ignition NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 3925 of 5121

![NISSAN TEANA 2008 Service Manual VENTILATION SEAT CONTROL UNIT

SE-61

< ECU DIAGNOSIS >[WITH VENTILATION SEAT]

C

D

E

F

G

H

I

K

L

MA

B

SE

N

O

P

49

LH:(O/B)

RH:(BR/W)Ground Ventilation seat HI indictor signal OutputVentilation seat HI i NISSAN TEANA 2008 Service Manual VENTILATION SEAT CONTROL UNIT

SE-61

< ECU DIAGNOSIS >[WITH VENTILATION SEAT]

C

D

E

F

G

H

I

K

L

MA

B

SE

N

O

P

49

LH:(O/B)

RH:(BR/W)Ground Ventilation seat HI indictor signal OutputVentilation seat HI i](/img/5/57391/w960_57391-3924.png)

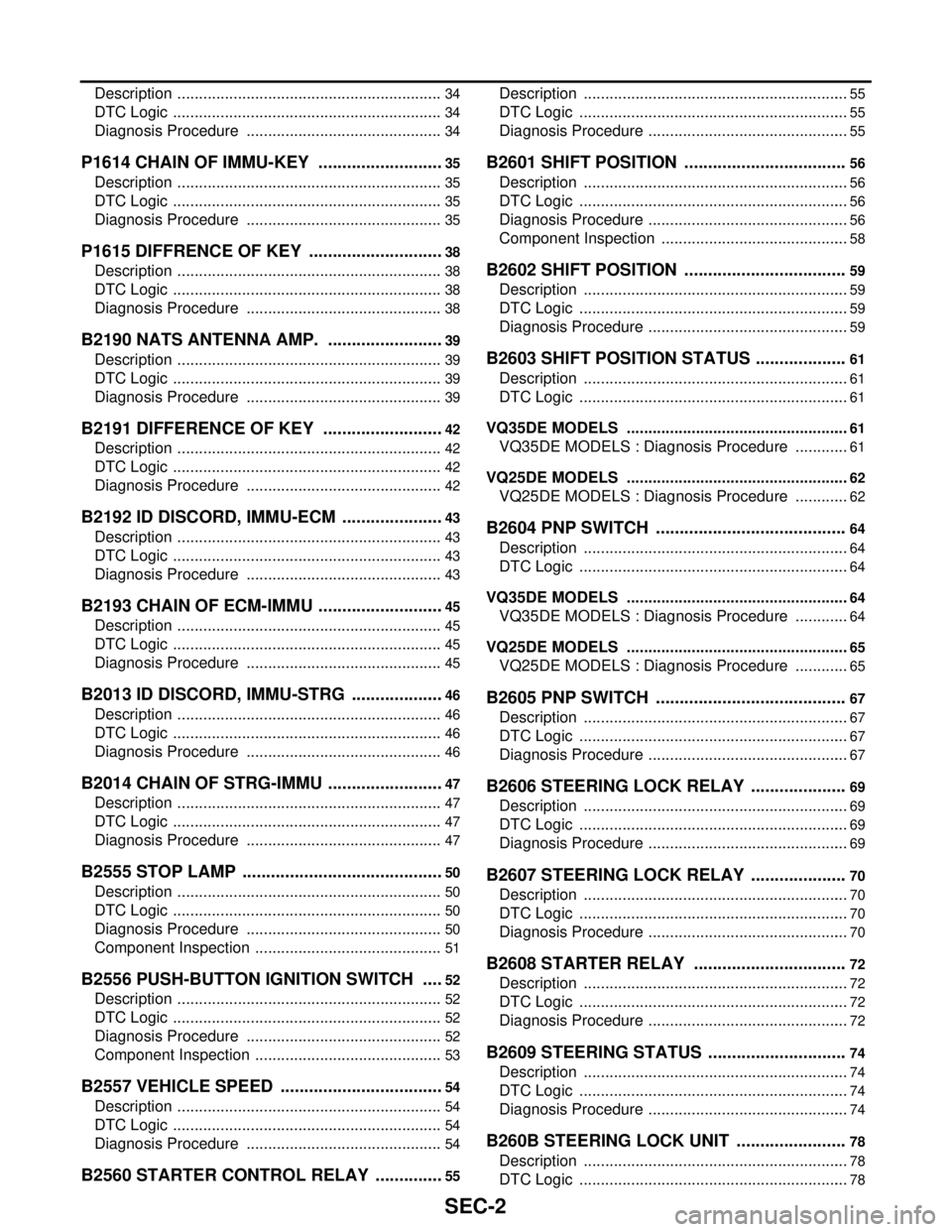

VENTILATION SEAT CONTROL UNIT

SE-61

< ECU DIAGNOSIS >[WITH VENTILATION SEAT]

