NISSAN TEANA 2008 Service Manual

Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 2021 of 5121

EM-146

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Unit: mm (in)

*: Total indicator reading

Main BearingINFOID:0000000003802308

MAIN BEARING

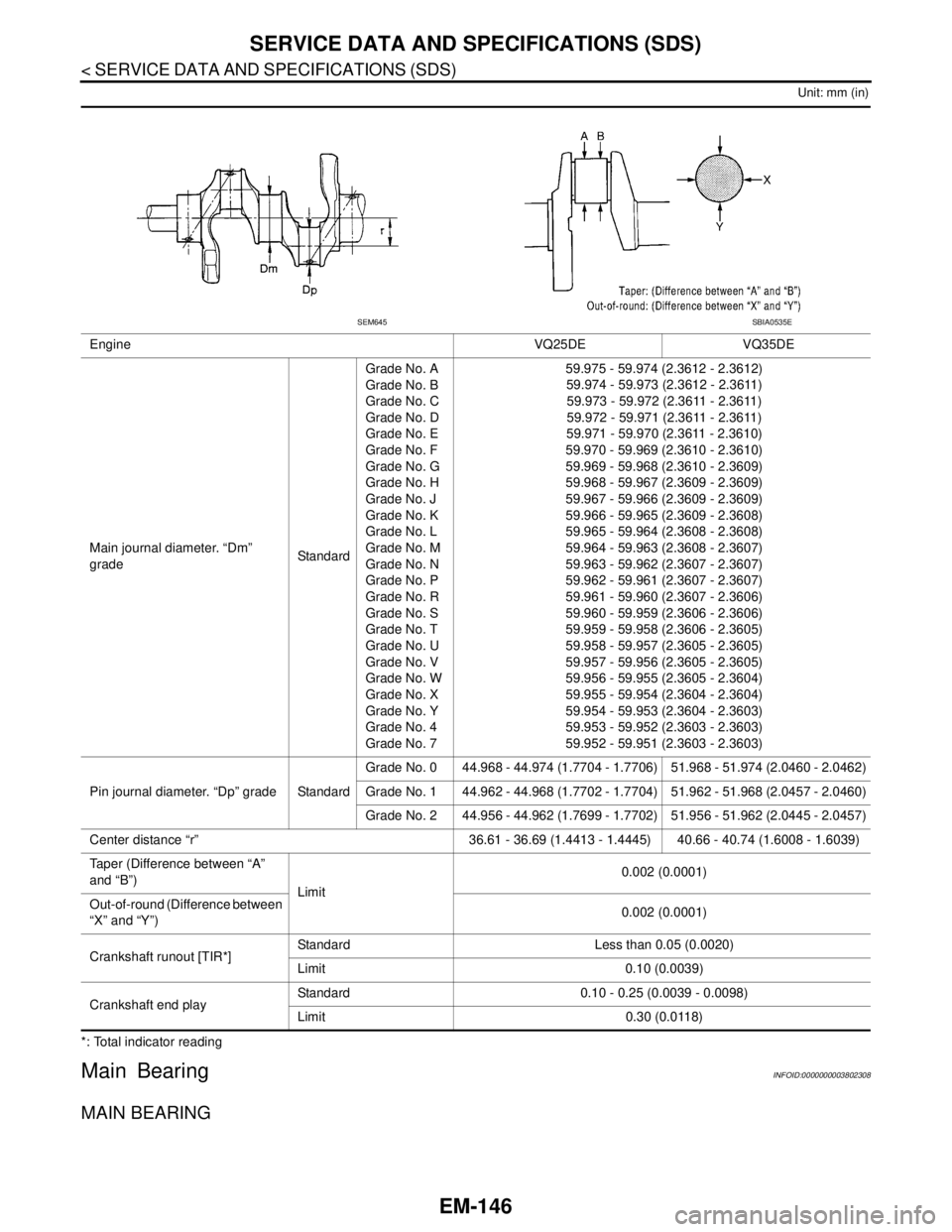

Engine VQ25DE VQ35DE

Main journal diameter. “Dm”

gradeStandardGrade No. A

Grade No. B

Grade No. C

Grade No. D

Grade No. E

Grade No. F

Grade No. G

Grade No. H

Grade No. J

Grade No. K

Grade No. L

Grade No. M

Grade No. N

Grade No. P

Grade No. R

Grade No. S

Grade No. T

Grade No. U

Grade No. V

Grade No. W

Grade No. X

Grade No. Y

Grade No. 4

Grade No. 759.975 - 59.974 (2.3612 - 2.3612)

