length NISSAN TEANA 2008 Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 2461 of 5121

FRONT DRIVE SHAFT

FAX-33

< ON-VEHICLE REPAIR >

C

E

F

G

H

I

J

K

L

MA

B

FA X

N

O

P

CAUTION:

If the boot installation length exceeds the standard, it may cause breakage in boot.

Be careful not to touch the inside of the boot with the tip of tool.

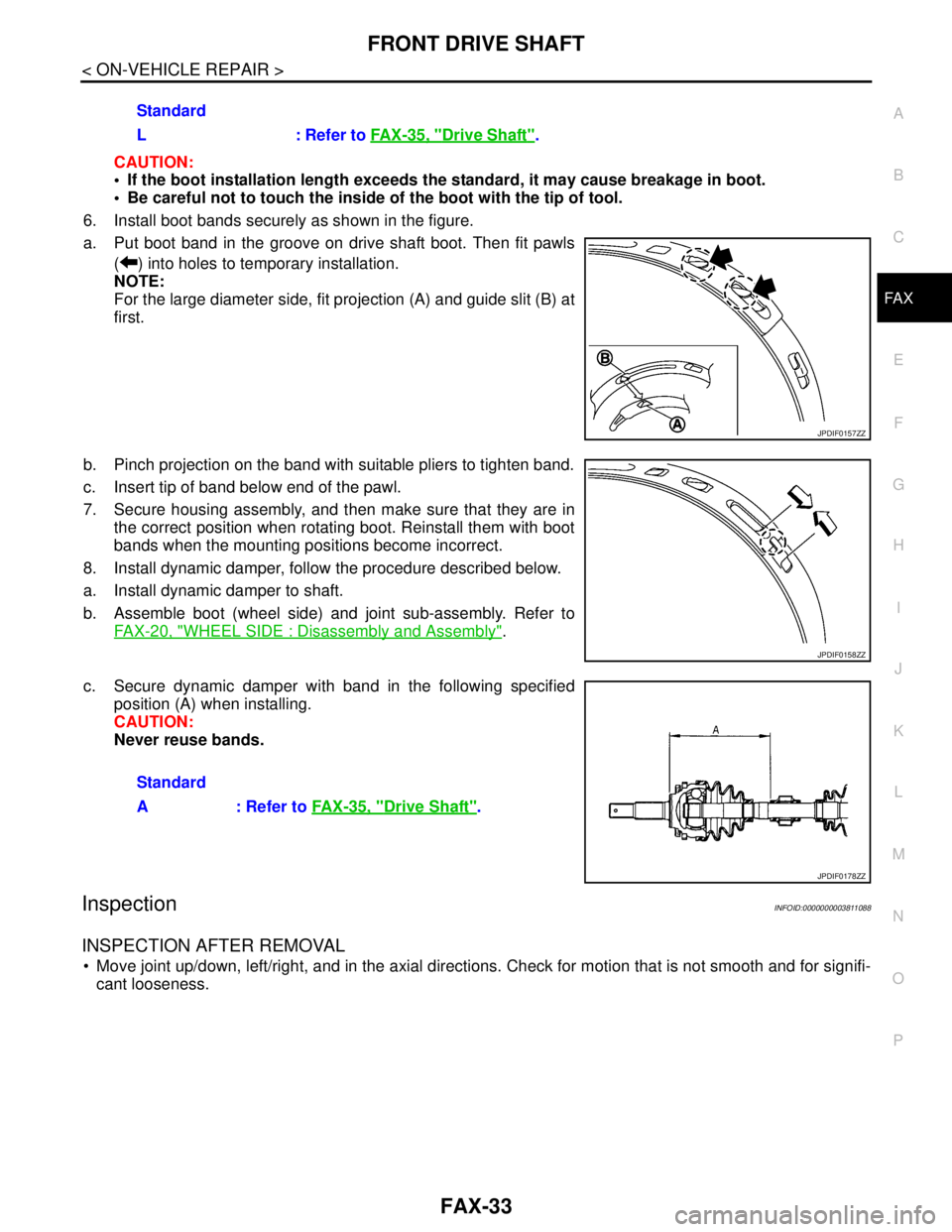

6. Install boot bands securely as shown in the figure.

a. Put boot band in the groove on drive shaft boot. Then fit pawls

( ) into holes to temporary installation.

NOTE:

For the large diameter side, fit projection (A) and guide slit (B) at

first.

