Ccu NISSAN TEANA 2008 Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 910 of 5121

BR-14

< ON-VEHICLE MAINTENANCE >

FRONT DISC BRAKE

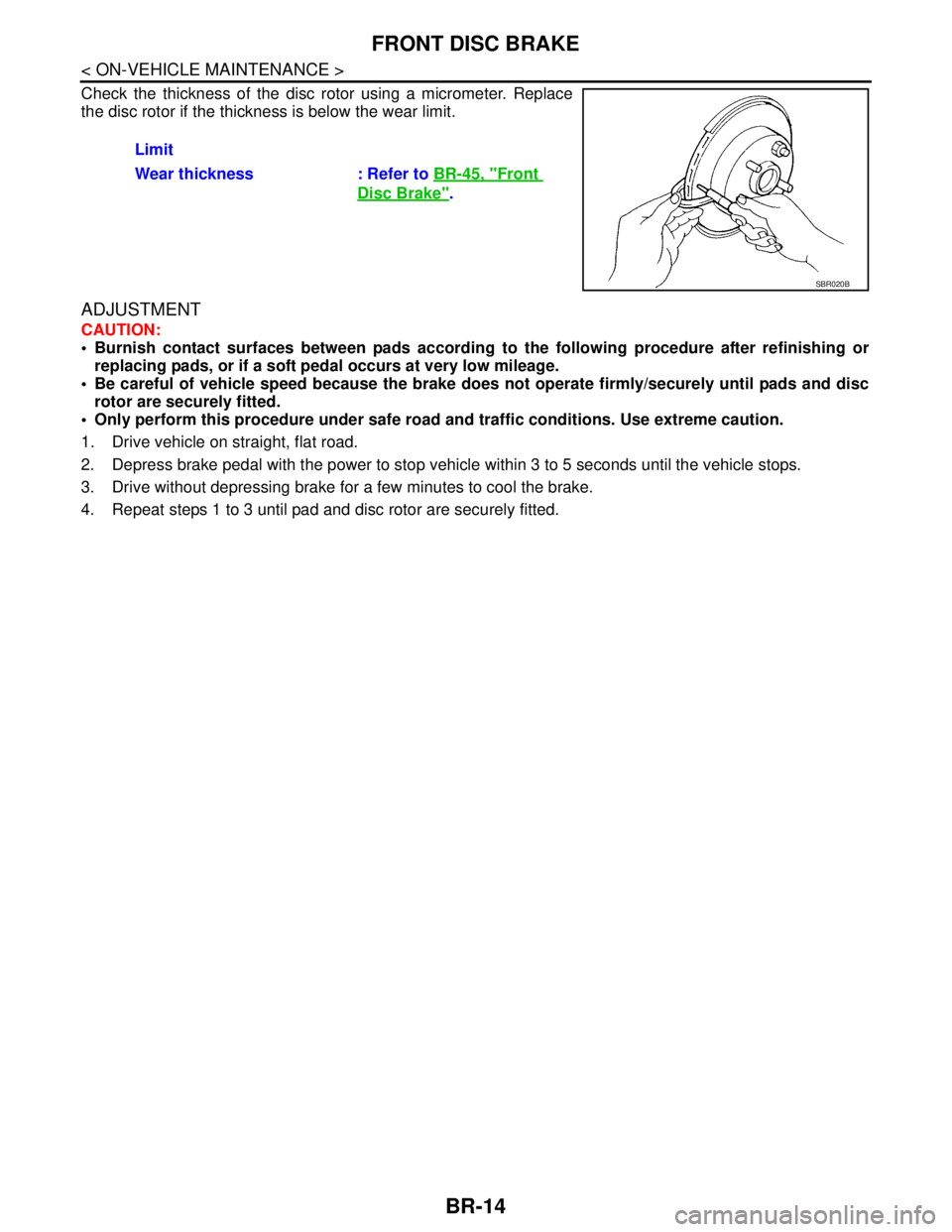

Check the thickness of the disc rotor using a micrometer. Replace

the disc rotor if the thickness is below the wear limit.

ADJUSTMENT

CAUTION:

Burnish contact surfaces between pads according to the following procedure after refinishing or

replacing pads, or if a soft pedal occurs at very low mileage.

Be careful of vehicle speed because the brake does not operate firmly/securely until pads and disc

rotor are securely fitted.

Only perform this procedure under safe road and traffic conditions. Use extreme caution.

1. Drive vehicle on straight, flat road.

2. Depress brake pedal with the power to stop vehicle within 3 to 5 seconds until the vehicle stops.

3. Drive without depressing brake for a few minutes to cool the brake.

4. Repeat steps 1 to 3 until pad and disc rotor are securely fitted.Limit

Wear thickness : Refer to BR-45, "

Front

Disc Brake".