59.974 - 59.973 (2.3612 - 2.3611)

59.973 - 59.972 (2.3611 - 2.3611)

59.972 - 59.971 (2.3611 - 2.3611)

59.971 - 59.970 (2.3611 - 2.3610)

59.970 - 59.969 (2.3610 - 2.3610)

59.969 - 59.968 (2.3610 - 2.3609)

59.968 - 59.967 (2.3609 - 2.3609)

59.967 - 59.966 (2.3609 - 2.3609)

59.966 - 59.965 (2.3609 - 2.3608)

59.965 - 59.964 (2.3608 - 2.3608)

59.964 - 59.963 (2.3608 - 2.3607)

59.963 - 59.962 (2.3607 - 2.3607)

59.962 - 59.961 (2.3607 - 2.3607)

59.961 - 59.960 (2.3607 - 2.3606)

59.960 - 59.959 (2.3606 - 2.3606)

59.959 - 59.958 (2.3606 - 2.3605)

59.958 - 59.957 (2.3605 - 2.3605)

59.957 - 59.956 (2.3605 - 2.3605)

59.956 - 59.955 (2.3605 - 2.3604)

59.955 - 59.954 (2.3604 - 2.3604)

59.954 - 59.953 (2.3604 - 2.3603)

59.953 - 59.952 (2.3603 - 2.3603)

59.952 - 59.951 (2.3603 - 2.3603)

Pin journal diameter. “Dp” grade StandardGrade No. 0 44.968 - 44.974 (1.7704 - 1.7706) 51.968 - 51.974 (2.0460 - 2.0462)

Grade No. 1 44.962 - 44.968 (1.7702 - 1.7704) 51.962 - 51.968 (2.0457 - 2.0460)

Grade No. 2 44.956 - 44.962 (1.7699 - 1.7702) 51.956 - 51.962 (2.0445 - 2.0457)

Center distance “r” 36.61 - 36.69 (1.4413 - 1.4445) 40.66 - 40.74 (1.6008 - 1.6039)

Taper (Difference between “A”

and “B”)

Limit0.002 (0.0001)

Out-of-round (Difference between

“X” and “Y”)0.002 (0.0001)

Crankshaft runout [TIR*]Standard Less than 0.05 (0.0020)

Limit 0.10 (0.0039)

Crankshaft end playStandard 0.10 - 0.25 (0.0039 - 0.0098)

Limit 0.30 (0.0118)

SEM645SBIA0535E

Page 2022 of 5121

SERVICE DATA AND SPECIFICATIONS (SDS)

EM-147

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

Unit: mm (in)

UNDERSIZE

Unit: mm (in)

MAIN BEARING OIL CLEARANCE

Unit: mm (in)

