diagram NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 4477 of 5121

TM-4

ROAD TEST .....................................................148

Description .............................................................148

Check before Engine Is Started .............................148

Check at Idle ..........................................................149

Cruise Test ............................................................150

CVT POSITION ................................................152

Inspection and Adjustment ....................................152

ON-VEHICLE REPAIR ...............................153

TRANSMISSION CONTROL MODULE ..........153

Exploded View .......................................................153

Removal and Installation .......................................153

Adjustment .............................................................154

CONTROL DEVICE .........................................155

Exploded View .......................................................155

Removal and Installation .......................................155

Inspection and Adjustment ....................................156

CONTROL CABLE ..........................................157

Exploded View .......................................................157

Removal and Installation .......................................157

Inspection and Adjustment ....................................158

OIL PAN ...........................................................159

Exploded View .......................................................159

Removal and Installation .......................................159

Inspection ..............................................................160

SECONDARY SPEED SENSOR .....................161

Exploded View .......................................................161

Removal and Installation .......................................161

Inspection ..............................................................161

DIFFERENTIAL SIDE OIL SEAL ....................162

Exploded View .......................................................162

Removal and Installation .......................................162

Inspection ..............................................................163

AIR BREATHER HOSE ...................................164

Exploded View .......................................................164

Removal and Installation .......................................164

FLUID COOLER SYSTEM ...............................165

Exploded View .......................................................165

Removal and Installation .......................................165

Inspection ..............................................................167

REMOVAL AND INSTALLATION ..............168

TRANSAXLE ASSEMBLY ..............................168

Exploded View .......................................................168

Removal and Installation .......................................168

Inspection ..............................................................170

DISASSEMBLY AND ASSEMBLY ............172

TORQUE CONVERTER ..................................172

Exploded View .......................................................172

Disassembly ..........................................................172

Assembly ..............................................................172

Inspection ..............................................................173

SERVICE DATA AND SPECIFICATIONS

(SDS) .........................................................

174

SERVICE DATA AND SPECIFICATIONS

(SDS) ................................................................

174

General Specification ............................................174

Vehicle Speed When Shifting Gears .....................174

Stall Speed ............................................................174

Line Pressure ........................................................174

Solenoid Valves ....................................................175

CVT Fluid Temperature Sensor ............................175

Primary Speed Sensor ..........................................175

Secondary Speed Sensor .....................................175

Step Motor ............................................................175

Torque Converter ..................................................175

CVT: RE0F10A

BASIC INSPECTION .................................

176

DIAGNOSIS AND REPAIR WORK FLOW .......176

Work Flow .............................................................176

Diagnostic Work Sheet .........................................177

INSPECTION AND ADJUSTMENT ..................179

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT ......................................................

179

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Service After Replacing TCM

and Transaxle Assembly .......................................

179

FUNCTION DIAGNOSIS ...........................181

CVT SYSTEM ...................................................181

System Diagram ...................................................181

Component Parts Location ...................................182

MECHANICAL SYSTEM ..................................183

Cross-Sectional View ............................................183

System Diagram ...................................................184

System Description ...............................................184

Component Parts Location ...................................185

Component Description ........................................186

HYDRAULIC CONTROL SYSTEM ..................187

System Diagram ...................................................187

System Description ...............................................187

Component Parts Location ...................................188

Component Description ........................................189

CONTROL SYSTEM .........................................190

System Diagram ...................................................190

System Description ...............................................190

Component Parts Location ...................................192

Component Description ........................................193

LOCK-UP AND SELECT CONTROL SYSTEM

..

194

Page 4478 of 5121

TM-5

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P System Diagram ....................................................

194

System Description ...............................................194

Component Parts Location ....................................195

Component Description .........................................196

SHIFT CONTROL SYSTEM .............................197

System Diagram ....................................................197

System Description ...............................................197

Component Parts Location ....................................198

Component Description .........................................199

SHIFT LOCK SYSTEM .....................................200

System Description ...............................................200

Component Parts Location ....................................201

Component Description .........................................201

ON BOARD DIAGNOSTIC (OBD) SYSTEM ....202

Diagnosis Description ...........................................202

DIAGNOSIS SYSTEM (TCM) ...........................204

CONSULT-III Function (TRANSMISSION) ...........204

Diagnostic Tool Function .......................................207

COMPONENT DIAGNOSIS .......................208

U1000 CAN COMM CIRCUIT ...........................208

Description ............................................................208

DTC Logic .............................................................208

Diagnosis Procedure .............................................208

U1010 CONTROL UNIT (CAN) ........................209

Description ............................................................209

DTC Logic .............................................................209

Diagnosis Procedure .............................................209

P0703 STOP LAMP SWITCH ..........................210

Description ............................................................210

DTC Logic .............................................................210

Diagnosis Procedure .............................................210

Component Inspection (Stop Lamp Switch) ..........211

P0705 PARK/NEUTRAL POSITION SWITCH ..213

Description ............................................................213

DTC Logic .............................................................213

Diagnosis Procedure .............................................213

Component Inspection (Park/Neutral Position

Switch) ..................................................................