SBR020B

Page 911 of 5121

REAR DISC BRAKE

BR-15

< ON-VEHICLE MAINTENANCE >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

REAR DISC BRAKE

BRAKE PAD

BRAKE PAD : Inspection and AdjustmentINFOID:0000000003811181

INSPECTION

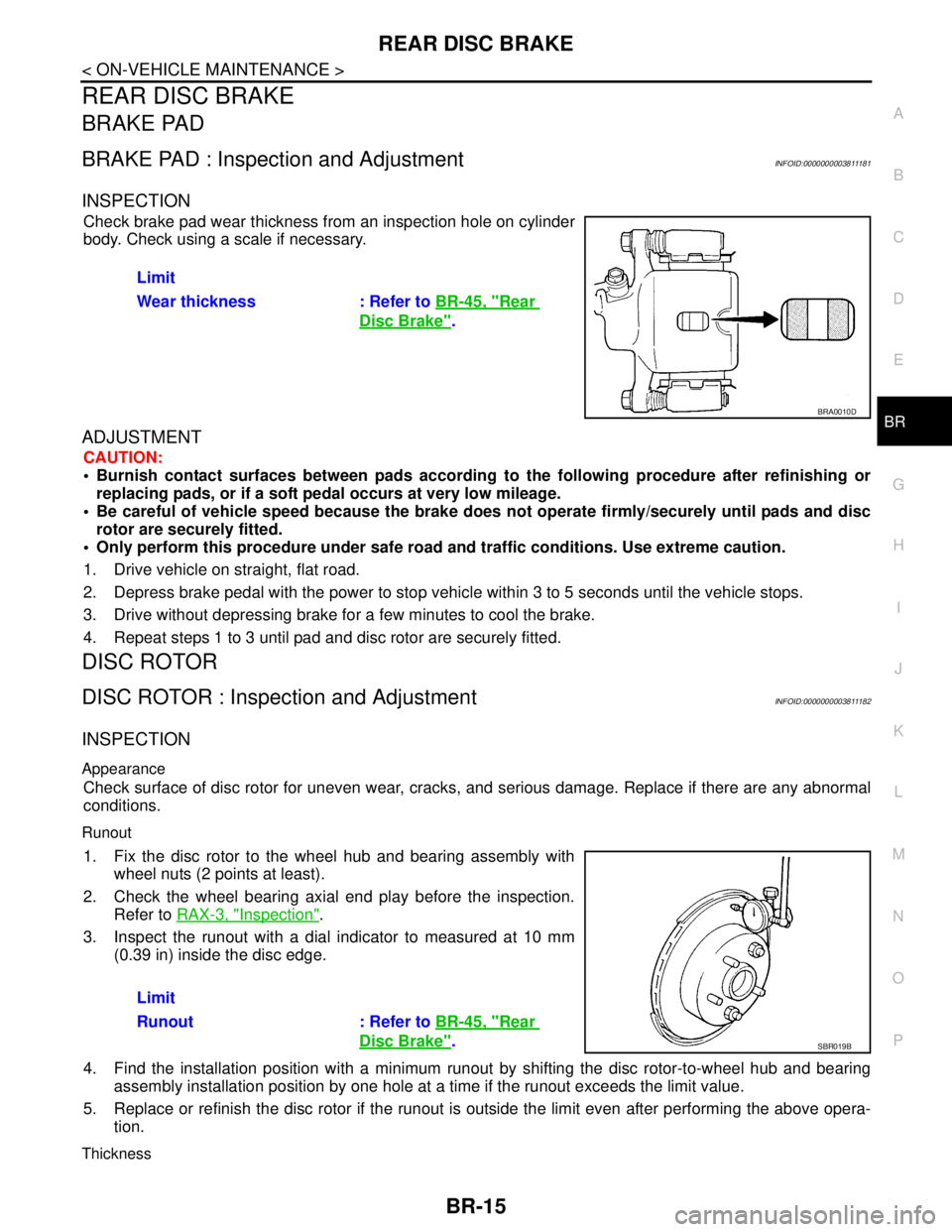

Check brake pad wear thickness from an inspection hole on cylinder

body. Check using a scale if necessary.

ADJUSTMENT

CAUTION:

Burnish contact surfaces between pads according to the following procedure after refinishing or

replacing pads, or if a soft pedal occurs at very low mileage.

Be careful of vehicle speed because the brake does not operate firmly/securely until pads and disc

rotor are securely fitted.

Only perform this procedure under safe road and traffic conditions. Use extreme caution.

1. Drive vehicle on straight, flat road.

2. Depress brake pedal with the power to stop vehicle within 3 to 5 seconds until the vehicle stops.

3. Drive without depressing brake for a few minutes to cool the brake.

4. Repeat steps 1 to 3 until pad and disc rotor are securely fitted.

DISC ROTOR

DISC ROTOR : Inspection and AdjustmentINFOID:0000000003811182

INSPECTION

Appearance

Check surface of disc rotor for uneven wear, cracks, and serious damage. Replace if there are any abnormal

conditions.

Runout

1. Fix the disc rotor to the wheel hub and bearing assembly with

wheel nuts (2 points at least).

2. Check the wheel bearing axial end play before the inspection.

Refer to RAX-3, "

Inspection".

3. Inspect the runout with a dial indicator to measured at 10 mm

(0.39 in) inside the disc edge.

4. Find the installation position with a minimum runout by shifting the disc rotor-to-wheel hub and bearing

assembly installation position by one hole at a time if the runout exceeds the limit value.

5. Replace or refinish the disc rotor if the runout is outside the limit even after performing the above opera-

tion.

Thickness

Limit

Wear thickness : Refer to BR-45, "

Rear

Disc Brake".

