battery location NISSAN TEANA 2008 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 1523 of 5121

![NISSAN TEANA 2008 User Guide EC-62

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

COOLING FAN CONTROL

Component Parts Location

INFOID:0000000003857775

1. Intake valve timing control solenoid

valve (bank 1)2. Intake valve timing control NISSAN TEANA 2008 User Guide EC-62

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

COOLING FAN CONTROL

Component Parts Location

INFOID:0000000003857775

1. Intake valve timing control solenoid

valve (bank 1)2. Intake valve timing control](/img/5/57391/w960_57391-1522.png)

EC-62

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

COOLING FAN CONTROL

Component Parts Location

INFOID:0000000003857775

1. Intake valve timing control solenoid

valve (bank 1)2. Intake valve timing control solenoid

valve (bank 2)3. Electronic controlled engine mount

control solenoid valve

4. Fuel injector (bank 2) 5. Cooling fan motor-2 6. A/F sensor 1 (bank 2)

7. Ignition coil (with power transistor)

and spark plug (bank 2)8. Camshaft position sensor (PHASE)

(bank 2)9. Crankshaft position sensor (POS)

10. Engine coolant temperature sensor 11. Cooling fan motor-1 12. ECM

13. Refrigerant pressure sensor 14. Battery current sensor 15. IPDM E/R

16. Mass air flow sensor (with intake air

temperature sensor)17. Electric throttle control actuator 18. Power valve actuator 2 (VQ35DE

models)

19. EVAP canister purge volume control

solenoid valve20. Camshaft position sensor (PHASE)

(bank 1)21. Ignition coil (with power transistor)

and spark plug (bank 1)

22. A/F sensor 1 (bank 1) 23. Fuel injector (bank 1) 24. VIAS control solenoid valve 1 and 2

(VQ35DE models)

25. Power valve actuator 1

JMBIA1373ZZ

Page 1531 of 5121

![NISSAN TEANA 2008 User Guide EC-70

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

ELECTRONIC CONTROLLED ENGINE MOUNT

The ECM controls the engine mount operation corresponding to the engine speed. The control system has a

2-step control [ NISSAN TEANA 2008 User Guide EC-70

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

ELECTRONIC CONTROLLED ENGINE MOUNT

The ECM controls the engine mount operation corresponding to the engine speed. The control system has a

2-step control [](/img/5/57391/w960_57391-1530.png)

EC-70

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

ELECTRONIC CONTROLLED ENGINE MOUNT

The ECM controls the engine mount operation corresponding to the engine speed. The control system has a

2-step control [Soft/Hard]

Component Parts LocationINFOID:0000000003860670

Vehicle condition Engine mount control

Engine speed: Below 950 rpm Soft

Engine speed: Above 950 rpm Hard

1. Intake valve timing control solenoid

valve (bank 1)2. Intake valve timing control solenoid

valve (bank 2)3. Electronic controlled engine mount

control solenoid valve

4. Fuel injector (bank 2) 5. Cooling fan motor-2 6. A/F sensor 1 (bank 2)

7. Ignition coil (with power transistor)

and spark plug (bank 2)8. Camshaft position sensor (PHASE)

(bank 2)9. Crankshaft position sensor (POS)

10. Engine coolant temperature sensor 11. Cooling fan motor-1 12. ECM

13. Refrigerant pressure sensor 14. Battery current sensor 15. IPDM E/R

16. Mass air flow sensor (with intake air

temperature sensor)17. Electric throttle control actuator 18. Power valve actuator 2 (VQ35DE

models)

19. EVAP canister purge volume control

solenoid valve20. Camshaft position sensor (PHASE)

(bank 1)21. Ignition coil (with power transistor)

and spark plug (bank 1)

JMBIA1373ZZ

Page 1541 of 5121

![NISSAN TEANA 2008 User Guide EC-80

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

EVAPORATIVE EMISSION SYSTEM

Component Parts Location

INFOID:0000000003857776

1. Intake valve timing control solenoid

valve (bank 1)2. Intake valve timing NISSAN TEANA 2008 User Guide EC-80

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

EVAPORATIVE EMISSION SYSTEM

Component Parts Location

INFOID:0000000003857776

1. Intake valve timing control solenoid

valve (bank 1)2. Intake valve timing](/img/5/57391/w960_57391-1540.png)

