air conditioning NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 1 of 5121

MODEL J32 SERIES

© 2008 NISSAN INTERNATIONAL SA

Allrightsreserved.NopartofthisElectronicServiceManualmaybereproducedorstoredinaretrievalsystem,ortransmittedinanyform,or by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior written permission of Nissan InternationalSA, Switzerland.

AGENERALINFORMATION

BENGINE

DTRANSMISSION&DRIVELINE

ESUSPENSION

FBRAKES

GSTEERING

HRESTRAINTS

IVENTILATION,HEATER&AIRCONDITIONER

JBODYINTERIOR

KBODYEXTERIOR,DOOR,ROOF&VEHICLESECURITY

LDRIVERCONTROLS

MELECTRICAL&POWERCONTROL

NDRIVERINFORMATION&MULTIMEDIA

PMAINTENANCE

GIGeneralInformation

EMEngineMechanical

LUEngineLubricationSystem

COEngineCoolingSystem

ECEngineControlSystem

FLFuelSystem

EXExhaustSystem

STRStartingSystem

ACCAcceleratorControlSystem

TMTransaxle &Transmission

FAXFrontAxle

RAXRearAxle

FSUFrontSuspension

RSURearSuspension

WTRoadWheels &Tires

BRBrakeSystem

PBParkingBrakeSystem

BRCBrakeControlSystem

STSteeringSystem

STCSteeringControlSystem

SBSeatBelt

SRSRSAirbag

SRCSRSAirbagControlSystem

VTLVentilationSystem

HAHeater &AirConditioningSystem

HACHeater &AirConditioningControlSystem

INTInterior

IPInstrumentPanel

SESeat

ADPAutomaticDrivePositioner

DLKDoor &Lock

SECSecurityControlSystem

GWGlass &WindowSystem

PWCPowerWindowControlSystem

RFRoof

EXTExterior

MIRMirrors

EXLExteriorLightingSystem

INLInteriorLightingSystem

WWWiper &Washer

DEFDefogger

HRNHorn

PWOPowerOutlet

BCSBodyControlSystem

LANLANSystem

PCSPowerControlSystem

CHGChargingSystem

PGPowerSupply,Ground&CircuitElements

MWIMeter,WarningLamp&Indicator

WCSWarningChimeSystem

AVAudio,Visual&NavigationSystem

MAMaintenance

QUICKREFERENCEINDEX

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

M

Publication Number:

SM8E00-1J32E0E

Page 1462 of 5121

EC-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION EC

A

EC

N

O P

CONTENTS

ENGINE CONTROL SYSTEM

VQ25DE, VQ35DE

BASIC INSPECTION ....... .............................

7

DIAGNOSIS AND REPAIR WORKFLOW ..... .....7

Work Flow ........................................................... ......7

Diagnostic Work Sheet ............................................10

INSPECTION AND ADJUSTMENT ....................11

BASIC INSPECTION ......... ........................................11

BASIC INSPECTION : Special Repair Require-

ment .................................................................... ....

11

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT .................................................... ....

14

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Description ................................

14

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Special Repair Requirement .....

14

IDLE SPEED .......................................................... ....14

IDLE SPEED : Description ........................ ..............14

IDLE SPEED : Special R epair Requirement ...........14

IGNITION TIMING .................................................. ....15

IGNITION TIMING : Description ..............................15

IGNITION TIMING : Special Repair Requirement ....15

ACCELERATOR PEDAL RELEASED POSITION

LEARNING ............................................................ ....

15

ACCELERATOR PEDAL RELEASED POSITION

LEARNING : Description .........................................

15

ACCELERATOR PEDAL RELEASED POSITION

LEARNING : Special Repair Requirement ..............

15

THROTTLE VALVE CLOSED POSITION LEARN-

ING ......................................................................... ....

16

THROTTLE VALVE CLOSED POSITION

LEARNING : Description .........................................

16

THROTTLE VALVE CLOSED POSITION

LEARNING : Special Repair Requirement ..............

16

IDLE AIR VOLUME LEARNING ............................ ....16

IDLE AIR VOLUME LEARNING : Description .........16

IDLE AIR VOLUME LEARNI NG : Special Repair

Requirement ........................................................ ....

16

MIXTURE RATIO SELF-LEARNING VALUE

CLEAR ................................................................... ....

18

MIXTURE RATIO SELF-LEARNING VALUE

CLEAR : Description ................................................

18

MIXTURE RATIO SELF-LEARNING VALUE

CLEAR : Special Repair Requirement .....................