C

D

E

F

G

H

I

K

L

MA

B

SE

N

O

P

49

LH:(O/B)

RH:(BR/W)Ground Ventilation seat HI indictor signal OutputVentilation seat HI indica-

torIlluminate 3 V

Other than

aboveBattery voltage

50

LH:(O/L)

RH:(BR/Y)Ground Ventilation seat LO indictor signal OutputVentilation seat LO indi-

catorIlluminate 3 V

Other than

aboveBattery voltage

51

LH:(P/L)

RH:(G/Y)Ground Heated seat switch HI signal Input Heated seat switch HIPressed 0 V

Other than

aboveBattery voltage

52

LH:(P/B)

RH:(G/R)Ground Heated seat switch LO signal Input Heated seat switch LOPressed 0 V

Other than

aboveBattery voltage

53

LH:(GR/R)

RH:(LG/B)Ground Heated seat HI indictor signal Output Heated seat HI indicatorIlluminate 3 V

Other than

aboveBattery voltage

54

LH:(GR/L)

RH:(LG/R)Ground Heated seat LO indictor signal Output Heated seat LO indicatorIlluminate 3 V

Other than

aboveBattery voltage

55

(B/W)Ground Ventilation motor ground — Ignition switch ON 0 V

56

LH:(L/B)

RH:(Y/R)GroundVentilation motor speed control

signal

(seatback)Output Ventilation seatLO mode 7 V

HI mode 8.8 V

57

LH:(L/W)

RH:(Y/B)GroundVentilation motor power supply

(seatback)Output Ventilation seatLO mode Battery voltage

HI mode Battery voltage

Other than

above0 V

58

LH:(G/W)

RH:(W)Ground Heated seat power supply Output Heated seatLO mode Battery voltage

HI mode Battery voltage

Other than

above0 V

59

LH:(G/B)

RH:(W/B)GroundGround

(Heated seat HI mode)— Heated seatLO mode 6.5 V

HI mode 0 V

Other than

above0 V

60

LH:(G)

RH:(W/G)GroundHeated seat HI mode power sup-

ply

Output

Heated seatLO mode 0 V

Heated seat LO mode ground —HI mode Battery voltage

Other than

above0 V

61

LH:(L/Y)

RH:(Y/L)GroundVentilation motor speed control

signal

(seat cushion)Output Ventilation seatLO mode 7 V

HI mode 10 V

62

LH:(L/R)

RH:(Y/G)GroundVentilation motor power supply

(seat cushion)Output Ventilation seatLO mode Battery voltage

HI mode Battery voltage

Other than

above0 V Te r m i n a l N o .

(Wire color)Description

ConditionVa l u e

(Approx.)

(+) (–) Signal nameInput/

Output

Page 3950 of 5121

![NISSAN TEANA 2008 Service Manual SE-86

< PRECAUTION >[WITH VENTILATION SEAT]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000003940149

The S NISSAN TEANA 2008 Service Manual SE-86

< PRECAUTION >[WITH VENTILATION SEAT]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000003940149

The S](/img/5/57391/w960_57391-3949.png)

SE-86

< PRECAUTION >[WITH VENTILATION SEAT]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000003940149

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the “SRS AIRBAG” and

“SEAT BELT” of this Service Manual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIRBAG”.

Never use electrical test equipment on any circuit related to the SRS unless instructed to in this Ser-

vice Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or harness

connectors.

Precaution Necessary for Steering Wheel Rotation after Battery Disconnect

INFOID:0000000003885169

NOTE:

Before removing and installing any control units, first turn the push-button ignition switch to the LOCK posi-

tion, then disconnect both battery cables.

After finishing work, confirm that all control unit connectors are connected properly, then re-connect both

battery cables.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If a DTC is detected, perform trouble diagnosis according to self-diagnosis results.

This vehicle is equipped with a push-button ignition switch and a steering lock unit.

If the battery is disconnected or discharged, the steering wheel will lock and cannot be turned.

If turning the steering wheel is required with the battery disconnected or discharged, follow the procedure

below before starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Turn the push-button ignition switch to ACC position.

(At this time, the steering lock will be released.)

3. Disconnect both battery cables. The steering lock will remain released with both battery cables discon-

nected and the steering wheel can be turned.

4. Perform the necessary repair operation.

5. When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button ignition switch is turned to LOCK position.)

6. Perform self-diagnosis check of all control units using CONSULT-III.

Service NoticeINFOID:0000000003809271

When removing or installing various parts, place a cloth or padding onto the vehicle body to prevent

scratches.

Handle trim, molding, instruments, grille, etc. carefully during removing or installing. Be careful not to oil or

damage them.

Apply sealing compound where necessary when installing parts.

