length NISSAN TEANA 2008 Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 4405 of 5121

STEERING COLUMN

ST-15

< ON-VEHICLE REPAIR >

C

D

E

F

H

I

J

K

L

MA

B

ST

N

O

P

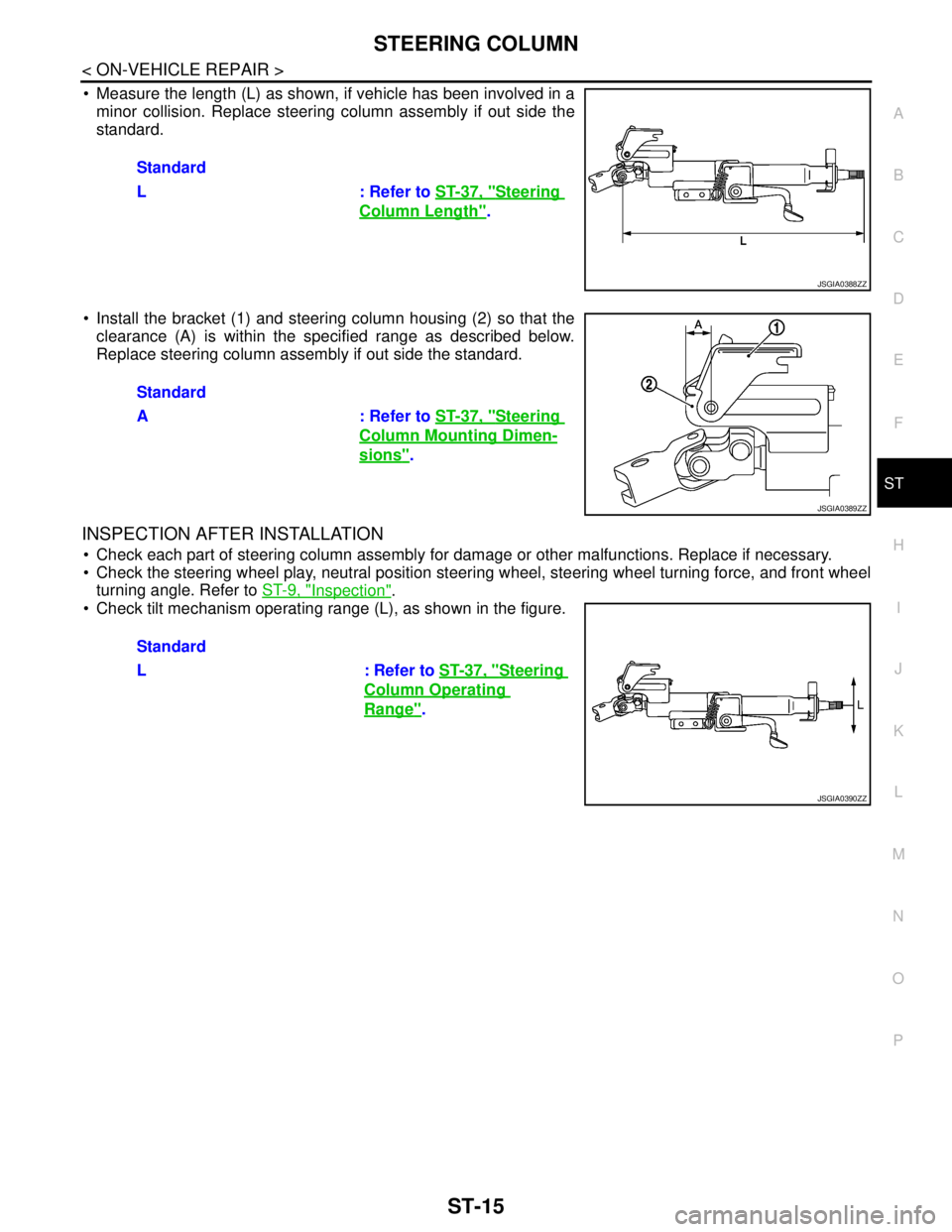

Measure the length (L) as shown, if vehicle has been involved in a

minor collision. Replace steering column assembly if out side the

standard.

Install the bracket (1) and steering column housing (2) so that the

clearance (A) is within the specified range as described below.

Replace steering column assembly if out side the standard.

INSPECTION AFTER INSTALLATION

Check each part of steering column assembly for damage or other malfunctions. Replace if necessary.

Check the steering wheel play, neutral position steering wheel, steering wheel turning force, and front wheel

turning angle. Refer to ST-9, "

Inspection".

Check tilt mechanism operating range (L), as shown in the figure.Standard

L : Refer to ST-37, "

Steering

Column Length".

JSGIA0388ZZ

Standard

A : Refer to ST-37, "

Steering

Column Mounting Dimen-

sions".

JSGIA0389ZZ

Standard

L : Refer to ST-37, "

Steering

Column Operating

Range".

