length NISSAN TEANA 2008 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 1957 of 5121

EM-82

< DISASSEMBLY AND ASSEMBLY >

REAR TIMING CHAIN CASE

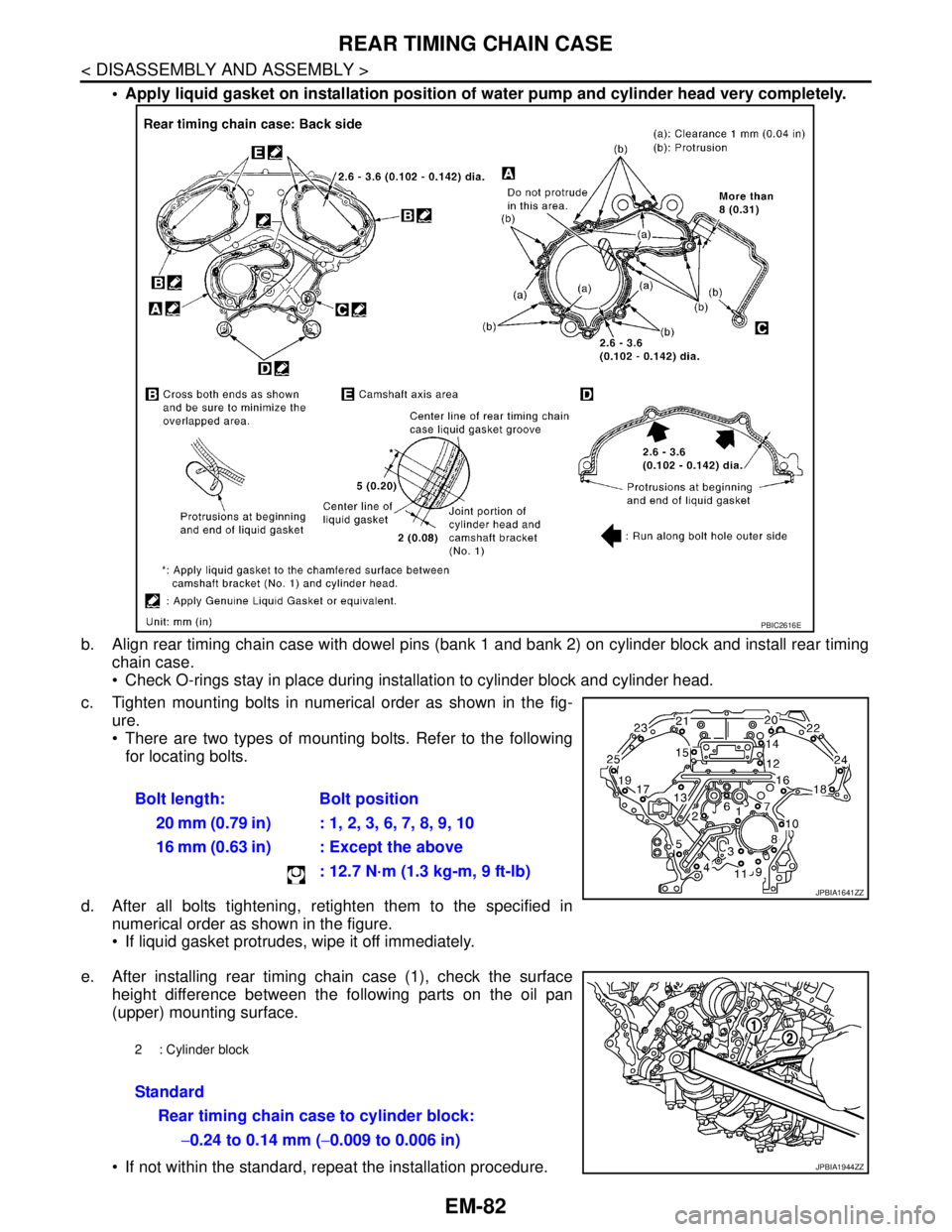

Apply liquid gasket on installation position of water pump and cylinder head very completely.

b. Align rear timing chain case with dowel pins (bank 1 and bank 2) on cylinder block and install rear timing

chain case.

Check O-rings stay in place during installation to cylinder block and cylinder head.

c. Tighten mounting bolts in numerical order as shown in the fig-

ure.

There are two types of mounting bolts. Refer to the following

for locating bolts.

d. After all bolts tightening, retighten them to the specified in

numerical order as shown in the figure.

If liquid gasket protrudes, wipe it off immediately.

e. After installing rear timing chain case (1), check the surface

height difference between the following parts on the oil pan

(upper) mounting surface.

If not within the standard, repeat the installation procedure.Bolt length: Bolt position

20 mm (0.79 in) : 1, 2, 3, 6, 7, 8, 9, 10

16 mm (0.63 in) : Except the above

: 12.7 N·m (1.3 kg-m, 9 ft-lb)

PBIC2616E

JPBIA1641ZZ

2 : Cylinder block

Standard

Rear timing chain case to cylinder block:

−0.24 to 0.14 mm (−0.009 to 0.006 in)

JPBIA1944ZZ

Page 2015 of 5121

EM-140

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Unit: mm (in)

VA LV E G U I D E

Unit: mm (in)

