NISSAN SENTRA 2002 B15 / 5.G Owners Manual

Manufacturer: NISSAN, Model Year: 2002, Model line: SENTRA, Model: NISSAN SENTRA 2002 B15 / 5.GPages: 235, PDF Size: 1.97 MB

Page 171 of 235

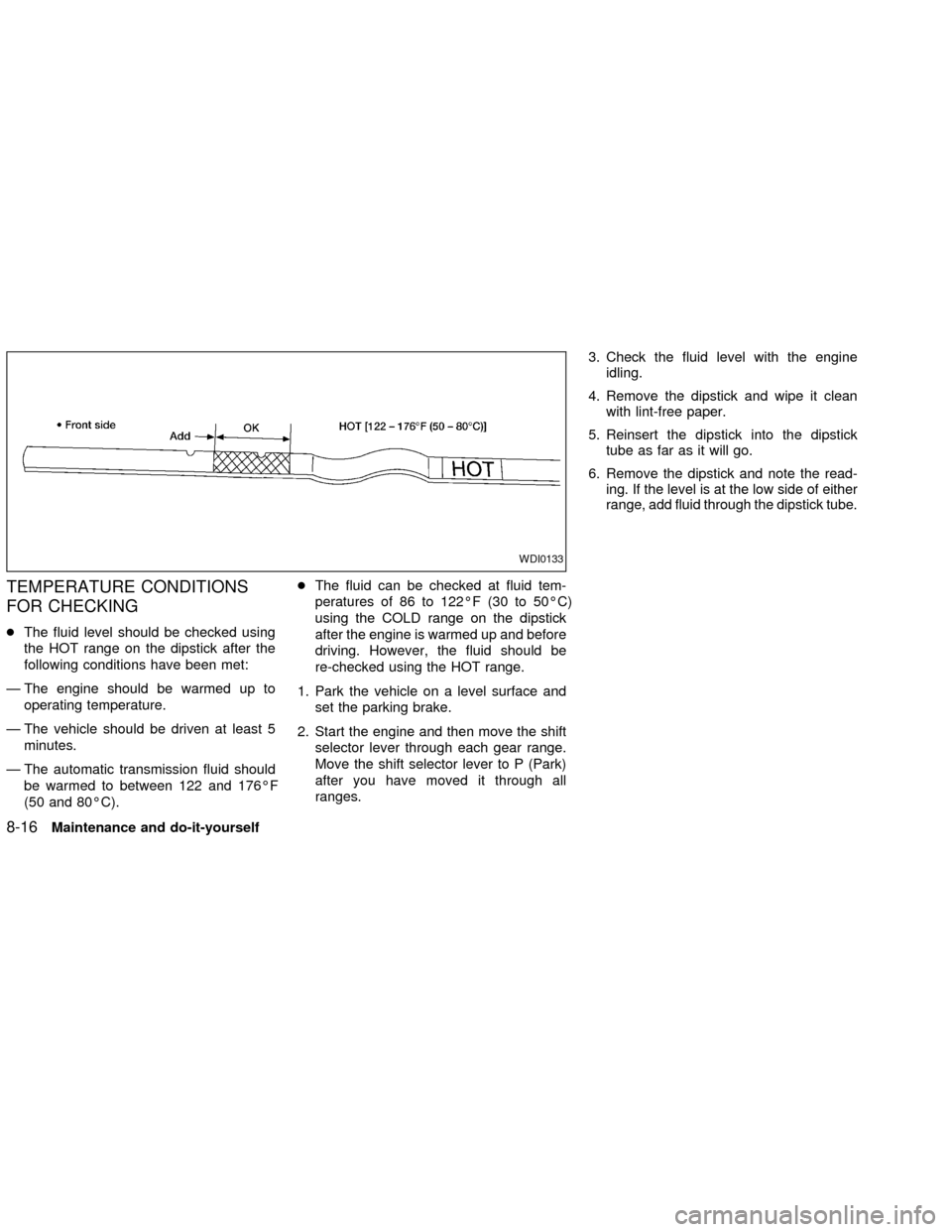

TEMPERATURE CONDITIONS

FOR CHECKING

cThe fluid level should be checked using

the HOT range on the dipstick after the

following conditions have been met:

Ð The engine should be warmed up to

operating temperature.

Ð The vehicle should be driven at least 5

minutes.

Ð The automatic transmission fluid should

be warmed to between 122 and 176ÉF

(50 and 80ÉC).cThe fluid can be checked at fluid tem-

peratures of 86 to 122ÉF (30 to 50ÉC)

using the COLD range on the dipstick

after the engine is warmed up and before

driving. However, the fluid should be

re-checked using the HOT range.

1. Park the vehicle on a level surface and

set the parking brake.

2. Start the engine and then move the shift

selector lever through each gear range.

Move the shift selector lever to P (Park)

after you have moved it through all

ranges.3. Check the fluid level with the engine

idling.

4. Remove the dipstick and wipe it clean

with lint-free paper.

5. Reinsert the dipstick into the dipstick

tube as far as it will go.

6. Remove the dipstick and note the read-

ing. If the level is at the low side of either

range, add fluid through the dipstick tube.

