Trans NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 1802 of 5121

![NISSAN TEANA 2008 Service Manual IGNITION SIGNAL

EC-341

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

IGNITION SIGNAL

DescriptionINFOID:0000000003856848

The ignition signal from the ECM is sent to and amplif NISSAN TEANA 2008 Service Manual IGNITION SIGNAL

EC-341

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

IGNITION SIGNAL

DescriptionINFOID:0000000003856848

The ignition signal from the ECM is sent to and amplif](/img/5/57391/w960_57391-1801.png)

IGNITION SIGNAL

EC-341

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

IGNITION SIGNAL

DescriptionINFOID:0000000003856848

The ignition signal from the ECM is sent to and amplified by the power transistor. The power transistor turns

ON and OFF the ignition coil primary circuit. This ON/OFF operation induces the proper high voltage in the coil

secondary circuit.

Component Function CheckINFOID:0000000003856849

1.INSPECTION START

Turn ignition switch OFF, and restart engine.

Does the engine start?

YES-1 >> With CONSULT-III: GO TO 2.

YES-2 >> Without CONSULT-III: GO TO 3.

NO >> Go to EC-341, "

Diagnosis Procedure".

2.CHECK IGNITION SIGNAL FUNCTION

With CONSULT-III

1. Perform “POWER BALANCE” in “ACTIVE TEST” mode with CONSULT-III.

2. Check that each circuit produces a momentary engine speed drop.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Go to EC-341, "

Diagnosis Procedure".

3.CHECK IGNITION SIGNAL FUNCTION

Without CONSULT-III

1. Let engine idle.

2. Read the voltage signal between ECM harness connector ground with an oscilloscope.

NOTE:

The pulse cycle changes depending on rpm at idle.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Go to EC-341, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000003856850

1.CHECK IGNITION COIL POWER SUPPLY CIRCUIT-I

1. Turn ignition switch OFF, wait at least 10 seconds and then turn it ON.

2. Check the voltage between ECM harness connector and ground.

ECM

Ground Voltage signal

Connector Terminal

F79

Ground 10

11

18

19

21

JMBIA0035GB

ECM

Ground Voltage

Connector Terminal

E16 105 Ground Battery voltage

Page 1804 of 5121

![NISSAN TEANA 2008 Service Manual IGNITION SIGNAL

EC-343

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

Is the inspection result normal?

YES >> GO TO 7.

NO >> Repair or replace harness or connectors.

7.CHECK I NISSAN TEANA 2008 Service Manual IGNITION SIGNAL

EC-343

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

Is the inspection result normal?

YES >> GO TO 7.

NO >> Repair or replace harness or connectors.

7.CHECK I](/img/5/57391/w960_57391-1803.png)

IGNITION SIGNAL

EC-343

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

Is the inspection result normal?

YES >> GO TO 7.

NO >> Repair or replace harness or connectors.

7.CHECK IGNITION COIL GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Check the continuity between ignition coil harness connector and ground.

3. Also check harness for short to power.

Is the inspection result normal?

YES >> GO TO 8.

NO >> Repair open circuit or short to power in harness or connectors.

8.CHECK IGNITION COIL OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check the continuity between ignition coil harness connector and ECM harness connector.

3. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES >> GO TO 9.

NO >> Repair open circuit, short to ground or short to power in harness or connectors.

9.CHECK IGNITION COIL WITH POWER TRANSISTOR

Refer to EC-344, "

Component Inspection (Ignition Coil with Power Transistor)".

Is the inspection result normal?

Ignition coil

Ground Voltage

Cylinder Connector Terminal

1F313

Ground Battery voltage 2F323

3F333

4F343

5F353

6F363

Ignition coil

Ground Continuity

Cylinder Connector Terminal

1F312

Ground Existed 2F322

3F332

4F342

5F352

6F362

Ignition coil ECM

Continuity

Cylinder Connector Terminal Connector Terminal

1F311

F711

Existed 2F321 10

3F331 9

4F341 21

5F351 19

6F361 18

Page 1805 of 5121

![NISSAN TEANA 2008 Service Manual EC-344

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

IGNITION SIGNAL

YES >> GO TO 10.