VALVE SEAT

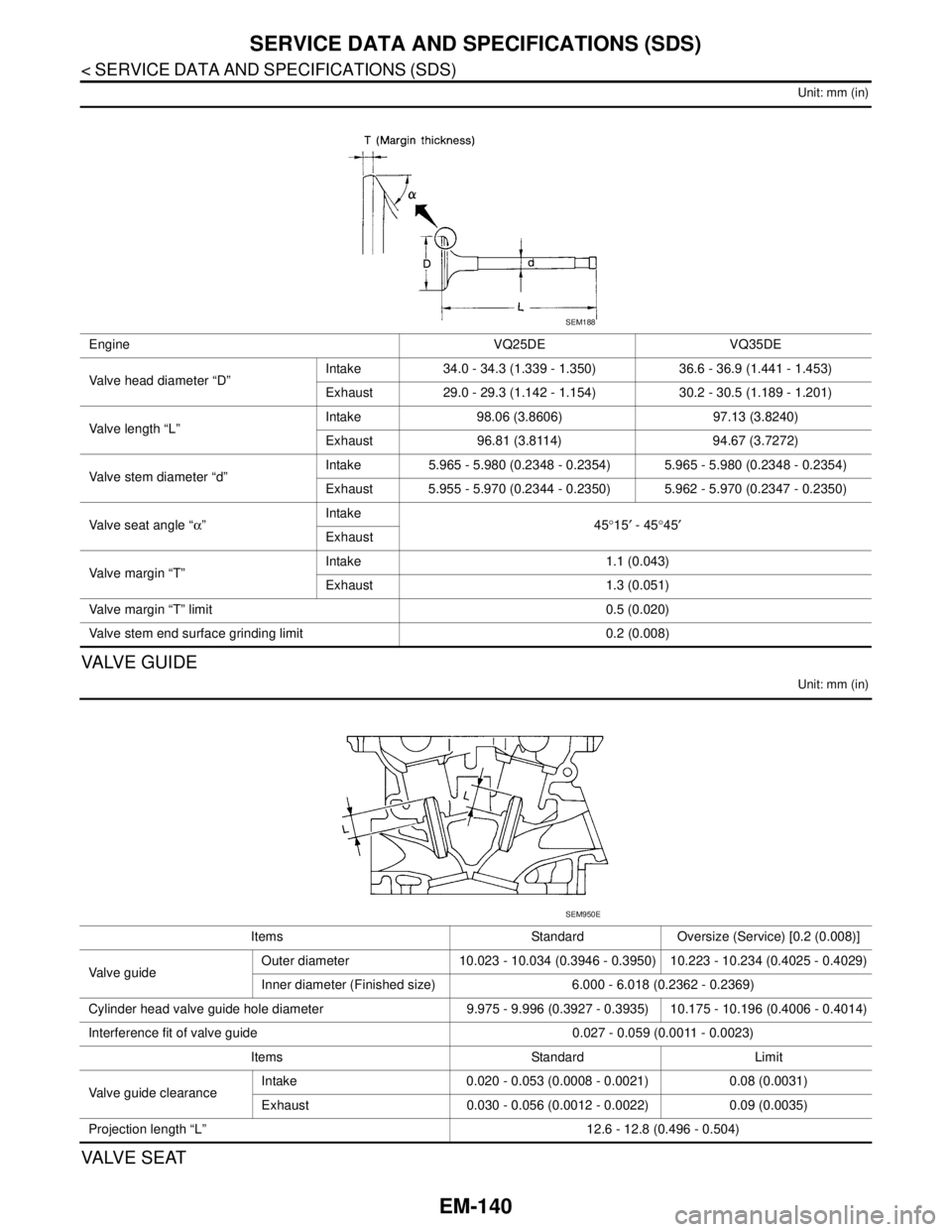

Engine VQ25DE VQ35DE

Valve head diameter “D”Intake 34.0 - 34.3 (1.339 - 1.350) 36.6 - 36.9 (1.441 - 1.453)

Exhaust 29.0 - 29.3 (1.142 - 1.154) 30.2 - 30.5 (1.189 - 1.201)

Valve length “L”Intake 98.06 (3.8606) 97.13 (3.8240)

Exhaust 96.81 (3.8114) 94.67 (3.7272)

Valve stem diameter “d”Intake 5.965 - 5.980 (0.2348 - 0.2354) 5.965 - 5.980 (0.2348 - 0.2354)

Exhaust 5.955 - 5.970 (0.2344 - 0.2350) 5.962 - 5.970 (0.2347 - 0.2350)

Valve seat angle “α”Intake

45°15′ - 45°45′

Exhaust

Valve margin “T”Intake 1.1 (0.043)

Exhaust 1.3 (0.051)

Valve margin “T” limit 0.5 (0.020)

Valve stem end surface grinding limit 0.2 (0.008)

SEM188

Items Standard Oversize (Service) [0.2 (0.008)]

Valve guideOuter diameter 10.023 - 10.034 (0.3946 - 0.3950) 10.223 - 10.234 (0.4025 - 0.4029)

Inner diameter (Finished size) 6.000 - 6.018 (0.2362 - 0.2369)

Cylinder head valve guide hole diameter 9.975 - 9.996 (0.3927 - 0.3935) 10.175 - 10.196 (0.4006 - 0.4014)

Interference fit of valve guide 0.027 - 0.059 (0.0011 - 0.0023)

Items Standard Limit

Valve guide clearanceIntake 0.020 - 0.053 (0.0008 - 0.0021) 0.08 (0.0031)

Exhaust 0.030 - 0.056 (0.0012 - 0.0022) 0.09 (0.0035)

Projection length “L” 12.6 - 12.8 (0.496 - 0.504)

SEM950E

Page 2440 of 5121

FAX-12

< ON-VEHICLE REPAIR >

FRONT DRIVE SHAFT BOOT

WHEEL SIDE

WHEEL SIDE : Removal and InstallationINFOID:0000000003811080

REMOVAL

1. Remove tires.

2. Remove wheel sensor and sensor harness. Refer to BRC-57, "

FRONT WHEEL SENSOR : Exploded

View" (without VDC), BRC-151, "FRONT WHEEL SENSOR : Exploded View" (with VDC).

3. Remove lock plate of brake hose from strut assembly. Refer to BR-19, "

FRONT : Exploded View".

4. Remove caliper assembly. Hang caliper assembly not to interfere with work. Refer to BR-34, "

BRAKE

CALIPER ASSEMBLY : Exploded View".

5. Remove disc rotor. Refer to BR-35, "

BRAKE CALIPER ASSEMBLY : Removal and Installation".

6. Remove cotter pin, and then loosen wheel hub lock nut. Refer to FA X - 8 , "

Exploded View".

