (4) show n on the illustration.

(d) Backprobe terminal C1 at the electronic

control unit using an LED t est lamp connected to the

positive battery terminal. If no circuit exists, renew

the electronic control unit. (e) If the fuse and fusible links are serviceable,

ensure that power is available at the white and pink

wires from the fuse and fusible link of the cooling fan

relay. Repair any faults in the wiring to that point if

necessary. (f) Switch the ignition Off. disconnect the

cooling fan wiring connector at the radiator and

connect power to the fan. Renew the fan if it does not

run.

(4) On air conditioned models, remove the

jumper lead from the ALDL connector if still in-

stalled, start the engine and allow it to idle. Switch the

air conditioning on and ensu re that the cooling fan

runs.

If the cooling fan is opera ting as described above

but cooling system problems still exist, refer to the

Trouble Shooting heading at the start of this section.

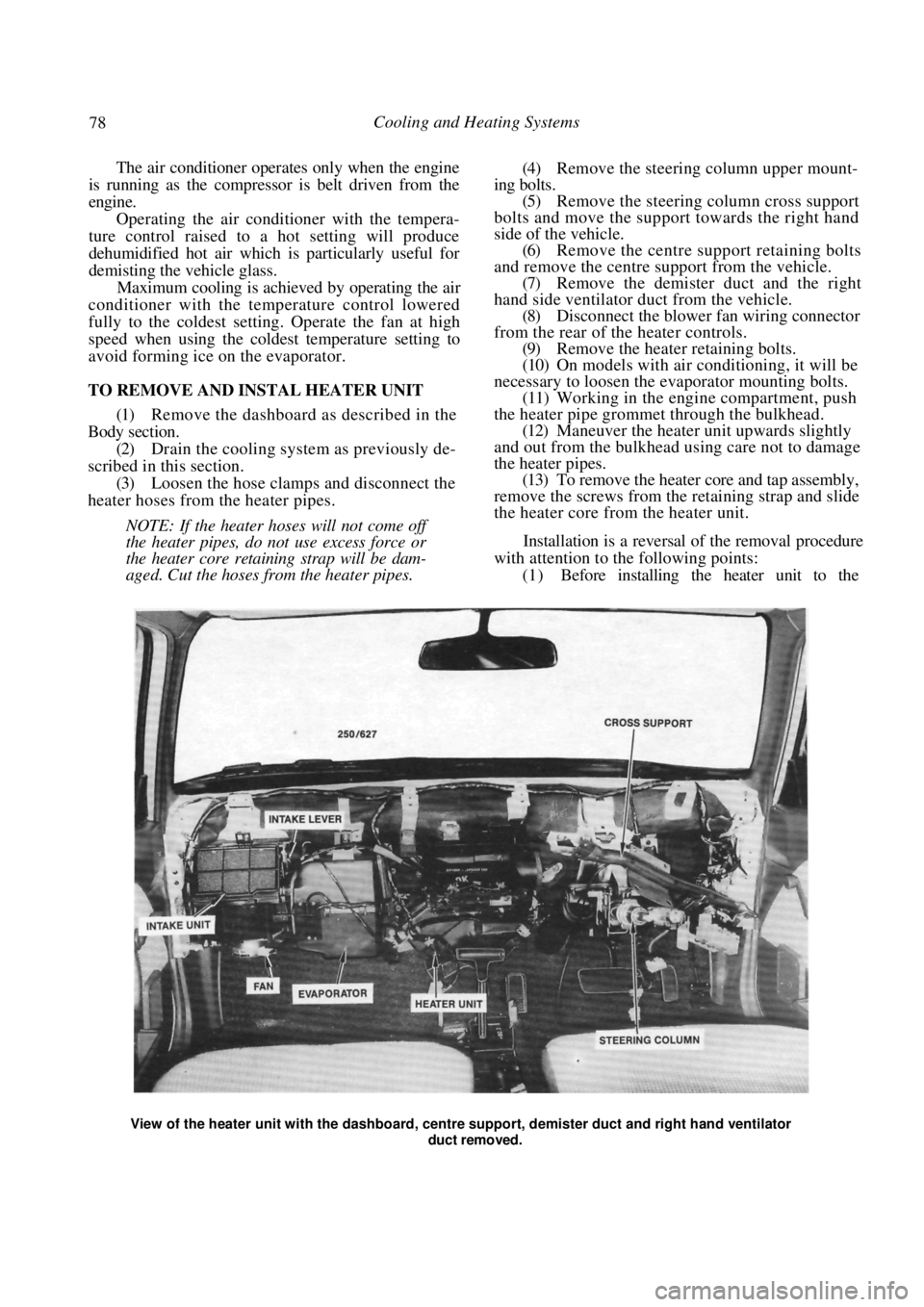

TO REMOVE AND INSTAL COOLING FAN

(1) Disconnect the negative battery terminal.

