cvt NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 42 of 5121

ADP-36

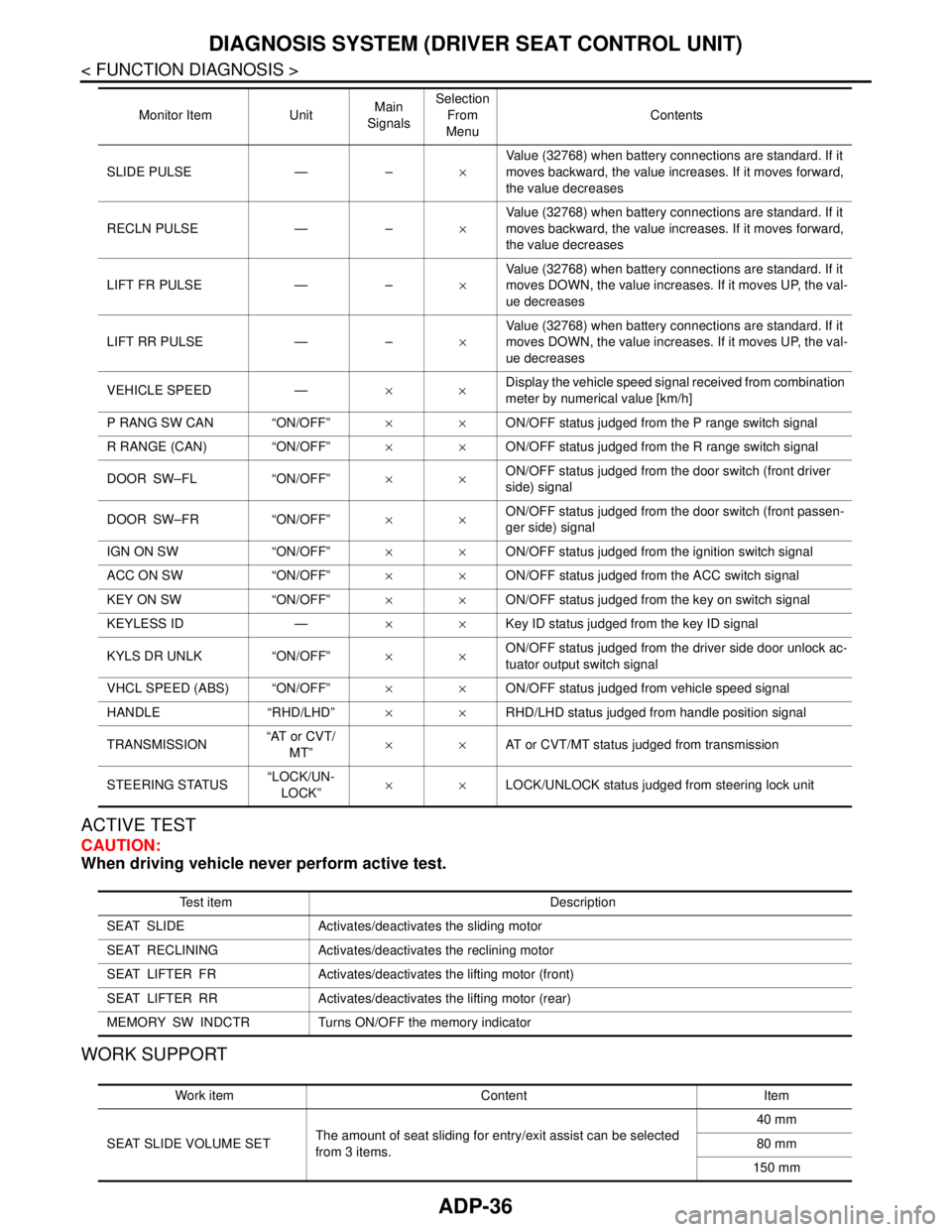

< FUNCTION DIAGNOSIS >

DIAGNOSIS SYSTEM (DRIVER SEAT CONTROL UNIT)

ACTIVE TEST

CAUTION:

When driving vehicle never perform active test.

WORK SUPPORT

SLIDE PULSE — –×Value (32768) when battery connections are standard. If it

moves backward, the value increases. If it moves forward,

the value decreases

RECLN PULSE — –×Value (32768) when battery connections are standard. If it

moves backward, the value increases. If it moves forward,

the value decreases

LIFT FR PULSE — –×Value (32768) when battery connections are standard. If it

moves DOWN, the value increases. If it moves UP, the val-

ue decreases

LIFT RR PULSE — –×Value (32768) when battery connections are standard. If it

moves DOWN, the value increases. If it moves UP, the val-

ue decreases

VEHICLE SPEED —××Display the vehicle speed signal received from combination

meter by numerical value [km/h]

P RANG SW CAN “ON/OFF”××ON/OFF status judged from the P range switch signal

R RANGE (CAN) “ON/OFF”××ON/OFF status judged from the R range switch signal

DOOR SW–FL “ON/OFF”××ON/OFF status judged from the door switch (front driver

side) signal

DOOR SW–FR “ON/OFF”××ON/OFF status judged from the door switch (front passen-

ger side) signal

IGN ON SW “ON/OFF”××ON/OFF status judged from the ignition switch signal

ACC ON SW “ON/OFF”××ON/OFF status judged from the ACC switch signal

KEY ON SW “ON/OFF”××ON/OFF status judged from the key on switch signal

KEYLESS ID —××Key ID status judged from the key ID signal

KYLS DR UNLK “ON/OFF”××ON/OFF status judged from the driver side door unlock ac-

tuator output switch signal

VHCL SPEED (ABS) “ON/OFF”××ON/OFF status judged from vehicle speed signal

HANDLE “RHD/LHD”××RHD/LHD status judged from handle position signal

TRANSMISSION“AT or CVT/

MT”××AT or CVT/MT status judged from transmission

STEERING STATUS“LOCK/UN-

LOCK”××LOCK/UNLOCK status judged from steering lock unit Monitor Item UnitMain

SignalsSelection

From

MenuContents

Test item Description

SEAT SLIDE Activates/deactivates the sliding motor

SEAT RECLINING Activates/deactivates the reclining motor

SEAT LIFTER FR Activates/deactivates the lifting motor (front)