NO >> Replace malfunctioning ignition coil with power transistor.

10.CHECK INTERMITTENT INCIDENT

Refer to GI-35, "

Inter NISSAN TEANA 2008 Service Manual EC-344

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

IGNITION SIGNAL

YES >> GO TO 10.

NO >> Replace malfunctioning ignition coil with power transistor.

10.CHECK INTERMITTENT INCIDENT

Refer to GI-35, "

Inter](/img/5/57391/w960_57391-1804.png)

EC-344

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

IGNITION SIGNAL

YES >> GO TO 10.

NO >> Replace malfunctioning ignition coil with power transistor.

10.CHECK INTERMITTENT INCIDENT

Refer to GI-35, "

Intermittent Incident".

>> INSPECTION END

Component Inspection (Ignition Coil with Power Transistor)INFOID:0000000003856851

1.CHECK IGNITION COIL WITH POWER TRANSISTOR-I

1. Turn ignition switch OFF.

2. Disconnect ignition coil harness connector.

3. Check resistance between ignition coil terminals as per the following.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Replace malfunctioning ignition coil with power transistor.

2.CHECK IGNITION COIL WITH POWER TRANSISTOR-II

CAUTION:

Perform the following procedure in a place with no combustible objects and good ventilation.

1. Turn ignition switch OFF.

2. Reconnect all harness connectors disconnected.

3. Remove fuel pump fuse in IPDM E/R to release fuel pressure.

NOTE:

Do not use CONSULT-III to release fuel pressure, or fuel pressure applies again during the following pro-

cedure.

4. Start engine.

5. After engine stalls, crank it 2 or 3 times to release all fuel pressure.

6. Turn ignition switch OFF.

7. Remove all ignition coil harness connectors to avoid the electrical discharge from the ignition coils.

8. Remove ignition coil and spark plug of the cylinder to be checked.

9. Crank engine for 5 seconds or more to remove combustion gas in the cylinder.

10. Connect spark plug and harness connector to ignition coil.

11. Fix ignition coil using a rope etc. with gap of 13 - 17 mm (0.52 -

0.66 in) between the edge of the spark plug and grounded metal

portion as shown in the figure.

12. Crank engine for about 3 seconds, and check whether spark is

generated between the spark plug and the grounded metal por-

tion.

CAUTION:

Never place to the spark plug and the ignition coil within

50 cm (19.7 in) each other. Be careful not to get an electri-

cal shock while checking, because the electrical dis-

charge voltage becomes 20 kV or more.

It might damage the ignition coil if the gap of more than 17 mm (0.66 in) is made.

NOTE:

When the gap is less than 13 mm (0.52 in), a spark might be generated even if the coil is a malfunc-

tioning.

Is the inspection result normal?

Terminal No. (Polarity) Resistance Ω [at 25°C (77°F)]

1 and 2 Except 0 or ∞

1 and 3

Except 0

2 and 3

Spark should be generated.

JMBIA0066GB

Page 1806 of 5121

![NISSAN TEANA 2008 Service Manual IGNITION SIGNAL

EC-345

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

YES >> INSPECTION END

NO >> Replace malfunctioning ignition coil with power transistor.

Component Inspect NISSAN TEANA 2008 Service Manual IGNITION SIGNAL

EC-345

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

YES >> INSPECTION END

NO >> Replace malfunctioning ignition coil with power transistor.

Component Inspect](/img/5/57391/w960_57391-1805.png)

IGNITION SIGNAL

EC-345

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

YES >> INSPECTION END

NO >> Replace malfunctioning ignition coil with power transistor.

Component Inspection (Condenser)INFOID:0000000003856852

1.CHECK CONDENSER

1. Turn ignition switch OFF.

2. Disconnect condenser harness connector.

3. Check resistance between condenser terminals as per the following.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace condenser.

