alternator NISSAN PULSAR 1987 Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1987, Model line: PULSAR, Model: NISSAN PULSAR 1987Pages: 238, PDF Size: 28.91 MB

Page 200 of 238

200 Electrical System

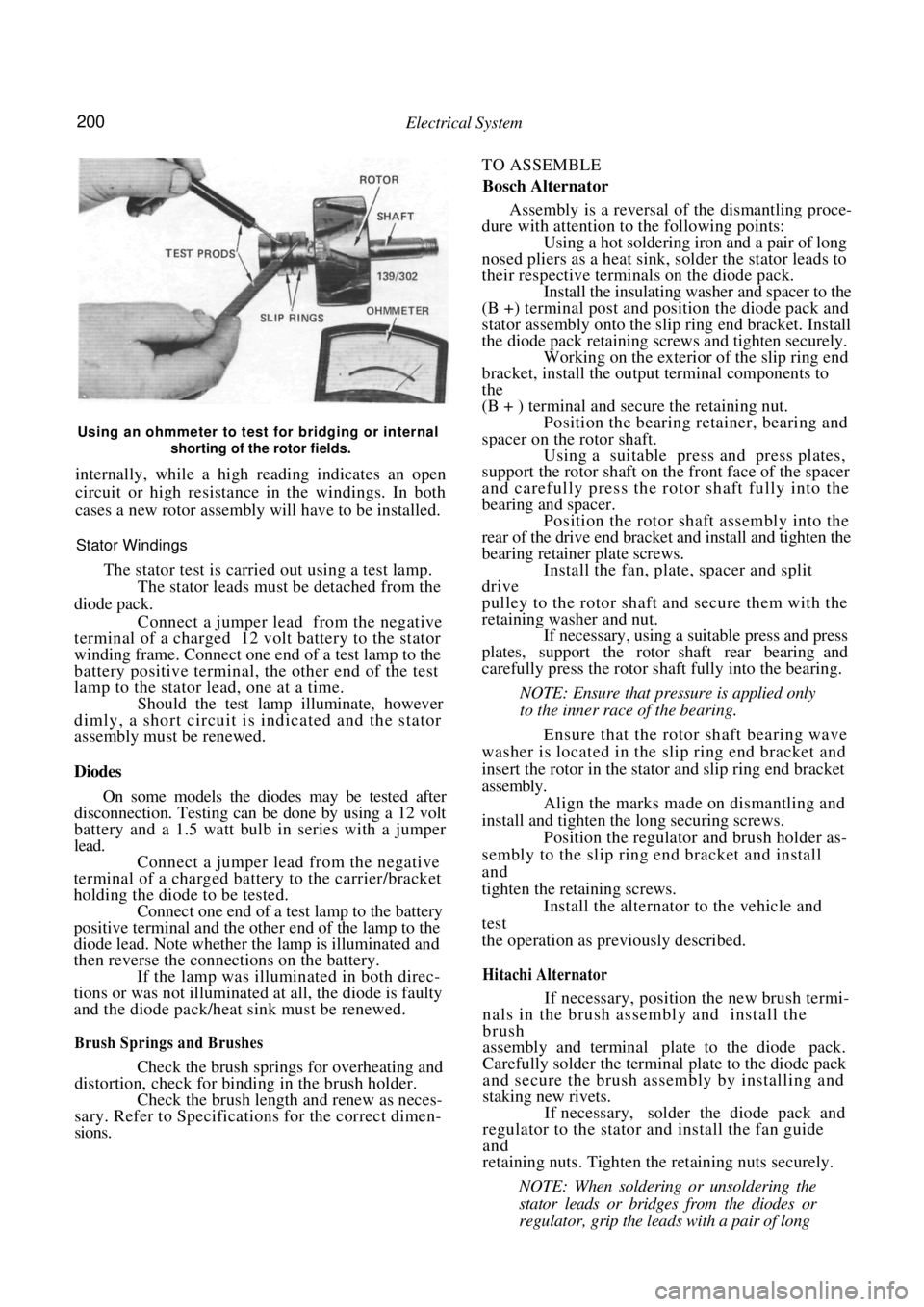

Using an ohmmeter to test for bridging or internal shorting of the rotor fields.

internally, while a high reading indicates an open

circuit or high resistance in the windings. In both

cases a new rotor assembly will have to be installed.

