display NISSAN PULSAR 1987 Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1987, Model line: PULSAR, Model: NISSAN PULSAR 1987Pages: 238, PDF Size: 28.91 MB

Page 11 of 238

General Information 11

Lifting Equipment

When using lifting equipment to lift heavy com-

ponents such as the engine and/or transmission, use

metal slings or chain in preference to rope. If rope

must be used, ensure that it is not placed against sharp

edges on the component.

Automotive Lubricants and Solvents

Avoid prolonged skin contact with oils, greases

and solvents as some can cause skin irritations and

dermatitis.

Exercise caution when us ing cleaning solvents as

many are inflammable. Do not smoke. Keep naked

flames and sparks clear of the work area.

Compressed Air

Never point an air hose at another person or allow

compressed air to blow onto your skin. High pressure

air forced against the skin can enter the bloodstream

and prove fatal.

Suspension and Steering Components

Damaged suspension and steering components

should not be welded. Many of these components are

fabricated from toughened metals. If welded they may

lose their strength or become brittle. Damaged com-

ponents should be renewed.

Air Conditioning

Avoid disconnecting air conditioning hoses as

escaping refrigerant can cause frostbite. The refriger-

ant is highly flammable and when burnt, a poisonous

gas is produced.

VEHICLE SAFETY

To prevent damage to the vehicle during servicing

or repair work, note the following precautions.

Brake Fluid

If spilt on the vehicle paintwork, brake fluid

should be immediately washed away with clean water

and allowed to dry naturally, not wiped with a cloth.

Catalytic Converter

The following should be observed to prevent

damage to the catalytic converter:

Do not operate the vehicle on leaded fuel.

Do not push or tow start the vehicle.

Do not allow the engine to idle for prolonged

periods.

Do not switch the ignition off while the vehicle is

in motion and the transmission is in gear.

Do not 'prime' the engine by pouring fuel into the

inlet manifold.

Do not operate the vehicle if the engine is

misfiring.

Avoid running the vehicle out of fuel.

Ensure that the engine oil is formulated to contain

low phosphorus levels.

Electronic Components

The electronic components of the ignition and

fuel injection systems can be damaged by the use of

incorrect testing equipment.

It is essential in all tests where voltage or resis-

tance is to be measured that a digital display multi-

meter with a minimum 10 megohm input impedance

be used.

Some types of tachometers, timing lights and

ignition system analyzers are not compatible with

certain engine electronic systems. It is therefore

recommended that the manufacturer of the test equip-

ment be consulted before using the equipment.

Jump starting, or being jump started by another

vehicle can cause damage to the electronic compon-

ents of the vehicle. Refer to the Roadside Trouble

shooting section for the correct jump starting proce-

dure.

3. GENERAL REPAIR PROCEDURES

SEIZED FASTENERS

Seized bolts, nuts or screws should first have a

liberal amount of penetrating oil applied. The fastener

should be left for a period of time to allow the oil to

penetrate and soften the corrosion which is causing

the binding.

Often, a sharp hammer blow to the head of the

fastener can dislodge the corrosion and permit it to be

loosened.

An impact driver, which can be fitted with a

socket or screwdriver bit, can be used to loosen a

seized fastener.

Another method is to heat the component in

which the fastener is seized. However, extreme cau-

tion should be exercised when heating aluminum

alloy components as the melting point is much lower

than that of steel.

If the above methods fail to free a seized nut,

carefully hacksaw through one side of the nut until it

can be split. Care should be taken that the threads of

the bolt or stud are not damaged.

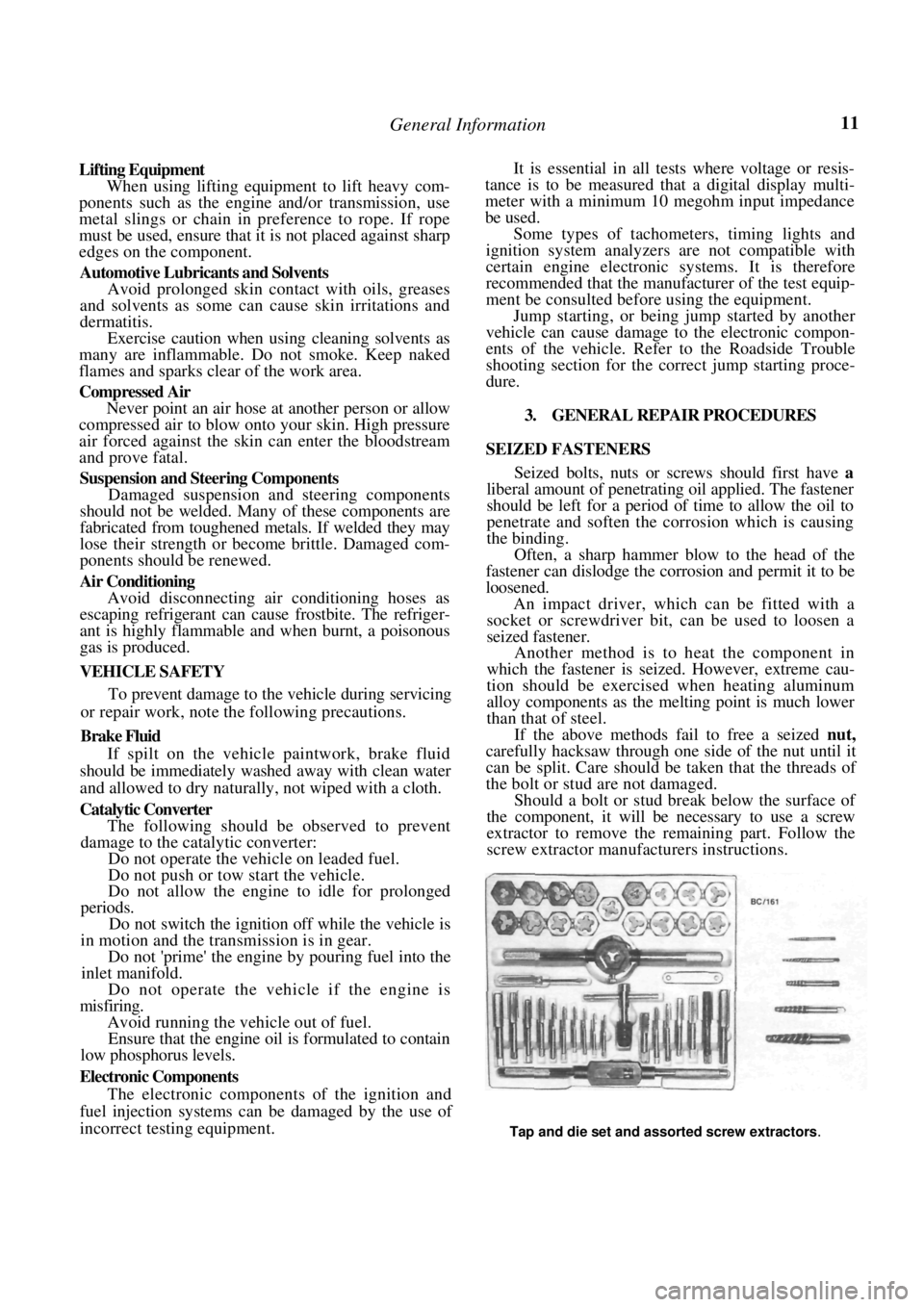

Should a bolt or stud break below the surface of

the component, it will be necessary to use a screw

extractor to remove the remaining part. Follow the

screw extractor manuf acturers instructions.

Tap and die set and assorted screw extractors.

Page 84 of 238

Fuel and Engine Management

(4) MAP sensor faulty or supply hose discon-

nected or blocked: Check the vacuum supply hose.

Check the operation of the MAP sensor.

EXCESSIVE FUEL CONSUMPTION

(1) Blocked air cleaner element: Check the ele-

ment and clean or renew as necessary.

(2) Incorrect fuel pressure: Check the fuel pump

and fuel pressure regulator. (3) Faulty coolant temperature sensor: Check

the connections and operation.

(4) Leaks in the fuel supply system: Check the

connections and components for leakage. (5) Leaking fuel injector(s): Clean or renew the

faulty injector(s). (6) Engine operating temperature too low:

Check the thermostat and electric cooling fan as

described in the Cooling an d Heating Systems section.