214

P0710 CVT FLUID TEMPERATURE SENSOR

..

216

Description ............................................................216

DTC Logic .............................................................216

Diagnosis Procedure .............................................216

Component Inspection (CVT Fluid Temperature

Sensor) ..................................................................

217

P0715 INPUT SPEED SENSOR (PRI SPEED

SENSOR) ..........................................................

218

Description ............................................................218

DTC Logic .............................................................218

Diagnosis Procedure .............................................218

P0720 VEHICLE SPEED SENSOR CVT (SEC-

ONDARY SPEED SENSOR) ...........................

222

Description .............................................................222

DTC Logic ..............................................................222

Diagnosis Procedure .............................................222

P0725 ENGINE SPEED SIGNAL ....................226

Description .............................................................226

DTC Logic ..............................................................226

Diagnosis Procedure .............................................226

P0730 BELT DAMAGE ...................................228

Description .............................................................228

DTC Logic ..............................................................228

Diagnosis Procedure .............................................228

P0740 TORQUE CONVERTER CLUTCH SO-

LENOID VALVE ..............................................

230

Description .............................................................230

DTC Logic ..............................................................230

Diagnosis Procedure .............................................230

Component Inspection (Torque Converter Clutch

Solenoid Valve) .....................................................

231

P0744 A/T TCC S/V FUNCTION (LOCK -UP) .232

Description .............................................................232

DTC Logic ..............................................................232

Diagnosis Procedure .............................................232

Component Inspection (Torque Converter Clutch

Solenoid Valve) .....................................................

233

Component Inspection (Lock-up Select Solenoid

Valve) ....................................................................

233

P0745 LINE PRESSURE SOLENOID VALVE .234

Description .............................................................234

DTC Logic ..............................................................234

Diagnosis Procedure .............................................234

Component Inspection [Pressure Control Sole-

noid Valve A (Line Pressure Solenoid Valve)] .......

235

P0746 PRESSURE CONTROL SOLENOID A

PERFORMANCE (LINE PRESSURE SOLE-

NOID VALVE) ..................................................

236

Description .............................................................236

DTC Logic ..............................................................236

Diagnosis Procedure .............................................236

Component Inspection [Pressure Control Sole-

noid Valve A (Line Pressure Solenoid Valve)] .......

237

P0776 PRESSURE CONTROL SOLENOID B

PERFORMANCE (SEC PRESSURE SOLE-

NOID VALVE) ..................................................

238

Description .............................................................238

DTC Logic ..............................................................238

Diagnosis Procedure .............................................238

Component Inspection [Pressure Control Sole-

noid Valve A (Line Pressure Solenoid Valve)] .......

239

Component Inspection [Pressure Control Sole-

noid Valve B (Secondary Pressure Solenoid

Valve)] ...................................................................

239

Page 4479 of 5121

TM-6

P0778 PRESSURE CONTROL SOLENOID B

ELECTRICAL (SEC PRESSURE SOLENOID

VALVE) ............................................................

240

Description .............................................................240

DTC Logic ..............................................................240

Diagnosis Procedure .............................................240

Component Inspection [Pressure Control Sole-

noid Valve B (Secondary Pressure Solenoid

Valve)] ...................................................................

241

P0840 TRANSMISSION FLUID PRESSURE

SENSOR A (SEC PRESSURE SENSOR) .......

242

Description .............................................................242

DTC Logic ..............................................................242

Diagnosis Procedure .............................................242

P0841 PRESSURE SENSOR FUNCTION ......245

Description .............................................................245

DTC Logic ..............................................................245

Diagnosis Procedure .............................................245

Component Inspection [Pressure Control Sole-

noid Valve A (Line Pressure Solenoid Valve)] .......

246

Component Inspection [Pressure Control Sole-

noid Valve B (Secondary Pressure Solenoid

Valve)] ...................................................................

