alternator NISSAN PULSAR 1987 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1987, Model line: PULSAR, Model: NISSAN PULSAR 1987Pages: 238, PDF Size: 28.91 MB

Page 89 of 238

Fuel and Engine Management 89

The procedure for fabricating an LED test lamp is

fully described in the El ectrical System section.

If a conventional test lamp with a filament type

bulb is to be used, ensure that the current draw of the

test lamp does not exceed 0.3 amp to avoid damage to

the electronic components.

To check the current draw connect an accurate

ammeter, such as the multimeter described previ-

ously, in series with the test lamp and a battery.

If the ammeter reads less than 0.3 amp the test

lamp is suitable.

Tachometer

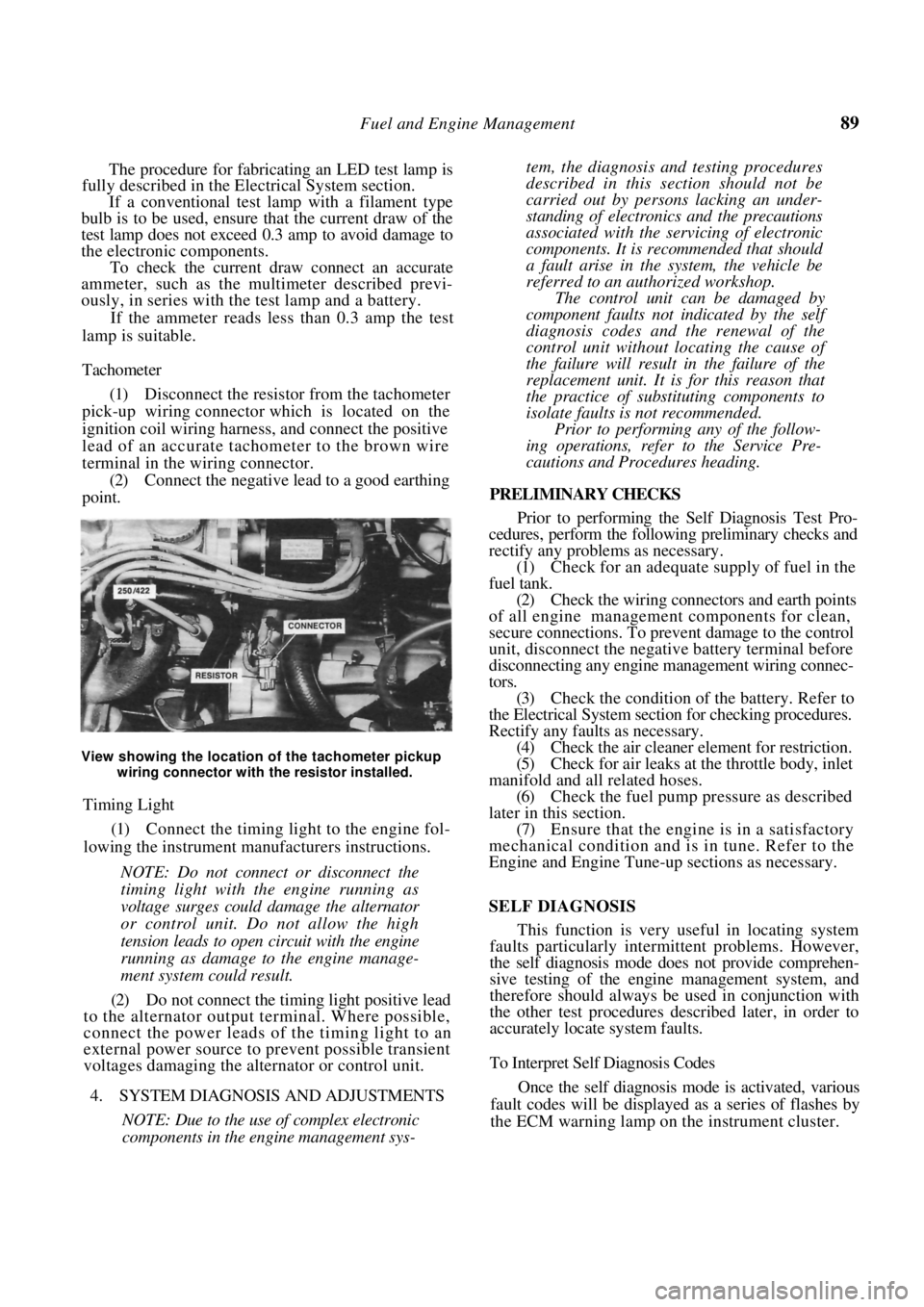

(1) Disconnect the resistor from the tachometer

pick-up wiring connector which is located on the

ignition coil wiring harness, and connect the positive

lead of an accurate tachometer to the brown wire

terminal in the wiring connector. (2) Connect the negative lead to a good earthing

point.

View showing the location of the tachometer pickup

wiring connector with the resistor installed.

Timing Light

(1) Connect the timing light to the engine fol-

lowing the instrument manufacturers instructions.

NOTE: Do not connect or disconnect the

timing light with the engine running as

voltage surges could damage the alternator

or control unit. Do not allow the high

tension leads to open circuit with the engine

running as damage to the engine manage-

ment system could result.

(2) Do not connect the timing light positive lead

to the alternator output terminal. Where possible,

connect the power leads of the timing light to an

external power source to prevent possible transient

voltages damaging the alternator or control unit.

4. SYSTEM DIAGNOSIS AND ADJUSTMENTS

NOTE: Due to the use of complex electronic

components in the engine management sys-

tem, the diagnosis and testing procedures

described in this section should not be

carried out by persons lacking an under-

standing of electronics and the precautions

associated with the servicing of electronic

components. It is rec ommended that should

a fault arise in the system, the vehicle be

referred to an authorized workshop.

The control unit can be damaged by

component faults not indicated by the self

diagnosis codes and the renewal of the

control unit without lo cating the cause of

the failure will result in the failure of the

replacement unit. It is for this reason that

the practice of substituting components to

isolate faults is not recommended.

Prior to performing any of the follow-

ing operations, refer to the Service Pre-

cautions and Procedures heading.

PRELIMINARY CHECKS

Prior to performing the Self Diagnosis Test Pro-

cedures, perform the following preliminary checks and

rectify any problems as necessary.

(1) Check for an adequate supply of fuel in the

fuel tank. (2) Check the wiring connectors and earth points

of all engine management components for clean,

secure connections. To prevent damage to the control

unit, disconnect the negative battery terminal before

disconnecting any engine ma nagement wiring connec-

tors. (3) Check the condition of the battery. Refer to

the Electrical System sectio n for checking procedures.

Rectify any faults as necessary. (4) Check the air cleaner element for restriction.

(5) Check for air leaks at the throttle body, inlet

manifold and all related hoses. (6) Check the fuel pump pr essure as described

later in this section. (7) Ensure that the engine is in a satisfactory

mechanical condition and is in tune. Refer to the

Engine and Engine Tune-up sections as necessary.