*: Actual clearance

Connecting Rod BearingINFOID:0000000003802309

CONNECTING ROD BEARING

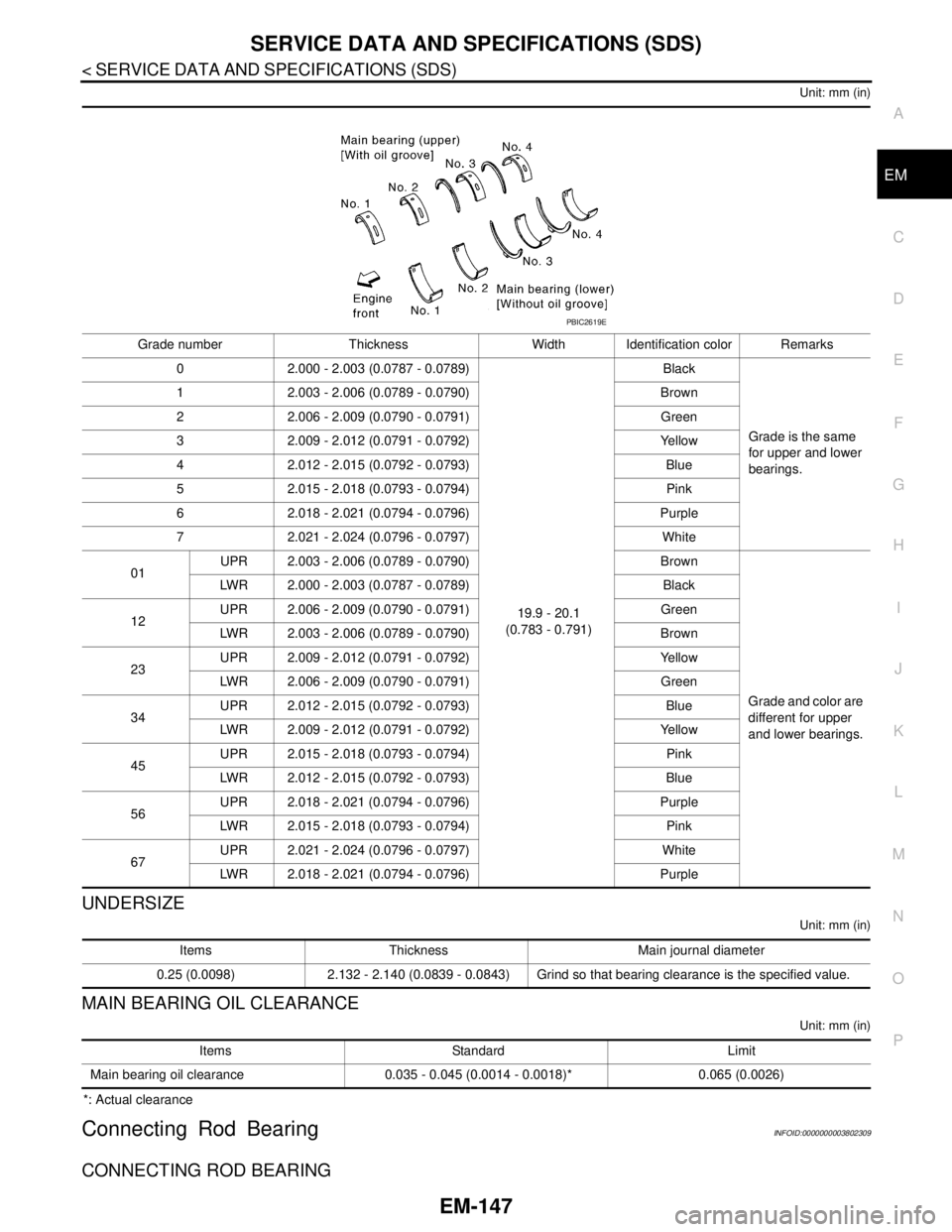

Grade number Thickness Width Identification color Remarks

0 2.000 - 2.003 (0.0787 - 0.0789)

