display NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 2872 of 5121

![NISSAN TEANA 2008 Service Manual HAC-244

< PRECAUTION >[WITH 7 INCH DISPLAY]

COMPRESSOR

COMPRESSOR

General PrecautionsINFOID:0000000003884820

CAUTION:

Plug all openings to prevent moisture and foreign matter from entering.

Store NISSAN TEANA 2008 Service Manual HAC-244

< PRECAUTION >[WITH 7 INCH DISPLAY]

COMPRESSOR

COMPRESSOR

General PrecautionsINFOID:0000000003884820

CAUTION:

Plug all openings to prevent moisture and foreign matter from entering.

Store](/img/5/57391/w960_57391-2871.png)

HAC-244

< PRECAUTION >[WITH 7 INCH DISPLAY]

COMPRESSOR

COMPRESSOR

General PrecautionsINFOID:0000000003884820

CAUTION:

Plug all openings to prevent moisture and foreign matter from entering.

Store it in the same way at it is when mounted on the car when the compressor is removed.

Follow “Maintenance of Lubricant Quantity in Compressor” exactly when replacing or repairing the

compressor. Refer to HA-28, "

Maintenance of Lubricant Quantity".

Keep friction surfaces between clutch and pulley clean. Wipe it off by using a clean waste cloth

moistened with thinner if the surface is contaminated with lubricant.

Turn the compressor shaft by hand more than five turns in both directions after compressor service

operation. This equally distributes lubricant inside the compressor. Let the engine idle and operate

the compressor for one hour after the compressor is installed.

Apply voltage to the new compressor and check for normal operation after replacing the compressor

magnet clutch.

Page 2873 of 5121

![NISSAN TEANA 2008 Service Manual FLUORESCENT LEAK DETECTOR

HAC-245

< PRECAUTION >[WITH 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

FLUORESCENT LEAK DETECTOR

General PrecautionsINFOID:0000000003884821

CAUTION:

The A/C system co NISSAN TEANA 2008 Service Manual FLUORESCENT LEAK DETECTOR

HAC-245

< PRECAUTION >[WITH 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

FLUORESCENT LEAK DETECTOR

General PrecautionsINFOID:0000000003884821

CAUTION:

The A/C system co](/img/5/57391/w960_57391-2872.png)

FLUORESCENT LEAK DETECTOR

HAC-245

< PRECAUTION >[WITH 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

FLUORESCENT LEAK DETECTOR

General PrecautionsINFOID:0000000003884821

CAUTION:

The A/C system contains a fluorescent leak detection dye used for locating refrigerant leakages. An

ultraviolet (UV) lamp is required to illuminate the dye when inspecting for leakages.

Always wear fluorescence enhancing UV safety goggles to protect eyes and enhance the visibility of

the fluorescent dye.

The fluorescent dye leak detector is not a replacement for an electrical leak detector (SST: J-41995).

The fluorescent dye leak detector should be used in conjunction with an electrical leak detector

(SST: J-41995) to pin-point refrigerant leakages.

Read and follow all manufacture operating instructions and precautions prior to performing the work

for the purpose of safety and customer satisfaction.

A compressor shaft seal should not necessarily be repaired because of dye seepage. The compres-

sor shaft seal should only be repaired after confirming the leakage with an electrical leak detector

(SST: J-41995).

Always remove any remaining dye from the leakage area after repairs are completed to avoid a mis-

diagnosis during future service.

Never allow dye to come into contact with painted body panels or interior components. Clean imme-

diately with the approved dye cleaner if dye is spilled. Fluorescent dye left on a surface for an

extended period of time cannot be removed.

Never spray the fluorescent dye cleaning agent on hot surfaces (engine exhaust manifold, etc.).

Never use more than one refrigerant dye bottle (1/4 ounce /7.4 cc) per A/C system.

Leak detection dyes for HFC-134a (R-134a) and CFC-12 (R-12) A/C systems are different. Never use

HFC-134a (R-134a) leak detection dye in CFC-12 (R-12) A/C system, or CFC-12 (R-12) leak detection

dye in HFC-134a (R-134a) A/C system, or A/C system damage may result.

The fluorescent properties of the dye remains for three or more years unless a compressor malfunc-

tion occurs.

IDENTIFICATION

NOTE:

Vehicles with factory installed fluorescent dye have a green label.

Vehicles without factory installed fluorescent dye have a blue label.

IDENTIFICATION LABEL FOR VEHICLE

Vehicles with factory installed fluorescent dye have an identification label on the front side of hood.

Page 2893 of 5121

INL-14

< FUNCTION DIAGNOSIS >

DIAGNOSIS SYSTEM (BCM)

DIAGNOSIS SYSTEM (BCM)