WDI0133

8-16Maintenance and do-it-yourself

ZX

Page 172 of 235

CAUTION

DO NOT OVERFILL. Use ONLY Nissan

Matic `D' (Continental U.S. and Alaska)

or Canada NISSAN Automatic Trans-

mission Fluid. Dexron

TMIII/MerconTM

or equivalent may also be used. Out-

side the continental United States and

Alaska contact an authorized NISSAN

dealership for more information re-

garding suitable fluids, including rec-

ommended brand(s) of Dexron

TM

III/MerconTMAutomatic Transmission

Fluid.

NOTE:

If the vehicle has been driven for a long

time at high speeds, or in city traffic in

hot weather, or if it is being used to pull

a trailer, the accurate fluid level cannot

be read. You should wait until the fluid

has cooled down (about 30 minutes) be-

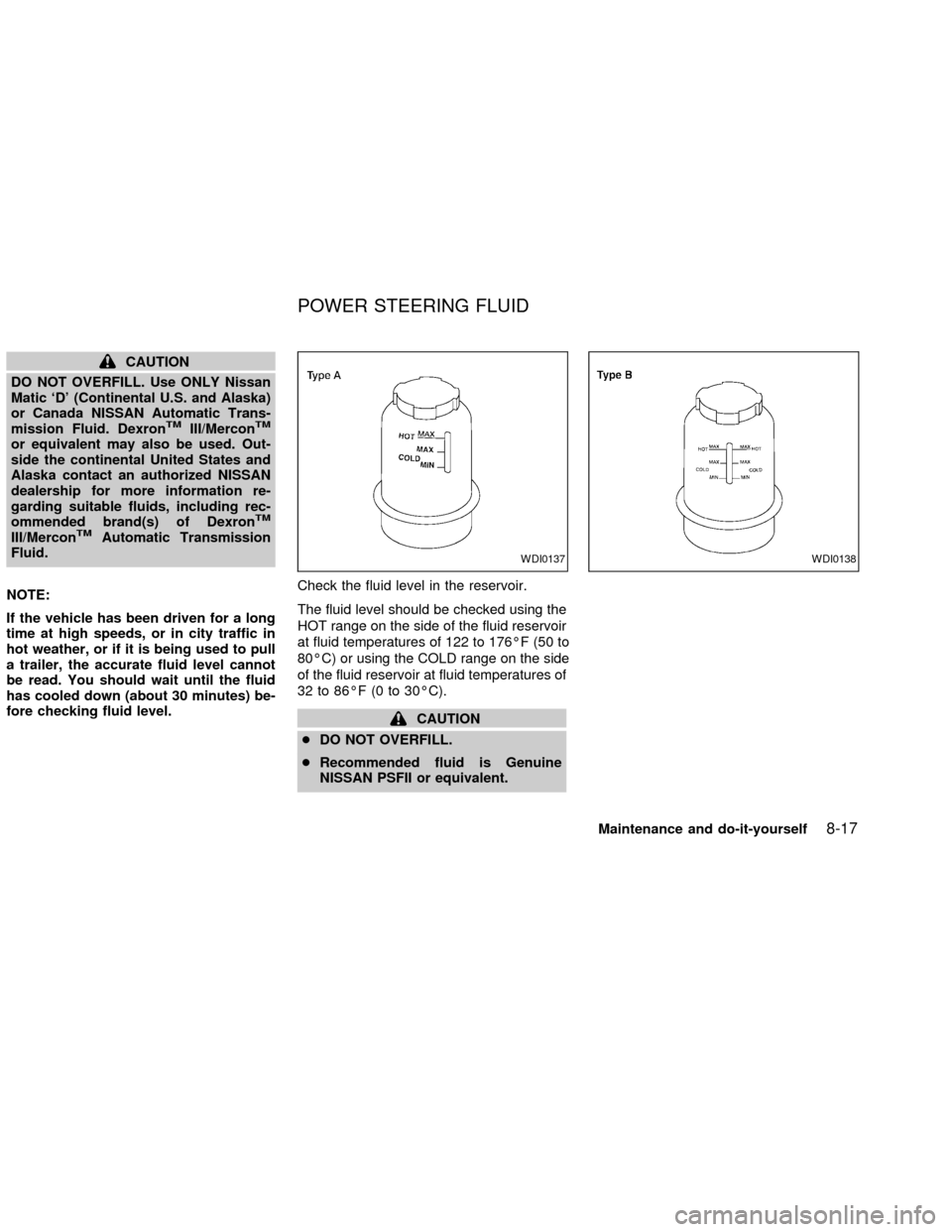

fore checking fluid level.Check the fluid level in the reservoir.

The fluid level should be checked using the

HOT range on the side of the fluid reservoir

at fluid temperatures of 122 to 176ÉF (50 to

80ÉC) or using the COLD range on the side

of the fluid reservoir at fluid temperatures of

32 to 86ÉF (0 to 30ÉC).

CAUTION

cDO NOT OVERFILL.

cRecommended fluid is Genuine

NISSAN PSFII or equivalent.