Terminals Resistance

1 and 2 Above 1 MΩ [at 25C° (77C°)]

Page 1809 of 5121

![NISSAN TEANA 2008 Service Manual EC-348

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

REFRIGERANT PRESSURE SENSOR

REFRIGERANT PRESSURE SENSOR

DescriptionINFOID:0000000003856862

The refrigerant pressure sensor is installed at the condenser NISSAN TEANA 2008 Service Manual EC-348

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

REFRIGERANT PRESSURE SENSOR

REFRIGERANT PRESSURE SENSOR

DescriptionINFOID:0000000003856862

The refrigerant pressure sensor is installed at the condenser](/img/5/57391/w960_57391-1808.png)

EC-348

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

REFRIGERANT PRESSURE SENSOR

REFRIGERANT PRESSURE SENSOR

DescriptionINFOID:0000000003856862

The refrigerant pressure sensor is installed at the condenser of the air conditioner system. The sensor uses an

electrostatic volume pressure transducer to convert refrigerant pressure to voltage. The voltage signal is sent

to ECM, and ECM controls cooling fan system.

Component Function CheckINFOID:0000000003856863

1.CHECK REFRIGERANT PRESSURE SENSOR FUNCTION

1. Start engine and warm it up to normal operating temperature.

2. Turn A/C switch and blower fan switch ON.

3. Check the voltage between ECM harness connector terminals under the following conditions.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Go to EC-348, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000003856864

1.CHECK GROUND CONNECTION

1. Turn A/C switch and blower fan switch OFF.

2. Stop engine.

3. Turn ignition switch OFF.

4. Check ground connection E38. Refer to Ground Inspection in GI-37, "

Circuit Inspection".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace ground connection.

2.CHECK REFRIGERANT PRESSURE SENSOR POWER SUPPLY CIRCUIT

1. Disconnect refrigerant pressure sensor harness connector.

2. Turn ignition switch ON.

3. Check the voltage between refrigerant pressure sensor harness connector and ground.

Is the inspection result normal?

YES >> GO TO 4.

PBIB2657E

ECM

Voltage (V)

Connector+–

Te r m i n a l Te r m i n a l

F839

(Refrigerant pressure sensor signal)40

(Sensor ground)1.0 - 4.0

Refrigerant pressure sensor

Ground Voltage (V)

Connector Terminal

E300 1 Ground Approx. 5

Page 1855 of 5121

![NISSAN TEANA 2008 Service Manual EC-394

< ECU DIAGNOSIS >[VQ25DE, VQ35DE]

ECM

Sea level

Flat road

Ambient air temperature: 20 - 30°C (68 - 86°F)

Diagnosis is performed as quickly as possible under normal conditions.

Under d NISSAN TEANA 2008 Service Manual EC-394

< ECU DIAGNOSIS >[VQ25DE, VQ35DE]

ECM

Sea level

Flat road

Ambient air temperature: 20 - 30°C (68 - 86°F)

Diagnosis is performed as quickly as possible under normal conditions.

Under d](/img/5/57391/w960_57391-1854.png)

EC-394

< ECU DIAGNOSIS >[VQ25DE, VQ35DE]

ECM

Sea level

Flat road

Ambient air temperature: 20 - 30°C (68 - 86°F)

Diagnosis is performed as quickly as possible under normal conditions.

Under different conditions [For example: ambient air temperature other than 20 - 30°C (68 - 86°F)], diagno-

sis may also be performed.

Pattern 1:

The engine is started at the engine coolant temperature of −10 to 35°C (14 to 95°F)

(where the voltage between the ECM terminal 46 and ground is 3.0 - 4.3 V).

The engine must be operated at idle speed until the engine coolant temperature is greater than 70°C

(158°F) (where the voltage between the ECM terminal 46 and ground is lower than 1.4 V).

The engine is started at the fuel tank temperature of warmer than 0°C (32°F) (where the voltage

between the ECM terminal 95 and ground is less than 4.1 V).

Pattern 2:

When steady-state driving is performed again even after it is interrupted, each diagnosis can be conducted.

In this case, the time required for diagnosis may be extended.

Pattern 3:

Operate vehicle following the driving pattern shown in the figure.

Release the accelerator pedal during deceleration of vehicle speed

from 90 km/h (56 MPH) to 0 km/h (0 MPH).