JSGIA0390ZZ

Page 4407 of 5121

LOWER SHAFT

ST-17

< ON-VEHICLE REPAIR >

C

D

E

F

H

I

J

K

L

MA

B

ST

N

O

P

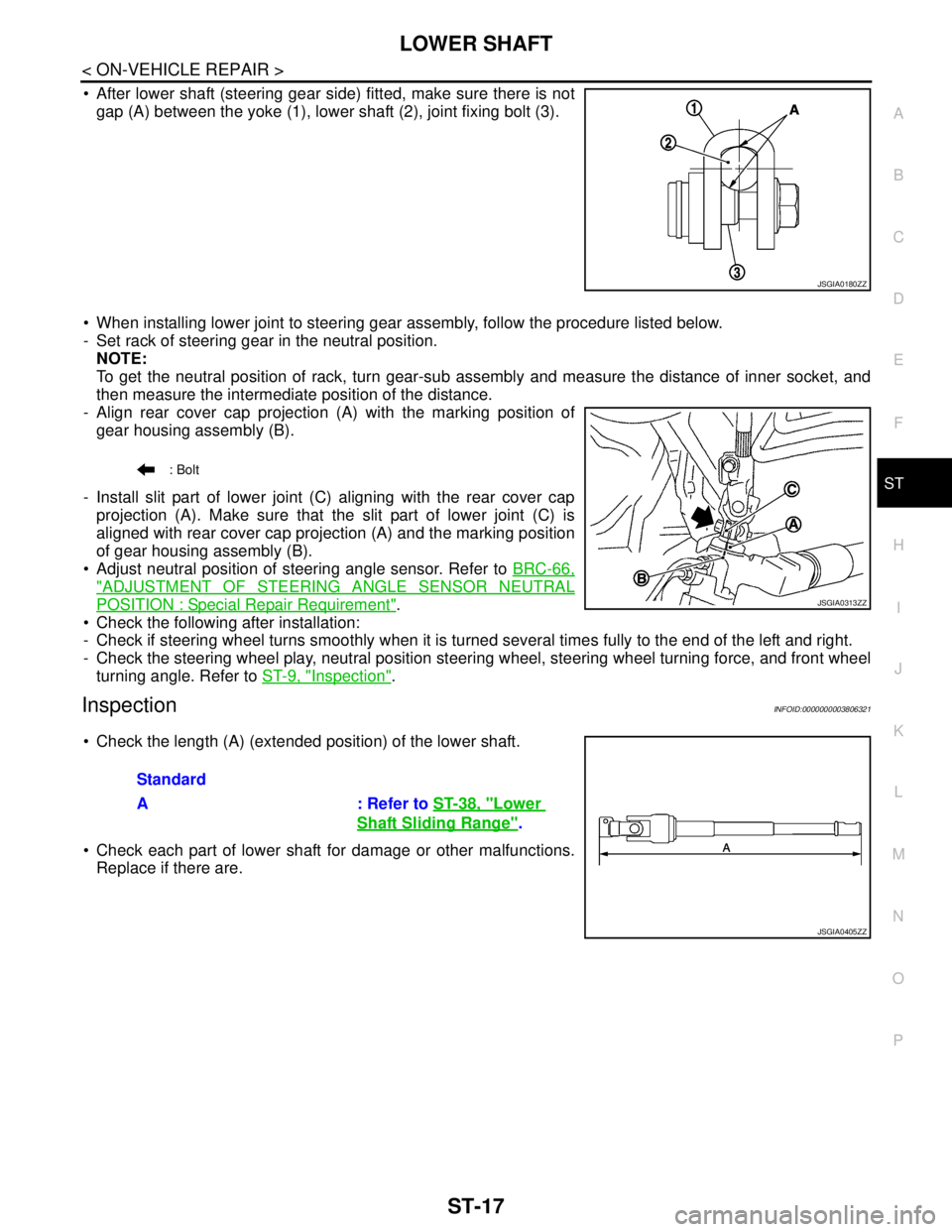

After lower shaft (steering gear side) fitted, make sure there is not

gap (A) between the yoke (1), lower shaft (2), joint fixing bolt (3).

When installing lower joint to steering gear assembly, follow the procedure listed below.

- Set rack of steering gear in the neutral position.

NOTE:

To get the neutral position of rack, turn gear-sub assembly and measure the distance of inner socket, and

then measure the intermediate position of the distance.

- Align rear cover cap projection (A) with the marking position of

gear housing assembly (B).

- Install slit part of lower joint (C) aligning with the rear cover cap

projection (A). Make sure that the slit part of lower joint (C) is

aligned with rear cover cap projection (A) and the marking position

of gear housing assembly (B).

Adjust neutral position of steering angle sensor. Refer to BRC-66,

"ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL

POSITION : Special Repair Requirement".

Check the following after installation:

- Check if steering wheel turns smoothly when it is turned several times fully to the end of the left and right.

- Check the steering wheel play, neutral position steering wheel, steering wheel turning force, and front wheel

turning angle. Refer to ST-9, "

Inspection".

InspectionINFOID:0000000003806321

Check the length (A) (extended position) of the lower shaft.

Check each part of lower shaft for damage or other malfunctions.

Replace if there are.

JSGIA0180ZZ

: Bolt

JSGIA0313ZZ

Standard

A : Refer to ST-38, "

Lower

Shaft Sliding Range".