18

FUNCTION DIAGNOSIS ..............................19

ENGINE CONTRO L SYSTEM ..........................19

System Diagram ................................................. ....19

System Description ..................................................20

Component Parts Location ....................................20

Component Description ...........................................25

MULTIPORT FUEL INJECTION SYSTEM .......27

System Diagram .....................................................27

System Description ..................................................27

Component Parts Location ....................................31

Component Description ...........................................36

ELECTRIC IGNITION SYSTEM ........................37

System Diagram .....................................................37

System Description ..................................................37

Component Parts Location ....................................38

Component Description ...........................................43

AIR CONDITIONING CUT CONTROL ..............44

System Diagram ......................................................44

System Description ..................................................44

Component Parts Location ....................................45

Component Description ...........................................50

AUTOMATIC SPEED CONTROL DEVICE

(ASCD) ..............................................................

51

System Diagram ......................................................51

System Description ..................................................51

Page 1477 of 5121

![NISSAN TEANA 2008 Service Manual EC-16

< BASIC INSPECTION >[VQ25DE, VQ35DE]

INSPECTION AND ADJUSTMENT

THROTTLE VALVE CLOSED POSITION LEARNING

THROTTLE VALVE CLOSED POSITION LEARNING : DescriptionINFOID:0000000003856455

Throttle Valve NISSAN TEANA 2008 Service Manual EC-16

< BASIC INSPECTION >[VQ25DE, VQ35DE]

INSPECTION AND ADJUSTMENT

THROTTLE VALVE CLOSED POSITION LEARNING

THROTTLE VALVE CLOSED POSITION LEARNING : DescriptionINFOID:0000000003856455

Throttle Valve](/img/5/57391/w960_57391-1476.png)

EC-16

< BASIC INSPECTION >[VQ25DE, VQ35DE]

INSPECTION AND ADJUSTMENT

THROTTLE VALVE CLOSED POSITION LEARNING

THROTTLE VALVE CLOSED POSITION LEARNING : DescriptionINFOID:0000000003856455

Throttle Valve Closed Position Learning is an operation to learn the fully closed position of the throttle valve by

monitoring the throttle position sensor output signal. It must be performed each time harness connector of

electric throttle control actuator or ECM is disconnected.

THROTTLE VALVE CLOSED POSITION LEARNING : Special Repair Requirement

INFOID:0000000003856456

1.START

1. Check that accelerator pedal is fully released.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

Check that throttle valve moves during above 10 seconds by confirming the operating sound.

>> END

IDLE AIR VOLUME LEARNING

IDLE AIR VOLUME LEARNING : DescriptionINFOID:0000000003856457

Idle Air Volume Learning is a function of ECM to learn the idle air volume that keeps engine idle speed within

the specific range. It must be performed under the following conditions:

Each time electric throttle control actuator or ECM is replaced.

Idle speed or ignition timing is out of specification.

IDLE AIR VOLUME LEARNING : Special Repair RequirementINFOID:0000000003856458

1.PRECONDITIONING

Before performing Idle Air Volume Learning, check that all of the following conditions are satisfied.

Learning will be cancelled if any of the following conditions are missed for even a moment.

Battery voltage: More than 12.9 V (At idle)

Engine coolant temperature: 70 - 100°C (158 - 212°F)

Selector lever: P or N

Electric load switch: OFF

(Air conditioner, head lamp, rear window defogger)

-For vehicle equipped with daytime light systems, perform one of the following procedures before

starting engine not to illuminate headlamps.

Apply parking brake

Set lighting switch to the 1st position

Steering wheel: Neutral (Straight-ahead position)

Vehicle speed: Stopped

Transmission: Warmed-up

- With CONSULT-III: Drive vehicle until “ATF TEMP SEN” in “DATA MONITOR” mode of “CVT” system indi-

cates less than 0.9 V.

- Without CONSULT-III: Drive vehicle for 10 minutes.

Will CONSULT-III be used?

YES >> GO TO 2.

NO >> GO TO 3.

2.PERFORM IDLE AIR VOLUME LEARNING

With CONSULT-III

1. Perform EC-15, "

ACCELERATOR PEDAL RELEASED POSITION LEARNING : Special Repair Require-

ment".

2. Perform EC-16, "

THROTTLE VALVE CLOSED POSITION LEARNING : Special Repair Requirement".