COMMON ITEM

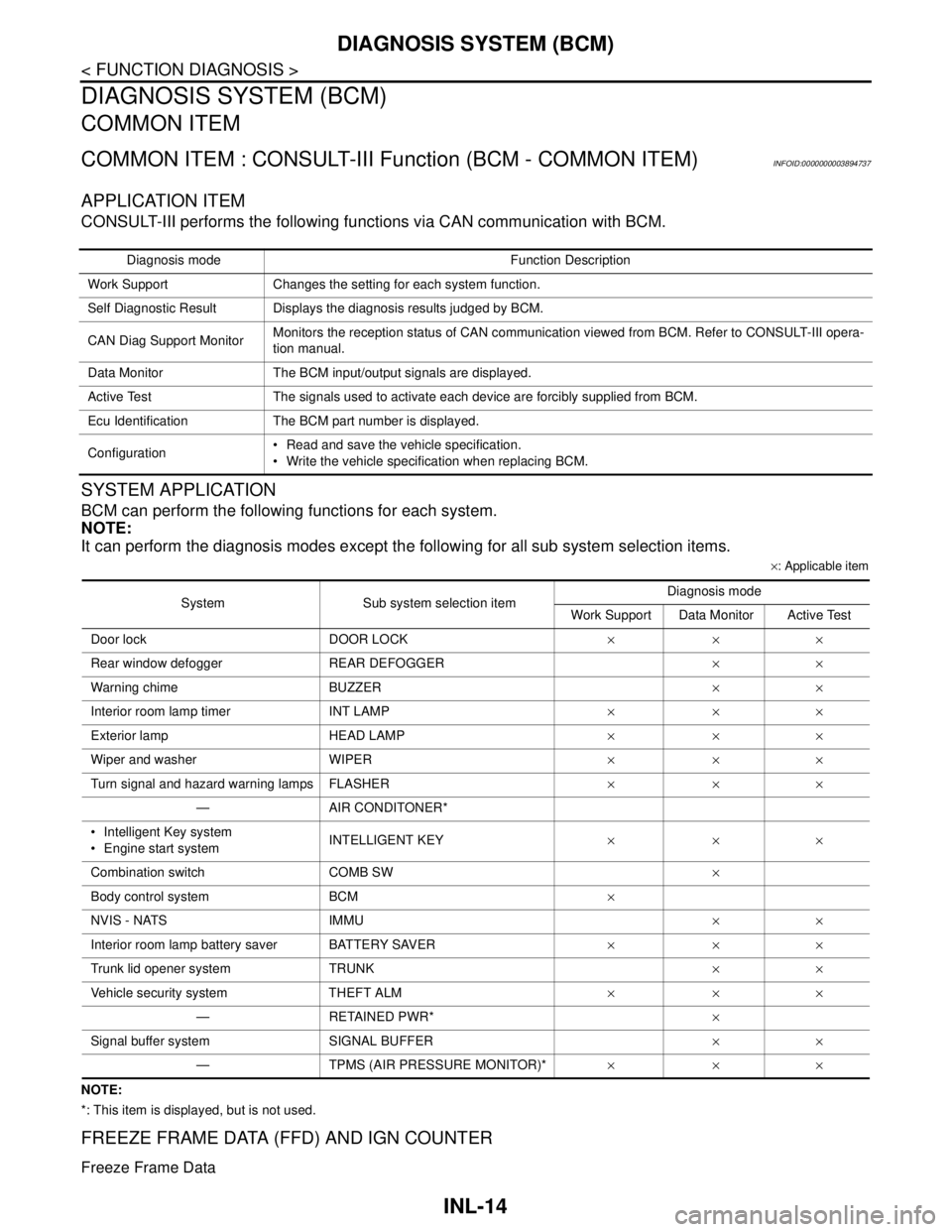

COMMON ITEM : CONSULT-III Function (BCM - COMMON ITEM)INFOID:0000000003894737

APPLICATION ITEM

CONSULT-III performs the following functions via CAN communication with BCM.

SYSTEM APPLICATION

BCM can perform the following functions for each system.

NOTE:

It can perform the diagnosis modes except the following for all sub system selection items.

×: Applicable item

NOTE:

*: This item is displayed, but is not used.

FREEZE FRAME DATA (FFD) AND IGN COUNTER

Freeze Frame Data

Diagnosis mode Function Description

Work Support Changes the setting for each system function.

Self Diagnostic Result Displays the diagnosis results judged by BCM.

CAN Diag Support MonitorMonitors the reception status of CAN communication viewed from BCM. Refer to CONSULT-III opera-

tion manual.

Data Monitor The BCM input/output signals are displayed.

Active Test The signals used to activate each device are forcibly supplied from BCM.

Ecu Identification The BCM part number is displayed.

Configuration Read and save the vehicle specification.

Write the vehicle specification when replacing BCM.

System Sub system selection itemDiagnosis mode

Work Support Data Monitor Active Test

Door lock DOOR LOCK×××

Rear window defogger REAR DEFOGGER××

Warning chime BUZZER××

Interior room lamp timer INT LAMP×××

Exterior lamp HEAD LAMP×××

Wiper and washer WIPER×××

Turn signal and hazard warning lamps FLASHER×××

— AIR CONDITONER*

Intelligent Key system

Engine start systemINTELLIGENT KEY×××

Combination switch COMB SW×

Body control system BCM×

NVIS - NATS IMMU××

Interior room lamp battery saver BATTERY SAVER×××

Trunk lid opener system TRUNK××

Vehicle security system THEFT ALM×××

— RETAINED PWR*×

Signal buffer system SIGNAL BUFFER××

— TPMS (AIR PRESSURE MONITOR)*×××

Page 2962 of 5121

BCM (BODY CONTROL MODULE)

