Ioni NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 1 of 5121

MODEL J32 SERIES

© 2008 NISSAN INTERNATIONAL SA

Allrightsreserved.NopartofthisElectronicServiceManualmaybereproducedorstoredinaretrievalsystem,ortransmittedinanyform,or by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior written permission of Nissan InternationalSA, Switzerland.

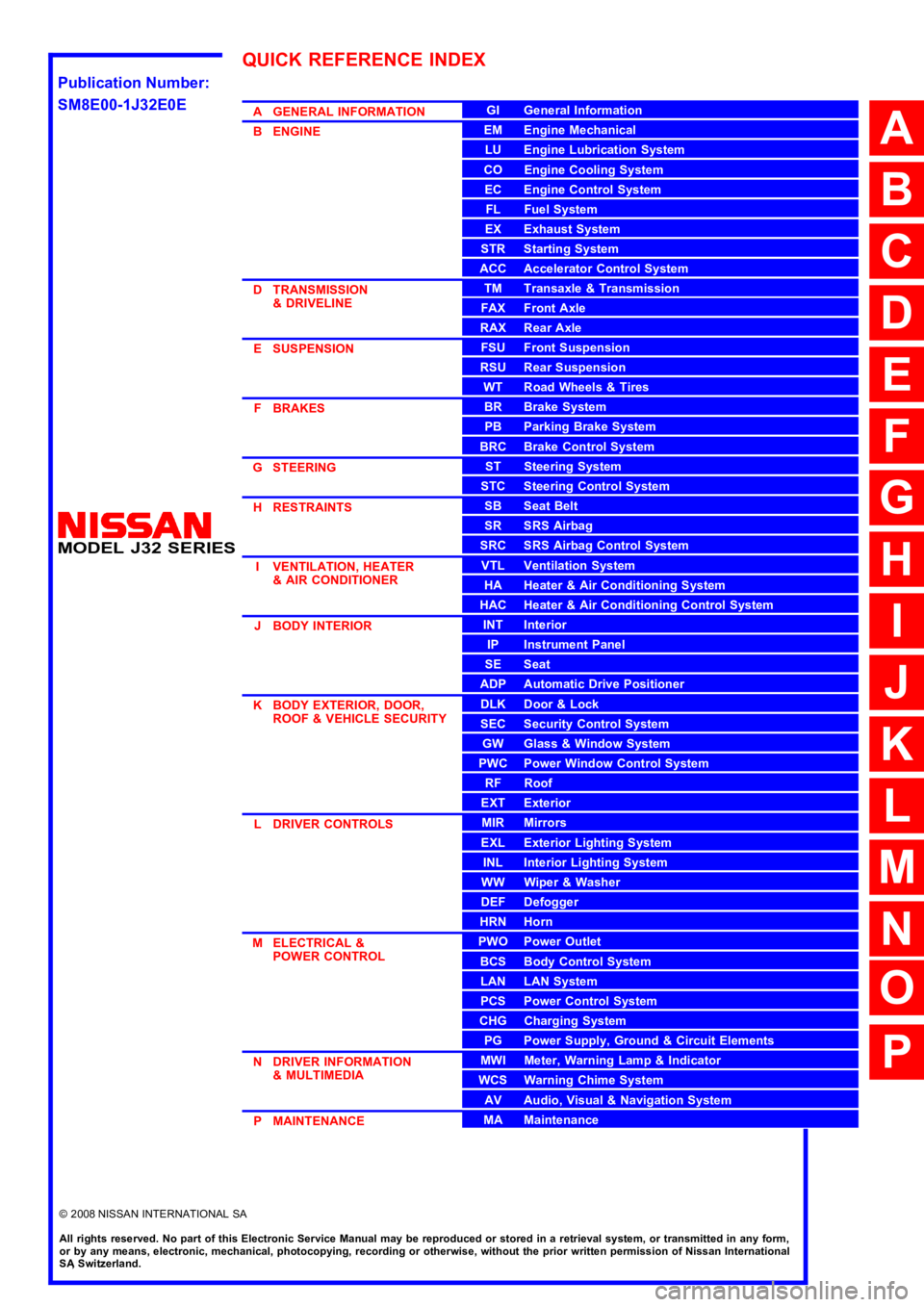

AGENERALINFORMATION

BENGINE

DTRANSMISSION&DRIVELINE

ESUSPENSION

FBRAKES

GSTEERING

HRESTRAINTS

IVENTILATION,HEATER&AIRCONDITIONER

JBODYINTERIOR

KBODYEXTERIOR,DOOR,ROOF&VEHICLESECURITY

LDRIVERCONTROLS

MELECTRICAL&POWERCONTROL

NDRIVERINFORMATION&MULTIMEDIA

PMAINTENANCE

GIGeneralInformation

EMEngineMechanical

LUEngineLubricationSystem

COEngineCoolingSystem

ECEngineControlSystem

FLFuelSystem

EXExhaustSystem

STRStartingSystem

ACCAcceleratorControlSystem

TMTransaxle &Transmission

FAXFrontAxle

RAXRearAxle

FSUFrontSuspension

RSURearSuspension

WTRoadWheels &Tires

BRBrakeSystem

PBParkingBrakeSystem

BRCBrakeControlSystem

STSteeringSystem

STCSteeringControlSystem

SBSeatBelt

SRSRSAirbag

SRCSRSAirbagControlSystem

VTLVentilationSystem

HAHeater &AirConditioningSystem

HACHeater &AirConditioningControlSystem

INTInterior

IPInstrumentPanel

SESeat

ADPAutomaticDrivePositioner

DLKDoor &Lock

SECSecurityControlSystem

GWGlass &WindowSystem

PWCPowerWindowControlSystem

RFRoof

EXTExterior

MIRMirrors

EXLExteriorLightingSystem

INLInteriorLightingSystem

WWWiper &Washer

DEFDefogger

HRNHorn

PWOPowerOutlet