19.9 - 20.1

(0.783 - 0.791)Black

Grade is the same

for upper and lower

bearings. 1 2.003 - 2.006 (0.0789 - 0.0790) Brown

2 2.006 - 2.009 (0.0790 - 0.0791) Green

3 2.009 - 2.012 (0.0791 - 0.0792) Yellow

4 2.012 - 2.015 (0.0792 - 0.0793) Blue

5 2.015 - 2.018 (0.0793 - 0.0794) Pink

6 2.018 - 2.021 (0.0794 - 0.0796) Purple

7 2.021 - 2.024 (0.0796 - 0.0797) White

01UPR 2.003 - 2.006 (0.0789 - 0.0790) Brown

Grade and color are

different for upper

and lower bearings. LWR 2.000 - 2.003 (0.0787 - 0.0789) Black

12UPR 2.006 - 2.009 (0.0790 - 0.0791) Green

LWR 2.003 - 2.006 (0.0789 - 0.0790) Brown

23UPR 2.009 - 2.012 (0.0791 - 0.0792) Yellow

LWR 2.006 - 2.009 (0.0790 - 0.0791) Green

34UPR 2.012 - 2.015 (0.0792 - 0.0793) Blue

LWR 2.009 - 2.012 (0.0791 - 0.0792) Yellow

45UPR 2.015 - 2.018 (0.0793 - 0.0794) Pink

LWR 2.012 - 2.015 (0.0792 - 0.0793) Blue

56UPR 2.018 - 2.021 (0.0794 - 0.0796) Purple

LWR 2.015 - 2.018 (0.0793 - 0.0794) Pink

67UPR 2.021 - 2.024 (0.0796 - 0.0797) White

LWR 2.018 - 2.021 (0.0794 - 0.0796) Purple

PBIC2619E

Items Thickness Main journal diameter

0.25 (0.0098) 2.132 - 2.140 (0.0839 - 0.0843) Grind so that bearing clearance is the specified value.

Items Standard Limit

Main bearing oil clearance 0.035 - 0.045 (0.0014 - 0.0018)* 0.065 (0.0026)

Page 2023 of 5121

EM-148

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Unit: mm (in)

UNDERSIZE

Unit: mm (in)

CONNECTING ROD BEARING OIL CLEARANCE

Unit: mm (in)

*: Actual clearanceGrade number Thickness Identification color (mark)

0 1.500 - 1.503 (0.0591 - 0.0592) Black

1 1.503 - 1.506 (0.0592 - 0.0593) Brown

2 1.506 - 1.509 (0.0593 - 0.0594) Green

Items Thickness Crank pin journal diameter

0.25 (0.0098) 1.626 - 1.634 (0.0640 - 0.0643) Grind so that bearing clearance is the specified value.

Items Standard Limit

Connecting rod bearing oil clearance 0.020 - 0.045 (0.0008 - 0.0018)* 0.070 (0.0028)

Page 2024 of 5121

EX-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION EX

A

EX

N

O P

CONTENTS

EXHAUST SYSTEM

PRECAUTION ................ ...............................2

PRECAUTIONS .............................................. .....2

Removal and Installation ..................................... ......2

PREPARATION ............................................3

PREPARATION .............................................. .....3

Commercial Service Tool .................................... ......3

ON-VEHICLE MAINTENANCE .....................4

EXHAUST SYSTEM ...........................................4

Inspection ............................................................ .....4

ON-VEHICLE REPAIR ..................................5

EXHAUST SYSTEM ...........................................5

Exploded View ..................................................... .....5

Removal and Installation ..........................................5

Inspection .................................................................6

Page 2025 of 5121

EX-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Removal and InstallationINFOID:0000000003793258

CAUTION:

• Be sure to use genuine exhaust system parts or equivalents which are specially designed for heat

resistance, corrosion resistance, and shape.

Perform the operation with the exhaust system fully cooled down because the system will be hot

just after engine stops.

Be careful not to cut your hand on the heat insulator edge.

Page 2026 of 5121

PREPARATION

EX-3

< PREPARATION >

C

D

E

F

G

H

I

J

K

L

MA

EX

N

P O

PREPARATION

PREPARATION

Commercial Service ToolINFOID:0000000003793259

Tool nameDescription

Power toolLoosening nuts and bolts

PBIC0190E

Page 2027 of 5121

EX-4

< ON-VEHICLE MAINTENANCE >

EXHAUST SYSTEM

ON-VEHICLE MAINTENANCE

EXHAUST SYSTEM

InspectionINFOID:0000000003793260

Check exhaust pipes, muffler and mounting for improper attachment,

leakage, cracks, damage or deterioration.

• If anything is found, repair or replace damaged parts.

