length NISSAN TEANA 2008 Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 4473 of 5121

STR-26

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

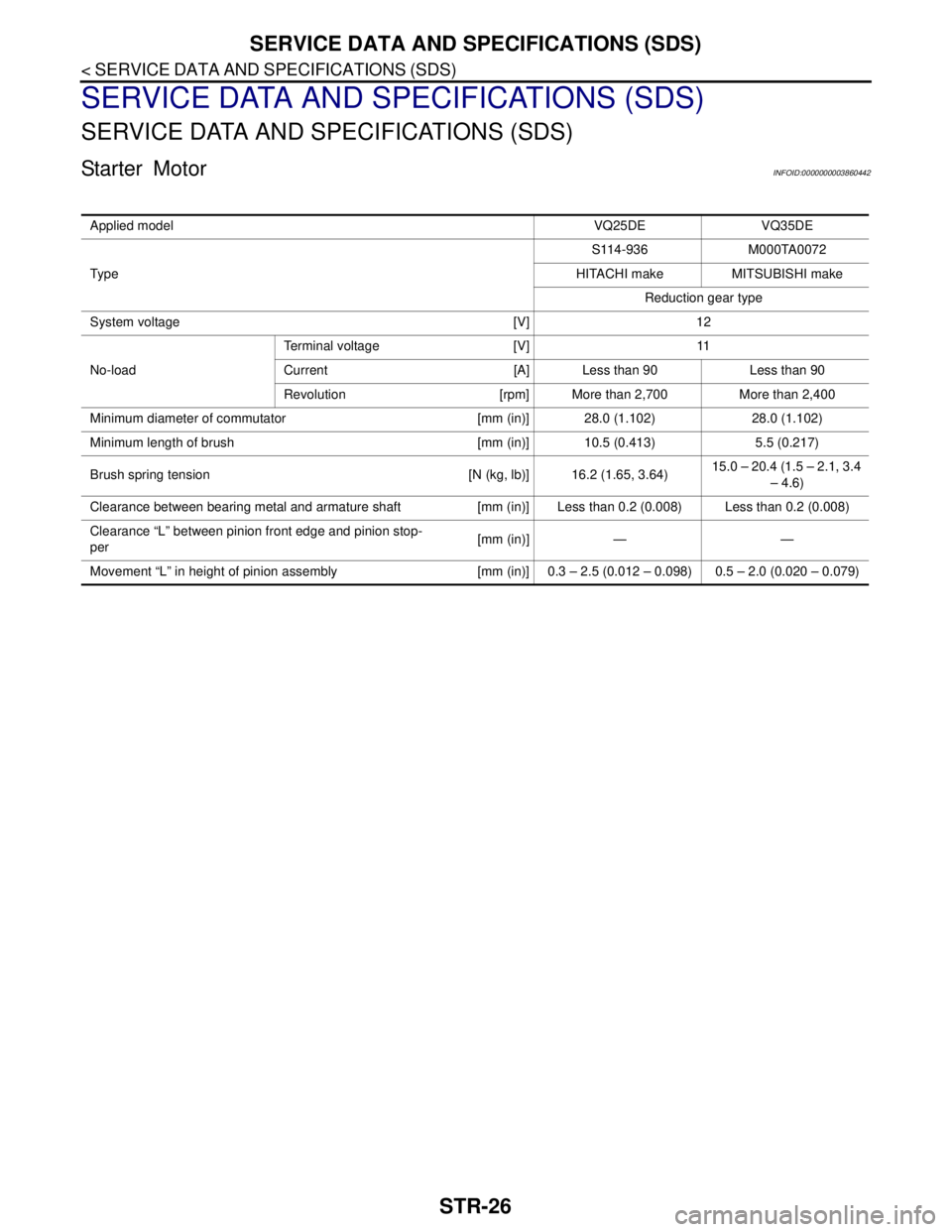

Starter MotorINFOID:0000000003860442

Applied model VQ25DE VQ35DE

Typ eS114-936 M000TA0072

HITACHI make MITSUBISHI make

Reduction gear type

System voltage [V] 12

No-loadTerminal voltage [V] 11

Current [A] Less than 90 Less than 90

Revolution [rpm] More than 2,700 More than 2,400

Minimum diameter of commutator [mm (in)] 28.0 (1.102) 28.0 (1.102)

Minimum length of brush [mm (in)] 10.5 (0.413) 5.5 (0.217)

Brush spring tension [N (kg, lb)] 16.2 (1.65, 3.64)15.0 – 20.4 (1.5 – 2.1, 3.4

– 4.6)

Clearance between bearing metal and armature shaft [mm (in)] Less than 0.2 (0.008) Less than 0.2 (0.008)

