brake NISSAN PULSAR 1987 Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1987, Model line: PULSAR, Model: NISSAN PULSAR 1987Pages: 238, PDF Size: 28.91 MB

Page 142 of 238

142 Automatic Transaxle

(8) Install the dipstick and start the engine and

recheck the fluid level.

NOTE; Do not overfill the transaxle or

foaming and unsatisfactory operation of the

transaxle will result.

TO DRAIN AND REFILL

This is not a normal maintenance and lubrication

procedure. It is only necessary to drain the complete

system, including the torq ue converter and the oil

cooler, when the transaxle assembly is removed for

overhaul or the renewal of transaxle components such

as bearings, clutches or as semblies. When this condi-

tion arises, the torque converter and the cooler should

be cleaned and flushed to remove any dirt or sludge.

After transaxle overhaul, install approximately 6

liters of new transaxle fluid, and top up as previously

described.

4. BRAKE BAND

Band adjustment is not a normal maintenance

procedure.

The adjustment entails removal of the valve body

and for this reason the vehicle should be taken to an

authorized dealer.

5. KICKDOWN CABLE

TO ADJUST

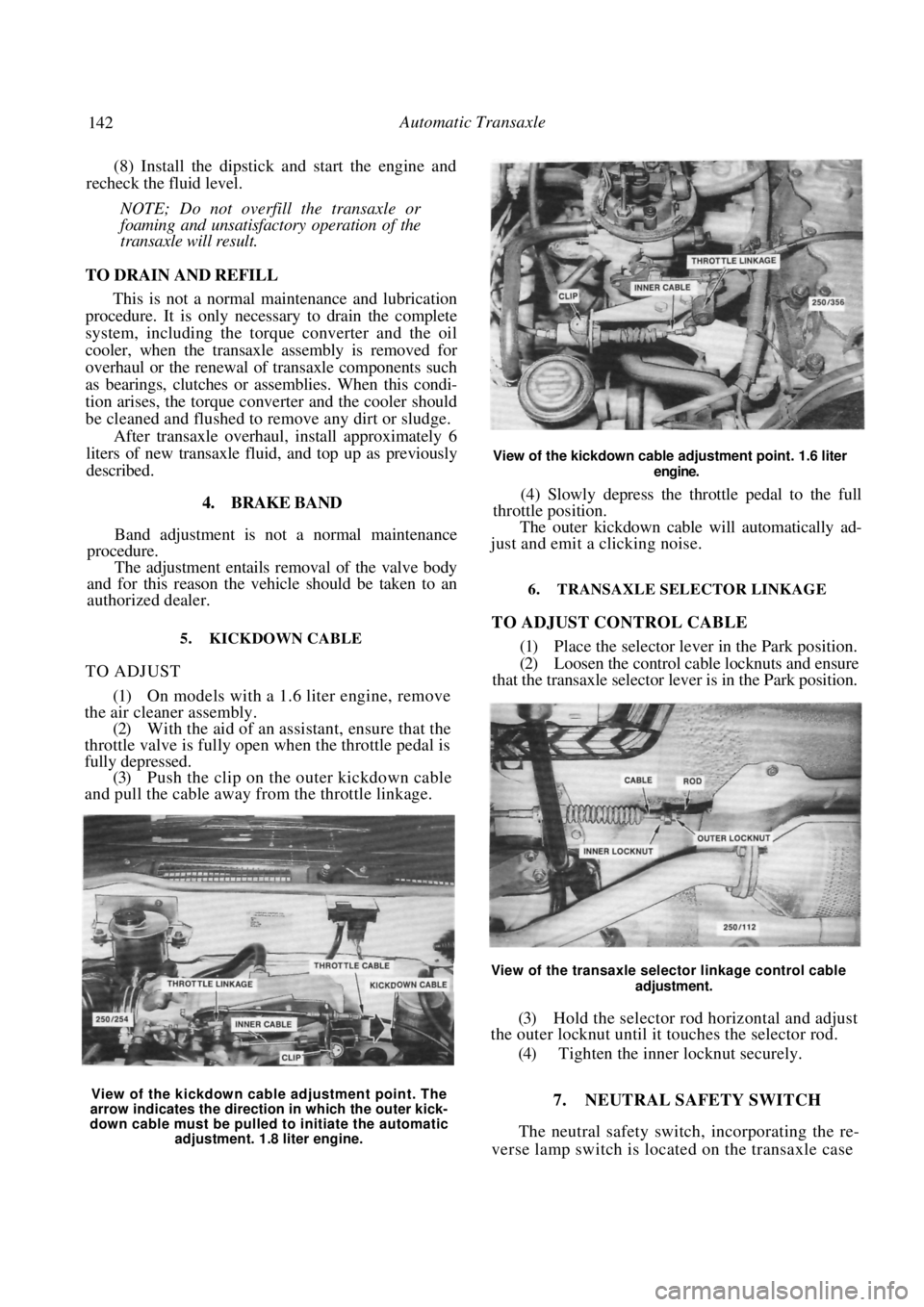

(1) On models with a 1.6 liter engine, remove

the air cleaner assembly. (2) With the aid of an assistant, ensure that the

throttle valve is fully open when the throttle pedal is

fully depressed. (3) Push the clip on the outer kickdown cable

and pull the cable away from the throttle linkage.