BRA0010D

Limit

Runout : Refer to BR-45, "

Rear

Disc Brake".SBR019B

Page 912 of 5121

BR-16

< ON-VEHICLE MAINTENANCE >

REAR DISC BRAKE

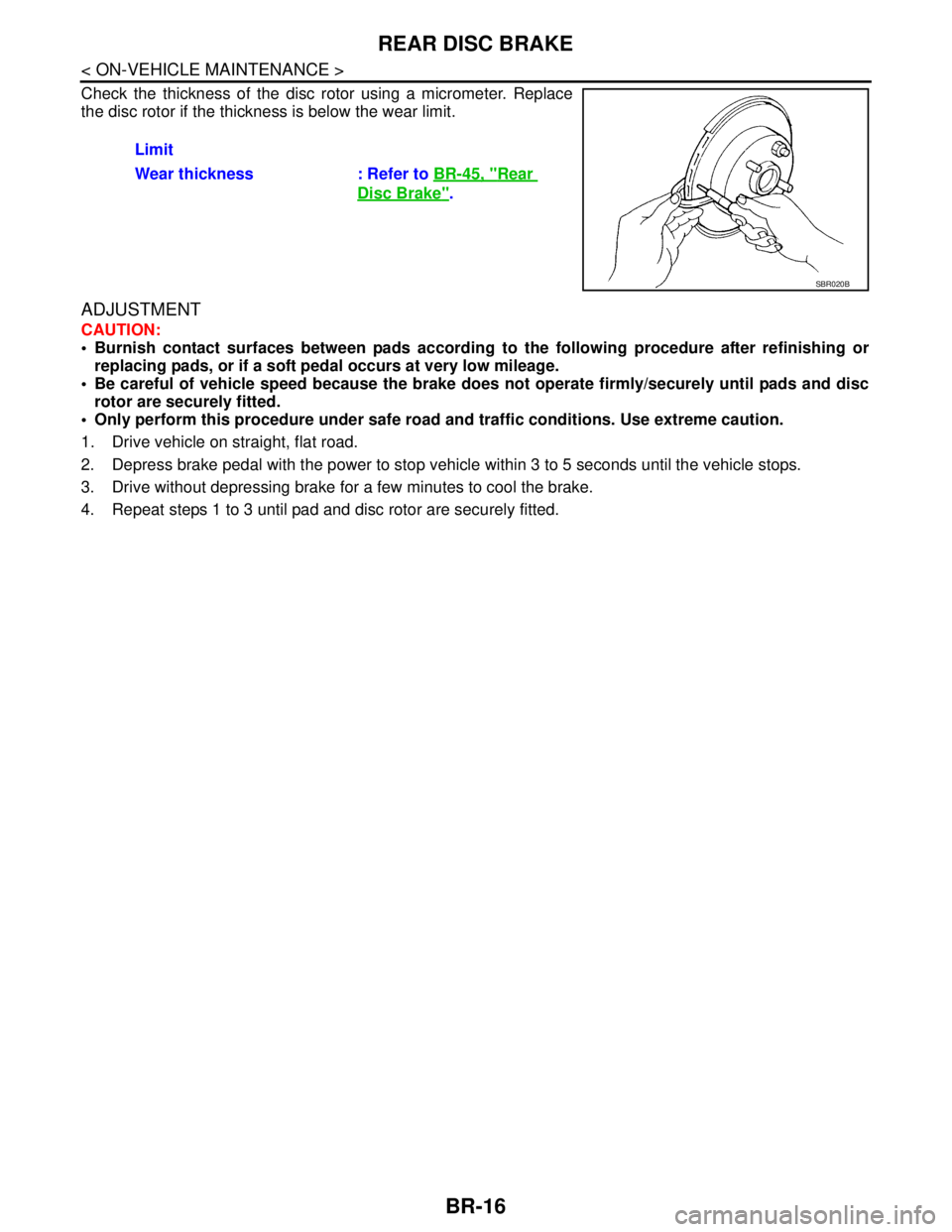

Check the thickness of the disc rotor using a micrometer. Replace

the disc rotor if the thickness is below the wear limit.

ADJUSTMENT

CAUTION:

Burnish contact surfaces between pads according to the following procedure after refinishing or

replacing pads, or if a soft pedal occurs at very low mileage.

Be careful of vehicle speed because the brake does not operate firmly/securely until pads and disc

rotor are securely fitted.

Only perform this procedure under safe road and traffic conditions. Use extreme caution.

1. Drive vehicle on straight, flat road.

2. Depress brake pedal with the power to stop vehicle within 3 to 5 seconds until the vehicle stops.

3. Drive without depressing brake for a few minutes to cool the brake.

4. Repeat steps 1 to 3 until pad and disc rotor are securely fitted.Limit

Wear thickness : Refer to BR-45, "

Rear

Disc Brake".

SBR020B

Page 926 of 5121

BR-30

< ON-VEHICLE REPAIR >

BRAKE BOOSTER

Idle the engine for 1 minute to apply vacuum to the brake booster,

and stop the engine. Then depress the brake pedal several times

at 5-second intervals until the accumulated vacuum is released to

atmospheric pressure. Check that the clearance between brake

pedal and dash lower panel gradually increases (A → B → C) each

time the brake pedal is depressed during this operation.

Depress the brake pedal with the engine running. Then stop the

engine while holding down the brake pedal. Check that the brake

pedal stroke does not change after holding down the brake pedal

for 30 seconds or more.

NOTE:

A slight impact with a small click may be felt on the pedal when the

brake pedal is fully depressed. This is a normal phenomenon due

to the brake system operation.

ADJUSTMENT AFTER INSTALLATION

Perform the brake pedal adjustment after installing the brake pedal assembly. Refer to BR-6, "Inspection and

Adjustment".

JPFIA0043ZZ

JPFIA0044ZZ

Page 930 of 5121

BR-34

< ON-VEHICLE REPAIR >

FRONT DISC BRAKE

1. Install the pad retainer to the torque member if the pad retainers has been removed.

CAUTION:

Securely assemble the pad retainers so that it will not be lifted up from the torque member.

Never deform the pad retainers.

2. Apply copper based brake grease to the mating faces between the brake pads and pad retainers.

3. Apply PBC (Poly Butyl Cuprysil) grease or silicone-based grease to the mating faces between the brake

pads, shims and shim cover, and install them to the brake pad.