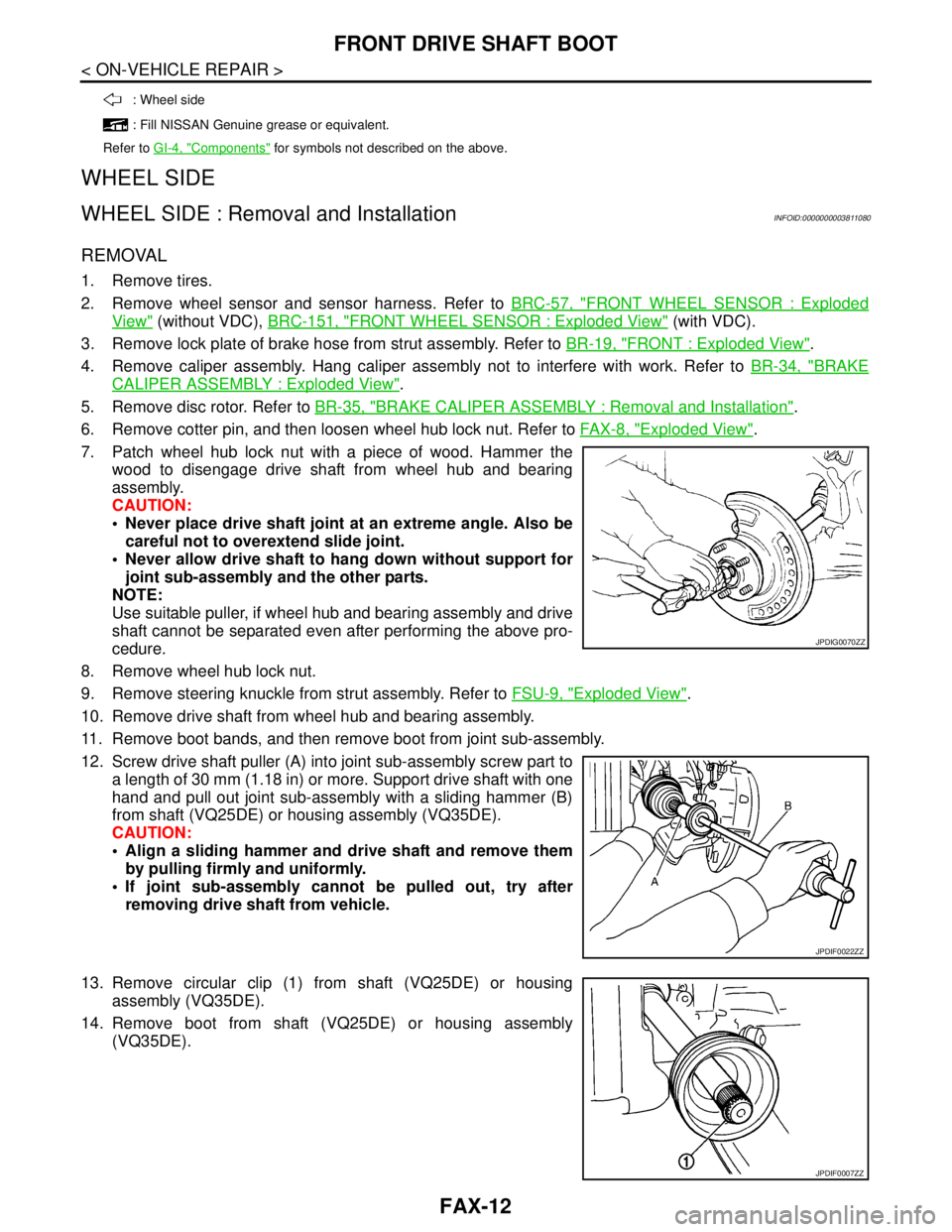

7. Patch wheel hub lock nut with a piece of wood. Hammer the

wood to disengage drive shaft from wheel hub and bearing

assembly.

CAUTION:

Never place drive shaft joint at an extreme angle. Also be

careful not to overextend slide joint.

Never allow drive shaft to hang down without support for

joint sub-assembly and the other parts.

NOTE:

Use suitable puller, if wheel hub and bearing assembly and drive

shaft cannot be separated even after performing the above pro-

cedure.

8. Remove wheel hub lock nut.

9. Remove steering knuckle from strut assembly. Refer to FSU-9, "

Exploded View".

10. Remove drive shaft from wheel hub and bearing assembly.

11. Remove boot bands, and then remove boot from joint sub-assembly.

12. Screw drive shaft puller (A) into joint sub-assembly screw part to

a length of 30 mm (1.18 in) or more. Support drive shaft with one

hand and pull out joint sub-assembly with a sliding hammer (B)

from shaft (VQ25DE) or housing assembly (VQ35DE).

CAUTION:

Align a sliding hammer and drive shaft and remove them

by pulling firmly and uniformly.

If joint sub-assembly cannot be pulled out, try after

removing drive shaft from vehicle.

13. Remove circular clip (1) from shaft (VQ25DE) or housing

assembly (VQ35DE).

14. Remove boot from shaft (VQ25DE) or housing assembly

(VQ35DE).

: Wheel side

: Fill NISSAN Genuine grease or equivalent.

Refer to GI-4, "

Components" for symbols not described on the above.