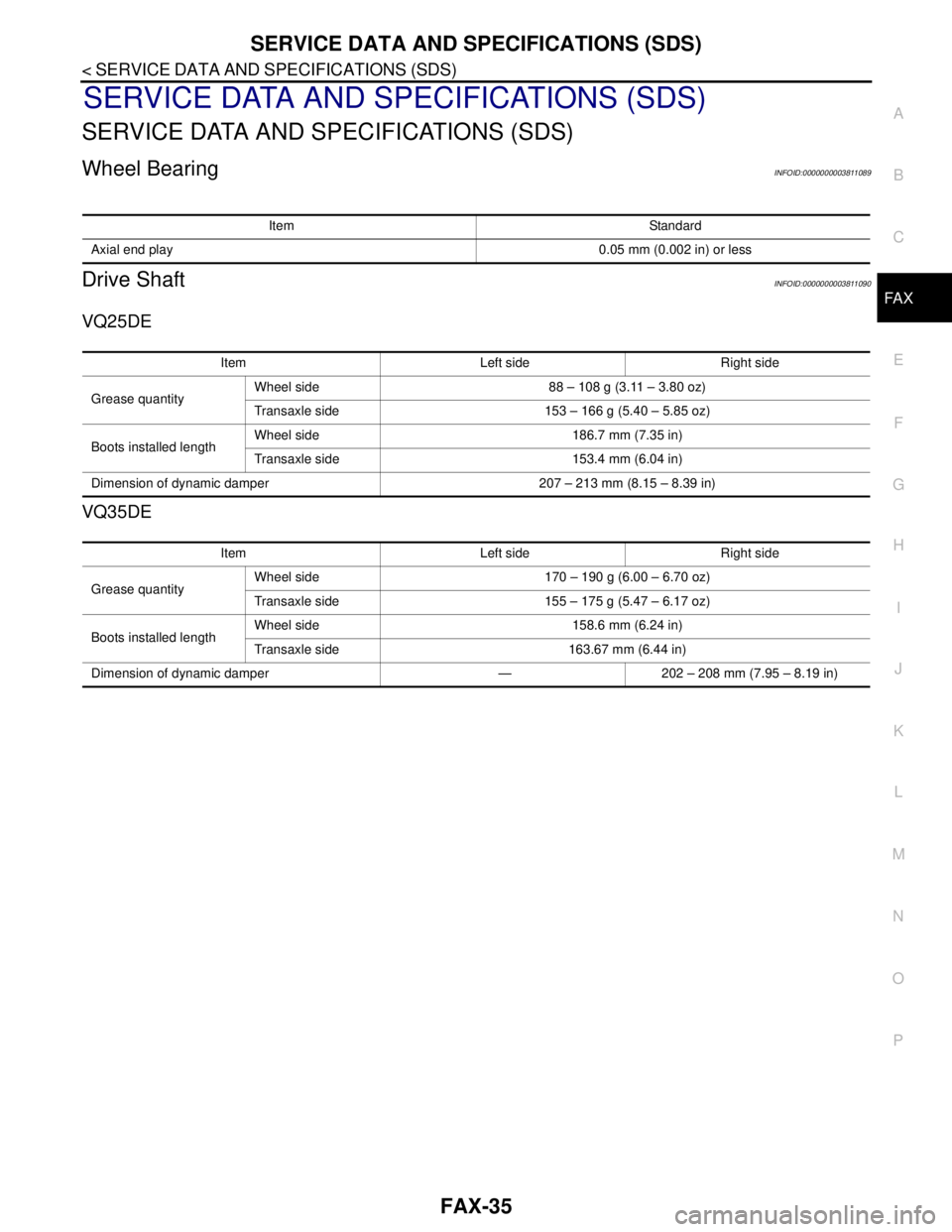

b. Pinch projection on the band with suitable pliers to tighten band.

c. Insert tip of band below end of the pawl.

7. Secure housing assembly, and then make sure that they are in

the correct position when rotating boot. Reinstall them with boot

bands when the mounting positions become incorrect.

8. Install dynamic damper, follow the procedure described below.

a. Install dynamic damper to shaft.

b. Assemble boot (wheel side) and joint sub-assembly. Refer to

FAX-20, "

WHEEL SIDE : Disassembly and Assembly".

c. Secure dynamic damper with band in the following specified

position (A) when installing.

CAUTION:

Never reuse bands.

InspectionINFOID:0000000003811088

INSPECTION AFTER REMOVAL

Move joint up/down, left/right, and in the axial directions. Check for motion that is not smooth and for signifi-

cant looseness.Standard

L : Refer to FAX-35, "

Drive Shaft".

JPDIF0157ZZ

JPDIF0158ZZ

Standard

A : Refer to FAX-35, "

Drive Shaft".

