ignition NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 1953 of 5121

EM-78

< DISASSEMBLY AND ASSEMBLY >

ENGINE UNIT

ENGINE UNIT

DisassemblyINFOID:0000000003802279

1. Remove intake manifold collector. Refer to EM-28, "Exploded View".

2. Remove intake manifold. Refer to EM-32, "

Exploded View".

3. Remove exhaust manifold. Refer to EM-34, "

Exploded View".

4. Remove oil pan (lower). Refer to EM-38, "

Exploded View".

5. Remove ignition coil, spark plug and rocker cover. Refer to EM-49, "

Exploded View".

6. Remove fuel injector and fuel tube. Refer to EM-44, "

Exploded View".

7. Remove timing chain and rear timing chain case. Refer to EM-52, "

Exploded View" and EM-79, "Exploded

View".

8. Remove camshaft. Refer to EM-84, "

Exploded View".

9. Remove cylinder head. Refer to EM-96, "

Exploded View".

AssemblyINFOID:0000000003802280

Assembly in the reverse order of disassembly.

Page 1967 of 5121

EM-92

< DISASSEMBLY AND ASSEMBLY >

CAMSHAFT

b. Disconnect ignition coil and injector harness connectors. Refer to EM-49, "Exploded View" and EM-44,

"Exploded View".

3. Remove intake valve timing control solenoid valve. Refer to EM-79, "

Exploded View".