WDI0137WDI0138

POWER STEERING FLUID

Maintenance and do-it-yourself8-17

ZX

Page 173 of 235

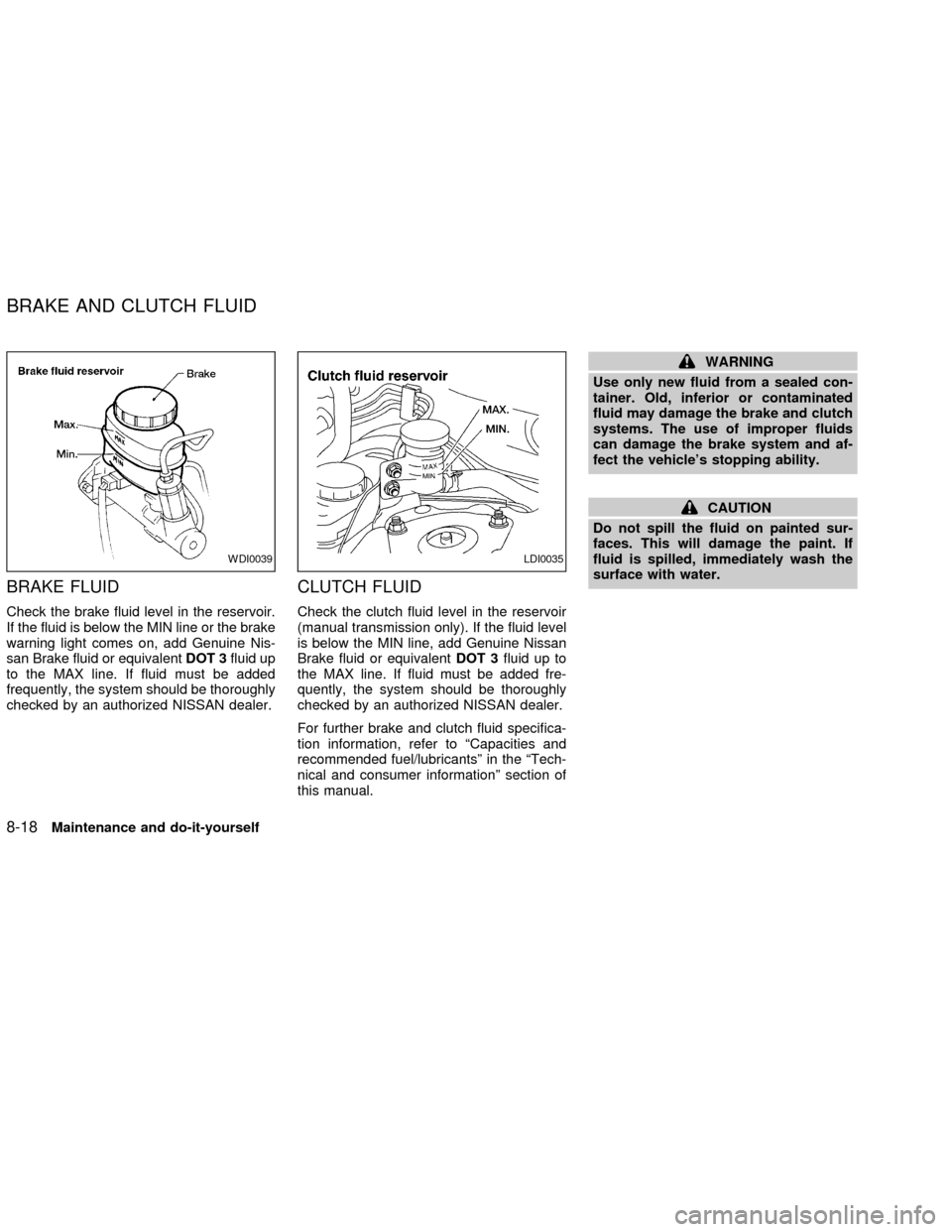

BRAKE FLUID

Check the brake fluid level in the reservoir.

If the fluid is below the MIN line or the brake

warning light comes on, add Genuine Nis-

san Brake fluid or equivalentDOT 3fluid up

to the MAX line. If fluid must be added

frequently, the system should be thoroughly

checked by an authorized NISSAN dealer.

CLUTCH FLUID

Check the clutch fluid level in the reservoir

(manual transmission only). If the fluid level

is below the MIN line, add Genuine Nissan

Brake fluid or equivalentDOT 3fluid up to

the MAX line. If fluid must be added fre-

quently, the system should be thoroughly

checked by an authorized NISSAN dealer.

For further brake and clutch fluid specifica-

tion information, refer to ªCapacities and

recommended fuel/lubricantsº in the ªTech-

nical and consumer informationº section of

this manual.

WARNING

Use only new fluid from a sealed con-

tainer. Old, inferior or contaminated

fluid may damage the brake and clutch

systems. The use of improper fluids

can damage the brake system and af-

fect the vehicle's stopping ability.

CAUTION

Do not spill the fluid on painted sur-

faces. This will damage the paint. If

fluid is spilled, immediately wash the

surface with water.