(2) Disconnect the cooling fa n and, if applicable,

the air conditioning fan wiring connectors at the

upper edge of the radiator. (3) On models with air conditioning, remove the

compressor hose bracket bolt from the centre of the

radiator support panel.

Dismantled view of the fans and the shroud assembly. Air conditioned model.

Page 78 of 238

78 Cooling and Heating Systems

The air conditioner operates only when the engine

is running as the compressor is belt driven from the

engine.

Operating the air conditioner with the tempera-

ture control raised to a hot setting will produce

dehumidified hot air which is particularly useful for

demisting the vehicle glass.

Maximum cooling is achieved by operating the air

conditioner with the temperature control lowered

fully to the coldest setting . Operate the fan at high

speed when using the coldest temperature setting to

avoid forming ice on the evaporator.

TO REMOVE AND INSTAL HEATER UNIT

(1) Remove the dashboard as described in the

Body section. (2) Drain the cooling system as previously de-

scribed in this section. (3) Loosen the hose clamps and disconnect the

heater hoses from the heater pipes.

NOTE: If the heater hos es will not come off

the heater pipes, do not use excess force or

the heater core retaining strap will be dam-

aged. Cut the hoses from the heater pipes.

(4) Remove the steering column upper mount-

ing bolts. (5) Remove the steering column cross support

bolts and move the support towards the right hand

side of the vehicle. (6) Remove the centre support retaining bolts

and remove the centre support from the vehicle.

(7) Remove the demister duct and the right

hand side ventilator duct from the vehicle. (8) Disconnect the blower fan wiring connector

from the rear of the heater controls. (9) Remove the heater retaining bolts.

(10) On models with air conditioning, it will be

necessary to loosen the evaporator mounting bolts. (11) Working in the engine compartment, push

the heater pipe grommet through the bulkhead. (12) Maneuver the heater unit upwards slightly

and out from the bulkhead using care not to damage

the heater pipes. (13) To remove the heater core and tap assembly,

remove the screws from the retaining strap and slide

the heater core from the heater unit.

Installation is a reversal of the removal procedure

with attention to the following points:

(1 ) Before installing the heater unit to the

View of the heater unit with the dashboard, centr e support, demister duct and right hand ventilator

duct removed.