246

P0868 SECONDARY PRESSURE DOWN ......247

Description .............................................................247

DTC Logic ..............................................................247

Diagnosis Procedure .............................................247

Component Inspection [Pressure Control Sole-

noid Valve A (Line Pressure Solenoid Valve)] .......

248

Component Inspection [Pressure Control Sole-

noid Valve B (Secondary Pressure Solenoid

Valve)] ...................................................................

248

P1701 TRANSMISSION CONTROL MODULE

(POWER SUPPLY) ..........................................

249

Description .............................................................249

DTC Logic ..............................................................249

Diagnosis Procedure .............................................249

P1705 THROTTLE POSITION SENSOR ........252

Description .............................................................252

DTC Logic ..............................................................252

Diagnosis Procedure .............................................252

P1722 ESTM VEHICLE SPEED SIGNAL ........253

Description .............................................................253

DTC Logic ..............................................................253

Diagnosis Procedure .............................................253

P1723 CVT SPEED SENSOR FUNCTION ......255

Description .............................................................255

DTC Logic ..............................................................255

Diagnosis Procedure .............................................255

P1726 ELECTRIC THROTTLE CONTROL

SYSTEM ...........................................................

257

Description .............................................................257

DTC Logic .............................................................257

Diagnosis Procedure .............................................257

P1740 LOCK-UP SELECT SOLENOID

VALVE ..............................................................

258

Description ............................................................258

DTC Logic .............................................................258

Diagnosis Procedure .............................................258

Component Inspection (Lock-up Select Solenoid

Valve) ....................................................................

259

P1745 LINE PRESSURE CONTROL ...............260

Description ............................................................260

DTC Logic .............................................................260

Diagnosis Procedure .............................................260

P1777 STEP MOTOR .......................................261

Description ............................................................261

DTC Logic .............................................................261

Diagnosis Procedure .............................................261

Component Inspection (Step Motor) .....................263

P1778 STEP MOTOR - FUNCTION .................264

Description ............................................................264

DTC Logic .............................................................264

Diagnosis Procedure .............................................264

SHIFT POSITION INDICATOR CIRCUIT .........266

Description ............................................................266

Component Function Check .................................266

Diagnosis Procedure .............................................266

SHIFT LOCK SYSTEM .....................................267

Description ............................................................267

Wiring Diagram - CVT SHIFT LOCK SYSTEM - ...267

Component Function Check .................................269

Diagnosis Procedure .............................................270

Component Inspection (Stop Lamp Switch) ..........271

SPORT MODE SWITCH ...................................272

Description ............................................................272

Component Function Check .................................272

Diagnosis Procedure .............................................272

ECU DIAGNOSIS ......................................275

TCM ..................................................................275

Reference Value ...................................................275

Wiring Diagram - CVT CONTROL SYSTEM - ......279

Fail-safe ................................................................283

DTC Inspection Priority Chart ...............................284

DTC Index .............................................................284

SYMPTOM DIAGNOSIS ...........................286

SYSTEM SYMPTOM ........................................286

Symptom Table .....................................................286

PRECAUTION ...........................................297

PRECAUTIONS ................................................297

Page 4486 of 5121

![NISSAN TEANA 2008 Service Manual CVT SYSTEM

TM-13

< FUNCTION DIAGNOSIS >[CVT: RE0F09B]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