JPDIF0178ZZ

Page 2463 of 5121

SERVICE DATA AND SPECIFICATIONS (SDS)

FAX-35

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

E

F

G

H

I

J

K

L

MA

B

FA X

N

O

P

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Wheel BearingINFOID:0000000003811089

Drive ShaftINFOID:0000000003811090

VQ25DE

VQ35DE

Item Standard

Axial end play0.05 mm (0.002 in) or less

Item Left side Right side

Grease quantityWheel side 88 – 108 g (3.11 – 3.80 oz)

Transaxle side 153 – 166 g (5.40 – 5.85 oz)

Boots installed lengthWheel side 186.7 mm (7.35 in)

Transaxle side 153.4 mm (6.04 in)

Dimension of dynamic damper 207 – 213 mm (8.15 – 8.39 in)

Item Left side Right side

Grease quantityWheel side 170 – 190 g (6.00 – 6.70 oz)

Transaxle side 155 – 175 g (5.47 – 6.17 oz)

Boots installed lengthWheel side 158.6 mm (6.24 in)

Transaxle side 163.67 mm (6.44 in)

Dimension of dynamic damper — 202 – 208 mm (7.95 – 8.19 in)

Page 2473 of 5121

FL-10

< ON-VEHICLE REPAIR >

FUEL TANK

4. Remove rear parking brake cables. Refer to PB-5, "Exploded View".

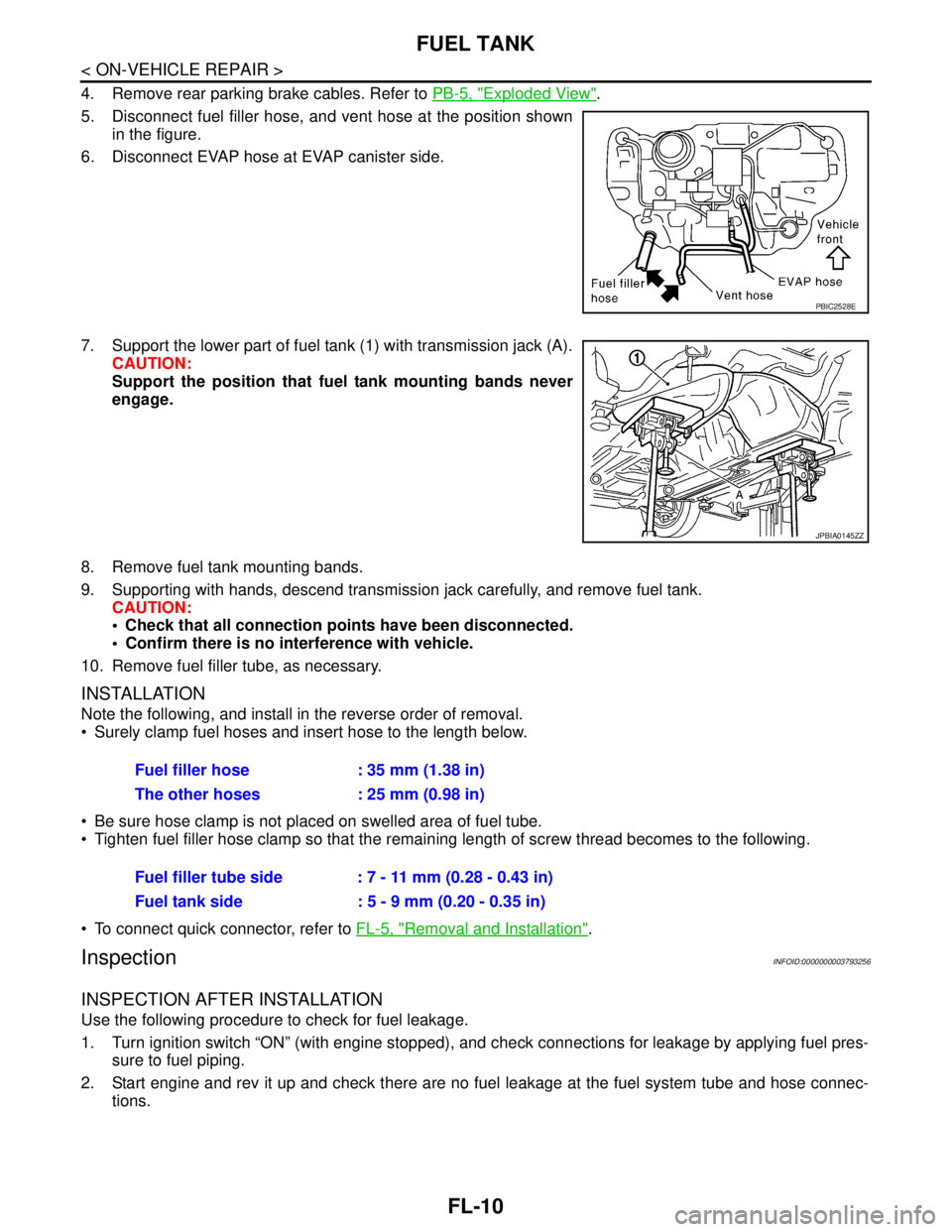

5. Disconnect fuel filler hose, and vent hose at the position shown

in the figure.