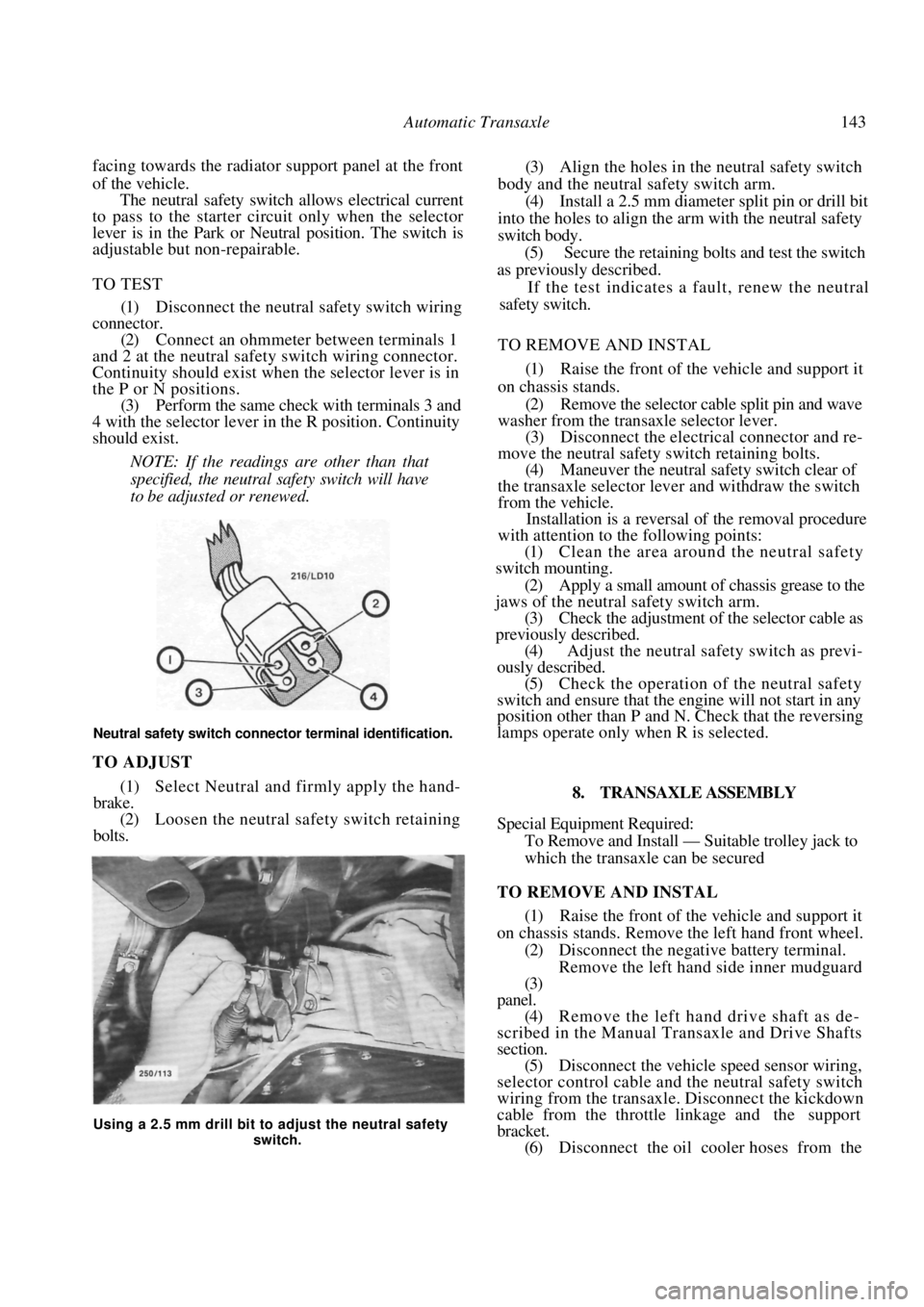

View of the kickdown cable adjustment point. 1.6 liter

engine.

(4) Slowly depress the throttle pedal to the full

throttle position.

The outer kickdown cable will automatically ad-

just and emit a clicking noise.

6. TRANSAXLE SELECTOR LINKAGE

TO ADJUST CONTROL CABLE

(1) Place the selector lever in the Park position.

(2) Loosen the control cable locknuts and ensure

that the transaxle selector lever is in the Park position.

View of the transaxle selector linkage control cable

adjustment.

(3) Hold the selector rod horizontal and adjust

the outer locknut until it touches the selector rod.

(4) Tighten the inner locknut securely.

7. NEUTRAL SAFETY SWITCH

The neutral safety switch, incorporating the re-

verse lamp switch is located on the transaxle case

View of the kickdown cable adjustment point. The

arrow indicates the direction in which the outer kick-

down cable must be pulled to initiate the automatic adjustment. 1.8 liter engine.

Page 143 of 238

Automatic Transaxle 143

facing towards the radiator support panel at the front

of the vehicle.

The neutral safety switch allows electrical current

to pass to the starter circ uit only when the selector

lever is in the Park or Neutral position. The switch is

adjustable but non-repairable.

TO TEST

(1) Disconnect the neutral safety switch wiring

connector.

(2) Connect an ohmmeter between terminals 1

and 2 at the neutral safety switch wiring connector.

Continuity should exist when the selector lever is in

the P or N positions. (3) Perform the same check with terminals 3 and

4 with the selector lever in the R position. Continuity

should exist.

NOTE: If the readings are other than that

specified, the neutral safety switch will have

to be adjusted or renewed.

Neutral safety switch connector terminal identification.

TO ADJUST

(1) Select Neutral and firmly apply the hand-

brake. (2) Loosen the neutral safety switch retaining

bolts.

(3) Align the holes in the neutral safety switch

body and the neutral safety switch arm. (4) Install a 2.5 mm diameter split pin or drill bit

into the holes to align the arm with the neutral safety

switch body. (5) Secure the retaining bolts and test the switch

as previously described.

If the test indicates a fault, renew the neutral

safety switch.

TO REMOVE AND INSTAL

(1) Raise the front of the vehicle and support it

on chassis stands. (2) Remove the selector cable split pin and wave

washer from the transaxle selector lever.

(3) Disconnect the electric al connector and re-

move the neutral safety switch retaining bolts. (4) Maneuver the neutral safety switch clear of

the transaxle selector lever and withdraw the switch

from the vehicle. Installation is a reversal of the removal procedure

with attention to the following points:

(1) Clean the area around the neutral safety

switch mounting.

(2) Apply a small amount of chassis grease to the

jaws of the neutral safety switch arm. (3) Check the adjustment of the selector cable as

previously described. (4) Adjust the neutral safety switch as previ-

ously described.