CAUTION:

Always replace the shims together with the shim cover when replacing the brake pad.

4. Install the cylinder body and brake pads to the torque member.

CAUTION:

Never damage the piston boot.

When replacing a pad with new one, check a brake fluid level in the reservoir tank because brake

fluid returns to master cylinder reservoir tank when pressing piston in.

NOTE:

Use a disc brake piston tool to easily press piston.

5. Install the lower sliding pin bolt and tighten it to the specified torque.

6. Depress the brake pedal several times to check that no drag feel is present for the front disc brake. Refer

to BR-34, "

BRAKE PAD : Inspection".

BRAKE PAD : InspectionINFOID:0000000003811206

INSPECTION AFTER REMOVAL

Replace the shims and the shim cover if rust is excessively attached.

INSPECTION AFTER INSTALLATION

1. Check a drag of front disc brake. If any drag is found, follow the procedure described below.

2. Remove brake pads.

3. Press the piston.

CAUTION:

Never damage the piston boot.

When replacing a pad with new one, check a brake fluid level in the reservoir tank because brake

fluid returns to master cylinder reservoir tank when pressing piston in.

NOTE:

Use a disc brake piston tool to easily press piston.

4. Install brake pads.

5. Depress the brake pedal several times.

6. Check a drag of front disc brake again. If any drag is found, disassemble the cylinder body. Refer to BR-

36, "BRAKE CALIPER ASSEMBLY : Disassembly and Assembly".

7. Burnish contact surfaces after refinishing or replacing pads, or if a soft pedal occurs at very low mileage.

Refer to BR-13, "

BRAKE PAD : Inspection and Adjustment".

BRAKE CALIPER ASSEMBLY

BRAKE CALIPER ASSEMBLY : Exploded ViewINFOID:0000000003811207

REMOVAL

Page 934 of 5121

BR-38

< ON-VEHICLE REPAIR >

FRONT DISC BRAKE

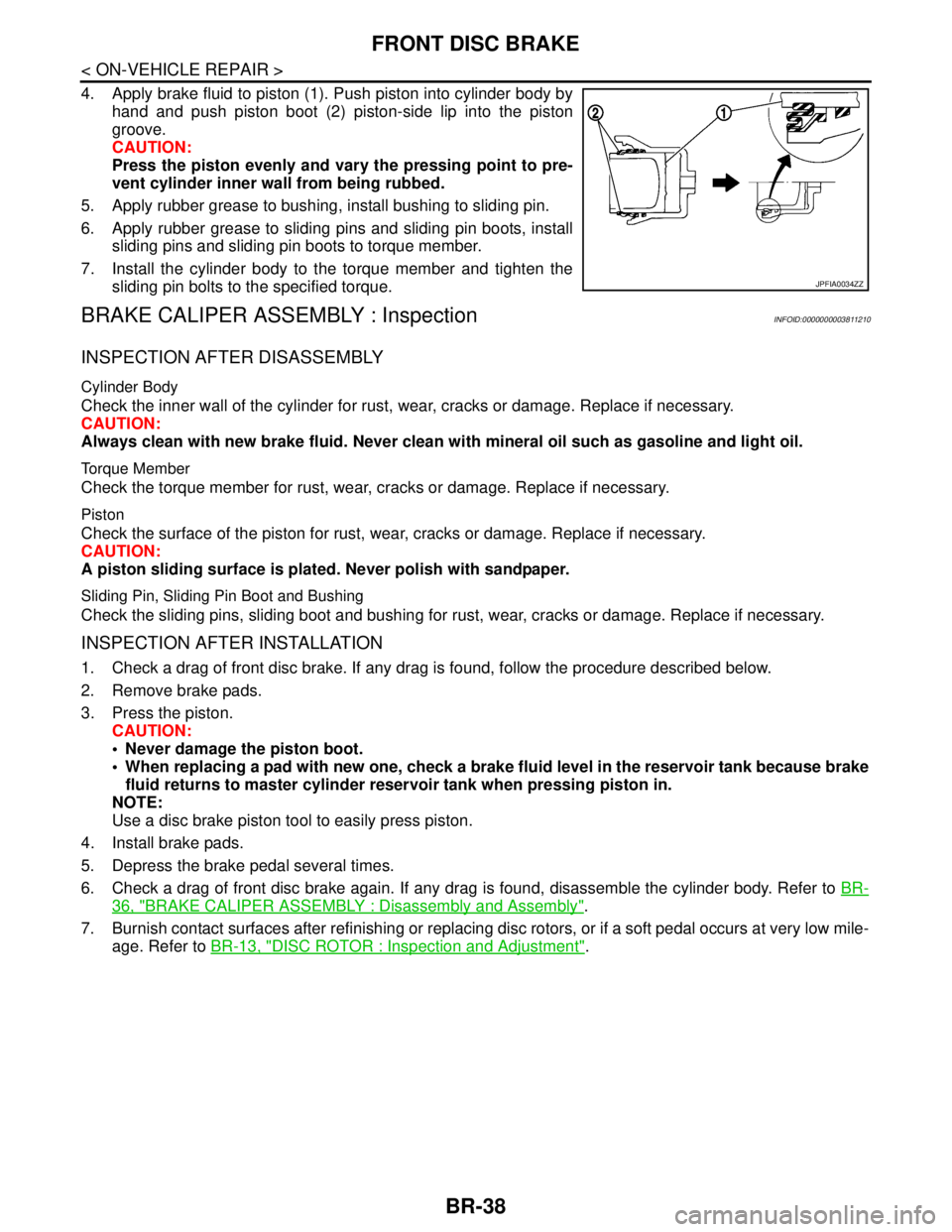

4. Apply brake fluid to piston (1). Push piston into cylinder body by

hand and push piston boot (2) piston-side lip into the piston

groove.