JSGIA0405ZZ

Page 4415 of 5121

STEERING GEAR AND LINKAGE

ST-25

< ON-VEHICLE REPAIR >

C

D

E

F

H

I

J

K

L

MA

B

ST

N

O

P

15. Install large end of boot to gear housing assembly.

16. Install small end of boot to inner socket boot mounting groove.

17. Install boot clamp to boot small end.

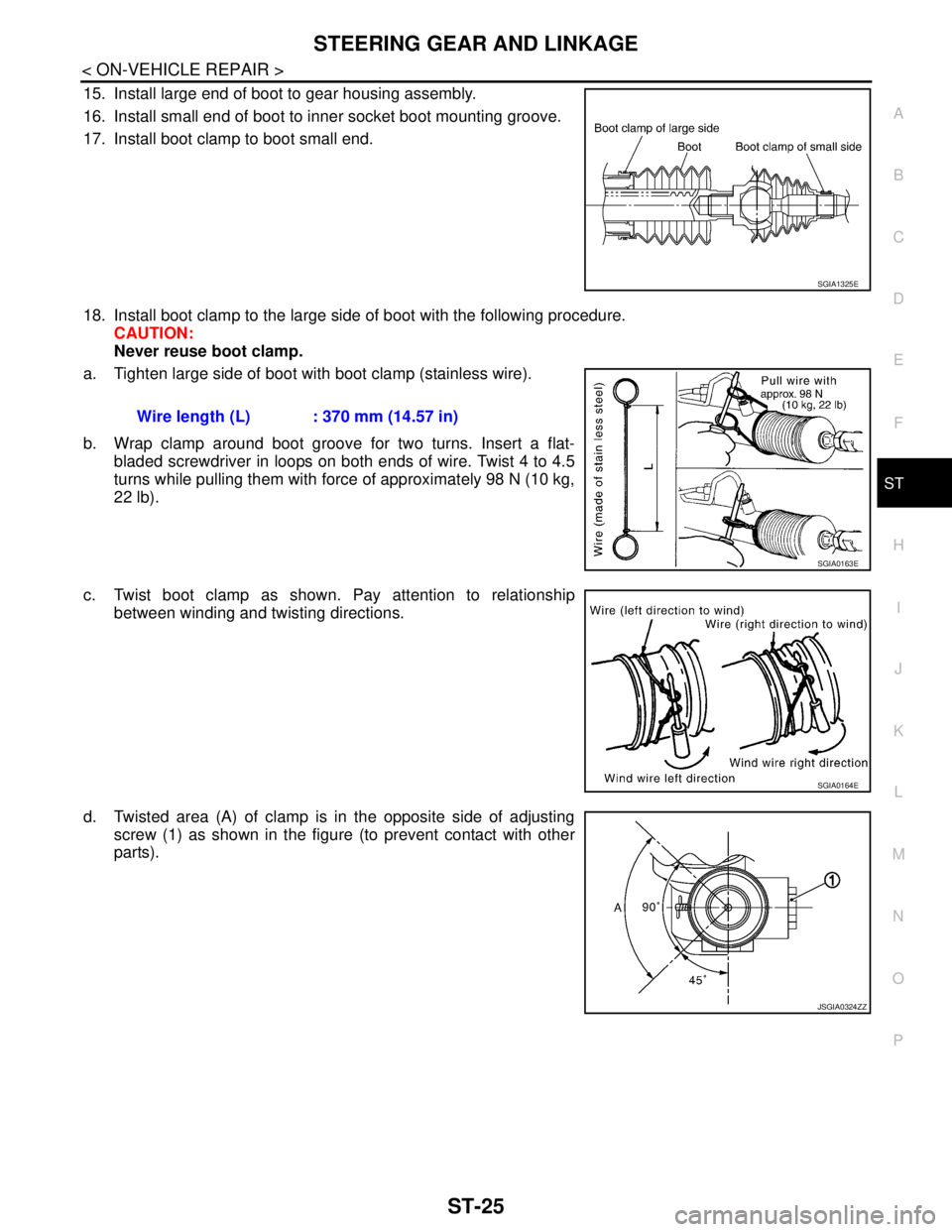

18. Install boot clamp to the large side of boot with the following procedure.

CAUTION:

Never reuse boot clamp.

a. Tighten large side of boot with boot clamp (stainless wire).

b. Wrap clamp around boot groove for two turns. Insert a flat-

bladed screwdriver in loops on both ends of wire. Twist 4 to 4.5

turns while pulling them with force of approximately 98 N (10 kg,

22 lb).

c. Twist boot clamp as shown. Pay attention to relationship

between winding and twisting directions.

d. Twisted area (A) of clamp is in the opposite side of adjusting

screw (1) as shown in the figure (to prevent contact with other

parts).

SGIA1325E

Wire length (L) : 370 mm (14.57 in)

SGIA0163E

SGIA0164E

JSGIA0324ZZ

Page 4416 of 5121

ST-26

< ON-VEHICLE REPAIR >

STEERING GEAR AND LINKAGE

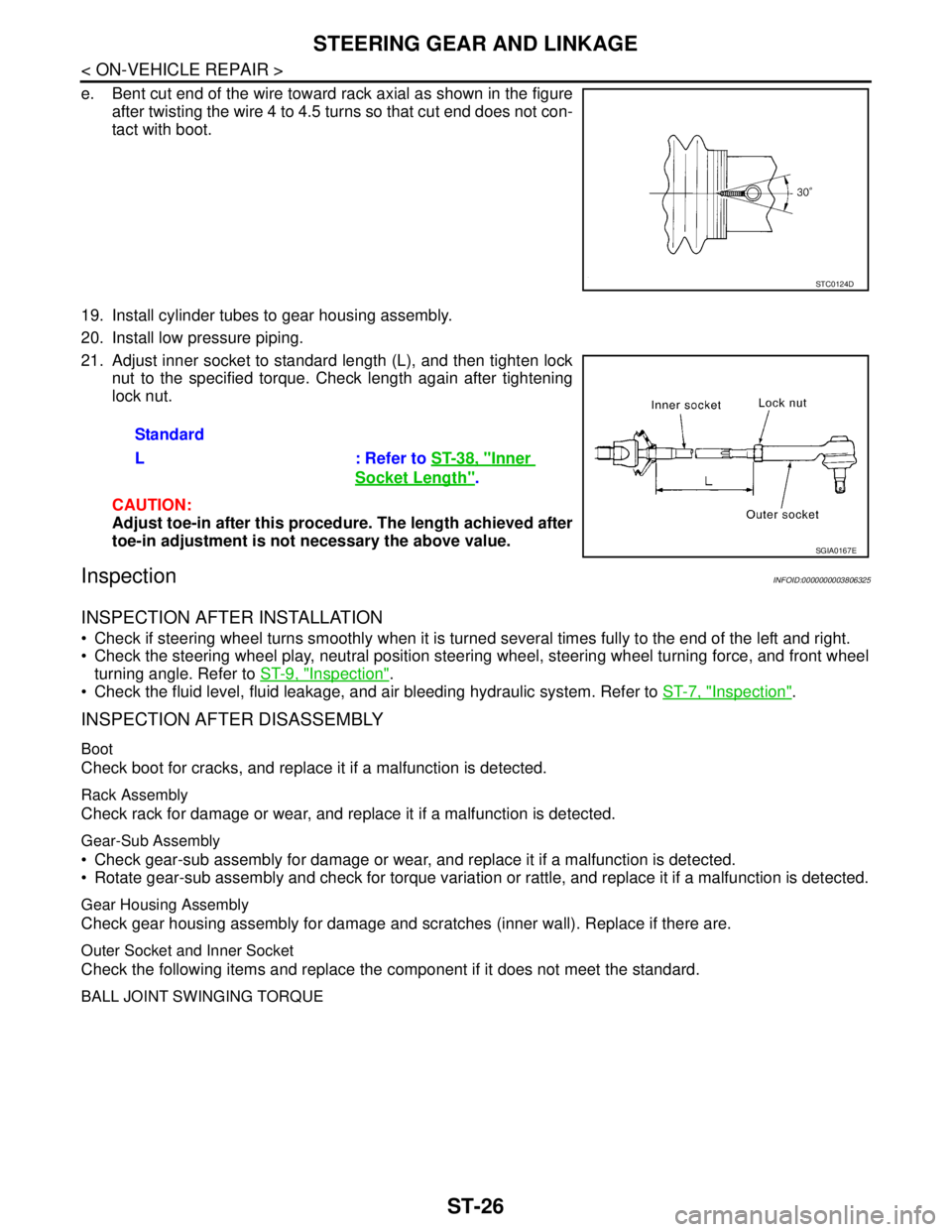

e. Bent cut end of the wire toward rack axial as shown in the figure

after twisting the wire 4 to 4.5 turns so that cut end does not con-

tact with boot.