(5) Check the operation of the neutral safety

switch and ensure that the engine will not start in any

position other than P and N. Check that the reversing

lamps operate only when R is selected.

8. TRANSAXLE ASSEMBLY

Special Equipment Required:

To Remove and Install — Suitable trolley jack to

which the transaxle can be secured

TO REMOVE AND INSTAL

(1) Raise the front of the vehicle and support it

on chassis stands. Remove the left hand front wheel.

(2) Disconnect the negative battery terminal. Remove the left hand side inner mudguard

(3)

panel.

(4) Remove the left hand drive shaft as de-

scribed in the Manual Tran saxle and Drive Shafts

section. (5) Disconnect the vehicle speed sensor wiring,

selector control cable and the neutral safety switch

wiring from the transaxle. Disconnect the kickdown

cable from the throttle linkage and the support

bracket. (6) Disconnect the oil cooler hoses from the

Using a 2.5 mm drill bit to adjust the neutral safety

switch.

Page 146 of 238

146 Steering — Part 1

STEERING PULLS TO ONE SIDE

(1) Uneven tire wear or pressures: Check the

condition of the tires and inflate to the recommended

pressures.

(2) Incorrect front wheel alignment: Check and

align the front end.

(3) Dragging brakes: Check each wheel for drag-

ging brakes. Overhaul the brakes as necessary. (4) Damaged suspension or crossmember: In-

spect and renew the damaged components. (5) Faulty power steering gear assembly: Re-

move the power steering gear for overhaul.

FRONT WHEEL WOBBLE OR SHIMMY

(1) Uneven tire wear or incorrect tire pressures;

Check the condition of the tires and inflate to the

recommended pressures. (2) Tire or wheel imbalance: Check and balance

as necessary (3) Worn or badly adjusted hub bearings: Check

the condition and adjust the front hub bearings.

(4) Faulty or worn suspension, units: Check and

overhaul or renew as a pair.

NOTE: Check the steering linkage as previ-

ously described. Raise the front of the vehi-

cle and check the adjustment of the hub

bearings by moving the road wheel in and

out at the top and bottom. No movement in

the bearings should be felt. Check the sus-

pension units as outlined in the Front Sus-

pension section.

STEERING ERRATIC OR WANDERING

(1) Incorrect or uneven wheel alignment setting:

Check and adjust th e steering geometry.

(2) Smooth front tires: Check and renew the

tires as necessary.

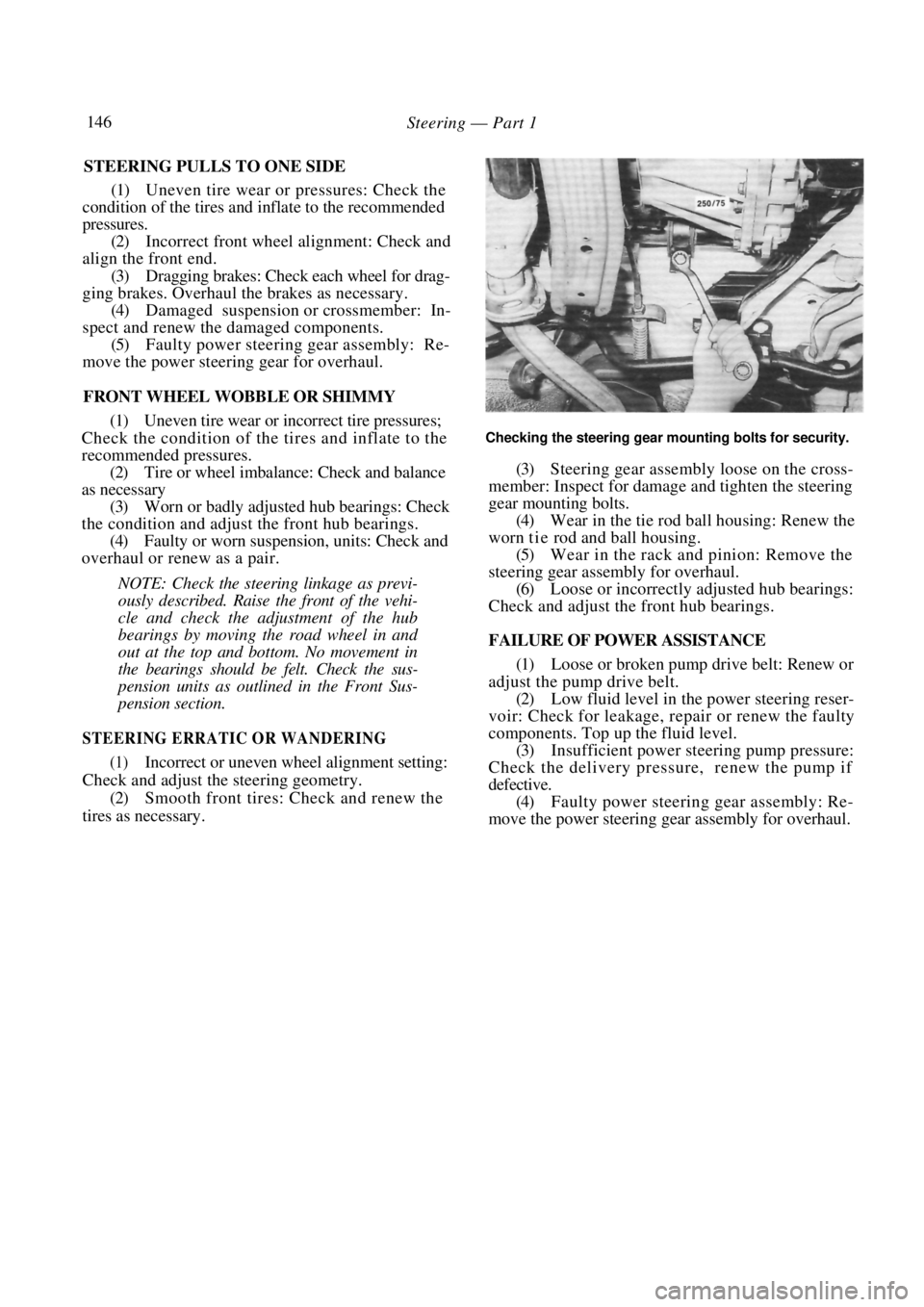

Checking the steering gear mounting bolts for security.