3. Start engine and warm it up to normal operating temperature.

4. Select “IDLE AIR VOL LEARN” in “WORK SUPPORT” mode.

5. Touch “START” and wait 20 seconds.

Page 1505 of 5121

![NISSAN TEANA 2008 Service Manual EC-44

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

AIR CONDITIONING CUT CONTROL

AIR CONDITIONING CUT CONTROL

System DiagramINFOID:0000000003856473

System DescriptionINFOID:0000000003856474

INPUT/OUTPUT SIGN NISSAN TEANA 2008 Service Manual EC-44

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

AIR CONDITIONING CUT CONTROL

AIR CONDITIONING CUT CONTROL

System DiagramINFOID:0000000003856473

System DescriptionINFOID:0000000003856474

INPUT/OUTPUT SIGN](/img/5/57391/w960_57391-1504.png)

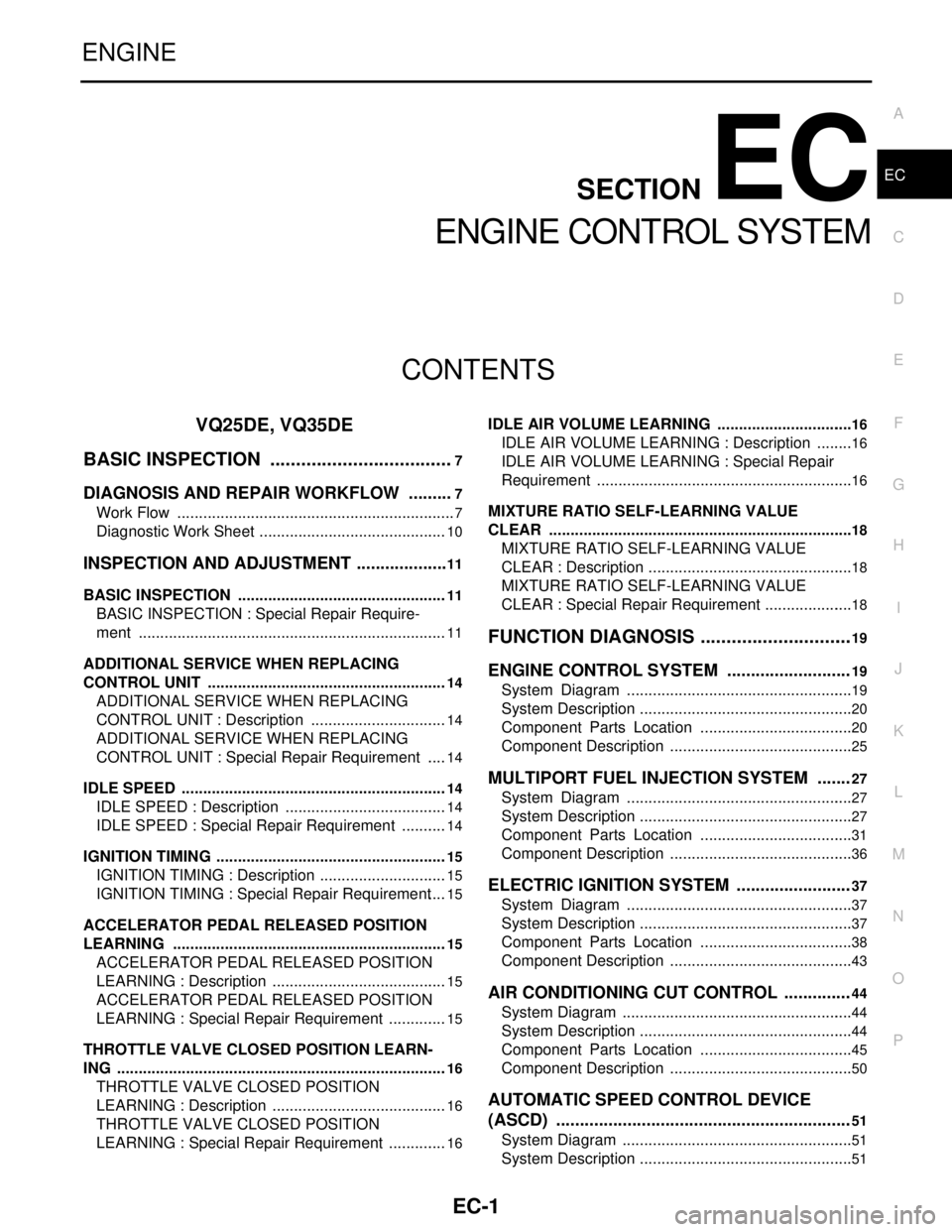

EC-44

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

AIR CONDITIONING CUT CONTROL

AIR CONDITIONING CUT CONTROL

System DiagramINFOID:0000000003856473

System DescriptionINFOID:0000000003856474

INPUT/OUTPUT SIGNAL CHART

*1: This signal is sent to the ECM through CAN communication line.