BCSBodyControlSystem

LANLANSystem

PCSPowerControlSystem

CHGChargingSystem

PGPowerSupply,Ground&CircuitElements

MWIMeter,WarningLamp&Indicator

WCSWarningChimeSystem

AVAudio,Visual&NavigationSystem

MAMaintenance

QUICKREFERENCEINDEX

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

M

Publication Number:

SM8E00-1J32E0E

Page 2 of 5121

FOREWORD

This manual contains maintenance and repair procedures for the NISSAN

TEANA,modelJ32 series.

In order to assure your safety and the efficient functioning of the vehicle,

this manual should be read thoroughly. It is especially important that the

PRECAUTIONS in the GI section be completely understood before starting

any repair task.

All information in this manual is based on the latest product information

at the time of publication. The right is reserved to make changes in speci-

fications and methods at any time without notice.

IMPORTANT SAFETY NOTICE

The proper performance of service is essential for both the safety of the

technician and the efficient functioning of the vehicle.

The service methods in this Service Manual are described in such a man-

ner that the service may be performed safely and accurately.

Service varies with the procedures used, the skills of the technician and the

tools and parts available. Accordingly, anyone using service procedures,

tools or parts which are not specifically recommended by NISSAN must

first be completely satisfied that neither personal safety nor the vehicle's

safety will be jeopardized by the service method selected.

