display NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 3162 of 5121

![NISSAN TEANA 2008 Service Manual LAN

AV BRANCH LINE CIRCUIT

LAN-95

< COMPONENT DIAGNOSIS >[CAN SYSTEM (TYPE 9)]

C

D

E

F

G

H

I

J

K

L B A

O

P N

AV BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000003841811

1.CHECK CONNECTOR

1. Turn NISSAN TEANA 2008 Service Manual LAN

AV BRANCH LINE CIRCUIT

LAN-95

< COMPONENT DIAGNOSIS >[CAN SYSTEM (TYPE 9)]

C

D

E

F

G

H

I

J

K

L B A

O

P N

AV BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000003841811

1.CHECK CONNECTOR

1. Turn](/img/5/57391/w960_57391-3161.png)

LAN

AV BRANCH LINE CIRCUIT

LAN-95

< COMPONENT DIAGNOSIS >[CAN SYSTEM (TYPE 9)]

C

D

E

F

G

H

I

J

K

L B A

O

P N

AV BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000003841811

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the terminals and connectors of the AV control unit for damage, bend and loose connection (unit

side and connector side).

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of AV control unit.

2. Check the resistance between the AV control unit harness connector terminals.

Is the measurement value within the specification?

YES >> GO TO 3.

NO >> Repair the AV control unit branch line.

3.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the AV control unit. Refer to the following.

Base audio and display system: AV-82, "

AV CONTROL UNIT : Diagnosis Procedure"

BOSE audio without navigation: AV-236, "AV CONTROL UNIT : Diagnosis Procedure"

BOSE audio with navigation: AV-464, "AV CONTROL UNIT : Diagnosis Procedure"

Is the inspection result normal?

YES (Present error)>>Replace the AV control unit. Refer to the following.

Base audio and display system: AV-170, "

Exploded View"

BOSE audio without navigation: AV-378, "Exploded View"

BOSE audio with navigation: AV-648, "Exploded View"

YES (Past error)>>Error was detected in the AV control unit branch line.

NO >> Repair the power supply and the ground circuit.

AV control unit harness connector

Resistance (Ω)

Connector No. Terminal No.

M131 86 87 Approx. 54 – 66

Page 3163 of 5121

![NISSAN TEANA 2008 Service Manual LAN-96

< COMPONENT DIAGNOSIS >[CAN SYSTEM (TYPE 9)]

HVAC BRANCH LINE CIRCUIT

HVAC BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000003841812

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. D NISSAN TEANA 2008 Service Manual LAN-96

< COMPONENT DIAGNOSIS >[CAN SYSTEM (TYPE 9)]

HVAC BRANCH LINE CIRCUIT

HVAC BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000003841812

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. D](/img/5/57391/w960_57391-3162.png)

LAN-96

< COMPONENT DIAGNOSIS >[CAN SYSTEM (TYPE 9)]

HVAC BRANCH LINE CIRCUIT

HVAC BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000003841812

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the terminals and connectors of the A/C auto amp. for damage, bend and loose connection (unit

side and connector side).

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of A/C auto amp.

2. Check the resistance between the A/C auto amp. harness connector terminals.

Is the measurement value within the specification?

YES >> GO TO 3.

NO >> Repair the A/C auto amp. branch line.

3.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the A/C auto amp. Refer to the following.

Without color display: HAC-65, "

A/C AUTO AMP. : Diagnosis Procedure"

With color display: HAC-191, "A/C AUTO AMP. : Diagnosis Procedure"

Is the inspection result normal?

YES (Present error)>>Replace the A/C auto amp. Refer to the following.

Without color display: VTL-23, "

Exploded View"

With color display: VTL-80, "Exploded View"

YES (Past error)>>Error was detected in the A/C auto amp. branch line.

NO >> Repair the power supply and the ground circuit.

A/C auto amp. harness connector

Resistance (Ω)

Connector No. Terminal No.