Clearance “L” between pinion front edge and pinion stop-

per[mm (in)] — —

Movement “L” in height of pinion assembly [mm (in)] 0.3 – 2.5 (0.012 – 0.098) 0.5 – 2.0 (0.020 – 0.079)

Page 4642 of 5121

![NISSAN TEANA 2008 Workshop Manual TRANSAXLE ASSEMBLY

TM-169

< REMOVAL AND INSTALLATION >[CVT: RE0F09B]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

3. Remove air breather hose. Refer to TM-164, "Exploded View".

4. Disconnect secondary speed sensor NISSAN TEANA 2008 Workshop Manual TRANSAXLE ASSEMBLY

TM-169

< REMOVAL AND INSTALLATION >[CVT: RE0F09B]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

3. Remove air breather hose. Refer to TM-164, "Exploded View".

4. Disconnect secondary speed sensor](/img/5/57391/w960_57391-4641.png)

TRANSAXLE ASSEMBLY

TM-169

< REMOVAL AND INSTALLATION >[CVT: RE0F09B]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

3. Remove air breather hose. Refer to TM-164, "Exploded View".

4. Disconnect secondary speed sensor connector. Refer to TM-161, "

Exploded View".

5. Disconnect CVT unit connector.

6. Disconnect air fuel ratio sensor 1 (bank 2). Refer to EM-34, "

Exploded View".

7. Remove crankshaft position sensor (POS). Refer to EM-38, "

Exploded View".

8. Remove CVT fluid charging pipe from transaxle assembly.

9. Remove transaxle assembly fixing bolts with power tool.

10. Remove transaxle assembly from engine assembly with a hoist.

11. Remove fluid cooler hose from transaxle assembly.

INSTALLATION

Note the following, and install in the reverse order of removal.

CAUTION:

Check fitting of dowel pins ( ) when installing transaxle

assembly to engine assembly.

When installing transaxle assembly to the engine assembly, attach

the fixing bolts in accordance with the following.

JPDIA0598ZZ

JPDIA0602ZZ

JPDIA0600ZZ

Insertion direction Transaxle assembly to engine assemblyEngine assembly to tran-

saxle assembly

Bolt position A B C D

Number of bolts 1 2 2 4

Bolt length mm (in) 55 (2.17) 39 (1.54) 108 (4.25) 40 (1.57)

Tightening torque

N·m (kg-m, ft-lb)74.5 (7.6, 55) 50 (4.3, 31)

Page 4807 of 5121

![NISSAN TEANA 2008 Workshop Manual TM-334

< REMOVAL AND INSTALLATION >[CVT: RE0F10A]

TRANSAXLE ASSEMBLY

Align the position of tightening bolts ( ) for drive plate with those

of the torque converter, and temporarily tighten the bolts. NISSAN TEANA 2008 Workshop Manual TM-334

< REMOVAL AND INSTALLATION >[CVT: RE0F10A]

TRANSAXLE ASSEMBLY

Align the position of tightening bolts ( ) for drive plate with those

of the torque converter, and temporarily tighten the bolts.](/img/5/57391/w960_57391-4806.png)

TM-334

< REMOVAL AND INSTALLATION >[CVT: RE0F10A]

TRANSAXLE ASSEMBLY

Align the position of tightening bolts ( ) for drive plate with those

of the torque converter, and temporarily tighten the bolts. Then,

tighten the bolts to the specified torque.

CAUTION:

When turning crankshaft, turn it clockwise as viewed from the

front of the engine.

When tightening the tightening bolts for the torque converter

after fixing the crankshaft pulley bolts, confirm the tightening

torque of the crankshaft pulley mounting bolts. Refer to EM-

53, "Removal and Installation".

After converter is installed to drive plate, rotate crankshaft

several turns and check that transaxle rotates freely without

binding.

InspectionINFOID:0000000003806553

INSPECTION BE FORE INSTALLATION

After inserting a torque converter to the CVT, check that distance

(A) within the reference value limit.

INSPECTION AFTER INSTALLATION

After completing installation, check the following item.

- CVT fluid leakage and CVT fluid level. Refer to TM-304, "

Inspection".

- CVT position. Refer to TM-314, "

Inspection and Adjustment".

Insertion direction Transaxle assembly to engine assembly Engine assembly to transaxle assembly

Bolt position A B C D

Number of bolts 2 1 1 4

Bolt length mm (in) 55 (2.17) 35 (1.38) 55 (2.17) 40 (1.57)

Tightening torque N·m (kg-m, ft-lb) 75 (7.7, 55) 50 (5.1, 37)

SCIA1861E

B: Scale

C : Straightedge

Distance A : Refer to TM-338, "Torque Converter".

JPDIA0740ZZ