Page 80 of 238

Cooling and Heating Systems

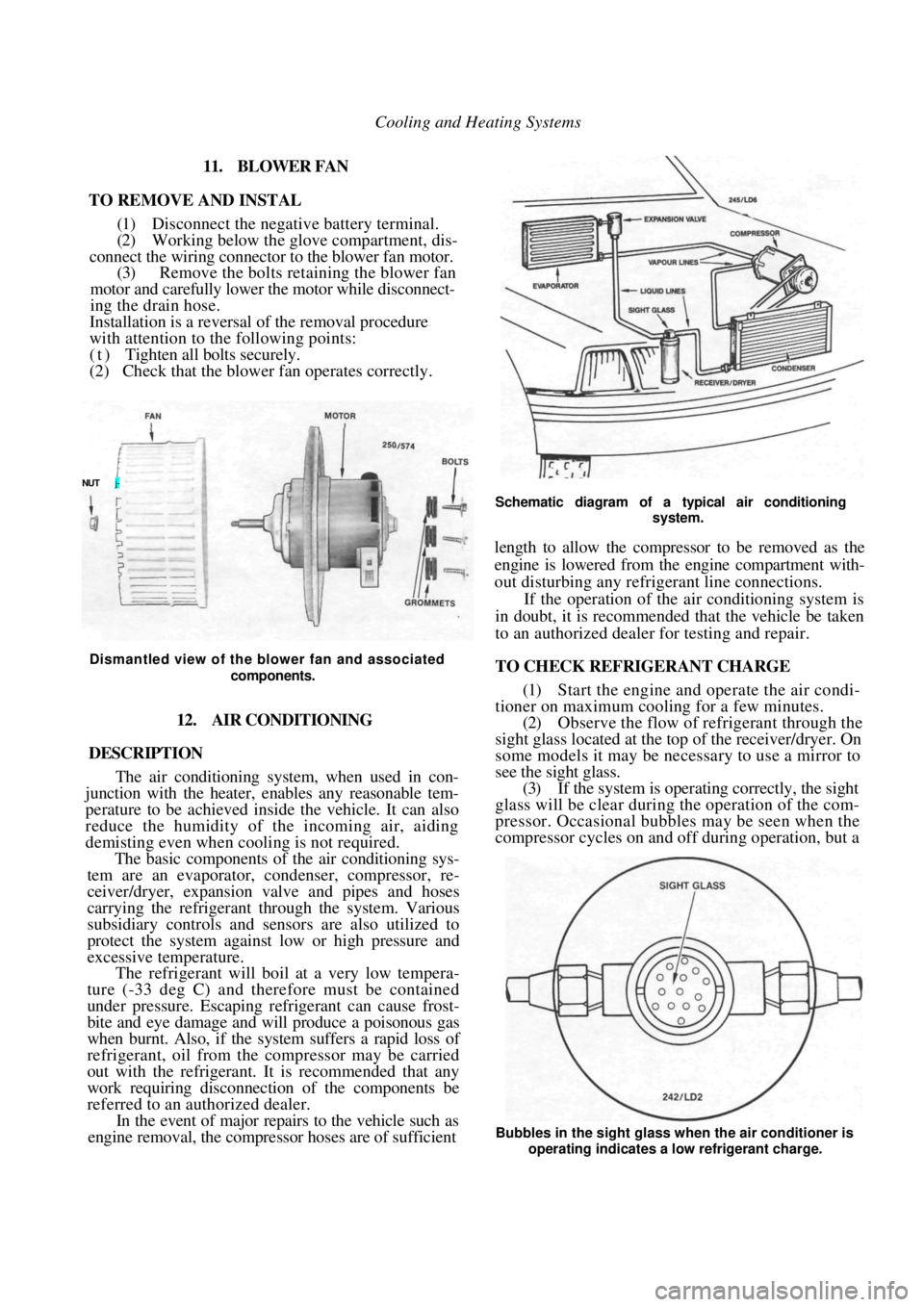

11. BLOWER FAN

TO REMOVE AND INSTAL

(1) Disconnect the negative battery terminal.

(2) Working below the glov e compartment, dis-

connect the wiring connector to the blower fan motor.

(3) Remove the bolts retaining the blower fan

motor and carefully lower the motor while disconnect-

ing the drain hose.

Installation is a reversal of the removal procedure

with attention to the following points:

( t ) Tighten all bolts securely.

(2) Check that the blow er fan operates correctly.

Dismantled view of the blower fan and associated

components.