(3) Steering gear assembly loose on the cross-

member: Inspect for damage and tighten the steering

gear mounting bolts.

(4) Wear in the tie rod ball housing: Renew the

worn t i e rod and ball housing. (5) Wear in the rack and pinion: Remove the

steering gear assembly for overhaul. (6) Loose or incorrectly adjusted hub bearings:

Check and adjust the front hub bearings.

FAILURE OF POWER ASSISTANCE

(1) Loose or broken pump drive belt: Renew or

adjust the pump drive belt.

(2) Low fluid level in the power steering reser-

voir: Check for leakage, repair or renew the faulty

components. Top up the fluid level. (3) Insufficient power steering pump pressure:

Check the delivery pressure, renew the pump if

defective. (4) Faulty power steering gear assembly: Re-

move the power steering gear assembly for overhaul.

Page 156 of 238

156

FRONT SUSPENSION

SPECIFICATIONS

Type.................. Independent MacPherson strut with

coil springs and control arms

Shock absorber .................. Hydraulic, non-repairable

Hub bearing end float (maximum) ............. 0.05 mm

Ball joint axial play (maximum) ....................0.7 mm

Ball joint turning torque (used)...............0.5-4.9 Nm

Wheel alignment:

Toe in ..................................................... 0-2 mm

Camber ........................................- 0 ° 1 0 ' ± 4 5 '

Caster ..............................................1 ° 1 0 ' ± 4 5 '

King pin inclination..................... 1 3 ° 5 5 ' ± 4 5 '

TORQUE WRENCH SETTINGS

Hub bearing nut..................................... 196-235 Nm

Suspension unit to steering knuckle nut ...... 118 Nm

Suspension unit to body nuts ......................... 29 Nm

Piston rod nut .................................................. 72 Nm

Brake caliper to steering knuckle bolts ........... 52 Nm

Ball joint to steering knuckle bolt ................... 86 Nm

Control arm bracket bolts ............................... 98 Nm

Control arm pivot bolt ................................ 118 Nm

Stabiliser bar link nuts..................................... 44 Nm

Stabiliser bar bracket bolts .............................. 21 Nm

1. FRONT SUSPENSION TROUBLE

SHOOTING

FRONT END NOISE

(1) Loose upper suspension mounting or piston

rod: Tighten the mounting or piston rod nuts. (2) Loose or worn suspension unit lower ball

joint: Tighten or renew the lower ball joint.

(3) Noise in the suspension unit: Renew the

faulty suspension unit, preferably in pairs.

(4) Worn or loose steering gear: Overhaul the

steering gear assembly. (5) Worn front hub bearings: Renew the hub

bearings:

(6) Loose or defective stab ilizer bar, control arm

or mountings: Check, tighten or renew the mounting

rubbers.

Check the ball joints for wear and deterioration.

(7) Worn stabilizer bar link ball joints: Renew

the stabilizer bar links.

(8) Drive shafts worn or insufficiently lubri-

cated: Check the lubricant and the dust boots and

renew as necessary. (9) Drive shaft splines in the hub or the

differential worn or dama ged: Check and renew as

necessary.

NOTE: To check the front suspension com-

ponents for wear, raise the front of the

vehicle, support it on chassis stands and

allow both front wheel to hang free. With an

assistant pushing and pulling the front

wheels in and out at the top and then at the

bottom, check for excessive looseness at the

front hub bearings and lower control arm

inner pivot bushes. Noise or vibration in the

front end can also be caused by excessive

tire or wheel unbalance. Drive shaft joint

noise is usually more pronounced when

moving slowly with the steering on full lock.

POOR OR ERRATIC ROAD HOLDING

ABILITY

(1) Low or uneven tire pressures: Inflate the

tires to the recommended pressures.

(2) Defective suspension unit: Renew the faulty

unit, preferably in pairs.

Page 158 of 238

158 Front Suspension

Installed view of the front suspension. When using a floor jack locate the head of the jack on the crossmember.

(2) Remove the cap, split pin, castellated re-

tainer and with the aid of an assistant applying the

brakes, loosen and remove the hub nut.

(3) Remove the split pin and the castellated nut

retaining the tie rod end to the steering knuckle. (4) Disconnect the tie rod end from the steering

knuckle using a suitable puller. Alternatively place a

suitable dolly or hammer against one side of the

steering knuckle eye and strike the opposite side with

a hammer.

(5) Remove the brake caliper anchor plate bolts,

withdraw the caliper from the disc and support it with

a piece of wire inside the inner mudguard. Ensure that

the brake hose is not twisted.

(6) Withdraw the brake disc from the hub.

(7) Loosely install the hub nut and tap on the nut

with a soft faced hammer to separate the drive shaft

from the hub. (8) Place a mark on the suspension unit to

steering knuckle cam head bolt to ensure correct wheel

alignment on assembly. (9) Remove the steering knuckle to suspension

unit nuts and bolts. (10) Remove the split pin and the castellated nut

retaining the lower ball joint stud to the steering

knuckle. (11) Disconnect the ball joint stud from the steering knuckle using a suitable puller or alternatively

place a suitable dolly or hammer against one side of

the steering knuckle eye and strike the opposite side

with a hammer.

(12)

Withdraw the steering knuckle from the

vehicle taking care not to drop the drive shaft or

damage its boot. (13) Clean and check the steering knuckle for

wear, cracks and damage. (14) If necessary, dismantle the hub and check

the bearing assembly using the dismantling procedure

described later in this section. Installation is a reversal of the removal procedure

with attention to the following points:

(1) Install the steering knuckle and hub assembly

over the drive shaft and loosely install the ball joint

stud nut and the suspension unit to knuckle bolts and

nuts.