SEAT LIFTER RR Activates/deactivates the lifting motor (rear)

MEMORY SW INDCTR Turns ON/OFF the memory indicator

Work item Content Item

SEAT SLIDE VOLUME SETThe amount of seat sliding for entry/exit assist can be selected

from 3 items.40 mm

80 mm

150 mm

Page 119 of 5121

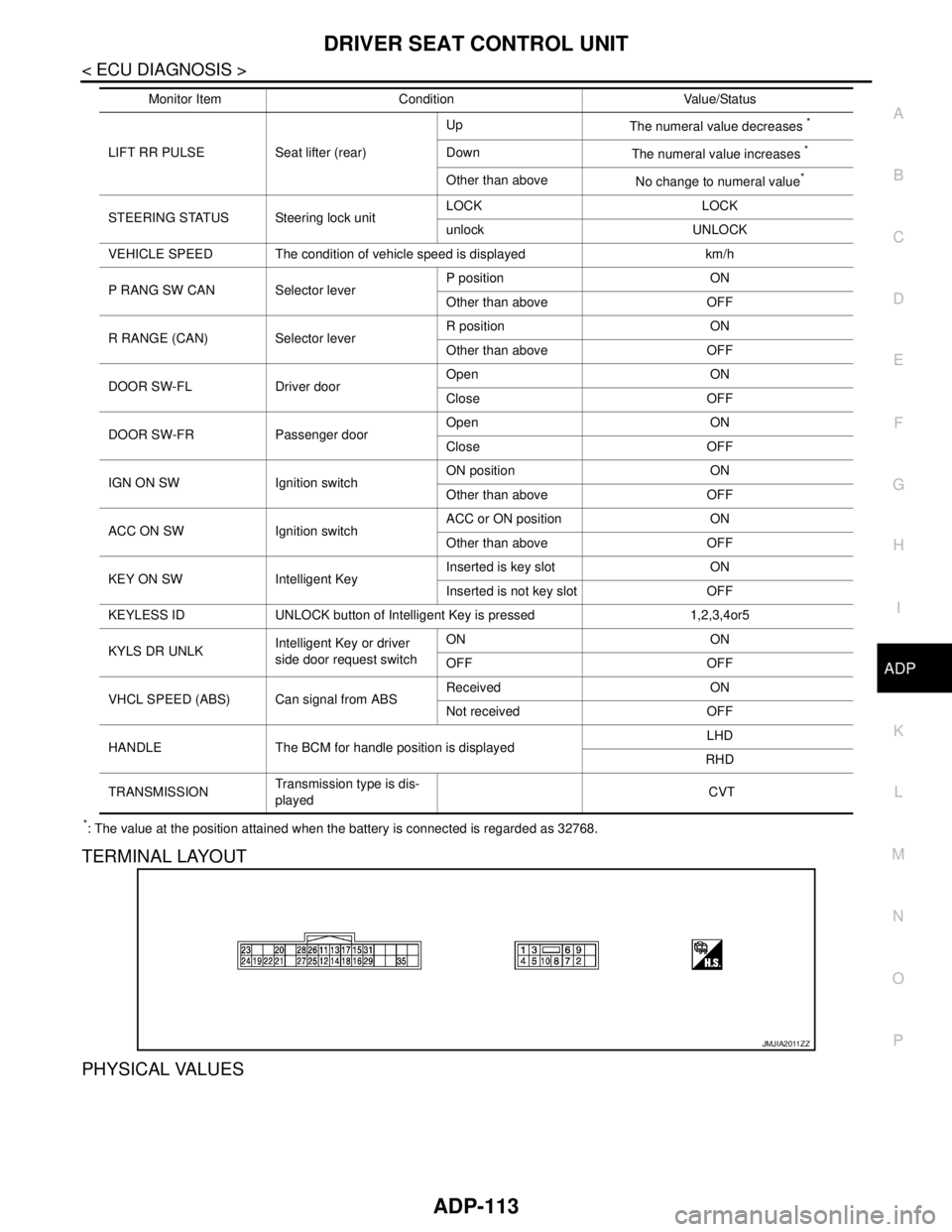

DRIVER SEAT CONTROL UNIT

ADP-113

< ECU DIAGNOSIS >

C

D

E

F

G

H

I

K

L

MA

B

ADP

N

O

P

*: The value at the position attained when the battery is connected is regarded as 32768.