Pattern 4:

The accelerator pedal must be held very steady during steady-

state driving.

If the accelerator pedal is moved, the test must be conducted

again.

*1: Depress the accelerator pedal until vehicle speed is 90 km/h (56

MPH), then release the accelerator pedal and keep it released for

more than 10 seconds. Depress the accelerator pedal until vehicle

speed is 90 km/h (56 MPH) again.

*2: Checking the vehicle speed with GST is advised.

Suggested Transmission Gear Position.

Selector lever position is D.

Test Value and Test LimitINFOID:0000000003856874

The following is the information specified in Service $06 of ISO 15031-5.

The test value is a parameter used to determine whether a system/circuit diagnostic test is OK or NG while

being monitored by the ECM during self-diagnosis. The test limit is a reference value which is specified as the

maximum or minimum value and is compared with the test value being monitored.

These data (test value and test limit) are specified by On Board Monitor ID (OBDMID), Test ID (TID), Unit and

Scaling ID and can be displayed on the GST screen.

The items of the test value and test limit will be displayed with GST screen which items are provided by the

ECM. (eg., if bank 2 is not applied on this vehicle, only the items of bank 1 is displayed)

PBIB2244E

Page 1867 of 5121

![NISSAN TEANA 2008 Service Manual EC-406

< PRECAUTION >[VQ25DE, VQ35DE]

PRECAUTIONS

CAUTION:

Always turn the ignition switch OFF and disconnect the negative battery cable before any repair or

inspection work. The open/short circuit NISSAN TEANA 2008 Service Manual EC-406

< PRECAUTION >[VQ25DE, VQ35DE]

PRECAUTIONS

CAUTION:

Always turn the ignition switch OFF and disconnect the negative battery cable before any repair or

inspection work. The open/short circuit](/img/5/57391/w960_57391-1866.png)

EC-406

< PRECAUTION >[VQ25DE, VQ35DE]

PRECAUTIONS

CAUTION:

Always turn the ignition switch OFF and disconnect the negative battery cable before any repair or

inspection work. The open/short circuit of related switches, sensors, solenoid valves, etc. will cause

the MI to illuminate.

Always connect and lock the connectors securely after work. A loose (unlocked) connector will

cause the MI to illuminate due to the open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

Certain systems and components, especially those related to OBD, may use a new style slide-lock-

ing type harness connector. For description and how to disconnect, refer to PG-96, "

Description".

Always to route and secure the harnesses properly after work. The interference of the harness with a

bracket, etc. may cause the MI to illuminate due to the short circuit.

Always connect rubber tubes properly after work. A misconnected or disconnected rubber tube may

cause the MI to illuminate due to the malfunction of the EVAP system or fuel injection system, etc.

Always erase the unnecessary malfunction information (repairs completed) from the ECM and TCM

(Transmission control module) before returning the vehicle to the customer.

General PrecautionsINFOID:0000000003856881

Always use a 12 volt battery as power source.

Never attempt to disconnect battery cables while engine is

running.

Before connecting or disconnecting the ECM harness con-

nector, turn ignition switch OFF and disconnect negative bat-

tery cable. Failure to do so may damage the ECM because

battery voltage is applied to ECM even if ignition switch is

turned OFF.

Before removing parts, turn ignition switch OFF and then dis-

connect battery ground cable.

Never disassemble ECM.

If a battery cable is disconnected, the memory will return to the ECM value.

The ECM will now start to self-control at its initial value. Thus, engine operation can vary slightly in

this case. However, this is not an indication of a malfunction. Never replace parts because of a slight

variation.

If the battery is disconnected, the following emission-related diagnostic information will be lost

within 24 hours.

-Diagnostic trouble codes

-1st trip diagnostic trouble codes

-Freeze frame data

-1st trip freeze frame data

-System readiness test (SRT) codes

-Test values

When connecting ECM harness connector, fasten (B) it

securely with a lever (1) as far as it will go as shown in the fig-

ure.