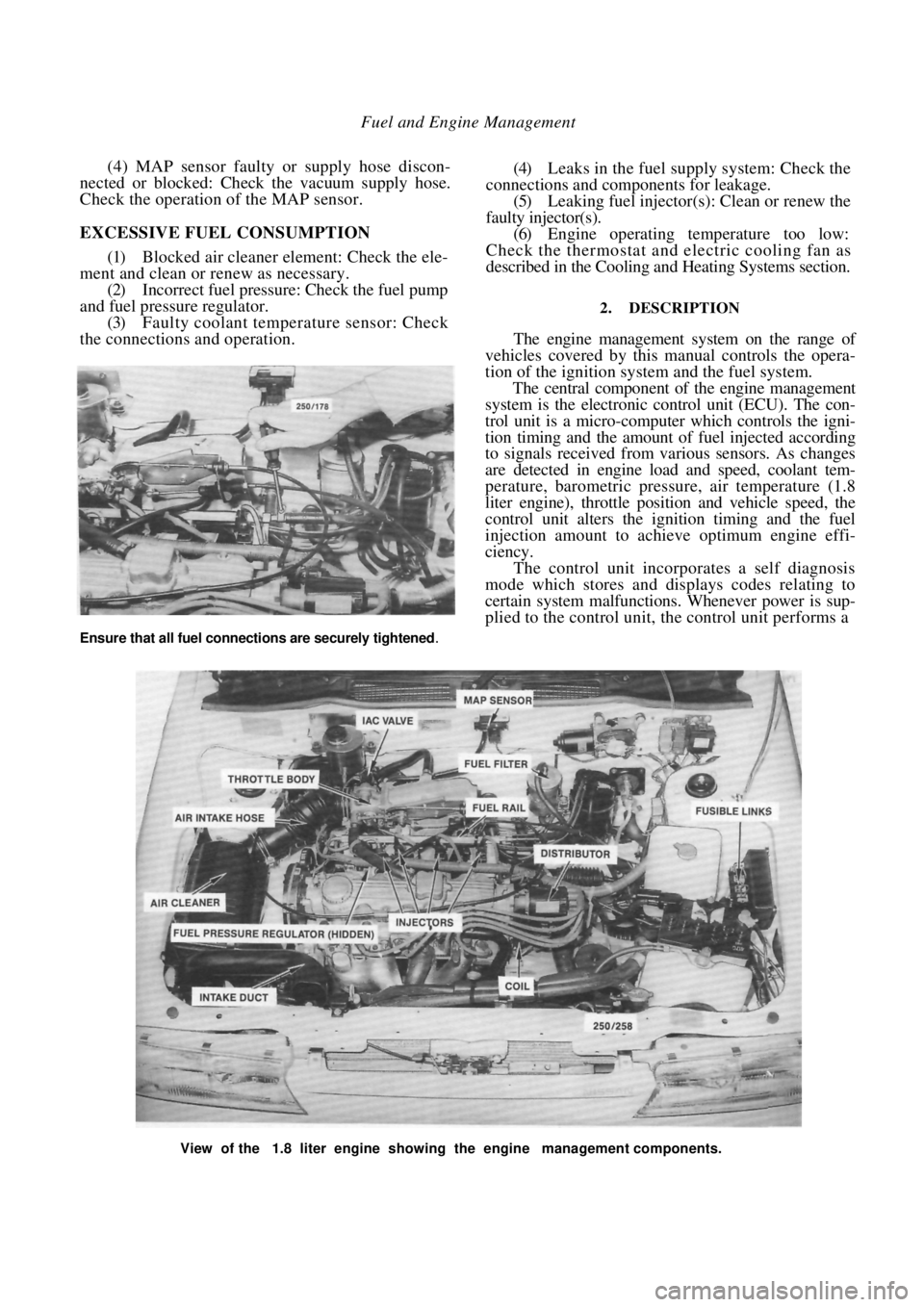

2. DESCRIPTION

The engine management system on the range of

vehicles covered by this manual controls the opera-

tion of the ignition system and the fuel system.

The central component of the engine management

system is the electronic control unit (ECU). The con-

trol unit is a micro-computer which controls the igni-

tion timing and the amount of fuel injected according

to signals received from various sensors. As changes

are detected in engine load and speed, coolant tem-

perature, barometric pressure, air temperature (1.8

liter engine), throttle position and vehicle speed, the

control unit alters the ignition timing and the fuel

injection amount to achieve optimum engine effi-

ciency.

The control unit incorporates a self diagnosis

mode which stores and displays codes relating to

certain system malfunctions. Whenever power is sup-

plied to the control unit, the control unit performs a

View of the 1.8 liter engine showing the engine management components.

Ensure that all fuel connections are securely tightened.

Page 86 of 238

86 Fuel and Engine Management

other. The fuel pressure is maintained at a constant

pressure relevant to the manifold vacuum. A dispos-

able paper element fuel filter is mounted on the engine

bulkhead.

The amount of fuel injected is relevant to the time

the injector remains open. The basic time the injector

remains open is governed by the control unit which

uses information from the various sensors to give

optimum engine efficiency for given conditions.

The idle air control (IAC) valve controls the fast

idle speed during engine warm up and maintains the

basic idle speed at a set value by compensating for

loads such as air conditioning or the selection of Drive

on automatic transaxle models.

The throttle body assembly is mounted to the

inlet manifold and controls the amount of air entering

the engine by the action of the throttle valve.

Efficient operation of the EFI system depends on

accurate signals being receiv ed by the control unit and

controlled air flow beyond the throttle valve. There-

fore it is essential that all air, fuel and electrical

connections be clean and tight.

3. SERVICE PRECAUTIONS AND

PROCEDURES

Electronic ignition systems can produce danger-

ously high voltages in both the primary and secondary

circuits. For this reason, extreme care must be taken

when working on or near the ignition system.

Do not start the engine if the battery terminals are

not clean and tight.

Do not use the fast charge or boost settings on a

battery charger to start the engine.

Do not disconnect the battery terminals while the

engine is running.

Disconnect the battery terminals before charging

the battery.

Disconnect the negative ba ttery terminal before

working on the engine management system.

Do not subject the control unit to temperatures

above 80 deg C.

Ensure that all wiring connectors are clean and

tight.

Disconnect the battery terminals and the control

unit wiring connectors before attempting any welding

operations.

Do not direct a steam cleaning or pressure

washing nozzle at engine management components

when cleaning the engine.

Ensure that the ignition is Off prior to disconnect-

ing the battery terminals, fusible links or the control

unit wiring connectors.

TO CONNECT ELECTRICAL TEST

EQUIPMENT

NOTE: Some types of tachometers, timing

lights and ignition system analysers are not

compatible with this engine management

system and may result in incorrect readings.

It is therefore recommended that the man-

ufacturer of the lest equipment be consulted

before proceeding to use the equipment.

If a test procedure requires the use of a

test lamp or voltmeter, ensure that only the

specified instrument is used to prevent mis-

leading diagnosis.

MULTIMETER

It is essential that in all tests where voltage or

resistance is to be measur ed, a digital display multi-

meter with a minimum 10 megohms impedance be

used.

The correct method of backprobing the wiring connec-

tors. The meter test probe should be modified with a piece of thin wire as shown.

All meter readings are to be performed with the

component wiring connectors installed unless other-

wise instructed. This can be done by inserting the

meter test probes from the wiring harness side of the

connector or backprobing. If the test probes are not

thin, they should be modified by attaching a thin piece

of wire to the end, giving a fine point that will not

damage the connector. Ensure that the wire is making

good contact with the probe.

If sealing plugs or boots are removed from wiring

connectors to facilitate bac kprobing, ensure that they

are correctly installed at the conclusion of the test

procedure.

To identify wiring connector terminals refer to the

wiring circuit diagrams.

Test Lamp

To avoid damage to the electronic components

when testing, the use of an LED (light emitting diode)

test lamp is recommended.

Page 89 of 238

Fuel and Engine Management 89

The procedure for fabricating an LED test lamp is

fully described in the El ectrical System section.

If a conventional test lamp with a filament type

bulb is to be used, ensure that the current draw of the

test lamp does not exceed 0.3 amp to avoid damage to

the electronic components.