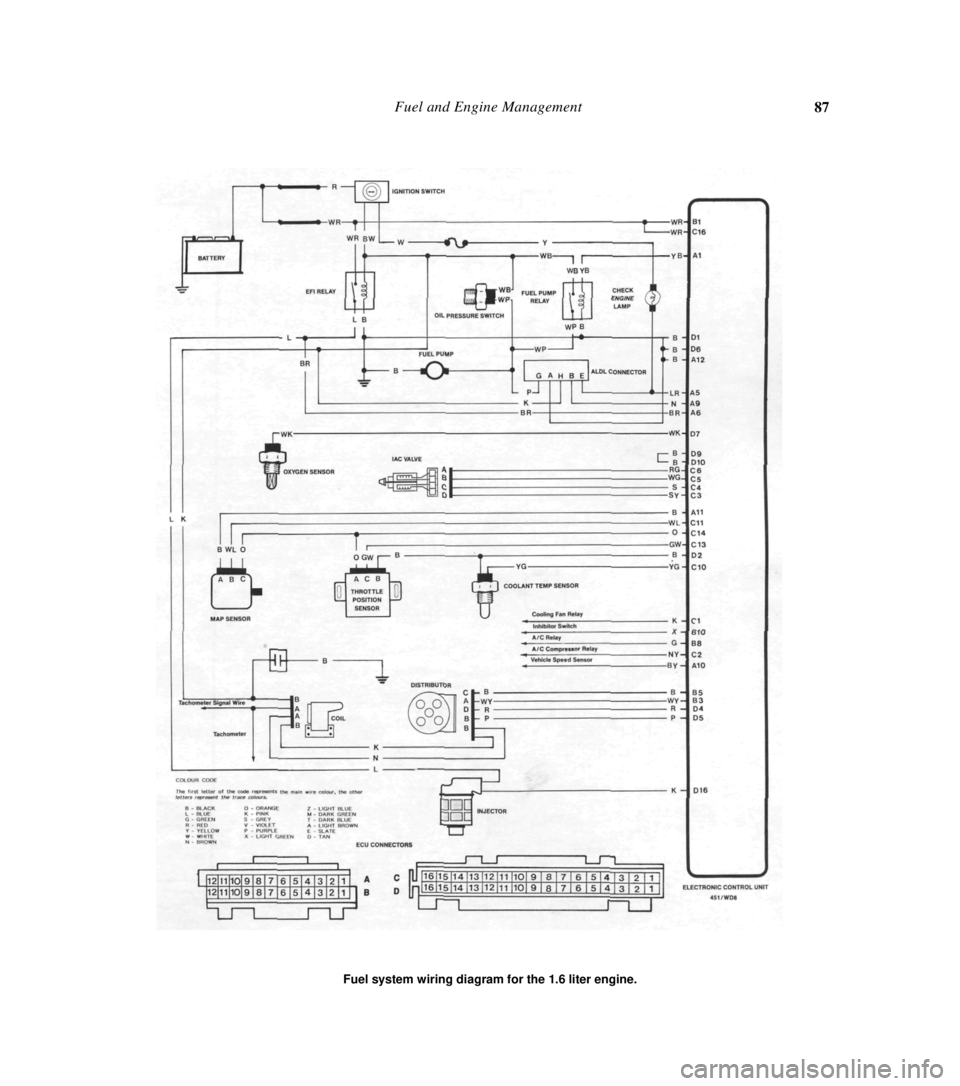

12. AIR CONDITIONING

DESCRIPTION

The air conditioning system, when used in con-

junction with the heater, enables any reasonable tem-

perature to be achieved inside the vehicle. It can also

reduce the humidity of the incoming air, aiding

demisting even when cooling is not required.

The basic components of the air conditioning sys-

tem are an evaporator, co ndenser, compressor, re-

ceiver/dryer, expansion valve and pipes and hoses

carrying the refrigerant through the system. Various

subsidiary controls and sensors are also utilized to

protect the system against low or high pressure and

excessive temperature.

The refrigerant will boil at a very low tempera-

ture (-33 deg C) and therefore must be contained

under pressure. Escaping refrigerant can cause frost-

bite and eye damage and will produce a poisonous gas

when burnt. Also, if the system suffers a rapid loss of

refrigerant, oil from the compressor may be carried

out with the refrigerant. It is recommended that any

work requiring disconnection of the components be

referred to an au thorized dealer.

In the event of major repair s to the vehicle such as

engine removal, the compress or hoses are of sufficient

Schematic diagram of a typical air conditioning

system.

length to allow the compressor to be removed as the

engine is lowered from the engine compartment with-

out disturbing any refrigerant line connections.

If the operation of the air conditioning system is

in doubt, it is recommended that the vehicle be taken

to an authorized dealer for testing and repair.

TO CHECK REFRIGERANT CHARGE

(1) Start the engine and operate the air condi-

tioner on maximum cooling for a few minutes.

(2) Observe the flow of refrigerant through the

sight glass located at the top of the receiver/dryer. On

some models it may be necessary to use a mirror to

see the sight glass. (3) If the system is operating correctly, the sight

glass will be clear during the operation of the com-

pressor. Occasional bubbles may be seen when the

compressor cycles on and off during operation, but a

NUT j-

Bubbles in the sight glass when the air conditioner is

operating indicates a low refrigerant charge.

Page 83 of 238

Fuel and Engine Management 83

the fuel pump will not operate until the oil

pressure is sufficient to extinguish the oil

pressure warning lamp. Therefore it will be

necessary to operate the starter motor for a

longer period than usual to start the engine.