When applying sealing compound, be careful that the sealing compound does not protrude from parts.

Page 3956 of 5121

![NISSAN TEANA 2008 Service Manual SE-92

< ON-VEHICLE REPAIR >[WITH VENTILATION SEAT]

FRONT SEAT

Removal and Installation

INFOID:0000000003812466

REMOVAL

CAUTION:

When removing and installing, use shop cloths to protect parts from da NISSAN TEANA 2008 Service Manual SE-92

< ON-VEHICLE REPAIR >[WITH VENTILATION SEAT]

FRONT SEAT

Removal and Installation

INFOID:0000000003812466

REMOVAL

CAUTION:

When removing and installing, use shop cloths to protect parts from da](/img/5/57391/w960_57391-3955.png)

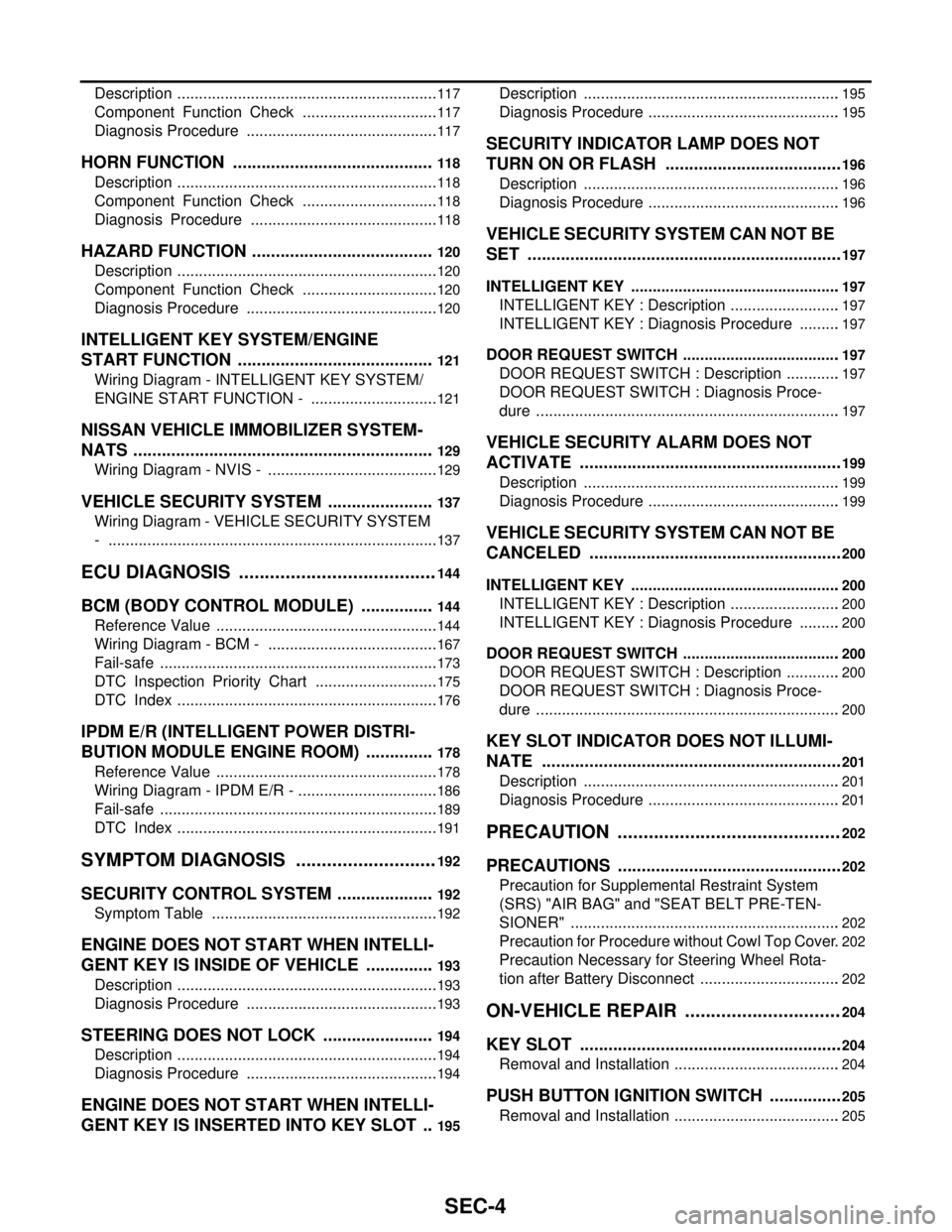

SE-92

< ON-VEHICLE REPAIR >[WITH VENTILATION SEAT]

FRONT SEAT

Removal and Installation

INFOID:0000000003812466

REMOVAL

CAUTION:

When removing and installing, use shop cloths to protect parts from damage.