INL-83

< ECU DIAGNOSIS >

C

D

E

F

G

H

I

J

K

MA

B

INL

N

O

P

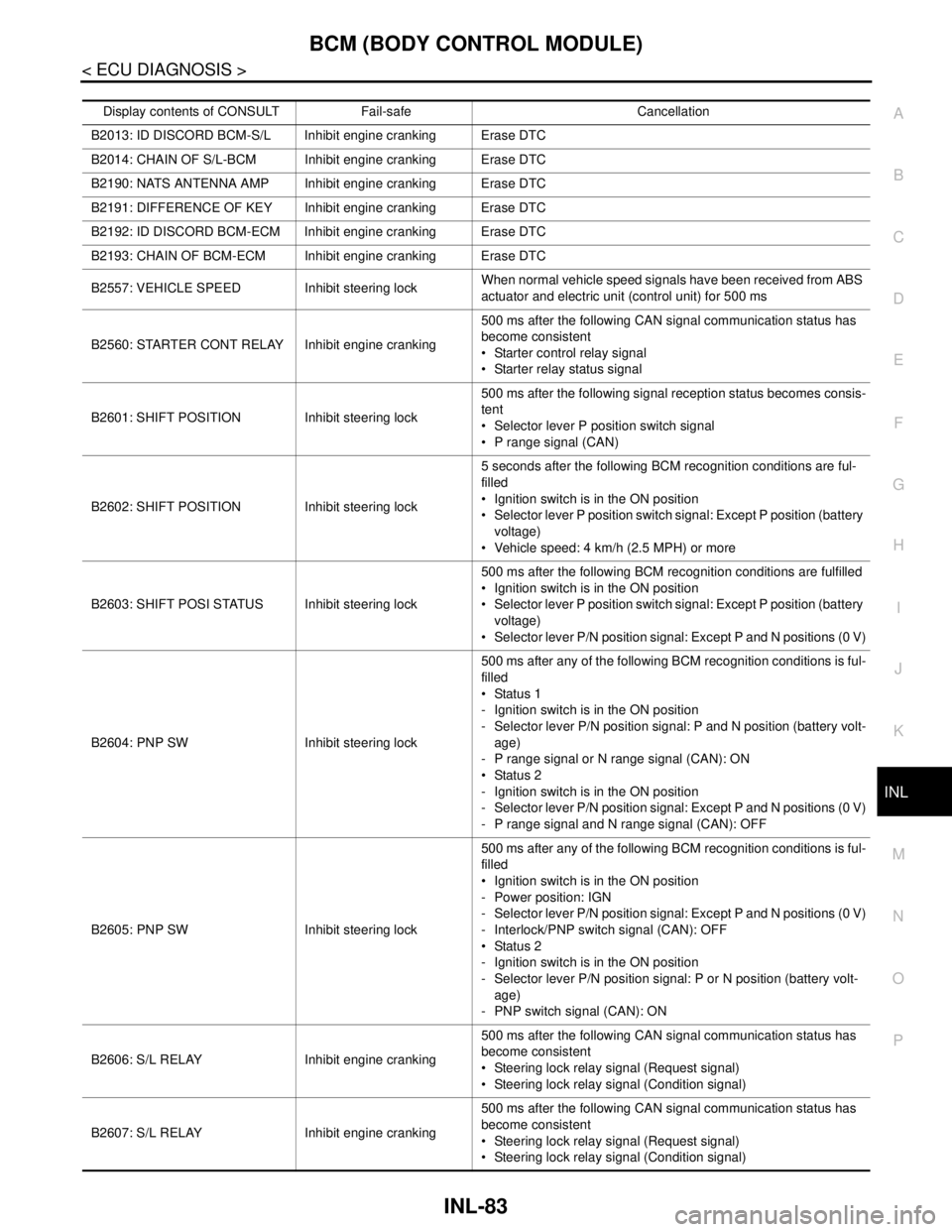

Display contents of CONSULT Fail-safe Cancellation

B2013: ID DISCORD BCM-S/L Inhibit engine cranking Erase DTC

B2014: CHAIN OF S/L-BCM Inhibit engine cranking Erase DTC

B2190: NATS ANTENNA AMP Inhibit engine cranking Erase DTC

B2191: DIFFERENCE OF KEY Inhibit engine cranking Erase DTC

B2192: ID DISCORD BCM-ECM Inhibit engine cranking Erase DTC

B2193: CHAIN OF BCM-ECM Inhibit engine cranking Erase DTC

B2557: VEHICLE SPEED Inhibit steering lockWhen normal vehicle speed signals have been received from ABS

actuator and electric unit (control unit) for 500 ms

B2560: STARTER CONT RELAY Inhibit engine cranking500 ms after the following CAN signal communication status has

become consistent

Starter control relay signal

Starter relay status signal

B2601: SHIFT POSITIONInhibit steering lock500 ms after the following signal reception status becomes consis-

tent

Selector lever P position switch signal

P range signal (CAN)

B2602: SHIFT POSITIONInhibit steering lock5 seconds after the following BCM recognition conditions are ful-

filled

Ignition switch is in the ON position

Selector lever P position switch signal: Except P position (battery

voltage)

Vehicle speed: 4 km/h (2.5 MPH) or more

B2603: SHIFT POSI STATUS Inhibit steering lock500 ms after the following BCM recognition conditions are fulfilled

Ignition switch is in the ON position

Selector lever P position switch signal: Except P position (battery

voltage)

Selector lever P/N position signal: Except P and N positions (0 V)

B2604: PNP SW Inhibit steering lock500 ms after any of the following BCM recognition conditions is ful-

filled

Status 1

- Ignition switch is in the ON position

- Selector lever P/N position signal: P and N position (battery volt-

age)

- P range signal or N range signal (CAN): ON

Status 2

- Ignition switch is in the ON position

- Selector lever P/N position signal: Except P and N positions (0 V)

- P range signal and N range signal (CAN): OFF

B2605: PNP SW Inhibit steering lock500 ms after any of the following BCM recognition conditions is ful-

filled

Ignition switch is in the ON position

- Power position: IGN

- Selector lever P/N position signal: Except P and N positions (0 V)

- Interlock/PNP switch signal (CAN): OFF

Status 2

- Ignition switch is in the ON position

- Selector lever P/N position signal: P or N position (battery volt-

age)

- PNP switch signal (CAN): ON

B2606: S/L RELAY Inhibit engine cranking500 ms after the following CAN signal communication status has

become consistent

Steering lock relay signal (Request signal)

Steering lock relay signal (Condition signal)

B2607: S/L RELAY Inhibit engine cranking500 ms after the following CAN signal communication status has

become consistent

Steering lock relay signal (Request signal)

Steering lock relay signal (Condition signal)

Page 2963 of 5121

INL-84

< ECU DIAGNOSIS >

BCM (BODY CONTROL MODULE)