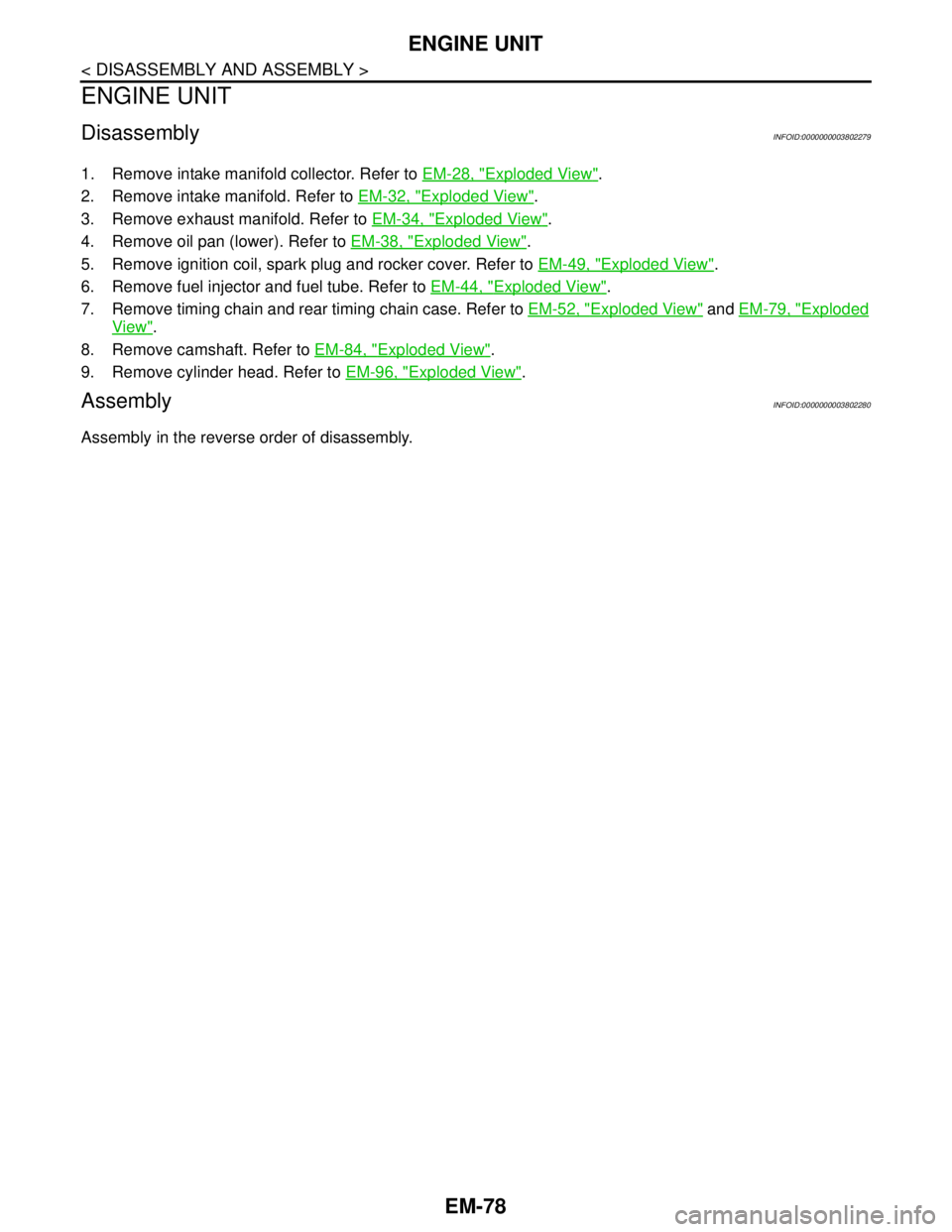

4. Crank engine, and then check that engine oil comes out from

intake valve timing control solenoid valve hole (A). End crank

after checking.

WARNING:

Be careful not to touch rotating parts. (drive belt, idler pul-

ley, and crankshaft pulley, etc.)

CAUTION:

Prevent splashing by using a shop cloth so as to prevent

the worker from injury from engine oil and so as to prevent engine oil contamination.

Prevent splashing by using a shop cloth so as to prevent engine oil from being splashed to

engine and vehicle. Especially, be careful no to apply engine oil to rubber parts of drive belt,

engine mounting insulator, etc. Wipe engine oil off immediately if it is splashed.

5. Perform the following inspection if engine oil does not come out from intake valve timing control solenoid

valve oil hole of the cylinder head.

Remove oil filter, and then clean it. Refer to LU-10, "

Removal and Installation".

Clean oil groove between oil strainer and intake valve timing control solenoid valve. Refer to LU-2,

"EngineLubricationSystem".

6. Remove components between intake valve timing control solenoid valve and camshaft sprocket (INT),

and then check each oil groove for clogging.

Clean oil groove if necessary. Refer to LU-2, "

EngineLubricationSystem".

7. After inspection, install removed parts in the reverse order.

Inspection for Leakage

The following are procedures for checking fluids leak, lubricates leak. Before starting engine, check oil/fluid levels including engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-11, "

Fluids and Lubricants".

Use procedure below to check for fuel leakage.

- Turn ignition switch “ON” (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak-

age at connection points.

- Start engine. With engine speed increased, check again for fuel leakage at connection points.

Run engine to check for unusual noise and vibration.

NOTE:

If hydraulic pressure inside timing chain tensioner drops after removal/installation, slack in the guide may

generate a pounding noise during and just after engine start. However, this is normal. Noise will stop after

hydraulic pressure rises.

Warm up engine thoroughly to check there is no leakage of fuel, or any oil/fluids including engine oil and

engine coolant.

Bleed air from lines and hoses of applicable lines, such as in cooling system.

After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the

specified level, if necessary.

Summary of the inspection items:

*: Transmission/transaxle/CVT fluid, power steering fluid, brake fluid, etc.1 : Valve timing control cover (bank 2)