NISSANINTERNATIONAL SA

Service Engineering SectionParis, France

Page 5 of 5121

ACCELERATOR CONTROL SYSTEM

ACC-3

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

L

MA

ACC

N

P O

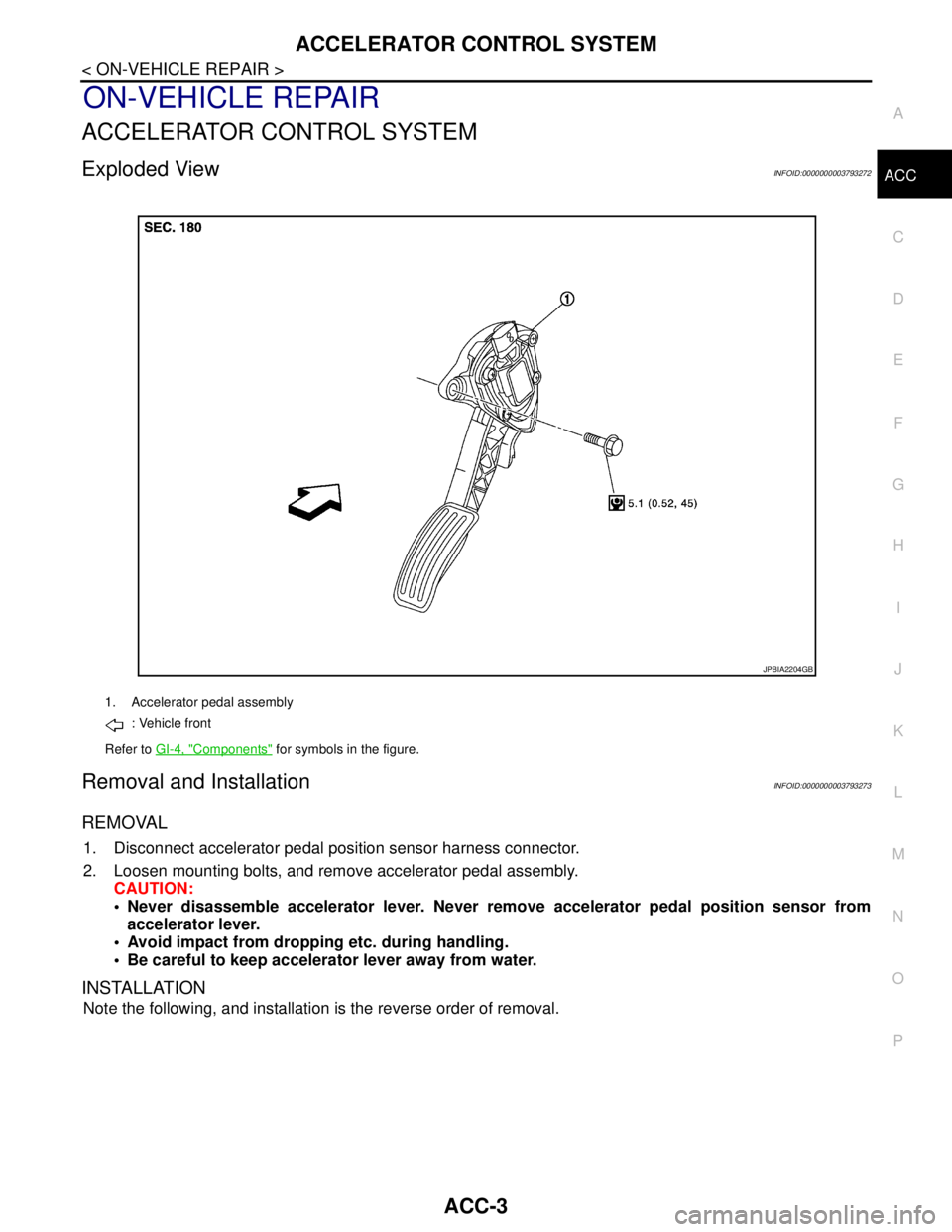

ON-VEHICLE REPAIR

ACCELERATOR CONTROL SYSTEM

Exploded ViewINFOID:0000000003793272

Removal and InstallationINFOID:0000000003793273

REMOVAL

1. Disconnect accelerator pedal position sensor harness connector.

2. Loosen mounting bolts, and remove accelerator pedal assembly.

CAUTION:

Never disassemble accelerator lever. Never remove accelerator pedal position sensor from

accelerator lever.

Avoid impact from dropping etc. during handling.

Be careful to keep accelerator lever away from water.

INSTALLATION

Note the following, and installation is the reverse order of removal.

1. Accelerator pedal assembly

: Vehicle front

Refer to GI-4, "

Components" for symbols in the figure.