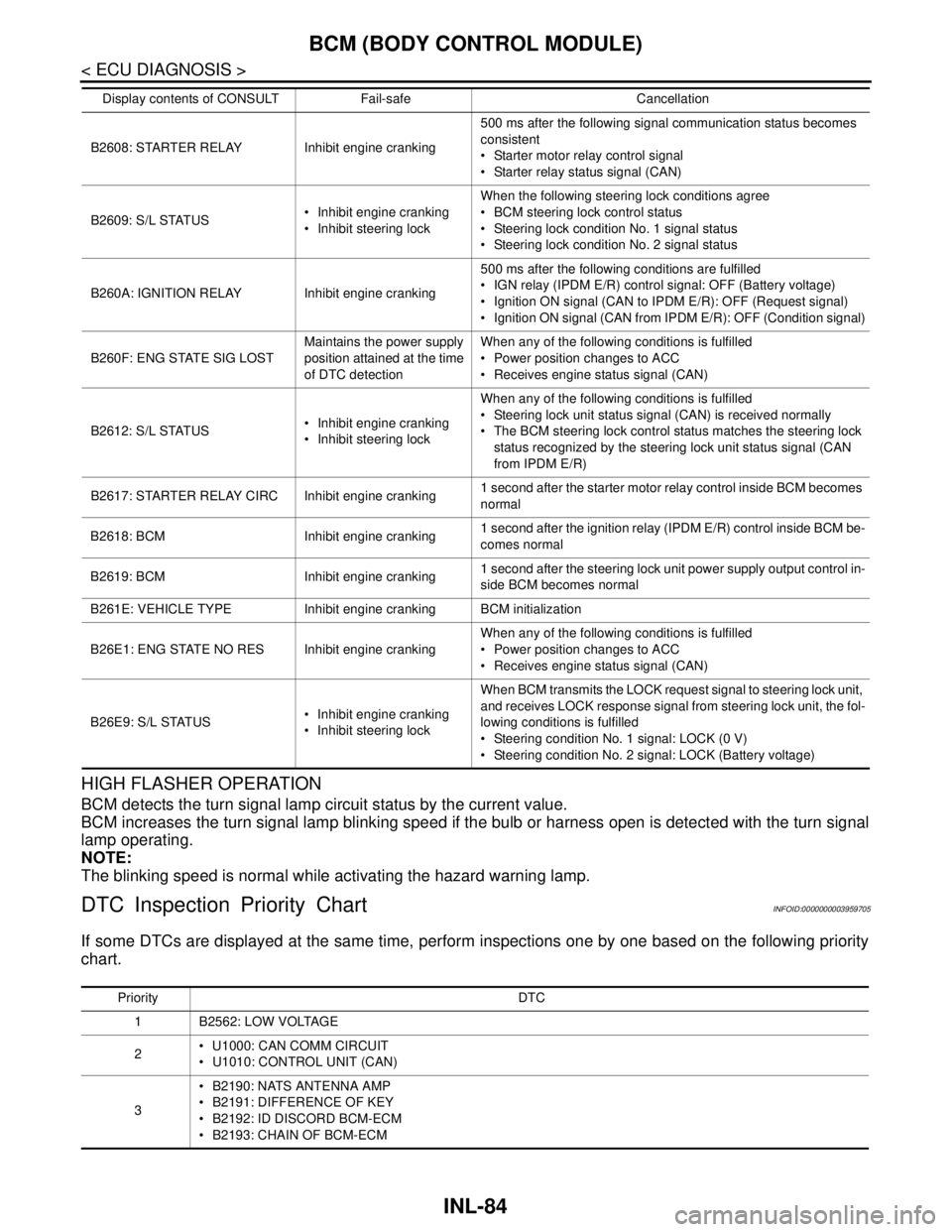

HIGH FLASHER OPERATION

BCM detects the turn signal lamp circuit status by the current value.

BCM increases the turn signal lamp blinking speed if the bulb or harness open is detected with the turn signal

lamp operating.

NOTE:

The blinking speed is normal while activating the hazard warning lamp.

DTC Inspection Priority ChartINFOID:0000000003959705

If some DTCs are displayed at the same time, perform inspections one by one based on the following priority

chart.

B2608: STARTER RELAY Inhibit engine cranking500 ms after the following signal communication status becomes

consistent

Starter motor relay control signal

Starter relay status signal (CAN)

B2609: S/L STATUS Inhibit engine cranking

Inhibit steering lockWhen the following steering lock conditions agree

BCM steering lock control status

Steering lock condition No. 1 signal status

Steering lock condition No. 2 signal status

B260A: IGNITION RELAY Inhibit engine cranking500 ms after the following conditions are fulfilled

IGN relay (IPDM E/R) control signal: OFF (Battery voltage)

Ignition ON signal (CAN to IPDM E/R): OFF (Request signal)

Ignition ON signal (CAN from IPDM E/R): OFF (Condition signal)

B260F: ENG STATE SIG LOSTMaintains the power supply

position attained at the time

of DTC detectionWhen any of the following conditions is fulfilled

Power position changes to ACC

Receives engine status signal (CAN)

B2612: S/L STATUS Inhibit engine cranking

Inhibit steering lockWhen any of the following conditions is fulfilled

Steering lock unit status signal (CAN) is received normally

The BCM steering lock control status matches the steering lock

status recognized by the steering lock unit status signal (CAN

from IPDM E/R)

B2617: STARTER RELAY CIRC Inhibit engine cranking1 second after the starter motor relay control inside BCM becomes

normal

B2618: BCM Inhibit engine cranking1 second after the ignition relay (IPDM E/R) control inside BCM be-

comes normal

B2619: BCM Inhibit engine cranking1 second after the steering lock unit power supply output control in-

side BCM becomes normal

B261E: VEHICLE TYPE Inhibit engine cranking BCM initialization

B26E1: ENG STATE NO RES Inhibit engine crankingWhen any of the following conditions is fulfilled

Power position changes to ACC

Receives engine status signal (CAN)

B26E9: S/L STATUS Inhibit engine cranking

Inhibit steering lockWhen BCM transmits the LOCK request signal to steering lock unit,

and receives LOCK response signal from steering lock unit, the fol-

lowing conditions is fulfilled

Steering condition No. 1 signal: LOCK (0 V)

Steering condition No. 2 signal: LOCK (Battery voltage) Display contents of CONSULT Fail-safe Cancellation

Priority DTC

1 B2562: LOW VOLTAGE

2 U1000: CAN COMM CIRCUIT

U1010: CONTROL UNIT (CAN)

3 B2190: NATS ANTENNA AMP

B2191: DIFFERENCE OF KEY

B2192: ID DISCORD BCM-ECM

B2193: CHAIN OF BCM-ECM

Page 2964 of 5121

BCM (BODY CONTROL MODULE)