JPDIG0070ZZ

JPDIF0022ZZ

JPDIF0007ZZ

Page 2442 of 5121

FAX-14

< ON-VEHICLE REPAIR >

FRONT DRIVE SHAFT BOOT

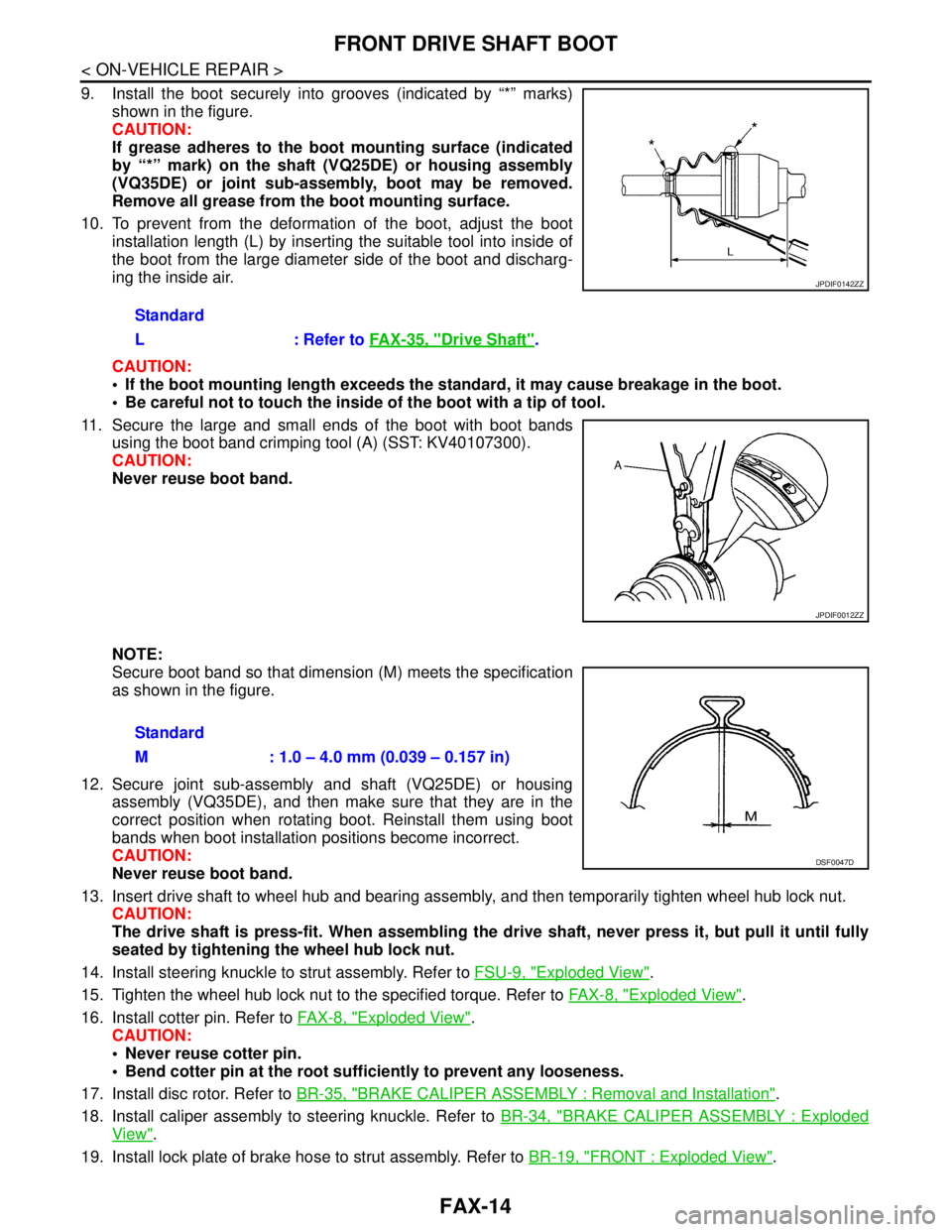

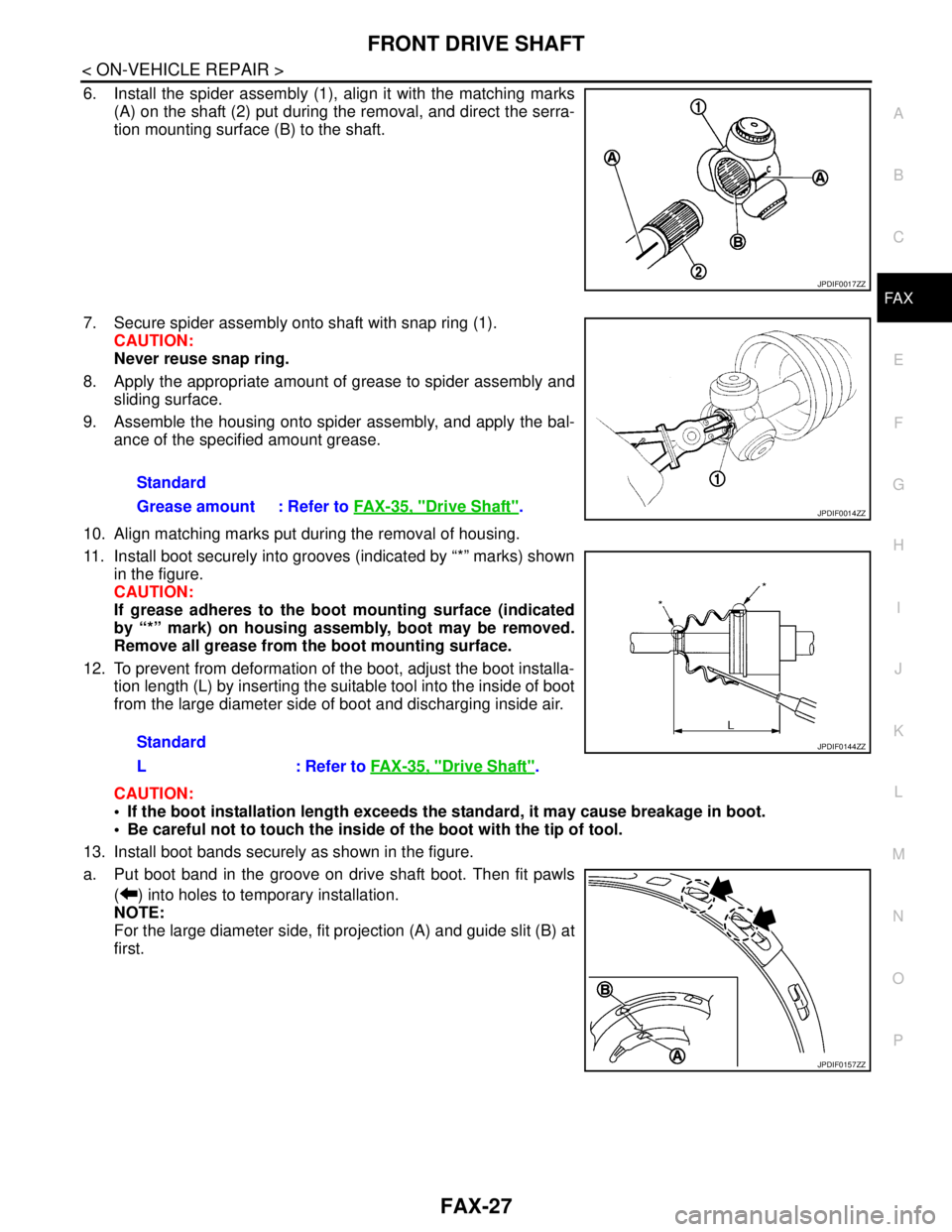

9. Install the boot securely into grooves (indicated by “*” marks)

shown in the figure.

CAUTION:

If grease adheres to the boot mounting surface (indicated

by “*” mark) on the shaft (VQ25DE) or housing assembly

(VQ35DE) or joint sub-assembly, boot may be removed.

Remove all grease from the boot mounting surface.

10. To prevent from the deformation of the boot, adjust the boot

installation length (L) by inserting the suitable tool into inside of

the boot from the large diameter side of the boot and discharg-

ing the inside air.

CAUTION:

If the boot mounting length exceeds the standard, it may cause breakage in the boot.

Be careful not to touch the inside of the boot with a tip of tool.

11. Secure the large and small ends of the boot with boot bands

using the boot band crimping tool (A) (SST: KV40107300).

CAUTION:

Never reuse boot band.

NOTE:

Secure boot band so that dimension (M) meets the specification

as shown in the figure.

12. Secure joint sub-assembly and shaft (VQ25DE) or housing

assembly (VQ35DE), and then make sure that they are in the

correct position when rotating boot. Reinstall them using boot

bands when boot installation positions become incorrect.

CAUTION:

Never reuse boot band.

13. Insert drive shaft to wheel hub and bearing assembly, and then temporarily tighten wheel hub lock nut.

CAUTION:

The drive shaft is press-fit. When assembling the drive shaft, never press it, but pull it until fully

seated by tightening the wheel hub lock nut.

14. Install steering knuckle to strut assembly. Refer to FSU-9, "

Exploded View".

15. Tighten the wheel hub lock nut to the specified torque. Refer to FA X - 8 , "

Exploded View".

16. Install cotter pin. Refer to FA X - 8 , "

Exploded View".

CAUTION:

Never reuse cotter pin.

Bend cotter pin at the root sufficiently to prevent any looseness.

17. Install disc rotor. Refer to BR-35, "

BRAKE CALIPER ASSEMBLY : Removal and Installation".

18. Install caliper assembly to steering knuckle. Refer to BR-34, "

BRAKE CALIPER ASSEMBLY : Exploded

View".

19. Install lock plate of brake hose to strut assembly. Refer to BR-19, "

FRONT : Exploded View". Standard

L : Refer to FAX-35, "

Drive Shaft".

JPDIF0142ZZ

JPDIF0012ZZ

Standard

M : 1.0 – 4.0 mm (0.039 – 0.157 in)

DSF0047D

Page 2448 of 5121

FAX-20

< ON-VEHICLE REPAIR >

FRONT DRIVE SHAFT

Always replace differential side oil seal with new one when installing drive shaft. Refer to TM-162, "Exploded

View" (CVT: RE0F09B), TM-325, "Exploded View" (CVT: RE0F10A).