WDI0039LDI0035

BRAKE AND CLUTCH FLUID

8-18Maintenance and do-it-yourself

ZX

Page 174 of 235

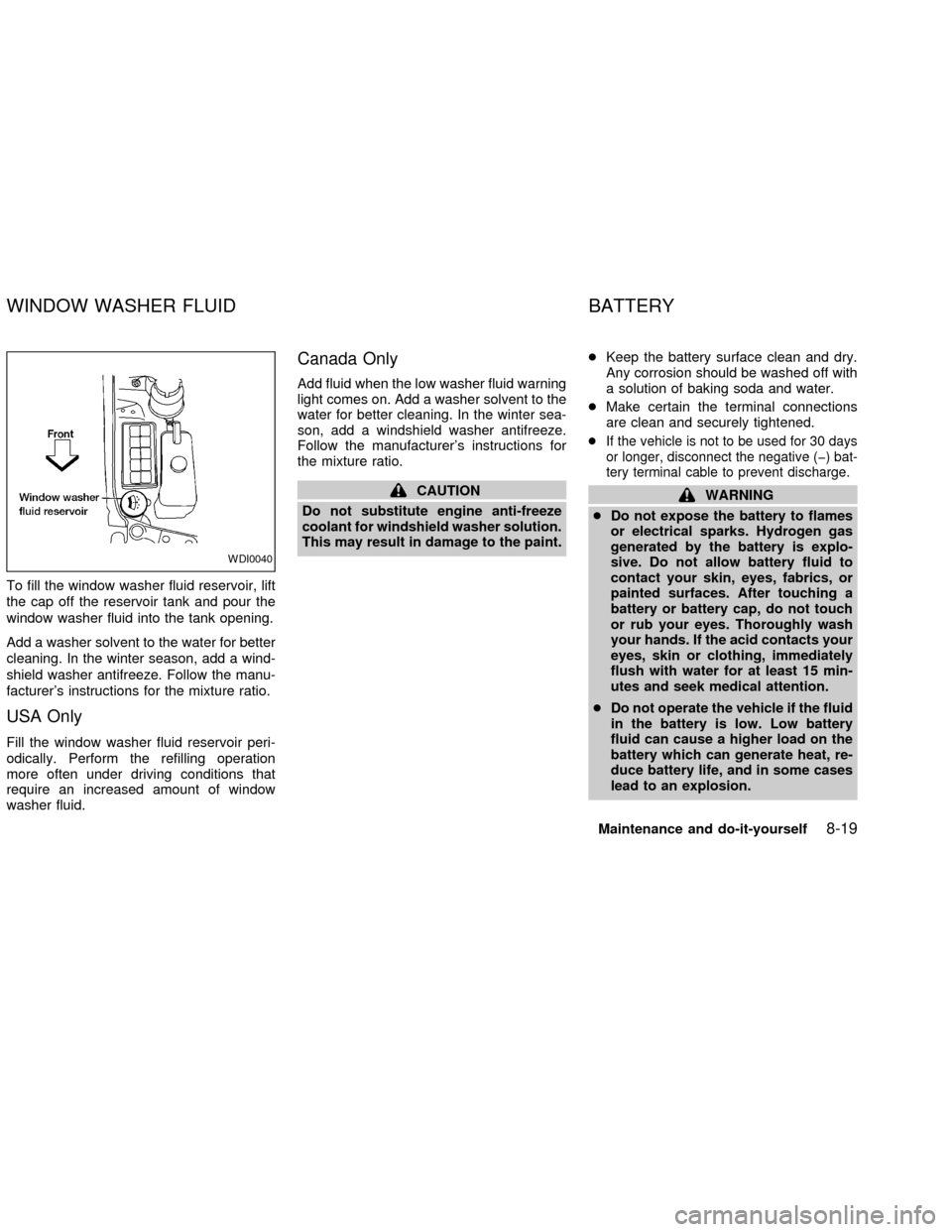

To fill the window washer fluid reservoir, lift

the cap off the reservoir tank and pour the

window washer fluid into the tank opening.

Add a washer solvent to the water for better

cleaning. In the winter season, add a wind-

shield washer antifreeze. Follow the manu-

facturer's instructions for the mixture ratio.

USA Only

Fill the window washer fluid reservoir peri-

odically. Perform the refilling operation

more often under driving conditions that

require an increased amount of window

washer fluid.

Canada Only

Add fluid when the low washer fluid warning

light comes on. Add a washer solvent to the

water for better cleaning. In the winter sea-

son, add a windshield washer antifreeze.

Follow the manufacturer's instructions for

the mixture ratio.

CAUTION

Do not substitute engine anti-freeze

coolant for windshield washer solution.

This may result in damage to the paint.cKeep the battery surface clean and dry.

Any corrosion should be washed off with

a solution of baking soda and water.

cMake certain the terminal connections

are clean and securely tightened.

cIf the vehicle is not to be used for 30 days

or longer, disconnect the negative (þ) bat-

tery terminal cable to prevent discharge.