*2: ECM determines the start signal status by the signals of engine speed and battery voltage.

SYSTEM DESCRIPTION

This system improves engine operation when the air conditioner is used.

Under the following conditions, the air conditioner is turned OFF.

When the accelerator pedal is fully depressed.

When cranking the engine.

At high engine speeds.

When the engine coolant temperature becomes excessively high.

When operating power steering during low engine speed or low vehicle speed.

When engine speed is excessively low.

When refrigerant pressure is excessively low or high.

JMBIA1414GB

Sensor Input Signal to ECM ECM function Actuator

BCM

Air conditioner ON signal*

1

Air conditioner

cut controlAir conditioner relay Accelerator pedal position sensor Accelerator pedal position

Crankshaft position sensor (POS)

Camshaft position sensor (PHASE)Engine speed*

2

Engine coolant temperature sensor Engine coolant temperature

Battery

Battery voltage*

2

Refrigerant pressure sensor Refrigerant pressure

Power steering pressure sensor Power steering operation

ABS actuator and electric unit (control unit)

Vehicle speed*

1

Page 1506 of 5121

![NISSAN TEANA 2008 Service Manual AIR CONDITIONING CUT CONTROL

EC-45

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

Component Parts LocationINFOID:0000000003857773

1. Intake valve timing control solenoid

valve NISSAN TEANA 2008 Service Manual AIR CONDITIONING CUT CONTROL

EC-45

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

Component Parts LocationINFOID:0000000003857773

1. Intake valve timing control solenoid

valve](/img/5/57391/w960_57391-1505.png)

AIR CONDITIONING CUT CONTROL

EC-45

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

Component Parts LocationINFOID:0000000003857773

1. Intake valve timing control solenoid

valve (bank 1)2. Intake valve timing control solenoid

valve (bank 2)3. Electronic controlled engine mount

control solenoid valve

4. Fuel injector (bank 2) 5. Cooling fan motor-2 6. A/F sensor 1 (bank 2)

7. Ignition coil (with power transistor)

and spark plug (bank 2)8. Camshaft position sensor (PHASE)

(bank 2)9. Crankshaft position sensor (POS)

10. Engine coolant temperature sensor 11. Cooling fan motor-1 12. ECM

13. Refrigerant pressure sensor 14. Battery current sensor 15. IPDM E/R

16. Mass air flow sensor (with intake air

temperature sensor)17. Electric throttle control actuator 18. Power valve actuator 2 (VQ35DE

models)

19. EVAP canister purge volume control

solenoid valve20. Camshaft position sensor (PHASE)

(bank 1)21. Ignition coil (with power transistor)

and spark plug (bank 1)

22. A/F sensor 1 (bank 1) 23. Fuel injector (bank 1) 24. VIAS control solenoid valve 1 and 2

(VQ35DE models)

25. Power valve actuator 1

JMBIA1373ZZ

Page 1507 of 5121

![NISSAN TEANA 2008 Service Manual EC-46

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

AIR CONDITIONING CUT CONTROL

1. Mass air flow sensor (with intake air

temperature sensor)2. Electric throttle control actuator

: Vehicle front

1. Ignition NISSAN TEANA 2008 Service Manual EC-46

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

AIR CONDITIONING CUT CONTROL

1. Mass air flow sensor (with intake air

temperature sensor)2. Electric throttle control actuator

: Vehicle front

1. Ignition](/img/5/57391/w960_57391-1506.png)

EC-46

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

AIR CONDITIONING CUT CONTROL

1. Mass air flow sensor (with intake air

temperature sensor)2. Electric throttle control actuator

: Vehicle front

1. Ignition coil (with power transistor)

and spark plug (bank 1)2. Fuel injector (bank 1) 3. Fuel injector (bank 2)

4. Ignition coil (with power transistor)

and spark plug (bank 2)5. EVAP canister

: Vehicle front

1. Knock sensor (bank 1) 2. Knock sensor (bank 2) 3. Knock sensor

: Vehicle front

JMBIA1374ZZ

JMBIA1375ZZ

JMBIA1376GB

JMBIA1377ZZ

Page 1508 of 5121

![NISSAN TEANA 2008 Service Manual AIR CONDITIONING CUT CONTROL

EC-47

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

1. Crankshaft position sensor (POS) 2. Camshaft position sensor (PHASE)

(bank 2)3. Camshaft p NISSAN TEANA 2008 Service Manual AIR CONDITIONING CUT CONTROL