(2) Ensure that the suspension unit to steering

knuckle cam head bolt mark s are aligned and tighten

the retaining nuts to the specified torque.

NOTE: If the cam head bolt is not installed

in its original position, a wheel alignment

should be performed.

(3) Tighten the ball joint to steering knuckle stud

bolt to the specified torque.

Page 159 of 238

Front Suspension 159

(4) Install the tie rod end to the steering knuckle

and tighten the castellated nut securely. Install a

new

split pin.

(5) Install the brake disc to the hub.

(6) Install the brake caliper to the steering

knuckle and tighten the retaining bolts to the specified

torque. (7) Install the hub nut and washer to the

drive

shaft and with the aid of an assistant applying the

brakes, tighten the hub nut to the specified torque. (8) Install the hub nut retainer and a new

split

pin to the drive shaft. (9) Check the hub end float as described later in

this section. (10) Install the fron t wheel and lower the vehicle

to the ground.

TO DISMANTLE

NOTE: The front wheel bearing assembly is

non-serviceable. If the wheel bearing is dis-

mantled for any reason it should be re-

newed.

(1) Remove the steering knuckle from the vehi-

cle as previously described. (2) Hold the steering knuckle assembly in a vice

with soft jaw guards. (3) Using a hammer and a suitable pipe or tube

that pushes on the inside of the hub, drive out the

wheel hub and outside inner race from the steering

knuckle assembly. (4) Using snap ring pliers, remove the snap ring

that retains the outer bearing race from the wheel side

of the steering knuckle. (5) Using a suitable press and press plates,

support the steering knuckle with the outside face

downwards. To aid in dismantling, position the inside

inner race in the bearing and press the assembly from

the steering knuckle. Discard the bearing assembly. (6) Using a bearing puller and a press, remove

the inner race from the hub assembly. If the inner race cannot be removed from the hub

in this manner, it may be necessary to grind the race

using an angle grinder and split the race using a cold

chisel.

(7) Thoroughly clean and dry the steering

knuckle and hub in a suitable solvent. (8) Inspect all the components for wear, damage

and cracks and renew if necessary.

TO ASSEMBLE

Assembly is a reversal of the dismantling proce-

dure with attention to the following points:

(1) Apply grease to the oil seal lips of the new

bearing assembly.

NOTE: Ensure that (he inside of the outer

race of the bearing is precoated with wheel

bearing grease. If necessary, pack the outer

race of the wheel bearing with wheel bearing

grease after it is installed to the steering

knuckle.

(2) Using the press and press plates, support the

steering knuckle with the outside face uppermost.

Using a suitable diameter steel tube that contacts on

the outer race only, press the outer race full into the

steering knuckle.

(3) Install the snap ring to the groove in the

steering knuckle.

(4) Install the inner races to the steering

knuckle

and support the inner race on the press using a

suitable tube or mandrel. (5) Using the press and a suitable tube press the

hub assembly into the steerin g knuckle. When using

the press ensure that the pressing force does not

exceed 29 kN. (6) With the press exerting a force of 44.1 kN

rotate the steering knuckle from side to side several

turns to ensure that the wh eel bearings are operating

smoothly.

(7) Install the steering knuckle to the vehicle

as

previously described.

TO CHECK HUB END FLOAT

(1) Raise the front of the vehicle and support it

on chassis stands. Remove the front wheel.

(2) Mount the dial gauge on the steering knuckle

so that the dial gauge plunger is against the wheel hub.

(3) Zero the dial gauge and attempt to move the

hub in and out. Total hub e nd float should not exceed

0.05 mm. (4) Renew the wheel bearing as previously de-

scribed if necessary.

4. SUSPENSION UNIT

Special Equipment Required:

To Dismantle — Spring compressor

TO REMOVE AND DISMANTLE

(1) Raise the front of the vehicle and support it

on chassis stands. Remove the front wheels.

Dismantled view of the steering knuckle and hub

components.

Page 160 of 238

160 Front Suspension

(2) Disconnect the flexible brake hoses from the

suspension unit bracket.

(3) Using quick drying paint, place mating

marks on the camber adjustin g cam head bolt and the

suspension unit lower mounti ng as an aid to installa-

tion. (4) Remove the bolts and nuts retaining the

suspension unit lower mounting to the steering

knuckle. (5) Open the bonnet and remove the nuts

retaining the suspension unit upper mounting to the

inner mudguard panel and remove the suspension

unit assembly from the vehicle. Use care when

removing not to damage the drive shaft boot.

(6) Remove the dust cover and loosen the piston

rod nut but do not remove it at this stage. (7) Install a spring compressor to the

suspension

unit assembly. Compress the coil spring and remove

the piston rod nut. (8) Remove the washer, upper mounting assem-

bly, the thrust washer, spring seat, insulator, coil

spring, bump rubber and dust cover from the suspen-

sion unit. (9) Check the operation of the suspension unit.

With the suspension unit in a vertical position, move

the piston rod up and down a number of times. A

Dismantled view of the front suspension unit.

uniform resistance should be felt with no abnormal

slack spots or noise evident. If the suspension unit is

defective, it should be renewed.

NOTE: It is recommended that the suspen-

sion unit on the opposite side be renewed at

the same time.

(10) Check the upper mounting assembly for

damage and fatigue. Check the thrust washer for wear.

Check all rubber components, the spring seat and

insulator for wear, damage and deterioration. Renew

worn or damaged components. (11) Check the coil spring for fatigue by compar-

ison with a new spring. Al so check the spring for

cracks and damage. If the coil spring is defective, it is

recommended that the springs on both sides be

renewed.

TO ASSEMBLE AND INSTAL

Assembly and installation is a reversal of the

removal and dismantling procedure with attention to

the following points:

View of the front suspension unit with the spring

compressor installed.