(3) Faulty EFI component wiring connections:

Check that all component wiring connections are

clean and secure.

(4) Manifold absolute pressure (MAP) sensor

vacuum hose blocked or disconnected: Clear or recon-

nect the vacuum hose. (5) Fault in the ignition system: Check the

primary and secondary ignition circuits.

(6) Engine flooded: Fully depress the throttle

pedal until the engine starts. Check the coolant

temperature sensor. Check th e injector(s) for leakage.

ENGINE STARTS THEN STALLS

(1) Water in the fuel: Dr ain the fuel from the

system and renew the fuel filter.

(2) Air leakage at the inlet manifold: Check all

joints and hoses for air leaks. (3) Faulty EFI wiring connections: Check that

all component wiring connections are clean and

secure.

(4) Ignition timing incorrectly set: Check and

adjust the timing. (5) MAP sensor faulty or supply hose discon-

nected or blocked: Check the vacuum supply hose.

Check the operation of the MAP sensor.

ENGINE MISFIRES

(1) Faulty, dirty or incorrectly adjusted spark

plugs: Renew or clean and adjust the spark plugs.

(2) Condensation in the distributor cap: Dry and

examine the cap for cracks. (3) Faulty high tension leads: Check and renew

the high tension leads.

Testing the fuel system pressure using a pressure

gauge.

(4) Faulty ignition coil: Check and renew the

ignition coil.

(5) Fuel blockage: Check for blockage in the fuel

filter, lines and injector(s). (6) Low fuel pressure: Check the fuel pump and

fuel pressure regulator. (7) Water in the fuel: Dr ain the fuel from the

system and renew the fuel filter. (8) Loose fuel supply wiring connectors: Check

all connectors for tightness. (9) Faulty fuel injector: Check the connections

and test the condition of the fuel injectors.

ENGINE LACKS POWER

(1) Ignition timing incorrectly set: Check and

adjust the timing.

(2) Water in the fuel: Dr ain the fuel from the

system and renew the fuel filter.

(3) Incorrectly adjusted throttle cable: Adjust the

throttle cable.

Check the distributor cap for cracks or tracking be- tween the terminals. The air filter element should be renewed at 40 000 km

intervals. 1.8 liter engine.

Page 86 of 238

86 Fuel and Engine Management

other. The fuel pressure is maintained at a constant

pressure relevant to the manifold vacuum. A dispos-

able paper element fuel filter is mounted on the engine

bulkhead.

The amount of fuel injected is relevant to the time

the injector remains open. The basic time the injector

remains open is governed by the control unit which

uses information from the various sensors to give

optimum engine efficiency for given conditions.

The idle air control (IAC) valve controls the fast

idle speed during engine warm up and maintains the

basic idle speed at a set value by compensating for

loads such as air conditioning or the selection of Drive

on automatic transaxle models.

The throttle body assembly is mounted to the

inlet manifold and controls the amount of air entering

the engine by the action of the throttle valve.

Efficient operation of the EFI system depends on

accurate signals being receiv ed by the control unit and

controlled air flow beyond the throttle valve. There-

fore it is essential that all air, fuel and electrical

connections be clean and tight.

3. SERVICE PRECAUTIONS AND

PROCEDURES

Electronic ignition systems can produce danger-

ously high voltages in both the primary and secondary

circuits. For this reason, extreme care must be taken

when working on or near the ignition system.

Do not start the engine if the battery terminals are

not clean and tight.

Do not use the fast charge or boost settings on a

battery charger to start the engine.

Do not disconnect the battery terminals while the

engine is running.

Disconnect the battery terminals before charging

the battery.

Disconnect the negative ba ttery terminal before

working on the engine management system.

Do not subject the control unit to temperatures

above 80 deg C.

Ensure that all wiring connectors are clean and

tight.

Disconnect the battery terminals and the control

unit wiring connectors before attempting any welding

operations.

Do not direct a steam cleaning or pressure

washing nozzle at engine management components

when cleaning the engine.

Ensure that the ignition is Off prior to disconnect-

ing the battery terminals, fusible links or the control

unit wiring connectors.