19. Install cylinder tubes to gear housing assembly.

20. Install low pressure piping.

21. Adjust inner socket to standard length (L), and then tighten lock

nut to the specified torque. Check length again after tightening

lock nut.

CAUTION:

Adjust toe-in after this procedure. The length achieved after

toe-in adjustment is not necessary the above value.

InspectionINFOID:0000000003806325

INSPECTION AFTER INSTALLATION

Check if steering wheel turns smoothly when it is turned several times fully to the end of the left and right.

Check the steering wheel play, neutral position steering wheel, steering wheel turning force, and front wheel

turning angle. Refer to ST-9, "

Inspection".

Check the fluid level, fluid leakage, and air bleeding hydraulic system. Refer to ST-7, "

Inspection".

INSPECTION AFTER DISASSEMBLY

Boot

Check boot for cracks, and replace it if a malfunction is detected.

Rack Assembly

Check rack for damage or wear, and replace it if a malfunction is detected.

Gear-Sub Assembly

Check gear-sub assembly for damage or wear, and replace it if a malfunction is detected.

Rotate gear-sub assembly and check for torque variation or rattle, and replace it if a malfunction is detected.

Gear Housing Assembly

Check gear housing assembly for damage and scratches (inner wall). Replace if there are.

Outer Socket and Inner Socket

Check the following items and replace the component if it does not meet the standard.

BALL JOINT SWINGING TORQUE

STC0124D

Standard

L : Refer to ST-38, "

Inner

Socket Length".

SGIA0167E

Page 4427 of 5121

SERVICE DATA AND SPECIFICATIONS (SDS)

ST-37

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

D

E

F

H

I

J

K

L

MA

B

ST

N

O

P

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

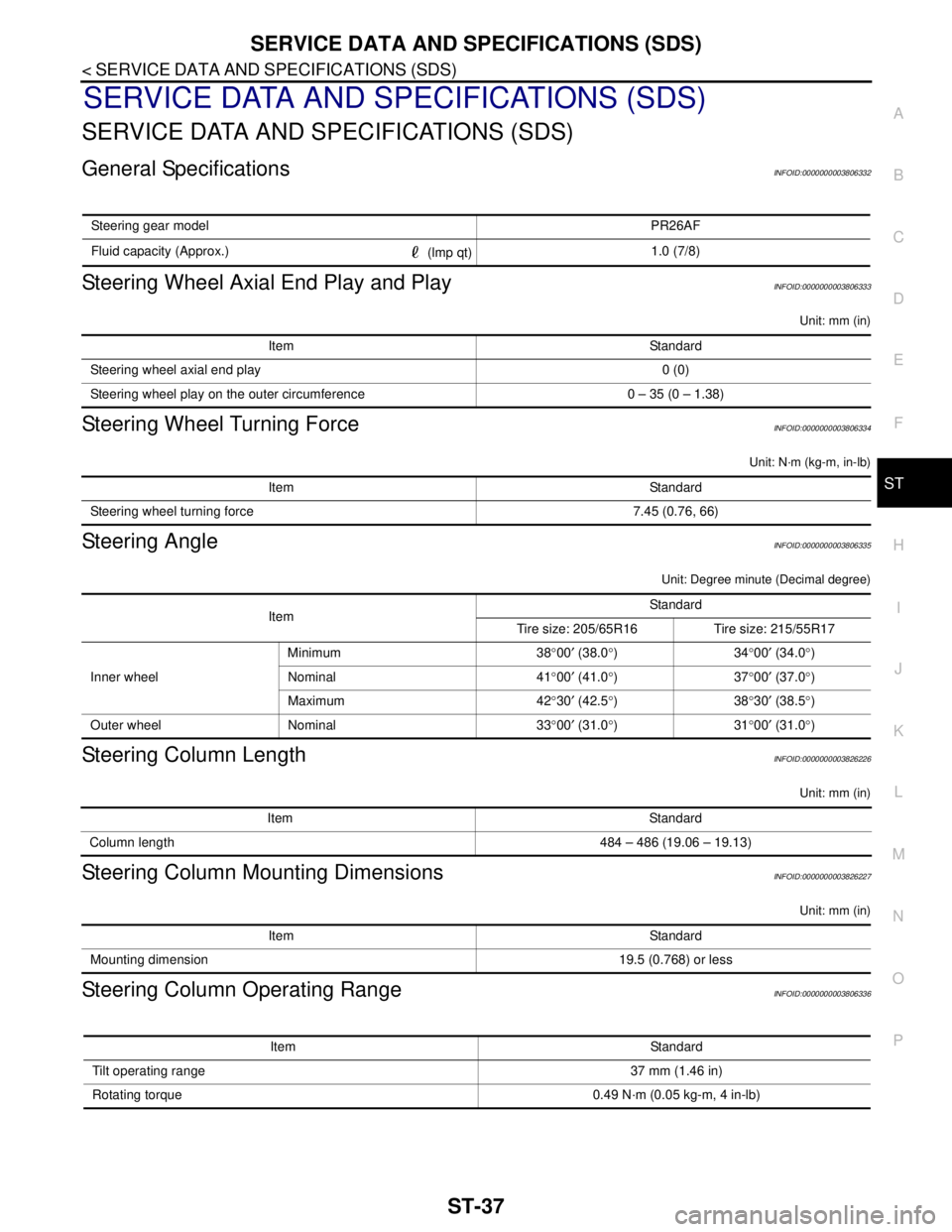

General SpecificationsINFOID:0000000003806332

Steering Wheel Axial End Play and PlayINFOID:0000000003806333

Unit: mm (in)

Steering Wheel Turning ForceINFOID:0000000003806334

Unit: N·m (kg-m, in-lb)

Steering AngleINFOID:0000000003806335

Unit: Degree minute (Decimal degree)

Steering Column LengthINFOID:0000000003826226

Unit: mm (in)

Steering Column Mounting DimensionsINFOID:0000000003826227

Unit: mm (in)

Steering Column Operating RangeINFOID:0000000003806336

Steering gear modelPR26AF

Fluid capacity (Approx.)