SEF289H

2: ECM

A : Loosen

PBIB2947E

Page 1869 of 5121

![NISSAN TEANA 2008 Service Manual EC-408

< PRECAUTION >[VQ25DE, VQ35DE]

PRECAUTIONS

When measuring ECM signals with a circuit tester, never allow

the two tester probes to contact.

Accidental contact of probes will cause a short circu NISSAN TEANA 2008 Service Manual EC-408

< PRECAUTION >[VQ25DE, VQ35DE]

PRECAUTIONS

When measuring ECM signals with a circuit tester, never allow

the two tester probes to contact.

Accidental contact of probes will cause a short circu](/img/5/57391/w960_57391-1868.png)

EC-408

< PRECAUTION >[VQ25DE, VQ35DE]

PRECAUTIONS

When measuring ECM signals with a circuit tester, never allow

the two tester probes to contact.

Accidental contact of probes will cause a short circuit and

damage the ECM power transistor.

Never use ECM ground terminals when measuring input/out-

put voltage. Doing so may result in damage to the ECM's tran-

sistor. Use a ground other than ECM terminals, such as the

ground.

B1 indicates bank 1, B2 indicates bank 2 as shown in the fig-

ure.

Never operate fuel pump when there is no fuel in lines.

Tighten fuel hose clamps to the specified torque.

Never depress accelerator pedal when starting.

Immediately after starting, never rev up engine unnecessarily.

Never rev up engine just prior to shutdown.

SEF348N

SEC893C

SEF709Y

Page 1914 of 5121

OIL PAN AND OIL STRAINER

EM-39

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

Splash guard (RH and LH): Refer to EXT-22, "FENDER PROTECTOR : Exploded View".

Exhaust front tube: Refer to EX-5, "

Exploded View".

Drive belt: Refer to EM-12, "

Removal and Installation".

4. Remove A/C compressor with piping connected, and temporarily secure it to aside. Refer to HA-36,

"Exploded View".

5. Remove oil level gauge. Refer to EM-96, "

Exploded View".

6. Remove front drive shaft (RH). Refer to FAX-16, "

Exploded View".

7. Remove three way catalyst (bank 1 and bank 2) from exhaust manifolds (bank 1 and bank 2). Refer to

EM-34, "

Exploded View".

8. Remove oil pressure switch.

9. Remove oil filter. Refer to LU-10, "

Removal and Installation".

10. Remove oil cooler and water pipes. Refer to LU-11, "

Exploded View".

11. Support transaxle assembly with a suitable jack.

CAUTION:

When setting the transmission jack, be careful not to allow it to collide against the drain plug.

12. Support front suspension member with a suitable jack.

13. Remove engine mounting insulator (rear). Refer to EM-67, "

Exploded View".

14. Remove engine mounting insulator (LH) mounting bolts from transaxle. Refer to EM-67, "

Exploded View".

15. Remove rear torque rod through bolts from rear torque rod bracket. Refer to EM-67, "

Exploded View".

16. Remove member stay, front suspension member fixing bolts and nuts. Refer to FSU-16, "

Exploded View".