To check the current draw connect an accurate

ammeter, such as the multimeter described previ-

ously, in series with the test lamp and a battery.

If the ammeter reads less than 0.3 amp the test

lamp is suitable.

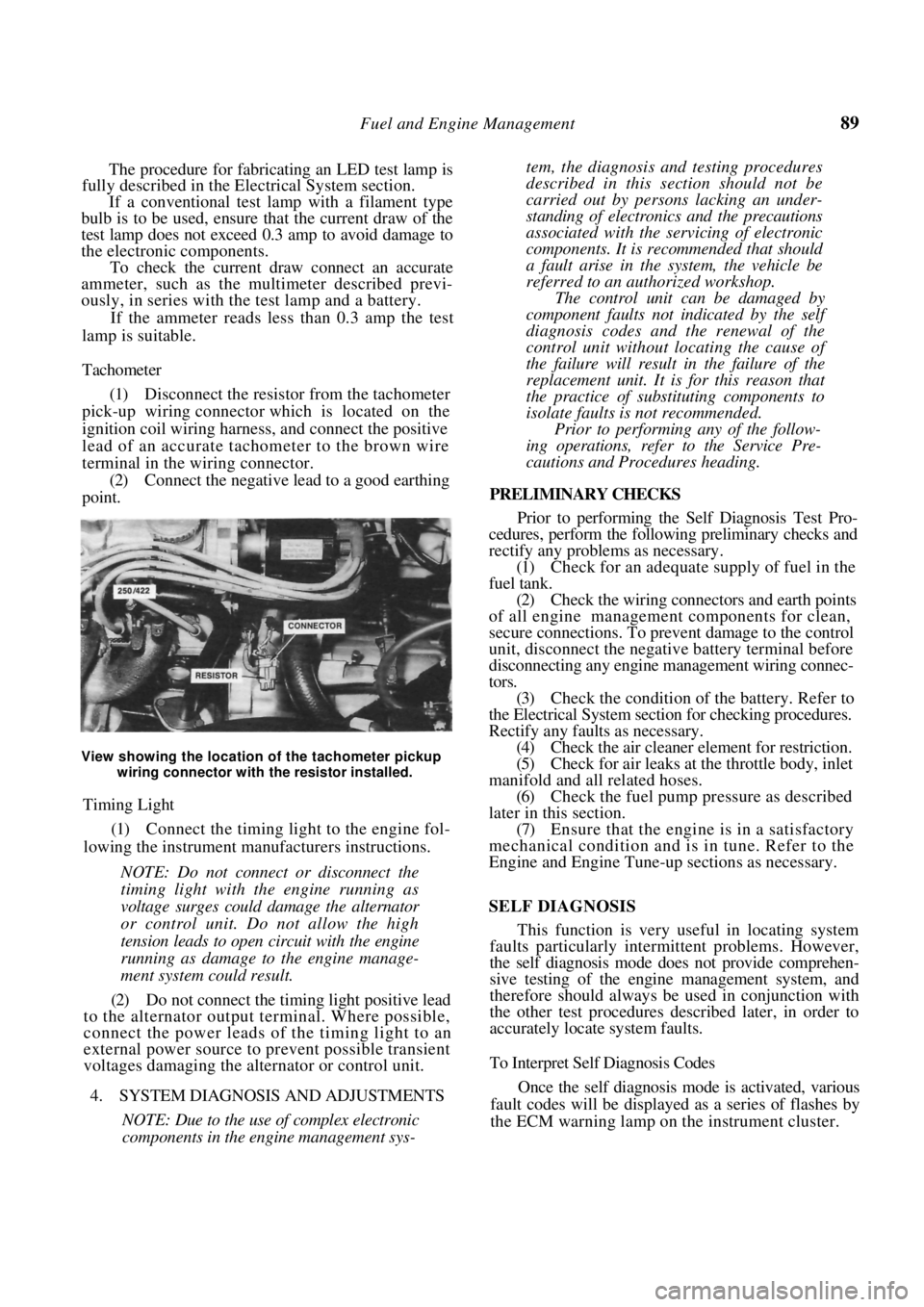

Tachometer

(1) Disconnect the resistor from the tachometer

pick-up wiring connector which is located on the

ignition coil wiring harness, and connect the positive

lead of an accurate tachometer to the brown wire

terminal in the wiring connector. (2) Connect the negative lead to a good earthing

point.

View showing the location of the tachometer pickup

wiring connector with the resistor installed.

Timing Light

(1) Connect the timing light to the engine fol-

lowing the instrument manufacturers instructions.

NOTE: Do not connect or disconnect the

timing light with the engine running as

voltage surges could damage the alternator

or control unit. Do not allow the high

tension leads to open circuit with the engine

running as damage to the engine manage-

ment system could result.

(2) Do not connect the timing light positive lead

to the alternator output terminal. Where possible,

connect the power leads of the timing light to an

external power source to prevent possible transient

voltages damaging the alternator or control unit.

4. SYSTEM DIAGNOSIS AND ADJUSTMENTS

NOTE: Due to the use of complex electronic

components in the engine management sys-

tem, the diagnosis and testing procedures

described in this section should not be

carried out by persons lacking an under-

standing of electronics and the precautions

associated with the servicing of electronic

components. It is rec ommended that should

a fault arise in the system, the vehicle be

referred to an authorized workshop.

The control unit can be damaged by

component faults not indicated by the self

diagnosis codes and the renewal of the

control unit without lo cating the cause of

the failure will result in the failure of the

replacement unit. It is for this reason that

the practice of substituting components to

isolate faults is not recommended.

Prior to performing any of the follow-

ing operations, refer to the Service Pre-

cautions and Procedures heading.

PRELIMINARY CHECKS

Prior to performing the Self Diagnosis Test Pro-

cedures, perform the following preliminary checks and

rectify any problems as necessary.

(1) Check for an adequate supply of fuel in the

fuel tank. (2) Check the wiring connectors and earth points

of all engine management components for clean,

secure connections. To prevent damage to the control

unit, disconnect the negative battery terminal before

disconnecting any engine ma nagement wiring connec-

tors. (3) Check the condition of the battery. Refer to

the Electrical System sectio n for checking procedures.

Rectify any faults as necessary. (4) Check the air cleaner element for restriction.

(5) Check for air leaks at the throttle body, inlet

manifold and all related hoses. (6) Check the fuel pump pr essure as described

later in this section. (7) Ensure that the engine is in a satisfactory

mechanical condition and is in tune. Refer to the

Engine and Engine Tune-up sections as necessary.

SELF DIAGNOSIS

This function is very useful in locating system

faults particularly intermittent problems. However,

the self diagnosis mode does not provide comprehen-

sive testing of the engine management system, and

therefore should always be used in conjunction with

the other test procedures described later, in order to

accurately locate system faults.