6. Disconnect EVAP hose at EVAP canister side.

7. Support the lower part of fuel tank (1) with transmission jack (A).

CAUTION:

Support the position that fuel tank mounting bands never

engage.

8. Remove fuel tank mounting bands.

9. Supporting with hands, descend transmission jack carefully, and remove fuel tank.

CAUTION:

Check that all connection points have been disconnected.

Confirm there is no interference with vehicle.

10. Remove fuel filler tube, as necessary.

INSTALLATION

Note the following, and install in the reverse order of removal.

Surely clamp fuel hoses and insert hose to the length below.

Be sure hose clamp is not placed on swelled area of fuel tube.

Tighten fuel filler hose clamp so that the remaining length of screw thread becomes to the following.

To connect quick connector, refer to FL-5, "

Removal and Installation".

InspectionINFOID:0000000003793256

INSPECTION AFTER INSTALLATION

Use the following procedure to check for fuel leakage.

1. Turn ignition switch “ON” (with engine stopped), and check connections for leakage by applying fuel pres-

sure to fuel piping.

2. Start engine and rev it up and check there are no fuel leakage at the fuel system tube and hose connec-

tions.

PBIC2528E

JPBIA0145ZZ

Fuel filler hose : 35 mm (1.38 in)

The other hoses : 25 mm (0.98 in)

Fuel filler tube side : 7 - 11 mm (0.28 - 0.43 in)

Fuel tank side : 5 - 9 mm (0.20 - 0.35 in)

Page 2482 of 5121

FSU-8

< ON-VEHICLE MAINTENANCE >

WHEEL ALIGNMENT

Kingpin inclination angle is reference value, no inspection is required.

Toe-In

Measure toe-in by the following procedure.

WARNING:

Always perform the following procedure on a flat surface.

Make sure that no person is in front of vehicle before pushing it.