SMA211A

Page 2028 of 5121

EXHAUST SYSTEM

EX-5

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

L

MA

EX

N

P O

ON-VEHICLE REPAIR

EXHAUST SYSTEM

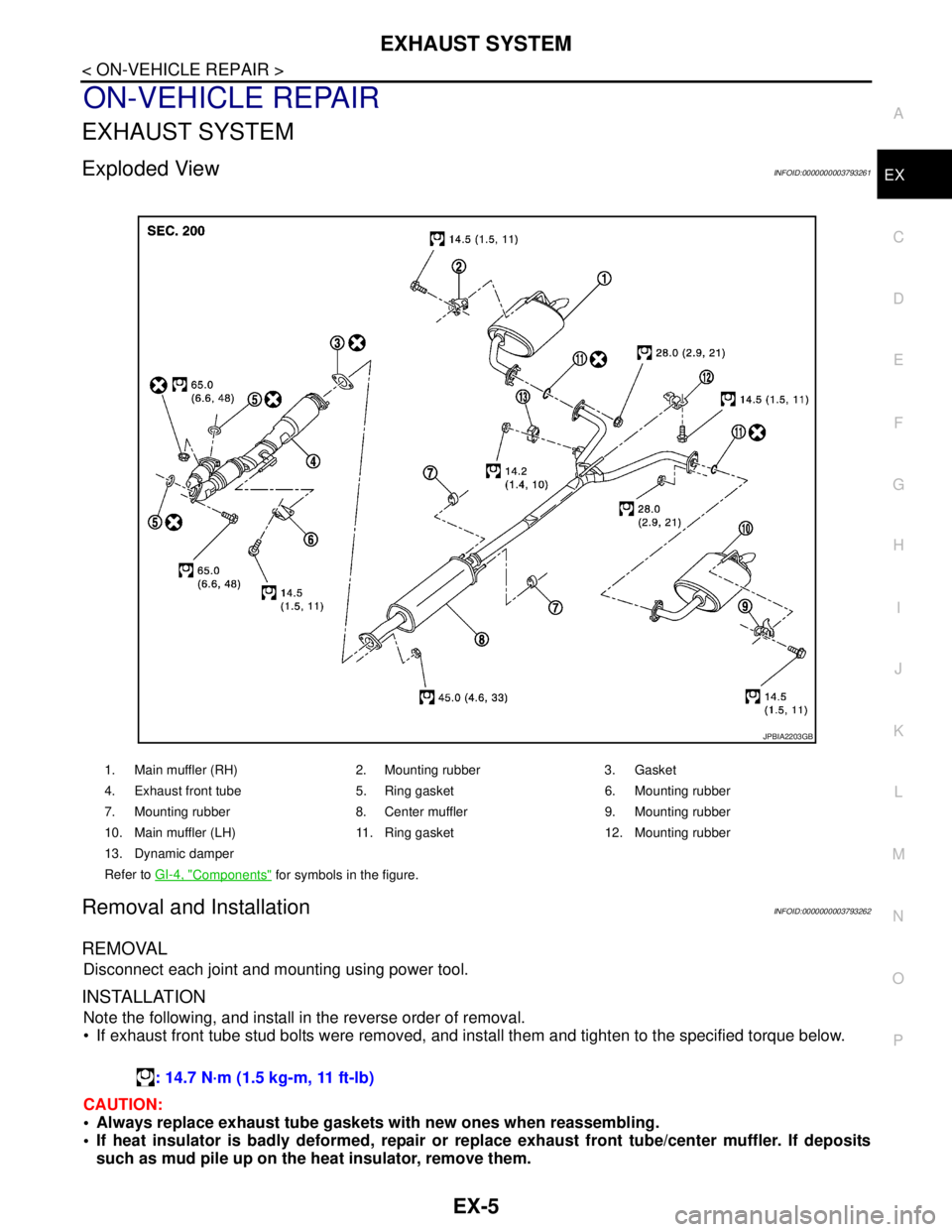

Exploded ViewINFOID:0000000003793261

Removal and InstallationINFOID:0000000003793262

REMOVAL

Disconnect each joint and mounting using power tool.

INSTALLATION

Note the following, and install in the reverse order of removal.

If exhaust front tube stud bolts were removed, and install them and tighten to the specified torque below.

CAUTION:

Always replace exhaust tube gaskets with new ones when reassembling.

If heat insulator is badly deformed, repair or replace exhaust front tube/center muffler. If deposits

such as mud pile up on the heat insulator, remove them.