Stator Windings

The stator test is carried out using a test lamp.

The stator leads must be detached from the

diode pack.

Connect a jumper lead from the negative

terminal of a charged 12 volt battery to the stator

winding frame. Connect one en d of a test lamp to the

battery positive terminal, the other end of the test

lamp to the stator lead, one at a time. Should the test lamp illuminate, however

dimly, a short circuit is indicated and the stator

assembly must be renewed.

Diodes

On some models the diod es may be tested after

disconnection. Testing can be done by using a 12 volt

battery and a 1.5 watt bulb in series with a jumper

lead.

Connect a jumper lead from the negative

terminal of a charged battery to the carrier/bracket

holding the diode to be tested. Connect one end of a test lamp to the battery

positive terminal and the other end of the lamp to the

diode lead. Note whether the lamp is illuminated and

then reverse the connections on the battery. If the lamp was illuminated in both direc-

tions or was not illuminated at all, the diode is faulty

and the diode pack/heat sink must be renewed.

Brush Springs and Brushes

Check the brush spring s for overheating and

distortion, check for binding in the brush holder.

Check the brush length and renew as neces-

sary. Refer to Specifications for the correct dimen-

sions. TO ASSEMBLE

Bosch Alternator

Assembly is a reversal of the dismantling proce-

dure with attention to the following points:

Using a hot soldering iron and a pair of long

nosed pliers as a heat sink, solder the stator leads to

their respective terminals on the diode pack. Install the insulating washer and spacer to the

(B +) terminal post and position the diode pack and

stator assembly onto the slip ring end bracket. Install

the diode pack retaining screws and tighten securely. Working on the exterior of the slip ring end

bracket, install the output terminal components to

the

(B + ) terminal and secure the retaining nut.

Position the bearing retainer, bearing and

spacer on the rotor shaft. Using a suitable press and press plates,

support the rotor sh aft on the front face of the spacer

and carefully press the rotor shaft fully into the

bearing and spacer. Position the rotor shaft assembly into the

rear of the drive end bracket and install and tighten the

bearing retainer plate screws. Install the fan, plate, spacer and split

drive

pulley to the rotor shaft and secure them with the

retaining washer and nut. If necessary, using a suitable press and press

plates, support the rotor shaft rear bearing and

carefully press the rotor shaft fully into the bearing.

NOTE: Ensure that pressure is applied only

to the inner race of the bearing.

Ensure that the rotor shaft bearing wave

washer is located in the slip ring end bracket and

insert the rotor in the stator and slip ring end bracket

assembly. Align the marks made on dismantling and

install and tighten the long securing screws.

Position the regulator and brush holder as-

sembly to the slip ring end bracket and install

and

tighten the retaining screws. Install the alternator to the vehicle and

test

the operation as prev iously described.

Hitachi Alternator

If necessary, position the new brush termi-

nals in the brush assembly and install the

brush

assembly and terminal plate to the diode pack.

Carefully solder the terminal plate to the diode pack

and secure the brush assembly by installing and

staking new rivets.

If necessary, solder the diode pack and

regulator to the stator and install the fan guide

and

retaining nuts. Tighten the retaining nuts securely.

NOTE: When soldering or unsoldering the

stator leads or bridges from the diodes or

regulator, grip the leads with a pair of long

Page 201 of 238

Electrical System 201

nosed pliers. This will safeguard the diodes

by transferring any excess heat to the jaws of

the pliers.

Using a suitable drift, install the bearing into

the drive end bracket, install the retainer plate and

screws. Tighten the screws securely. Using a suitable press and press plates, install

the bearing to the slip ring end of the rotor shaft.

Ensure that pressure is ex erted only on the inner race

and that the stop ring groove is nearest to the sl i p

rings. Ensure that the rotor sh aft rear bearing stop

ring is positioned so that the protruding part of the

ring is located in the deepest part of the groove. Install the stator, diode pack and

regulator

assembly to the slip ring e nd bracket. Install the

retaining nuts and washers and tighten securely. Install the nut and insulator to the terminal

and tighten securely. Using a piece of wire, hold the brushes in a

retracted position. Hold the drive end bracket in a soft jawed

vice and install the rotor shaft assembly to the drive

end bracket. Install the pulley, retaining nut and washer to

the rotor shaft and tighten the retaining nut to the

specified torque. Apply a heated 200 watt soldering iron to the

slip ring end bracket at the bearing mounting boss for

3-4 minutes to heat the bracket and allow the

installation of the rotor shaft rear bearing. Aligning the marks made on dismantling and

ensuring that the rotor sh aft rear bearing retaining

ring protrusion is located in the deepest part of its

groove, install the rotor/stator assembly to the slip ring

end bracket.