JPBIA2204GB

Page 6 of 5121

ACC-4

< ON-VEHICLE REPAIR >

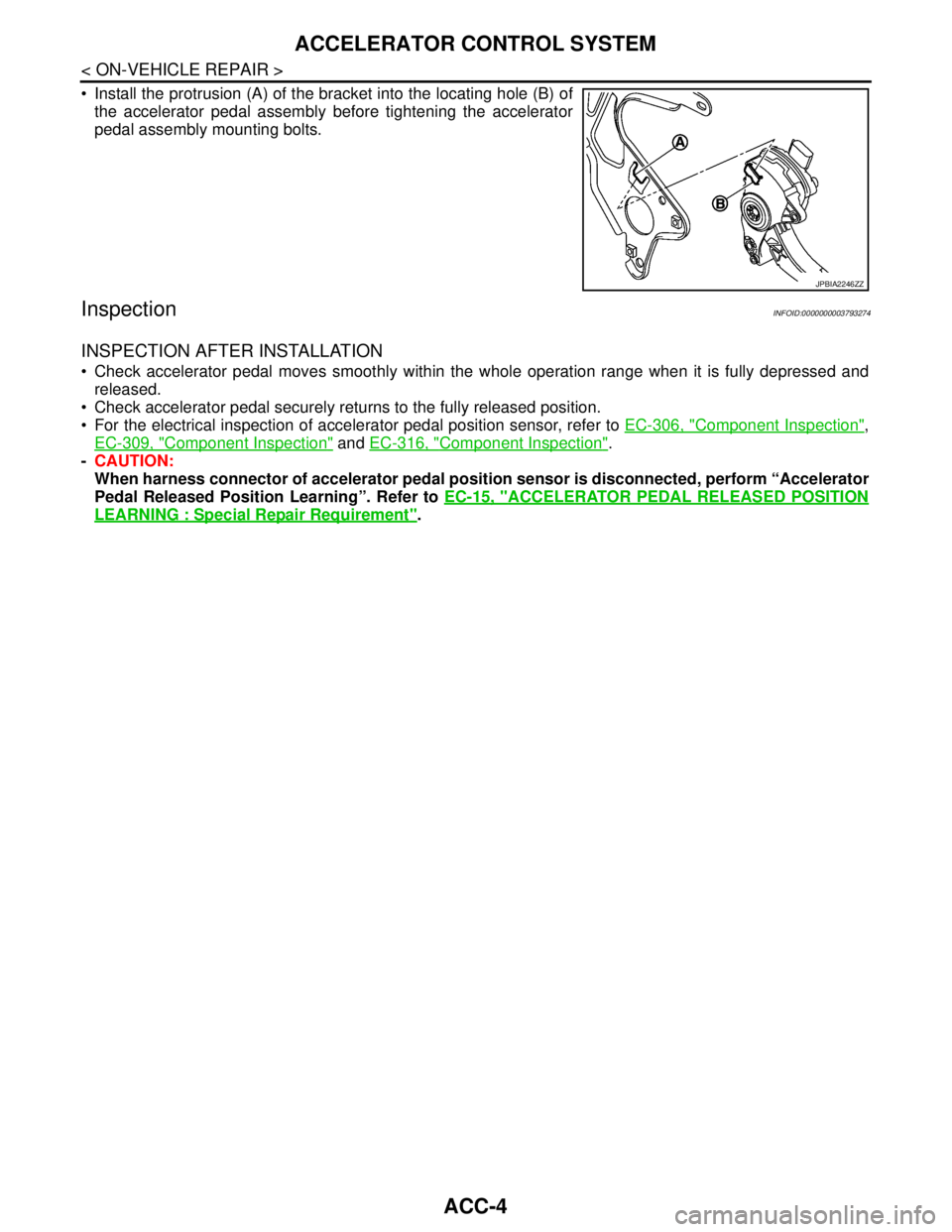

ACCELERATOR CONTROL SYSTEM

Install the protrusion (A) of the bracket into the locating hole (B) of

the accelerator pedal assembly before tightening the accelerator

pedal assembly mounting bolts.

InspectionINFOID:0000000003793274

INSPECTION AFTER INSTALLATION

Check accelerator pedal moves smoothly within the whole operation range when it is fully depressed and

released.

Check accelerator pedal securely returns to the fully released position.