Before removal, turn ignition switch OFF, disconnect battery negative terminal and then wait for at

least 3 minutes.

NOTE:

Confirm the position of connector before starting work.

1. Remove the headrest.

2. Slide the seat to the frontmost position.

3. Remove the rear outer mounting TORX bolt.

4. Remove the rear inner mounting TORX bolt.

5. Slide the seat to the rearmost position.

6. Remove the front slide cover.

Open the front end of the front slide cover to release the

pawls.

Slide the front slide cover forward to release the pawls.

7. Remove the front outer mounting TORX bolt.

8. Remove the front inner mounting TORX bolt.

9. Set seatback in a standing position.

10. Lift the seat to the uppermost position.

11. Lift the ottoman to the uppermost position. (With ottoman model)

12. Disconnect harness connector under the seat and remove harness clamps.

13. Remove seat from the vehicle.

INSTALLATION

Install in the reverse order of removal.

CAUTION:

Before installation, turn ignition switch OFF, disconnect battery negative terminal, and then wait for

at least 3 minutes.

Clamp the harness in position.

19. Clip 20. Seatback duct C 21. Front slide cover

22. Ottoman trim and pad 23. Front outer link cover 24. Rear outer link cover

25. Ottoman unit assembly 26. Front inner link cover 27. Rear inner link cover

28. Ottoman protector 29. Seat cushion inner finisher inside 30. Seat cushion inner finisher

31. Seat belt buckle 32. Seat cushion heater unit 33. Seat cushion pad

34. Seat cushion trim 35. Seatback pad 36. Seatback trim

37. Headrest 38. Seatback heater unit 39. Seatback silencer

40. Reclining device inner cover 41. Reclining device outer cover 42. Rear slide cover

43. End cap 44. Seat cushion outer finisher inside 45. Seat control switch

46. TORX bolt 47. TORX bolt 48. Seat frame assembly

49. Seat slide inner cover 50. Headrest holder (locked) 51. Headrest holder (free)

Refer to GI-4, "

Components" for symbols in the figure.

: Pawl

JMJIA1863ZZ

Page 3972 of 5121

![NISSAN TEANA 2008 Service Manual SE-108

< FUNCTION DIAGNOSIS >[WITHOUT VENTILATION SEAT]

POWER SEAT

FUNCTION DIAGNOSIS

POWER SEAT

System DescriptionINFOID:0000000003839942

BCM can operate regardless of the ignition switch position, b NISSAN TEANA 2008 Service Manual SE-108

< FUNCTION DIAGNOSIS >[WITHOUT VENTILATION SEAT]

POWER SEAT

FUNCTION DIAGNOSIS

POWER SEAT

System DescriptionINFOID:0000000003839942

BCM can operate regardless of the ignition switch position, b](/img/5/57391/w960_57391-3971.png)

SE-108

< FUNCTION DIAGNOSIS >[WITHOUT VENTILATION SEAT]

POWER SEAT

FUNCTION DIAGNOSIS

POWER SEAT

System DescriptionINFOID:0000000003839942

BCM can operate regardless of the ignition switch position, because battery power is supplied at all times to

power seat switch.

SLIDING OPERATION

While operating the sliding switch located in power seat switch, sliding motor operates and adjusts the front

and back position of the seat.

RECLINING OPERATION

While operating the reclining switch located in power seat switch, reclining motor operates and adjusts the for-

ward and backward position of the seatback.

LIFTING OPERATION

While operating the lifting switch located in power seat switch (driver side), lifting motor operates and adjusts

the up and down position of the seat cushion.

Component Parts LocationINFOID:0000000003839943

Component DescriptionINFOID:0000000003839944

1. Sliding switch and lifting switch (driv-

er side) B4142. Reclining switch (driver side) B4143. Reclining motor (driver side) B415

4. Lifting motor (front) (driver side)

B4175. Sliding motor (driver side) B416 6. Lifting motor (rear) (driver side) B418

A. View with seat cushion pad and seat-

back pad are removed.B. Backside of seat cushion

(driver side)

JMJIA1948ZZ

Item Function

BCM Supplies at all times the power received from battery to power seat switch

Power seat switch

(driver side)Built-in reclining switch, sliding switch and lifting switch, controls the power supplied to each motor

Power seat switch

(passenger side)Built-in reclining switch, sliding switch, controls the power supplied to each motor

Reclining motorWith the power supplied from power seat switch, operates forward and backward movement of

seatback

Page 3974 of 5121

![NISSAN TEANA 2008 Service Manual SE-110

< FUNCTION DIAGNOSIS >[WITHOUT VENTILATION SEAT]

HEATED SEAT

HEATED SEAT

System DescriptionINFOID:0000000003839949

Heated seat is a system that operates when ignition switch is in the ON positi NISSAN TEANA 2008 Service Manual SE-110

< FUNCTION DIAGNOSIS >[WITHOUT VENTILATION SEAT]

HEATED SEAT

HEATED SEAT

System DescriptionINFOID:0000000003839949

Heated seat is a system that operates when ignition switch is in the ON positi](/img/5/57391/w960_57391-3973.png)

SE-110

< FUNCTION DIAGNOSIS >[WITHOUT VENTILATION SEAT]

HEATED SEAT

HEATED SEAT

System DescriptionINFOID:0000000003839949

Heated seat is a system that operates when ignition switch is in the ON position.