WARNING

cDo not expose the battery to flames

or electrical sparks. Hydrogen gas

generated by the battery is explo-

sive. Do not allow battery fluid to

contact your skin, eyes, fabrics, or

painted surfaces. After touching a

battery or battery cap, do not touch

or rub your eyes. Thoroughly wash

your hands. If the acid contacts your

eyes, skin or clothing, immediately

flush with water for at least 15 min-

utes and seek medical attention.

cDo not operate the vehicle if the fluid

in the battery is low. Low battery

fluid can cause a higher load on the

battery which can generate heat, re-

duce battery life, and in some cases

lead to an explosion.

WDI0040

WINDOW WASHER FLUID BATTERY

Maintenance and do-it-yourself8-19

ZX

Page 175 of 235

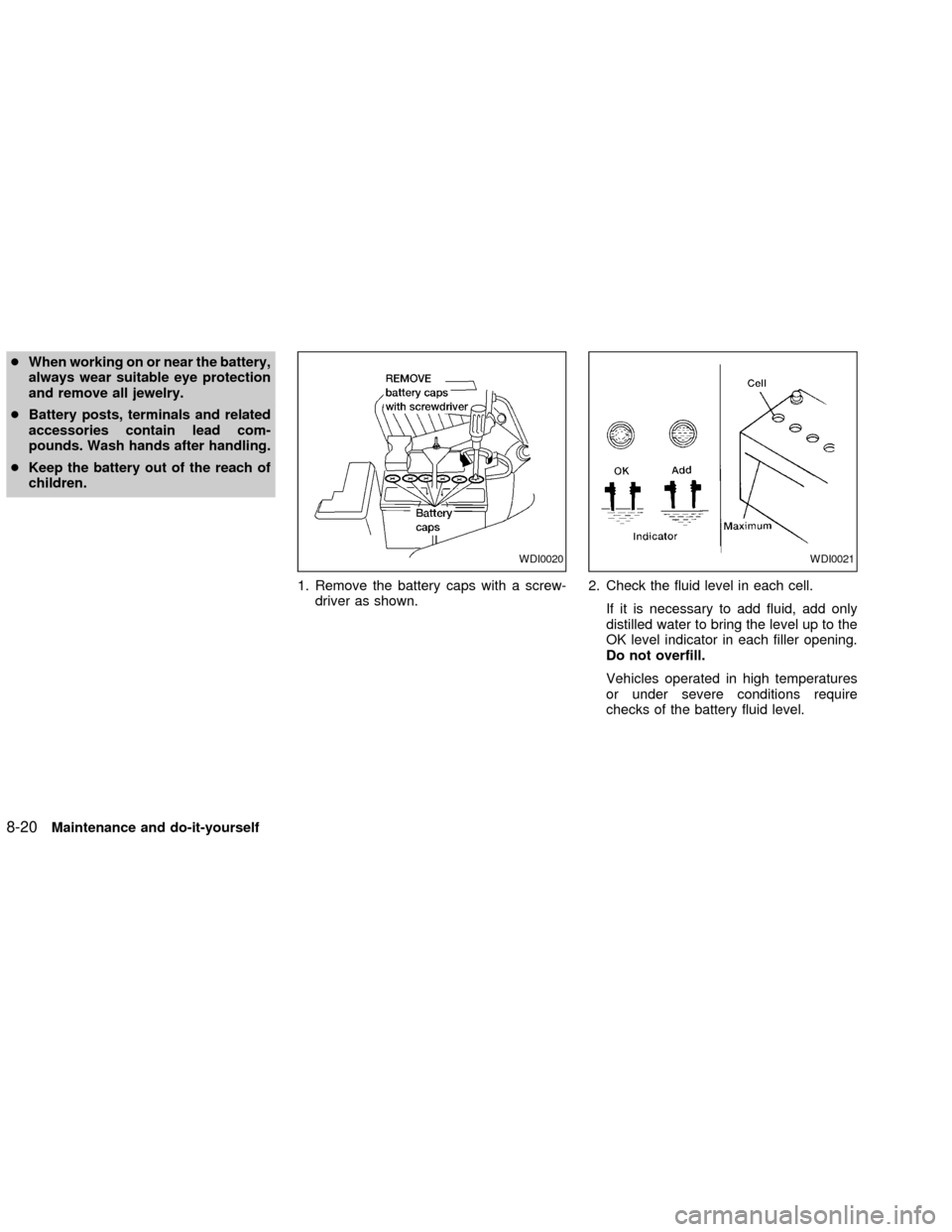

cWhen working on or near the battery,

always wear suitable eye protection

and remove all jewelry.

cBattery posts, terminals and related

accessories contain lead com-

pounds. Wash hands after handling.

cKeep the battery out of the reach of

children.

1. Remove the battery caps with a screw-

driver as shown.2. Check the fluid level in each cell.

If it is necessary to add fluid, add only

distilled water to bring the level up to the

OK level indicator in each filler opening.

Do not overfill.

Vehicles operated in high temperatures

or under severe conditions require

checks of the battery fluid level.

WDI0020WDI0021

8-20Maintenance and do-it-yourself

ZX

Page 176 of 235

JUMP STARTING

If jump starting is necessary, see the ``In

case of emergency'' section of this owner's

manual. If the engine does not start by jump

starting, the battery may have to be re-

placed. Contact an authorized NISSAN

dealer.