TERMINAL LAYOUT

PHYSICAL VALUES

LIFT RR PULSE Seat lifter (rear)Up

The numeral value decreases

*

Down

The numeral value increases *

Other than above

No change to numeral value*

STEERING STATUS Steering lock unitLOCK LOCK

unlock UNLOCK

VEHICLE SPEED The condition of vehicle speed is displayed km/h

P RANG SW CAN Selector leverP position ON

Other than above OFF

R RANGE (CAN) Selector leverR position ON

Other than above OFF

DOOR SW-FL Driver doorOpen ON

Close OFF

DOOR SW-FR Passenger doorOpen ON

Close OFF

IGN ON SW Ignition switchON position ON

Other than above OFF

ACC ON SW Ignition switchACC or ON position ON

Other than above OFF

KEY ON SW Intelligent KeyInserted is key slot ON

Inserted is not key slot OFF

KEYLESS ID UNLOCK button of Intelligent Key is pressed 1,2,3,4or5

KYLS DR UNLKIntelligent Key or driver

side door request switchON ON

OFF OFF

VHCL SPEED (ABS) Can signal from ABSReceived ON

Not received OFF

HANDLE The BCM for handle position is displayedLHD

RHD

TRANSMISSIONTransmission type is dis-

played CVT Monitor Item Condition Value/Status

JMJIA2011ZZ

Page 843 of 5121

BCS-26

< FUNCTION DIAGNOSIS >

DIAGNOSIS SYSTEM (BCM)

SELF-DIAG RESULT

Refer to BCS-74, "DTCIndex".

DATA MONITOR

INSIDE ANT DIAGNOSIS This function allows inside key antenna self-diagnosis.

HORN WITH KEYLESS LOCKHorn reminder function mode by Intelligent Key button can be changed to operate (ON) or not op-

erate (OFF) in this mode. Monitor item Description

Monitor Item Condition

REQ SW -DR Indicates [ON/OFF] condition of door request switch (driver side).

REQ SW -AS Indicates [ON/OFF] condition of door request switch (passenger side).

REQ SW -BD/TR Indicates [ON/OFF] condition of trunk lid opener request switch.

PUSH SW Indicates [ON/OFF] condition of push-button ignition switch.

IGN RLY2 -F/B Indicates [ON/OFF] condition of ignition relay 2.

CLUCH SWNOTE:

This item is displayed, but cannot be monitored.

BRAKE SW 1 Indicates [ON/OFF] condition of brake switch.

DETE/CANCL SW Indicates [ON/OFF] condition of the P position.

SFT PN/N SW Indicates [ON/OFF] condition of the P or N position.

S/L -LOCK Indicates [ON/OFF] condition of steering lock unit (LOCK).

S/L -UNLOCK Indicates [ON/OFF] condition of steering lock unit (UNLOCK).

S/L RELAY -F/B Indicates [ON/OFF] condition of steering lock relay.

UNLK SEN -DR Indicates [ON/OFF] condition of driver door UNLOCK status.

PUSH SW -IPDM Indicates [ON/OFF] condition of push-button ignition switch.

IGN RLY1 -F/B Indicates [ON/OFF] condition of ignition relay 1.

DETE SW -IPDM Indicates [ON/OFF] condition of the P position.

SFT PN -IPDM Indicates [ON/OFF] condition of the P or N position.

SFT P -MET Indicates [ON/OFF] condition of the P position.

SFT N -MET Indicates [ON/OFF] condition of the N position.

ENGINE STATE Indicates [STOP/STALL/CRANK/RUN] condition of engine states.

S/L LOCK-IPDM Indicates [ON/OFF] condition of steering lock unit (LOCK).

S/L UNLK-IPDM Indicates [ON/OFF] condition of steering lock unit (UNLOCK).

S/L RELAY-REQ Indicates [ON/OFF] condition of steering lock relay.

VEH SPEED 1 Displays the vehicle speed signal received from combination meter by numerical value [Km/h].

VEH SPEED 2 Displays the vehicle speed signal received from ABS, VDC or CVT by numerical value [Km/h].

DOOR STAT-DR Indicates [LOCK/READY/UNLK] condition of driver side door status.

DOOR STAT-AS Indicates [LOCK/READY/UNLK] condition of passenger side door status.

ID OK FLAG Indicates [SET/RESET] condition of key ID.

PRMT ENG STRT Indicates [SET/RESET] condition of engine start possibility.

PRMT RKE STRTNOTE:

This item is displayed, but cannot be monitored.

KEY SW -SLOT Indicates [ON/OFF] condition of key slot.

TRNK/HAT MNTR Indicates [ON/OFF] condition of trunk lid.

RKE-LOCK Indicates [ON/OFF] condition of LOCK signal from Intelligent Key.

RKE-UNLOCK Indicates [ON/OFF] condition of UNLOCK signal from Intelligent Key.

RKE-TR/BD Indicates [ON/OFF] condition of TRUNK OPEN signal from Intelligent Key.

Page 1012 of 5121

![NISSAN TEANA 2008 Service Manual TCS

BRC-71

< FUNCTION DIAGNOSIS >[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

TCS

System DiagramINFOID:0000000003767312

System DescriptionINFOID:0000000003766890

Traction Control System is a funct NISSAN TEANA 2008 Service Manual TCS

BRC-71

< FUNCTION DIAGNOSIS >[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

TCS

System DiagramINFOID:0000000003767312

System DescriptionINFOID:0000000003766890

Traction Control System is a funct](/img/5/57391/w960_57391-1011.png)

TCS

BRC-71

< FUNCTION DIAGNOSIS >[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

TCS

System DiagramINFOID:0000000003767312

System DescriptionINFOID:0000000003766890

Traction Control System is a function that electronically controls engine torque, brake fluid pressure and

CVT shift position to ensure the optimum slippage ratio at drive wheels by computing wheel speed signals

from 4 wheel sensors. When ABS actuator and electric unit (control unit) detects a spin at drive wheels (rear

wheels), it compares wheel speed signals from all 4 wheels. At this time, LH and RH rear brake fluid pres-

sure are controlled, while fuel being cut to engine and throttle valve being closed to reduce engine torque by

the control unit. Further more, throttle position is continuously controlled to ensure the optimum engine

torque at all times.