HEATER OPERATION

While operating the heated seat switch, seat cushion heater and seatback heater operate.

Temperature of seat can be adjusted by operating the heated seat switch.

Component Parts LocationINFOID:0000000003839950

Component DescriptionINFOID:0000000003839951

1. Front heated seat switch (driver

side) M2022. Front heated seat switch (passenger

side) M2033. Seatback heater

Driver side B464

Passenger side B433

4. Seat cushion heater

Driver side B463

Passenger side B432

JMJIA1839ZZ

Item Function

Heated seat switch Power is supplied to each heater

Depending on LO/HI position of switch, the temperature is changeable

Seat cushion heater Built-in seat cushion, heater operates with the power supplied from heater seat switch

Seatback heater Built-in seatback, heater operates with the power supplied from heater seat switch

Page 3991 of 5121

![NISSAN TEANA 2008 Service Manual PRECAUTIONS

SE-127

< PRECAUTION >[WITHOUT VENTILATION SEAT]

C

D

E

F

G

H

I

K

L

MA

B

SE

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENS NISSAN TEANA 2008 Service Manual PRECAUTIONS

SE-127

< PRECAUTION >[WITHOUT VENTILATION SEAT]

C

D

E

F

G

H

I

K

L

MA

B

SE

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENS](/img/5/57391/w960_57391-3990.png)

PRECAUTIONS

SE-127

< PRECAUTION >[WITHOUT VENTILATION SEAT]

C

D

E

F

G

H

I

K

L

MA

B

SE

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000003940150

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the “SRS AIRBAG” and

“SEAT BELT” of this Service Manual.

WARNING:

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIRBAG”.

Never use electrical test equipment on any circuit related to the SRS unless instructed to in this Ser-

vice Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or harness

connectors.

Precaution Necessary for Steering Wheel Rotation after Battery Disconnect

INFOID:0000000003885171

NOTE:

Before removing and installing any control units, first turn the push-button ignition switch to the LOCK posi-

tion, then disconnect both battery cables.

After finishing work, confirm that all control unit connectors are connected properly, then re-connect both

battery cables.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If a DTC is detected, perform trouble diagnosis according to self-diagnosis results.

This vehicle is equipped with a push-button ignition switch and a steering lock unit.

If the battery is disconnected or discharged, the steering wheel will lock and cannot be turned.

If turning the steering wheel is required with the battery disconnected or discharged, follow the procedure

below before starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Turn the push-button ignition switch to ACC position.

(At this time, the steering lock will be released.)

3. Disconnect both battery cables. The steering lock will remain released with both battery cables discon-

nected and the steering wheel can be turned.

4. Perform the necessary repair operation.

5. When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button ignition switch is turned to LOCK position.)

6. Perform self-diagnosis check of all control units using CONSULT-III.

Service NoticeINFOID:0000000003840019

When removing or installing various parts, place a cloth or padding onto the vehicle body to prevent

scratches.

Handle trim, molding, instruments, grille, etc. carefully during removing or installing. Be careful not to oil or

damage them.

Apply sealing compound where necessary when installing parts.

When applying sealing compound, be careful that the sealing compound does not protrude from parts.

Page 3999 of 5121

![NISSAN TEANA 2008 Service Manual FRONT SEAT

SE-135

< ON-VEHICLE REPAIR >[WITHOUT VENTILATION SEAT]

C

D

E

F

G

H

I

K

L

MA

B

SE

N

O

P

Removal and InstallationINFOID:0000000003840024

REMOVAL

CAUTION:

When removing and installing, use s NISSAN TEANA 2008 Service Manual FRONT SEAT

SE-135

< ON-VEHICLE REPAIR >[WITHOUT VENTILATION SEAT]

C

D

E

F

G

H

I

K

L

MA

B

SE

N

O

P

Removal and InstallationINFOID:0000000003840024

REMOVAL

CAUTION:

When removing and installing, use s](/img/5/57391/w960_57391-3998.png)

FRONT SEAT

SE-135

< ON-VEHICLE REPAIR >[WITHOUT VENTILATION SEAT]

C

D

E

F

G

H

I

K

L

MA

B

SE

N

O

P

Removal and InstallationINFOID:0000000003840024

REMOVAL

CAUTION:

When removing and installing, use shop cloths to protect parts from damage.