For the electrical inspection of accelerator pedal position sensor, refer to EC-306, "

Component Inspection",

EC-309, "

Component Inspection" and EC-316, "Component Inspection".

-CAUTION:

When harness connector of accelerator pedal position sensor is disconnected, perform “Accelerator

Pedal Released Position Learning”. Refer to EC-15, "

ACCELERATOR PEDAL RELEASED POSITION

LEARNING : Special Repair Requirement".

JPBIA2246ZZ

Page 11 of 5121

DIAGNOSIS AND REPAIR WORKFLOW

ADP-5

< BASIC INSPECTION >

C

D

E

F

G

H

I

K

L

MA

B

ADP

N

O

P

1.GET INFORMATION FOR SYMPTOM

Get detailed information from the customer about the symptom (the condition and the environment when the

incident/malfunction occurs).

>> GO TO 2.

2.CHECK DTC WITH AUTOMATIC DRIVE POSITIONER SYSTEM

Check “Self Diagnostic Result” with CONSULT-III. Refer to ADP-124, "

DTCIndex"

Are any symptoms described and any DTC displayed?

Symptom is described, DTC is detected.>>GO TO 3.

Symptom is not described, DTC is detected.>>GO TO 6.

Symptom is described, DTC is not detected.>>GO TO 4.

3.CONFIRM THE SYMPTOM

Try to confirm the symptom described by the customer.

>> GO TO 6.

4.CONFIRM THE SYMPTOM

Try to confirm the symptom described by the customer.

>> GO TO 5.

5.CHECK NORMAL OPERATING CONDITION

Check normal operating condition. Refer to ADP-134, "

Description".

Is the incident a normal operation?

YES >> GO TO 10.

NO >> GO TO 7.

6.PERFORM DTC CONFIRMATION PROCEDURE

Perform the confirmation procedure for the detected DTC.

Is the DTC displayed?

YES >> GO TO 8.

NO >> Check intermittent incident. Refer to GI-35, "

Intermittent Incident".

7.PERFORM COMPONENT FUNCTION CHECK

Perform the component function check for the isolated malfunctioning point.

>> GO TO 8.

8.DETECT MALFUNCTIONING PART BY DIAGNOSTIC PROCEDURE

Isolate the malfunctioning point by performing the diagnosis procedure relevant to the symptom during the

component diagnosis.

>> GO TO 9.

9.REPARE OR REPLACE

Repair or replace the malfunctioning part.

>> GO TO 10.

10.FINAL CHECK

Perform the DTC confirmation procedure (if DTC is detected) or component function check (if no DTC is

detected) again. Check that the malfunction is repaired.

Are all malfunctions repaired?

Page 14 of 5121

ADP-8

< BASIC INSPECTION >

INSPECTION AND ADJUSTMENT

quirement

INFOID:0000000003759061

1.SYSTEM INITIALIZATION

Perform system initialization. Refer to ADP-8, "

SYSTEM INITIALIZATION : Description".

>> GO TO 2.

2.SYSTEM SETTING

Perform system setting. Refer to ADP-9, "

SYSTEM SETTING : Description".

>> GO TO 3.

3.MEMORY STORAGE

Perform memory storage. Refer to ADP-8, "

MEMORY STORING : Description".

>> END

SYSTEM INITIALIZATION

SYSTEM INITIALIZATION : DescriptionINFOID:0000000003759062

Always perform the initialization when the battery terminal is disconnected or the driver seat control unit is

replaced.

The entry/exit assist function will not operate normally unless initialization is performed.

SYSTEM INITIALIZATION : Special Repair RequirementINFOID:0000000003759063

INITIALIZATION PROCEDURE

1. CHOOSE METHOD

There are two initialization methods.

Which method do you use?

With door switch>>GO TO 2.

With vehicle speed>>GO TO 4.

2. STEP A-1

Turn ignition switch from the ACC to the OFF position.

>> GO TO 3.

3. STEP A-2

Driver door switch is ON (open) → OFF (close) → ON (open).

>> END

4. STEP B-1

Drive the vehicle at more than 25 km/h (16 MPH).