17. Lower the jack for the front suspension member to the height.

18. Remove oil pan (lower) as follows:

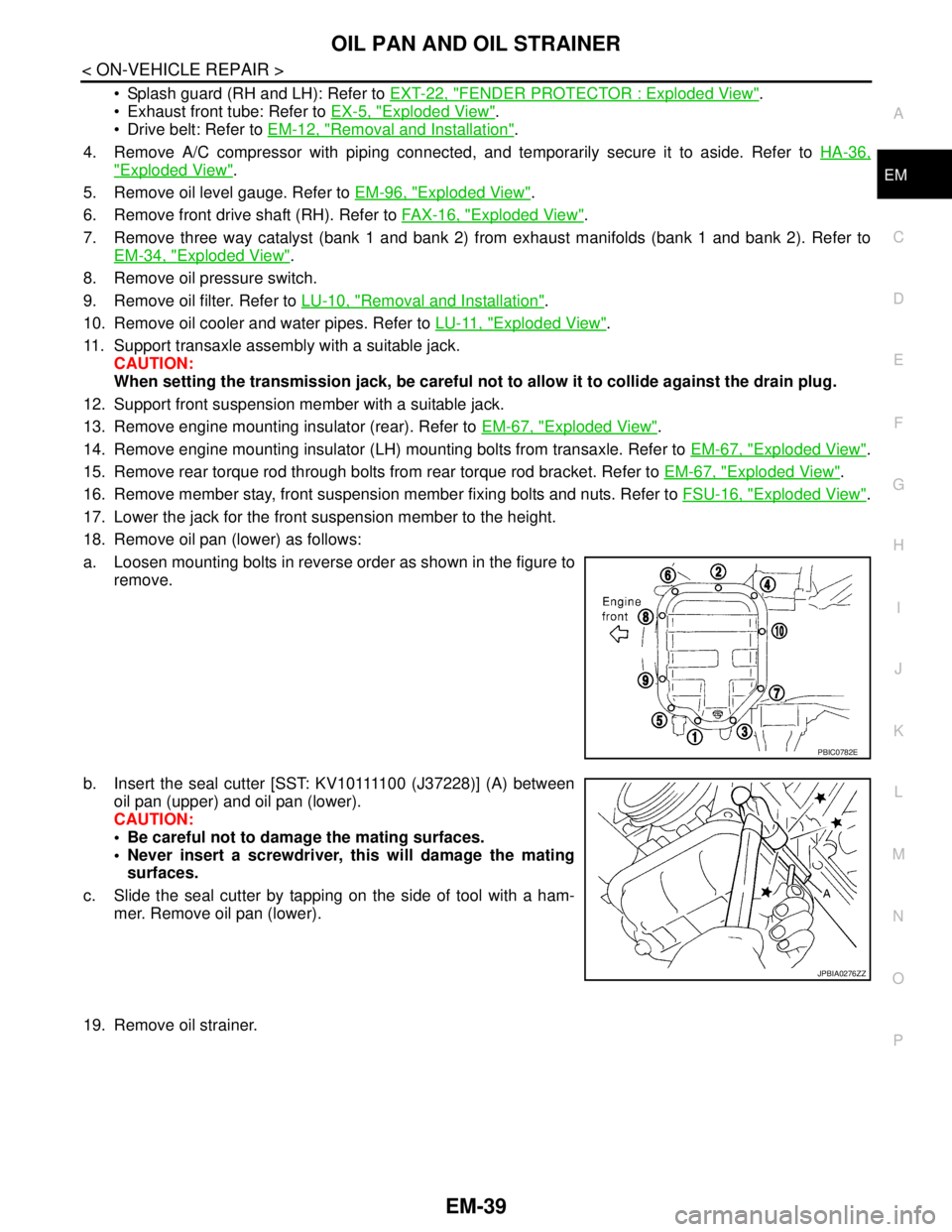

a. Loosen mounting bolts in reverse order as shown in the figure to

remove.