EC-80

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

EVAPORATIVE EMISSION SYSTEM

Component Parts Location

INFOID:0000000003857776

1. Intake valve timing control solenoid

valve (bank 1)2. Intake valve timing control solenoid

valve (bank 2)3. Electronic controlled engine mount

control solenoid valve

4. Fuel injector (bank 2) 5. Cooling fan motor-2 6. A/F sensor 1 (bank 2)

7. Ignition coil (with power transistor)

and spark plug (bank 2)8. Camshaft position sensor (PHASE)

(bank 2)9. Crankshaft position sensor (POS)

10. Engine coolant temperature sensor 11. Cooling fan motor-1 12. ECM

13. Refrigerant pressure sensor 14. Battery current sensor 15. IPDM E/R

16. Mass air flow sensor (with intake air

temperature sensor)17. Electric throttle control actuator 18. Power valve actuator 2 (VQ35DE

models)

19. EVAP canister purge volume control

solenoid valve20. Camshaft position sensor (PHASE)

(bank 1)21. Ignition coil (with power transistor)

and spark plug (bank 1)

22. A/F sensor 1 (bank 1) 23. Fuel injector (bank 1) 24. VIAS control solenoid valve 1 and 2

(VQ35DE models)

25. Power valve actuator 1

JMBIA1373ZZ

Page 1548 of 5121

![NISSAN TEANA 2008 User Guide INTAKE VALVE TIMING CONTROL

EC-87

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

Component Parts LocationINFOID:0000000003857777

1. Intake valve timing control solenoid

valve NISSAN TEANA 2008 User Guide INTAKE VALVE TIMING CONTROL

EC-87

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

Component Parts LocationINFOID:0000000003857777

1. Intake valve timing control solenoid

valve](/img/5/57391/w960_57391-1547.png)

INTAKE VALVE TIMING CONTROL

EC-87

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

Component Parts LocationINFOID:0000000003857777

1. Intake valve timing control solenoid

valve (bank 1)2. Intake valve timing control solenoid

valve (bank 2)3. Electronic controlled engine mount

control solenoid valve

4. Fuel injector (bank 2) 5. Cooling fan motor-2 6. A/F sensor 1 (bank 2)

7. Ignition coil (with power transistor)

and spark plug (bank 2)8. Camshaft position sensor (PHASE)

(bank 2)9. Crankshaft position sensor (POS)

10. Engine coolant temperature sensor 11. Cooling fan motor-1 12. ECM

13. Refrigerant pressure sensor 14. Battery current sensor 15. IPDM E/R

16. Mass air flow sensor (with intake air

temperature sensor)17. Electric throttle control actuator 18. Power valve actuator 2 (VQ35DE

models)

19. EVAP canister purge volume control

solenoid valve20. Camshaft position sensor (PHASE)

(bank 1)21. Ignition coil (with power transistor)

and spark plug (bank 1)

22. A/F sensor 1 (bank 1) 23. Fuel injector (bank 1) 24. VIAS control solenoid valve 1 and 2

(VQ35DE models)

25. Power valve actuator 1

JMBIA1373ZZ

Page 1557 of 5121

![NISSAN TEANA 2008 User Guide EC-96

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

VARIABLE INDUCTION AIR SYSTEM

Component Parts Location

INFOID:0000000003860679

1. Intake valve timing control solenoid

valve (bank 1)2. Intake valve timin NISSAN TEANA 2008 User Guide EC-96

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

VARIABLE INDUCTION AIR SYSTEM

Component Parts Location

INFOID:0000000003860679

1. Intake valve timing control solenoid

valve (bank 1)2. Intake valve timin](/img/5/57391/w960_57391-1556.png)

EC-96

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

VARIABLE INDUCTION AIR SYSTEM

Component Parts Location

INFOID:0000000003860679

1. Intake valve timing control solenoid

valve (bank 1)2. Intake valve timing control solenoid

valve (bank 2)3. Electronic controlled engine mount

control solenoid valve

4. Fuel injector (bank 2) 5. Cooling fan motor-2 6. A/F sensor 1 (bank 2)

7. Ignition coil (with power transistor)

and spark plug (bank 2)8. Camshaft position sensor (PHASE)

(bank 2)9. Crankshaft position sensor (POS)

10. Engine coolant temperature sensor 11. Cooling fan motor-1 12. ECM

13. Refrigerant pressure sensor 14. Battery current sensor 15. IPDM E/R

16. Mass air flow sensor (with intake air

temperature sensor)17. Electric throttle control actuator 18. Power valve actuator 2 (VQ35DE

models)

19. EVAP canister purge volume control

solenoid valve20. Camshaft position sensor (PHASE)

(bank 1)21. Ignition coil (with power transistor)

and spark plug (bank 1)

22. A/F sensor 1 (bank 1) 23. Fuel injector (bank 1) 24. VIAS control solenoid valve 1 and 2

(VQ35DE models)

25. Power valve actuator 1

JMBIA1373ZZ

Page 1735 of 5121

![NISSAN TEANA 2008 User Guide EC-274

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

P1572 ASCD BRAKE SWITCH

Follow the procedure “With CONSULT-III” above.