(lmp qt)1.0 (7/8)

Item Standard

Steering wheel axial end play 0 (0)

Steering wheel play on the outer circumference 0 – 35 (0 – 1.38)

Item Standard

Steering wheel turning force 7.45 (0.76, 66)

ItemStandard

Tire size: 205/65R16 Tire size: 215/55R17

Inner wheelMinimum 38°00′ (38.0°)34°00′ (34.0°)

Nominal 41°00′ (41.0°)37°00′ (37.0°)

Maximum 42°30′ (42.5°)38°30′ (38.5°)

Outer wheel Nominal 33°00′ (31.0°)31°00′ (31.0°)

Item Standard

Column length484 – 486 (19.06 – 19.13)

Item Standard

Mounting dimension 19.5 (0.768) or less

Item Standard

Tilt operating range 37 mm (1.46 in)

Rotating torque 0.49 N·m (0.05 kg-m, 4 in-lb)

Page 4428 of 5121

ST-38

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

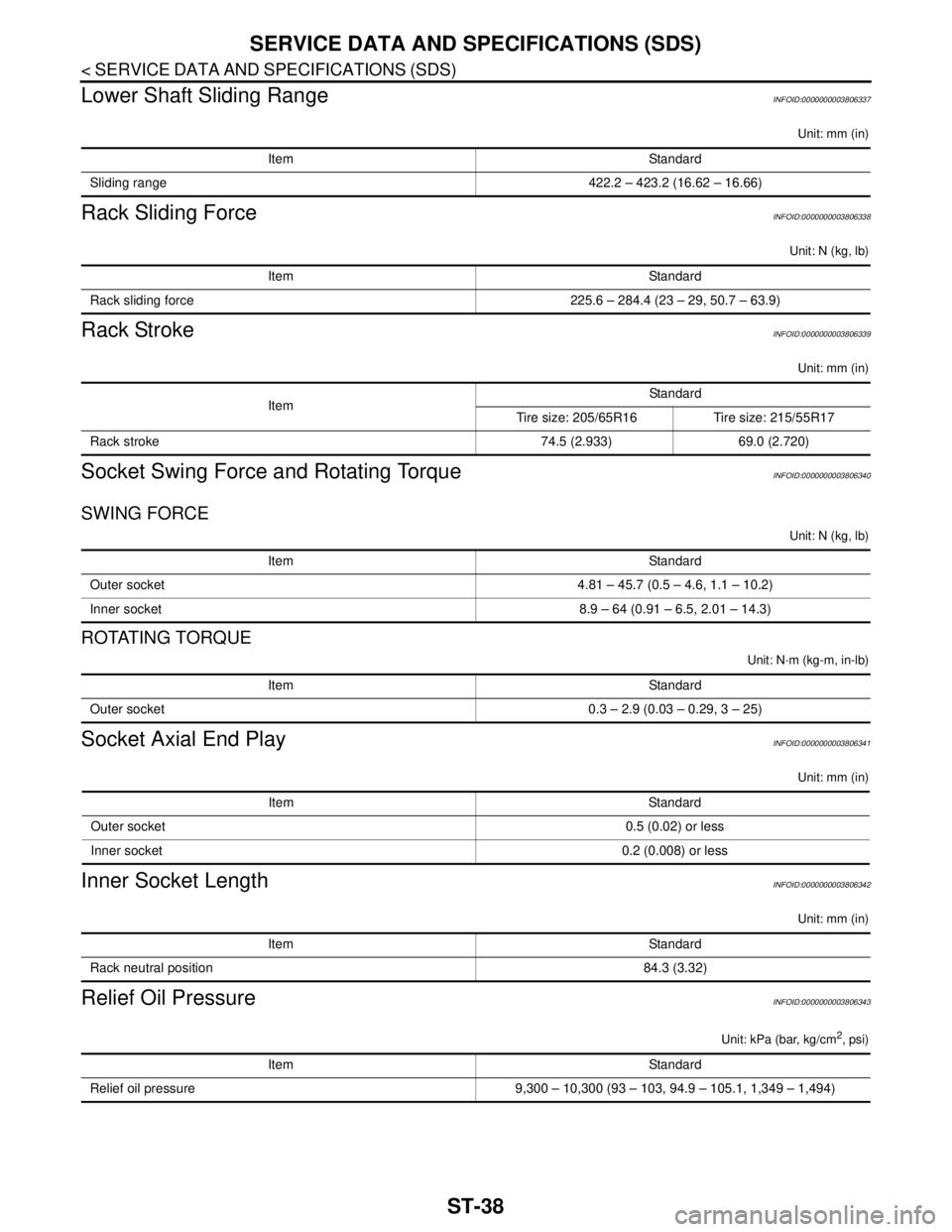

Lower Shaft Sliding Range

INFOID:0000000003806337

Unit: mm (in)

Rack Sliding ForceINFOID:0000000003806338

Unit: N (kg, lb)

Rack StrokeINFOID:0000000003806339

Unit: mm (in)

Socket Swing Force and Rotating TorqueINFOID:0000000003806340

SWING FORCE

Unit: N (kg, lb)

ROTATING TORQUE

Unit: N·m (kg-m, in-lb)

Socket Axial End PlayINFOID:0000000003806341

Unit: mm (in)

Inner Socket LengthINFOID:0000000003806342

Unit: mm (in)

Relief Oil PressureINFOID:0000000003806343

Unit: kPa (bar, kg/cm2, psi)

Item Standard

Sliding range422.2 – 423.2 (16.62 – 16.66)

Item Standard

Rack sliding force 225.6 – 284.4 (23 – 29, 50.7 – 63.9)

ItemStandard

Tire size: 205/65R16 Tire size: 215/55R17

Rack stroke 74.5 (2.933) 69.0 (2.720)

Item Standard

Outer socket 4.81 – 45.7 (0.5 – 4.6, 1.1 – 10.2)

Inner socket 8.9 – 64 (0.91 – 6.5, 2.01 – 14.3)

Item Standard

Outer socket 0.3 – 2.9 (0.03 – 0.29, 3 – 25)

Item Standard

Outer socket0.5 (0.02) or less

Inner socket0.2 (0.008) or less

Item Standard

Rack neutral position84.3 (3.32)

Item Standard

Relief oil pressure 9,300 – 10,300 (93 – 103, 94.9 – 105.1, 1,349 – 1,494)