>> END

MEMORY STORING

MEMORY STORING : DescriptionINFOID:0000000003759064

Always perform memory storage when the battery terminal is disconnected or the driver seat control unit is

replaced. The memory function and Intelligent Key interlock function will not operate normally unless memory

storage is performed.

Page 15 of 5121

INSPECTION AND ADJUSTMENT

ADP-9

< BASIC INSPECTION >

C

D

E

F

G

H

I

K

L

MA

B

ADP

N

O

P

MEMORY STORING : Special Repair RequirementINFOID:0000000003759065

Memory Storage Procedure

Two positions for the driver seat can be stored for memory operation by the following procedure.

1.STEP 1

Shift selector lever to the P position.

>> GO TO 2.

2.STEP 2

Turn ignition switch ON.

>> GO TO 3.

3.STEP 3

Adjust driver seat position manually.

>> GO TO 4.

4.STEP 4

1. Push set switch.

NOTE:

Memory indicator for which driver seat position is already retained in memory is illuminated for 5 sec-

onds.

Memory indicator for which driver seat position is not retained in memory is illuminated for 0.5 seconds.

2. Push the memory switch (1 or 2) for at least 1 second within 5 seconds after pushing the set switch.

NOTE:

When entering driver seat positions into blank memory, memory indicator turns ON for 5 seconds.

When changing driver seat positions, memory indicator turns OFF for 0.5 seconds, then turns ON for 5

seconds.

NOTE:

If memory is stored in the same memory switch, the previous memory will be deleted.

Do you need to link Intelligent Keys?

YES >> GO TO 5.

NO >> END

5.STEP 6

Push the Intelligent Key unlock button within 5 seconds after pushing memory switch (while the memory indi-

cator is ON).

>> GO TO 6.

6.STEP 7

Confirm the operation of each part with memory operation and Intelligent Key interlock operation.

>> END

SYSTEM SETTING

SYSTEM SETTING : DescriptionINFOID:0000000003759066

The settings of the automatic driving positioner system can be changed, using CONSULT-III, the display unit

in the center of the instrument panel and the set switch. Always check the settings before and after discon-

necting the battery terminal or replacing driver seat control unit.