SELF DIAGNOSIS

This function is very useful in locating system

faults particularly intermittent problems. However,

the self diagnosis mode does not provide comprehen-

sive testing of the engine management system, and

therefore should always be used in conjunction with

the other test procedures described later, in order to

accurately locate system faults.

To Interpret Self Diagnosis Codes

Once the self diagnosis mode is activated, various

fault codes will be displayed as a series of flashes by

the ECM warning lamp on the instrument cluster.

Page 101 of 238

Fuel and Engine Management 101

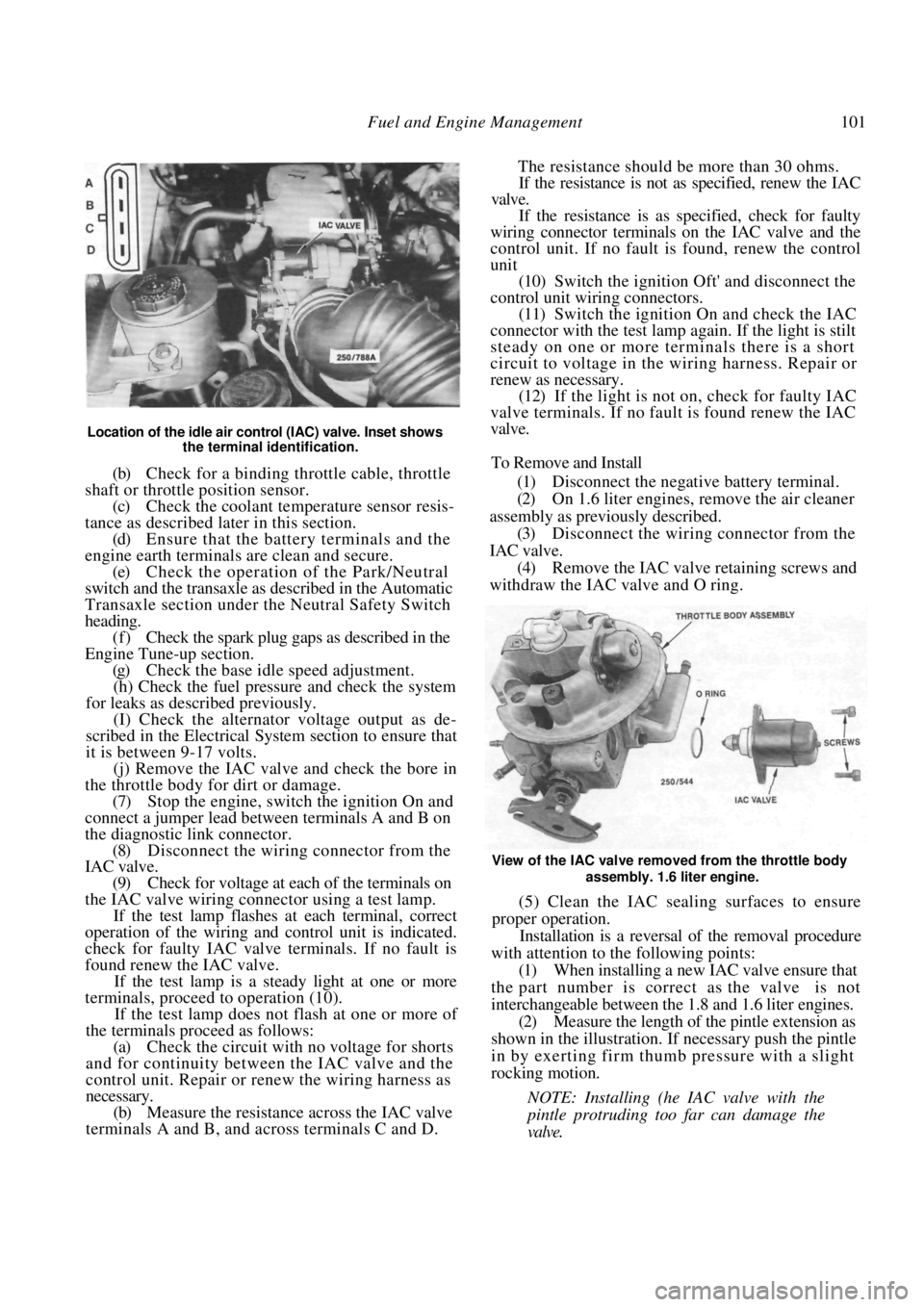

Location of the idle air control (IAC) valve. Inset shows the terminal identification.

(b) Check for a binding throttle cable, throttle

shaft or throttle position sensor. (c) Check the coolant temperature sensor resis-

tance as described later in this section. (d) Ensure that the battery terminals and the

engine earth terminals are clean and secure.

(e) Check the operation of the Park/Neutral

switch and the transaxle as described in the Automatic

Transaxle section under the Neutral Safety Switch

heading. (f) Check the spark plug gaps as described in the

Engine Tune-up section.

(g) Check the base idle speed adjustment.

(h) Check the fuel pressure and check the system

for leaks as described previously.

(I) Check the alternator voltage output as de-

scribed in the Electrical System section to ensure that

it is between 9-17 volts.

(j) Remove the IAC valve and check the bore in

the throttle body for dirt or damage.

(7) Stop the engine, switch the ignition On and

connect a jumper lead between terminals A and B on

the diagnostic link connector. (8) Disconnect the wiring connector from the

IAC valve.

(9) Check for voltage at each of the terminals on

the IAC valve wiring connector using a test lamp. If the test lamp flashes at each terminal, correct

operation of the wiring and control unit is indicated.

check for faulty IAC valve terminals. If no fault is

found renew the IAC valve.

If the test lamp is a steady light at one or more

terminals, proceed to operation (10).

If the test lamp does not flash at one or more of

the terminals proceed as follows:

(a) Check the circuit with no voltage for shorts

and for continuity between the IAC valve and the

control unit. Repair or renew the wiring harness as

necessary.

(b) Measure the resistance across the IAC valve

terminals A and B, and across terminals C and D. The resistance should be more than 30 ohms.

If the resistance is not as specified, renew the IAC

valve.

If the resistance is as specified, check for faulty

wiring connector terminals on the IAC valve and the

control unit. If no fault is found, renew the control

unit

(10) Switch the ignition Oft' and disconnect the

control unit wiring connectors. (11) Switch the ignition On and check the IAC

connector with the test lamp again. If the light is stilt

steady on one or more terminals there is a short

circuit to voltage in the wiring harness. Repair or

renew as necessary. (12) If the light is not on, check for faulty IAC

valve terminals. If no fault is found renew the IAC

valve.

To Remove and Install

(1) Disconnect the negative battery terminal.

(2) On 1.6 liter engines, remove the air cleaner

assembly as previously described. (3) Disconnect the wiring connector from the

IAC valve. (4) Remove the IAC valve retaining screws and

withdraw the IAC valve and O ring.

View of the IAC valve removed from the throttle body

assembly. 1.6 liter engine.

(5) Clean the IAC sealing surfaces to ensure

proper operation.