Page 4464 of 5121

STARTER MOTOR

STR-17

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

L

MA

STR

N

P O

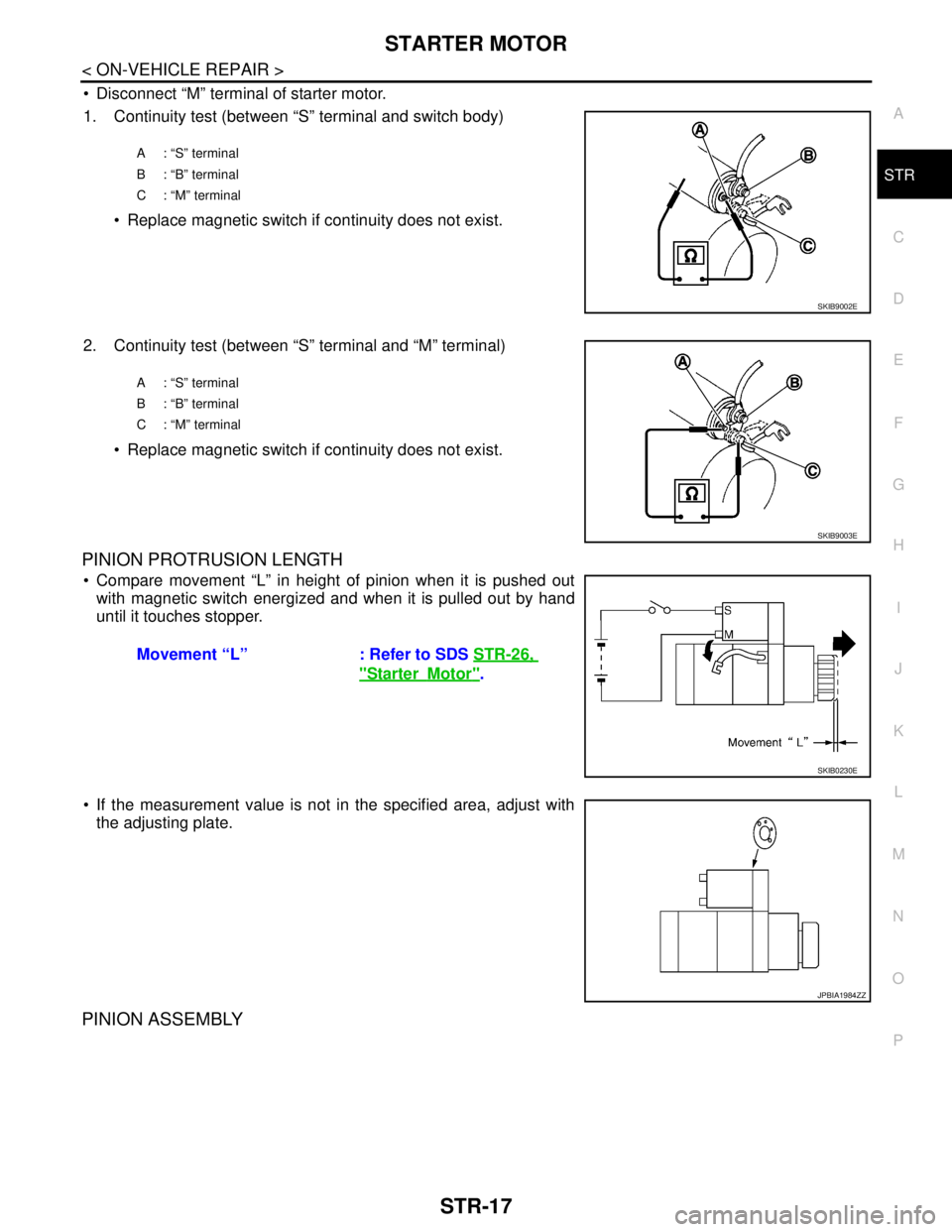

Disconnect “M” terminal of starter motor.

1. Continuity test (between “S” terminal and switch body)

Replace magnetic switch if continuity does not exist.

2. Continuity test (between “S” terminal and “M” terminal)

Replace magnetic switch if continuity does not exist.

PINION PROTRUSION LENGTH

Compare movement “L” in height of pinion when it is pushed out

with magnetic switch energized and when it is pulled out by hand

until it touches stopper.

If the measurement value is not in the specified area, adjust with

the adjusting plate.

PINION ASSEMBLY

A : “S” terminal

B : “B” terminal

C : “M” terminal

SKIB9002E

A : “S” terminal

B : “B” terminal

C : “M” terminal

SKIB9003E

Movement “L” : Refer to SDS STR-26,

"StarterMotor".