M50 1 2 Approx. 54 – 66

Page 3255 of 5121

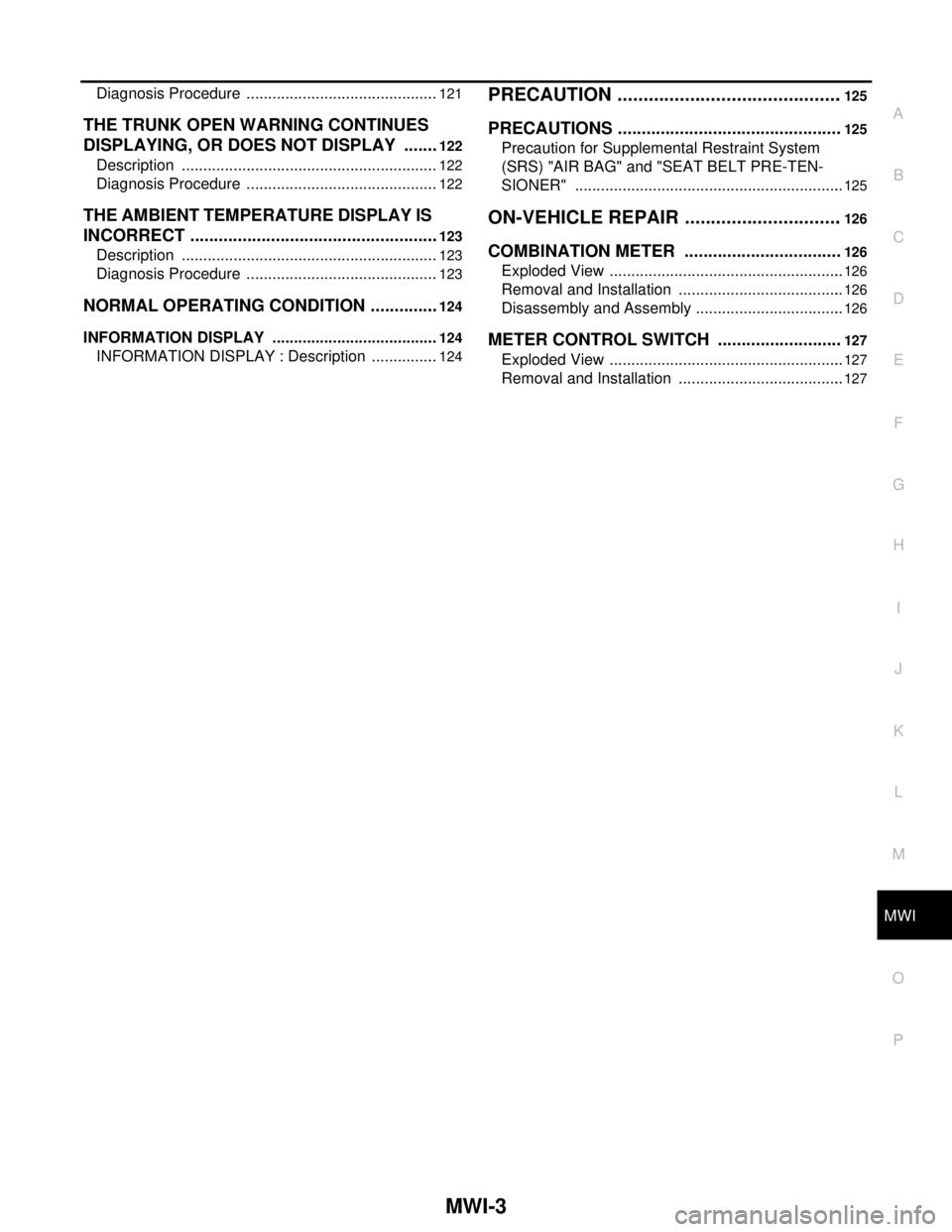

MWI

MWI-1

DRIVER INFORMATION & MULTIMEDIA

C

D

E

F

G

H

I

J

K

L

MB

SECTION MWI

A

O

P

CONTENTS

METER, WARNING LAMP & INDICATOR

BASIC INSPECTION ....................................4

DIAGNOSIS AND REPAIR WORKFLOW ..........4

Work flow ..................................................................4

FUNCTION DIAGNOSIS ...............................6

METER SYSTEM .................................................6

METER SYSTEM .........................................................6

METER SYSTEM : System Diagram ........................6

METER SYSTEM : System Description ....................6

METER SYSTEM : Component Parts Location ........9

METER SYSTEM : Component Description ...........10

SPEEDOMETER ........................................................10

SPEEDOMETER : System Diagram .......................10

SPEEDOMETER : System Description ...................10

SPEEDOMETER : Component Parts Location .......11

SPEEDOMETER : Component Description ............12

TACHOMETER ..........................................................12

TACHOMETER : System Diagram .........................12

TACHOMETER : System Description .....................12

TACHOMETER : Component Parts Location .........13

TACHOMETER : Component Description ..............14

ENGINE COOLANT TEMPERATURE GAUGE ........14

ENGINE COOLANT TEMPERATURE GAUGE :

System Diagram ......................................................

14

ENGINE COOLANT TEMPERATURE GAUGE :

System Description .................................................

14

ENGINE COOLANT TEMPERATURE GAUGE :

Component Parts Location ......................................

15

ENGINE COOLANT TEMPERATURE GAUGE :

Component Description ...........................................

16

FUEL GAUGE ............................................................16

FUEL GAUGE : System Diagram ...........................16

FUEL GAUGE : System Description .......................16

FUEL GAUGE : Component Parts Location ...........17

FUEL GAUGE : Component Description ................18

ODO/TRIP METER .....................................................18

ODO/TRIP METER : System Diagram ....................18

ODO/TRIP METER : System Description ................18

ODO/TRIP METER : Component Parts Location ....19

ODO/TRIP METER : Component Description .........20

SHIFT POSITION INDICATOR ..................................20

SHIFT POSITION INDICATOR : System Diagram ....20

SHIFT POSITION INDICATOR : System Descrip-

tion ...........................................................................

20

SHIFT POSITION INDICATOR : Component

Parts Location ..........................................................

21

SHIFT POSITION INDICATOR : Component De-

scription ...................................................................

22

WARNING LAMPS/INDICATOR LAMPS ..................22

WARNING LAMPS/INDICATOR LAMPS : System

Diagram ...................................................................

22

WARNING LAMPS/INDICATOR LAMPS : System

Description ...............................................................

22

WARNING LAMPS/INDICATOR LAMPS : Com-

ponent Parts Location ..............................................

23

WARNING LAMPS/INDICATOR LAMPS : Com-

ponent Description ...................................................

24

METER ILLUMINATION CONTROL .........................24

METER ILLUMINATION CONTROL : System Di-

agram ......................................................................

24

METER ILLUMINATION CONTROL : System De-

scription ...................................................................

24

METER ILLUMINATION CONTROL : Component

Parts Location ..........................................................

26

METER ILLUMINATION CONTROL : Component

Description ...............................................................