CAUTION:

Press the piston evenly and vary the pressing point to pre-

vent cylinder inner wall from being rubbed.

5. Apply rubber grease to bushing, install bushing to sliding pin.

6. Apply rubber grease to sliding pins and sliding pin boots, install

sliding pins and sliding pin boots to torque member.

7. Install the cylinder body to the torque member and tighten the

sliding pin bolts to the specified torque.

BRAKE CALIPER ASSEMBLY : InspectionINFOID:0000000003811210

INSPECTION AFTER DISASSEMBLY

Cylinder Body

Check the inner wall of the cylinder for rust, wear, cracks or damage. Replace if necessary.

CAUTION:

Always clean with new brake fluid. Never clean with mineral oil such as gasoline and light oil.

Torque Member

Check the torque member for rust, wear, cracks or damage. Replace if necessary.

Piston

Check the surface of the piston for rust, wear, cracks or damage. Replace if necessary.

CAUTION:

A piston sliding surface is plated. Never polish with sandpaper.

Sliding Pin, Sliding Pin Boot and Bushing

Check the sliding pins, sliding boot and bushing for rust, wear, cracks or damage. Replace if necessary.

INSPECTION AFTER INSTALLATION

1. Check a drag of front disc brake. If any drag is found, follow the procedure described below.

2. Remove brake pads.

3. Press the piston.

CAUTION:

Never damage the piston boot.

When replacing a pad with new one, check a brake fluid level in the reservoir tank because brake

fluid returns to master cylinder reservoir tank when pressing piston in.

NOTE:

Use a disc brake piston tool to easily press piston.

4. Install brake pads.

5. Depress the brake pedal several times.

6. Check a drag of front disc brake again. If any drag is found, disassemble the cylinder body. Refer to BR-

36, "BRAKE CALIPER ASSEMBLY : Disassembly and Assembly".

7. Burnish contact surfaces after refinishing or replacing disc rotors, or if a soft pedal occurs at very low mile-

age. Refer to BR-13, "

DISC ROTOR : Inspection and Adjustment".

JPFIA0034ZZ

Page 936 of 5121

BR-40

< ON-VEHICLE REPAIR >

REAR DISC BRAKE

Never depress the brake pedal while removing the brake pads or the cylinder body because the pis-

ton may pop out.

Never spill or splash brake fluid on the disc rotor.

1. Install the pad retainers to the torque member if the pad retainers has been removed.

CAUTION:

Securely assemble the pad retainers not to be lifted up from the torque member.

Never deform the pad retainers.

2. Apply PBC (Poly Butyl Cuprysil) grease or silicone-based grease to the mating faces between the brake

pads, the shims and pawls part of cylinder body, and install them to the brake pad.

CAUTION:

Always replace the shims together when replacing the brake pad.

3. Install cylinder body and brake pads to torque member.

CAUTION:

Never damage the piston boot.

When replacing pads with new one, check a brake fluid level in the reservoir tank because brake

fluid returns to master cylinder reservoir tank when pressing piston in.

NOTE:

Use a disc brake piston tool to easily press piston.

4. Install the upper sliding pin bolt and tighten it to the specified torque.

5. Depress the brake pedal several times to check that no drag feel is present for the rear disc brake. Refer

to BR-40, "

BRAKE PAD : Inspection".

BRAKE PAD : InspectionINFOID:0000000003811213

INSPECTION AFTER REMOVAL

Replace the shims if rust is excessively attached.

INSPECTION AFTER INSTALLATION

1. Check a drag of rear disc brake. If any drag is found, follow the procedure described below.

2. Remove brake pads.

3. Press the piston.

CAUTION:

Never damage the piston boot.

When replacing a pad with new one, check a brake fluid level in the reservoir tank because brake

fluid returns to master cylinder reservoir tank when pressing piston in.

NOTE:

Use a disc brake piston tool to easily press piston.

4. Install brake pads.

5. Depress the brake pedal several times.

6. Check a drag of rear disc brake again. If any drag is found, disassemble the cylinder body. Refer to BR-

42, "BRAKE CALIPER ASSEMBLY : Disassembly and Assembly".

7. Burnish contact surfaces after refinishing or replacing pads, or if a soft pedal occurs at very low mileage.

Refer to BR-15, "

BRAKE PAD : Inspection and Adjustment".