Setting Change

Page 18 of 5121

ADP-12

< FUNCTION DIAGNOSIS >

AUTOMATIC DRIVE POSITIONER SYSTEM

FUNCTION DIAGNOSIS

AUTOMATIC DRIVE POSITIONER SYSTEM

AUTOMATIC DRIVE POSITIONER SYSTEM

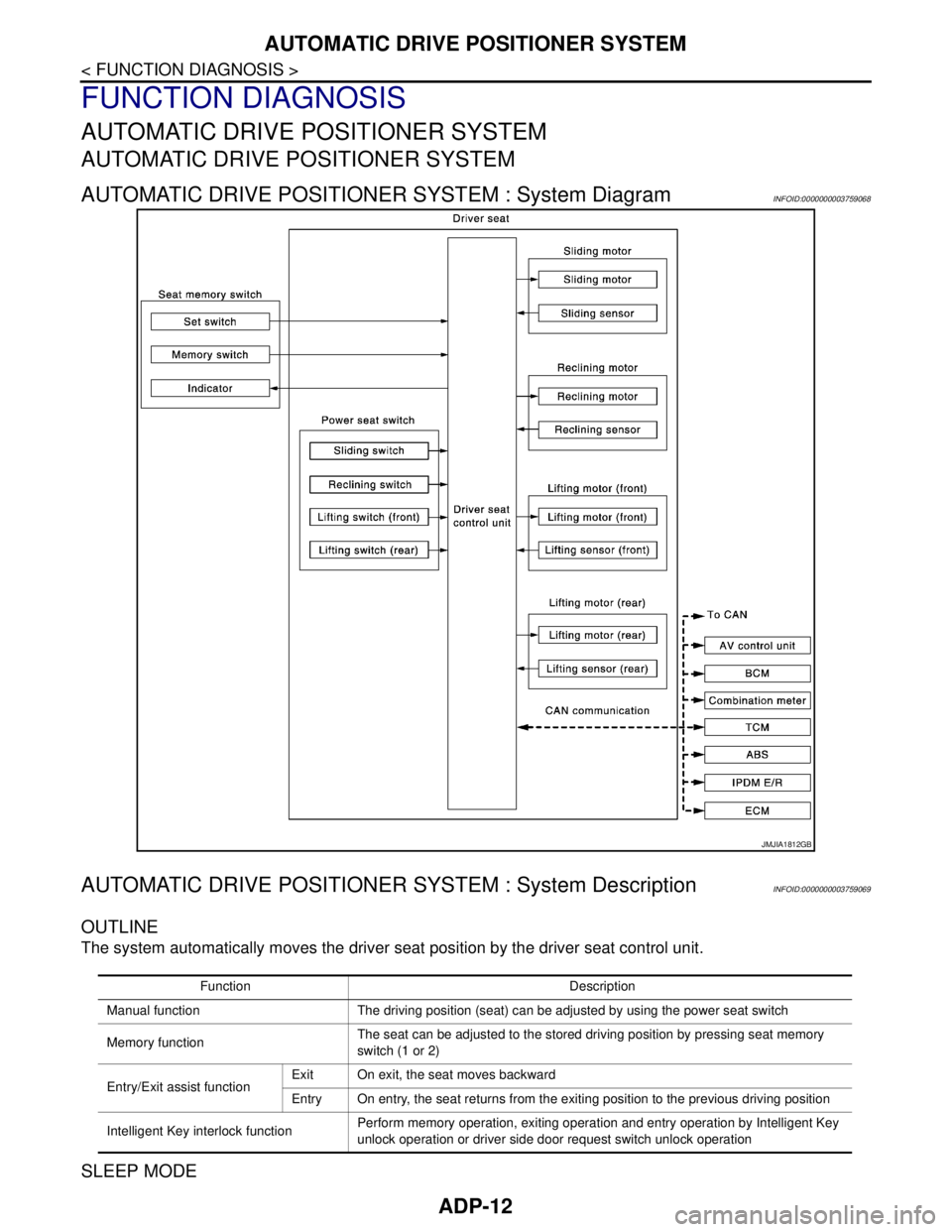

AUTOMATIC DRIVE POSITIONER SYSTEM : System DiagramINFOID:0000000003759068

AUTOMATIC DRIVE POSITIONER SYSTEM : System DescriptionINFOID:0000000003759069

OUTLINE

The system automatically moves the driver seat position by the driver seat control unit.

SLEEP MODE

JMJIA1812GB

Function Description

Manual function The driving position (seat) can be adjusted by using the power seat switch

Memory functionThe seat can be adjusted to the stored driving position by pressing seat memory

switch (1 or 2)

Entry/Exit assist functionExit On exit, the seat moves backward

Entry On entry, the seat returns from the exiting position to the previous driving position

Intelligent Key interlock functionPerform memory operation, exiting operation and entry operation by Intelligent Key