Installation is a reversal of the removal procedure

with attention to the following points:

(1) When installing a new IAC valve ensure that

the part number is correct as the valve is not

interchangeable between the 1.8 and 1.6 liter engines.

(2) Measure the length of the pintle extension as

shown in the illustration. If necessary push the pintle

in by exerting firm thum b pressure with a slight

rocking motion.

NOTE: Installing (he IAC valve with the

pintle protruding too far can damage the

valve.

Page 190 of 238

190

ELECTRICAL SYSTEM

CAUTION: To prevent severe electrical shock extreme care must be taken when

working on or near the electronic ignition system as dangerous high tension voltages

are produced in both the primary and secondary circuits. See the text fo\

r

precautionary notes.

SPECIFICATIONS

BATTERY

Type ..................................................12 volt lead acid

Polarity to earth .................................... Negative ( - )

Specific gravity:

Fully charged ................................... A bove 1.250

Fully discharged ................................Below 1.130

ALTERNATOR

Make .................................................Bosch or Hitachi

Maximum output .......................................... 70 amps

Polarity to earth .................................... Negative ( - )

Stator windings ......................................... Star wound

Regulator type ................................................ Integral

Brush length minimum:

Bosch ........................................................ 5.0 mm

Hitachi ............................. 6.0 mm or limit mark

STARTER MOTOR

Make .................................................Hitach i or Bosch

Type ............................ 4 pole 4 brush reduction gear

Operation control.................................. Solenoid and

overrunning clutch

Undercut of commutator (maximum):

Hitachi ...................................................... 0.8 mm

Brush length (minimum):

Bosch ........................................................ 8.0 mm

Hitachi ........................................................11 mm

Brush spring tension;

Hitachi ............................................... 15.7-19.6 N

Hitachi:

Drive pinion stopper clearance ........ 0.3-1.5 mm

Selective fit adjuster plates ........ 0.5 and 0.8 mm

IGNITION SYSTEM

The ignition system is an integral part of the

engine management system. The Specifications, testing

and overhaul procedures are fully covered in the Fuel

and Engine Management section.

TORQUE WRENCH SETTINGS

Alternator pulley retaining nut:

Bosch ......................................................... 50 Nm

Hitachi ....................................................... 59 Nm

1. BATTERY AND CHARGING SYSTEM

TROUBLE SHOOTING

BATTERY UNDERCHARGED

3. Loose or broken drive belt: Adjust or renew

the drive belt. 4. Faulty alternator regulator; Renew the regu-

lator unit.

5. Faulty battery: Install a new battery of

the

recommended type and capacity. 6. Faulty alternator: Overhaul or renew the

alternator. 7. Fault in the charging circuit wiring: Check

and repair or renew the wiring harness. 8. Faulty connections in the charging circuit:

Check and repair the connections. 9. Fusible link blown; Rectify the fault and

renew as necessary.

NOTE: Check the state of charge (specific

gravity) of the battery- as described under

the

Battery heading in this section. If the battery

is undercharged, check the possible causes in

the order given.

BATTERY OVERCHARGED

• Faulty alternator regulator unit:

Renew the

regulator unit.

• Faulty alternator: Overhaul or

renew the

alternator. • Faulty charging circuit wiring or

connec-

tions: Check and renew or repair the faulty

compo-

nents.

NOTE: An overcharged battery is indicated

by continual loss of water through boiling.

Page 191 of 238

Electrical System 191

This is usually accompanied by discoloura-

tion of the electrolyte.

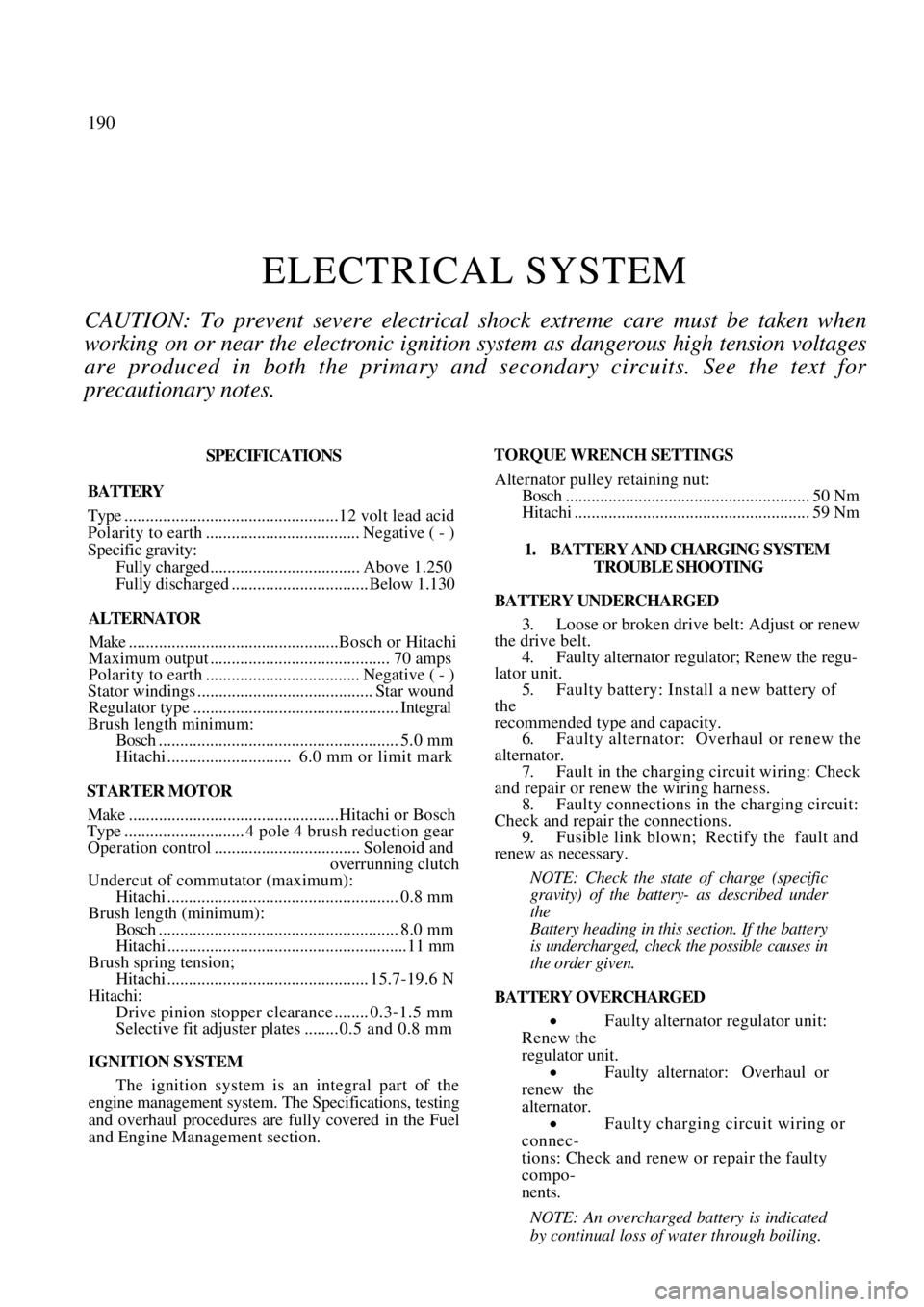

CHARGE INDICATOR LAMP REMAINS ON

• Loose or broken alternator drive belt: Adjust

or renew the drive belt.