Before removal, turn ignition switch OFF, disconnect battery negative terminal, and then wait for at

least 3 minutes.

NOTE:

Confirming a position of connector before work.

1. Remove the headrest.

2. Slide the seat to the frontmost position.

3. Remove the rear outer mounting TORX bolt.

4. Remove the rear inner mounting TORX bolt.

5. Slide the seat to the rearmost position.

6. Remove the front slide cover.

Open the front end of the front slide cover to release the

pawls.

Slide the front slide cover forward to release the pawls.

7. Remove the front outer mounting TORX bolt.

8. Remove the front inner mounting TORX bolt.

9. Set seatback in a standing position.

10. Lift the seat to the uppermost position.

11. Disconnect harness connector under the seat and remove harness clamps.

12. Remove seat from the vehicle.

INSTALLATION

Install in the reverse order of removal.

CAUTION:

Before installation, turn ignition switch OFF, disconnect battery negative terminal, and then wait for

at least 3 minutes.

Clamp the harness in position.

Disassembly and AssemblyINFOID:0000000003840025

SEATBACK

19. Clip 20. Seatback duct C 21. Front slide cover

22. Ottoman trim and pad 23. Front outer link cover 24. Rear outer link cover

25. Ottoman unit assembly 26. Front inner link cover 27. Rear inner link cover

28. Ottoman protector 29. Seat cushion inner finisher inside 30. Seat cushion inner finisher

31. Seat belt buckle 32. Seat cushion heater unit 33. Seat cushion pad

34. Seat cushion trim 35. Seatback pad 36. Seatback trim

37. Headrest 38. Seatback heater unit 39. Seatback silencer

40. Reclining device inner cover 41. Reclining device outer cover 42. Rear slide cover

43. End cap 44. Seat cushion outer finisher inside 45. Seat control switch

46. TORX bolt 47. TORX bolt 48. Seat frame assembly

49. Seat slide inner cover 50. Headrest holder (locked) 51. Headrest holder (free)

Refer to GI-4, "

Components" for symbols in the figure.