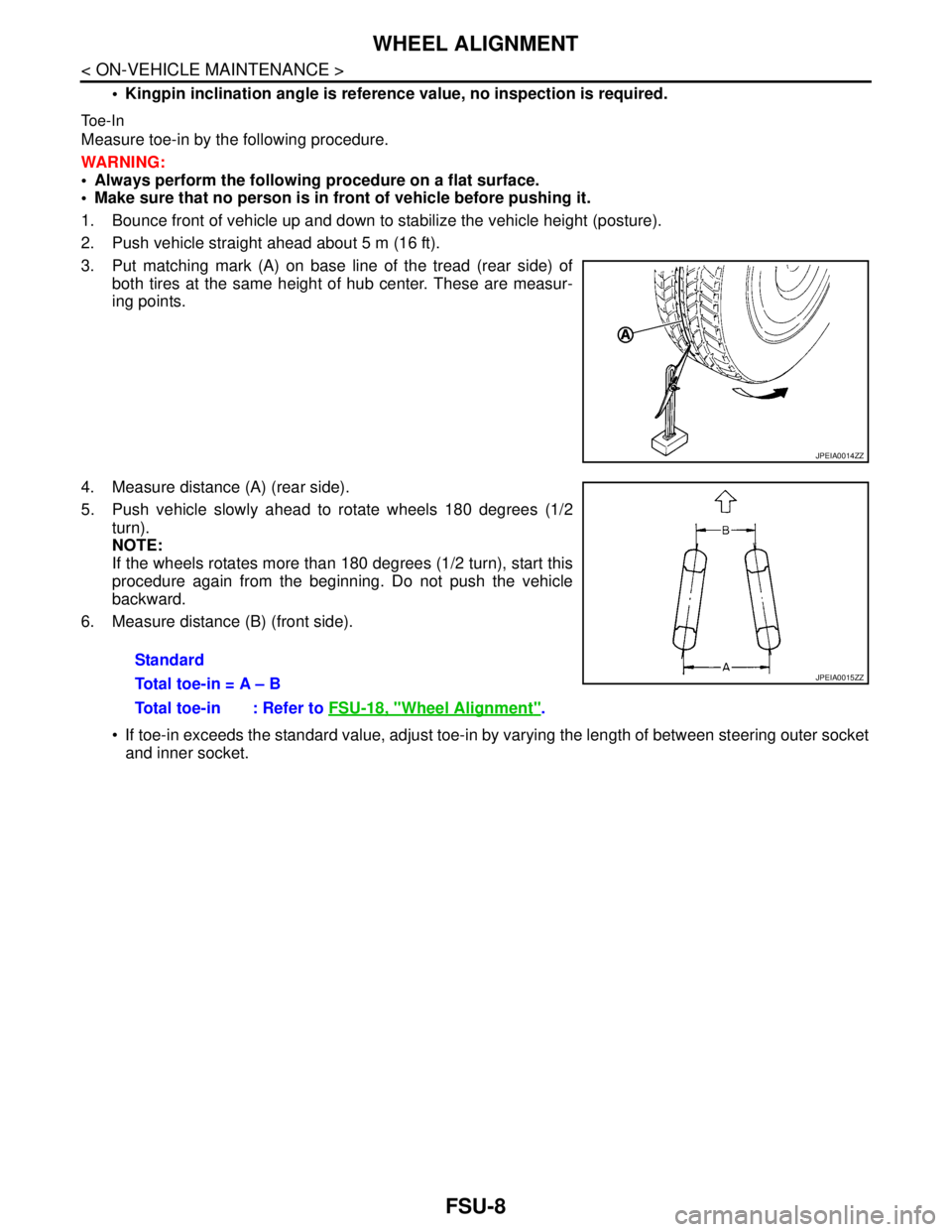

1. Bounce front of vehicle up and down to stabilize the vehicle height (posture).

2. Push vehicle straight ahead about 5 m (16 ft).

3. Put matching mark (A) on base line of the tread (rear side) of

both tires at the same height of hub center. These are measur-

ing points.

4. Measure distance (A) (rear side).

5. Push vehicle slowly ahead to rotate wheels 180 degrees (1/2

turn).

NOTE:

If the wheels rotates more than 180 degrees (1/2 turn), start this

procedure again from the beginning. Do not push the vehicle

backward.

6. Measure distance (B) (front side).

If toe-in exceeds the standard value, adjust toe-in by varying the length of between steering outer socket

and inner socket.

JPEIA0014ZZ

Standard

Total toe-in = A – B

Total toe-in : Refer to FSU-18, "

Wheel Alignment".

JPEIA0015ZZ

Page 2516 of 5121

IDENTIFICATION INFORMATION

GI-23

< FEATURES OF NEW MODEL >

C

D

E

F

G

H

I

J

K

L

MB

GI

N

O

P CVT Unit (RE0F10A)

CVT Unit (RE0F09B)

DimensionsINFOID:0000000003852774

Unit: mm (in)

*1: 205/65R16 tire model

*2: 215/55R17 tire model

Wheels & TiresINFOID:0000000003852775

: Vehicle front

SAIA1496E

: Unit front

SAIA0360E

Overall length 4,850 (190.9)

Overall width 1,795 (70.7)

Overall height 1,475 (58.1)

Front tread 1,560 (61.4)*1, 1,550 (61.0)*2

Rear tread 1,560 (61.4)*1, 1,550 (61.0)*2

Wheelbase 2,775 (109.3)

Application Conventional Spare

Road wheel/offset mm (in)16 X 6-1/2J/40 (1.57)

17 X 7J/45 (1.77)

Conventional

Tire size205/65R16 95H

215/55R17 94V

Page 2520 of 5121

PRECAUTIONS

GI-27

< PRECAUTION >

C

D

E

F

G

H

I

J

K

L

MB

GI

N

O

P

system. The connectors should be disconnected only when working according to the WORK FLOW of

TROUBLE DIAGNOSES in EC and AT sections.

Three Way CatalystINFOID:0000000003852782

If a large amount of unburned fuel flows into the catalyst, the catalyst temperature will be excessively high. To

prevent this, follow the instructions.

Use unleaded gasoline only. Leaded gasoline will seriously damage the three way catalyst.

When checking for ignition spark or measuring engine compression, make tests quickly and only when nec-

essary.

Do not run engine when the fuel tank level is low, otherwise the engine may misfire, causing damage to the

catalyst.

Do not place the vehicle on flammable material. Keep flammable material off the exhaust pipe and the three

way catalyst.

Multiport Fuel Injection System or Engine Control SystemINFOID:0000000003852783

Before connecting or disconnecting any harness connector for the

multiport fuel injection system or ECM:

Turn ignition switch to “OFF” position.

Disconnect negative battery terminal.

Otherwise, there may be damage to ECM.

Before disconnecting pressurized fuel line from fuel pump to injec-

tors, be sure to release fuel pressure.

Be careful not to jar components such as ECM and mass air flow

sensor.

HosesINFOID:0000000003852784

HOSE REMOVAL AND INSTALLATION

To prevent damage to rubber hose, do not pry off rubber hose with

tapered tool or screwdriver.

To reinstall the rubber hose securely, make sure that hose insertion

length and orientation is correct. (If tube is equipped with hose

stopper, insert rubber hose into tube until it butts up against hose

stopper.)

HOSE CLAMPING

SGI787

SMA019D

SMA020D

Page 3855 of 5121

FRONT SEAT BELT

SB-3

< ON-VEHICLE REPAIR >

C

D

E

F

G

I

J

K

L

MA

B

SB

N

O

P

ON-VEHICLE REPAIR

FRONT SEAT BELT

SEAT BELT RETRACTOR

SEAT BELT RETRACTOR : InspectionINFOID:0000000003848852

AFTER A COLLISION

WARNING:

Inspect all seat belt assemblies including retractors and attached hardware after any collision.