Maintenance and do-it-yourself

8-21

ZX

Page 177 of 235

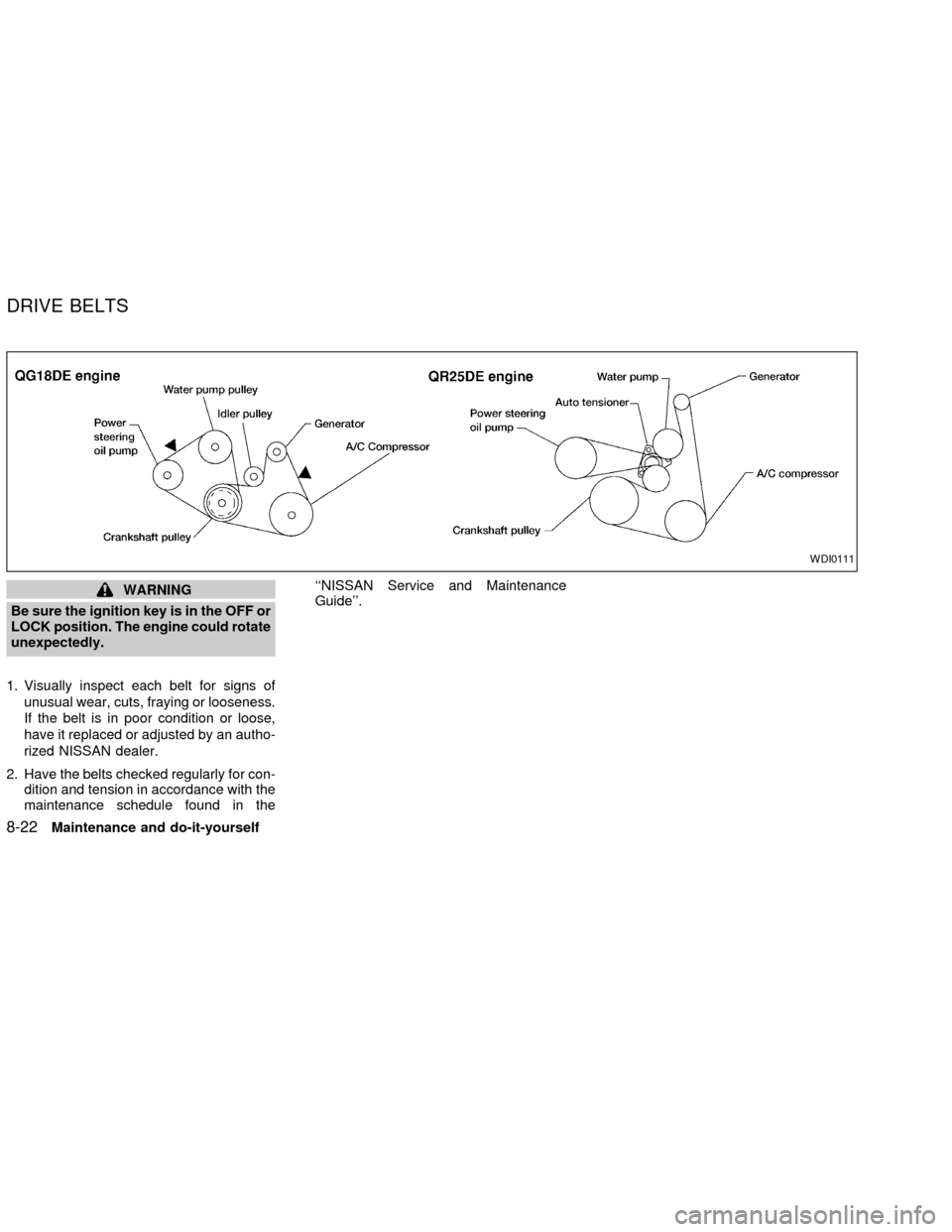

WARNING

Be sure the ignition key is in the OFF or

LOCK position. The engine could rotate

unexpectedly.

1. Visually inspect each belt for signs of

unusual wear, cuts, fraying or looseness.

If the belt is in poor condition or loose,

have it replaced or adjusted by an autho-

rized NISSAN dealer.

2. Have the belts checked regularly for con-

dition and tension in accordance with the

maintenance schedule found in the``NISSAN Service and Maintenance

Guide''.

WDI0111

DRIVE BELTS

8-22Maintenance and do-it-yourself

ZX

Page 178 of 235

WARNING

Be sure the engine and ignition switch

are off and that the parking brake is

engaged securely.

CAUTION

Be sure to use the correct socket to

remove the spark plugs. An incorrect

socket can damage the spark plugs.

REPLACING SPARK PLUGS

Platinum-tipped spark plugs

It is not necessary to replace platinum-

tipped spark plugs as frequently as conven-

tional type spark plugs because they last

much longer. Follow the maintenance

schedule, but do not reuse the spark plugs

by cleaning or regapping.

cAlways replace spark plugs with rec-

ommended or equivalent ones.1. On the 1.8L engine, disconnect the igni-

tion coil connectors. Remove the ignition

coil bolts.