• Faulty regulator unit: Check and renew the

regulator unit. • Faulty alternator: Check and overhaul the

alternator. • Short to earth in the warning lamp circuit:

Check and repair the circuit.

Checking the alternator drive belt for deterioration.

CHARGE INDICATOR LAMP DOES NOT

OPERATE

• Lamp bulb blown: Check and renew the

faulty bulb. • Open circuit in the wi ring or bulb socket:

Check and rectify the open circuit. • Faulty alternator diode: Overhaul the alter-

nator.

NOISE IN DRIVE BELT OR ALTERNATOR

(1) Drive belt frayed or out of alignment with

the pulleys: Renew the drive bell or align the pulleys.

• Loose alternator moun ting bolts or worn

bearings: Tighten the mounting bolts or renew the

bearings. • Loose alternator pulley: Tighten the pulley

retaining nut.

• Faulty alternator: Overhaul or renew the

alternator. • Faulty diodes in the alternator: Overhaul the

alternator, install a new heat sink.

NOTE: To check if the noise is in the

alternator or drive belt, loosen the alternator

and remove the drive belt. If the noise is

gone when the engine is run for a short time

check the serviceability of the belt and

alternator components.

2. BATTERY AND STARTING SYSTEM TROUBLE SHOOTING

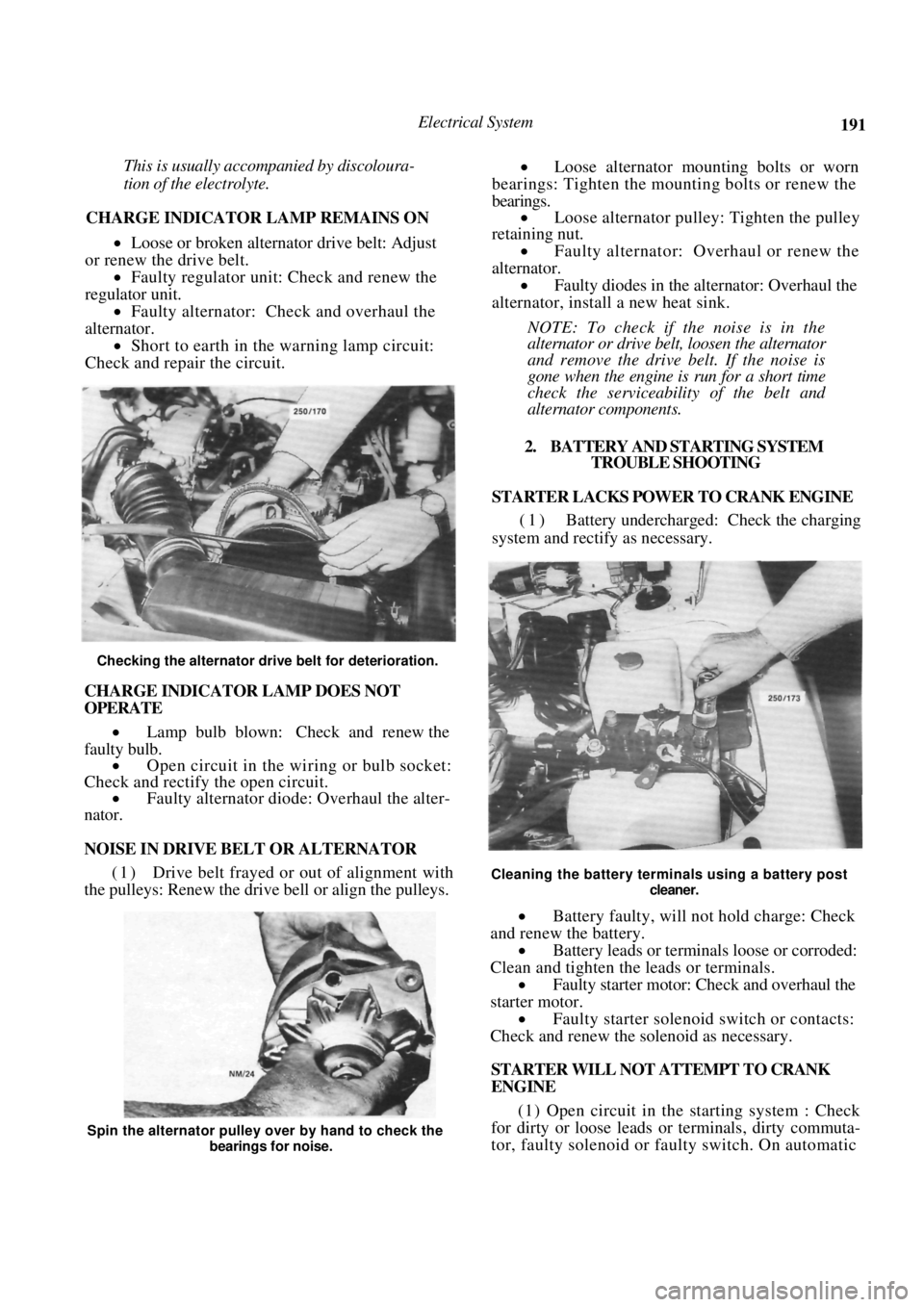

STARTER LACKS POWER TO CRANK ENGINE

(1) Battery undercharged: Check the charging

system and rectify as necessary.

Cleaning the battery terminals using a battery post

cleaner.

• Battery faulty, will not hold charge: Check

and renew the battery. • Battery leads or terminals loose or corroded:

Clean and tighten the leads or terminals.

• Faulty starter motor: Check and overhaul the

starter motor. • Faulty starter solenoid switch or contacts:

Check and renew the solenoid as necessary.

STARTER WILL NOT ATTEMPT TO CRANK

ENGINE

(1 ) Open circuit in the starting system : Check

for dirty or loose leads or terminals, dirty commuta-

tor, faulty solenoid or faulty switch. On automatic

Spin the alternator pulley over by hand to check the

bearings for noise.

Page 192 of 238

192 Electrical System

transaxle models, check for a faulty or incorrectly

adjusted neutral safety switch.

1. Discharged battery: Check for a fault or short

circuit in the system. 2. Battery fully charged but will not crank

engine. Check for a locked drive and ring gear,

internal starter faul t or seized engine.

3. Fusible link blown: Check and repair the

cause and renew as necessary.

NOTE: Rotate the engine by hand to ensure

that the starter drive is not locked with the

flywheel ring gear and t hat the engine is not

seized. Ensure that the ignition key is

turned off before rotating the engine.