During TCS operation, TCS informs driver of system operation by flashing SLIP indicator lamp.

Electrical system diagnosis by CONSULT-III is available.

JSFIA0259GB

Page 1136 of 5121

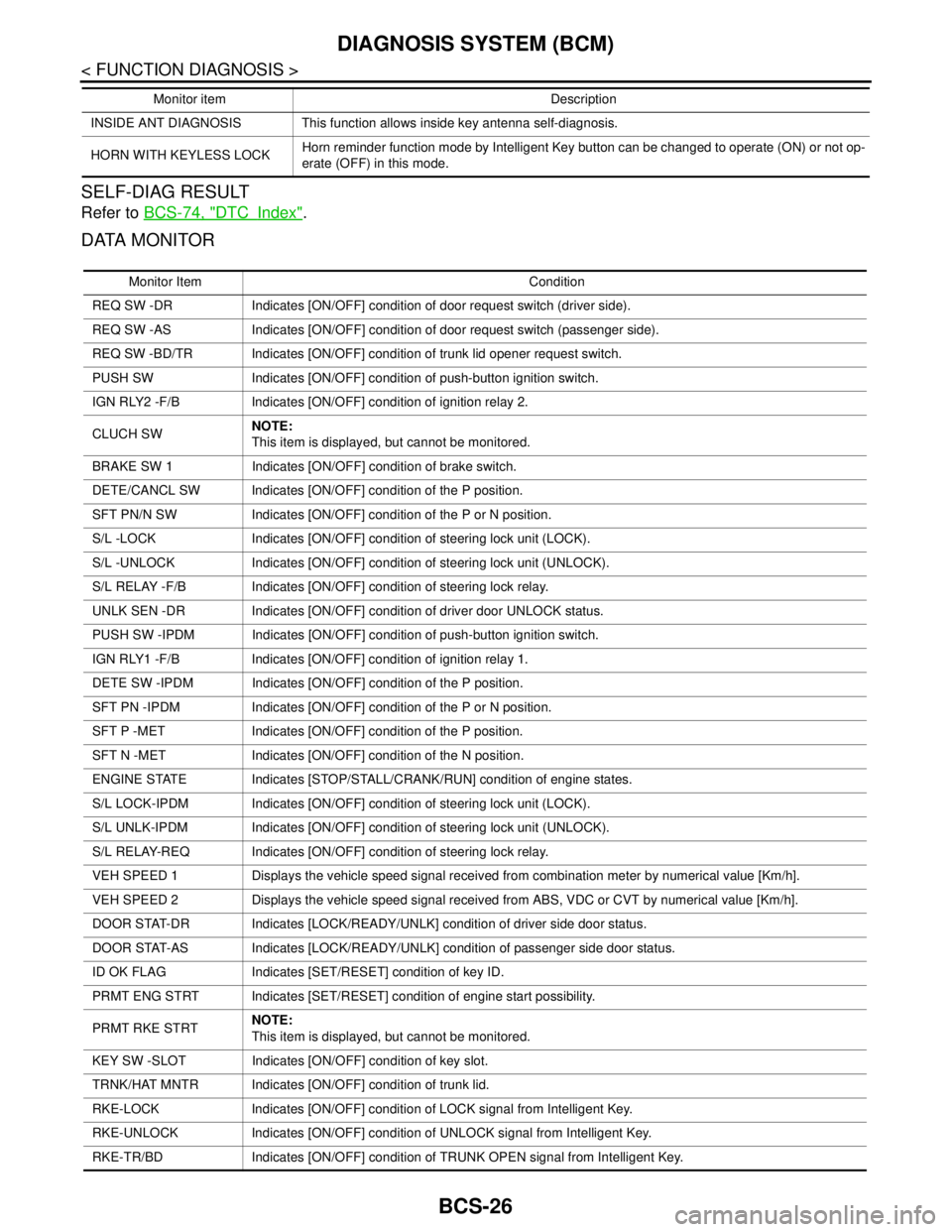

RADIATOR

CO-13

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

L

MA

CO

N

P O

ON-VEHICLE REPAIR

RADIATOR

Exploded ViewINFOID:0000000003793172

Removal and InstallationINFOID:0000000003793173

REMOVAL

1. Reservoir tank cap 2. Reservoir tank 3. Clamp

4. Reservoir tank hose 5. Radiator cap 6. Radiator cap adapter

7. Radiator pipe (upper) 8. Clamp 9. Radiator hose (upper)

10. Radiator hose (upper) 11. O-ring 12. Drain plug

13. Water drain hose 14. Mounting rubber (upper) 15. Radiator upper clip

16. Radiator 17. Mounting rubber (lower) 18. Radiator pipe (lower)

19. Radiator hose (lower) 20. Clamp 21. CVT fluid cooler hose

22. CVT fluid cooler hose 23. Grommet 24. Cooling fan assembly

25. Radiator hose (lower)

A. To water outlet B. To transaxle assembly C. To water inlet

Refer to GI-4, "

Components" for symbols in the figure.

JPBIA2200GB

Page 1137 of 5121

CO-14

< ON-VEHICLE REPAIR >

RADIATOR

WARNING:

Never remove radiator cap when engine is hot. Serious burns could occur from high-pressure engine

coolant escaping from radiator. Wrap a thick cloth around the cap. Slowly turn it a quarter of a turn to

release built-up pressure. Carefully remove radiator cap by turning it all the way.

1. Remove the following parts:

Engine under cover.

Air duct (inlet): Refer to EM-26, "

Exploded View".