27

INFORMATION DISPLAY ..........................................27

INFORMATION DISPLAY : System Diagram ..........27

INFORMATION DISPLAY : System Description .....27

INFORMATION DISPLAY : Component Parts Lo-

cation .......................................................................

30

INFORMATION DISPLAY : Component Descrip-

tion ...........................................................................

31

Page 3256 of 5121

MWI-2

DIAGNOSIS SYSTEM (METER) .......................32

Diagnosis Description .............................................32

CONSULT-III Function (METER/M&A) ...................33

COMPONENT DIAGNOSIS ........................37

U1000 CAN COMM CIRCUIT ............................37

Description ..............................................................37

DTC Logic ...............................................................37

Diagnosis Procedure .............................................37

U1010 CONTROL UNIT (CAN) .........................38

Description ..............................................................38

DTC Logic ...............................................................38

Diagnosis Procedure ..............................................38

B2205 VEHICLE SPEED ...................................39

Description ..............................................................39

DTC Logic ...............................................................39

Diagnosis Procedure .............................................39

B2267 ENGINE SPEED .....................................40

Description ..............................................................40

DTC Logic ...............................................................40

Diagnosis Procedure ..............................................40

B2268 WATER TEMP ........................................41

Description ..............................................................41

DTC Logic ...............................................................41

Diagnosis Procedure ..............................................41

POWER SUPPLY AND GROUND CIRCUIT .....42

COMBINATION METER ...........................................42

COMBINATION METER : Diagnosis Procedure ....42

BCM (BODY CONTROL MODULE) .........................42

BCM (BODY CONTROL MODULE) : Diagnosis

Procedure ...............................................................

42

IPDM E/R (INTELLIGENT POWER DISTRIBU-

TION MODULE ENGINE ROOM) .............................

43

IPDM E/R (INTELLIGENT POWER DISTRIBU-

TION MODULE ENGINE ROOM) : Diagnosis Pro-

cedure .....................................................................

43

FUEL LEVEL SENSOR SIGNAL CIRCUIT .......45

Description ..............................................................45

Component Function Check ...................................45

Diagnosis Procedure .............................................45

Component Inspection ............................................46

METER CONTROL SWITCH SIGNAL CIR-

CUIT ...................................................................

48

Description ..............................................................48

Diagnosis Procedure ..............................................48

Component Inspection ............................................49

OIL PRESSURE SWITCH SIGNAL CIRCUIT ...50

Description ..............................................................50

Component Function Check ...................................50

Diagnosis Procedure ..............................................50

Component Inspection ............................................50

PARKING BRAKE SWITCH SIGNAL CIR-

CUIT ...................................................................

52

Description ..............................................................52

Diagnosis Procedure ...............................................52

Component Inspection ............................................52

ECU DIAGNOSIS .......................................53

COMBINATION METER ....................................53

Reference Value .....................................................53

Wiring Diagram - METER - .....................................59

Fail-Safe ..................................................................66

DTC Index ...............................................................67

BCM (BODY CONTROL MODULE) ..................68

Reference Value .....................................................68

Wiring Diagram - BCM - ..........................................91

Fail-safe ..................................................................97

DTC Inspection Priority Chart ...............................99

DTC Index ............................................................100

IPDM E/R (INTELLIGENT POWER DISTRI-

BUTION MODULE ENGINE ROOM) ................

102

Reference Value ...................................................102

Wiring Diagram - IPDM E/R - ................................110

Fail-safe ................................................................113

DTC Index ............................................................115

SYMPTOM DIAGNOSIS ...........................116

THE FUEL GAUGE POINTER DOES NOT

MOVE ................................................................

116

Description ............................................................116

Diagnosis Procedure .............................................116

THE METER CONTROL SWITCH IS INOPER-

ATIVE ................................................................

117

Description ............................................................117

Diagnosis Procedure .............................................117

THE OIL PRESSURE WARNING LAMP

DOES NOT TURN ON ......................................

118

Description ............................................................118

Diagnosis Procedure .............................................118

THE OIL PRESSURE WARNING LAMP

DOES NOT TURN OFF ....................................

119

Description ............................................................119

Diagnosis Procedure .............................................119

THE PARKING BRAKE RELEASE WARNING

CONTINUES DISPLAYING, OR DOES NOT

DISPLAY ...........................................................

120

Description ............................................................120

Diagnosis Procedure .............................................120

THE DOOR OPEN WARNING CONTINUES

DISPLAYING, OR DOES NOT DISPLAY ........

121

Description ............................................................121

Page 3257 of 5121

MWI

MWI-3

C

D

E

F

G

H

I

J

K

L

MB A

O

P Diagnosis Procedure .............................................

121

THE TRUNK OPEN WARNING CONTINUES

DISPLAYING, OR DOES NOT DISPLAY ........

122

Description ............................................................122

Diagnosis Procedure .............................................122

THE AMBIENT TEMPERATURE DISPLAY IS

INCORRECT .....................................................

123

Description ............................................................123

Diagnosis Procedure .............................................123

NORMAL OPERATING CONDITION ...............124

INFORMATION DISPLAY .......................................124

INFORMATION DISPLAY : Description ................124

PRECAUTION ............................................125

PRECAUTIONS ...............................................125

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...............................................................