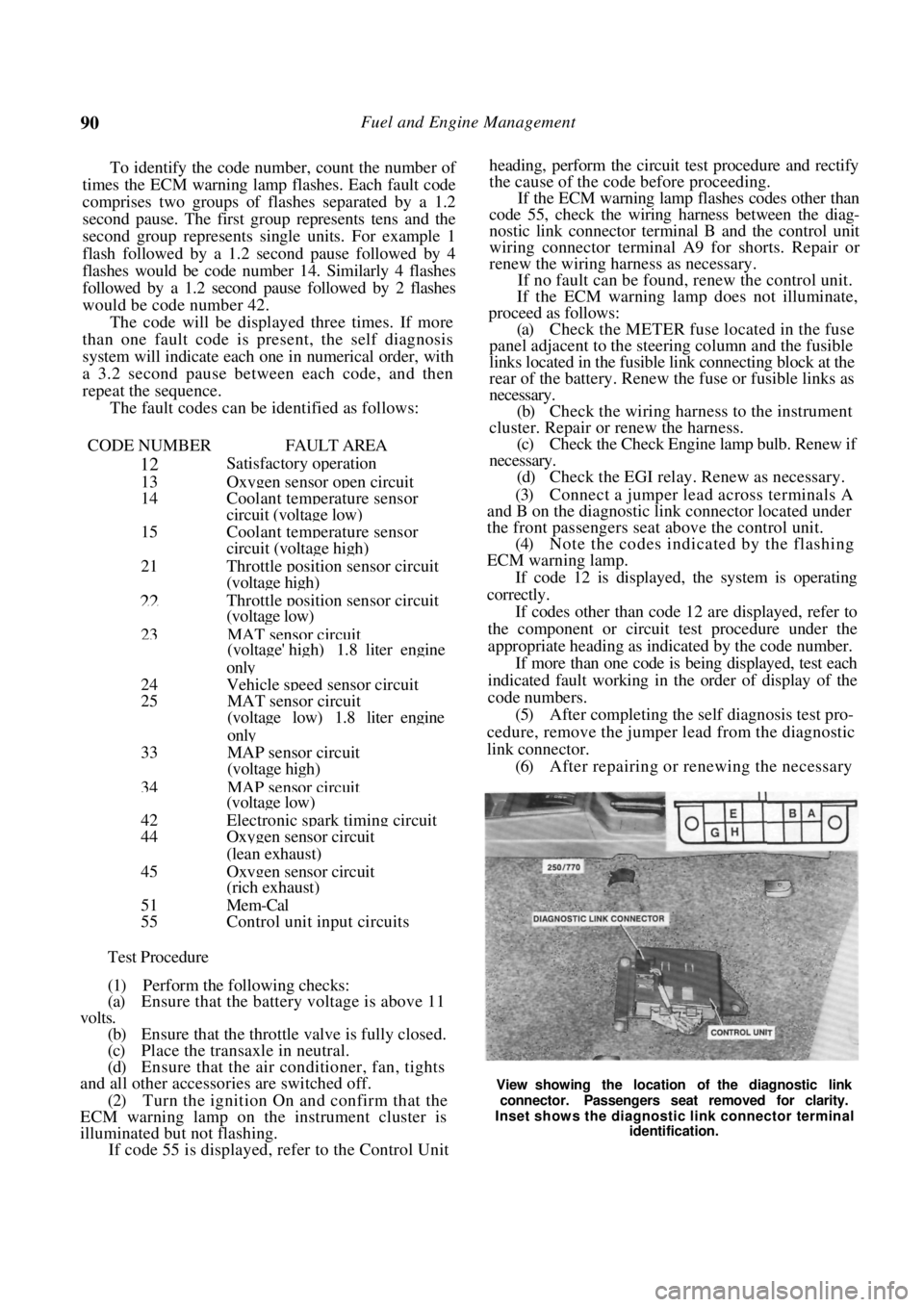

To Interpret Self Diagnosis Codes

Once the self diagnosis mode is activated, various

fault codes will be displayed as a series of flashes by

the ECM warning lamp on the instrument cluster.

Page 90 of 238

90 Fuel and Engine Management

To identify the code number, count the number of

times the ECM warning lamp flashes. Each fault code

comprises two groups of flashes separated by a 1.2

second pause. The first group represents tens and the

second group represents single units. For example 1

flash followed by a 1.2 second pause followed by 4

flashes would be code number 14. Similarly 4 flashes

followed by a 1.2 second pause followed by 2 flashes

would be code number 42.

The code will be displayed three times. If more

than one fault code is present, the self diagnosis

system will indicate each one in numerical order, with

a 3.2 second pause between each code, and then

repeat the sequence.

The fault codes can be identified as follows:

CODE NUMBER FAULT AREA

12 Satisfactory operation

13 Oxygen sensor open circuit

14 Coolant temperature sensor circuit (voltage low)

15 Coolant temperature sensor circuit (voltage high)

21 Throttle position sensor circuit (voltage high)

22Throttle position sensor circuit (voltage low)

23MAT sensor circuit (voltage' high) 1.8 liter engine

only

24 Vehicle speed sensor circuit

25 MAT sensor circuit

(voltage low) 1.8 liter engine

only

33 MAP sensor circuit

(voltage high)

34MAP sensor circuit (voltage low)

42 Electronic spark timing circuit

44

Oxygen sensor circuit

(lean exhaust)

45Oxygen sensor circuit (rich exhaust)

51 Mem-Cal

55 Control unit input circuits

Test Procedure

(1) Perform the following checks:

(a) Ensure that the battery voltage is above 11

volts. (b) Ensure that the throttle valve is fully closed.

(c) Place the transaxle in neutral.

(d) Ensure that the air conditioner, fan, tights

and all other accessories are switched off.

(2) Turn the ignition On and confirm that the

ECM warning lamp on the instrument cluster is

illuminated but not flashing.

If code 55 is displayed, refer to the Control Unit

heading, perform the circuit test procedure and rectify

the cause of the code before proceeding.

If the ECM warning lamp flashes codes other than

code 55, check the wiring harness between the diag-

nostic link connector terminal B and the control unit

wiring connector terminal A9 for shorts. Repair or

renew the wiring harness as necessary.

If no fault can be found, renew the control unit.

If the ECM warning lamp does not illuminate,

proceed as follows:

(a) Check the METER fuse located in the fuse

panel adjacent to the steering column and the fusible

links located in the fusible link connecting block at the

rear of the battery. Renew the fuse or fusible links as

necessary. (b) Check the wiring harness to the instrument

cluster. Repair or renew the harness. (c) Check the Check Engine lamp bulb. Renew if

necessary. (d) Check the EGI relay. Renew as necessary.

(3) Connect a jumper lead across terminals A

and B on the diagnostic link connector located under

the front passengers seat above the control unit.

(4) Note the codes indicated by the flashing

ECM warning lamp.

If code 12 is displayed, the system is operating

correctly.

If codes other than code 12 are displayed, refer to

the component or circuit test procedure under the

appropriate heading as indicated by the code number.

If more than one code is being displayed, test each

indicated fault working in the order of display of the

code numbers.

(5) After completing the self diagnosis test pro-

cedure, remove the jumper lead from the diagnostic

link connector. (6) After repairing or renewing the necessary

View showing the location of the diagnostic link

connector. Passengers seat removed for clarity.

Inset shows the diagnostic link connector terminal identification.

Page 91 of 238

Fuel and Engine Management 91

components, erase the self diagnosis memory as

described under the following heading.

(7) Repeat the self diagnosis test procedure and

ensure that code 12 is displayed.