SKIB0230E

JPBIA1984ZZ

Page 4465 of 5121

STR-18

< ON-VEHICLE REPAIR >

STARTER MOTOR

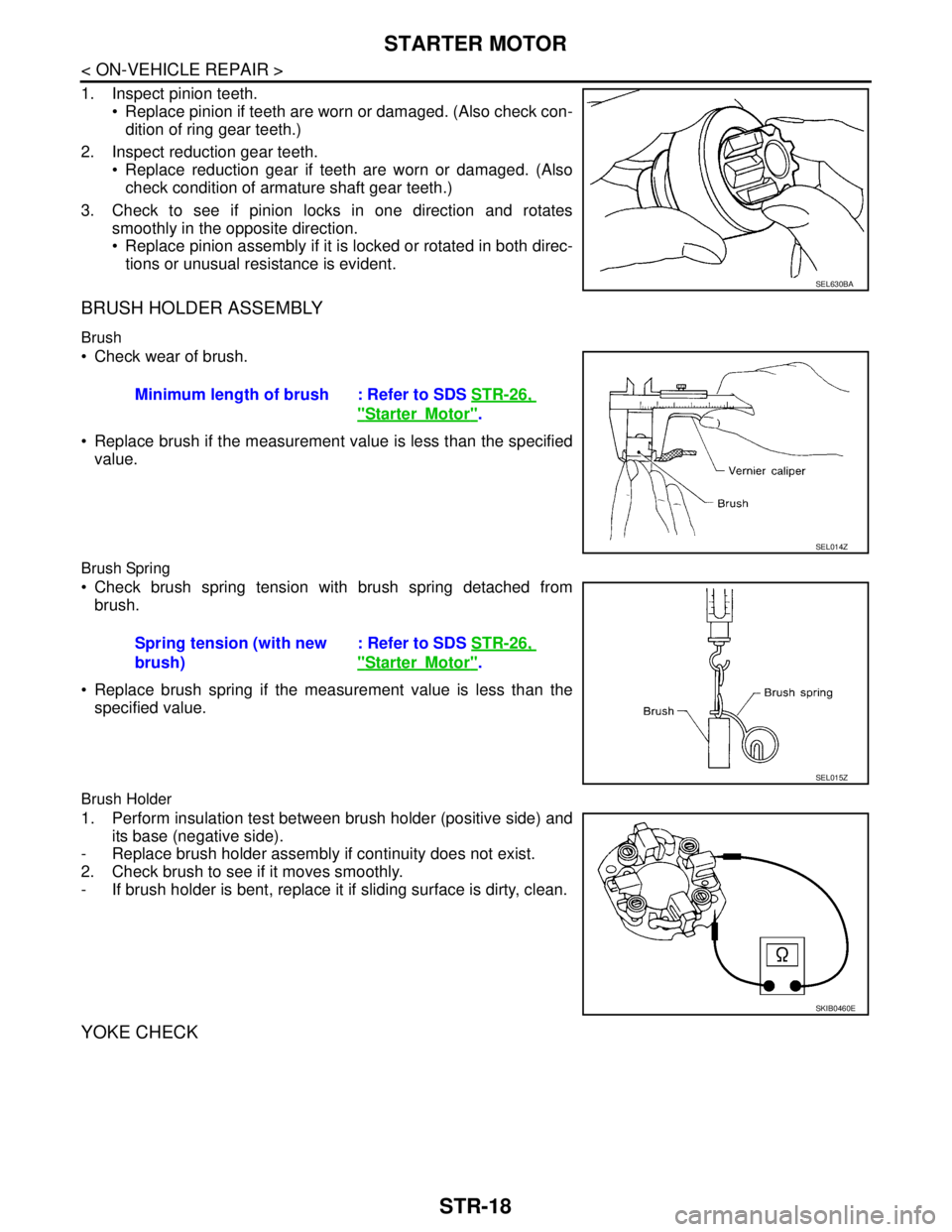

1. Inspect pinion teeth.

Replace pinion if teeth are worn or damaged. (Also check con-

dition of ring gear teeth.)

2. Inspect reduction gear teeth.

Replace reduction gear if teeth are worn or damaged. (Also

check condition of armature shaft gear teeth.)

3. Check to see if pinion locks in one direction and rotates

smoothly in the opposite direction.

Replace pinion assembly if it is locked or rotated in both direc-

tions or unusual resistance is evident.

BRUSH HOLDER ASSEMBLY

Brush

Check wear of brush.

Replace brush if the measurement value is less than the specified

value.

Brush Spring

Check brush spring tension with brush spring detached from

brush.

Replace brush spring if the measurement value is less than the

specified value.

Brush Holder

1. Perform insulation test between brush holder (positive side) and

its base (negative side).

- Replace brush holder assembly if continuity does not exist.

2. Check brush to see if it moves smoothly.

- If brush holder is bent, replace it if sliding surface is dirty, clean.

YOKE CHECK

SEL630BA

Minimum length of brush : Refer to SDS STR-26,

"StarterMotor".

SEL014Z

Spring tension (with new

brush): Refer to SDS STR-26,

"StarterMotor".

SEL015Z

SKIB0460E

Page 4469 of 5121

STR-22

< ON-VEHICLE REPAIR >

STARTER MOTOR

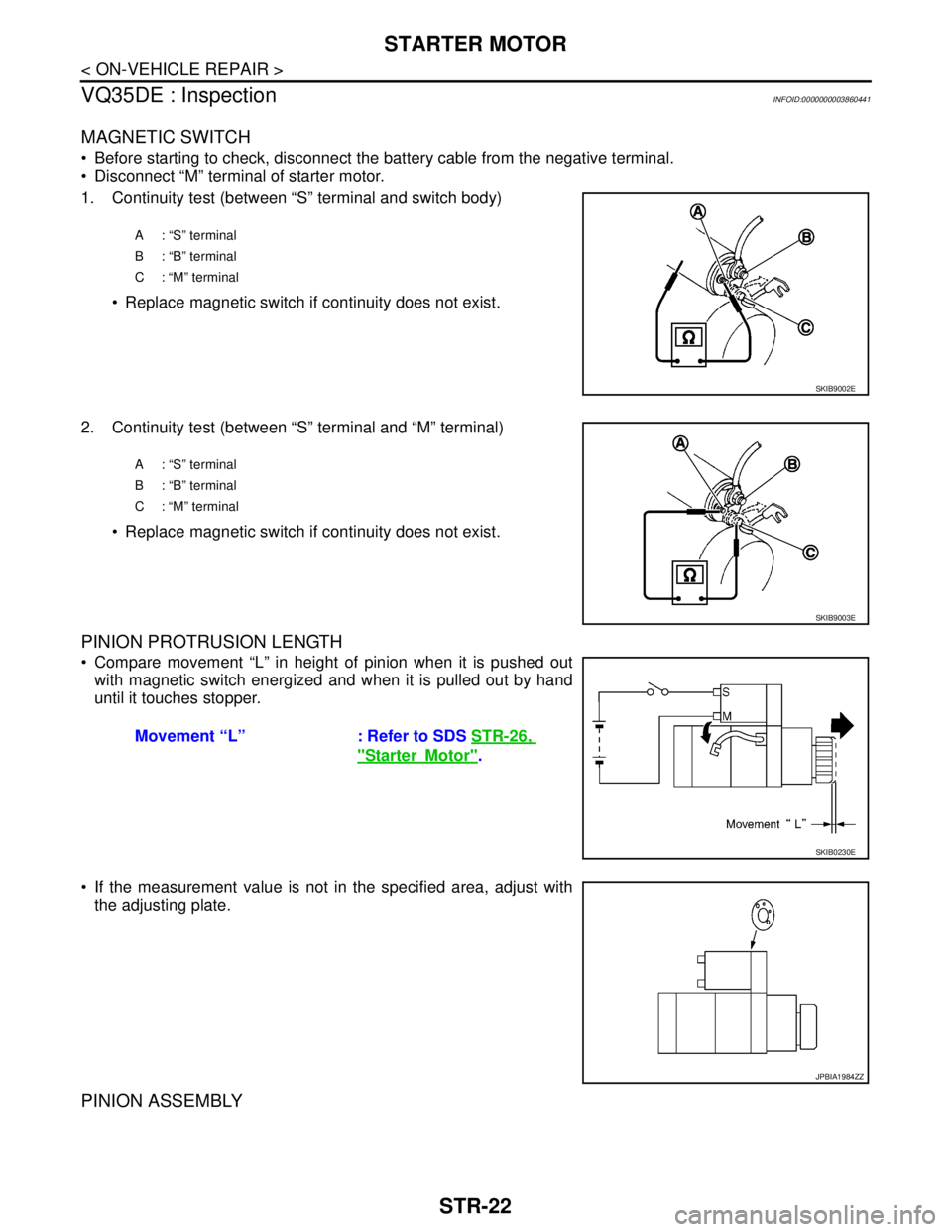

VQ35DE : Inspection

INFOID:0000000003860441

MAGNETIC SWITCH

Before starting to check, disconnect the battery cable from the negative terminal.