125

ON-VEHICLE REPAIR ...............................126

COMBINATION METER .................................126

Exploded View .......................................................126

Removal and Installation .......................................126

Disassembly and Assembly ...................................126

METER CONTROL SWITCH ..........................127

Exploded View .......................................................127

Removal and Installation .......................................127

Page 3259 of 5121

MWI

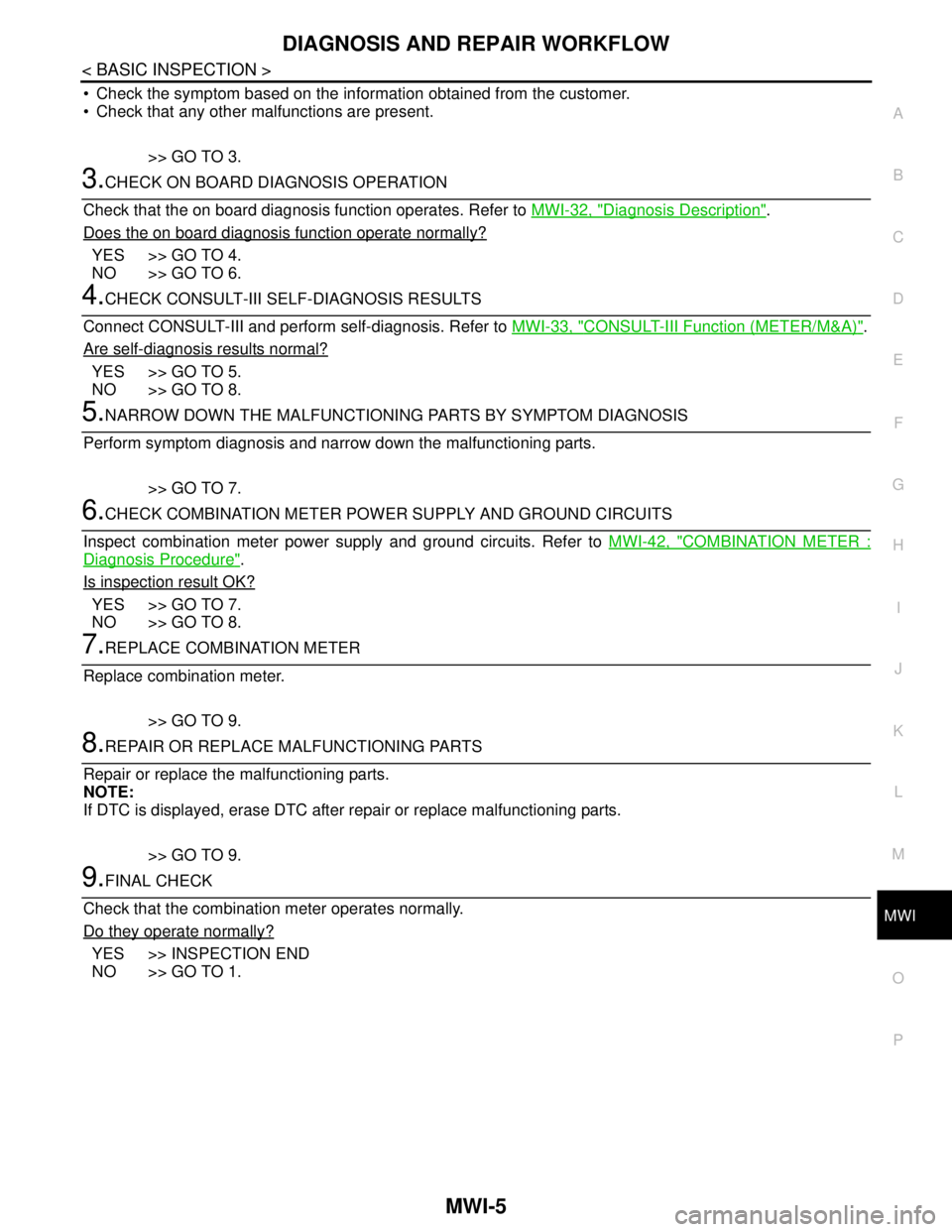

DIAGNOSIS AND REPAIR WORKFLOW

MWI-5

< BASIC INSPECTION >

C

D

E

F

G

H

I

J

K

L

MB A

O

P

Check the symptom based on the information obtained from the customer.

Check that any other malfunctions are present.

>> GO TO 3.

3.CHECK ON BOARD DIAGNOSIS OPERATION

Check that the on board diagnosis function operates. Refer to MWI-32, "

Diagnosis Description".

Does the on board diagnosis function operate normally?

YES >> GO TO 4.

NO >> GO TO 6.

4.CHECK CONSULT-III SELF-DIAGNOSIS RESULTS

Connect CONSULT-III and perform self-diagnosis. Refer to MWI-33, "

CONSULT-III Function (METER/M&A)".

Are self-diagnosis results normal?

YES >> GO TO 5.

NO >> GO TO 8.

5.NARROW DOWN THE MALFUNCTIONING PARTS BY SYMPTOM DIAGNOSIS

Perform symptom diagnosis and narrow down the malfunctioning parts.

>> GO TO 7.

6.CHECK COMBINATION METER POWER SUPPLY AND GROUND CIRCUITS

Inspect combination meter power supply and ground circuits. Refer to MWI-42, "

COMBINATION METER :

Diagnosis Procedure".

Is inspection result OK?

YES >> GO TO 7.

NO >> GO TO 8.

7.REPLACE COMBINATION METER

Replace combination meter.

>> GO TO 9.

8.REPAIR OR REPLACE MALFUNCTIONING PARTS

Repair or replace the malfunctioning parts.

NOTE:

If DTC is displayed, erase DTC after repair or replace malfunctioning parts.

>> GO TO 9.