Is 1st trip DTC detected?

YES >> Go to EC-274, "Diagnosis Procedure".

NO >> GO NISSAN TEANA 2008 User Guide EC-274

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

P1572 ASCD BRAKE SWITCH

Follow the procedure “With CONSULT-III” above.

Is 1st trip DTC detected?

YES >> Go to EC-274, "Diagnosis Procedure".

NO >> GO](/img/5/57391/w960_57391-1734.png)

EC-274

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

P1572 ASCD BRAKE SWITCH

Follow the procedure “With CONSULT-III” above.

Is 1st trip DTC detected?

YES >> Go to EC-274, "Diagnosis Procedure".

NO >> GO TO 3.

3.PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT-III

1. Drive the vehicle for at least 5 consecutive seconds under the following conditions.

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

This procedure may be conducted with the drive wheels lifted in the shop or by driving the vehicle.

If a road test is expected to be easier, it is unnecessary to lift the vehicle.

2. Check 1st trip DTC.

With GST

Follow the procedure “With CONSULT-III” above.

Is 1st trip DTC detected?

YES >> Go to EC-274, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000003856755

1.CHECK OVERALL FUNCTION-I

With CONSULT-III

1. Turn ignition switch ON.

2. Select “BRAKE SW1” in “DATA MONITOR” mode with CONSULT-III.

3. Check “BRAKE SW1” indication under the following conditions.

Without CONSULT-III

1. Turn ignition switch ON.

2. Check the voltage between ECM harness connector and ground.

Is the inspection result normal?

YES >> GO TO 2.

NO >> GO TO 3.

2.CHECK OVERALL FUNCTION-II

With CONSULT-III

Check “BRAKE SW2” indication in “DATA MONITOR” mode.

VHCL SPEED SE More than 30 km/h (19 mph)

Selector lever Suitable position

Driving locationDepress the brake pedal for more than 5

seconds so as not to come off from the

above-mentioned vehicle speed.