Horn: Refer to HRN-6, "

Exploded View".

Hood lock: Refer to DLK-220, "

Exploded View".

2. Drain engine coolant from radiator. Refer to CO-8, "

Draining".

CAUTION:

Perform this step when the engine is cold.

Never spill engine coolant on drive belt.

3. Disconnect reservoir tank hose from radiator pipe (upper).

4. Disconnect CVT fluid cooler hoses from radiator.

Install blind plug to avoid leakage of CVT fluid.

5. Disconnect Low-pressure flexible hose from lower pressure pipe, and then move it to aside. Refer to HA-

38, "Exploded View".

6. Remove radiator cap adapter and radiator hoses (upper) and radiator pipe (upper) assembly.

CAUTION:

Be careful not to allow engine coolant to contact drive belt.

7. Disconnect radiator hose (lower) from radiator.

8. Remove condenser. Refer to HA-46, "

Exploded View".

CAUTION:

Be careful not to damage condenser core.

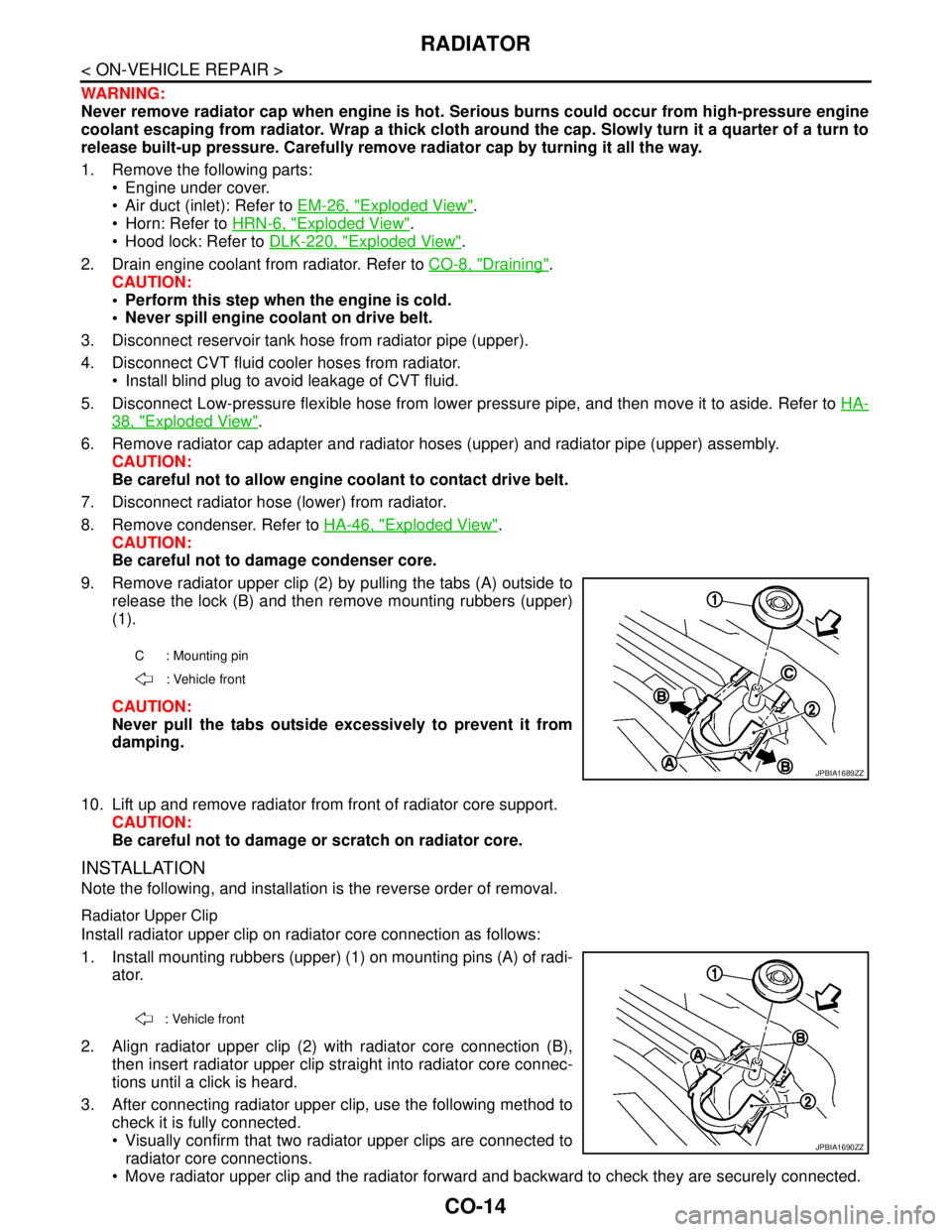

9. Remove radiator upper clip (2) by pulling the tabs (A) outside to

release the lock (B) and then remove mounting rubbers (upper)

(1).

CAUTION:

Never pull the tabs outside excessively to prevent it from

damping.

10. Lift up and remove radiator from front of radiator core support.

CAUTION:

Be careful not to damage or scratch on radiator core.

INSTALLATION

Note the following, and installation is the reverse order of removal.