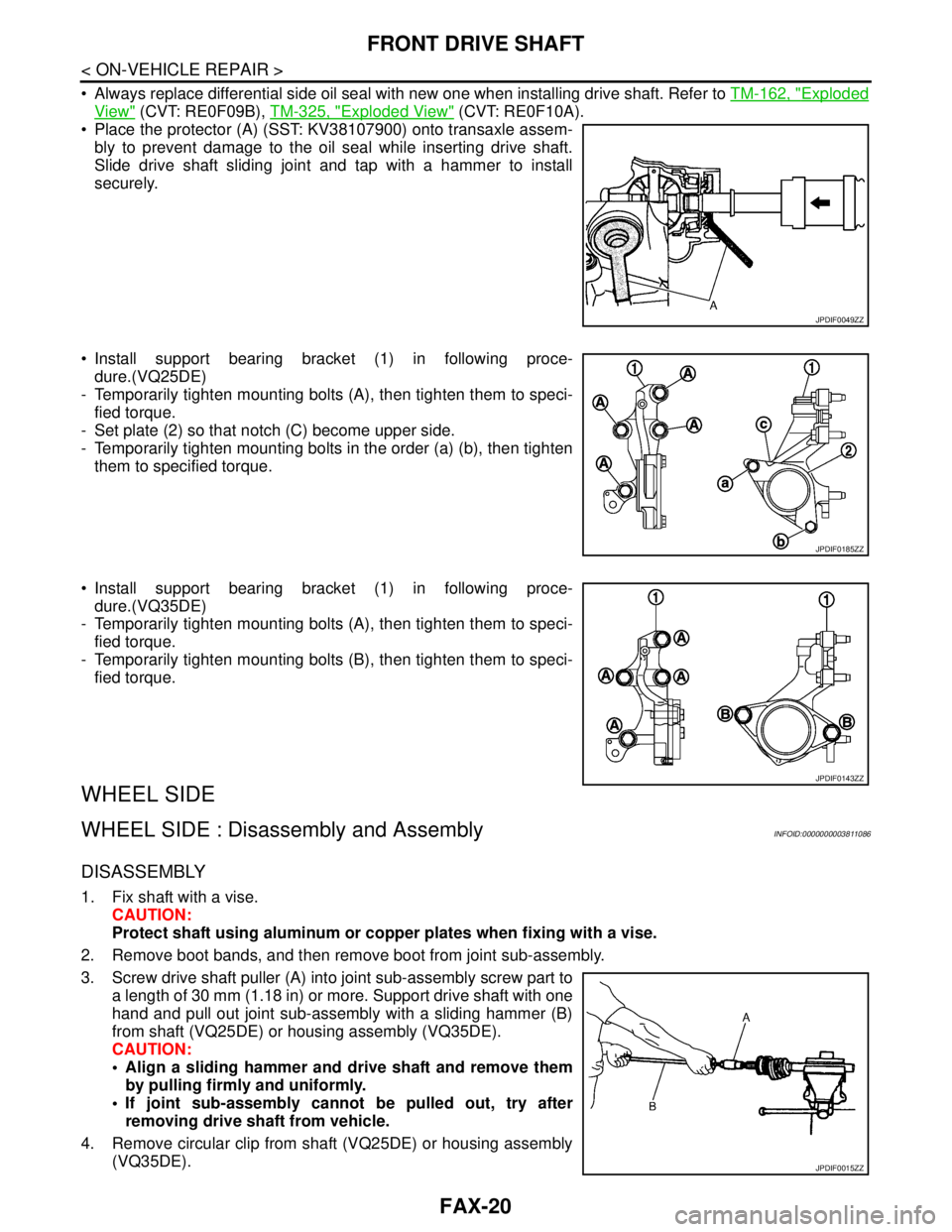

Place the protector (A) (SST: KV38107900) onto transaxle assem-

bly to prevent damage to the oil seal while inserting drive shaft.

Slide drive shaft sliding joint and tap with a hammer to install

securely.

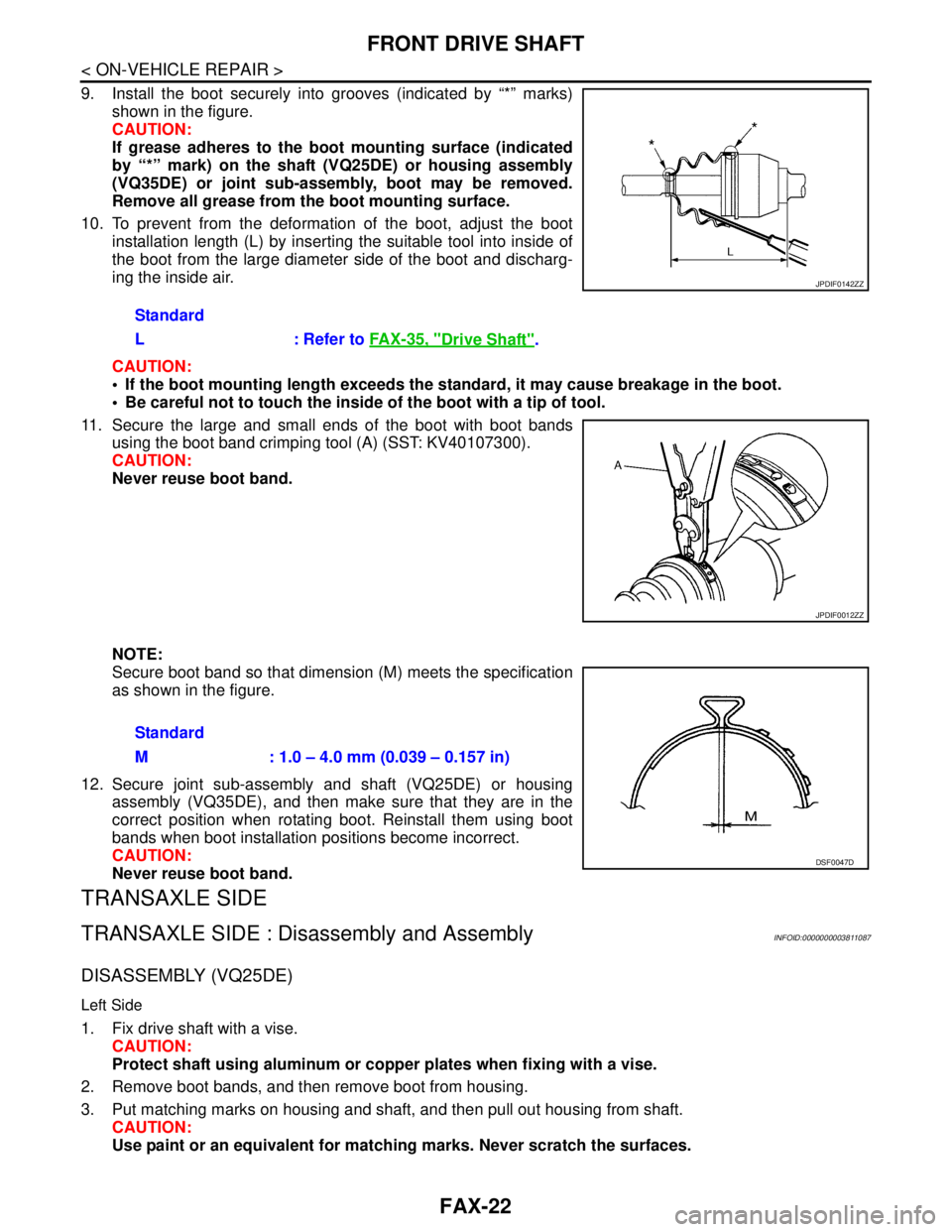

Install support bearing bracket (1) in following proce-

dure.(VQ25DE)

- Temporarily tighten mounting bolts (A), then tighten them to speci-

fied torque.

- Set plate (2) so that notch (C) become upper side.