Monitor item Condition Indication

BRAKE SW1 Brake pedalSlightly depressed OFF

Fully released ON

ECM

Condition Voltage +−

Connector Terminal Connector Terminal

E1611 0

(ASCD brake switch signal)E16 112 Brake pedalSlightly depressed Approx. 0V

Fully released Battery voltage

Page 1897 of 5121

EM-22

< ON-VEHICLE MAINTENANCE >

COMPRESSION PRESSURE

COMPRESSION PRESSURE

InspectionINFOID:0000000003802245

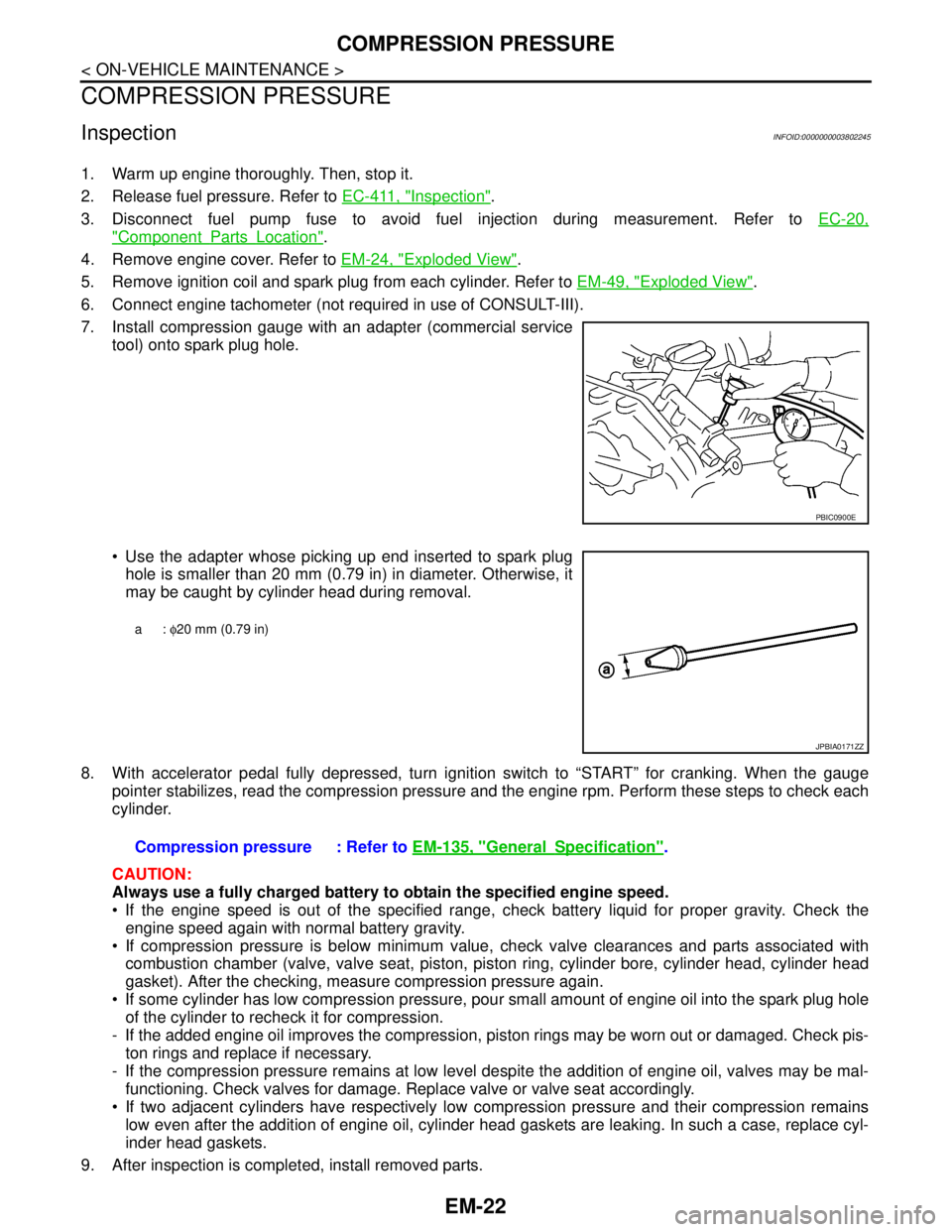

1. Warm up engine thoroughly. Then, stop it.

2. Release fuel pressure. Refer to EC-411, "

Inspection".

3. Disconnect fuel pump fuse to avoid fuel injection during measurement. Refer to EC-20,

"ComponentPartsLocation".

4. Remove engine cover. Refer to EM-24, "

Exploded View".

5. Remove ignition coil and spark plug from each cylinder. Refer to EM-49, "

Exploded View".

6. Connect engine tachometer (not required in use of CONSULT-III).

7. Install compression gauge with an adapter (commercial service

tool) onto spark plug hole.

Use the adapter whose picking up end inserted to spark plug

hole is smaller than 20 mm (0.79 in) in diameter. Otherwise, it

may be caught by cylinder head during removal.

8. With accelerator pedal fully depressed, turn ignition switch to “START” for cranking. When the gauge

pointer stabilizes, read the compression pressure and the engine rpm. Perform these steps to check each

cylinder.

CAUTION:

Always use a fully charged battery to obtain the specified engine speed.

If the engine speed is out of the specified range, check battery liquid for proper gravity. Check the

engine speed again with normal battery gravity.

If compression pressure is below minimum value, check valve clearances and parts associated with

combustion chamber (valve, valve seat, piston, piston ring, cylinder bore, cylinder head, cylinder head

gasket). After the checking, measure compression pressure again.

If some cylinder has low compression pressure, pour small amount of engine oil into the spark plug hole

of the cylinder to recheck it for compression.

- If the added engine oil improves the compression, piston rings may be worn out or damaged. Check pis-

ton rings and replace if necessary.

- If the compression pressure remains at low level despite the addition of engine oil, valves may be mal-

functioning. Check valves for damage. Replace valve or valve seat accordingly.

If two adjacent cylinders have respectively low compression pressure and their compression remains

low even after the addition of engine oil, cylinder head gaskets are leaking. In such a case, replace cyl-

inder head gaskets.