TO CONNECT ELECTRICAL TEST

EQUIPMENT

NOTE: Some types of tachometers, timing

lights and ignition system analysers are not

compatible with this engine management

system and may result in incorrect readings.

It is therefore recommended that the man-

ufacturer of the lest equipment be consulted

before proceeding to use the equipment.

If a test procedure requires the use of a

test lamp or voltmeter, ensure that only the

specified instrument is used to prevent mis-

leading diagnosis.

MULTIMETER

It is essential that in all tests where voltage or

resistance is to be measur ed, a digital display multi-

meter with a minimum 10 megohms impedance be

used.

The correct method of backprobing the wiring connec-

tors. The meter test probe should be modified with a piece of thin wire as shown.

All meter readings are to be performed with the

component wiring connectors installed unless other-

wise instructed. This can be done by inserting the

meter test probes from the wiring harness side of the

connector or backprobing. If the test probes are not

thin, they should be modified by attaching a thin piece

of wire to the end, giving a fine point that will not

damage the connector. Ensure that the wire is making

good contact with the probe.

If sealing plugs or boots are removed from wiring

connectors to facilitate bac kprobing, ensure that they

are correctly installed at the conclusion of the test

procedure.

To identify wiring connector terminals refer to the

wiring circuit diagrams.

Test Lamp

To avoid damage to the electronic components

when testing, the use of an LED (light emitting diode)

test lamp is recommended.