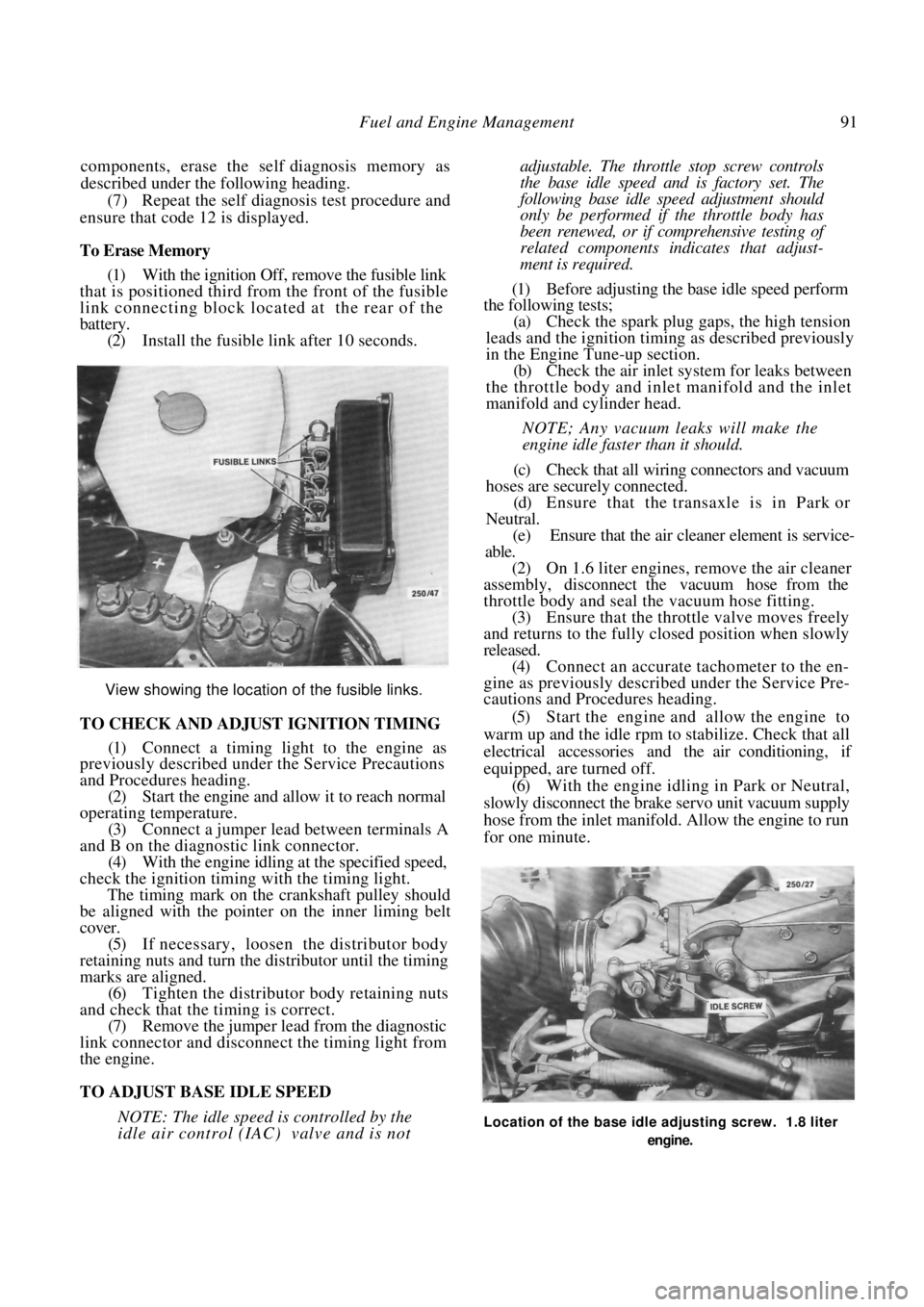

To Erase Memory

(1) With the ignition Off, remove the fusible link

that is positioned third from the front of the fusible

link connecting block located at the rear of the

battery. (2) Install the fusible link after 10 seconds.

View showing the location of the fusible links.

TO CHECK AND ADJUST IGNITION TIMING

(1) Connect a timing light to the engine as

previously described under the Service Precautions

and Procedures heading.

(2) Start the engine and allow it to reach normal

operating temperature. (3) Connect a jumper lead between terminals A

and B on the diagnostic link connector. (4) With the engine idling at the specified speed,

check the ignition timing with the timing light.

The timing mark on the crankshaft pulley should

be aligned with the pointer on the inner liming belt

cover.

(5) If necessary, loosen the distributor body

retaining nuts and turn the distributor until the timing

marks are aligned. (6) Tighten the distributor body retaining nuts

and check that the timing is correct. (7) Remove the jumper lead from the diagnostic

link connector and disconnect the timing light from

the engine.

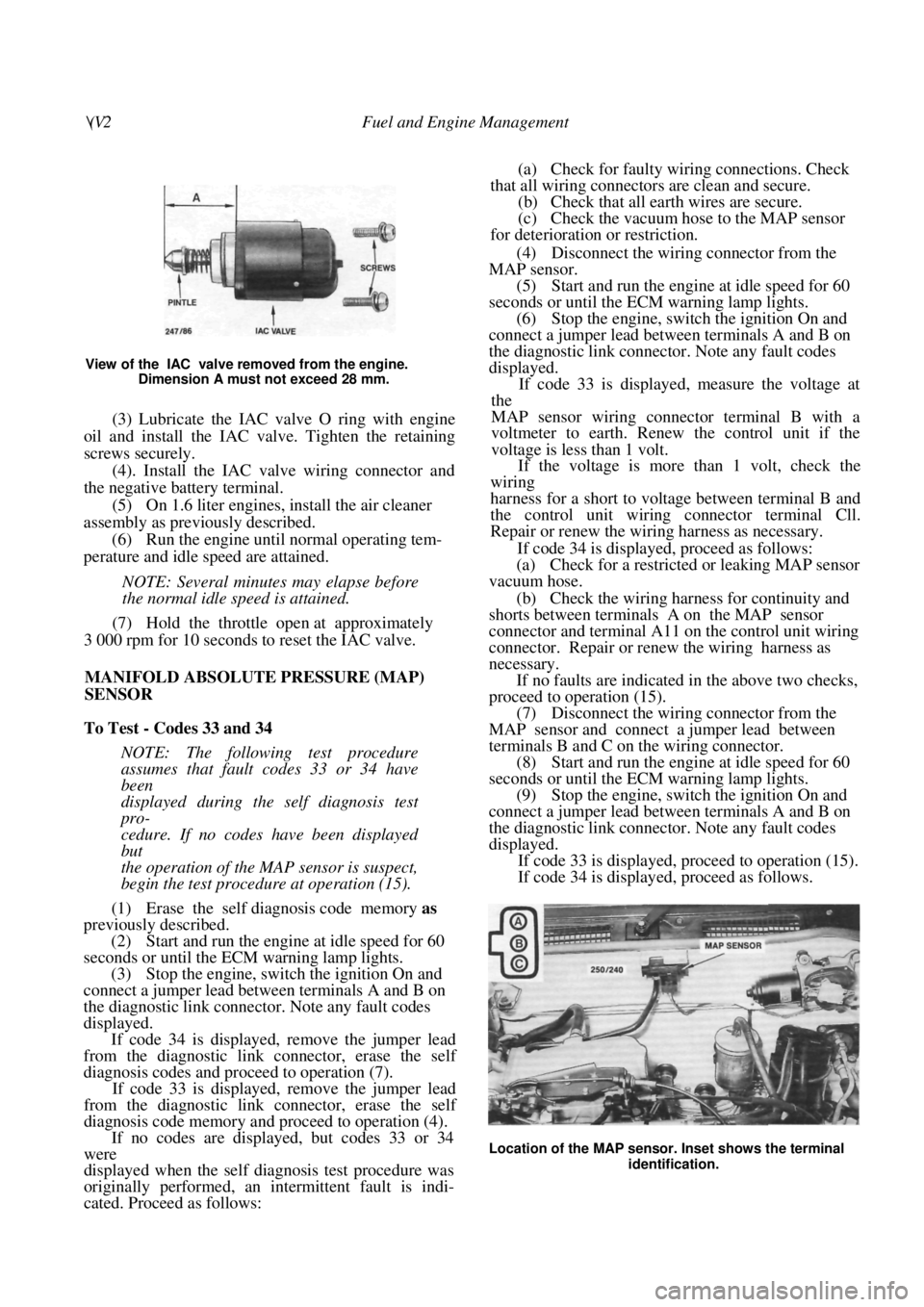

TO ADJUST BASE IDLE SPEED

NOTE: The idle speed is controlled by the

idle air control (IAC) valve and is not

adjustable. The throttle stop screw controls

the base idle speed a nd is factory set. The

following base idle speed adjustment should

only be performed if the throttle body has

been renewed, or if comprehensive testing of

related components indicates that adjust-

ment is required.

(1) Before adjusting the base idle speed perform

the following tests;

(a) Check the spark plug gaps, the high tension

leads and the ignition timin g as described previously

in the Engine Tune-up section.

(b) Check the air inlet syst em for leaks between

the throttle body and inlet manifold and the inlet

manifold and cylinder head.

NOTE; Any vacuum leaks will make the

engine idle faster than it should.

(c) Check that all wiring connectors and vacuum

hoses are securely connected. (d) Ensure that the transaxle is in Park or

Neutral. (e) Ensure that the air cleaner element is service-

able.

(2) On 1.6 liter engines, remove the air cleaner

assembly, disconnect the vacuum hose from the

throttle body and seal the vacuum hose fitting.

(3) Ensure that the throttle valve moves freely

and returns to the fully closed position when slowly

released. (4) Connect an accurate tachometer to the en-

gine as previously descri bed under the Service Pre-

cautions and Procedures heading.

(5) Start the engine and allow the engine to

warm up and the idle rpm to stabilize. Check that all

electrical accessories and the air conditioning, if

equipped, are turned off. (6) With the engine idling in Park or Neutral,

slowly disconnect the brake servo unit vacuum supply

hose from the inlet manifold. Allow the engine to run

for one minute.

Location of the base idle adjusting screw. 1.8 liter

engine.

Page 102 of 238

\(V2 Fuel and Engine Management

View of the IAC valve removed from the engine. Dimension A must not exceed 28 mm.