Page 161 of 238

Front Suspension 161

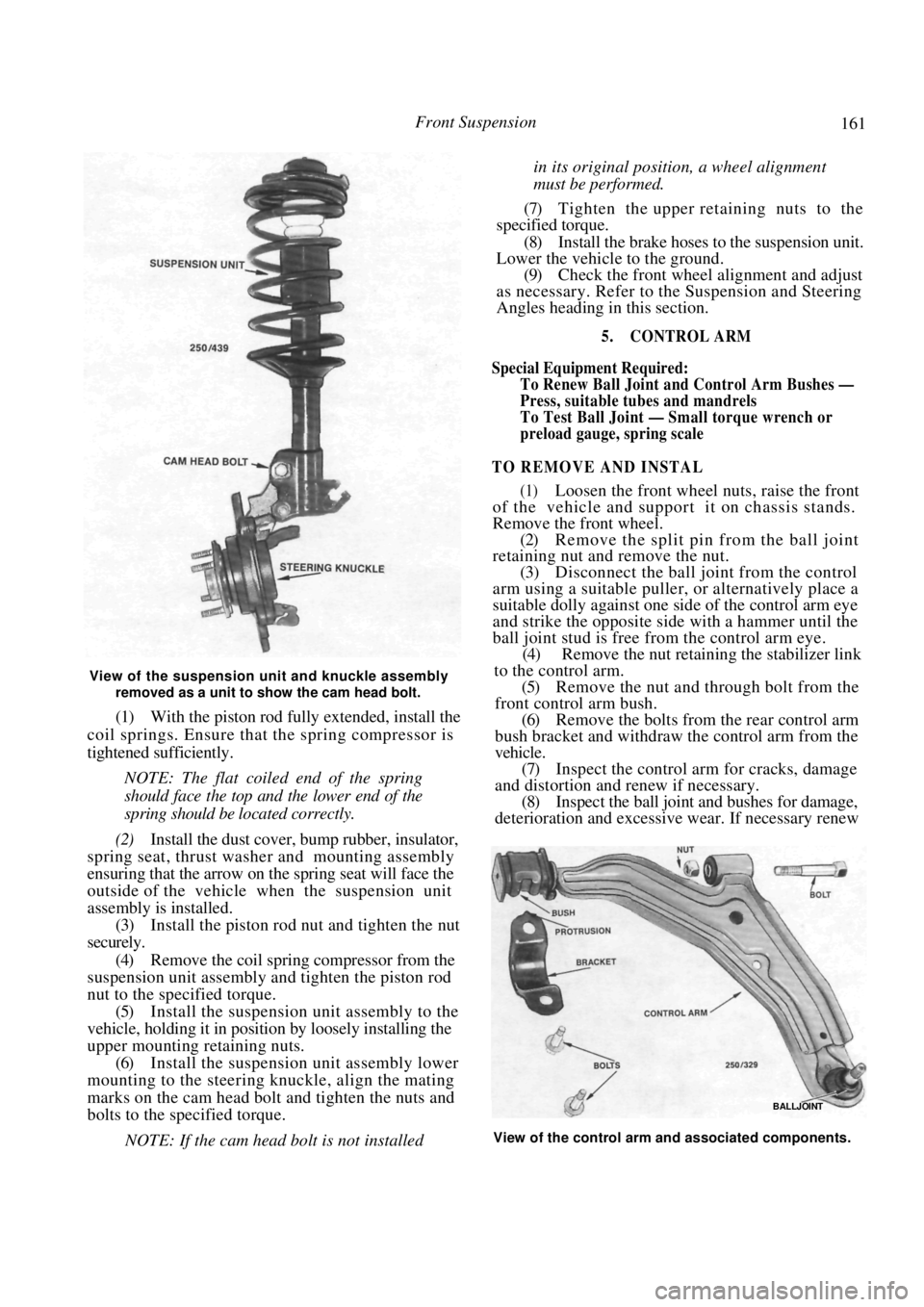

View of the suspension unit and knuckle assembly removed as a unit to show the cam head bolt.

(1) With the piston rod fully extended, install the

coil springs. Ensure that the spring compressor is

tightened sufficiently.

NOTE: The flat coiled end of the spring

should face the top and the lower end of the

spring should be located correctly.

(2) Install the dust cover, bump rubber, insulator,

spring seat, thrust washer and mounting assembly

ensuring that the arrow on the spring seat will face the

outside of the vehicle when the suspension unit

assembly is installed.

(3) Install the piston rod nut and tighten the nut

securely.

(4) Remove the coil spring compressor from the

suspension unit assembly and tighten the piston rod

nut to the specified torque. (5) Install the suspension unit assembly to the

vehicle, holding it in position by loosely installing the

upper mounting retaining nuts. (6) Install the suspension unit assembly lower

mounting to the steering knuckle, align the mating

marks on the cam head bolt and tighten the nuts and

bolts to the specified torque.

NOTE: If the cam head bolt is not installed

in its original position, a wheel alignment

must be performed.

(7) Tighten the upper retaining nuts to the

specified torque.

(8) Install the brake hoses to the suspension unit.

Lower the vehicle to the ground.

(9) Check the front wheel alignment and adjust

as necessary. Refer to the Suspension and Steering

Angles heading in this section.

5. CONTROL ARM

Special Equipment Required:

To Renew Ball Joint and Control Arm Bushes —

Press, suitable t ubes and mandrels

To Test Ball Joint — Small torque wrench or

preload gauge, spring scale

TO REMOVE AND INSTAL

(1) Loosen the front wheel nuts, raise the front

of the vehicle and support it on chassis stands.

Remove the front wheel.

(2) Remove the split pin from the ball joint

retaining nut and remove the nut.

(3) Disconnect the ball joint from the control

arm using a suitable puller, or alternatively place a

suitable dolly against one si de of the control arm eye

and strike the opposite side with a hammer until the

ball joint stud is free from the control arm eye. (4) Remove the nut retaining the stabilizer link

to the control arm.