3. LIGHTING SYSTEM TROUBLE SHOOTING

LAMP OR LAMPS FAIL TO LIGHT

1. Faulty bulb(s): Check and renew the faulty

bulb(s). 2. Open circuit in the wiring or connections:

Check the lamp circuits and rectify as necessary.

1. Faulty lamp switch: Check and if necessary

renew the lamp switch. 2. Faulty fuse or fuse connection: Repair the

fuse connection or renew the fuse. 3. Lamp relay faulty: Check and renew as

necessary.

NOTE: Switch on the lamps concerned and

using a test lamp, check that the lamp

circuits are operating. This is best done by

starting at the lamp wiring connector or

bulb holder and work ing back to the power

source.

LAMP OR LAMPS INCORRECTLY

ILLUMINATED

1. Lamp or lamps incorrectly earthed: Check

the lamp earth for loosene ss or clean the contact,

either at the lamp body or wire.

2. Incorrect bulbs installe d: Check the bulb

wattage and voltage and renew with the correct type if

necessary. 3. Dirty or damaged lamp reflector: Clean or

renew the lamp reflector. 4. Faulty bulb: Check with a known serviceable

bulb and renew if necessary. 5. Dirty lamp lens: Clean or renew the lamp

lens. 6. High resistance or faulty connections be-

tween the alternator and battery: Check the circuit

and rectify th e condition.

7. Poor earth connection between the battery

and the engine or alternat or: Check the battery earth

lead and the strap between the engine and the body. 8. Voltage regulator faulty: Check and renew

the voltage regulator.

NOTE: The most common cause for this

condition is dirty t erminals on the earth

leads. Check all earth leads at their earthing

points.

4. TURN SIGNAL LAMP TROUBLE SHOOTING

TURN SIGNAL LAMP DOES NOT LIGHT AND

NO AUDIBLE NOISE FROM FLASHER UNIT

(1) Fuse blown: Rectify the fault and renew the

fuse.

(2) The Flasher unit is faulty: Renew the unit

(3) Turn signal switch faulty: Renew the switch

(4) Fault in the wiring circuit: Check and repair

the fault.

TURN SIGNAL WARNING LAMP DOES NOT

FLASH BUT AUDIBLE CLICKING FROM

FLASHER UNIT

(1) Warning lamp bulb blown: Check and renew

the bulb.

Checking the rear combination lamp circuit using a test

lamp.

Checking the headlamp circuit using a test lamp.

Page 195 of 238

Electrical System 195

(2) Remove the battery holding clamp and lift

the battery from the vehicle.

Installation is a reversal of the removal procedure

with attention to the following points:

Ensure that the terminals and posts are

clean. When connecting the l eads to the battery,

ensure that the polarity is correct. Connect the

positive lead first. Do not over tighten the terminal clamp

nuts.

Apply petroleum jelly to the battery termi-

nals to prevent corrosion.

MAINTENANCE

Battery maintenance should be performed at the

scheduled services.

NOTE: Keep naked flames away from the

battery as the battery gases are highly

explosive.

(1) Keep the battery and the surrounding area

clean and dry. In particular, ensure that the top of the

battery is free from dirt and moisture to prevent a

voltage drop between the terminals.

If necessary, clean the battery case as follows:

Remove the battery from the vehicle as

previously described.

Pour hot water over the battery being careful

not to allow any water to enter the battery through the

filler cap vent holes. Wipe the battery case clean.

Clean the battery terminals and posts using a

battery post cleaner, wire brush or emery cloth.

Remove all dirt and corrosion.

Remove the filler caps and check that the

vent holes are clear. Check the electrolyte le vel and replenish with distilled water as necessary. The correct level is just

above the top of the plates. Do not overfill the battery.

Do not transfer electrolyte from one cell to another.

(5) If the battery electrolyte requires frequent

replenishing, check the batt ery case for cracks. If the

case is damaged, renew the battery.

Check for overcharging by measuring the output

of the alternator as described later in this section.

Apply petroleum jelly to the battery termi-

nals to prevent corrosion. If the electrolyte has overflowed and contam-

inated the battery carrier and surrounding body

panels, proceed as follows:

With the battery removed from the vehicle,

sprinkle bicarbonate of soda over the contaminated

areas.

Pour hot water over the bicarbonate of soda.

The bicarbonate of soda will react with the water and

begin to foam. When the bicarbonate of soda has stopped

foaming, rinse the area with clean water and allow to

dry. Remove any blistered paint from the con-

laminated areas. Paint the contaminated areas with a corro-

sion inhibiting paint.

TO TEST AND CHARGE

(1) Using a hydrometer, test the specific gravity

of the battery electrolyte. Refer to the following chart

which shows charge conditi ons for various specific

gravity readings.

1.110-1.130............................... Fully discharged

1.140-1.160..............................Nearly discharged

1.170-1.190 ........................... Approximately one

quarter charged

1.200-1.220..................................... Half charged

1.230-1.250......................... Approximately three

quarters charged

1.250-1.280..................................... Fully charged

These readings are for electrolyte at a temperature

of 20 deg C. For every 10 deg above 20 deg C, add

0.007. For every 10 deg below 20 deg C, subtract

0.007.

NOTE: An accurate specific gravity reading

cannot be obtained if distilled water has

recently been added to the electrolyte. If the

electrolyte level is below the battery plates,

replenish with distilled water and charge the

battery before testing the specific gravity.

(2) If a low state of charge is indicated, or if the

specific gravity readings vary more than 0.030 be-

tween cells, the battery s hould be 'charged, using a

battery charger, with attention to the following points:

(a) Disconnect the negati ve and positive battery

terminals.

Cleaning the battery terminals using a battery post

cleaner.

Page 196 of 238

196 Electrical System

Check the specific gravity in each cell with a hydro-

meter.

Check the battery electrolyte level and re-

plenish as necessary. Remove the filler cap s from the battery.

Follow the battery charger manufacturers

instructions. (3) Should the battery fail to operate satisfacto-

rily after charging, it is recommended that it be taken

to a workshop with the necessary equipment to per-

form a load test. Load testing, when performed in

conjunction with the specific gravity tests described

above will give an accurate indication of the service-

ability of the battery.