(3) Lubricate the IAC valve O ring with engine

oil and install the IAC valve. Tighten the retaining

screws securely.

(4). Install the IAC valve wiring connector and

the negative battery terminal.

(5) On 1.6 liter engines, install the air cleaner

assembly as previously described. (6) Run the engine until normal operating tem-

perature and idle speed are attained.

NOTE: Several minutes may elapse before

the normal idle speed is attained.

(7) Hold the throttle open at approximately

3 000 rpm for 10 seconds to reset the IAC valve.

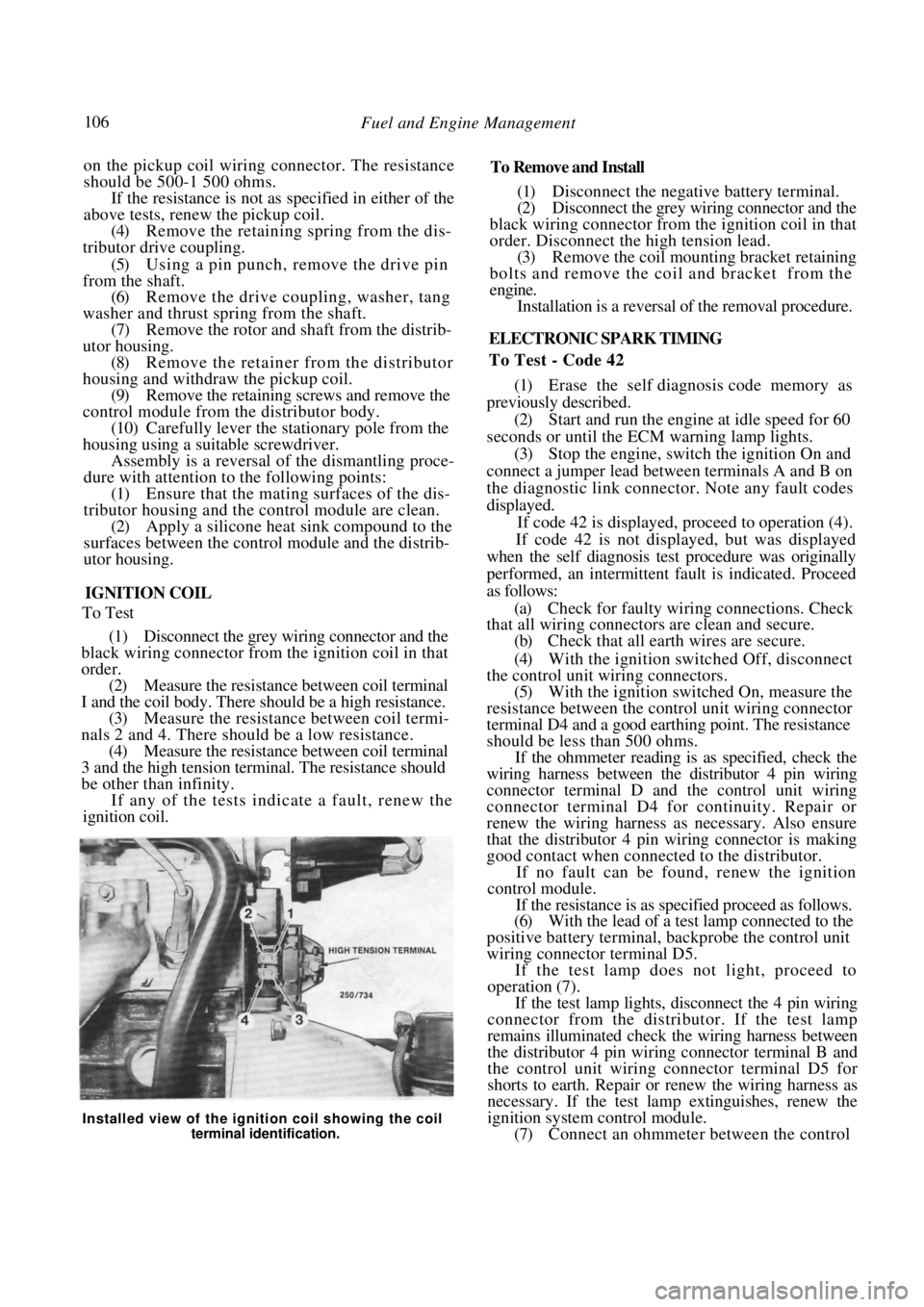

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSOR

To Test - Codes 33 and 34

NOTE: The following test procedure

assumes that fault codes 33 or 34 have

been

displayed during the self diagnosis test

pro-

cedure. If no codes have been displayed

but

the operation of the MAP sensor is suspect,

begin the test procedure at operation (15).

(1) Erase the self diagnosis code memory as

previously described.

(2) Start and run the engine at idle speed for 60

seconds or until the ECM warning lamp lights.

(3) Stop the engine, switch the ignition On and

connect a jumper lead between terminals A and B on

the diagnostic link connector. Note any fault codes

displayed. If code 34 is displayed, remove the jumper lead

from the diagnostic link connector, erase the self

diagnosis codes and proceed to operation (7).

If code 33 is displayed, remove the jumper lead

from the diagnostic link connector, erase the self

diagnosis code memory and proceed to operation (4).

If no codes are displayed, but codes 33 or 34

were

displayed when the self diagnosis test procedure was

originally performed, an intermittent fault is indi-

cated. Proceed as follows:

(a) Check for faulty wiring connections. Check

that all wiring connectors are clean and secure. (b) Check that all earth wires are secure.

(c) Check the vacuum hose to the MAP sensor

for deterioration or restriction.

(4) Disconnect the wiring connector from the

MAP sensor. (5) Start and run the engine at idle speed for 60

seconds or until the ECM warning lamp lights. (6) Stop the engine, switch the ignition On and

connect a jumper lead between terminals A and B on

the diagnostic link connector. Note any fault codes

displayed.

If code 33 is displayed, measure the voltage at

the

MAP sensor wiring connector terminal B with a

voltmeter to earth. Renew the control unit if the

voltage is less than 1 volt.

If the voltage is more than 1 volt, check the

wiring

harness for a short to voltage between terminal B and

the control unit wiring connector terminal Cll.

Repair or renew the wiring harness as necessary.

If code 34 is displayed, proceed as follows:

(a) Check for a restricted or leaking MAP sensor

vacuum hose.

(b) Check the wiring harness for continuity and

shorts between terminals A on the MAP sensor

connector and terminal A11 on the control unit wiring

connector. Repair or renew the wiring harness as

necessary.

If no faults are indicated in the above two checks,

proceed to operation (15).

(7) Disconnect the wiring connector from the

MAP sensor and connect a jumper lead between

terminals B and C on the wiring connector. (8) Start and run the engine at idle speed for 60

seconds or until the ECM warning lamp lights. (9) Stop the engine, switch the ignition On and

connect a jumper lead between terminals A and B on

the diagnostic link connector. Note any fault codes

displayed.

If code 33 is displayed, proceed to operation (15).

If code 34 is displayed, proceed as follows.

Location of the MAP sensor. Inset shows the terminal

identification.

Page 106 of 238

106 Fuel and Engine Management

on the pickup coil wiring connector. The resistance

should be 500-1 500 ohms.

If the resistance is not as specified in either of the

above tests, renew the pickup coil.

(4) Remove the retaining spring from the dis-

tributor drive coupling.

(5) Using a pin punch, remove the drive pin

from the shaft. (6) Remove the drive coupling, washer, tang

washer and thrust spring from the shaft. (7) Remove the rotor and sh aft from the distrib-

utor housing. (8) Remove the retainer from the distributor

housing and withdraw the pickup coil. (9) Remove the retaining sc rews and remove the

control module from the distributor body. (10) Carefully lever the stationary pole from the

housing using a suitable screwdriver. Assembly is a reversal of the dismantling proce-

dure with attention to the following points:

(1) Ensure that the mating surfaces of the dis-

tributor housing and the control module are clean.

(2) Apply a silicone heat sink compound to the

surfaces between the control module and the distrib-

utor housing.