2. Disconnect the spark plug cables from

the spark plugs.

When disconnecting, always hold the

boots, not the cables. Mark all cables to

identify their original locations.

3. Remove the spark plugs with a spark

plug socket.

The plug socket has a rubber seal that

holds the spark plug so it does not fall

when it is pulled out. Make sure each

spark plug is snugly fitted into the spark

plug socket.

4. Fit the new plugs, one at a time, into the

spark plug socket and install them.Use

only the specified spark plugs.Turn

each plug several full turns by hand, then

tighten with the spark plug socket to the

correct torque. Do not overtighten.

Spark plug tightening torque:

14 to 22 ft-lb (20 to 29 Nzm)

DI1229MADI1100

SPARK PLUG

Maintenance and do-it-yourself8-23

ZX

Page 179 of 235

5. Holding the boot, reconnect each high

tension cable to its proper spark plug by

pushing it on until you feel a snap.

6. On the 1.8L engine, install the ignition

coil bolt.

Ignition coil bolt tightening torque:

33 to 44 in-lb (3.8 - 5.0 Nzm)

Connect the ignition coil connector.

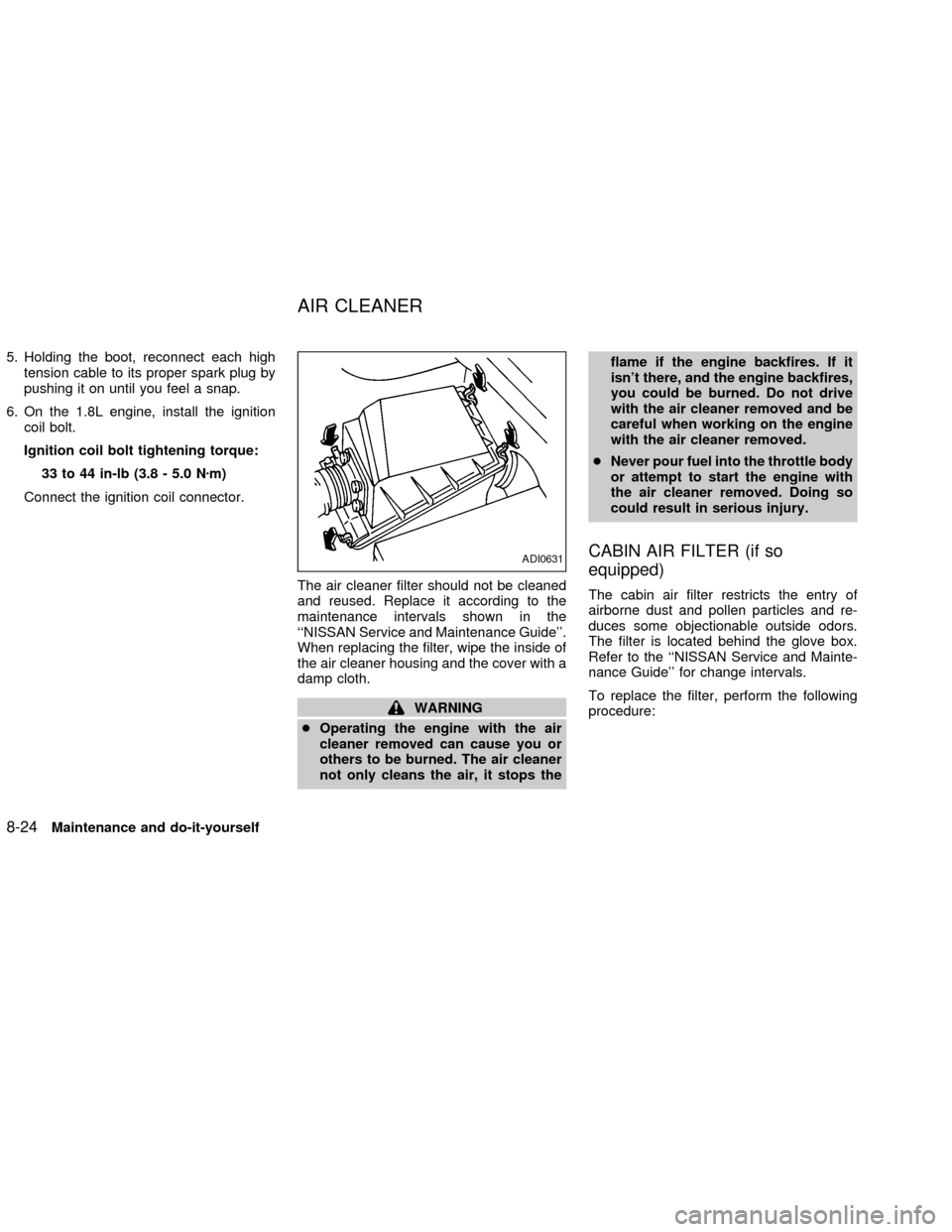

The air cleaner filter should not be cleaned

and reused. Replace it according to the

maintenance intervals shown in the

``NISSAN Service and Maintenance Guide''.

When replacing the filter, wipe the inside of

the air cleaner housing and the cover with a

damp cloth.