(5) Remove the nut and through bolt from the

front control arm bush. (6) Remove the bolts from the rear control arm

bush bracket and withdraw the control arm from the

vehicle. (7) Inspect the control arm for cracks, damage

and distortion and renew if necessary. (8) Inspect the ball joint and bushes for damage,

deterioration and excessive wear. If necessary renew

BALLJOINT

View of the control arm and associated components.

Page 165 of 238

Rear Suspension 165

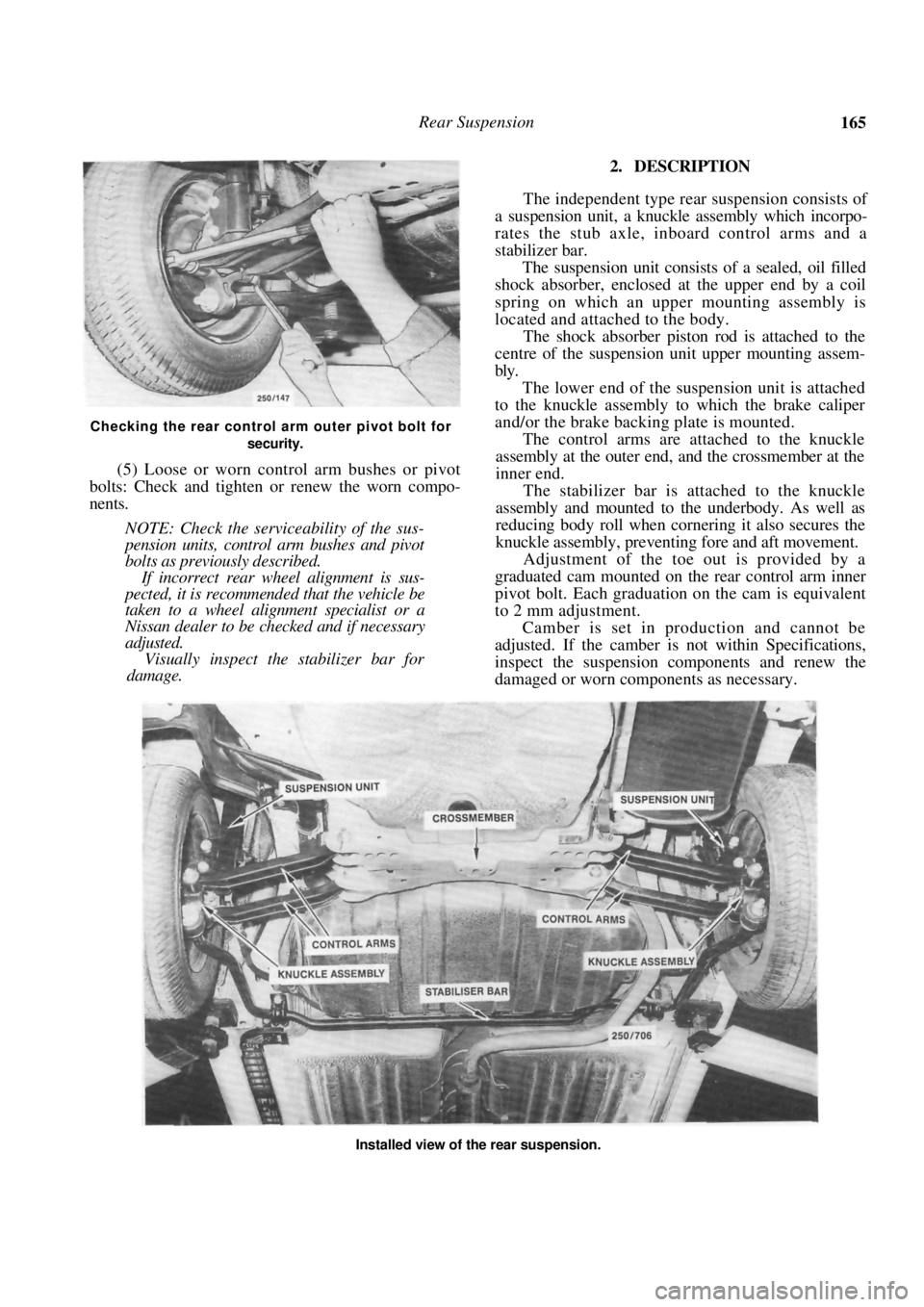

Checking the rear control arm outer pivot bolt for security.

(5) Loose or worn control arm bushes or pivot

bolts: Check and tighten or renew the worn compo-

nents.

NOTE: Check the service ability of the sus-

pension units, control arm bushes and pivot

bolts as previously described.

If incorrect rear wheel alignment is sus-

pected, it is recommended that the vehicle be

taken to a wheel alignment specialist or a

Nissan dealer to be checked and if necessary

adjusted.

Visually inspect the stabilizer bar for

damage.

2. DESCRIPTION

The independent type rear suspension consists of

a suspension unit, a knuckle assembly which incorpo-

rates the stub axle, inboard control arms and a

stabilizer bar.

The suspension unit consists of a sealed, oil filled

shock absorber, enclosed at the upper end by a coil

spring on which an upper mounting assembly is

located and attached to the body.

The shock absorber piston rod is attached to the

centre of the suspension unit upper mounting assem-

bly.

The lower end of the suspension unit is attached

to the knuckle assembly to which the brake caliper

and/or the brake backing plate is mounted.

The control arms are attached to the knuckle

assembly at the outer end, and the crossmember at the

inner end.

The stabilizer bar is attached to the knuckle

assembly and mounted to the underbody. As well as

reducing body roll when cornering it also secures the

knuckle assembly, preventing fore and aft movement.

Adjustment of the toe out is provided by a

graduated cam mounted on the rear control arm inner

pivot bolt. Each graduation on the cam is equivalent

to 2 mm adjustment.

Camber is set in production and cannot be

adjusted. If the camber is not within Specifications,

inspect the suspension components and renew the

damaged or worn components as necessary.