BRAKE CALIPER ASSEMBLY

BRAKE CALIPER ASSEMBLY : Exploded ViewINFOID:0000000003811214

REMOVAL

Page 940 of 5121

BR-44

< ON-VEHICLE REPAIR >

REAR DISC BRAKE

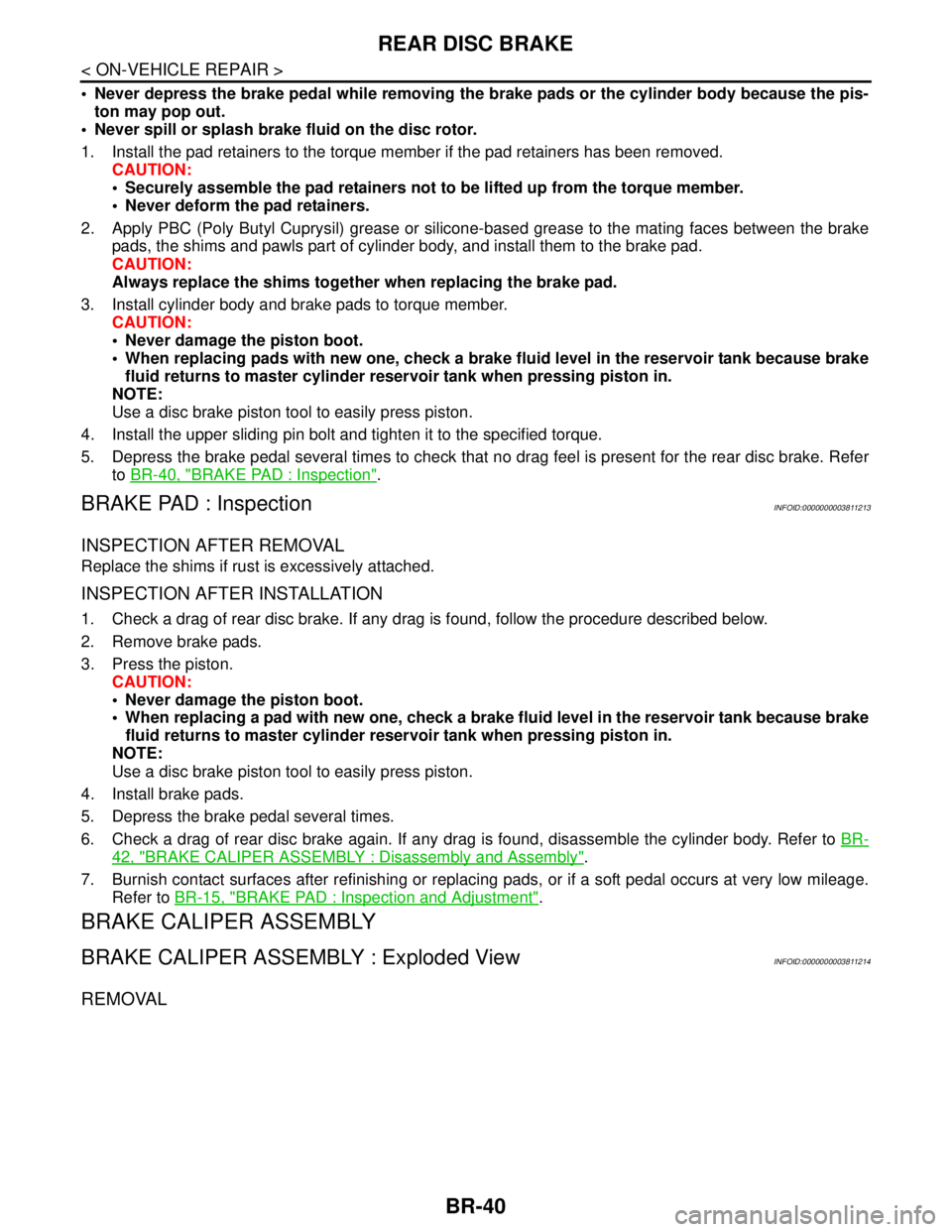

4. Apply brake fluid to piston (1). Push piston into cylinder body by

hand and push piston boot (2) piston side lip into the piston

groove.

CAUTION:

Press the piston evenly and vary the pressing point to pre-

vent cylinder inner wall from being rubbed.

5. Apply rubber grease to bushing, install bushing to sliding pin

bolt.

6. Apply rubber grease to the sliding pin bolts and the sliding pin

boots, install sliding pin boot to torque member.

7. Install the cylinder body to the torque member and tighten the

sliding pin bolts to the specified torque.

BRAKE CALIPER ASSEMBLY : InspectionINFOID:0000000003811217

INSPECTION AFTER DISASSEMBLY

Cylinder Body

Check the inner wall of the cylinder for rust, wear, cracks or damage. Replace the cylinder if any abnormal

condition is detected.

CAUTION:

Always clean with new brake fluid. Never clean with mineral oil such as gasoline and light oil.

Torque Member

Check the torque member for rust, wear, cracks or damage. Replace the member if any abnormal condition is

detected.

Piston

Check the piston for rust, wear, cracks or damage. Replace the piston if any abnormal condition is detected.

CAUTION:

A piston sliding surface is plated. Never polish with sandpaper.

Sliding Pin Bolt, Sliding Pin Boot and Bushing

Check the sliding pin bolts and sliding pin boots for rust, wear, cracks or damage. Replace the parts if any

abnormal condition is detected.

INSPECTION AFTER INSTALLATION

1. Check a drag of rear disc brake. If any drag is found, follow the procedure described below.

2. Remove brake pads.

3. Press the piston.

CAUTION:

Never damage the piston boot.

When replacing a pad with new one, check a brake fluid level in the reservoir tank because brake

fluid returns to master cylinder reservoir tank when pressing piston in.

NOTE:

Use a disc brake piston tool to easily press piston.

4. Install brake pads.

5. Depress the brake pedal several times.

6. Check a drag of rear disc brake again. If any drag is found, disassemble the cylinder body. Refer to BR-

42, "BRAKE CALIPER ASSEMBLY : Disassembly and Assembly".

7. Burnish contact surfaces after refinishing or replacing disc rotors, or if a soft pedal occurs at very low mile-

age. Refer to BR-15, "

DISC ROTOR : Inspection and Adjustment".