Remove the brush retr acting wire from the

alternator, ensure that the alternator component

marks are aligned, install the retaining through bolts

and tighten them securely. Check the alternator rotor for smooth oper-

ation and install the al ternator to the vehicle

as

previously described.

Check the alternator operation on the vehicle

as previously described.

8. STARTER MOTOR

Special Equipment Required:

To Renew Brushes — Soldering iron

To Renew Armature Bearings — Bearing puller

DESCRIPTION

Two types of starter motors are installed to the

range of vehicles covere d by this manual, either

Hitachi or Bosch.

The starter motor is the induced pole type with

four brushes and four pole shoes with field coils.

A solenoid switch is attached to the starter drive

end bracket. The solenoid plunger is connected to

the overrunning clutch and drive pinion assembly

through a lever and pivot arrangement.

When the solenoid windings are energized, the

plunger acting on the lever and pivot engages the drive

pinion with the flywheel ri ng gear and at the same

time closes the switch supplying power from the

positive lead of the battery to the starter motor field

coils and armature to operate the motor.

As the engine fires, the over-running clutch of the

drive pinion assembly prevents high speed rotation of.

and possible damage to, the starter armature if the

solenoid windings are not immediately de-energized

by releasing the ignition key.

The starter solenoid switch windings are energized

by the ignition switch.

TO TEST ON VEHICLE

Should the starter motor fail to operate when the

ignition switch is turned to the Start position, check

the following points:

Check the battery condition and state of

charge. Refer to the Battery heading for the correct

procedure.

Clean the battery terminals, taking particular

care to remove the scale from the positive ( + )

terminal post and terminal. Check the earth connection for tightness and

cleanliness.

Switch on the headlamps and turn the igni-

tion switch to Start. If the lamps dim but the starter

motor does not operate, it could indicate that a short

circuit has developed in the starting system. Check that the engine is not seized or that the

starter motor drive pinion and ring gear are not

locked as these conditions would -give the same

indications as above.

(5) If the lamps do not dim and the starter

motor does not operate, this would indicate an open

circuit such as a broken or disconnected wire or a

switch not operating.

If the vehicle is equipped with an automatic

transaxle, turn the ignition switch to Start and move

the selector lever through all the gear selection range.

If the starter motor operates in any position other

than N or P, the neutral safety switch is faulty.

(6) Check all the external wiring to ensure that

the fault is not external. If the external circuit proves

satisfactory, indicating that the problem is in the

starter motor, the unit will have to be removed and

tested.

TO REMOVE AND INSTAL

Disconnect the negative battery terminal.