: Engine front

JPBIA1783ZZ

Items Before starting engine Engine running After engine stopped

Engine coolant Level Leakage Level

Engine oil Level Leakage Level

Other oils and fluid* Level Leakage Level

Fuel Leakage Leakage Leakage

Page 1981 of 5121

EM-106

< DISASSEMBLY AND ASSEMBLY >

CYLINDER HEAD

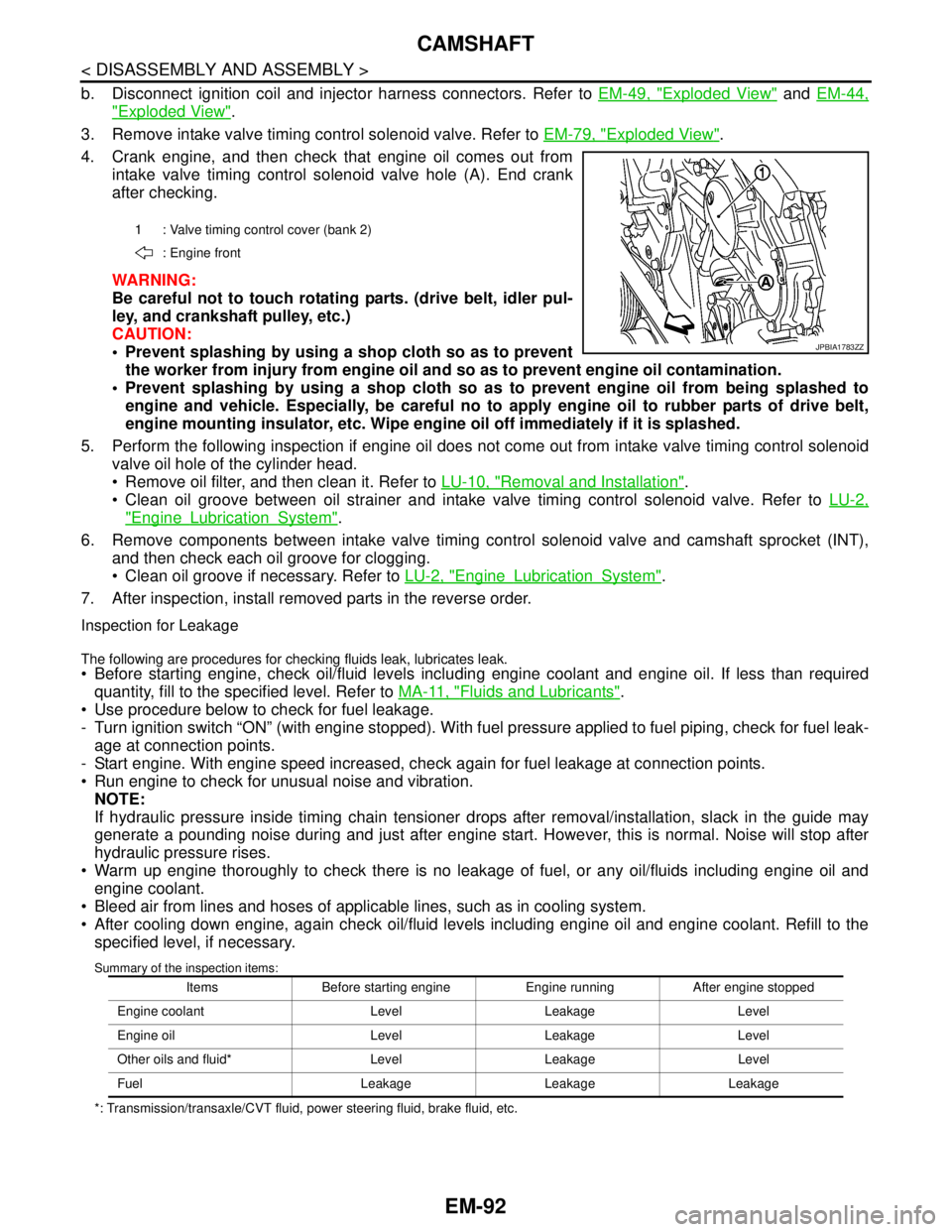

Check the valve spring pressure at specified spring height.

If the installation load or load with valve open is out of the stan-

dard, replace valve spring.

INSPECTION AFTER INSTALLATION

Inspection for Leakage

The following are procedures for checking fluids leak, lubricates leak and exhaust gases leak.

Before starting engine, check oil/fluid levels including engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-11, "

Fluids and Lubricants".

Use procedure below to check for fuel leakage.

- Turn ignition switch “ON” (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak-

age at connection points.

- Start engine. With engine speed increased, check again for fuel leakage at connection points.

Run engine to check for unusual noise and vibration.

Warm up engine thoroughly to check there is no leakage of fuel, exhaust gases, or any oil/fluids including

engine oil and engine coolant.

Bleed air from lines and hoses of applicable lines, such as in cooling system.

After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the

specified level, if necessary.

Summary of the inspection items:

*: Transmission/transaxle/CVT fluid, power steering fluid, brake fluid, etc.