9.FINAL CHECK

Check that the combination meter operates normally.

Do they operate normally?

YES >> INSPECTION END

NO >> GO TO 1.

Page 3260 of 5121

MWI-6

< FUNCTION DIAGNOSIS >

METER SYSTEM

FUNCTION DIAGNOSIS

METER SYSTEM

METER SYSTEM

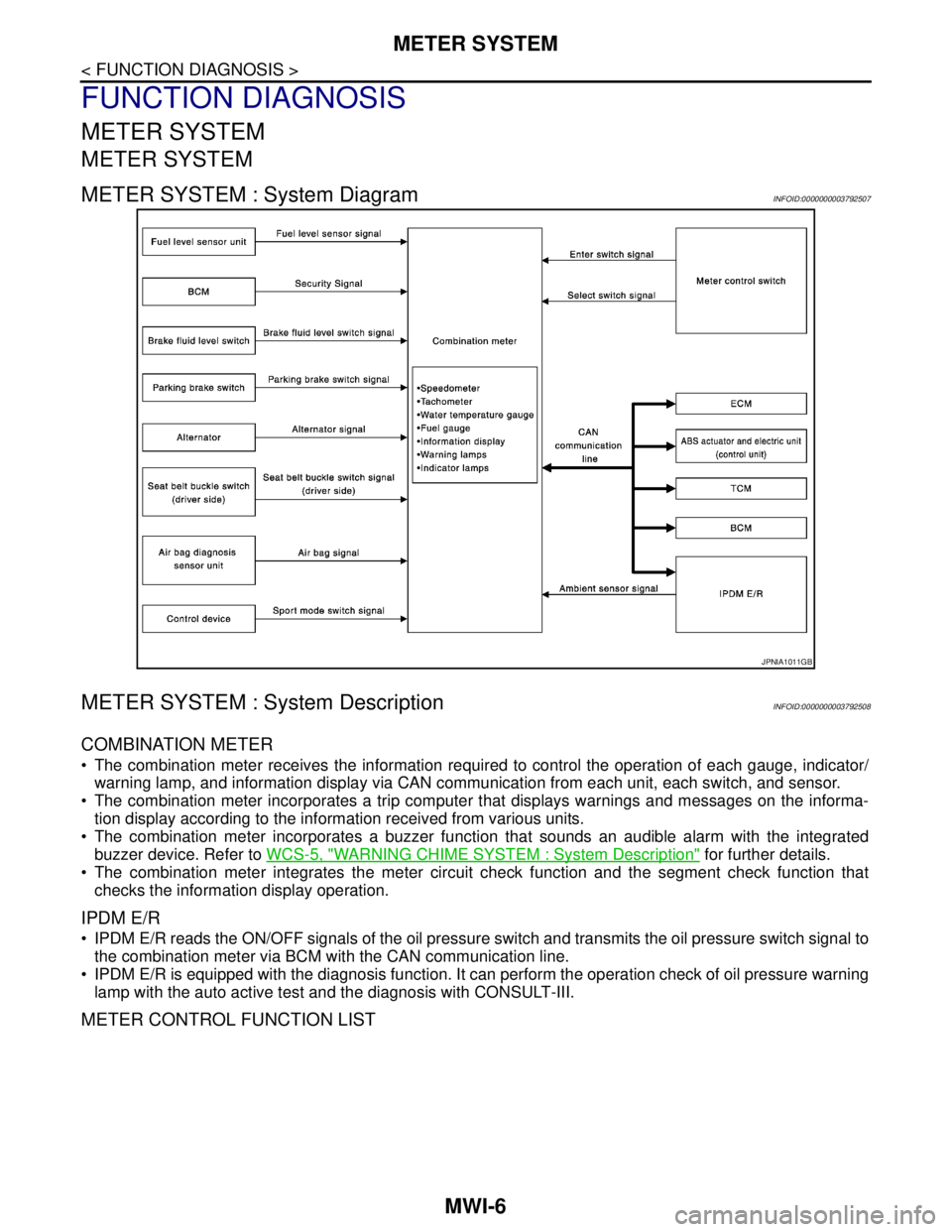

METER SYSTEM : System DiagramINFOID:0000000003792507

METER SYSTEM : System DescriptionINFOID:0000000003792508

COMBINATION METER

The combination meter receives the information required to control the operation of each gauge, indicator/

warning lamp, and information display via CAN communication from each unit, each switch, and sensor.

The combination meter incorporates a trip computer that displays warnings and messages on the informa-

tion display according to the information received from various units.

The combination meter incorporates a buzzer function that sounds an audible alarm with the integrated

buzzer device. Refer to WCS-5, "

WARNING CHIME SYSTEM : System Description" for further details.

The combination meter integrates the meter circuit check function and the segment check function that

checks the information display operation.

IPDM E/R

IPDM E/R reads the ON/OFF signals of the oil pressure switch and transmits the oil pressure switch signal to

the combination meter via BCM with the CAN communication line.

IPDM E/R is equipped with the diagnosis function. It can perform the operation check of oil pressure warning

lamp with the auto active test and the diagnosis with CONSULT-III.