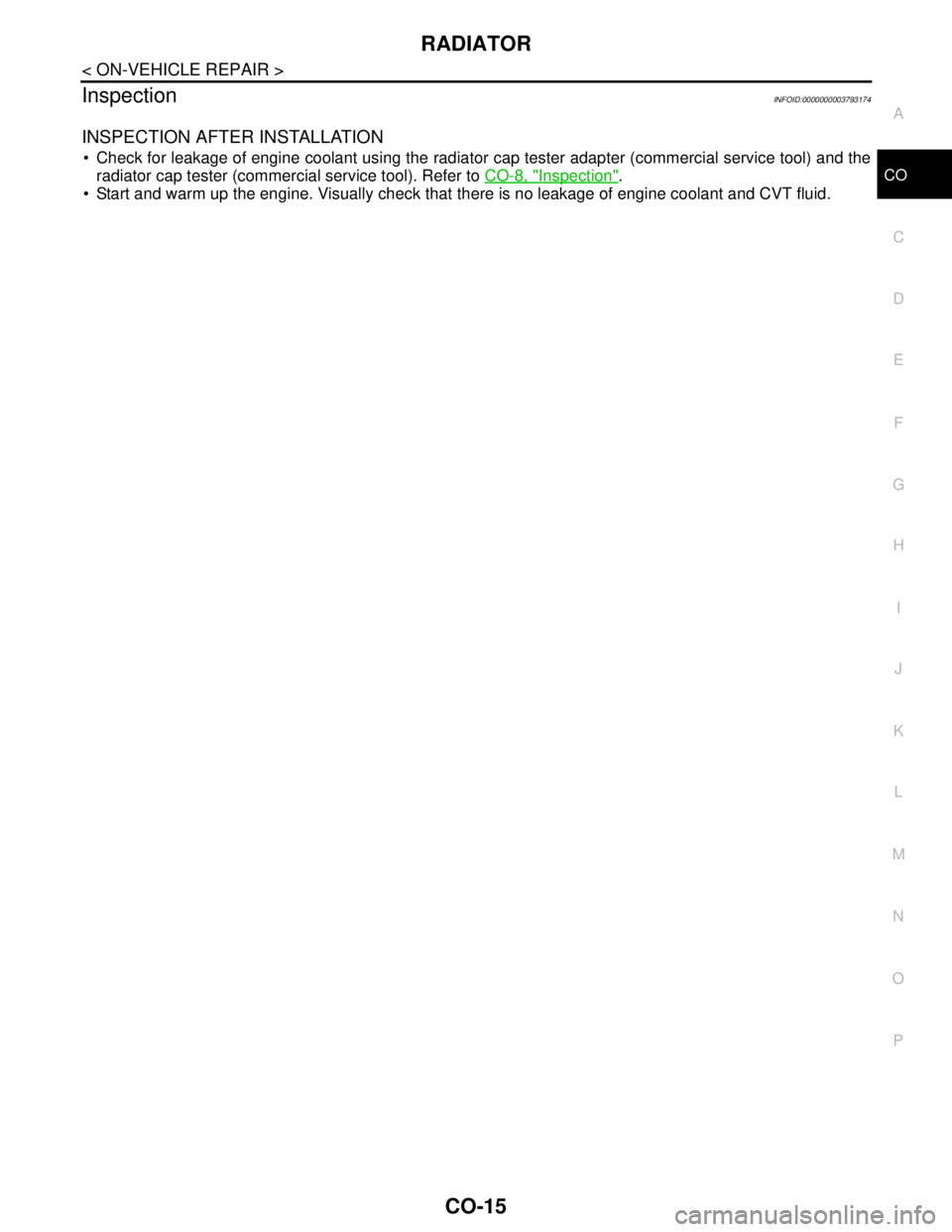

Radiator Upper Clip

Install radiator upper clip on radiator core connection as follows:

1. Install mounting rubbers (upper) (1) on mounting pins (A) of radi-

ator.

2. Align radiator upper clip (2) with radiator core connection (B),

then insert radiator upper clip straight into radiator core connec-

tions until a click is heard.

3. After connecting radiator upper clip, use the following method to

check it is fully connected.

Visually confirm that two radiator upper clips are connected to

radiator core connections.

Move radiator upper clip and the radiator forward and backward to check they are securely connected.

C : Mounting pin

: Vehicle front

JPBIA1689ZZ

: Vehicle front

JPBIA1690ZZ

Page 1138 of 5121

RADIATOR

CO-15

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

L

MA

CO

N

P O

InspectionINFOID:0000000003793174

INSPECTION AFTER INSTALLATION

Check for leakage of engine coolant using the radiator cap tester adapter (commercial service tool) and the

radiator cap tester (commercial service tool). Refer to CO-8, "

Inspection".

Start and warm up the engine. Visually check that there is no leakage of engine coolant and CVT fluid.

Page 1149 of 5121

CO-26

< ON-VEHICLE REPAIR >

WATER OUTLET AND WATER PIPING

5. Remove CVT fluid charging pipe and CVT fluid level gauge. Refer to TM-332, "Exploded View" (VQ25DE)

or TM-168, "

Exploded View" (VQ35DE).

6. Move CVT control cable aside. Refer to TM-319, "

Exploded View" (VQ25DE) or TM-157, "Exploded View"

(VQ35DE).

7. Remove vacuum pipe (front) mounting bolt from water outlet. Refer to EM-67, "

Exploded View".

8. Remove radiator hose (upper) from water outlet.

9. Remove water hoses and heater hoses.

10. Disconnect harness connectors, and move harness to aside.

11. Remove engine coolant temperature sensor as necessary.

CAUTION:

Be careful not to damage engine coolant temperature sensor.

12. Remove water outlet, heater pipe, water bypass pipe and water connector.

INSTALLATION

Note the following, and install in the reverse order of removal.

Securely insert each hose, and install clamp at a position where it does not interfere with the pipe bulge.

When inserting water bypass pipe and heater pipe into water connector, apply neutral detergent to O-ring.