: Pawl

JMJIA1863ZZ

Page 4011 of 5121

SEC-2

Description ..............................................................34

DTC Logic ...............................................................34

Diagnosis Procedure ..............................................34

P1614 CHAIN OF IMMU-KEY ...........................35

Description ..............................................................35

DTC Logic ...............................................................35

Diagnosis Procedure ..............................................35

P1615 DIFFRENCE OF KEY .............................38

Description ..............................................................38

DTC Logic ...............................................................38

Diagnosis Procedure ..............................................38

B2190 NATS ANTENNA AMP. .........................39

Description ..............................................................39

DTC Logic ...............................................................39

Diagnosis Procedure ..............................................39

B2191 DIFFERENCE OF KEY ..........................42

Description ..............................................................42

DTC Logic ...............................................................42

Diagnosis Procedure ..............................................42

B2192 ID DISCORD, IMMU-ECM ......................43

Description ..............................................................43

DTC Logic ...............................................................43

Diagnosis Procedure ..............................................43

B2193 CHAIN OF ECM-IMMU ...........................45

Description ..............................................................45

DTC Logic ...............................................................45

Diagnosis Procedure ..............................................45

B2013 ID DISCORD, IMMU-STRG ....................46

Description ..............................................................46

DTC Logic ...............................................................46

Diagnosis Procedure ..............................................46

B2014 CHAIN OF STRG-IMMU .........................47

Description ..............................................................47

DTC Logic ...............................................................47

Diagnosis Procedure ..............................................47

B2555 STOP LAMP ...........................................50

Description ..............................................................50

DTC Logic ...............................................................50

Diagnosis Procedure ..............................................50

Component Inspection ............................................51

B2556 PUSH-BUTTON IGNITION SWITCH .....52

Description ..............................................................52

DTC Logic ...............................................................52

Diagnosis Procedure ..............................................52

Component Inspection ............................................53

B2557 VEHICLE SPEED ...................................54

Description ..............................................................54

DTC Logic ...............................................................54

Diagnosis Procedure ..............................................54

B2560 STARTER CONTROL RELAY ...............55

Description ..............................................................55

DTC Logic ...............................................................55

Diagnosis Procedure ...............................................55

B2601 SHIFT POSITION ...................................56

Description ..............................................................56

DTC Logic ...............................................................56

Diagnosis Procedure ...............................................56

Component Inspection ............................................58

B2602 SHIFT POSITION ...................................59

Description ..............................................................59

DTC Logic ...............................................................59

Diagnosis Procedure ...............................................59

B2603 SHIFT POSITION STATUS ....................61

Description ..............................................................61

DTC Logic ...............................................................61

VQ35DE MODELS ....................................................61

VQ35DE MODELS : Diagnosis Procedure .............61

VQ25DE MODELS ....................................................62

VQ25DE MODELS : Diagnosis Procedure .............62

B2604 PNP SWITCH .........................................64

Description ..............................................................64

DTC Logic ...............................................................64

VQ35DE MODELS ....................................................64

VQ35DE MODELS : Diagnosis Procedure .............64

VQ25DE MODELS ....................................................65

VQ25DE MODELS : Diagnosis Procedure .............65

B2605 PNP SWITCH .........................................67

Description ..............................................................67

DTC Logic ...............................................................67

Diagnosis Procedure ...............................................67

B2606 STEERING LOCK RELAY .....................69

Description ..............................................................69

DTC Logic ...............................................................69

Diagnosis Procedure ...............................................69

B2607 STEERING LOCK RELAY .....................70

Description ..............................................................70

DTC Logic ...............................................................70

Diagnosis Procedure ...............................................70

B2608 STARTER RELAY .................................72

Description ..............................................................72

DTC Logic ...............................................................72

Diagnosis Procedure ...............................................72

B2609 STEERING STATUS ..............................74

Description ..............................................................74

DTC Logic ...............................................................74

Diagnosis Procedure ...............................................74

B260B STEERING LOCK UNIT ........................78

Description ..............................................................78

DTC Logic ...............................................................78

Page 4012 of 5121

SEC-3

C

D

E

F

G

H

I

J

L

MA

B

SEC

N

O

P Diagnosis Procedure ...............................................

78

B260C STEERING LOCK UNIT .........................79

Description ..............................................................79

DTC Logic ...............................................................79

Diagnosis Procedure ...............................................79

B260D STEERING LOCK UNIT .........................80

Description ..............................................................80

DTC Logic ...............................................................80

Diagnosis Procedure ...............................................80

B260F ENGINE STATUS ...................................81

Description ..............................................................81

DTC Logic ...............................................................81

Diagnosis Procedure ...............................................81

B26E1 NO RECEPTION OF ENGINE STA-

TUS SIGNAL ......................................................

82

Description ..............................................................82

DTC Logic ...............................................................82

Diagnosis Procedure ...............................................82

B26E9 STEERING STATUS ..............................83

Description ..............................................................83

DTC Logic ...............................................................83

Diagnosis Procedure ...............................................83

B26EA KEY REGISTRATION ............................84

Description ..............................................................84

DTC Logic ...............................................................84

Diagnosis Procedure ...............................................84

B2612 STEERING STATUS ...............................85

Description ..............................................................85

DTC Logic ...............................................................85

Diagnosis Procedure ...............................................85

B2617 STARTER RELAY CIRCUIT ...................89

Description ..............................................................89

DTC Logic ...............................................................89

Diagnosis Procedure ...............................................89

B2619 BCM ........................................................91

Description ..............................................................91

DTC Logic ...............................................................91

Diagnosis Procedure ...............................................91

B261A PUSH-BUTTON IGNITION SWITCH .....92

Description ..............................................................92

DTC Logic ...............................................................92

Diagnosis Procedure ...............................................92

B261E VEHICLE TYPE ......................................95

Description ..............................................................95

DTC Logic ...............................................................95

Diagnosis Procedure ...............................................95

B2108 STEERING LOCK RELAY ......................96

Description ..............................................................96

DTC Logic ...............................................................96

Diagnosis Procedure ...............................................96

B2109 STEERING LOCK RELAY ....................97

Description ...............................................................97

DTC Logic ................................................................97

Diagnosis Procedure ...............................................97

B210A STEERING LOCK CONDITION

SWITCH .............................................................