7. ALTERNATOR

Special Equipment Required

To Test On Vehicle - Voltmeter, 100-0-100

amp ammeter, ohmmeter

To Dismantle — 200 watt soldering iron,

bearing

puller, press

To Assemble — 200 watt soldering iron

DESCRIPTION

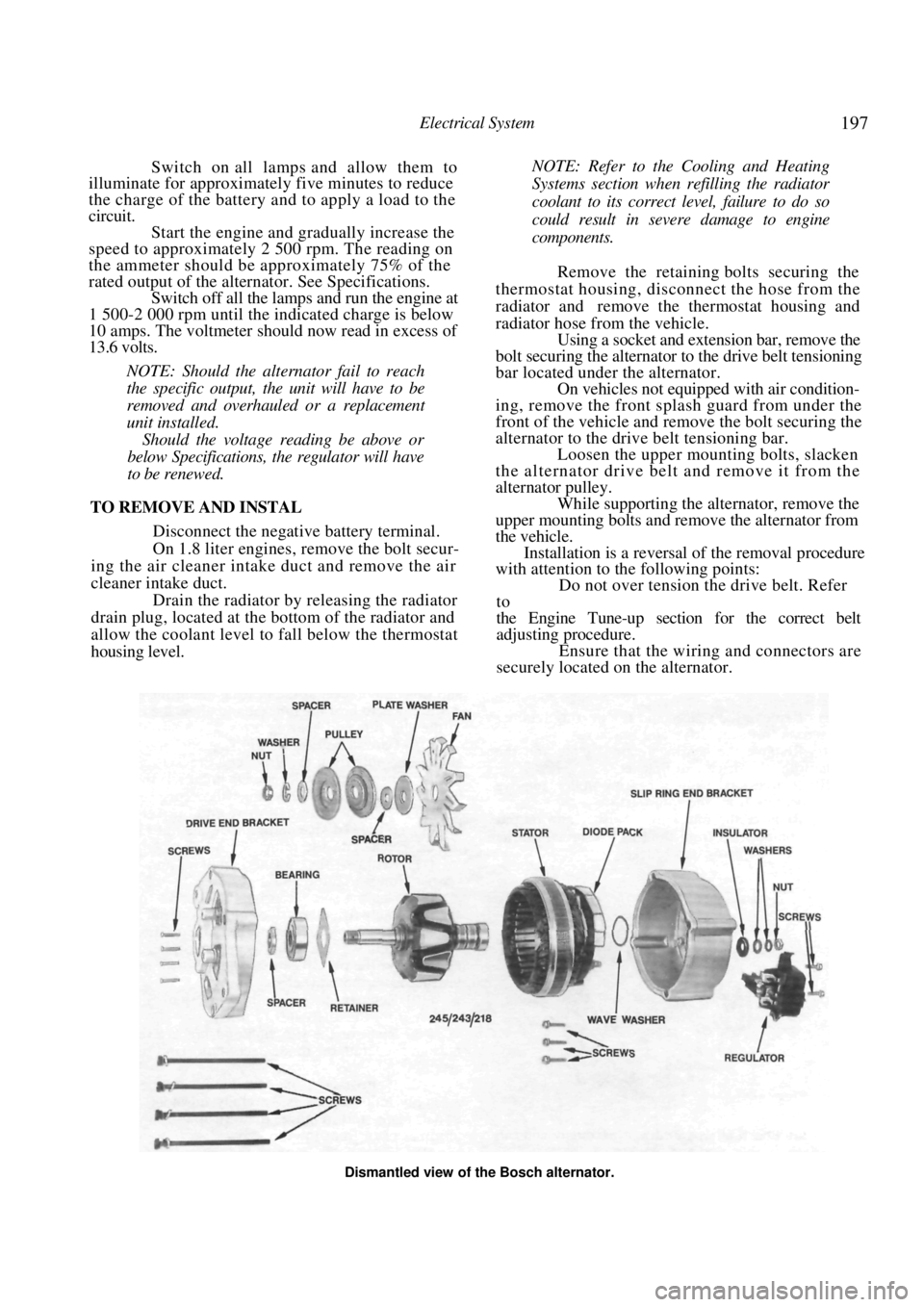

Two types of alternator are installed to the range

of vehicles covered by this manual, either Hitachi or

Bosch. In the alternator, the field and pole shoe assembly

is the moving part and it is shaped to form the rotor.

Since only a low amperage current flows between the

slip rings on the rotor shaft and the brushes, wear on

the brushes and slip rings is very slight and mainte-

nance is reduced to a minimum. The output current is generated in the fixed stator

windings and is a three phase alternating current

(AC). The stator windings are wound on a laminated

soft iron former, star connected and installed between

the end brackets. As it is not possible to charge a storage battery

with alternating current, it is necessary to rectify the

output of the stator windings to direct current (DC). This is done by a bank of diodes mounted within the

alternator slip ring end bracket.

The output of the alternator is governed by the

regulator and the built in ch aracteristics of the alter-

nator.

The regulator and brush holder assembly on

Hitachi alternators is mounted within the alternator

on the slip ring end bracket side. On Bosch

alternators

the regulator and brush holder unit is mounted to the

outside of the slip ring end bracket. An electrical cut out unit is not necessary with the

alternator charging system as the diodes prevent a

reverse current flow through the alternator.

SERVICE PRECAUTIONS

Ensure that the battery is connected with the

correct polarity to earth. Refer to Specifications.

Do not short out or ground any terminals

common to the charging circuit. Always disconnect the battery before con-

necting a battery charger.

If a booster battery is used, always connect it

in a parallel circuit i.e. positive to positive ( + to + )

and negative to negative (- to -) to maintain a 12

volt supply. Never disconnect the battery or terminals in

the charging circuit while the engine is running. Regularly check that the alternator drive belt

tension is as specified. Refer to the Engine Tune-up

section.

Keep the battery terminals clean and all

electrical connections tight. Disconnect the battery and alternator when

electric welding on the vehicle.

TO TEST ON VEHICLE If the charge indicator lamp stays on after the

engine has been started and run at approximately

1 000 rpm, carry out the following tests. Stop the engine.

Check the condition and adjustment of the

alternator drive belt. Clean the battery terminals, tighten all elec-

trical connections, check the wiring for shorts to earth

and/or bridged circuits. Ensure that the battery is fully

charged. If the battery is discharged charge it or

replace it with one fully charged. Start the engine and allow it to run until

normal operating temperature is reached.

Stop the engine and disconnect the negative

battery terminal.

Remove the nut and washer from the alter-

nator output terminal (B +) and disconnect the alter-

nator output lead. Connect one lead of an ammeter to the

alternator output terminal and the other lead to the

lead removed from the output terminal. Connect the negative battery terminal and

connect a voltmeter across the battery terminals.

Page 197 of 238

Electrical System 197

Switch on all lamps and allow them to

illuminate for approximately five minutes to reduce

the charge of the battery and to apply a load to the

circuit.

Start the engine and gradually increase the

speed to approximately 2 500 rpm. The reading on

the ammeter should be approximately 75% of the

rated output of the altern ator. See Specifications.

Switch off all the lamps and run the engine at

1 500-2 000 rpm until the indicated charge is below

10 amps. The voltmeter should now read in excess of

13.6 volts.

NOTE: Should the alternator fail to reach

the specific output, the unit will have to be

removed and overhauled or a replacement

unit installed.

Should the voltage reading be above or

below Specifications, the regulator will have

to be renewed.

TO REMOVE AND INSTAL

Disconnect the negative battery terminal.

On 1.8 liter engines, remove the bolt secur-

ing the air cleaner intake duct and remove the air

cleaner intake duct. Drain the radiator by releasing the radiator

drain plug, located at the bottom of the radiator and

allow the coolant level to fall below the thermostat

housing level. NOTE: Refer to the Cooling and Heating

Systems section when refilling the radiator

coolant to its correct l

evel, failure to do so

could result in severe damage to engine

components.