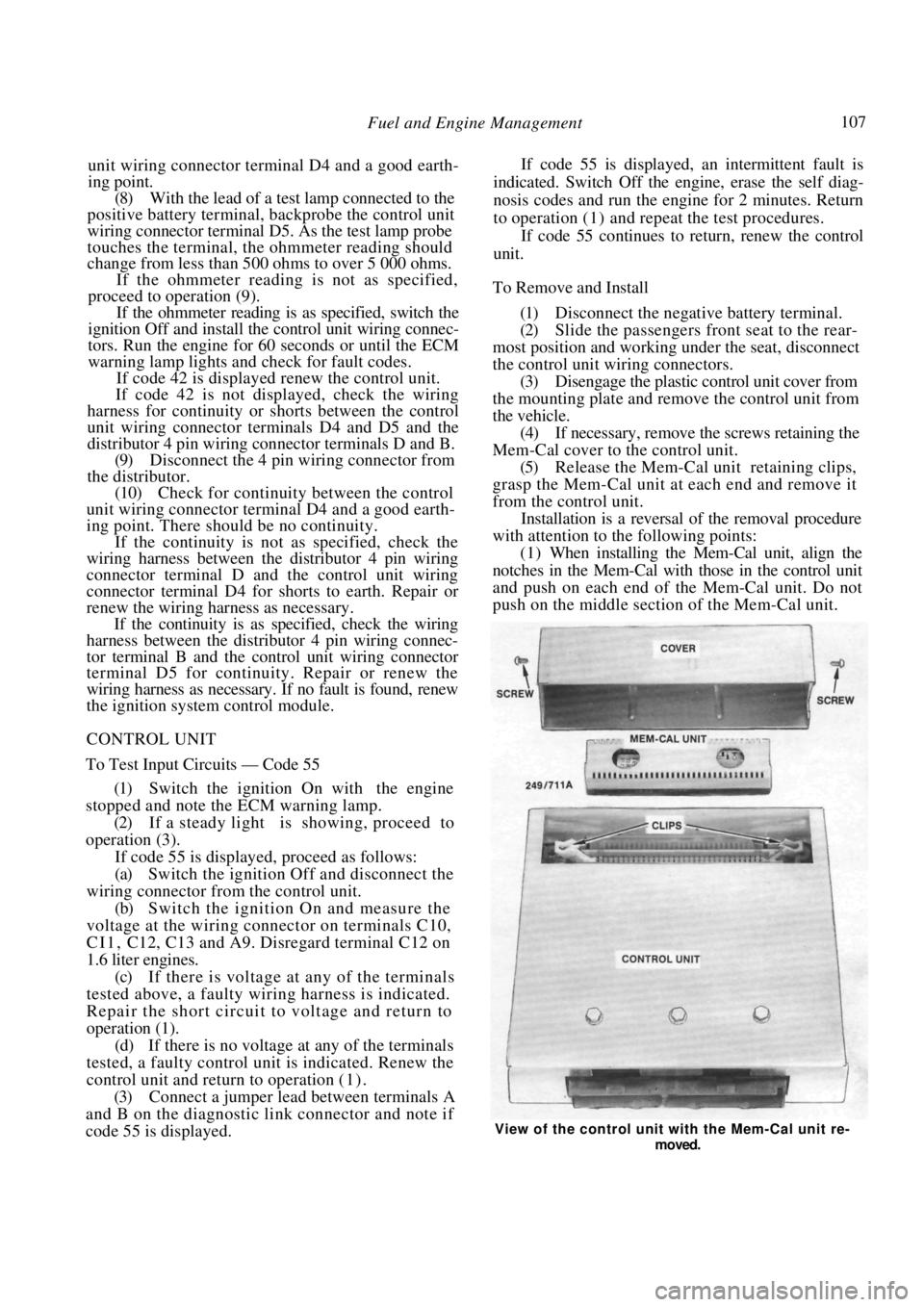

IGNITION COIL

To Test

(1) Disconnect the grey wiring connector and the

black wiring connector from the ignition coil in that

order. (2) Measure the resistance between coil terminal

I and the coil body. There should be a high resistance. (3) Measure the resistance between coil termi-

nals 2 and 4. There should be a low resistance. (4) Measure the resistance between coil terminal

3 and the high tension termin al. The resistance should

be other than infinity.

If any of the tests indicate a fault, renew the

ignition coil.

To Remove and Install

(1) Disconnect the negative battery terminal.

(2) Disconnect the grey wiring connector and the

black wiring connector from the ignition coil in that

order. Disconnect the high tension lead. (3) Remove the coil mounting bracket retaining

bolts and remove the coil and bracket from the

engine. Installation is a reversal of the removal procedure.

ELECTRONIC SPARK TIMING

To Test - Code 42

(1) Erase the self diagnosis code memory as

previously described. (2) Start and run the engine at idle speed for 60

seconds or until the ECM warning lamp lights.

(3) Stop the engine, switch the ignition On and

connect a jumper lead between terminals A and B on

the diagnostic link connector . Note any fault codes

displayed. If code 42 is displayed, proceed to operation (4).

If code 42 is not displayed, but was displayed

when the self diagnosis test procedure was originally

performed, an intermittent fault is indicated. Proceed

as follows:

(a) Check for faulty wiri ng connections. Check

that all wiring connectors are clean and secure.

(b) Check that all earth wires are secure.

(4) With the ignition switched Off, disconnect

the control unit wiring connectors. (5) With the ignition switched On, measure the

resistance between the contro l unit wiring connector

terminal D4 and a good earthing point. The resistance

should be less than 500 ohms.

If the ohmmeter reading is as specified, check the

wiring harness between the distributor 4 pin wiring

connector terminal D and the control unit wiring

connector terminal D4 for continuity. Repair or

renew the wiring harness as necessary. Also ensure

that the distributor 4 pin wiring connector is making

good contact when connected to the distributor.

If no fault can be found, renew the ignition

control module.

If the resistance is as specified proceed as follows.

(6) With the lead of a test lamp connected to the

positive battery terminal, backprobe the control unit

wiring connector terminal D5.

If the test lamp does not light, proceed to

operation (7).

If the test lamp lights, disconnect the 4 pin wiring

connector from the distributor. If the test lamp

remains illuminated check the wiring harness between

the distributor 4 pin wiring connector terminal B and

the control unit wiring connector terminal D5 for

shorts to earth. Repair or renew the wiring harness as

necessary. If the test lamp extinguishes, renew the

ignition system control module.

(7) Connect an ohmmeter between the control

Installed view of the ignition coil showing the coil

terminal identification.

Page 107 of 238

Fuel and Engine Management 107

unit wiring connector terminal D4 and a good earth-

ing point.

(8) With the lead of a test lamp connected to the

positive battery terminal, backprobe the control unit

wiring connector terminal D5. As the test lamp probe

touches the terminal, the ohmmeter reading should

change from less than 500 ohms to over 5 000 ohms.

If the ohmmeter reading is not as specified,

proceed to operation (9).

If the ohmmeter reading is as specified, switch the

ignition Off and install the control unit wiring connec-

tors. Run the engine for 60 seconds or until the ECM

warning lamp lights and check for fault codes.

If code 42 is displayed renew the control unit.

If code 42 is not displayed, check the wiring

harness for continuity or sh orts between the control

unit wiring connector terminals D4 and D5 and the

distributor 4 pin wiring connector terminals D and B.

(9) Disconnect the 4 pin wiring connector from

the distributor.

(10) Check for continuity between the control

unit wiring connector termin al D4 and a good earth-

ing point. There should be no continuity.

If the continuity is not as specified, check the

wiring harness between the distributor 4 pin wiring

connector terminal D and the control unit wiring

connector terminal D4 for shorts to earth. Repair or

renew the wiring harness as necessary.

If the continuity is as specified, check the wiring

harness between the distributor 4 pin wiring connec-

tor terminal B and the control unit wiring connector

terminal D5 for continuity. Repair or renew the

wiring harness as necessary. If no fault is found, renew

the ignition system control module.

CONTROL UNIT

To Test Input Circuits — Code 55

(1) Switch the ignition On with the engine

stopped and note the ECM warning lamp. (2) If a steady light is showing, proceed to

operation (3). If code 55 is displayed, proceed as follows:

(a) Switch the ignition Off and disconnect the

wiring connector from the control unit.