98

Description ...............................................................98

DTC Logic ................................................................98

Diagnosis Procedure ...............................................98

B210B STARTER CONTROL RELAY ............102

Description .............................................................102

DTC Logic ..............................................................102

Diagnosis Procedure .............................................102

B210C STARTER CONTROL RELAY ............103

Description .............................................................103

DTC Logic ..............................................................103

Diagnosis Procedure .............................................103

B210D STARTER RELAY ..............................104

Description .............................................................104

DTC Logic ..............................................................104

Diagnosis Procedure .............................................104

B210E STARTER RELAY ...............................105

Description .............................................................105

DTC Logic ..............................................................105

Diagnosis Procedure .............................................105

B210F PNP/CLUTCH INTERLOCK SWITCH .107

Description .............................................................107

DTC Logic ..............................................................107

Diagnosis Procedure .............................................107

B2110 PNP/CLUTCH INTERLOCK SWITCH .109

Description .............................................................109

DTC Logic ..............................................................109

Diagnosis Procedure .............................................109

POWER SUPPLY AND GROUND CIRCUIT ..111

BCM .........................................................................111

BCM : Diagnosis Procedure ..................................111

IPDM E/R ..................................................................111

IPDM E/R : Diagnosis Procedure ..........................111

HOOD SWITCH ...............................................113

Description .............................................................113

Component Function Check ................................113

Diagnosis Procedure ............................................113

Component Inspection ...........................................114

SECURITY INDICATOR LAMP ......................115

Description .............................................................115

Component Function Check ................................115

Diagnosis Procedure .............................................115

Component Inspection ...........................................116

KEY WARNING LAMP ....................................117

Page 4013 of 5121

SEC-4

Description .............................................................117

Component Function Check ................................117

Diagnosis Procedure .............................................117

HORN FUNCTION ...........................................118

Description .............................................................118

Component Function Check ................................118

Diagnosis Procedure ............................................118

HAZARD FUNCTION .......................................120

Description .............................................................120

Component Function Check ................................120

Diagnosis Procedure .............................................120

INTELLIGENT KEY SYSTEM/ENGINE

START FUNCTION ..........................................

121

Wiring Diagram - INTELLIGENT KEY SYSTEM/

ENGINE START FUNCTION - ..............................

121

NISSAN VEHICLE IMMOBILIZER SYSTEM-

NATS ................................................................

129

Wiring Diagram - NVIS - ........................................129

VEHICLE SECURITY SYSTEM .......................137

Wiring Diagram - VEHICLE SECURITY SYSTEM

- .............................................................................

137

ECU DIAGNOSIS .......................................144

BCM (BODY CONTROL MODULE) ................144

Reference Value ....................................................144

Wiring Diagram - BCM - ........................................167

Fail-safe .................................................................173

DTC Inspection Priority Chart .............................175

DTC Index .............................................................176

IPDM E/R (INTELLIGENT POWER DISTRI-

BUTION MODULE ENGINE ROOM) ...............

178

Reference Value ....................................................178

Wiring Diagram - IPDM E/R - .................................186

Fail-safe .................................................................189

DTC Index .............................................................191

SYMPTOM DIAGNOSIS ............................192

SECURITY CONTROL SYSTEM .....................192

Symptom Table .....................................................192

ENGINE DOES NOT START WHEN INTELLI-

GENT KEY IS INSIDE OF VEHICLE ...............

193

Description .............................................................193

Diagnosis Procedure .............................................193

STEERING DOES NOT LOCK ........................194

Description .............................................................194

Diagnosis Procedure .............................................194

ENGINE DOES NOT START WHEN INTELLI-

GENT KEY IS INSERTED INTO KEY SLOT ...

195

Description ............................................................195

Diagnosis Procedure .............................................195

SECURITY INDICATOR LAMP DOES NOT

TURN ON OR FLASH ......................................

196

Description ............................................................196

Diagnosis Procedure .............................................196

VEHICLE SECURITY SYSTEM CAN NOT BE

SET ...................................................................

197

INTELLIGENT KEY .................................................197

INTELLIGENT KEY : Description ..........................197

INTELLIGENT KEY : Diagnosis Procedure ..........197

DOOR REQUEST SWITCH .....................................197

DOOR REQUEST SWITCH : Description .............197

DOOR REQUEST SWITCH : Diagnosis Proce-

dure .......................................................................

197

VEHICLE SECURITY ALARM DOES NOT

ACTIVATE ........................................................

199

Description ............................................................199

Diagnosis Procedure .............................................199

VEHICLE SECURITY SYSTEM CAN NOT BE

CANCELED ......................................................

200

INTELLIGENT KEY .................................................200

INTELLIGENT KEY : Description ..........................200

INTELLIGENT KEY : Diagnosis Procedure ..........200

DOOR REQUEST SWITCH .....................................200

DOOR REQUEST SWITCH : Description .............200

DOOR REQUEST SWITCH : Diagnosis Proce-

dure .......................................................................

200

KEY SLOT INDICATOR DOES NOT ILLUMI-

NATE ................................................................

201

Description ............................................................201

Diagnosis Procedure .............................................201

PRECAUTION ...........................................202

PRECAUTIONS ................................................202

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...............................................................

202

Precaution for Procedure without Cowl Top Cover .202

Precaution Necessary for Steering Wheel Rota-

tion after Battery Disconnect .................................

202

ON-VEHICLE REPAIR ..............................204

KEY SLOT ........................................................204

Removal and Installation .......................................204

PUSH BUTTON IGNITION SWITCH ................205

Removal and Installation .......................................205