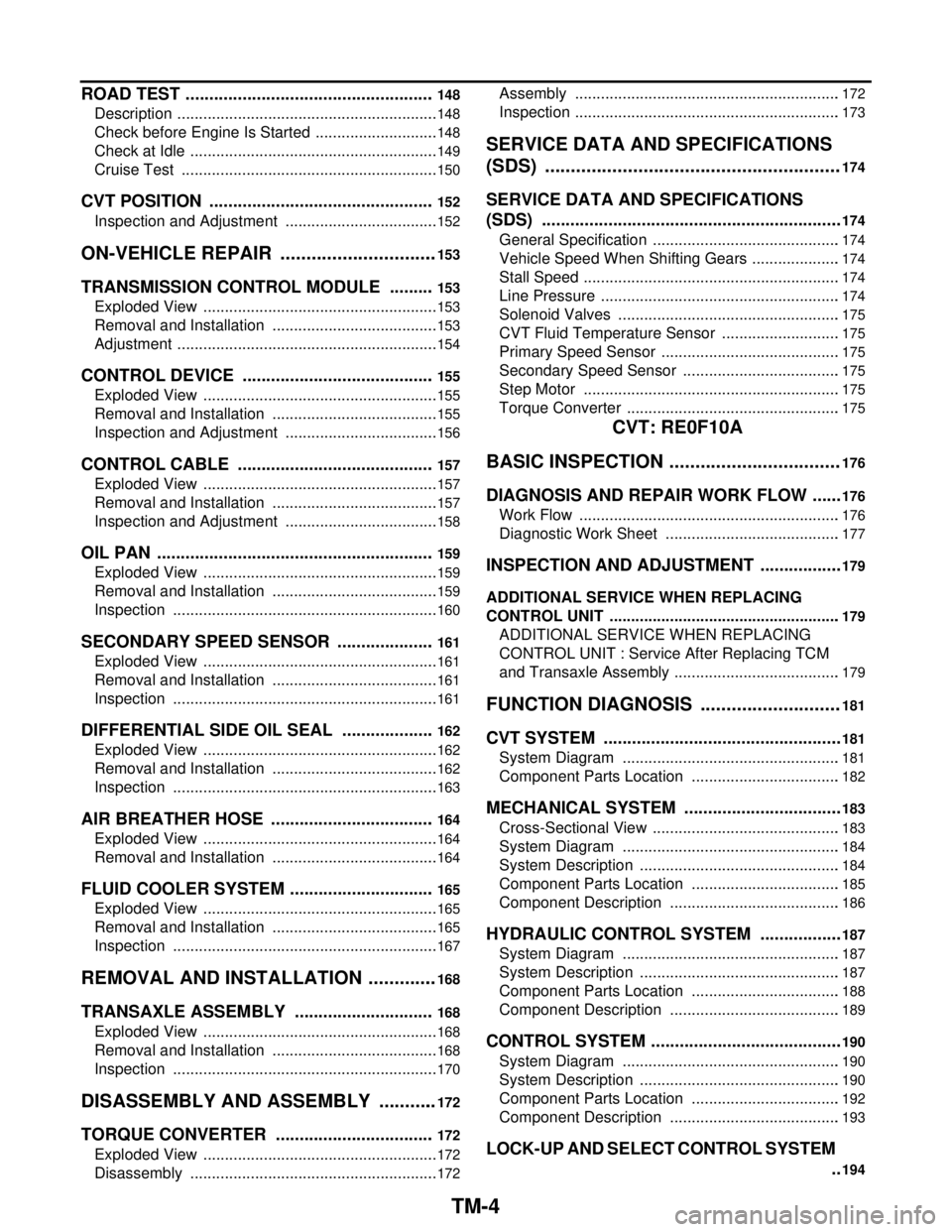

FUNCTION DIAGNOSIS

CVT SYSTEM

System DiagramINFOID:0000000003848917

JPDIA0755GB NISSAN TEANA 2008 Service Manual CVT SYSTEM

TM-13

< FUNCTION DIAGNOSIS >[CVT: RE0F09B]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

FUNCTION DIAGNOSIS

CVT SYSTEM

System DiagramINFOID:0000000003848917

JPDIA0755GB](/img/5/57391/w960_57391-4485.png)

CVT SYSTEM

TM-13

< FUNCTION DIAGNOSIS >[CVT: RE0F09B]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

FUNCTION DIAGNOSIS

CVT SYSTEM

System DiagramINFOID:0000000003848917

JPDIA0755GB

Page 4490 of 5121

![NISSAN TEANA 2008 Service Manual MECHANICAL SYSTEM

TM-17

< FUNCTION DIAGNOSIS >[CVT: RE0F09B]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

System DiagramINFOID:0000000003848920

System DescriptionINFOID:0000000003848921

Transmits the power from th NISSAN TEANA 2008 Service Manual MECHANICAL SYSTEM

TM-17

< FUNCTION DIAGNOSIS >[CVT: RE0F09B]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

System DiagramINFOID:0000000003848920

System DescriptionINFOID:0000000003848921

Transmits the power from th](/img/5/57391/w960_57391-4489.png)