JPFIA0041ZZ

Page 943 of 5121

BRC-2

Description ..............................................................36

DTC Logic ...............................................................36

Diagnosis Procedure ..............................................36

Component Inspection ............................................37

U1000, U1002 CAN COMM CIRCUIT ...............38

Description ..............................................................38

DTC Logic ...............................................................38

Diagnosis Procedure ..............................................38

POWER SUPPLY AND GROUND CIRCUIT .....39

Description ..............................................................39

Diagnosis Procedure ..............................................39

ABS WARNING LAMP ......................................40

Description ..............................................................40

Component Function Check ...................................40

Diagnosis Procedure ..............................................40

BRAKE WARNING LAMP .................................41

Description ..............................................................41

Component Function Check ...................................41

Diagnosis Procedure ..............................................41

ECU DIAGNOSIS ........................................42

ABS ACTUATOR AND ELECTRIC UNIT

(CONTROL UNIT) ..............................................

42

Reference Value .....................................................42

Wiring Diagram - BRAKE CONTROL SYSTEM - ...44

Fail-Safe .................................................................47

DTC No. Index ........................................................48

SYMPTOM DIAGNOSIS .............................49

EXCESSIVE ABS FUNCTION OPERATION

FREQUENCY .....................................................

49

Diagnosis Procedure ..............................................49

UNEXPECTED PEDAL REACTION ..................50

Diagnosis Procedure ..............................................50

THE BRAKING DISTANCE IS LONG ...............51

Diagnosis Procedure ..............................................51

ABS FUNCTION DOES NOT OPERATE ..........52

Diagnosis Procedure ..............................................52

PEDAL VIBRATION OR ABS OPERATION

SOUND OCCURS ..............................................

53

Diagnosis Procedure ..............................................53

NORMAL OPERATING CONDITION ................54

Description ..............................................................54

PRECAUTION .............................................55

PRECAUTIONS .................................................55

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .................................................................

55

Precaution for Procedure without Cowl Top Cover ...55

Precaution for Brake System ..................................55

Precaution for Brake Control ...................................56

Precautions for Harness Repair ..............................56

ON-VEHICLE REPAIR ...............................57

WHEEL SENSOR ..............................................57

FRONT WHEEL SENSOR ........................................57

FRONT WHEEL SENSOR : Exploded View ...........57

FRONT WHEEL SENSOR : Removal and Instal-

lation .......................................................................

57

REAR WHEEL SENSOR ...........................................58

REAR WHEEL SENSOR : Exploded View .............58

REAR WHEEL SENSOR : Removal and Installa-

tion ..........................................................................

58

SENSOR ROTOR ..............................................59

FRONT SENSOR ROTOR ........................................59

FRONT SENSOR ROTOR : Exploded View ...........59

FRONT SENSOR ROTOR : Removal and Instal-

lation .......................................................................

59

REAR SENSOR ROTOR ...........................................59

REAR SENSOR ROTOR : Exploded View .............59

REAR SENSOR ROTOR : Removal and Installa-

tion ..........................................................................

59

ABS ACTUATOR AND ELECTRIC UNIT

(CONTROL UNIT) ..............................................

60

Exploded View ........................................................60

Removal and Installation .........................................60

VDC/TCS/ABS

BASIC INSPECTION ..................................

62

DIAGNOSIS AND REPAIR WORK FLOW ........62

Work Flow ...............................................................62

Diagnostic Work Sheet ...........................................65

INSPECTION AND ADJUSTMENT ...................66

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT ........................................................

66

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Description ................................

66

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Special Repair Requirement .....

66

ADJUSTMENT OF STEERING ANGLE SENSOR

NEUTRAL POSITION ................................................

66

ADJUSTMENT OF STEERING ANGLE SENSOR

NEUTRAL POSITION : Description ........................

66

ADJUSTMENT OF STEERING ANGLE SENSOR

NEUTRAL POSITION : Special Repair Require-

ment ........................................................................