Disconnect the wiring from the starter motor

solenoid. Remove the starter motor mounting bolts,

Page 219 of 238

Electrical System 219

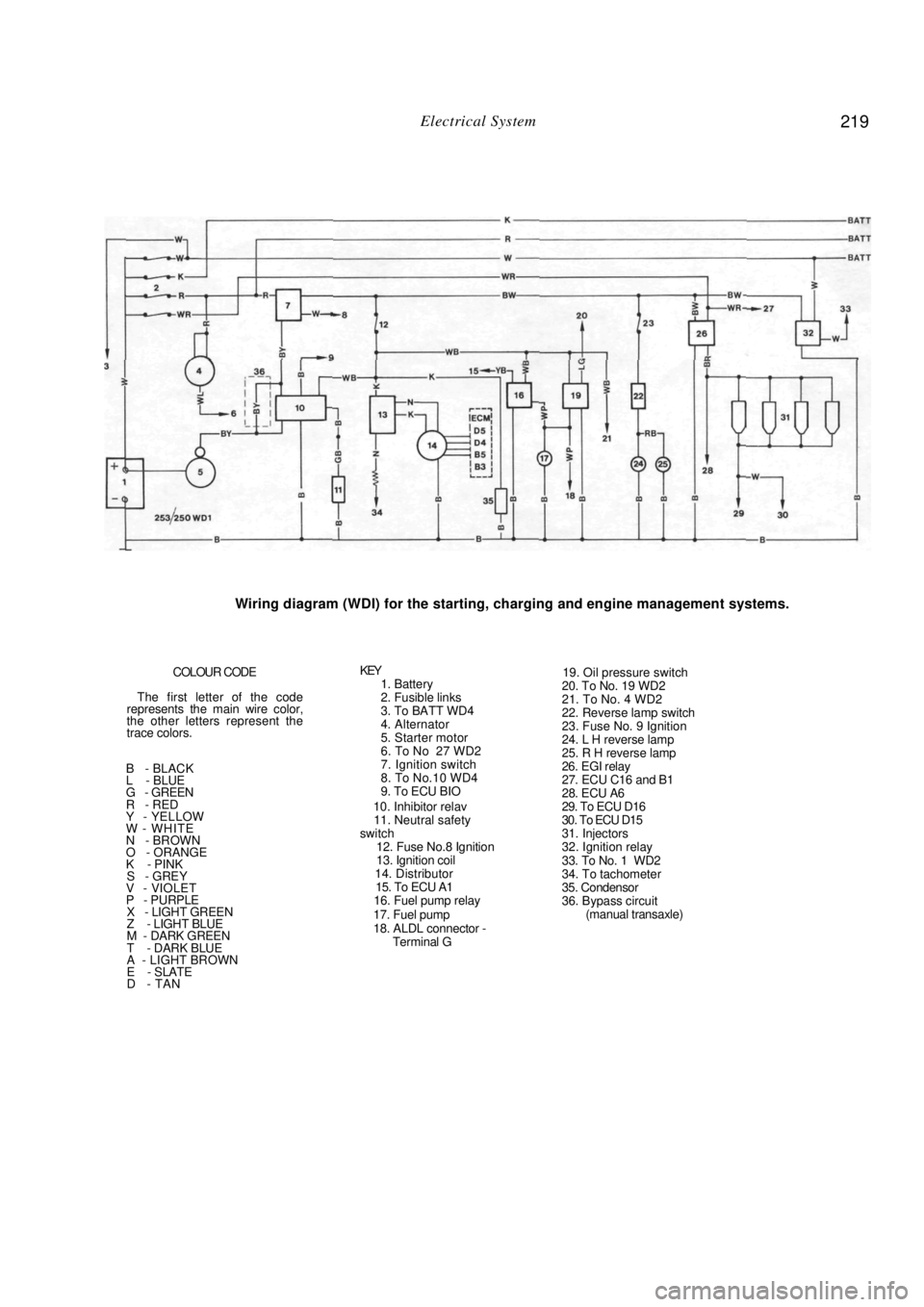

Wiring diagram (WDI) for the starting, charging and engine management systems.

COLOUR CODE

The first letter of the code

represents the main wire color,

the other letters represent the

trace colors.

B - BLACK

L - BLUE

G - GREEN

R - RED

Y - YELLOW

W - WHITE

N - BROWN

O - ORANGE

K - PINK

S - GREY V - VIOLET

P - PURPLE X - LIGHT GREEN

Z - LIGHT BLUE

M - DARK GREEN

T - DARK BLUE

A - LIGHT BROWN

E - SLATE

D - TAN

KEY 1. Battery

2. Fusible links

3. To BATT WD4

4. Alternator

5. Starter motor

6. To No 27 WD2

7. Ignition switch

8. To No.10 WD4

9. To ECU BIO

10. Inhibitor relav

11. Neutral safety

switch

12. Fuse No.8 Ignition

13. Ignition coil

14. Distributor

15. To ECU A1

16. Fuel pump relay

17. Fuel pump

18. ALDL connector - Terminal G

19. Oil pressure switch

20. To No. 19 WD2

21. To No. 4 WD2

22. Reverse lamp switch

23. Fuse No. 9 Ignition

24. L H reverse lamp

25. R H reverse lamp

26. EGI relay

27. ECU C16 and B1

28. ECU A6

29. To ECU D16

30. To ECU D15

31. Injectors

32. Ignition relay

33. To No. 1 WD2

34. To tachometer

35. Condensor

36. Bypass circuit (manual transaxle)