NISSAN/INFINITI recommends that all seat belt assemblies in use during a collision be replaced

unless the collision is minor and the belts show no damage and continue to operate properly. Not

doing so could result in serious personal injury in an accident. Seat belt assemblies not in use during

a collision must also be replaced if either damage or improper operation is noted. Seat belt pre-ten-

sioners must be replaced even if the seat belts are not in use during a frontal collision in which the air

bags are deployed.

Replace any seat belt assembly (including anchor bolts) if:

The seat belt was in use at the time of a collision (except for minor collisions and the belts, retractors and

buckles show no damage and continue to operate properly).

The seat belt was damaged in an accident (i.e. torn webbing, bent retractor or guide, etc.).

The seat belt attaching point was damaged in an accident. Inspect the seat belt attaching area for damage

or distortion and repair as necessary before installing a new seat belt assembly.

Anchor bolts are deformed or worn out.

The seat belt pre-tensioners should be replaced even if the seat belts are not in use during the collision in

which the air bags are deployed.

PRELIMINARY CHECKS

1. Check the seat belt warning lamp/chime for proper operation as follows:

a. Turn ignition switch ON. The seat belt warning lamp should illuminate. Also, the seat belt warning chime

should sound for about six seconds.

b. Fasten driver seat belt. The seat belt warning lamp should turn off and the chime (if sounding) should

stop.

2. If the air bag warning lamp is blinking, conduct self-diagnosis with CONSULT-III and air bag warning lamp.

Refer to SRC-10, "

Diagnosis Description".

3. Check that the seat belt retractor, seat belt anchor and buckle bolts are securely attached.

4. Check the shoulder seat belt guide and shoulder belt height adjuster for front seats. Ensure guide swivels

freely and that webbing lays flat and does not bind in guide. Ensure height adjuster operates properly and

holds securely.

5. Check retractor operation:

a. Fully extend the seat belt webbing and check for twists, tears or other damage.

b. Allow the seat belt to retract. Ensure that webbing returns smoothly and completely into the retractor. If

the seat belt does not return smoothly, wipe the inside of the loops with a clean paper cloth. Because dirt

build-up in the loops of the upper anchors can cause the seat belts to retract slowly.

c. Fasten the seat belt. Check that seat belt returns smoothly and completely to the retractor. If the webbing

does not return smoothly, the cause may be an accumulation of dust or dirt. Use the “SEAT BELT TAPE

SET” and perform the following steps.

Inspect the front seat belt through-anchor

1. Pull the seat belt out to a length of 500 mm (19.69 in) or more.

2. Fix the seat belt at the center pillar webbing opening with a clip or other device.

3. Pass a thin wire through the through-anchor webbing opening. Hold both ends of the wire and pull it

tauntly while moving it up and down several times along the webbing opening surface to remove dirt

stuck there.

4. Any dirt that cannot be removed with the wire can be removed by cleaning the opening with a clean

cloth.

5. Apply tape at the point where the webbing contacts the through-anchor webbing opening.

NOTE:

Apply the tape so that there is no looseness or wrinkling.

Page 3856 of 5121

SB-4

< ON-VEHICLE REPAIR >

FRONT SEAT BELT

6. Remove the clip fixing the seat belt and check that the webbing returns smoothly.

6. Repeat steps above as necessary to check the other seat belts.

SEAT BELT RETRACTOR ON-VEHICLE CHECK

Emergency Locking Retractors (ELR) and Automatic Locking Retractors (ALR)

NOTE:

All seat belt retractors are Emergency Locking Retractors (ELR) type. In an emergency (sudden stop) the

retractor will lock and prevent the webbing from extending any further. All 3-point type seat belt retractors

except the driver seat belt also have an Automatic Locking Retractors (ALR) mode. The ALR mode (also

called child restraint mode) is used when installing child seats. The ALR mode is activated when the seat belt

is fully extended. When the webbing is then retracted partially, the ALR mode automatically locks the seat belt

in a specific position so the webbing cannot be extended any further. To cancel the ALR mode, allow the seat

belt to fully wind back into the retractor.

Check the seat belt retractors with the following test(s) to determine if a retractor assembly is operating prop-

erly.

ELR Function Stationary Check

Grasp the shoulder webbing and pull forward quickly. The retractor should lock and prevent the belt from

extending further.

ALR Function Stationary Check

1. Pull out the entire length of seat belt from retractor until a click is heard.

2. Retract the webbing partially. A clicking noise should be heard as the webbing retracts indicating that the

retractor is in the Automatic Locking Retractors (ALR) mode.

3. Grasp the seat belt and try to pull out the retractor. The webbing must lock and not extend any further. If

NG, replace the retractor assembly.