Page 87 of 238

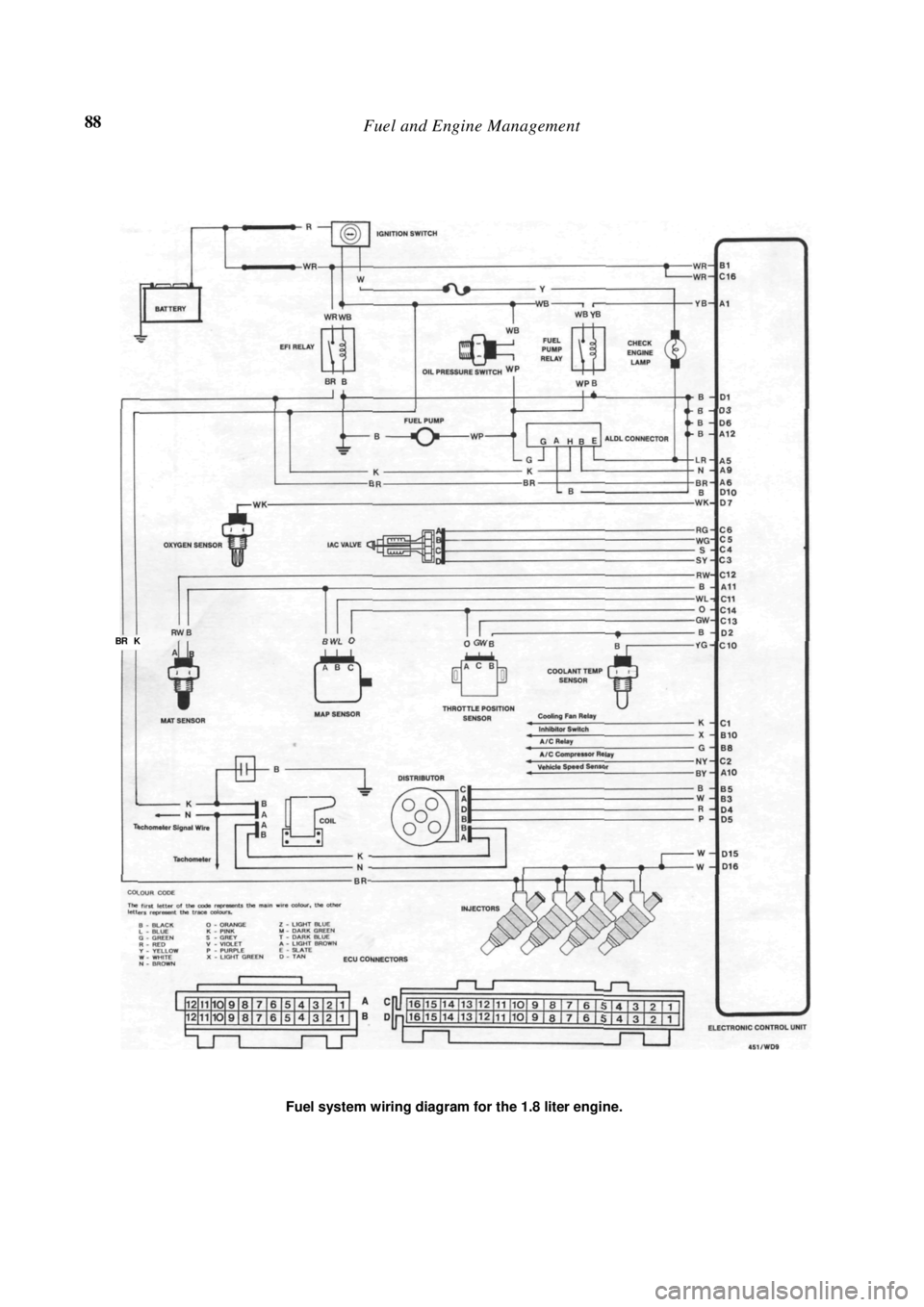

Fuel and Engine Management 87

Fuel system wiring diagram for the 1.6 liter engine.