WARNING

cOperating the engine with the air

cleaner removed can cause you or

others to be burned. The air cleaner

not only cleans the air, it stops theflame if the engine backfires. If it

isn't there, and the engine backfires,

you could be burned. Do not drive

with the air cleaner removed and be

careful when working on the engine

with the air cleaner removed.

cNever pour fuel into the throttle body

or attempt to start the engine with

the air cleaner removed. Doing so

could result in serious injury.

CABIN AIR FILTER (if so

equipped)

The cabin air filter restricts the entry of

airborne dust and pollen particles and re-

duces some objectionable outside odors.

The filter is located behind the glove box.

Refer to the ``NISSAN Service and Mainte-

nance Guide'' for change intervals.

To replace the filter, perform the following

procedure:

ADI0631

AIR CLEANER

8-24Maintenance and do-it-yourself

ZX

Page 180 of 235

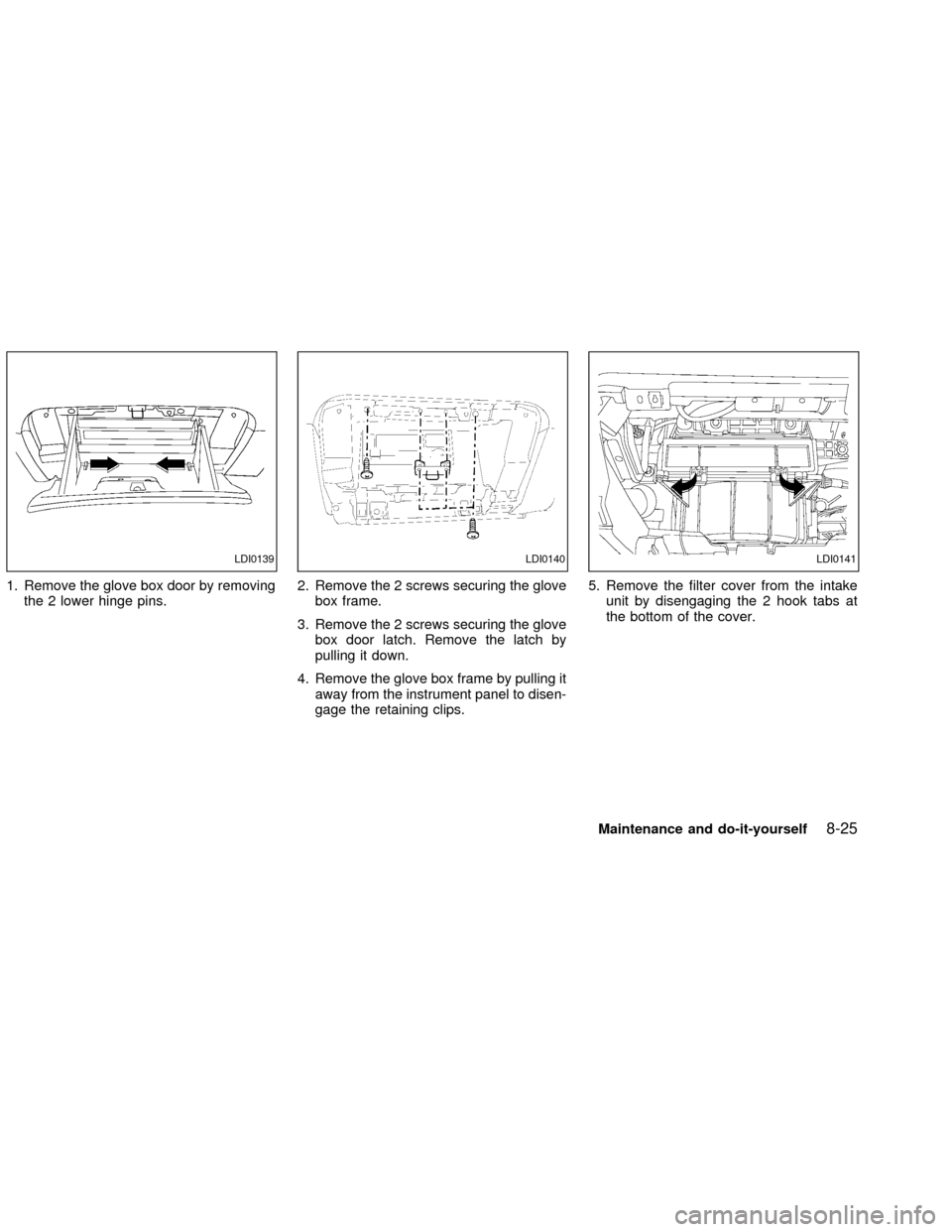

1. Remove the glove box door by removing

the 2 lower hinge pins.2. Remove the 2 screws securing the glove

box frame.

3. Remove the 2 screws securing the glove

box door latch. Remove the latch by

pulling it down.

4. Remove the glove box frame by pulling it

away from the instrument panel to disen-

gage the retaining clips.5. Remove the filter cover from the intake

unit by disengaging the 2 hook tabs at

the bottom of the cover.

LDI0139LDI0140LDI0141

Maintenance and do-it-yourself8-25

ZX