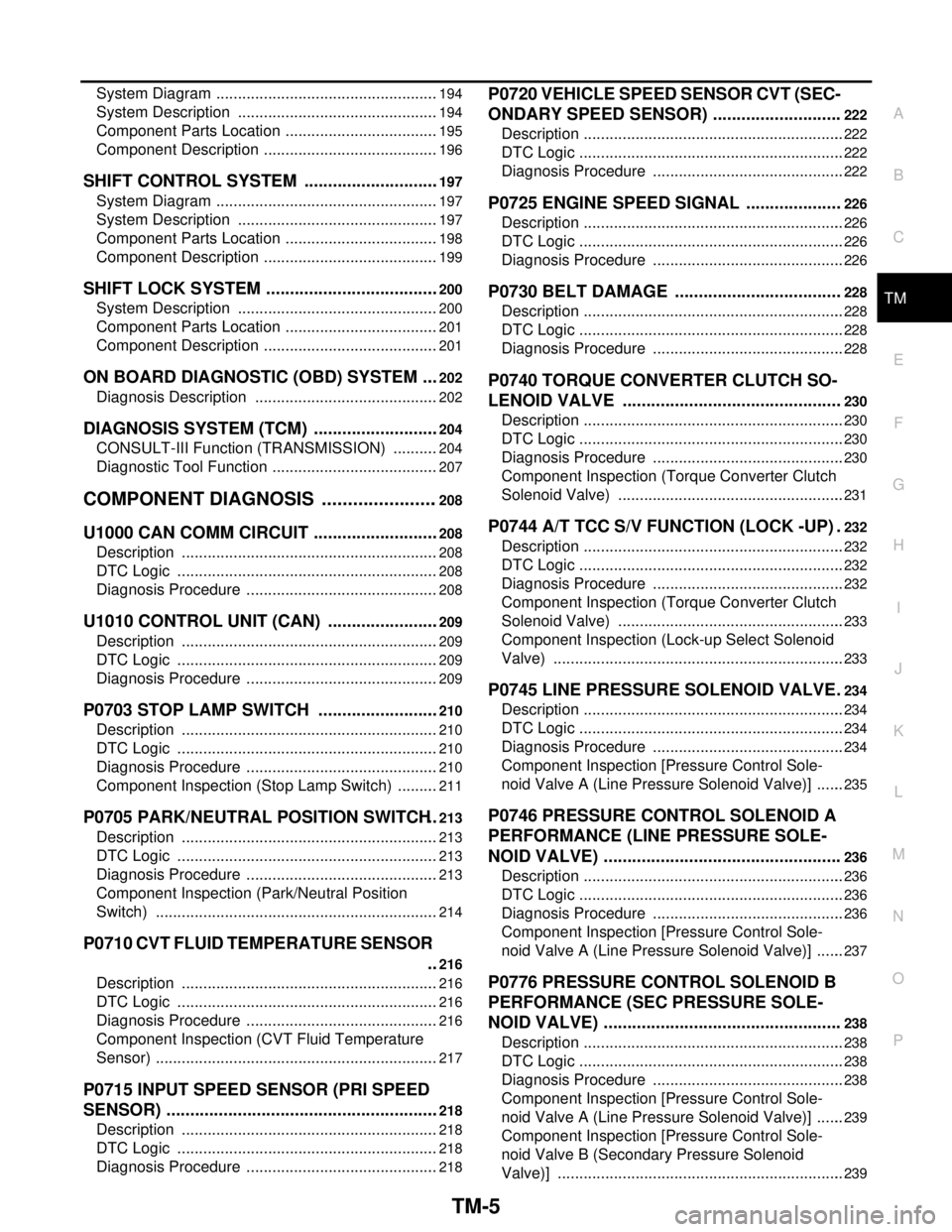

MECHANICAL SYSTEM

TM-17

< FUNCTION DIAGNOSIS >[CVT: RE0F09B]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

System DiagramINFOID:0000000003848920

System DescriptionINFOID:0000000003848921

Transmits the power from the engine to the drive wheel.

JPDIA0755GB

Page 4493 of 5121

![NISSAN TEANA 2008 Service Manual TM-20

< FUNCTION DIAGNOSIS >[CVT: RE0F09B]

HYDRAULIC CONTROL SYSTEM

HYDRAULIC CONTROL SYSTEM

System DiagramINFOID:0000000003848924

System DescriptionINFOID:0000000003848925

The hydraulic control mecha NISSAN TEANA 2008 Service Manual TM-20

< FUNCTION DIAGNOSIS >[CVT: RE0F09B]

HYDRAULIC CONTROL SYSTEM

HYDRAULIC CONTROL SYSTEM

System DiagramINFOID:0000000003848924

System DescriptionINFOID:0000000003848925

The hydraulic control mecha](/img/5/57391/w960_57391-4492.png)