INL-85

< ECU DIAGNOSIS >

C

D

E

F

G

H

I

J

K

MA

B

INL

N

O

P

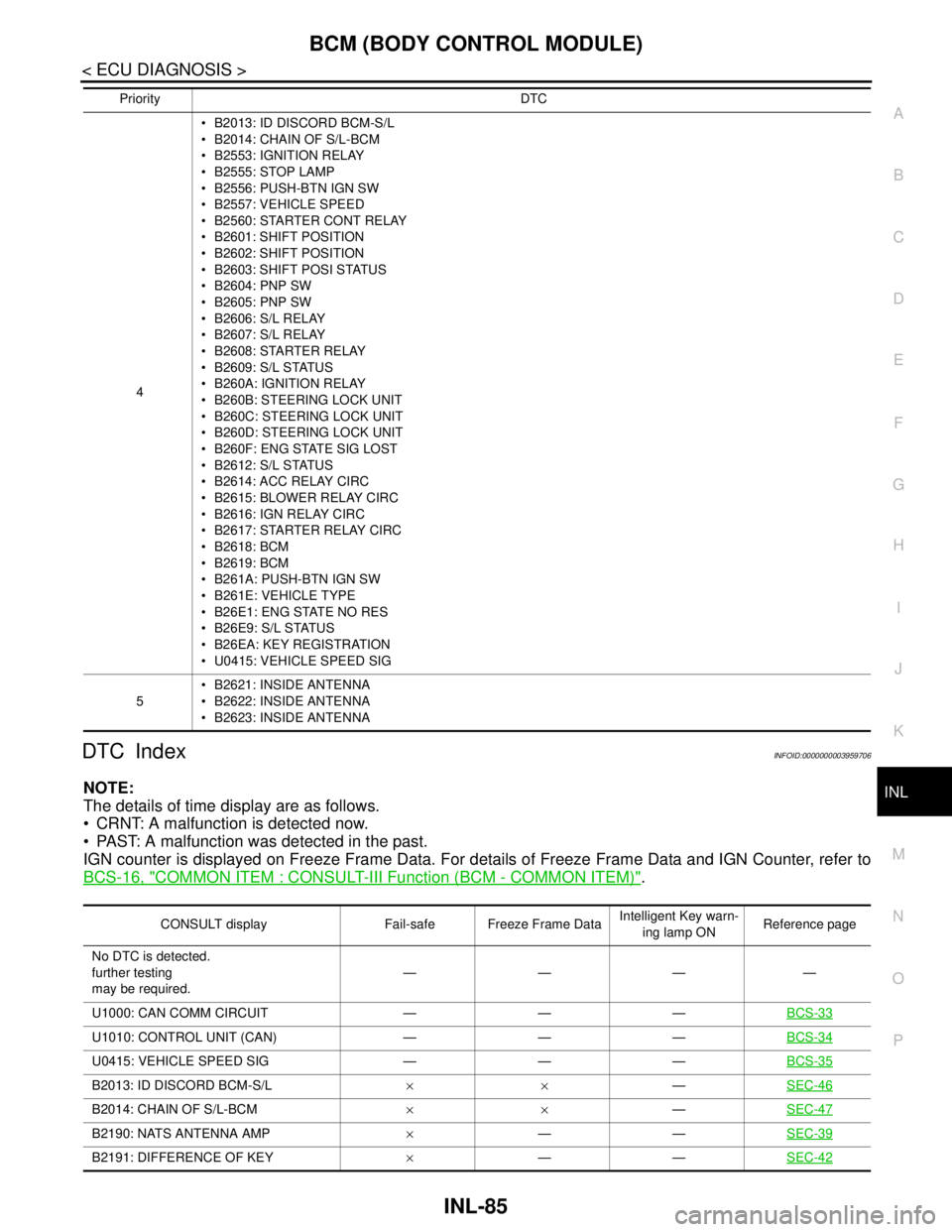

DTC IndexINFOID:0000000003959706

NOTE:

The details of time display are as follows.

CRNT: A malfunction is detected now.

PAST: A malfunction was detected in the past.

IGN counter is displayed on Freeze Frame Data. For details of Freeze Frame Data and IGN Counter, refer to

BCS-16, "

COMMON ITEM : CONSULT-III Function (BCM - COMMON ITEM)".