- Temporarily tighten mounting bolts in the order (a) (b), then tighten

them to specified torque.

Install support bearing bracket (1) in following proce-

dure.(VQ35DE)

- Temporarily tighten mounting bolts (A), then tighten them to speci-

fied torque.

- Temporarily tighten mounting bolts (B), then tighten them to speci-

fied torque.

WHEEL SIDE

WHEEL SIDE : Disassembly and AssemblyINFOID:0000000003811086

DISASSEMBLY

1. Fix shaft with a vise.

CAUTION:

Protect shaft using aluminum or copper plates when fixing with a vise.

2. Remove boot bands, and then remove boot from joint sub-assembly.

3. Screw drive shaft puller (A) into joint sub-assembly screw part to

a length of 30 mm (1.18 in) or more. Support drive shaft with one

hand and pull out joint sub-assembly with a sliding hammer (B)

from shaft (VQ25DE) or housing assembly (VQ35DE).

CAUTION:

Align a sliding hammer and drive shaft and remove them

by pulling firmly and uniformly.

If joint sub-assembly cannot be pulled out, try after

removing drive shaft from vehicle.

4. Remove circular clip from shaft (VQ25DE) or housing assembly

(VQ35DE).

JPDIF0049ZZ

JPDIF0185ZZ

JPDIF0143ZZ

JPDIF0015ZZ

Page 2450 of 5121

FAX-22

< ON-VEHICLE REPAIR >

FRONT DRIVE SHAFT

9. Install the boot securely into grooves (indicated by “*” marks)

shown in the figure.

CAUTION:

If grease adheres to the boot mounting surface (indicated

by “*” mark) on the shaft (VQ25DE) or housing assembly

(VQ35DE) or joint sub-assembly, boot may be removed.

Remove all grease from the boot mounting surface.

10. To prevent from the deformation of the boot, adjust the boot

installation length (L) by inserting the suitable tool into inside of

the boot from the large diameter side of the boot and discharg-

ing the inside air.

CAUTION:

If the boot mounting length exceeds the standard, it may cause breakage in the boot.

Be careful not to touch the inside of the boot with a tip of tool.

11. Secure the large and small ends of the boot with boot bands

using the boot band crimping tool (A) (SST: KV40107300).

CAUTION:

Never reuse boot band.

NOTE:

Secure boot band so that dimension (M) meets the specification

as shown in the figure.

12. Secure joint sub-assembly and shaft (VQ25DE) or housing

assembly (VQ35DE), and then make sure that they are in the

correct position when rotating boot. Reinstall them using boot

bands when boot installation positions become incorrect.

CAUTION:

Never reuse boot band.

TRANSAXLE SIDE

TRANSAXLE SIDE : Disassembly and AssemblyINFOID:0000000003811087

DISASSEMBLY (VQ25DE)

Left Side

1. Fix drive shaft with a vise.

CAUTION:

Protect shaft using aluminum or copper plates when fixing with a vise.

2. Remove boot bands, and then remove boot from housing.

3. Put matching marks on housing and shaft, and then pull out housing from shaft.

CAUTION:

Use paint or an equivalent for matching marks. Never scratch the surfaces. Standard

L : Refer to FAX-35, "

Drive Shaft".

JPDIF0142ZZ

JPDIF0012ZZ

Standard

M : 1.0 – 4.0 mm (0.039 – 0.157 in)

DSF0047D

Page 2455 of 5121

FRONT DRIVE SHAFT

FAX-27

< ON-VEHICLE REPAIR >

C

E

F

G

H

I

J

K

L

MA

B

FA X

N

O

P

6. Install the spider assembly (1), align it with the matching marks

(A) on the shaft (2) put during the removal, and direct the serra-

tion mounting surface (B) to the shaft.

7. Secure spider assembly onto shaft with snap ring (1).

CAUTION:

Never reuse snap ring.

8. Apply the appropriate amount of grease to spider assembly and

sliding surface.

9. Assemble the housing onto spider assembly, and apply the bal-

ance of the specified amount grease.

10. Align matching marks put during the removal of housing.

11. Install boot securely into grooves (indicated by “*” marks) shown

in the figure.

CAUTION:

If grease adheres to the boot mounting surface (indicated

by “*” mark) on housing assembly, boot may be removed.

Remove all grease from the boot mounting surface.

12. To prevent from deformation of the boot, adjust the boot installa-

tion length (L) by inserting the suitable tool into the inside of boot

from the large diameter side of boot and discharging inside air.

CAUTION:

If the boot installation length exceeds the standard, it may cause breakage in boot.

Be careful not to touch the inside of the boot with the tip of tool.