1. Main muffler (RH) 2. Mounting rubber 3. Gasket

4. Exhaust front tube 5. Ring gasket 6. Mounting rubber

7. Mounting rubber 8. Center muffler 9. Mounting rubber

10. Main muffler (LH) 11. Ring gasket 12. Mounting rubber

13. Dynamic damper

Refer to GI-4, "

Components" for symbols in the figure.

JPBIA2203GB

: 14.7 N·m (1.5 kg-m, 11 ft-lb)

Page 2029 of 5121

EX-6

< ON-VEHICLE REPAIR >

EXHAUST SYSTEM

Remove deposits from the sealing surface of each connection. Connect them securely to avoid

gases leakage.

When installing each mounting rubber, use silicon oil to avoid twisting.

Temporarily tighten mounting nuts and bolts. Check each part for unusual interference, and then

tighten them to the specified torque.

When installing each mounting rubber, avoid twisting or unusual extension in up/down, front/rear

and right/left directions.

InspectionINFOID:0000000003793263

INSPECTION AFTER INSTALLATION

Check clearance between tail tube and rear bumper is even.

With engine running, check exhaust tube joints for gas leakage and unusual noises.

Check to ensure that mounting brackets and mounting rubbers are installed properly and free from undue

stress. Improper installation could result in excessive noise and vibration.

Page 2030 of 5121

EXL-1

DRIVER CONTROLS

C

DE

F

G H

I

J

K

M

SECTION EXL

A

B

EXL

N

O P

CONTENTS

EXTERIOR LIGHTING SYSTEM

XENON TYPE

BASIC INSPECTION ....... .............................

7

DIAGNOSIS AND REPAIR WORKFLOW ..... .....7

Work Flow ........................................................... ......7

INSPECTION AND ADJUSTMENT .....................9

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT .................................................... ......

9

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Description ..................................

9

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Special Repair Requirement .......

9

CONFIGURATION (HEADLAMP LEVELIZER) .... ......9

CONFIGURATION (HEADLAMP LEVELIZER) :

Description ................................................................

9

CONFIGURATION (HEADLAMP LEVELIZER) :

Special Repair Requirement .....................................

9

SENSOR INITIALIZE ............................................. ......9

SENSOR INITIALIZE : Description .........................10

SENSOR INITIALIZE : Special Repair Require-

ment (HEADLAMP AIMING CONTROL SYSTEM)

....

10

FUNCTION DIAGNOSIS ..............................11

HEADLAMP SYSTEM .................................... ....11

System Diagram .................................................. ....11

System Description .................................................11

Component Parts Location ......................................12

Component Description ..........................................12

AUTO LIGHT SYSTEM ......................................13

System Diagram .................................................. ....13

System Description .................................................13

Component Parts Location ......................................14

Component Description ..........................................14

HEADLAMP AIMING CONTROL SYSTEM

(AUTO) ..............................................................

15

System Diagram .................................................. ....15

System Description ..................................................15

Component Parts Location ......................................16

Component Description ...........................................16

FRONT FOG LAMP SYSTEM ...........................17

System Diagram ......................................................17

System Description ..................................................17

Component Parts Location ......................................18

Component Description ..........................................18

TURN SIGNAL AND HAZARD WARNING

LAMP SYSTEM .................................................

19

System Diagram ......................................................19

System Description ..................................................19

Component Parts Location ......................................20

Component Description ..........................................20

PARKING, LICENSE PLATE AND TAIL

LAMPS SYSTEM ..............................................

21

System Diagram .................................................. ....21

System Description ..................................................21

Component Parts Location ......................................22

Component Description ..........................................22

REAR FOG LAMP SYSTEM .............................23

System Diagram ......................................................23

System Description ..................................................23

Component Parts Location ......................................24

Component Description ..........................................24

EXTERIOR LAMP BATTERY SAVER SYS-

TEM ...................................................................

25

System Diagram ......................................................25

System Description ..................................................25

Component Parts Location ......................................26

Component Description ..........................................26

DIAGNOSIS SYSTEM (BCM) ...........................27