Remove the retaining bolts securing the

thermostat housing, disconnect the hose from the

radiator and remove the thermostat housing and

radiator hose from the vehicle. Using a socket and extension bar, remove the

bolt securing the alternator to the drive belt tensioning

bar located under the alternator. On vehicles not equipped with air condition-

ing, remove the front splash guard from under the

front of the vehicle and remove the bolt securing the

alternator to the drive belt tensioning bar. Loosen the upper mounting bolts, slacken

the alternator drive belt and remove it from the

alternator pulley.

While supporting the alternator, remove the

upper mounting bolts and remove the alternator from

the vehicle. Installation is a reversal of the removal procedure

with attention to the following points:

Do not over tension the drive belt. Refer

to

the Engine Tune-up section for the correct belt

adjusting procedure. Ensure that the wiring and connectors are

securely located on the alternator.

Dismantled view of the Bosch alternator.

Page 198 of 238

198 Electrical System

(3) Replenish the coolant in the radiator. Refer

to the Cooling and Heating Systems section for the

correct procedure.

TO DISMANTLE

Bosch Alternator

Remove the alternator from the vehicle as

previously described.

Scribe a mark across the drive end bracket,

stator and slip ring end bracket to facilitate correct

alignment during assembly. Remove the screws and washers securing the

regulator and brush holder assembly. Withdraw the

regulator and brush holder assembly from the alter-

nator. Remove the long screws securing the drive

end bracket to the slip ring end bracket and withdraw

the drive end bracket, rotor and pulley assembly.

NOTE: Ensure that the wave washer behind

the rotor shaft rear bearing in the slip ring

end bracket is not mislaid.

Holding the rotor in a soft jawed vice,

remove the split drive pulley retaining nut, washer

and spacer from the rotor shaft. Remove the split driv e pulley, spacer, plate

washer and fan from the rotor shaft. Using a suitable pres s and press plates,

support the drive end bracket with the pulley end of

the rotor shaft uppermost a nd carefully press the rotor

shaft from the spacer, bearing and the drive end

bracket.

Remove the spacer and the bearing retainer

plate screws from the drive end bracket. Remove the bearing retainer plate and the

bearing from the drive end bracket. If necessary, using a bearing puller, remove

the rear bearing from the rotor shaft. Remove the nut, spring washer and output

terminal components from the {B + ) terminal on the

outside of the slip ring end bracket.

(12) Working inside the slip ring end bracket,

remove the screws securing the diode pack to the

bracket and withdraw the stator and diode pack as an

assembly. Remove the insulating spacer and washer

from the (B +) terminal.

NOTE: The diode pack is supplied as an

assembly and in the event of a component

'failure, must be renewed as a complete unit.

Mark all wiring connections prior to removal

to aid assembly. Where necessary, unsolder the stator leads

from the connector terminals to separate the diode

pack.

NOTE: When soldering or unsoldering the

stator leads from the diodes, grip the leads

with a pair of long nosed pliers. This will

safeguard the diodes by transferring any

excess heat to the jaws of the pliers.

Hitachi Alternator

Remove the alternator from the vehicle as

previously described.

Scribe a mark across the drive end bracket,

stator and slip ring end bracket to facilitate correct

alignment during assembly. Remove the through bolts retaining the drive

end bracket to the slip ring end bracket. Apply a heated 200 watt soldering iron to the

slip ring end bracket at the bearing mounting boss for

3-4 minutes to heat the bracket and allow the removal

of the slip ring end bearing. Carefully prise the slip ring end bracket and

stator assembly from the drive end bracket and rotor

assembly using suitable levers. Do not insert the levers

too far or damage to the stator will occur.

Hold the rotor and driv e end bracket assem-

bly in a soft jawed vice and remove the nut retaining

the drive pulley to the rotor. Remove the washer, pulley and spacer

washer from the rotor shaft.

Using a soft faced hammer, drive the rotor

shaft assembly from the drive end bracket and remove

the inner spacer washer from the rotor shaft.

Remove the bearing retainer plate screws

and remove the plate. Using a suitable drift, drive the

bearing from the bracket. Remove the retaining nut and insulator

washer from the alternator terminal. Remove the slip ring end bracket retaining

nuts and separate the diode pack, stator and regulator

assembly.