Installed view of the rear suspension.

Page 166 of 238

166 Rear Suspension

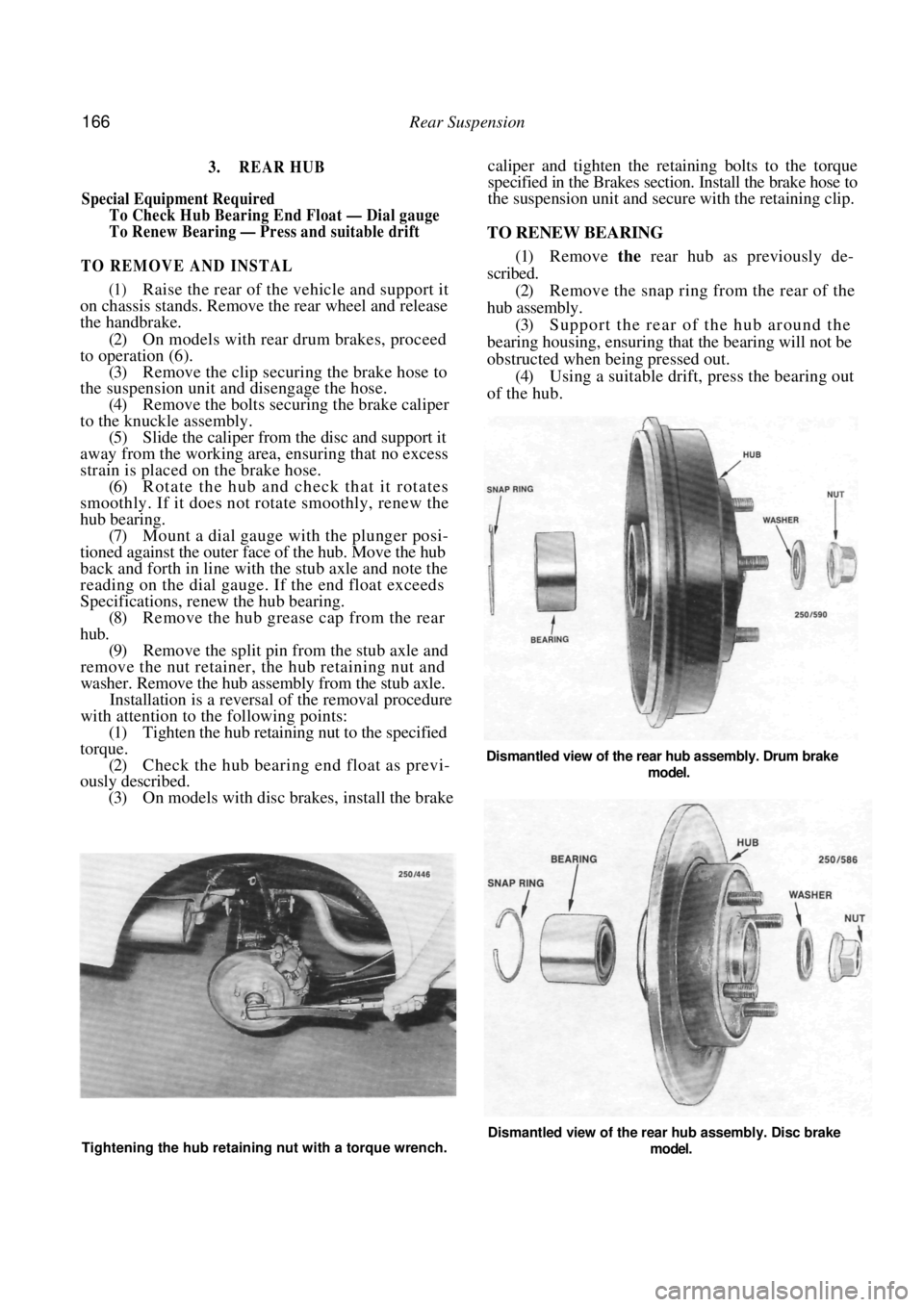

3. REAR HUB

Special Equipment Required

To Check Hub Bearing End Float — Dial gauge

To Renew Bearing — Press and suitable drift

TO REMOVE AND INSTAL

(1) Raise the rear of the vehicle and support it

on chassis stands. Remove the rear wheel and release

the handbrake.

(2) On models with rear drum brakes, proceed

to operation (6).

(3) Remove the clip securing the brake hose to

the suspension unit and disengage the hose.

(4) Remove the bolts securing the brake caliper

to the knuckle assembly. (5) Slide the caliper from the disc and support it

away from the working area, ensuring that no excess

strain is placed on the brake hose. (6) Rotate the hub and check that it rotates

smoothly. If it does not rotate smoothly, renew the

hub bearing. (7) Mount a dial gauge with the plunger posi-

tioned against the outer face of the hub. Move the hub

back and forth in line with the stub axle and note the

reading on the dial gauge. If the end float exceeds

Specifications, renew the hub bearing.

(8) Remove the hub grease cap from the rear

hub. (9) Remove the split pin from the stub axle and

remove the nut retainer, the hub retaining nut and

washer. Remove the hub assembly from the stub axle. Installation is a reversal of the removal procedure

with attention to the following points:

(1) Tighten the hub retaining nut to the specified

torque. (2) Check the hub bearing end float as previ-

ously described.

(3) On models with disc brakes, install the brake

caliper and tighten the retaining bolts to the torque

specified in the Brakes section. Install the brake hose to

the suspension unit and secure with the retaining clip.

TO RENEW BEARING

(1) Remove the rear hub as previously de-

scribed. (2) Remove the snap ring from the rear of the

hub assembly. (3) Support the rear of the hub around the

bearing housing, ensuring that the bearing will not be

obstructed when being pressed out. (4) Using a suitable drift, press the bearing out

of the hub.

Dismantled view of the rear hub assembly. Drum brake

model.

Tightening the hub retaining nut with a torque wrench. Dismantled view of the rear hub assembly. Disc brake

model.