(b) Switch the ignition On and measure the

voltage at the wiring connector on terminals C10,

C I 1 , C12, C13 and A9. Disregard terminal C12 on

1.6 liter engines. (c) If there is voltage at any of the terminals

tested above, a faulty wi ring harness is indicated.

Repair the short circuit to voltage and return to

operation (1). (d) If there is no voltage at any of the terminals

tested, a faulty control unit is indicated. Renew the

control unit and return to operation ( 1 ) . (3) Connect a jumper lead between terminals A

and B on the diagnostic link connector and note if

code 55 is displayed.

If code 55 is displayed, an intermittent fault is

indicated. Switch Off the engine, erase the self diag-

nosis codes and run the engine for 2 minutes. Return

to operation (1 ) and repeat the test procedures.

If code 55 continues to return, renew the control

unit.

To Remove and Install

(1) Disconnect the negative battery terminal.

(2) Slide the passengers front seat to the rear-

most position and working under the seat, disconnect

the control unit wiring connectors. (3) Disengage the plastic control unit cover from

the mounting plate and remove the control unit from

the vehicle. (4) If necessary, remove the screws retaining the

Mem-Cal cover to the control unit.

(5) Release the Mem-Cal unit retaining clips,

grasp the Mem-Cal unit at each end and remove it

from the control unit. Installation is a reversal of the removal procedure

with attention to the following points:

(1) When installing the Mem-Cal unit, align the

notches in the Mem-Cal with those in the control unit

and push on each end of the Mem-Cal unit. Do not

push on the middle section of the Mem-Cal unit.

View of the control unit with the Mem-Cal unit re-

moved.

Page 108 of 238

108 Fuel and Engine Management

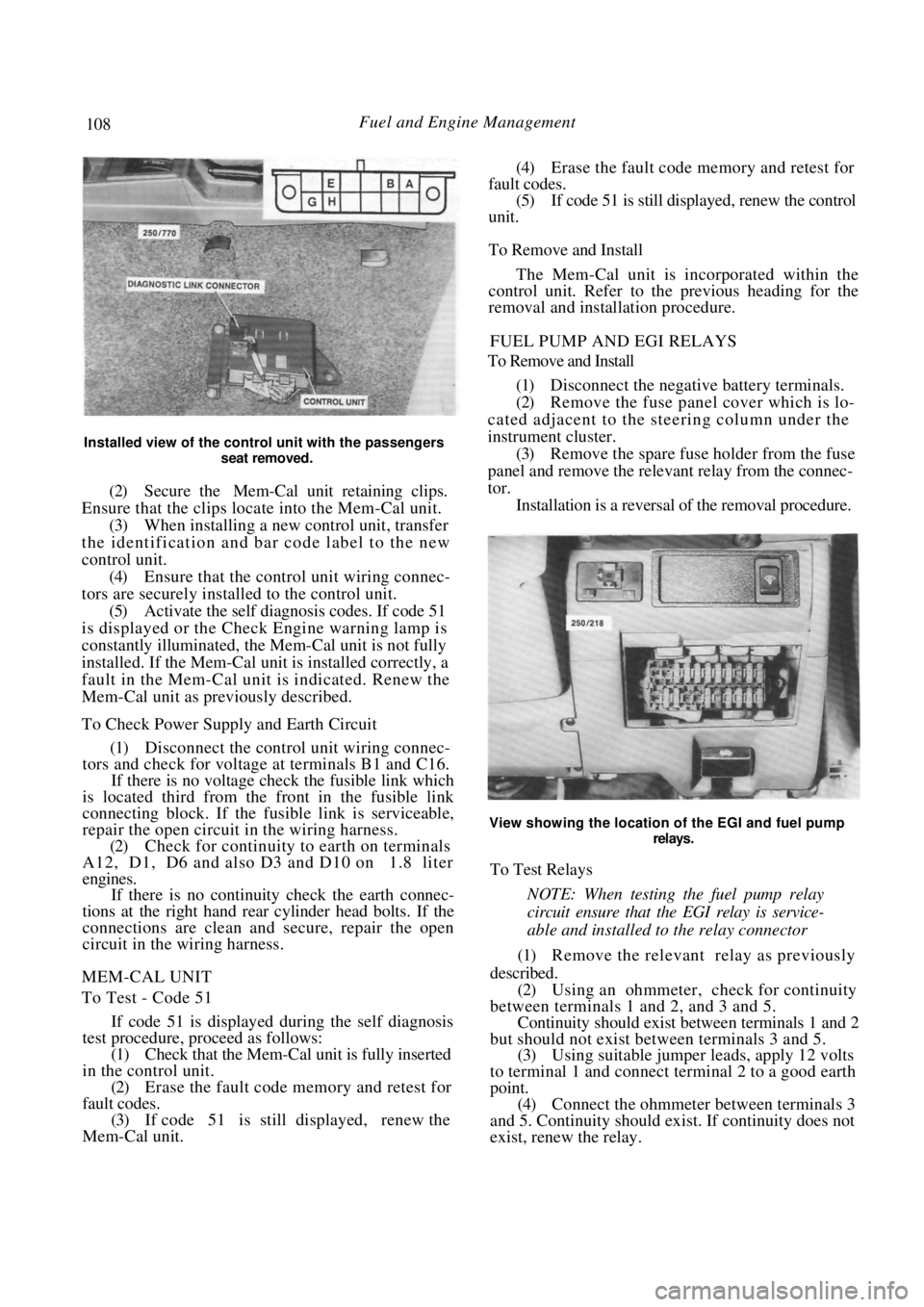

Installed view of the control unit with the passengers seat removed.

(2) Secure the Mem-Cal unit retaining clips.

Ensure that the clips locate into the Mem-Cal unit. (3) When installing a new control unit, transfer

the identification and bar code label to the new

control unit. (4) Ensure that the control unit wiring connec-

tors are securely installed to the control unit. (5) Activate the self diagnosis codes. If code 51

is displayed or the Check Engine warning lamp is

constantly illuminated, the Mem-Cal unit is not fully

installed. If the Mem-Cal uni t is installed correctly, a

fault in the Mem-Cal unit is indicated. Renew the

Mem-Cal unit as previously described.

To Check Power Supply and Earth Circuit

(1) Disconnect the control unit wiring connec-

tors and check for voltage at terminals B1 and C16.

If there is no voltage check the fusible link which

is located third from the front in the fusible link

connecting block. If the fu sible link is serviceable,

repair the open circuit in the wiring harness.

(2) Check for continuity to earth on terminals

A12, D1, D6 and also D3 and D10 on 1.8 liter

engines.

If there is no continuity check the earth connec-

tions at the right hand rear cylinder head bolts. If the

connections are clean and secure, repair the open

circuit in the wiring harness.

MEM-CAL UNIT

To Test - Code 51

If code 51 is displayed during the self diagnosis

test procedure, pr oceed as follows:

(1) Check that the Mem-Cal unit is fully inserted

in the control unit. (2) Erase the fault code memory and retest for

fault codes. (3) If code 51 is still displayed, renew the

Mem-Cal unit.

(4) Erase the fault code memory and retest for

fault codes. (5) If code 51 is still displayed, renew the control

unit.

To Remove and Install

The Mem-Cal unit is incorporated within the

control unit. Refer to the previous heading for the

removal and installation procedure.

FUEL PUMP AND EGI RELAYS

To Remove and Install

(1) Disconnect the negative battery terminals.

(2) Remove the fuse panel cover which is lo-

cated adjacent to the steering column under the

instrument cluster. (3) Remove the spare fuse holder from the fuse

panel and remove the releva nt relay from the connec-

tor. Installation is a reversal of the removal procedure.

View showing the location of the EGI and fuel pump

relays.

To Test Relays

NOTE: When testing the fuel pump relay

circuit ensure that th e EGI relay is service-

able and installed to the relay connector

(1) Remove the relevant relay as previously

described. (2) Using an ohmmeter, check for continuity

between terminals 1 and 2, and 3 and 5. Continuity should exist be tween terminals 1 and 2

but should not exist between terminals 3 and 5.

(3) Using suitable jumper leads, apply 12 volts

to terminal 1 and connect terminal 2 to a good earth

point. (4) Connect the ohmmeter between terminals 3

and 5. Continuity should exist. If continuity does not

exist, renew the relay.