9. After inspection is completed, install removed parts.

PBIC0900E

a: φ20 mm (0.79 in)

JPBIA0171ZZ

Compression pressure : Refer to EM-135, "GeneralSpecification".

Page 2030 of 5121

EXL-1

DRIVER CONTROLS

C

DE

F

G H

I

J

K

M

SECTION EXL

A

B

EXL

N

O P

CONTENTS

EXTERIOR LIGHTING SYSTEM

XENON TYPE

BASIC INSPECTION ....... .............................

7

DIAGNOSIS AND REPAIR WORKFLOW ..... .....7

Work Flow ........................................................... ......7

INSPECTION AND ADJUSTMENT .....................9

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT .................................................... ......

9

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Description ..................................

9

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Special Repair Requirement .......

9

CONFIGURATION (HEADLAMP LEVELIZER) .... ......9

CONFIGURATION (HEADLAMP LEVELIZER) :

Description ................................................................

9

CONFIGURATION (HEADLAMP LEVELIZER) :

Special Repair Requirement .....................................

9

SENSOR INITIALIZE ............................................. ......9

SENSOR INITIALIZE : Description .........................10

SENSOR INITIALIZE : Special Repair Require-

ment (HEADLAMP AIMING CONTROL SYSTEM)

....

10

FUNCTION DIAGNOSIS ..............................11

HEADLAMP SYSTEM .................................... ....11

System Diagram .................................................. ....11

System Description .................................................11

Component Parts Location ......................................12

Component Description ..........................................12

AUTO LIGHT SYSTEM ......................................13

System Diagram .................................................. ....13

System Description .................................................13

Component Parts Location ......................................14

Component Description ..........................................14

HEADLAMP AIMING CONTROL SYSTEM

(AUTO) ..............................................................

15

System Diagram .................................................. ....15

System Description ..................................................15

Component Parts Location ......................................16

Component Description ...........................................16

FRONT FOG LAMP SYSTEM ...........................17

System Diagram ......................................................17

System Description ..................................................17

Component Parts Location ......................................18

Component Description ..........................................18

TURN SIGNAL AND HAZARD WARNING

LAMP SYSTEM .................................................

19

System Diagram ......................................................19

System Description ..................................................19

Component Parts Location ......................................20

Component Description ..........................................20

PARKING, LICENSE PLATE AND TAIL

LAMPS SYSTEM ..............................................

21

System Diagram .................................................. ....21

System Description ..................................................21

Component Parts Location ......................................22

Component Description ..........................................22

REAR FOG LAMP SYSTEM .............................23

System Diagram ......................................................23

System Description ..................................................23

Component Parts Location ......................................24

Component Description ..........................................24

EXTERIOR LAMP BATTERY SAVER SYS-

TEM ...................................................................

25

System Diagram ......................................................25

System Description ..................................................25

Component Parts Location ......................................26

Component Description ..........................................26

DIAGNOSIS SYSTEM (BCM) ...........................27

Page 2033 of 5121

EXL-4

OPTICAL SENSOR .........................................185

Exploded View .......................................................185

Removal and Installation .......................................185

LIGHTING & TURN SIGNAL SWITCH ............186

Exploded View .......................................................186

Removal and Installation .......................................186

HAZARD SWITCH ...........................................187

Exploded View .......................................................187

Removal and Installation .......................................187

SIDE TURN SIGNAL LAMP ............................188

Exploded View .......................................................188

Removal and Installation .......................................188

AUTO LEVELIZER CONTROL UNIT ..............190

Exploded View .......................................................190

Removal and Installation .......................................190

REAR COMBINATION LAMP .........................191

Exploded View .......................................................191

Removal and Installation .......................................191

Replacement .........................................................192

HIGH-MOUNTED STOP LAMP .......................193

Exploded View .......................................................193

Removal and Installation .......................................193

REAR FOG LAMP ...........................................194

Exploded View .......................................................194

Removal and Installation .......................................194

Replacement .........................................................194

LICENSE PLATE LAMP ..................................195

Exploded View .......................................................195

Removal and Installation .......................................195

Replacement .........................................................195

SERVICE DATA AND SPECIFICATIONS

(SDS) ..........................................................

197

SERVICE DATA AND SPECIFICATIONS

(SDS) ................................................................

197

Bulb Specifications ................................................197

HALOGEN TYPE

BASIC INSPECTION ..................................