4 B2013: ID DISCORD BCM-S/L

B2014: CHAIN OF S/L-BCM

B2553: IGNITION RELAY

B2555: STOP LAMP

B2556: PUSH-BTN IGN SW

B2557: VEHICLE SPEED

B2560: STARTER CONT RELAY

B2601: SHIFT POSITION

B2602: SHIFT POSITION

B2603: SHIFT POSI STATUS

B2604: PNP SW

B2605: PNP SW

B2606: S/L RELAY

B2607: S/L RELAY

B2608: STARTER RELAY

B2609: S/L STATUS

B260A: IGNITION RELAY

B260B: STEERING LOCK UNIT

B260C: STEERING LOCK UNIT

B260D: STEERING LOCK UNIT

B260F: ENG STATE SIG LOST

B2612: S/L STATUS

B2614: ACC RELAY CIRC

B2615: BLOWER RELAY CIRC

B2616: IGN RELAY CIRC

B2617: STARTER RELAY CIRC

B2618: BCM

B2619: BCM

B261A: PUSH-BTN IGN SW

B261E: VEHICLE TYPE

B26E1: ENG STATE NO RES

B26E9: S/L STATUS

B26EA: KEY REGISTRATION

U0415: VEHICLE SPEED SIG

5 B2621: INSIDE ANTENNA

B2622: INSIDE ANTENNA

B2623: INSIDE ANTENNA Priority DTC

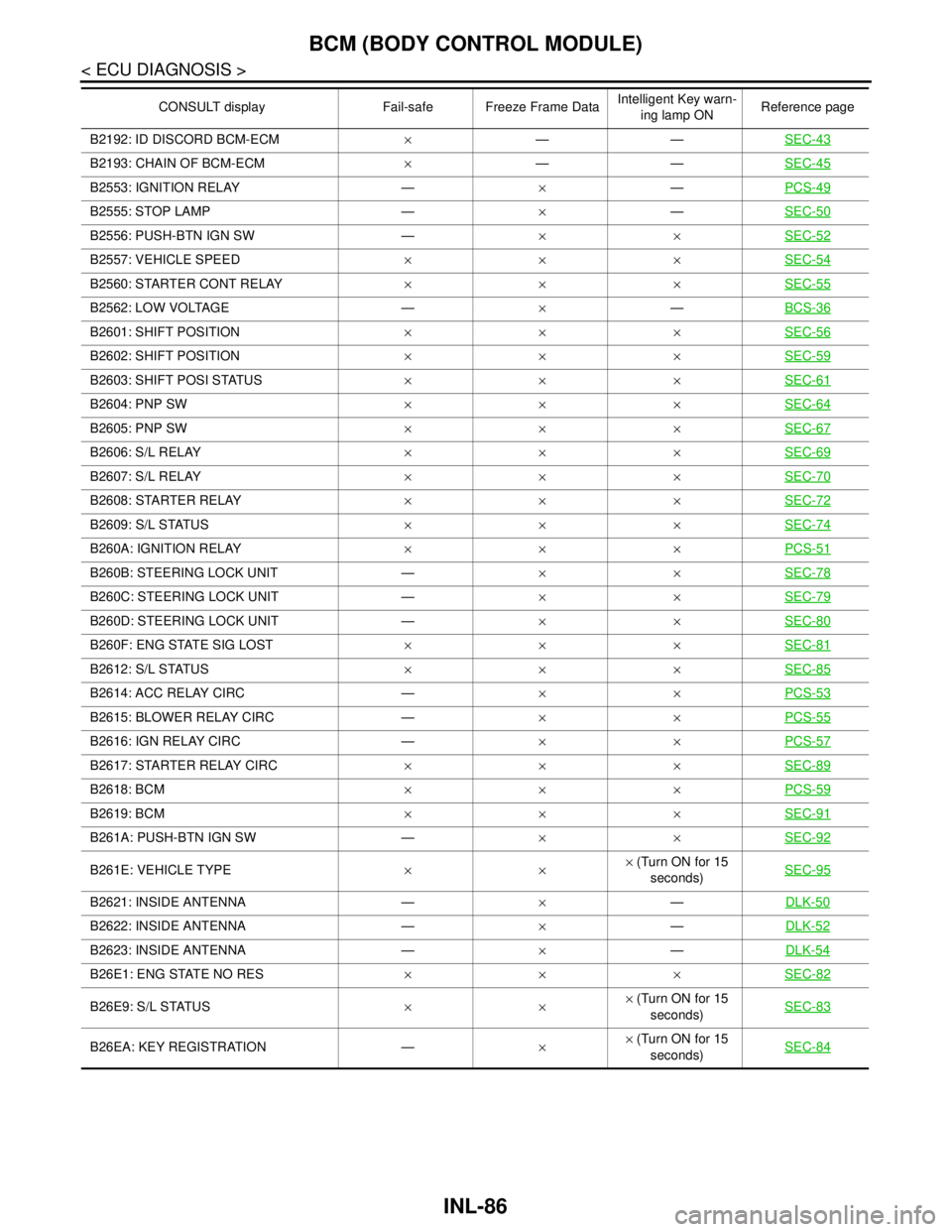

CONSULT display Fail-safe Freeze Frame DataIntelligent Key warn-

ing lamp ONReference page

No DTC is detected.

further testing

may be required.————

U1000: CAN COMM CIRCUIT — — —BCS-33

U1010: CONTROL UNIT (CAN) — — —BCS-34

U0415: VEHICLE SPEED SIG — — —BCS-35

B2013: ID DISCORD BCM-S/L××—SEC-46

B2014: CHAIN OF S/L-BCM××—SEC-47

B2190: NATS ANTENNA AMP×——SEC-39

B2191: DIFFERENCE OF KEY×——SEC-42

Page 2965 of 5121

INL-86

< ECU DIAGNOSIS >

BCM (BODY CONTROL MODULE)