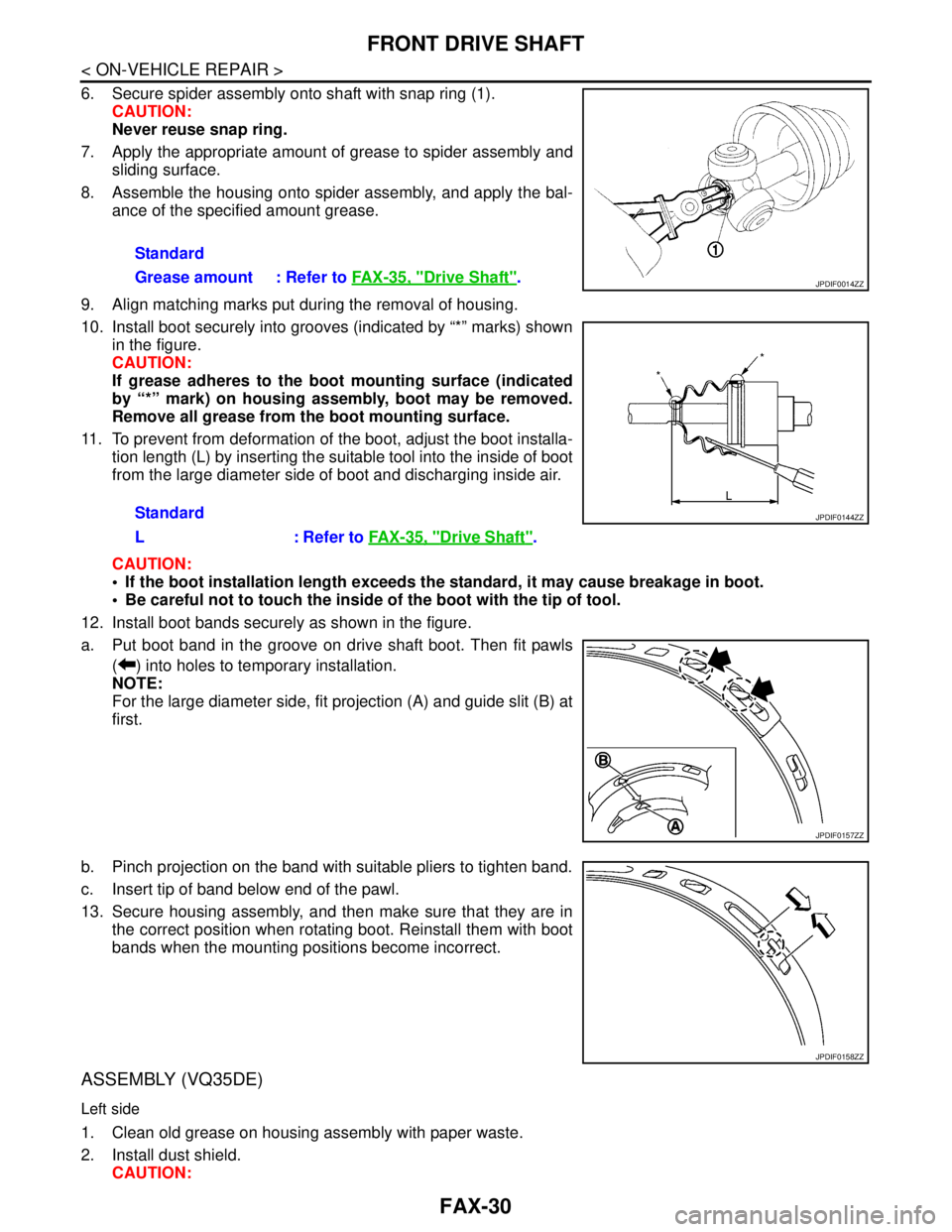

13. Install boot bands securely as shown in the figure.

a. Put boot band in the groove on drive shaft boot. Then fit pawls

( ) into holes to temporary installation.

NOTE:

For the large diameter side, fit projection (A) and guide slit (B) at

first.

JPDIF0017ZZ

Standard

Grease amount : Refer to FAX-35, "

Drive Shaft".

Standard

L : Refer to FAX-35, "

Drive Shaft".

JPDIF0014ZZ

JPDIF0144ZZ

JPDIF0157ZZ

Page 2458 of 5121

FAX-30

< ON-VEHICLE REPAIR >

FRONT DRIVE SHAFT

6. Secure spider assembly onto shaft with snap ring (1).

CAUTION:

Never reuse snap ring.

7. Apply the appropriate amount of grease to spider assembly and

sliding surface.

8. Assemble the housing onto spider assembly, and apply the bal-

ance of the specified amount grease.

9. Align matching marks put during the removal of housing.

10. Install boot securely into grooves (indicated by “*” marks) shown

in the figure.

CAUTION:

If grease adheres to the boot mounting surface (indicated

by “*” mark) on housing assembly, boot may be removed.

Remove all grease from the boot mounting surface.

11. To prevent from deformation of the boot, adjust the boot installa-

tion length (L) by inserting the suitable tool into the inside of boot

from the large diameter side of boot and discharging inside air.

CAUTION:

If the boot installation length exceeds the standard, it may cause breakage in boot.

Be careful not to touch the inside of the boot with the tip of tool.

12. Install boot bands securely as shown in the figure.

a. Put boot band in the groove on drive shaft boot. Then fit pawls

( ) into holes to temporary installation.

NOTE:

For the large diameter side, fit projection (A) and guide slit (B) at

first.

b. Pinch projection on the band with suitable pliers to tighten band.

c. Insert tip of band below end of the pawl.

13. Secure housing assembly, and then make sure that they are in

the correct position when rotating boot. Reinstall them with boot

bands when the mounting positions become incorrect.

ASSEMBLY (VQ35DE)

Left side

1. Clean old grease on housing assembly with paper waste.

2. Install dust shield.

CAUTION:Standard

Grease amount : Refer to FAX-35, "

Drive Shaft".

Standard

L: Refer to FAX-35, "

Drive Shaft".

JPDIF0014ZZ

JPDIF0144ZZ

JPDIF0157ZZ

JPDIF0158ZZ

Page 2459 of 5121

FRONT DRIVE SHAFT

FAX-31

< ON-VEHICLE REPAIR >

C

E

F

G

H

I

J

K

L

MA

B

FA X

N

O

P

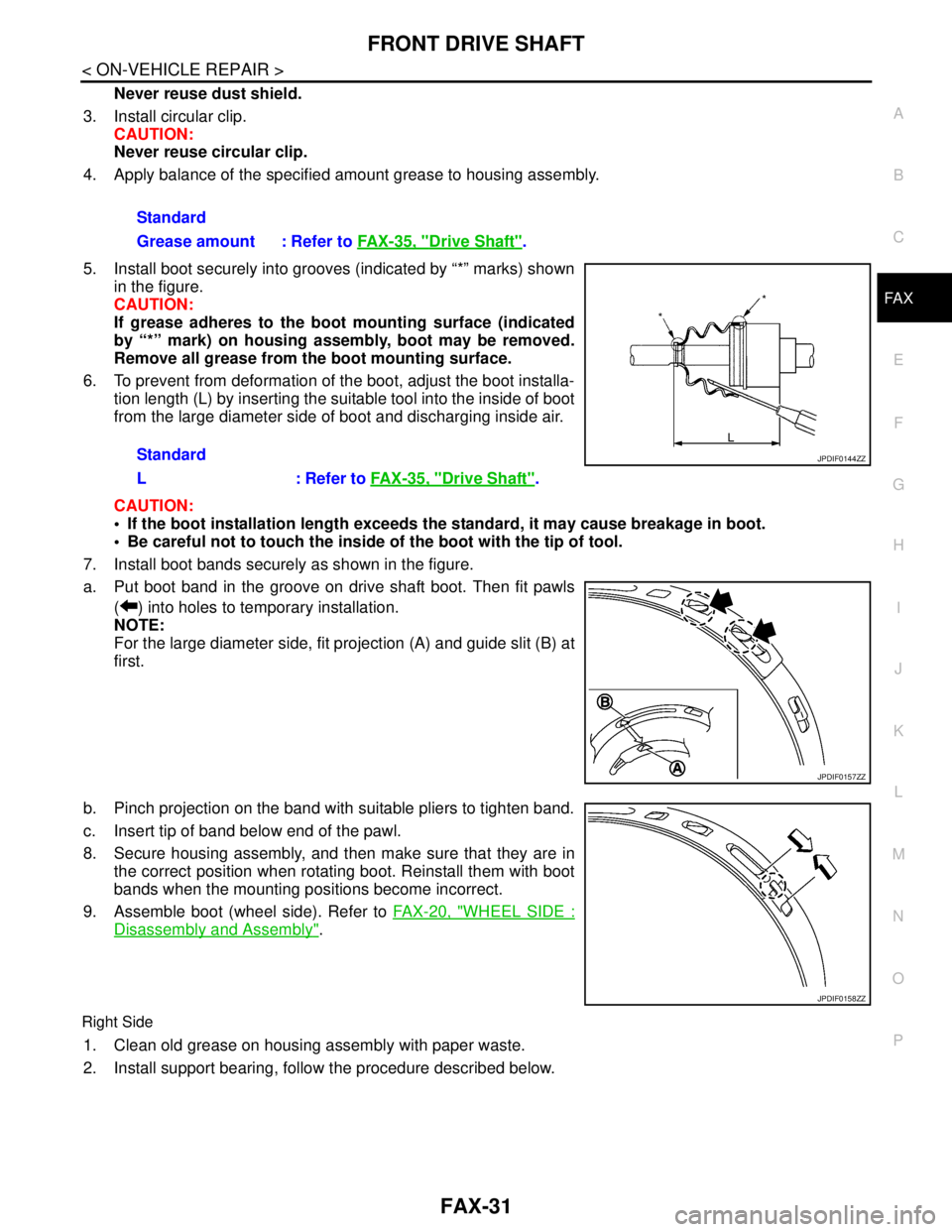

Never reuse dust shield.