EC-47

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

1. Crankshaft position sensor (POS) 2. Camshaft position sensor (PHASE)

(bank 2)3. Camshaft p](/img/5/57391/w960_57391-1507.png)

AIR CONDITIONING CUT CONTROL

EC-47

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

1. Crankshaft position sensor (POS) 2. Camshaft position sensor (PHASE)

(bank 2)3. Camshaft position sensor (PHASE)

(bank 1)

: Vehicle front

1. Refrigerant pressure sensor 2. Battery current sensor

: Vehicle front

1. ECM 2. Fuel pump fuse 3. IPDM E/R

: Vehicle front

JMBIA1378ZZ

JMBIA1379ZZ

PBIB1686E

Page 1509 of 5121

![NISSAN TEANA 2008 Service Manual EC-48

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

AIR CONDITIONING CUT CONTROL

1. A/F sensor 1 (bank 1) harness con-

nector2. A/F sensor 1 (bank 1) 3. A/F sensor 1 (bank 2) harness con-

nector

4. A/F senso NISSAN TEANA 2008 Service Manual EC-48

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

AIR CONDITIONING CUT CONTROL

1. A/F sensor 1 (bank 1) harness con-

nector2. A/F sensor 1 (bank 1) 3. A/F sensor 1 (bank 2) harness con-

nector

4. A/F senso](/img/5/57391/w960_57391-1508.png)

EC-48

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

AIR CONDITIONING CUT CONTROL

1. A/F sensor 1 (bank 1) harness con-

nector2. A/F sensor 1 (bank 1) 3. A/F sensor 1 (bank 2) harness con-

nector

4. A/F sensor 1 (bank 2)

: Vehicle front

1. HO2S2 (bank 1) 2. HO2S2 (bank 2) 3. HO2S2 (bank 2) harness connector

4. Tie-rod (RH) 5. Power steering pressure sensor 6. HO2S2 (bank 1) harness connector

: Vehicle front

1. Electronic controlled engine mount

control solenoid valve2. VIAS control solenoid valve 1 3. VIAS control solenoid valve 2

4. EVAP canister purge volume control

solenoid valve

JMBIA1116ZZ

JMBIA1380ZZ

JMBIA1381GB

Page 1510 of 5121

![NISSAN TEANA 2008 Service Manual AIR CONDITIONING CUT CONTROL

EC-49

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

1. Electronic controlled engine mount

control solenoid valve2. VIAS control solenoid valve 3. NISSAN TEANA 2008 Service Manual AIR CONDITIONING CUT CONTROL

EC-49

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

1. Electronic controlled engine mount

control solenoid valve2. VIAS control solenoid valve 3.](/img/5/57391/w960_57391-1509.png)

AIR CONDITIONING CUT CONTROL

EC-49

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

1. Electronic controlled engine mount

control solenoid valve2. VIAS control solenoid valve 3. EVAP canister purge volume control

solenoid valve

1. Intake valve timing control solenoid

valve (bank 1)2. Intake valve timing control solenoid

valve (bank 2)3. Data link connector

1. Stop lamp switch 2. ASCD brake switch 3. Accelerator pedal position sensor

1. ASCD steering switch 2. CANCEL switch 3. RESUME/ACCELERATE switch

4. SET/COAST switch 5. MAIN switch

JMBIA1382GB

JMBIA1383ZZ

JMBIA1384ZZ

JMBIA1120ZZ

Page 1511 of 5121

![NISSAN TEANA 2008 Service Manual EC-50

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

AIR CONDITIONING CUT CONTROL

Component Description

INFOID:0000000003856476

1. Fuel level sensor unit and fuel pump

harness connector2. Fuel pressure regul NISSAN TEANA 2008 Service Manual EC-50

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

AIR CONDITIONING CUT CONTROL

Component Description

INFOID:0000000003856476

1. Fuel level sensor unit and fuel pump

harness connector2. Fuel pressure regul](/img/5/57391/w960_57391-1510.png)

EC-50

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

AIR CONDITIONING CUT CONTROL

Component Description

INFOID:0000000003856476

1. Fuel level sensor unit and fuel pump

harness connector2. Fuel pressure regulator 3. Fuel level sensor unit and fuel pump

: Vehicle front

JMBIA1385ZZ

Component Reference

Accelerator pedal position sensorEC-304, "

Description"

Camshaft position sensor (PHASE)EC-222, "Description"

Crankshaft position sensor (POS)EC-218, "Description"

Engine coolant temperature sensorEC-157, "Description"

Power steering pressure sensorEC-236, "Description"

Refrigerant pressure sensorEC-348, "Description"