B2192: ID DISCORD BCM-ECM×——SEC-43

B2193: CHAIN OF BCM-ECM×——SEC-45

B2553: IGNITION RELAY —×—PCS-49

B2555: STOP LAMP —×—SEC-50

B2556: PUSH-BTN IGN SW —××SEC-52

B2557: VEHICLE SPEED×××SEC-54

B2560: STARTER CONT RELAY×××SEC-55

B2562: LOW VOLTAGE —×—BCS-36

B2601: SHIFT POSITION×××SEC-56

B2602: SHIFT POSITION×××SEC-59

B2603: SHIFT POSI STATUS×××SEC-61

B2604: PNP SW×××SEC-64

B2605: PNP SW×××SEC-67

B2606: S/L RELAY×××SEC-69

B2607: S/L RELAY×××SEC-70

B2608: STARTER RELAY×××SEC-72

B2609: S/L STATUS×××SEC-74

B260A: IGNITION RELAY×××PCS-51

B260B: STEERING LOCK UNIT —××SEC-78

B260C: STEERING LOCK UNIT —××SEC-79

B260D: STEERING LOCK UNIT —××SEC-80

B260F: ENG STATE SIG LOST×××SEC-81

B2612: S/L STATUS×××SEC-85

B2614: ACC RELAY CIRC —××PCS-53

B2615: BLOWER RELAY CIRC —××PCS-55

B2616: IGN RELAY CIRC —××PCS-57

B2617: STARTER RELAY CIRC×××SEC-89

B2618: BCM×××PCS-59

B2619: BCM×××SEC-91

B261A: PUSH-BTN IGN SW —××SEC-92

B261E: VEHICLE TYPE××× (Turn ON for 15

seconds)SEC-95

B2621: INSIDE ANTENNA —×—DLK-50

B2622: INSIDE ANTENNA —×—DLK-52

B2623: INSIDE ANTENNA —×—DLK-54

B26E1: ENG STATE NO RES×××SEC-82

B26E9: S/L STATUS××× (Turn ON for 15

seconds)SEC-83

B26EA: KEY REGISTRATION —×× (Turn ON for 15

seconds)SEC-84

CONSULT display Fail-safe Freeze Frame DataIntelligent Key warn-

ing lamp ONReference page

Page 3052 of 5121

IP-12

< ON-VEHICLE REPAIR >

INSTRUMENT PANEL ASSEMBLY

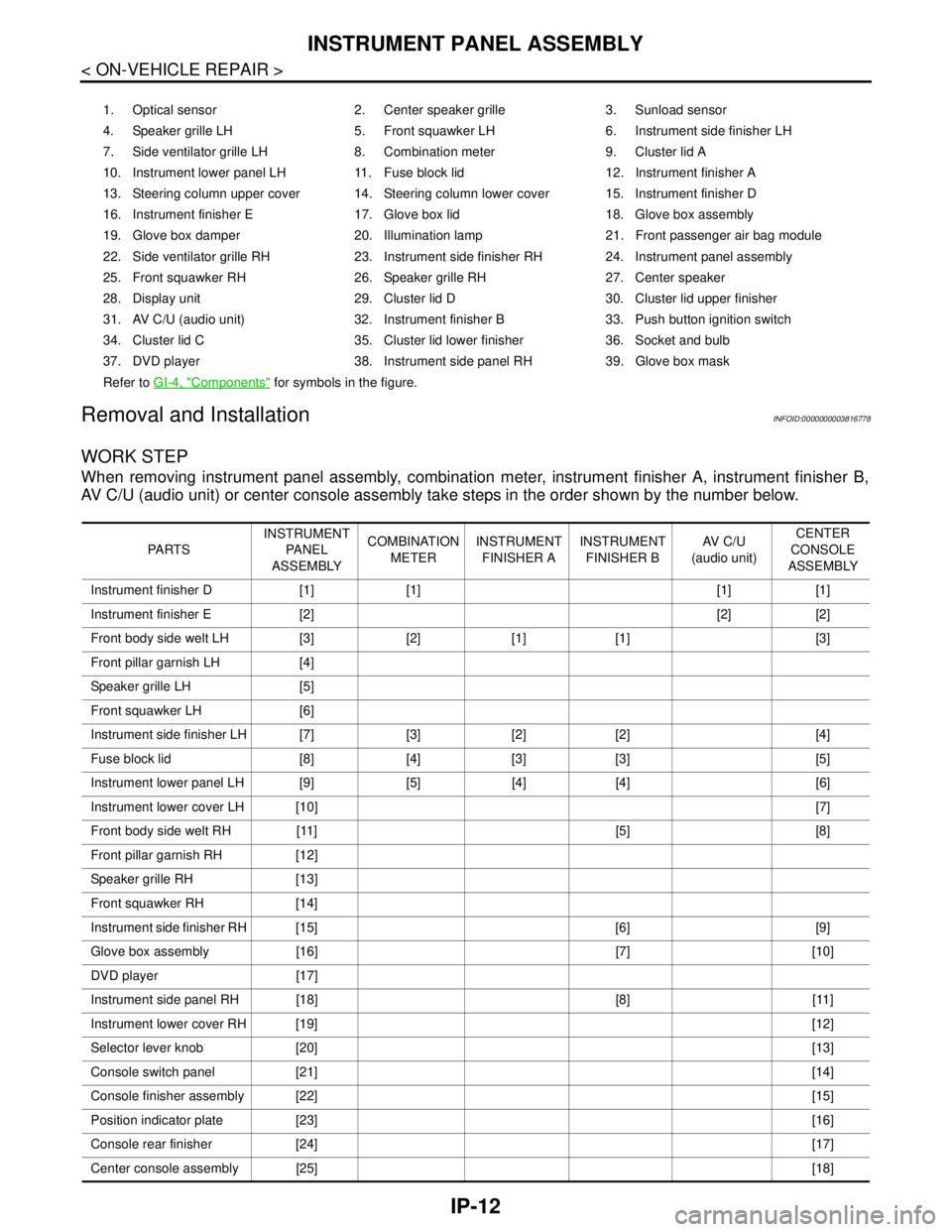

Removal and Installation

INFOID:0000000003816778

WORK STEP

When removing instrument panel assembly, combination meter, instrument finisher A, instrument finisher B,

AV C/U (audio unit) or center console assembly take steps in the order shown by the number below.

1. Optical sensor 2. Center speaker grille 3. Sunload sensor

4. Speaker grille LH 5. Front squawker LH 6. Instrument side finisher LH

7. Side ventilator grille LH 8. Combination meter 9. Cluster lid A

10. Instrument lower panel LH 11. Fuse block lid 12. Instrument finisher A

13. Steering column upper cover 14. Steering column lower cover 15. Instrument finisher D

16. Instrument finisher E 17. Glove box lid 18. Glove box assembly

19. Glove box damper 20. Illumination lamp 21. Front passenger air bag module

22. Side ventilator grille RH 23. Instrument side finisher RH 24. Instrument panel assembly

25. Front squawker RH 26. Speaker grille RH 27. Center speaker

28. Display unit 29. Cluster lid D 30. Cluster lid upper finisher

31. AV C/U (audio unit) 32. Instrument finisher B 33. Push button ignition switch

34. Cluster lid C 35. Cluster lid lower finisher 36. Socket and bulb

37. DVD player 38. Instrument side panel RH 39. Glove box mask

Refer to GI-4, "

Components" for symbols in the figure.

PA R T SINSTRUMENT

PA N E L

ASSEMBLYCOMBINATION

METERINSTRUMENT

FINISHER AINSTRUMENT

FINISHER BAV C / U

(audio unit)CENTER

CONSOLE

ASSEMBLY

Instrument finisher D [1] [1] [1] [1]

Instrument finisher E [2] [2] [2]

Front body side welt LH [3] [2] [1] [1] [3]

Front pillar garnish LH [4]

Speaker grille LH [5]

Front squawker LH [6]

Instrument side finisher LH [7] [3] [2] [2] [4]

Fuse block lid [8] [4] [3] [3] [5]

Instrument lower panel LH [9] [5] [4] [4] [6]

Instrument lower cover LH [10][7]

Front body side welt RH [11] [5] [8]

Front pillar garnish RH [12]

Speaker grille RH [13]

Front squawker RH [14]

Instrument side finisher RH [15] [6] [9]

Glove box assembly [16] [7] [10]

DVD player [17]

Instrument side panel RH [18] [8] [11]

Instrument lower cover RH [19][12]

Selector lever knob [20][13]

Console switch panel [21][14]

Console finisher assembly [22][15]

Position indicator plate [23][16]

Console rear finisher [24][17]

Center console assembly [25][18]

Page 3053 of 5121

![NISSAN TEANA 2008 Service Manual INSTRUMENT PANEL ASSEMBLY

IP-13

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

K

L

MA

B

IP

N

O

P

[ ]: Number indicates step in removal procedures.

REMOVAL

1. Remove instrument finisher D.

Remove instrument fi NISSAN TEANA 2008 Service Manual INSTRUMENT PANEL ASSEMBLY

IP-13

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

K

L

MA

B

IP

N

O

P

[ ]: Number indicates step in removal procedures.

REMOVAL

1. Remove instrument finisher D.

Remove instrument fi](/img/5/57391/w960_57391-3052.png)

INSTRUMENT PANEL ASSEMBLY

IP-13

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

K

L

MA

B

IP

N

O

P

[ ]: Number indicates step in removal procedures.