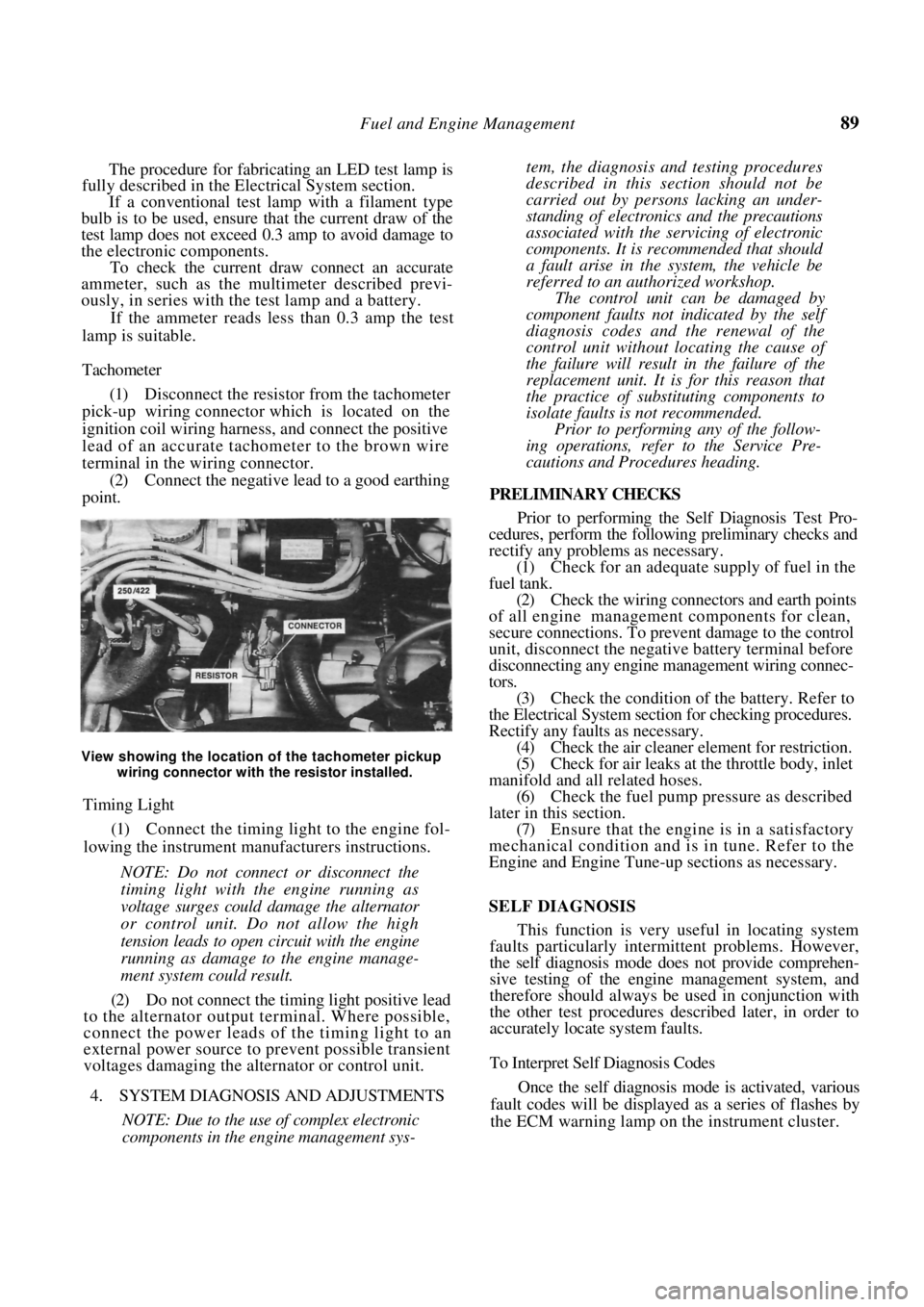

Page 88 of 238

88 Fuel and Engine Management

Fuel system wiring diagram for the 1.8 liter engine.

BR K

Page 89 of 238

Fuel and Engine Management 89

The procedure for fabricating an LED test lamp is

fully described in the El ectrical System section.

If a conventional test lamp with a filament type

bulb is to be used, ensure that the current draw of the

test lamp does not exceed 0.3 amp to avoid damage to

the electronic components.

To check the current draw connect an accurate

ammeter, such as the multimeter described previ-

ously, in series with the test lamp and a battery.

If the ammeter reads less than 0.3 amp the test

lamp is suitable.

Tachometer

(1) Disconnect the resistor from the tachometer

pick-up wiring connector which is located on the

ignition coil wiring harness, and connect the positive

lead of an accurate tachometer to the brown wire

terminal in the wiring connector. (2) Connect the negative lead to a good earthing

point.

View showing the location of the tachometer pickup

wiring connector with the resistor installed.

Timing Light

(1) Connect the timing light to the engine fol-

lowing the instrument manufacturers instructions.

NOTE: Do not connect or disconnect the

timing light with the engine running as

voltage surges could damage the alternator

or control unit. Do not allow the high

tension leads to open circuit with the engine

running as damage to the engine manage-

ment system could result.

(2) Do not connect the timing light positive lead

to the alternator output terminal. Where possible,

connect the power leads of the timing light to an

external power source to prevent possible transient

voltages damaging the alternator or control unit.

4. SYSTEM DIAGNOSIS AND ADJUSTMENTS

NOTE: Due to the use of complex electronic

components in the engine management sys-

tem, the diagnosis and testing procedures

described in this section should not be

carried out by persons lacking an under-

standing of electronics and the precautions

associated with the servicing of electronic

components. It is rec ommended that should

a fault arise in the system, the vehicle be

referred to an authorized workshop.

The control unit can be damaged by

component faults not indicated by the self

diagnosis codes and the renewal of the

control unit without lo cating the cause of

the failure will result in the failure of the

replacement unit. It is for this reason that

the practice of substituting components to

isolate faults is not recommended.

Prior to performing any of the follow-

ing operations, refer to the Service Pre-

cautions and Procedures heading.

PRELIMINARY CHECKS

Prior to performing the Self Diagnosis Test Pro-

cedures, perform the following preliminary checks and

rectify any problems as necessary.

(1) Check for an adequate supply of fuel in the

fuel tank. (2) Check the wiring connectors and earth points

of all engine management components for clean,

secure connections. To prevent damage to the control

unit, disconnect the negative battery terminal before

disconnecting any engine ma nagement wiring connec-

tors. (3) Check the condition of the battery. Refer to

the Electrical System sectio n for checking procedures.

Rectify any faults as necessary. (4) Check the air cleaner element for restriction.

(5) Check for air leaks at the throttle body, inlet

manifold and all related hoses. (6) Check the fuel pump pr essure as described

later in this section. (7) Ensure that the engine is in a satisfactory

mechanical condition and is in tune. Refer to the

Engine and Engine Tune-up sections as necessary.

SELF DIAGNOSIS

This function is very useful in locating system

faults particularly intermittent problems. However,

the self diagnosis mode does not provide comprehen-

sive testing of the engine management system, and

therefore should always be used in conjunction with

the other test procedures described later, in order to

accurately locate system faults.

To Interpret Self Diagnosis Codes

Once the self diagnosis mode is activated, various

fault codes will be displayed as a series of flashes by

the ECM warning lamp on the instrument cluster.