METER CONTROL FUNCTION LIST

JPNIA1011GB

Page 3261 of 5121

MWI

METER SYSTEM

MWI-7

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

MB A

O

P

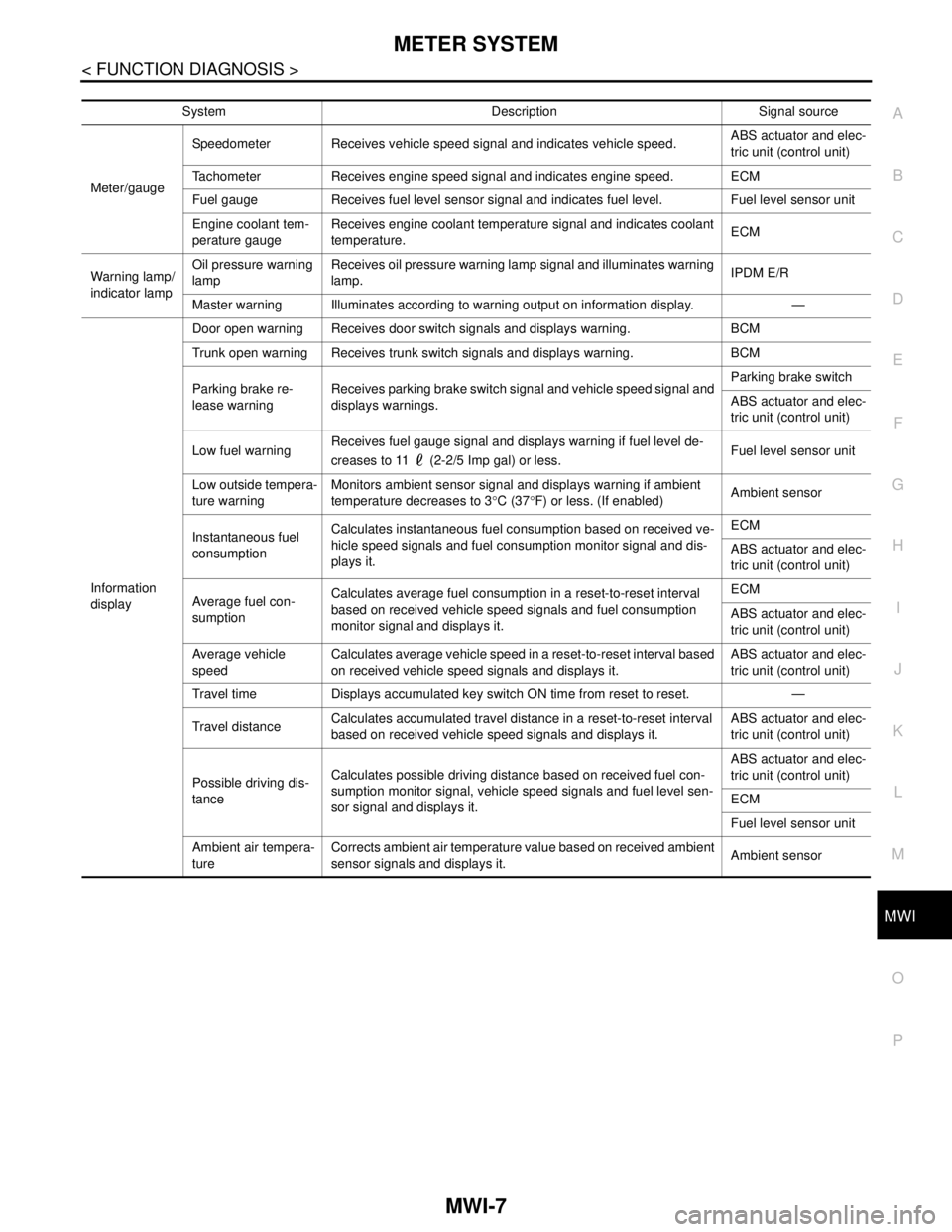

System Description Signal source

Meter/gaugeSpeedometer Receives vehicle speed signal and indicates vehicle speed.ABS actuator and elec-

tric unit (control unit)

Tachometer Receives engine speed signal and indicates engine speed. ECM

Fuel gauge Receives fuel level sensor signal and indicates fuel level. Fuel level sensor unit

Engine coolant tem-

perature gaugeReceives engine coolant temperature signal and indicates coolant

temperature.ECM

Warning lamp/

indicator lampOil pressure warning

lampReceives oil pressure warning lamp signal and illuminates warning

lamp.IPDM E/R

Master warning Illuminates according to warning output on information display. —

Information

displayDoor open warning Receives door switch signals and displays warning. BCM

Trunk open warning Receives trunk switch signals and displays warning. BCM

Parking brake re-

lease warningReceives parking brake switch signal and vehicle speed signal and

displays warnings.Parking brake switch

ABS actuator and elec-

tric unit (control unit)

Low fuel warningReceives fuel gauge signal and displays warning if fuel level de-

creases to 11 (2-2/5 Imp gal) or less.Fuel level sensor unit

Low outside tempera-

ture warningMonitors ambient sensor signal and displays warning if ambient

temperature decreases to 3°C (37°F) or less. (If enabled)Ambient sensor

Instantaneous fuel

consumptionCalculates instantaneous fuel consumption based on received ve-

hicle speed signals and fuel consumption monitor signal and dis-

plays it.ECM

ABS actuator and elec-

tric unit (control unit)

Average fuel con-

sumptionCalculates average fuel consumption in a reset-to-reset interval

based on received vehicle speed signals and fuel consumption

monitor signal and displays it.ECM

ABS actuator and elec-

tric unit (control unit)

Average vehicle

speedCalculates average vehicle speed in a reset-to-reset interval based

on received vehicle speed signals and displays it.ABS actuator and elec-

tric unit (control unit)