REMOVAL

1. Remove instrument finisher D.

Remove instrument finisher D (1) fixing clips with remover tool

(A).

Pull back instrument finisher D, and then remove instrument

finisher D.

2. Remove instrument finisher E.

Remove instrument finisher E (1) fixing clips with remover tool

(A).

Pull back instrument finisher E, and then remove instrument

finisher E.

3. Remove front body side welt LH. Refer to INT-39, "

Removal and Installation".

4. Remove front pillar garnish LH. Refer to INT-39, "

Removal and Installation".

Steering wheel [26]

Steering column cover [27] [6] [9]

Combination switch [28] [7] [10]

Spiral cable [29]

Instrument finisher A [30] [8] [5] [11]

Cluster lid A [31] [9] [12]

Combination meter [32] [10]

Cluster lid D [33]

Push button ignition switch [34] [13]

Cluster lid lower finisher [35] [14]

Cluster lid C [36] [15]

Instrument finisher B [16]

AV C/U (audio unit) [37] [3]

Display unit [38]

Center speaker grille [39]

Center speaker [40]

Instrument panel assembly [41]

: Clip

JMJIA1892ZZ

: Clip

JMJIA1893ZZ

Page 3060 of 5121

IP-20

< ON-VEHICLE REPAIR >

INSTRUMENT PANEL ASSEMBLY

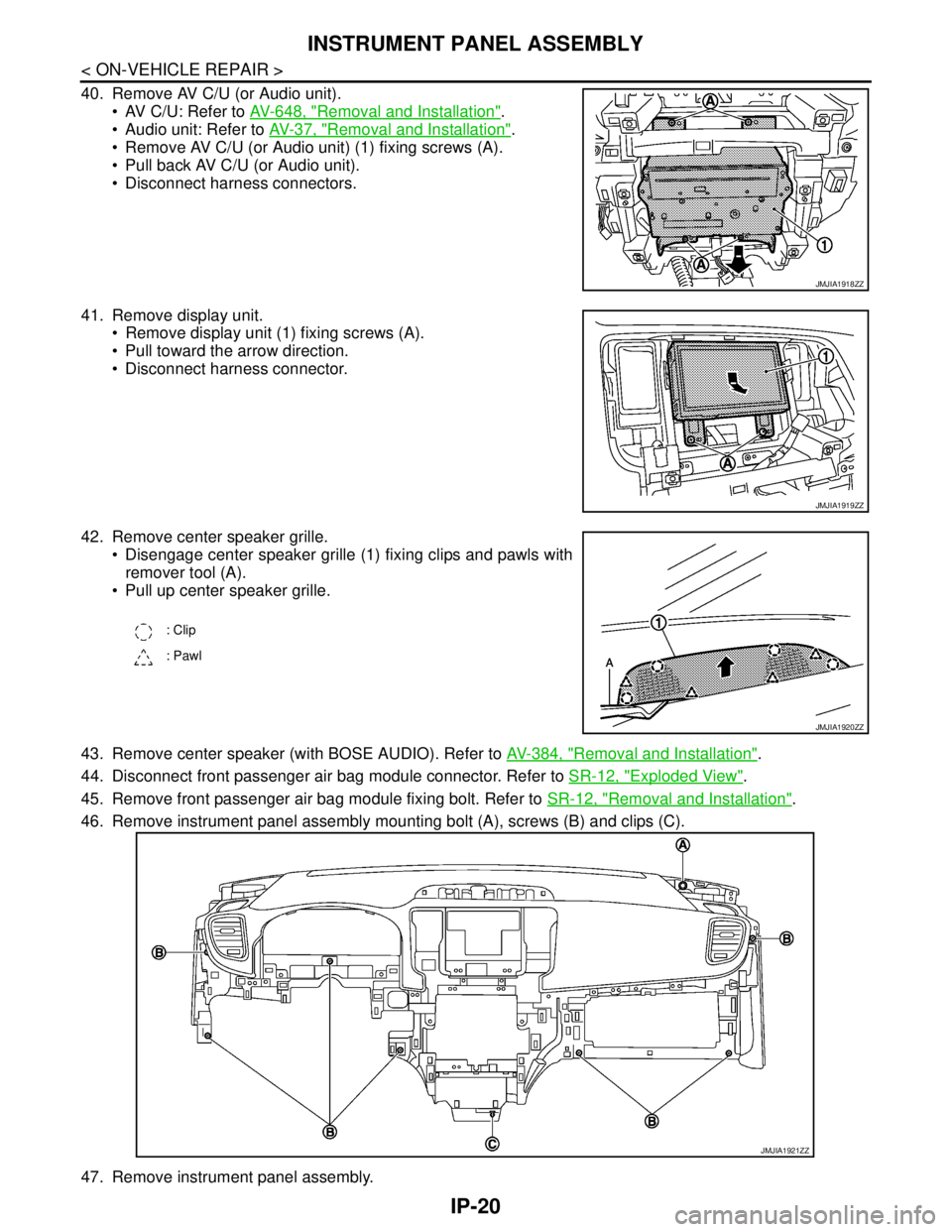

40. Remove AV C/U (or Audio unit).

AV C/U: Refer to AV-648, "

Removal and Installation".

Audio unit: Refer to AV-37, "

Removal and Installation".

Remove AV C/U (or Audio unit) (1) fixing screws (A).

Pull back AV C/U (or Audio unit).

Disconnect harness connectors.

41. Remove display unit.

Remove display unit (1) fixing screws (A).

Pull toward the arrow direction.

Disconnect harness connector.

42. Remove center speaker grille.

Disengage center speaker grille (1) fixing clips and pawls with

remover tool (A).

Pull up center speaker grille.

43. Remove center speaker (with BOSE AUDIO). Refer to AV-384, "

Removal and Installation".

44. Disconnect front passenger air bag module connector. Refer to SR-12, "

Exploded View".

45. Remove front passenger air bag module fixing bolt. Refer to SR-12, "

Removal and Installation".

46. Remove instrument panel assembly mounting bolt (A), screws (B) and clips (C).

47. Remove instrument panel assembly.

JMJIA1918ZZ

JMJIA1919ZZ

: Clip

: Pawl

JMJIA1920ZZ

JMJIA1921ZZ