Standard (Intake and exhaust)

: Refer to EM-139,

"CylinderHead". Free height

Installation height

Installation load

Height during valve open

Load with valve open

SEM113

Items Before starting engine Engine running After engine stopped

Engine coolant Level Leakage Level

Engine oil Level Leakage Level

Other oils and fluid* Level Leakage Level

Fuel Leakage Leakage Leakage

Exhaust gases — Leakage —

Page 2039 of 5121

![NISSAN TEANA 2008 Service Manual EXL-10

< BASIC INSPECTION >[XENON TYPE]

INSPECTION AND ADJUSTMENT

SENSOR INITIALIZE : Description

INFOID:0000000003774311

HEADLAMP AIMING CONTROL SYSTEM

Perform the sensor initialize when installing, NISSAN TEANA 2008 Service Manual EXL-10

< BASIC INSPECTION >[XENON TYPE]

INSPECTION AND ADJUSTMENT

SENSOR INITIALIZE : Description

INFOID:0000000003774311

HEADLAMP AIMING CONTROL SYSTEM

Perform the sensor initialize when installing,](/img/5/57391/w960_57391-2038.png)

EXL-10

< BASIC INSPECTION >[XENON TYPE]

INSPECTION AND ADJUSTMENT

SENSOR INITIALIZE : Description

INFOID:0000000003774311

HEADLAMP AIMING CONTROL SYSTEM

Perform the sensor initialize when installing, removing and replacing the auto levelizer control unit and sus-

pension components.

SENSOR INITIALIZE : Special Repair Requirement (HEADLAMP AIMING CONTROL

SYSTEM)

INFOID:0000000003774312

1.VEHICLE CONDITION CHECK

1. Park the vehicle in the straight-forward position.

2. Unload the vehicle (no passenger aboard).

>> GO TO 2.

2.SENSOR INITIALIZE

CONSULT-III WORK SUPPORT

1. Select "SENSOR INITIALIZE" of HEADLAMP LEVELIZER work support item.

2. Select "START".

3. When "INITIALIZE COMPLETE", select "END".

CAUTION:

If "INITIALIZE NOT DONE" is indicated, auto levelizer control unit detects that the sensor lever sig-

nal changes. The sensor initialize is cancelled. In this case, turn the ignition switch OFF to prevent

the vehicle from the height change. Perform the sensor initialize again.

Is the sensor initialize completed?

YES >> GO TO 3.

NO >> Perform the sensor initialize again.

3.SELF-DIAGNOSIS RESULT CHECK

Perform the self-diagnosis with CONSULT-III. Check that any DTC is not detected.

Is any DTC detected?

YES >> GO TO 2.

NO >> Sensor initialize completed

Page 2042 of 5121

![NISSAN TEANA 2008 Service Manual AUTO LIGHT SYSTEM

EXL-13

< FUNCTION DIAGNOSIS >[XENON TYPE]

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

AUTO LIGHT SYSTEM

System DiagramINFOID:0000000003773527

System DescriptionINFOID:0000000003773528

OUTLINE

NISSAN TEANA 2008 Service Manual AUTO LIGHT SYSTEM

EXL-13

< FUNCTION DIAGNOSIS >[XENON TYPE]

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

AUTO LIGHT SYSTEM

System DiagramINFOID:0000000003773527

System DescriptionINFOID:0000000003773528

OUTLINE

](/img/5/57391/w960_57391-2041.png)

AUTO LIGHT SYSTEM

EXL-13

< FUNCTION DIAGNOSIS >[XENON TYPE]

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

AUTO LIGHT SYSTEM

System DiagramINFOID:0000000003773527

System DescriptionINFOID:0000000003773528

OUTLINE

Auto light system is controlled by each function of BCM and IPDM E/R.

Control by BCM- Combination switch reading function

- Headlamp control function

- Auto light function

- Delay timer function

Control by IPDM E/R- Relay control function

Auto light system has the auto light function and the delay timer function.

- Auto light function turns the exterior lamps* and each illumination ON/OFF automatically according to the

outside brightness.

- When auto light system turns the exterior lamps ON with the ignition switch OFF, delay timer function turns

the exterior lamps OFF depending on the vehicle condition with the auto light function after a certain period

of time.

*: Headlamp (LO/HI), parking lamp, tail lamp and front fog lamp (Headlamp HI and front fog lamp depend on

the combination switch condition.)

AUTO LIGHT FUNCTION

BCM detects the combination switch condition with the combination switch reading function.

BCM supplies voltage to optical sensor when the ignition switch is turned ON or ACC.

Optical sensor converts outside brightness (lux) to voltage and transmits the optical sensor signal to BCM.

BCM judges outside brightness from the optical sensor signal and judges ON/OFF condition of the exterior

lamp and each illumination according to the outside brightness.

BCM transmits each request signal to IPDM E/R with CAN communication according to ON/OFF condition

by the auto light function.