If necessary, file the ends of the brush

assembly retaining rivets, caref ully unsolder the ter-

minal plate and remove the brush assembly and

terminal plate from the diode pack. If necessary, remove the fan guide retaining

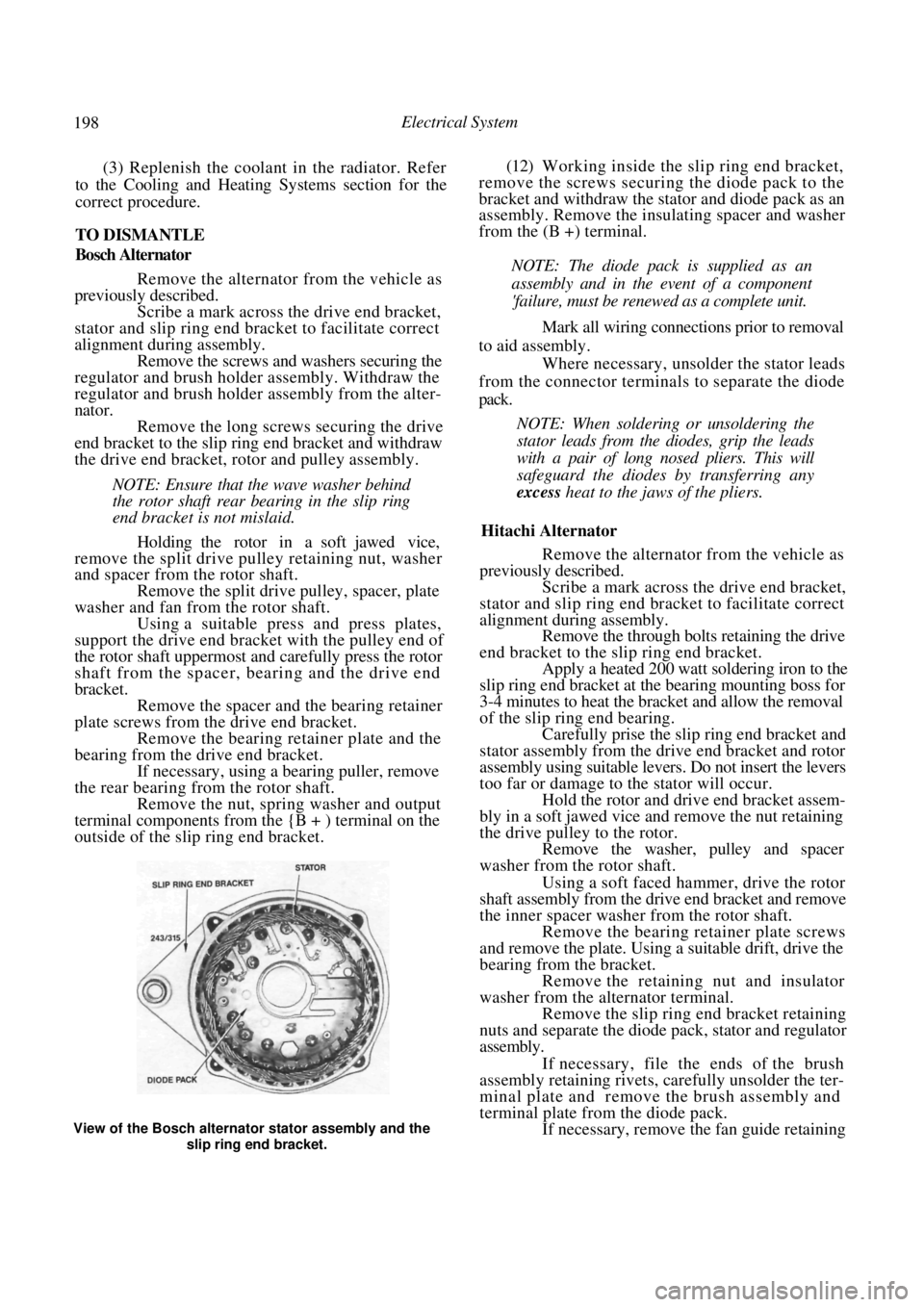

View of the Bosch alternator stator assembly and the

slip ring end bracket.

Page 199 of 238

Electrical System 199

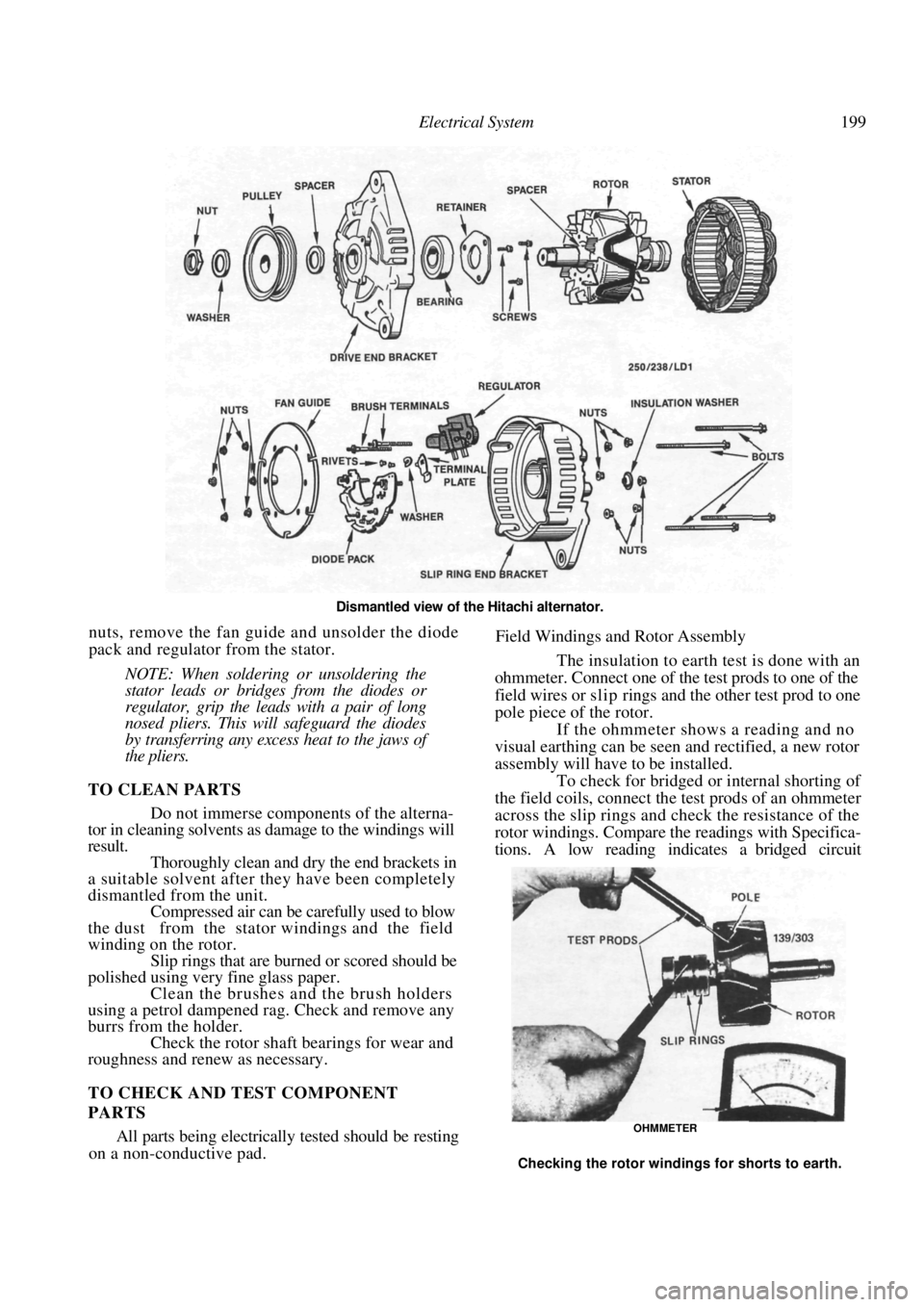

Dismantled view of the Hitachi alternator.

nuts, remove the fan guide and unsolder the diode

pack and regulator from the stator.

NOTE: When soldering or unsoldering the

stator leads or bridges from the diodes or

regulator, grip the leads with a pair of long

nosed pliers. This will safeguard the diodes

by transferring any excess heat to the jaws of

the pliers.

TO CLEAN PARTS

Do not immerse components of the alterna-

tor in cleaning solvents as damage to the windings will

result. Thoroughly clean and dry the end brackets in

a suitable solvent after they have been completely

dismantled from the unit. Compressed air can be carefully used to blow

the dust from the stator windings and the field

winding on the rotor. Slip rings that are burned or scored should be

polished using very fine glass paper. Clean the brushes and the brush holders

using a petrol dampened rag. Check and remove any

burrs from the holder. Check the rotor shaft bearings for wear and

roughness and renew as necessary.

TO CHECK AND TEST COMPONENT

PARTS

All parts being electrically tested should be resting

on a non-conductive pad.

Field Windings and Rotor Assembly

The insulation to earth test is done with an

ohmmeter. Connect one of the test prods to one of the

field wires or s l i p rings and the other test prod to one

pole piece of the rotor. If the ohmmeter shows a reading and no

visual earthing can be seen and rectified, a new rotor

assembly will have to be installed. To check for bridged or internal shorting of

the field coils, connect the te st prods of an ohmmeter

across the slip rings and check the resistance of the

rotor windings. Compare the readings with Specifica-

tions. A low reading i ndicates a bridged circuit

OHMMETER

Checking the rotor windings for shorts to earth.