Travel time Displays accumulated key switch ON time from reset to reset. —

Travel distanceCalculates accumulated travel distance in a reset-to-reset interval

based on received vehicle speed signals and displays it.ABS actuator and elec-

tric unit (control unit)

Possible driving dis-

tanceCalculates possible driving distance based on received fuel con-

sumption monitor signal, vehicle speed signals and fuel level sen-

sor signal and displays it.ABS actuator and elec-

tric unit (control unit)

ECM

Fuel level sensor unit

Ambient air tempera-

tureCorrects ambient air temperature value based on received ambient

sensor signals and displays it.Ambient sensor

Page 3264 of 5121

MWI-10

< FUNCTION DIAGNOSIS >

METER SYSTEM

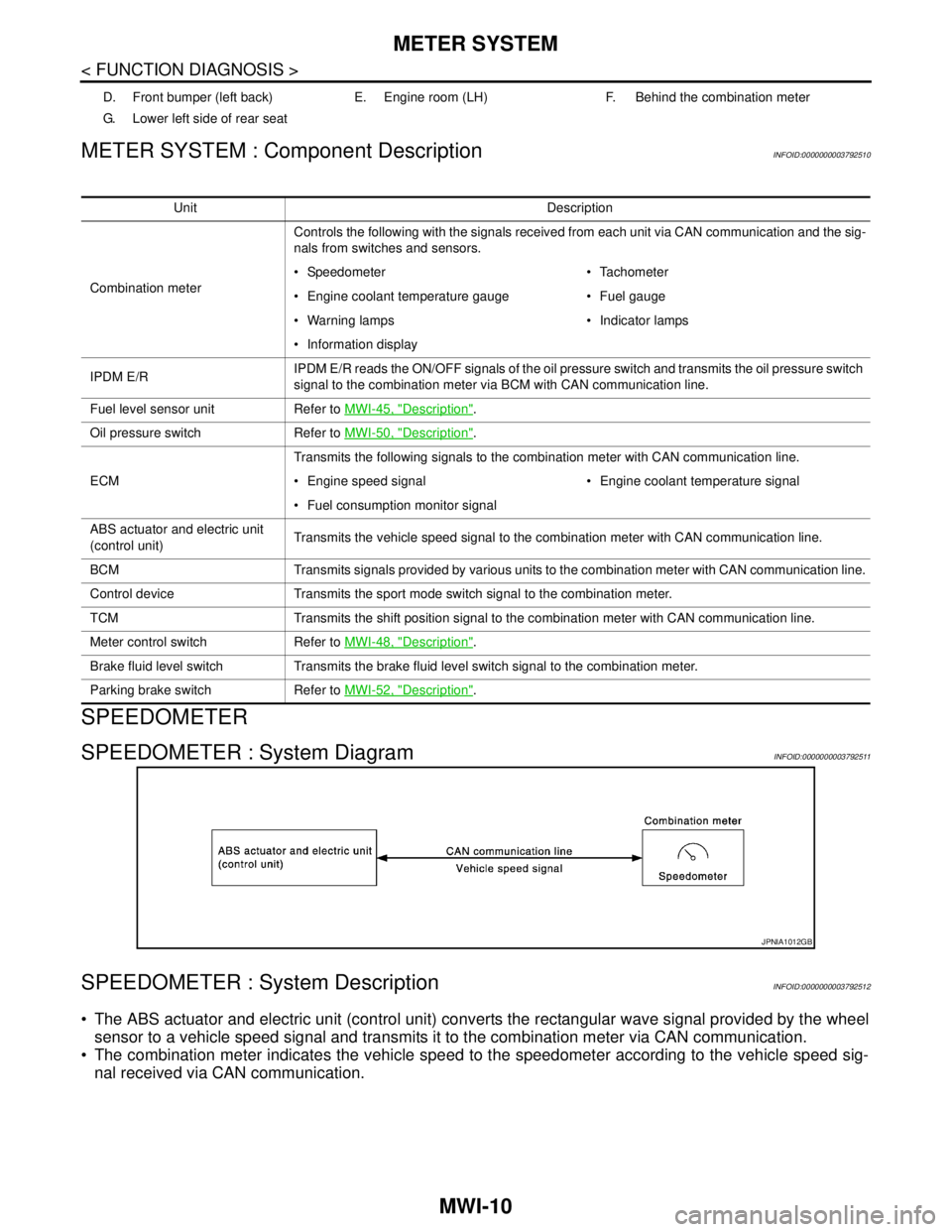

METER SYSTEM : Component Description

INFOID:0000000003792510

SPEEDOMETER

SPEEDOMETER : System DiagramINFOID:0000000003792511

SPEEDOMETER : System DescriptionINFOID:0000000003792512

The ABS actuator and electric unit (control unit) converts the rectangular wave signal provided by the wheel

sensor to a vehicle speed signal and transmits it to the combination meter via CAN communication.

The combination meter indicates the vehicle speed to the speedometer according to the vehicle speed sig-

nal received via CAN communication.

D. Front bumper (left back) E. Engine room (LH) F. Behind the combination meter

G. Lower left side of rear seat

Unit Description

Combination meterControls the following with the signals received from each unit via CAN communication and the sig-

nals from switches and sensors.

Speedometer Tachometer

Engine coolant temperature gauge Fuel gauge

Warning lamps Indicator lamps

Information display

IPDM E/RIPDM E/R reads the ON/OFF signals of the oil pressure switch and transmits the oil pressure switch

signal to the combination meter via BCM with CAN communication line.

Fuel level sensor unit Refer to MWI-45, "

Description".