198

DIAGNOSIS AND REPAIR WORKFLOW .......198

Work Flow ..............................................................198

FUNCTION DIAGNOSIS ............................200

HEADLAMP SYSTEM .....................................200

System Diagram ....................................................200

System Description ................................................200

Component Parts Location ....................................201

Component Description ........................................201

AUTO LIGHT SYSTEM ....................................202

System Diagram ....................................................202

System Description ...............................................202

Component Parts Location ...................................203

Component Description ........................................203

FRONT FOG LAMP SYSTEM ..........................204

System Diagram ...................................................204

System Description ...............................................204

Component Parts Location ...................................205

Component Description ........................................205

TURN SIGNAL AND HAZARD WARNING

LAMP SYSTEM ................................................

206

System Diagram ...................................................206

System Description ...............................................206

Component Parts Location ...................................207

Component Description ........................................207

PARKING, LICENSE PLATE AND TAIL

LAMPS SYSTEM ..............................................

208

System Diagram ...................................................208

System Description ...............................................208

Component Parts Location ...................................209

Component Description ........................................209

REAR FOG LAMP SYSTEM ............................210

System Diagram ...................................................210

System Description ...............................................210

Component Parts Location ...................................211

Component Description ........................................211

EXTERIOR LAMP BATTERY SAVER SYS-

TEM ...................................................................

212

System Diagram ...................................................212

System Description ...............................................212

Component Parts Location ...................................213

Component Description ........................................213

DIAGNOSIS SYSTEM (BCM) ...........................214

COMMON ITEM .......................................................214

COMMON ITEM : CONSULT-III Function (BCM -

COMMON ITEM) ..................................................

214

HEADLAMP .............................................................215

HEADLAMP : CONSULT-III Function (BCM -

HEAD LAMP) ........................................................

215

FLASHER ................................................................217

FLASHER : CONSULT-III Function (BCM -

FLASHER) ............................................................

217

DIAGNOSIS SYSTEM (IPDM E/R) ...................219

Diagnosis Description ...........................................219

CONSULT-III Function (IPDM E/R) ......................221

COMPONENT DIAGNOSIS ......................224

POWER SUPPLY AND GROUND CIRCUIT ....224

BCM (BODY CONTROL MODULE) ........................224

BCM (BODY CONTROL MODULE) : Diagnosis

Procedure .............................................................

224

Page 2043 of 5121

![NISSAN TEANA 2008 User Guide EXL-14

< FUNCTION DIAGNOSIS >[XENON TYPE]

AUTO LIGHT SYSTEM

Turns the exterior lamp OFF with the ignition switch ACC or the light switch OFF.

*: The preset time is 45 seconds. The timer operating ti NISSAN TEANA 2008 User Guide EXL-14

< FUNCTION DIAGNOSIS >[XENON TYPE]

AUTO LIGHT SYSTEM

Turns the exterior lamp OFF with the ignition switch ACC or the light switch OFF.

*: The preset time is 45 seconds. The timer operating ti](/img/5/57391/w960_57391-2042.png)

EXL-14

< FUNCTION DIAGNOSIS >[XENON TYPE]

AUTO LIGHT SYSTEM

Turns the exterior lamp OFF with the ignition switch ACC or the light switch OFF.

*: The preset time is 45 seconds. The timer operating time can be set by CONSULT-III. Refer to EXL-28,

"HEADLAMP : CONSULT-III Function (BCM - HEAD LAMP)".

NOTE:

When any position other than the light switch AUTO is set, the auto light system function switches to the exte-

rior lamp battery saver function.

Component Parts LocationINFOID:0000000003773529

Component DescriptionINFOID:0000000003773530

1. Combination switch 2. Optical sensor 3. IPDM E/R

4. BCM

A. Instrument upper panel (RH) B. Engine room (LH) C. Behind the combination meter

J P L I A 111 9 Z Z

Part Description

BCM Detects each switch condition by the combination switch reading function.

Judges the outside brightness from the optical sensor signal.

Judges the OFF timing according to the vehicle condition.

Judges the ON/OFF status of the exterior lamp and each illumination according to the

outside brightness and the vehicle condition.

Requests ON/OFF of each relay to IPDM E/R (with CAN communication).

IPDM E/RControls the integrated relay, and supplies voltage to the load according to the request

from BCM (with CAN communication).

Combination switch

(Lighting & turn signal switch)Refer to BCS-8, "

System Diagram".

Optical sensor Refer to EXL-69, "

Description".