NOTE:

ON/OFF timing differs based on the sensitivity from the setting. The setting can be set by CONSULT-III. Refer

to EXL-28, "

HEADLAMP : CONSULT-III Function (BCM - HEAD LAMP)".

DELAY TIMER FUNCTION

BCM turns the exterior lamp OFF depending on the vehicle condition with the auto light function when the igni-

tion switch is turned OFF.

Turns the exterior lamp OFF 5 minutes after detecting that any door opens (Door switch ON).

Turns the exterior lamp OFF a certain period of time* after closing all doors (Door switch ON→OFF).

JPLIA0804GB

Page 2043 of 5121

![NISSAN TEANA 2008 Service Manual EXL-14

< FUNCTION DIAGNOSIS >[XENON TYPE]

AUTO LIGHT SYSTEM

Turns the exterior lamp OFF with the ignition switch ACC or the light switch OFF.

*: The preset time is 45 seconds. The timer operating ti NISSAN TEANA 2008 Service Manual EXL-14

< FUNCTION DIAGNOSIS >[XENON TYPE]

AUTO LIGHT SYSTEM

Turns the exterior lamp OFF with the ignition switch ACC or the light switch OFF.

*: The preset time is 45 seconds. The timer operating ti](/img/5/57391/w960_57391-2042.png)

EXL-14

< FUNCTION DIAGNOSIS >[XENON TYPE]

AUTO LIGHT SYSTEM

Turns the exterior lamp OFF with the ignition switch ACC or the light switch OFF.

*: The preset time is 45 seconds. The timer operating time can be set by CONSULT-III. Refer to EXL-28,

"HEADLAMP : CONSULT-III Function (BCM - HEAD LAMP)".

NOTE:

When any position other than the light switch AUTO is set, the auto light system function switches to the exte-

rior lamp battery saver function.

Component Parts LocationINFOID:0000000003773529

Component DescriptionINFOID:0000000003773530

1. Combination switch 2. Optical sensor 3. IPDM E/R

4. BCM

A. Instrument upper panel (RH) B. Engine room (LH) C. Behind the combination meter

J P L I A 111 9 Z Z

Part Description

BCM Detects each switch condition by the combination switch reading function.

Judges the outside brightness from the optical sensor signal.

Judges the OFF timing according to the vehicle condition.

Judges the ON/OFF status of the exterior lamp and each illumination according to the

outside brightness and the vehicle condition.

Requests ON/OFF of each relay to IPDM E/R (with CAN communication).

IPDM E/RControls the integrated relay, and supplies voltage to the load according to the request

from BCM (with CAN communication).

Combination switch

(Lighting & turn signal switch)Refer to BCS-8, "

System Diagram".

Optical sensor Refer to EXL-69, "

Description".

Page 2044 of 5121

![NISSAN TEANA 2008 Service Manual HEADLAMP AIMING CONTROL SYSTEM (AUTO)

EXL-15

< FUNCTION DIAGNOSIS >[XENON TYPE]

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

HEADLAMP AIMING CONTROL SYSTEM (AUTO)

System DiagramINFOID:0000000003774320

System Desc NISSAN TEANA 2008 Service Manual HEADLAMP AIMING CONTROL SYSTEM (AUTO)

EXL-15

< FUNCTION DIAGNOSIS >[XENON TYPE]

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

HEADLAMP AIMING CONTROL SYSTEM (AUTO)

System DiagramINFOID:0000000003774320

System Desc](/img/5/57391/w960_57391-2043.png)

HEADLAMP AIMING CONTROL SYSTEM (AUTO)

EXL-15

< FUNCTION DIAGNOSIS >[XENON TYPE]

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

HEADLAMP AIMING CONTROL SYSTEM (AUTO)

System DiagramINFOID:0000000003774320

System DescriptionINFOID:0000000003774321

OUTLINE

Headlamp aiming control system is controlled by auto levelizer control unit.

Auto levelizer control unit controls the headlamp light axis height appropriately depending on the vehicle rear

height.

Auto levelizer control unit detects the vehicle condition necessary for the aiming motor control with the fol-

lowing signals.

- Sensor lever signal (detected by the sensor lever)

- Tail lamp signal (inputted from IPDM E/R)

- Vehicle speed signal (8-pulse) (inputted from combination meter)

HEADLAMP AUTO AIMING OPERATION

Auto levelizer control unit calculates vehicle pitch angle from sensor lever signal and determines the neces-

sary correction to compensate the deviation from standard light axis position.