Oil pressure switch Refer to MWI-50, "

Description".

ECMTransmits the following signals to the combination meter with CAN communication line.

Engine speed signal Engine coolant temperature signal

Fuel consumption monitor signal

ABS actuator and electric unit

(control unit)Transmits the vehicle speed signal to the combination meter with CAN communication line.

BCM Transmits signals provided by various units to the combination meter with CAN communication line.

Control device Transmits the sport mode switch signal to the combination meter.

TCM Transmits the shift position signal to the combination meter with CAN communication line.

Meter control switch Refer to MWI-48, "

Description".

Brake fluid level switch Transmits the brake fluid level switch signal to the combination meter.

Parking brake switch Refer to MWI-52, "

Description".

JPNIA1012GB

Page 3272 of 5121

MWI-18

< FUNCTION DIAGNOSIS >

METER SYSTEM

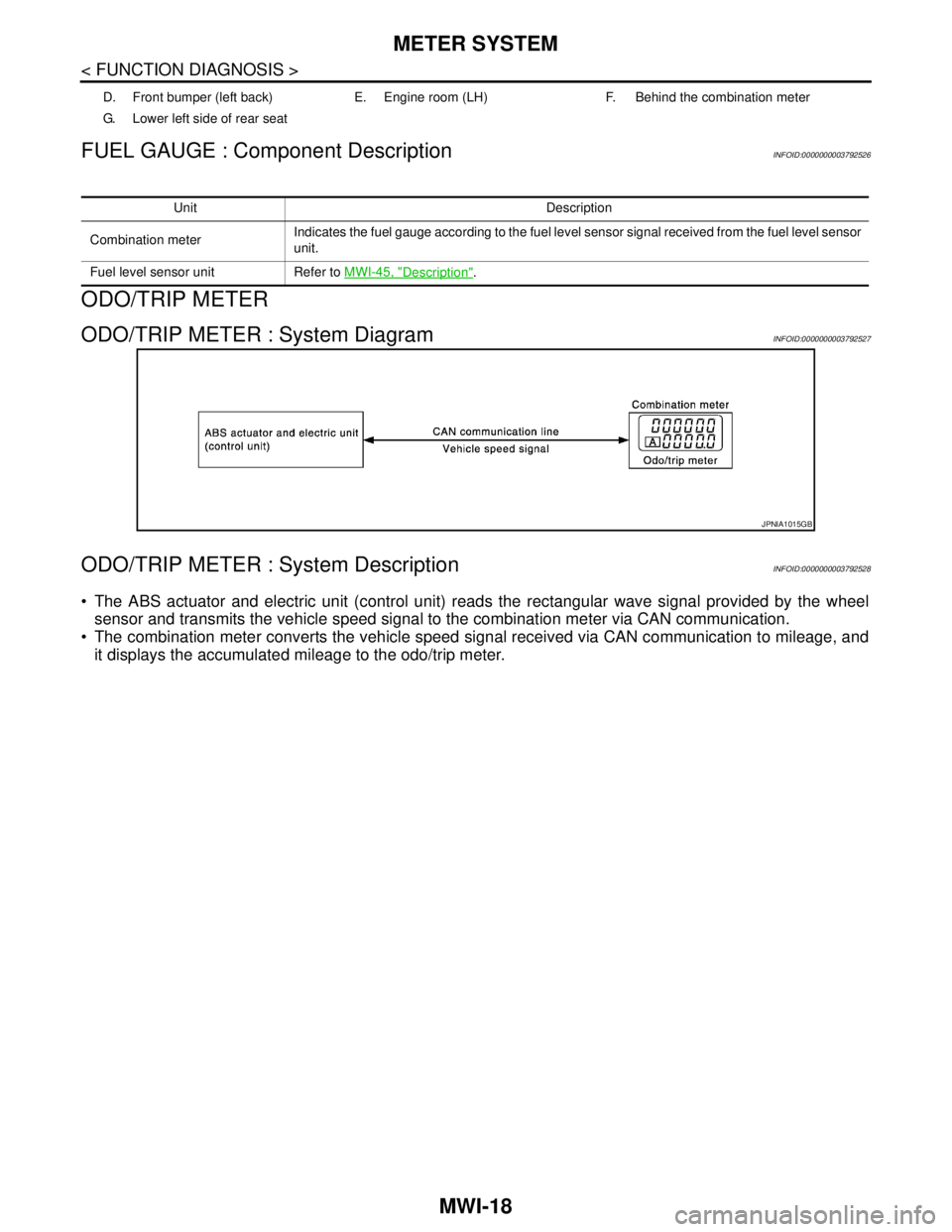

FUEL GAUGE : Component Description

INFOID:0000000003792526

ODO/TRIP METER

ODO/TRIP METER : System DiagramINFOID:0000000003792527

ODO/TRIP METER : System DescriptionINFOID:0000000003792528

The ABS actuator and electric unit (control unit) reads the rectangular wave signal provided by the wheel

sensor and transmits the vehicle speed signal to the combination meter via CAN communication.

The combination meter converts the vehicle speed signal received via CAN communication to mileage, and

it displays the accumulated mileage to the odo/trip meter.

D. Front bumper (left back) E. Engine room (LH) F. Behind the combination meter

G. Lower left side of rear seat

Unit Description

Combination meterIndicates the fuel gauge according to the fuel level sensor signal received from the fuel level sensor

unit.

Fuel level sensor unit Refer to MWI-45, "

Description".

JPNIA1015GB