InspectionINFOID:0000000003793187

INSPECTION AFTER INSTALLATION

Check for leakage of engine coolant using the radiator cap tester adapter (commercial service tool) and the

radiator cap tester (commercial service tool). Refer to CO-8, "

Inspection".

Start and warm up the engine. Visually check that there is no leakage of engine coolant.

Page 1261 of 5121

![NISSAN TEANA 2008 Service Manual DIAGNOSIS SYSTEM (BCM)

DLK-45

< FUNCTION DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

DLK

N

O

P

ACTIVE TEST

CLUCH SWNOTE:

This item is displayed, but cannot be monitored.

BRAKE SW NISSAN TEANA 2008 Service Manual DIAGNOSIS SYSTEM (BCM)

DLK-45

< FUNCTION DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

DLK

N

O

P

ACTIVE TEST

CLUCH SWNOTE:

This item is displayed, but cannot be monitored.

BRAKE SW](/img/5/57391/w960_57391-1260.png)

DIAGNOSIS SYSTEM (BCM)

DLK-45

< FUNCTION DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

DLK

N

O

P

ACTIVE TEST

CLUCH SWNOTE:

This item is displayed, but cannot be monitored.

BRAKE SW 1 Indicates [ON/OFF] condition of brake switch.

DETE/CANCL SW Indicates [ON/OFF] condition of the P position.

SFT PN/N SW Indicates [ON/OFF] condition of the P or N position.

S/L -LOCK Indicates [ON/OFF] condition of steering lock unit (LOCK).

S/L -UNLOCK Indicates [ON/OFF] condition of steering lock unit (UNLOCK).

S/L RELAY -F/B Indicates [ON/OFF] condition of steering lock relay.

UNLK SEN -DR Indicates [ON/OFF] condition of driver door UNLOCK status.

PUSH SW -IPDM Indicates [ON/OFF] condition of push-button ignition switch.

IGN RLY1 -F/B Indicates [ON/OFF] condition of ignition relay 1.

DETE SW -IPDM Indicates [ON/OFF] condition of the P position.

SFT PN -IPDM Indicates [ON/OFF] condition of the P or N position.

SFT P -MET Indicates [ON/OFF] condition of the P position.

SFT N -MET Indicates [ON/OFF] condition of the N position.

ENGINE STATE Indicates [STOP/STALL/CRANK/RUN] condition of engine states.

S/L LOCK-IPDM Indicates [ON/OFF] condition of steering lock unit (LOCK).

S/L UNLK-IPDM Indicates [ON/OFF] condition of steering lock unit (UNLOCK).

S/L RELAY-REQ Indicates [ON/OFF] condition of steering lock relay.

VEH SPEED 1 Displays the vehicle speed signal received from combination meter by numerical value [Km/h].

VEH SPEED 2 Displays the vehicle speed signal received from ABS, VDC or CVT by numerical value [Km/h].

DOOR STAT-DR Indicates [LOCK/READY/UNLK] condition of driver side door status.

DOOR STAT-AS Indicates [LOCK/READY/UNLK] condition of passenger side door status.

ID OK FLAG Indicates [SET/RESET] condition of key ID.

PRMT ENG STRT Indicates [SET/RESET] condition of engine start possibility.

PRMT RKE STRTNOTE:

This item is displayed, but cannot be monitored.

KEY SW -SLOT Indicates [ON/OFF] condition of key slot.

TRNK/HAT MNTR Indicates [ON/OFF] condition of trunk lid.

RKE-LOCK Indicates [ON/OFF] condition of LOCK signal from Intelligent Key.

RKE-UNLOCK Indicates [ON/OFF] condition of UNLOCK signal from Intelligent Key.

RKE-TR/BD Indicates [ON/OFF] condition of TRUNK OPEN signal from Intelligent Key.

RKE-PANICNOTE:

This item is displayed, but cannot be monitored.

RKE-P/W OPENNOTE:

This item is displayed, but cannot be monitored.

RKE-MODE CHG Indicates [ON/OFF] condition of MODE CHANGE signal from Intelligent Key.

RKE OPE COUN1When remote keyless entry receiver receives the signal transmitted while operating on Intelligent Key, the

numerical values start changing.

RKE OPE COUN2NOTE:

This item is displayed, but cannot be monitored. Monitor Item Condition

Page 1413 of 5121

![NISSAN TEANA 2008 Service Manual RADIATOR CORE SUPPORT

DLK-197

< ON-VEHICLE REPAIR >[WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

DLK

N

O

P

13. Disconnect connector of refrigerant pressure sensor. Refer to HA-50, "Exploded Vie NISSAN TEANA 2008 Service Manual RADIATOR CORE SUPPORT

DLK-197

< ON-VEHICLE REPAIR >[WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

DLK

N

O

P

13. Disconnect connector of refrigerant pressure sensor. Refer to HA-50, "Exploded Vie](/img/5/57391/w960_57391-1412.png)

RADIATOR CORE SUPPORT

DLK-197

< ON-VEHICLE REPAIR >[WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

DLK

N

O

P

13. Disconnect connector of refrigerant pressure sensor. Refer to HA-50, "Exploded View".

14. Remove mounting bolt, and then remove engine coolant reservoir tank. Refer to CO-13, "

Exploded View".

15. Remove mounting bolts, and then disconnect condenser pipe assembly. Refer to HA-48, "

Exploded

View".

16. Remove condenser. Refer to HA-46, "

Removal and Installation".

17. Remove mounting nut of radiator upper hose from radiator core support, and then remove radiator upper

hose and hood switch bracket. Refer to CO-25, "

Exploded View".