Auto levelizer control unit outputs aiming motor drive signal when operating conditions are satisfied.

Operating condition

- Ignition switch ON

- Tail lamp ON

Auto levelizer control unit changes the aiming motor drive signal when any of the correcting condition is

detected. Output is maintained if other condition is detected.

Correcting condition- Tail lamp is turned ON.

- Vehicle posture becomes stable after the vehicle posture change is detected with the tail lamp ON and the

vehicle stopped.

- Vehicle speed is maintained with the tail lamp ON and the vehicle driven.

CAUTION:

Adjusted axis position may differ from the preset position although the headlamp auto aiming acti-

vates properly when the suspension is replaced or worn.

JPLIA0171GB

Page 2048 of 5121

![NISSAN TEANA 2008 Service Manual TURN SIGNAL AND HAZARD WARNING LAMP SYSTEM

EXL-19

< FUNCTION DIAGNOSIS >[XENON TYPE]

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

TURN SIGNAL AND HAZARD WARNING LAMP SYSTEM

System DiagramINFOID:0000000003773535

S NISSAN TEANA 2008 Service Manual TURN SIGNAL AND HAZARD WARNING LAMP SYSTEM

EXL-19

< FUNCTION DIAGNOSIS >[XENON TYPE]

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

TURN SIGNAL AND HAZARD WARNING LAMP SYSTEM

System DiagramINFOID:0000000003773535

S](/img/5/57391/w960_57391-2047.png)

TURN SIGNAL AND HAZARD WARNING LAMP SYSTEM

EXL-19

< FUNCTION DIAGNOSIS >[XENON TYPE]

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

TURN SIGNAL AND HAZARD WARNING LAMP SYSTEM

System DiagramINFOID:0000000003773535

System DescriptionINFOID:0000000003773536

OUTLINE

Turn signal lamp and the hazard warning lamp is controlled by combination switch reading function and the

flasher control function of BCM.

TURN SIGNAL LAMP OPERATION

BCM detects the combination switch condition by the combination switch reading function.

BCM supplies voltage to the right (left) turn signal lamp circuit when the ignition switch is turned ON and the

turn signal switch is in the right (left) position. BCM blinks the turn signal lamp.

HAZARD WARNING LAMP OPERATION

BCM supplies voltage to both turn signal lamp circuit when the hazard switch is turned ON. BCM blinks the

hazard warning lamp.

TURN SIGNAL INDICATOR LAMP AND TURN SIGNAL SOUND OPERATION

BCM transmits the turn indicator signal to the combination meter with CAN communication while the turn sig-

nal lamp and the hazard warning lamp are operating.

Combination meter outputs the turn signal sound with the integrated buzzer while blinking the turn signal

indicator lamp according to the turn indicator signal.

HIGH FLASHER OPERATION (FAIL-SAFE)

BCM detects the turn signal lamp circuit status by the terminal current value.

BCM increases the turn signal lamp blinking speed if the bulb or harness open is detected with the turn sig-

nal lamp operating.

NOTE:

The blinking speed is normal while operating the hazard warning lamp.

JPLIA0180GB

Page 2054 of 5121

![NISSAN TEANA 2008 Service Manual EXTERIOR LAMP BATTERY SAVER SYSTEM

EXL-25

< FUNCTION DIAGNOSIS >[XENON TYPE]

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

EXTERIOR LAMP BATTERY SAVER SYSTEM

System DiagramINFOID:0000000003773543

System Descriptio NISSAN TEANA 2008 Service Manual EXTERIOR LAMP BATTERY SAVER SYSTEM

EXL-25

< FUNCTION DIAGNOSIS >[XENON TYPE]

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

EXTERIOR LAMP BATTERY SAVER SYSTEM

System DiagramINFOID:0000000003773543

System Descriptio](/img/5/57391/w960_57391-2053.png)

EXTERIOR LAMP BATTERY SAVER SYSTEM

EXL-25

< FUNCTION DIAGNOSIS >[XENON TYPE]

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

EXTERIOR LAMP BATTERY SAVER SYSTEM

System DiagramINFOID:0000000003773543

System DescriptionINFOID:0000000003773544

OUTLINE

Exterior lamp battery saver system is controlled by each function of BCM and IPDM E/R.