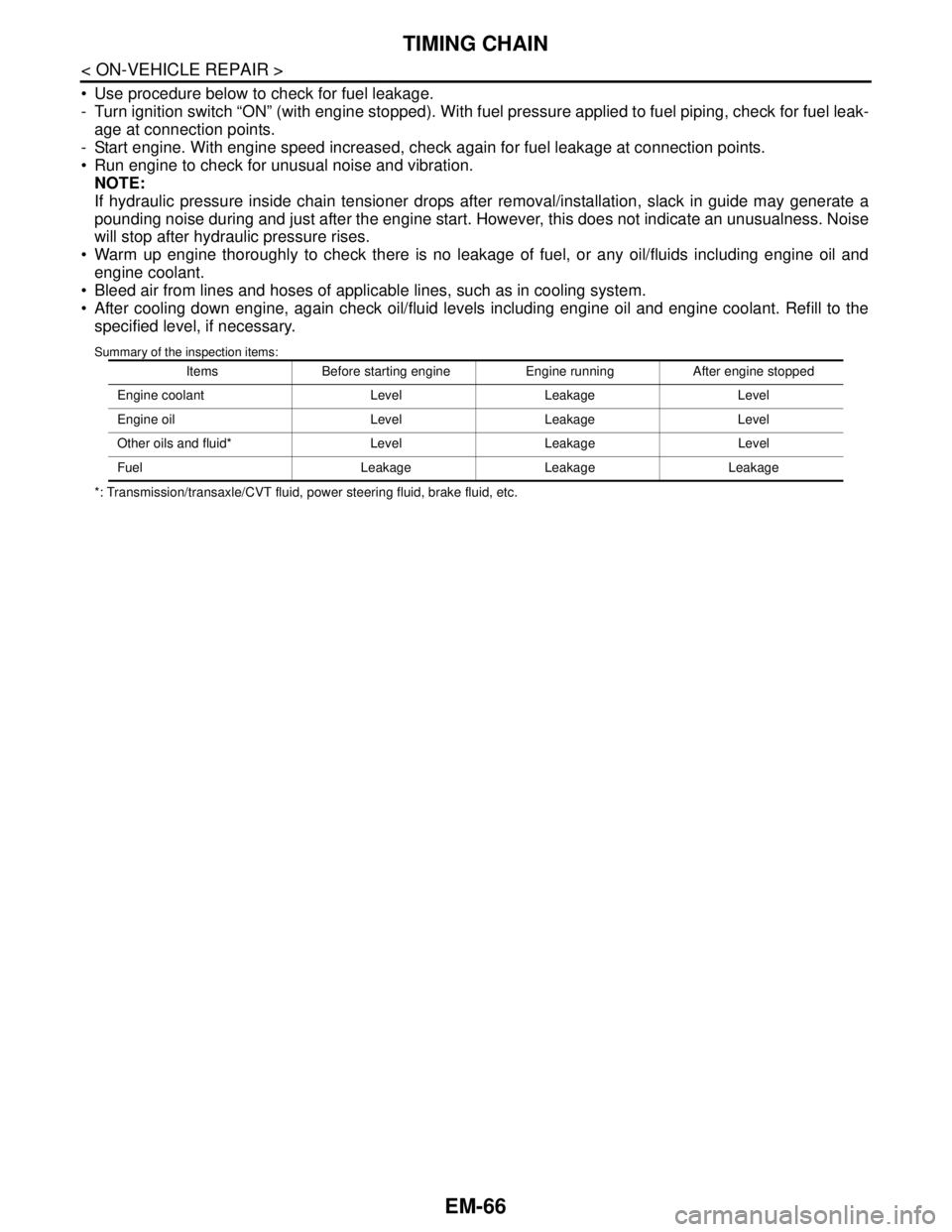

b. Insert the seal cutter [SST: KV10111100 (J37228)] (A) between

oil pan (upper) and oil pan (lower).

CAUTION:

Be careful not to damage the mating surfaces.

Never insert a screwdriver, this will damage the mating

surfaces.

c. Slide the seal cutter by tapping on the side of tool with a ham-

mer. Remove oil pan (lower).

19. Remove oil strainer.

PBIC0782E

JPBIA0276ZZ

Page 1941 of 5121

EM-66

< ON-VEHICLE REPAIR >

TIMING CHAIN

Use procedure below to check for fuel leakage.

- Turn ignition switch “ON” (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak-

age at connection points.

- Start engine. With engine speed increased, check again for fuel leakage at connection points.

Run engine to check for unusual noise and vibration.

NOTE:

If hydraulic pressure inside chain tensioner drops after removal/installation, slack in guide may generate a

pounding noise during and just after the engine start. However, this does not indicate an unusualness. Noise

will stop after hydraulic pressure rises.

Warm up engine thoroughly to check there is no leakage of fuel, or any oil/fluids including engine oil and

engine coolant.

Bleed air from lines and hoses of applicable lines, such as in cooling system.

After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the

specified level, if necessary.

Summary of the inspection items:

*: Transmission/transaxle/CVT fluid, power steering fluid, brake fluid, etc.Items Before starting engine Engine running After engine stopped

Engine coolant Level Leakage Level

Engine oil Level Leakage Level

Other oils and fluid* Level Leakage Level

Fuel Leakage Leakage Leakage