4. Allow the entire length of the webbing to retract to cancel the automatic locking mode.

ELR Function Moving Check

WARNING:

Perform the following test in a safe, open area clear of other vehicles and obstructions (for example, a

large, empty parking lot). Road surface must be paved and dry. Never perform the following test on

wet or gravel roads or on public streets and highways. This could result in an accident and serious

personal injury. The driver and passenger must be prepared to brace themselves in the event that the

retractor does not lock.

1. Fasten driver seat belt. Buckle a passenger into the seat for the belt that is to be tested.

2. Proceed to the designated safe area.

3. Drive the vehicle at approximately 16 km/h (10 MPH). Notify any passengers of a pending sudden stop

and the driver and passenger must be prepared to brace themselves in the event that the retractor does

not lock, apply brakes firmly and make a very hard stop.

During stopping, seat belts should lock and not be extended. If the seat belt retractor assembly does not lock,

perform the retractor off-vehicle check.

SEAT BELT RETRACTOR OFF-VEHICLE CHECK

1. Remove the seat belt retractor.

Remove the front seat belt assembly, refer to SB-5, "

SEAT BELT RETRACTOR : Removal and Installa-

tion".

2. Slowly pull out webbing while tilting the retractor assembly forward from the mounted position without

twisting the retractor assembly as shown in the illustration.

Page 3861 of 5121

REAR SEAT BELT

SB-9

< ON-VEHICLE REPAIR >

C

D

E

F

G

I

J

K

L

MA

B

SB

N

O

P

Grasp the shoulder webbing and pull forward quickly. The retractor should lock and prevent the belt from

extending further.

ALR Function Stationary Check

1. Pull out the entire length of seat belt from retractor until a click is heard.

2. Retract the webbing partially. A clicking noise should be heard as the webbing retracts indicating that the

retractor is in the Automatic Locking Retractors (ALR) mode.

3. Grasp the seat belt and try to pull out the retractor. The webbing must lock and not extend any further. If

NG, replace the retractor assembly.

4. Allow the entire length of the webbing to retract to cancel the automatic locking mode.

ELR Function Moving Check

WARNING:

Perform the following test in a safe, open area clear of other vehicles and obstructions (for example, a

large, empty parking lot). Road surface must be paved and dry. NEVER perform the following test on

wet or gravel roads or on public streets and highways. This could result in an accident and serious

personal injury. The driver and passenger must be prepared to brace themselves in the event that the

retractor does not lock.

1. Fasten driver seat belt. Buckle a passenger into the seat for the belt that is to be tested.

2. Proceed to the designated safe area.

3. Drive the vehicle at approximately 16 km/h (10 MPH). Notify any passengers of a pending sudden stop

and the driver and passenger must be prepared to brace themselves in the event that the retractor does

not lock, apply brakes firmly and make a very hard stop.

During stopping, seat belts should lock and not be extended. If the seat belt retractor assembly does not lock,

perform the retractor off-vehicle check.