Disconnect “M” terminal of starter motor.

1. Continuity test (between “S” terminal and switch body)

Replace magnetic switch if continuity does not exist.

2. Continuity test (between “S” terminal and “M” terminal)

Replace magnetic switch if continuity does not exist.

PINION PROTRUSION LENGTH

Compare movement “L” in height of pinion when it is pushed out

with magnetic switch energized and when it is pulled out by hand

until it touches stopper.

If the measurement value is not in the specified area, adjust with

the adjusting plate.

PINION ASSEMBLY

A : “S” terminal

B : “B” terminal

C : “M” terminal

SKIB9002E

A : “S” terminal

B : “B” terminal

C : “M” terminal

SKIB9003E

Movement “L” : Refer to SDS STR-26,

"StarterMotor".

SKIB0230E

JPBIA1984ZZ

Page 4470 of 5121

STARTER MOTOR

STR-23

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

L

MA

STR

N

P O

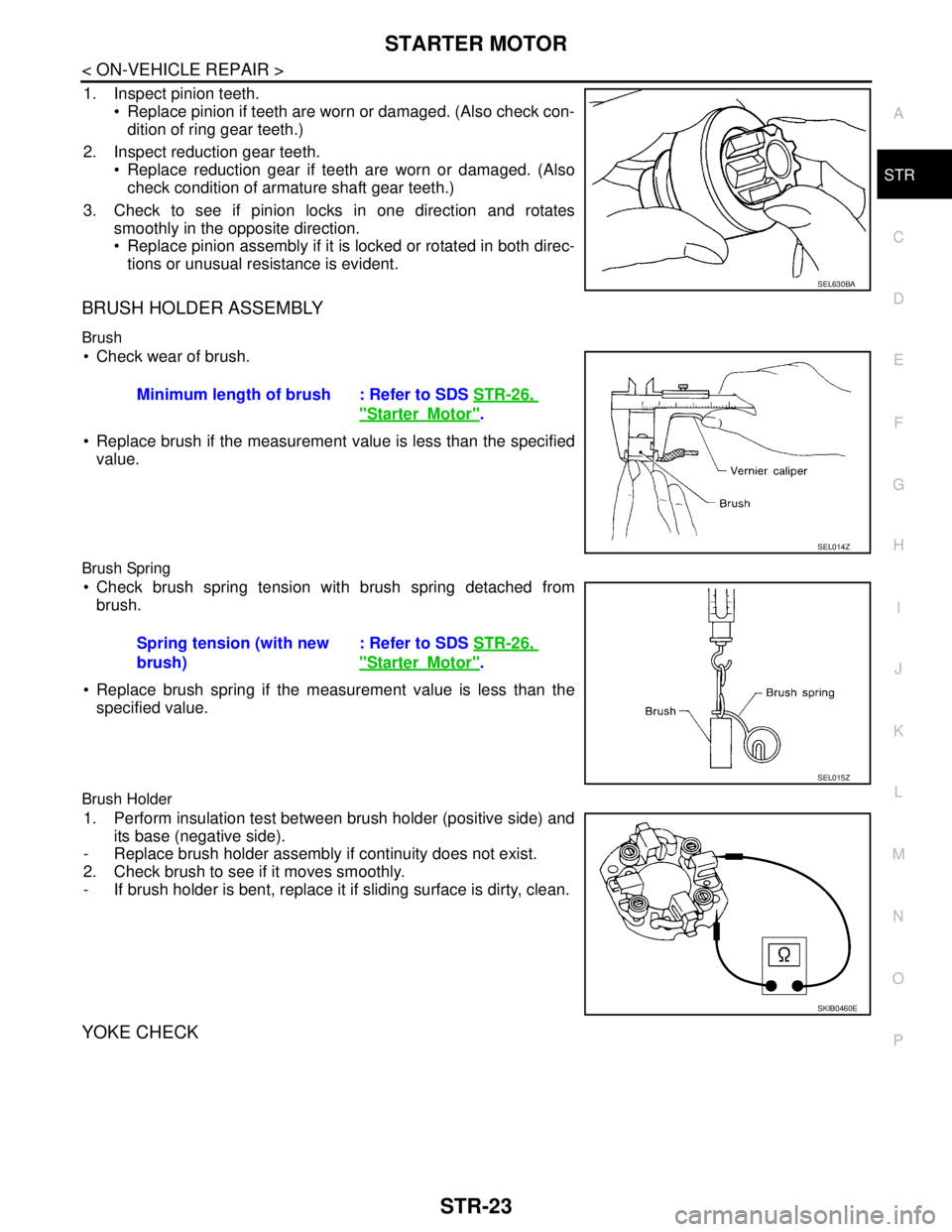

1. Inspect pinion teeth.

Replace pinion if teeth are worn or damaged. (Also check con-

dition of ring gear teeth.)

2. Inspect reduction gear teeth.

Replace reduction gear if teeth are worn or damaged. (Also

check condition of armature shaft gear teeth.)

3. Check to see if pinion locks in one direction and rotates

smoothly in the opposite direction.

Replace pinion assembly if it is locked or rotated in both direc-

tions or unusual resistance is evident.

BRUSH HOLDER ASSEMBLY

Brush

Check wear of brush.

Replace brush if the measurement value is less than the specified

value.

Brush Spring

Check brush spring tension with brush spring detached from

brush.

Replace brush spring if the measurement value is less than the

specified value.

Brush Holder

1. Perform insulation test between brush holder (positive side) and

its base (negative side).

- Replace brush holder assembly if continuity does not exist.

2. Check brush to see if it moves smoothly.

- If brush holder is bent, replace it if sliding surface is dirty, clean.

YOKE CHECK

SEL630BA

Minimum length of brush : Refer to SDS STR-26,

"StarterMotor".

SEL014Z

Spring tension (with new

brush): Refer to SDS STR-26,

"StarterMotor".

SEL015Z

SKIB0460E