Control by BCM- Combination switch reading function

- Headlamp control function

- Exterior lamp battery saver function

Control by IPDM E/R- Relay control function

BCM turns the exterior lamp* OFF after a period of time to prevent the battery from over-discharge when the

ignition switch is turned OFF with the exterior lamp ON.

*: Headlamp (LO/HI), parking lamp, tail lamp, license plate lamp, front fog lamp and rear fog lamp.

EXTERIOR LAMP BATTERY SAVER ACTIVATION

BCM activates the timer and turns the exterior lamp OFF 5 minutes after the ignition switch is turned from ON

→ OFF with the exterior lamps ON.

NOTE:

Headlamp control function turns the exterior lamps ON normally when the ignition switch is turned ACC or

the engine started (both before and after the exterior lamp battery saver is turned OFF).

The timer starts at the time that the lighting switch is turned from OFF → 1ST or 2ND with the exterior lamp

OFF.

JPLIA1084GB

Page 2057 of 5121

![NISSAN TEANA 2008 Service Manual EXL-28

< FUNCTION DIAGNOSIS >[XENON TYPE]

DIAGNOSIS SYSTEM (BCM)

The BCM records the following condition at the moment a particular DTC is detected.

Vehicle Speed

Odo/Trip Meter

Vehicle Conditio NISSAN TEANA 2008 Service Manual EXL-28

< FUNCTION DIAGNOSIS >[XENON TYPE]

DIAGNOSIS SYSTEM (BCM)

The BCM records the following condition at the moment a particular DTC is detected.

Vehicle Speed

Odo/Trip Meter

Vehicle Conditio](/img/5/57391/w960_57391-2056.png)

EXL-28

< FUNCTION DIAGNOSIS >[XENON TYPE]

DIAGNOSIS SYSTEM (BCM)

The BCM records the following condition at the moment a particular DTC is detected.

Vehicle Speed

Odo/Trip Meter

Vehicle Condition (BCM detected condition)

IGN Counter

IGN counter indicates the number of times that ignition switch is turned ON after DTC is detected.

The number is 0 when a malfunction is detected now.

The number increases like 1 → 2 → 3...38 → 39 after returning to the normal condition whenever ignition

switch OFF → ON.

The number is fixed to 39 until the self-diagnosis results are erased if it is over 39.

HEADLAMP

HEADLAMP : CONSULT-III Function (BCM - HEAD LAMP)INFOID:0000000003773548

WORK SUPPORT

CONSULT screen terms Description

SLEEP>LOCKWhile turning BCM status from low power consumption mode to normal mode (Power supply

position is “LOCK”.)

SLEEP>OFFWhile turning BCM status from low power consumption mode to normal mode (Power supply

position is “OFF”.)

LOCK>ACC While turning power supply position from “LOCK” to “ACC”

ACC>ON While turning power supply position from “ACC” to “IGN”

RUN>ACCWhile turning power supply position from “RUN” to “ACC” (Vehicle is stopping and selector

lever is except P position.)

CRANK>RUNWhile turning power supply position from “CRANKING” to “RUN” (From cranking up the en-

gine to run it)

RUN>URGENT While turning power supply position from “RUN“ to “ACC” (Emergency stop operation)

ACC>OFF While turning power supply position from “ACC” to “OFF”

OFF>LOCK While turning power supply position from “OFF” to “LOCK”

OFF>ACC While turning power supply position from “OFF” to “ACC”

ON>CRANK While turning power supply position from “IGN” to “CRANKING”

OFF>SLEEPWhile turning BCM status from normal mode (Power supply position is “OFF”.) to low power

consumption mode

LOCK>SLEEPWhile turning BCM status from normal mode (Power supply position is “LOCK”.) to low pow-

er consumption mode

LOCK Power supply position is “LOCK” (Ignition switch OFF with steering is locked.)

OFF Power supply position is “OFF” (Ignition switch OFF with steering is unlocked.)

ACC Power supply position is “ACC” (Ignition switch ACC)

ON Power supply position is “IGN” (Ignition switch ON with engine stopped)

ENGINE RUN Power supply position is “RUN” (Ignition switch ON with engine running)

CRANKING Power supply position is “CRANKING” (At engine cranking)

Service item Setting item Setting

BATTERY SAVER SETOn* With the exterior lamp battery saver function

Off Without the exterior lamp battery saver function