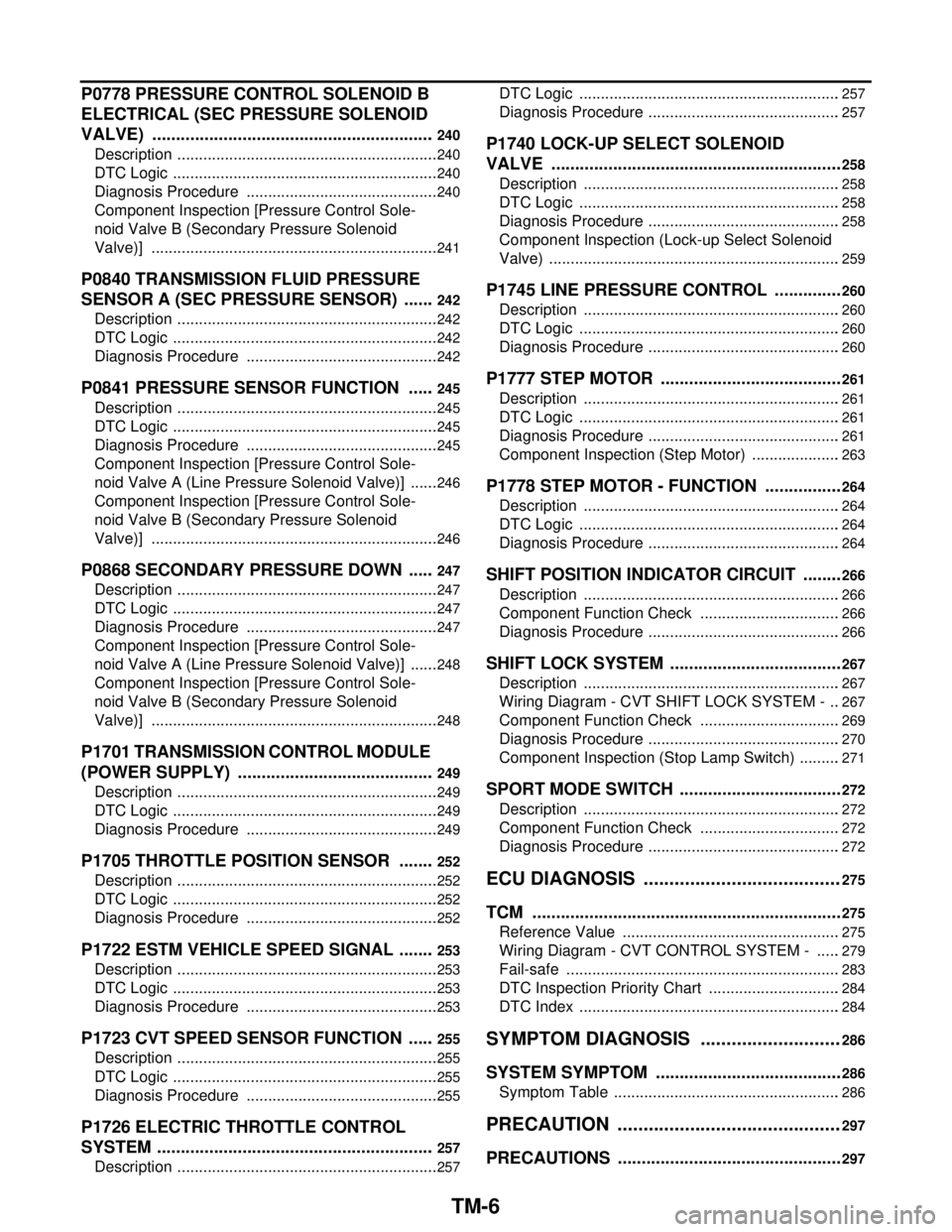

TM-20

< FUNCTION DIAGNOSIS >[CVT: RE0F09B]

HYDRAULIC CONTROL SYSTEM

HYDRAULIC CONTROL SYSTEM

System DiagramINFOID:0000000003848924

System DescriptionINFOID:0000000003848925

The hydraulic control mechanism consists of the oil pump directly driven by the engine, the hydraulic control

valve that controls line pressure and transmission, and the input signal line.

LINE PRESSURE AND SECONDARY PRESSURE CONTROL

When an input torque signal equivalent to the engine driving force is transmitted from the ECM to the TCM,

the TCM controls the line pressure solenoid valve and secondary pressure solenoid valve.

Line pressure solenoid valve activates pressure regulator valve, and line pressure from oil pump is adjusted

for the optimum driving condition. Secondary pressure is controlled by lowering line pressure.