18. Disconnect radiator upper hose from radiator pipe (upper). Refer to CO-25, "

Exploded View".

19. Disconnect radiator lower hose (3). Refer to CO-25, "

Exploded View".

20. Disconnect CVT fluid cooler hose on radiator side. Refer to TM-165, "

Exploded View" (CVT: RE0F09B) or

TM-329, "

Exploded View" (CVT: RE0F10A).

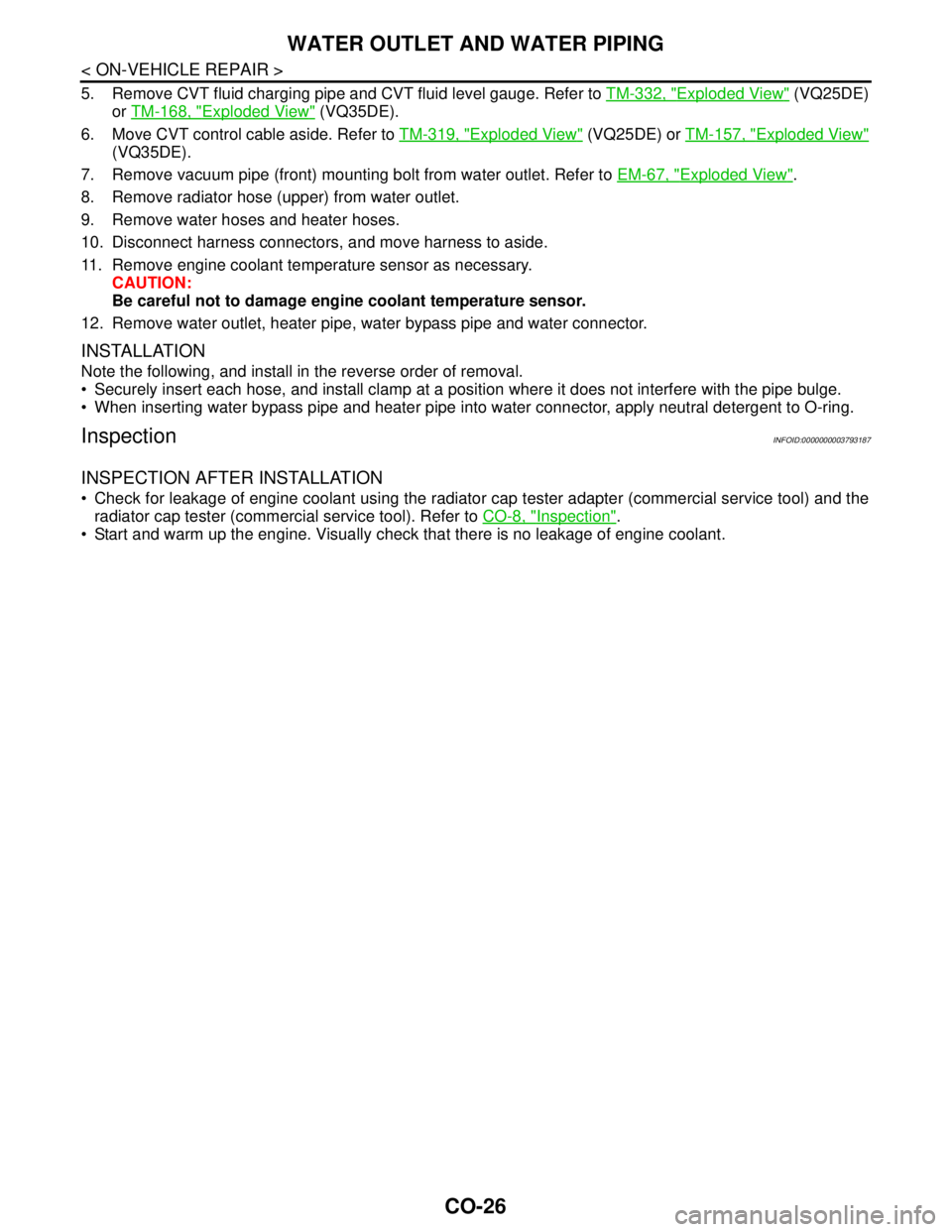

21. Remove power steering oil cooler pipe from radiator core sup-

port at point shown by arrows in the figure.

22. Disconnect connectors of the following parts.

Cooling fan (RH/LH). Refer to CO-16, "

Exploded View".

Crash zone sensor. Refer to SR-18, "

Removal and Installation".

23. Remove radiator upper clip. Refer to CO-13, "

Exploded View".

24. Remove all harness clips from radiator core support.

CAUTION:

Never damage radiator.

25. Support hood assembly with a proper material to prevent it from falling.

WARNING:

Bodily injury may occur if no supporting rod is holding the hood open when removing the hood

stay.

26. Remove hood support rod. Refer to DLK-195, "

HOOD SUPPORT ROD : Removal and Installation".

27. Remove mounting bolts, and then remove radiator core support.

CAUTION:

Operate with two workers, because of its heavy weight.

Never damage power steering oil cooler pipe.

28. Remove the following parts after removing radiator core support.

Radiator lower hose, radiator upper hose, radiator pipe. Refer to CO-25, "

Exploded View".

Radiator. Refer to CO-13, "

Exploded View".

Cooling fan (RH/LH). Refer to CO-16, "

Exploded View".

Crash zone sensor. Refer to SR-18, "

Exploded View".

Power steering oil cooler pipe clip. Refer to ST-34, "

Exploded View".

INSTALLATION

Install in the reverse order of removal.

JMKIA2395ZZ

: harness clip

JMKIA2396ZZ