66

FUNCTION DIAGNOSIS ............................68

VDC ....................................................................68

Page 945 of 5121

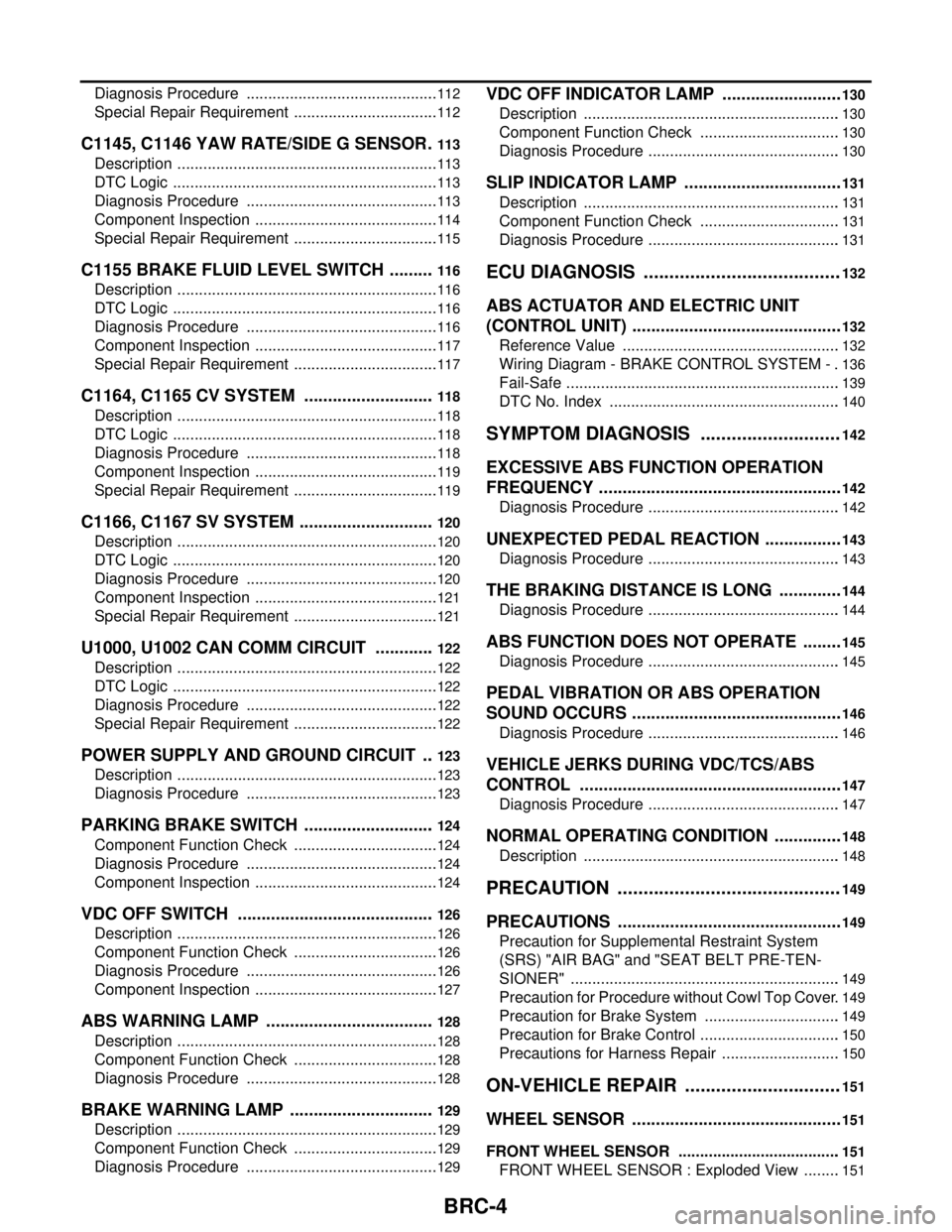

BRC-4

Diagnosis Procedure .............................................112

Special Repair Requirement ..................................112

C1145, C1146 YAW RATE/SIDE G SENSOR .113

Description .............................................................113

DTC Logic ..............................................................113

Diagnosis Procedure .............................................113

Component Inspection ...........................................114

Special Repair Requirement ..................................115

C1155 BRAKE FLUID LEVEL SWITCH ..........116

Description .............................................................116

DTC Logic ..............................................................116

Diagnosis Procedure .............................................116

Component Inspection ...........................................117

Special Repair Requirement ..................................117

C1164, C1165 CV SYSTEM ............................118

Description .............................................................118

DTC Logic ..............................................................118

Diagnosis Procedure .............................................118

Component Inspection ...........................................119

Special Repair Requirement ..................................119

C1166, C1167 SV SYSTEM .............................120

Description .............................................................120

DTC Logic ..............................................................120

Diagnosis Procedure .............................................120

Component Inspection ...........................................121

Special Repair Requirement ..................................121

U1000, U1002 CAN COMM CIRCUIT .............122

Description .............................................................122

DTC Logic ..............................................................122

Diagnosis Procedure .............................................122

Special Repair Requirement ..................................122

POWER SUPPLY AND GROUND CIRCUIT ...123

Description .............................................................123

Diagnosis Procedure .............................................123

PARKING BRAKE SWITCH ............................124

Component Function Check ..................................124

Diagnosis Procedure .............................................124

Component Inspection ...........................................124

VDC OFF SWITCH ..........................................126

Description .............................................................126

Component Function Check ..................................126

Diagnosis Procedure .............................................126

Component Inspection ...........................................127

ABS WARNING LAMP ....................................128

Description .............................................................128

Component Function Check ..................................128

Diagnosis Procedure .............................................128

BRAKE WARNING LAMP ...............................129

Description .............................................................129

Component Function Check ..................................129

Diagnosis Procedure .............................................129

VDC OFF INDICATOR LAMP ..........................130

Description ............................................................130

Component Function Check .................................130

Diagnosis Procedure .............................................130

SLIP INDICATOR LAMP ..................................131

Description ............................................................131

Component Function Check .................................131

Diagnosis Procedure .............................................131

ECU DIAGNOSIS ......................................132

ABS ACTUATOR AND ELECTRIC UNIT

(CONTROL UNIT) .............................................

132

Reference Value ...................................................132

Wiring Diagram - BRAKE CONTROL SYSTEM - .136

Fail-Safe ................................................................139

DTC No. Index ......................................................140

SYMPTOM DIAGNOSIS ...........................142

EXCESSIVE ABS FUNCTION OPERATION

FREQUENCY ....................................................

142

Diagnosis Procedure .............................................142

UNEXPECTED PEDAL REACTION .................143

Diagnosis Procedure .............................................143

THE BRAKING DISTANCE IS LONG ..............144

Diagnosis Procedure .............................................144

ABS FUNCTION DOES NOT OPERATE .........145

Diagnosis Procedure .............................................145

PEDAL VIBRATION OR ABS OPERATION

SOUND OCCURS .............................................

146

Diagnosis Procedure .............................................146

VEHICLE JERKS DURING VDC/TCS/ABS

CONTROL ........................................................

147

Diagnosis Procedure .............................................147

NORMAL OPERATING CONDITION ...............148

Description ............................................................148

PRECAUTION ...........................................149

PRECAUTIONS ................................................149

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...............................................................

149

Precaution for Procedure without Cowl Top Cover .149

Precaution for Brake System ................................149

Precaution for Brake Control .................................150

Precautions for Harness Repair ............................150

ON-VEHICLE REPAIR ..............................151

WHEEL SENSOR .............................................151

FRONT WHEEL SENSOR ......................................151

FRONT WHEEL SENSOR : Exploded View .........151