JPDIA0589GB

SCIA1846E

Page 4496 of 5121

![NISSAN TEANA 2008 Service Manual CONTROL SYSTEM

TM-23

< FUNCTION DIAGNOSIS >[CVT: RE0F09B]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

CONTROL SYSTEM

System DiagramINFOID:0000000003848928

System DescriptionINFOID:0000000003848929

The CVT senses NISSAN TEANA 2008 Service Manual CONTROL SYSTEM

TM-23

< FUNCTION DIAGNOSIS >[CVT: RE0F09B]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

CONTROL SYSTEM

System DiagramINFOID:0000000003848928

System DescriptionINFOID:0000000003848929

The CVT senses](/img/5/57391/w960_57391-4495.png)

CONTROL SYSTEM

TM-23

< FUNCTION DIAGNOSIS >[CVT: RE0F09B]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

CONTROL SYSTEM

System DiagramINFOID:0000000003848928

System DescriptionINFOID:0000000003848929

The CVT senses vehicle operating conditions through various sensors. It always controls the optimum shift

position and reduces shifting and lock-up shocks.

TCM FUNCTION

The function of the TCM is to:

Receive input signals sent from various switches and sensors.

Determine required line pressure, shifting point, and lock-up operation.

Send required output signals to the step motor and the respective solenoids.

INPUT/OUTPUT SIGNAL OF TCM

JPDIA0809GB

SENSORS (or SIGNAL)

⇒TCM

⇒ACTUATORS

PNP switch

Accelerator pedal position signal

Closed throttle position signal

Engine speed signal

CVT fluid temperature sensor

Vehicle speed signal

Sport mode switch signal

Stop lamp switch signal

Primary speed sensor

Secondary speed sensor

Primary pressure sensor

Secondary pressure sensorShift control

Line pressure control

Primary pressure control

Secondary pressure control

Lock-up control

Engine brake control

Vehicle speed control

Fail-safe control

Self-diagnosis

CONSULT-III communication line

Duet-EA control

CAN system

On board diagnosisStep motor

Torque converter clutch solenoid

valve

Lock-up select solenoid valve

Line pressure solenoid valve

Secondary pressure solenoid valve

SPORT indicator lamp

Shift position indicator

Stater relay

Page 4500 of 5121

![NISSAN TEANA 2008 Service Manual LOCK-UP AND SELECT CONTROL SYSTEM

TM-27

< FUNCTION DIAGNOSIS >[CVT: RE0F09B]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

LOCK-UP AND SELECT CONTROL SYSTEM

System DiagramINFOID:0000000003848932

System DescriptionI NISSAN TEANA 2008 Service Manual LOCK-UP AND SELECT CONTROL SYSTEM

TM-27

< FUNCTION DIAGNOSIS >[CVT: RE0F09B]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

LOCK-UP AND SELECT CONTROL SYSTEM

System DiagramINFOID:0000000003848932

System DescriptionI](/img/5/57391/w960_57391-4499.png)

LOCK-UP AND SELECT CONTROL SYSTEM

TM-27

< FUNCTION DIAGNOSIS >[CVT: RE0F09B]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

LOCK-UP AND SELECT CONTROL SYSTEM

System DiagramINFOID:0000000003848932

System DescriptionINFOID:0000000003848933

The torque converter clutch piston in the torque converter is engaged to eliminate torque converter slip to

increase power transmission efficiency.

The torque converter clutch control valve operation is controlled by the torque converter clutch solenoid

valve, which is controlled by a signal from TCM. The torque converter clutch control valve engages or

releases the torque converter clutch piston.

When shifting between “N” (“P”) ⇔“D” (“R”), torque converter clutch solenoid valve controls engagement

power of forward clutch and reverse brake.

The lock-up applied gear range was expanded by locking up the

torque converter at a lower vehicle speed than conventional CVT

models.

TORQUE CONVERTER CLUTCH AND SELECT CONTROL VALVE CONTROL

Lock-up Released

In the lock-up released state, the torque converter clutch control valve is set into the unlocked state by the

torque converter clutch solenoid valve and the lock-up apply pressure is drained.

In this way, the torque converter clutch piston is not coupled.

Lock-up Applied

In the lock-up applied state, the torque converter clutch control valve is set into the locked state by the torque

converter clutch solenoid valve and lock-up apply pressure is generated.

In this way, the torque converter clutch piston is pressed and coupled.

Select Control

When shifting between “N” (“P”) ⇔“D” (“R”), optimize the operating pressure on the basis of the throttle posi-

tion, the engine speed, and the secondary pulley (output) revolution speed to lessen the shift shock.

SCIA2374E

JPDIA0312GB

Page 4503 of 5121

![NISSAN TEANA 2008 Service Manual TM-30

< FUNCTION DIAGNOSIS >[CVT: RE0F09B]

SHIFT CONTROL SYSTEM

SHIFT CONTROL SYSTEM

System DiagramINFOID:0000000003848936

NOTE:

The gear ratio is set for each position separately.