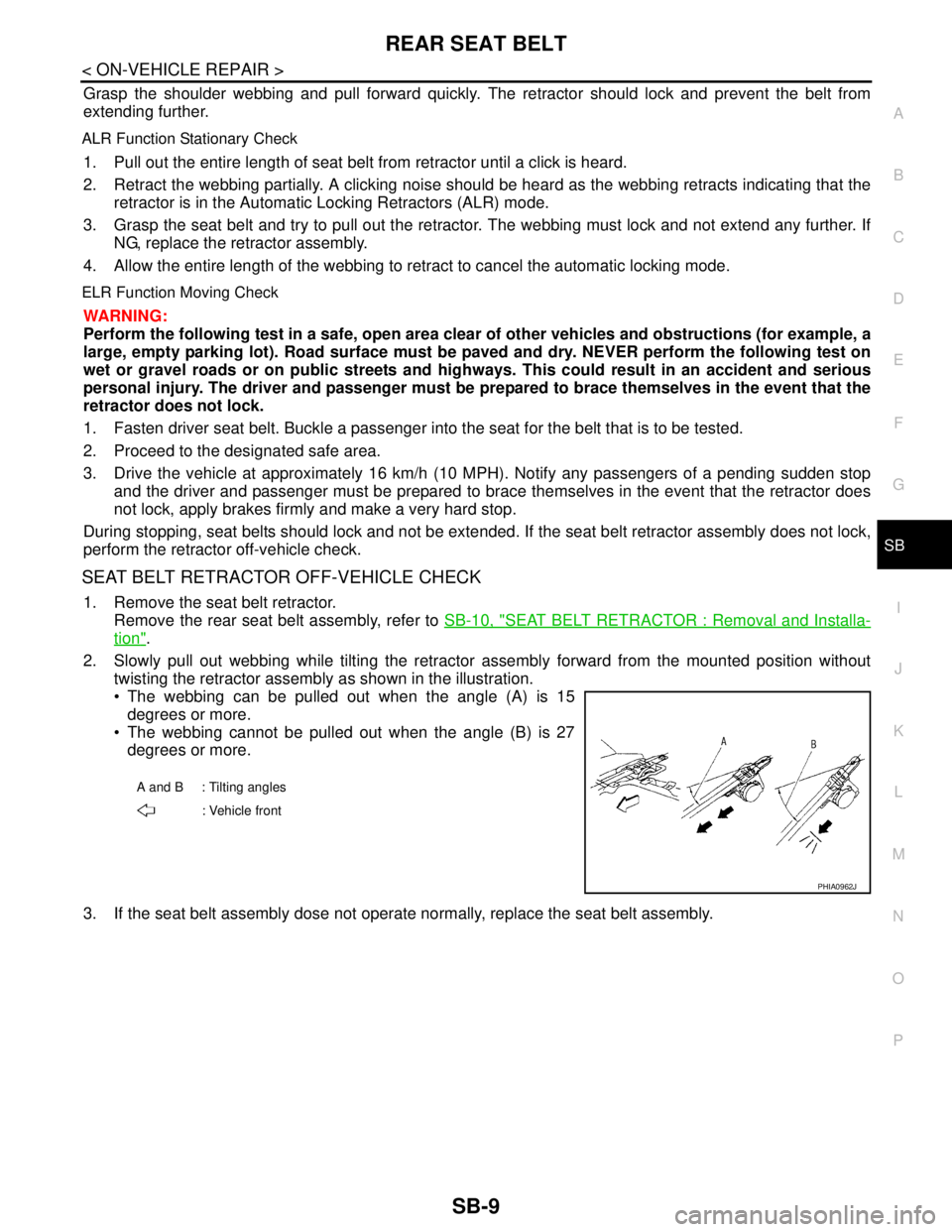

SEAT BELT RETRACTOR OFF-VEHICLE CHECK

1. Remove the seat belt retractor.

Remove the rear seat belt assembly, refer to SB-10, "

SEAT BELT RETRACTOR : Removal and Installa-

tion".

2. Slowly pull out webbing while tilting the retractor assembly forward from the mounted position without

twisting the retractor assembly as shown in the illustration.

The webbing can be pulled out when the angle (A) is 15

degrees or more.

The webbing cannot be pulled out when the angle (B) is 27

degrees or more.

3. If the seat belt assembly dose not operate normally, replace the seat belt assembly.

A and B : Tilting angles

: Vehicle front

PHIA0962J

Page 4391 of 5121

ST-1

STEERING

C

DE

F

H I

J

K L

M

SECTION ST

A

B

ST

N

O P

CONTENTS

STEERING SYSTEM

SYMPTOM DIAGNOSIS ..... ..........................2

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ........................ .....

2

NVH Troubleshooting Chart ................................ ......2

PRECAUTION ...............................................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary for Steering Wheel Rota-

tion after Battery Disconnect .....................................

3

Service Notice or Precautions for Steering System

......

3

PREPARATION ............................................5

PREPARATION .............................................. .....5

Special Service Tools .......................................... ......5

ON-VEHICLE MAINTENANCE .....................7

POWER STEERING FLUID ........................... .....7

Inspection ............................................................ ......7

STEERING WHEEL .............................................9

Inspection ............................................................ ......9

ON-VEHICLE REPAIR .................................12

STEERING WHEEL ........................................ ....12

Exploded View .................................................... ....12

Removal and Installation .........................................12

STEERING COLUMN .........................................13

Exploded View .................................................... ....13

Removal and Installation .........................................13

Inspection ................................................................14

LOWER SHAFT ................................................16

Exploded View ..................................................... ....16

Removal and Installation .........................................16

Inspection ................................................................17

STEERING GEAR AND LINKAGE ...................18

Exploded View .........................................................18

Removal and Installation .........................................19

Disassembly and Assembly .....................................20

Inspection ................................................................26

POWER STEERING OIL PUMP .......................28

Exploded View .........................................................28

Removal and Installation .........................................29

Disassembly and Assembly .....................................29

Inspection ................................................................32

HYDRAULIC LINE ............................................34

Exploded View .........................................................34

Removal and Installation .........................................35

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .............................................

37

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

37

General Specifications ......................................... ....37

Steering Wheel Axial End Play and Play .................37

Steering Wheel Turning Force .................................37

Steering Angle .........................................................37

Steering Column Length ..........................................37

Steering Column Mounting Dimensions ..................37

Steering Column Operating Range .........................37

Lower Shaft Sliding Range ......................................38

Rack Sliding Force ..................................................38

Rack Stroke .............................................................38

Socket Swing Force and Rotating Torque ...............38

Socket Axial End Play .............................................38

Inner Socket Length ................................................38

Relief Oil Pressure ...................................................38