3. Install circular clip.

CAUTION:

Never reuse circular clip.

4. Apply balance of the specified amount grease to housing assembly.

5. Install boot securely into grooves (indicated by “*” marks) shown

in the figure.

CAUTION:

If grease adheres to the boot mounting surface (indicated

by “*” mark) on housing assembly, boot may be removed.

Remove all grease from the boot mounting surface.

6. To prevent from deformation of the boot, adjust the boot installa-

tion length (L) by inserting the suitable tool into the inside of boot

from the large diameter side of boot and discharging inside air.

CAUTION:

If the boot installation length exceeds the standard, it may cause breakage in boot.

Be careful not to touch the inside of the boot with the tip of tool.

7. Install boot bands securely as shown in the figure.

a. Put boot band in the groove on drive shaft boot. Then fit pawls

( ) into holes to temporary installation.

NOTE:

For the large diameter side, fit projection (A) and guide slit (B) at

first.

b. Pinch projection on the band with suitable pliers to tighten band.

c. Insert tip of band below end of the pawl.

8. Secure housing assembly, and then make sure that they are in

the correct position when rotating boot. Reinstall them with boot

bands when the mounting positions become incorrect.

9. Assemble boot (wheel side). Refer to FAX-20, "

WHEEL SIDE :

Disassembly and Assembly".

Right Side

1. Clean old grease on housing assembly with paper waste.

2. Install support bearing, follow the procedure described below. Standard

Grease amount : Refer to FAX-35, "

Drive Shaft".

Standard

L : Refer to FAX-35, "

Drive Shaft".

JPDIF0144ZZ

JPDIF0157ZZ

JPDIF0158ZZ

Page 2460 of 5121

FAX-32

< ON-VEHICLE REPAIR >

FRONT DRIVE SHAFT

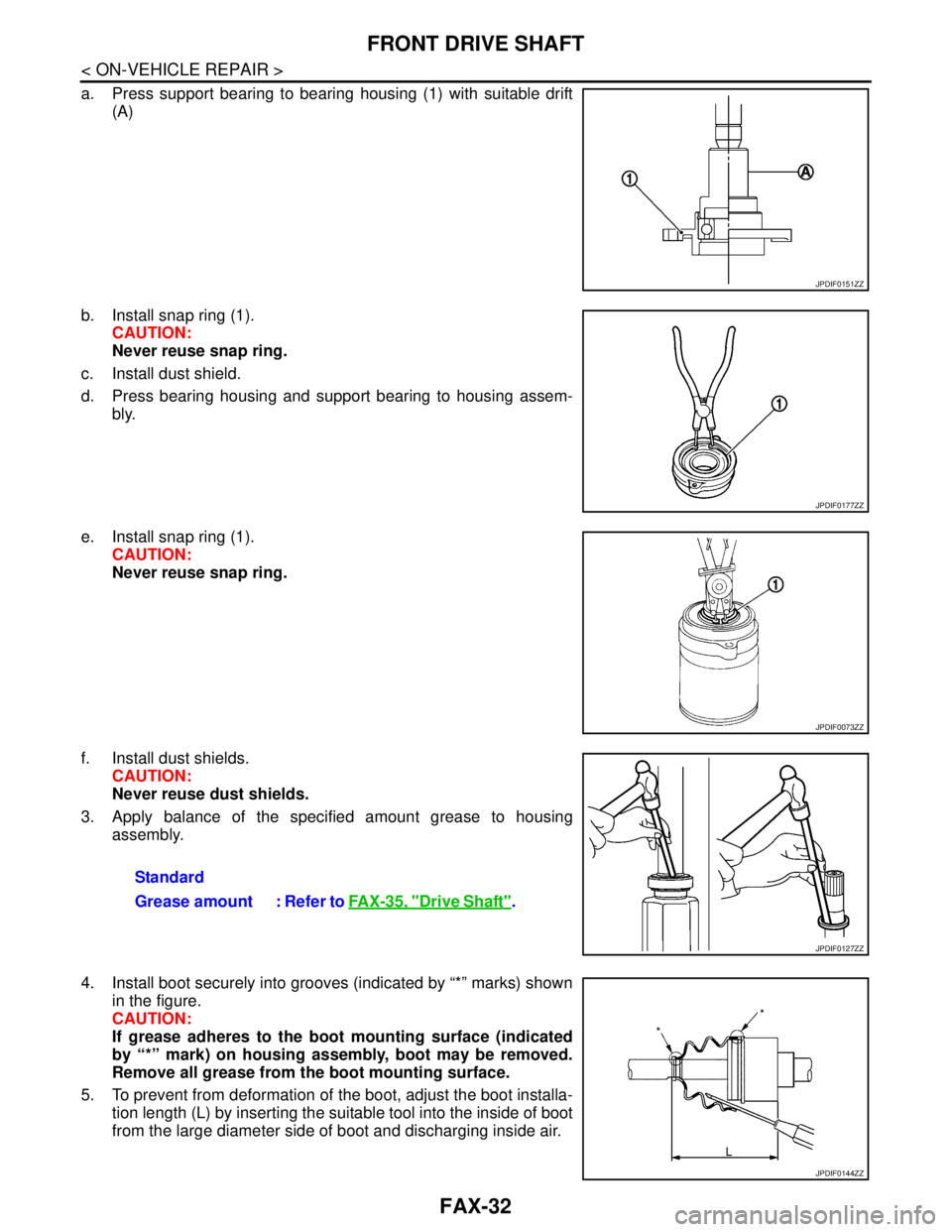

a. Press support bearing to bearing housing (1) with suitable drift

(A)

b. Install snap ring (1).

CAUTION:

Never reuse snap ring.

c. Install dust shield.

d. Press bearing housing and support bearing to housing assem-

bly.

e. Install snap ring (1).

CAUTION:

Never reuse snap ring.

f. Install dust shields.

CAUTION:

Never reuse dust shields.

3. Apply balance of the specified amount grease to housing

assembly.

4. Install boot securely into grooves (indicated by “*” marks) shown

in the figure.

CAUTION:

If grease adheres to the boot mounting surface (indicated

by “*” mark) on housing assembly, boot may be removed.

Remove all grease from the boot mounting surface.

5. To prevent from deformation of the boot, adjust the boot installa-

tion length (L) by inserting the suitable tool into the inside of boot

from the large diameter side of boot and discharging inside air.

JPDIF0151ZZ

JPDIF0177ZZ

JPDIF0073ZZ

Standard

Grease amount : Refer to FAX-35, "

Drive Shaft".

JPDIF0127ZZ

JPDIF0144ZZ