System DescriptionI NISSAN TEANA 2008 Service Manual TM-30

< FUNCTION DIAGNOSIS >[CVT: RE0F09B]

SHIFT CONTROL SYSTEM

SHIFT CONTROL SYSTEM

System DiagramINFOID:0000000003848936

NOTE:

The gear ratio is set for each position separately.

System DescriptionI](/img/5/57391/w960_57391-4502.png)

TM-30

< FUNCTION DIAGNOSIS >[CVT: RE0F09B]

SHIFT CONTROL SYSTEM

SHIFT CONTROL SYSTEM

System DiagramINFOID:0000000003848936

NOTE:

The gear ratio is set for each position separately.

System DescriptionINFOID:0000000003848937

In order to select the gear ratio that can obtain the driving force in accordance with driver's intention and the

vehicle condition, TCM monitors the driving conditions, such as the vehicle speed and the throttle position,

selects the optimum gear ratio, and determines the gear change steps to the gear ratio. Then TCM sends the

command to the step motor, controls the inflow/outflow of line pressure from the primary pulley to determine

the position of the moving-pulley and controls the gear ratio.

“D” POSITION

Shifting over all the ranges of gear ratios from the lowest to the high-

est.

SPORT MODE

Use this position for improved engine braking.

“L” POSITION

JPDIA0745GB

SCIA1953E

JPDIA0685GB

Page 4510 of 5121

![NISSAN TEANA 2008 Service Manual DIAGNOSIS SYSTEM (TCM)

TM-37

< FUNCTION DIAGNOSIS >[CVT: RE0F09B]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

DIAGNOSIS SYSTEM (TCM)

CONSULT-III Function (TRANSMISSION)INFOID:0000000003848944

FUNCTION

CONSULT-III NISSAN TEANA 2008 Service Manual DIAGNOSIS SYSTEM (TCM)

TM-37

< FUNCTION DIAGNOSIS >[CVT: RE0F09B]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

DIAGNOSIS SYSTEM (TCM)

CONSULT-III Function (TRANSMISSION)INFOID:0000000003848944

FUNCTION

CONSULT-III](/img/5/57391/w960_57391-4509.png)

DIAGNOSIS SYSTEM (TCM)

TM-37

< FUNCTION DIAGNOSIS >[CVT: RE0F09B]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

DIAGNOSIS SYSTEM (TCM)

CONSULT-III Function (TRANSMISSION)INFOID:0000000003848944

FUNCTION

CONSULT-III can display each diagnostic item using the diagnostic test modes shown following.

WORK SUPPORT MODE

Display Item List

Engine Brake Adjustment

CAUTION:

Mode of “+1”“0”“−1”“−2”“OFF” can be selected by touching “UP”or “DOWN” on CONSULT-III screen.

However, do not select a mode other than “0” and “OFF”. Selecting “+1” or “−1” or “–2” may cause

irregular driveability.

Check CVT Fluid Deterioration Date

CAUTION:

Touch “CLEAR” after changing CVT fluid, and then erase “CVTF DETERIORATION DATE”.

SELF-DIAGNOSTIC RESULT MODE

Display Items List

Refer to TM-121, "DTC Index".

DATA MONITOR MODE

Display Items List

Diagnostic test mode Function

Work Support This mode enables a technician to adjust some devices faster and more accurately.

Self-Diagnostic Results Retrieve DTC from ECU and display diagnostic items.

Data Monitor Monitor the input/output signal of the control unit in real time.

CAN Diagnosis This mode displays a network diagnosis result about CAN by a diagram.

CAN Diagnostic Support Monitor It monitors the status of CAN communication.

Function TestThis mode can show results of self-diagnosis of ECU with either “OK” or “NG”. For en-

gine, more practical tests regarding sensors/switches and/or actuators are available.

ECU Identification Display the ECU identification number (part number etc.) of the selected system.

Special Function Other results or histories, etc. that are recorded in ECU are displayed.

Item name Description

ENGINE BRAKE ADJ. The engine brake level setting can be canceled.

CONFORM CVTF DETERIORTN The CVT fluid deterioration level can be checked.

“ENGINE BRAKE LEVEL”

0 : Initial set value (Engine brake level control is activated)

OFF : Engine brake level control is deactivated.

“CVTF DETERIORATION DATE”

More than 210000 : It is necessary to change CVT fluid.

Less than 210000 : It is not necessary to change CVT fluid.