unlock operation or driver side door request switch unlock operation

Page 21 of 5121

AUTOMATIC DRIVE POSITIONER SYSTEM

ADP-15

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

I

K

L

MA

B

ADP

N

O

P

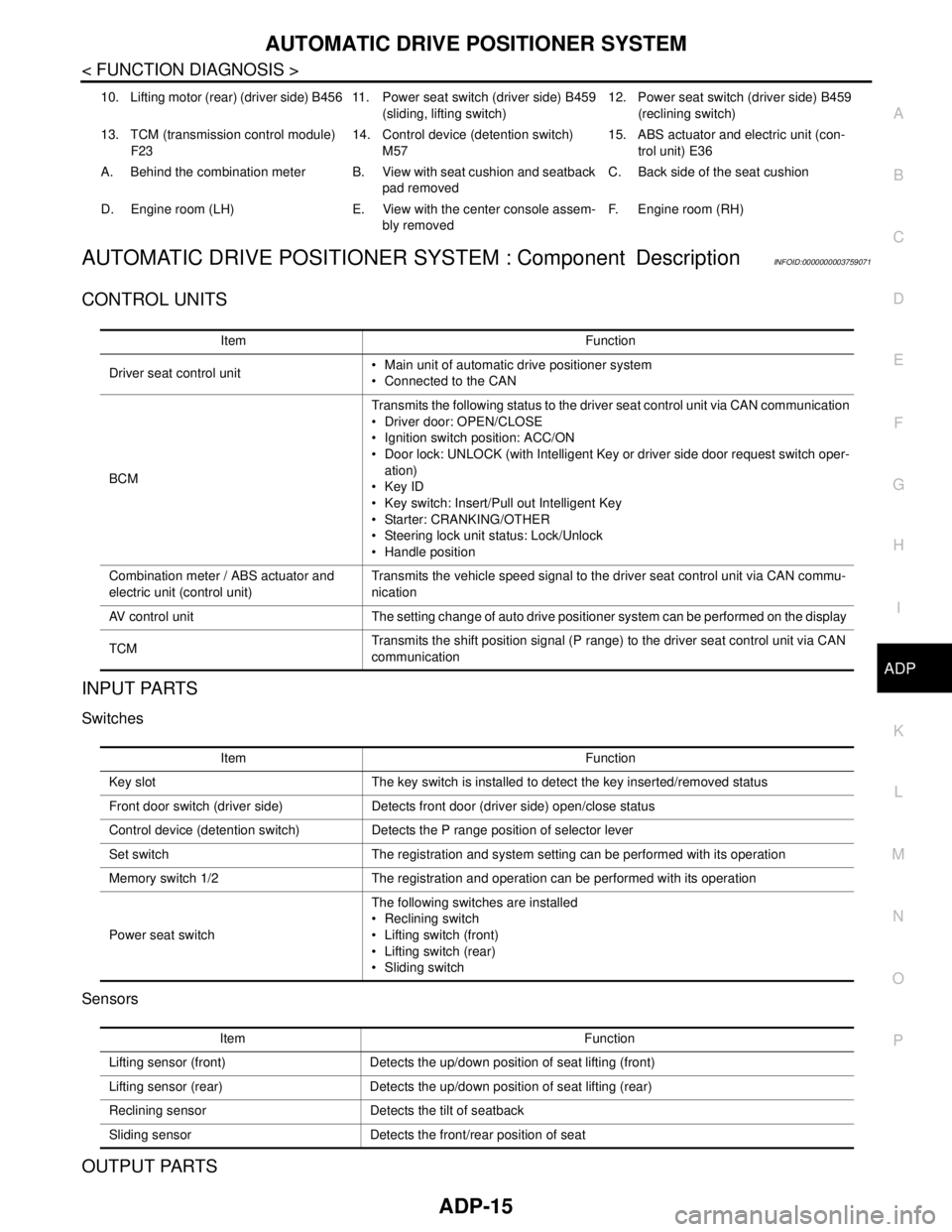

AUTOMATIC DRIVE POSITIONER SYSTEM : Component DescriptionINFOID:0000000003759071

CONTROL UNITS

INPUT PARTS

Switches

Sensors

OUTPUT PARTS

10. Lifting motor (rear) (driver side) B456 11. Power seat switch (driver side) B459

(sliding, lifting switch)12. Power seat switch (driver side) B459

(reclining switch)

13. TCM (transmission control module)

F2314. Control device (detention switch)

M5715. ABS actuator and electric unit (con-

trol unit) E36

A. Behind the combination meter B. View with seat cushion and seatback

pad removedC. Back side of the seat cushion

D. Engine room (LH) E. View with the center console assem-

bly removedF. Engine room (RH)

Item Function

Driver seat control unit Main unit of automatic drive positioner system

Connected to the CAN

BCMTransmits the following status to the driver seat control unit via CAN communication

Driver door: OPEN/CLOSE

Ignition switch position: ACC/ON

Door lock: UNLOCK (with Intelligent Key or driver side door request switch oper-

ation)

Key ID

Key switch: Insert/Pull out Intelligent Key

Starter: CRANKING/OTHER

Steering lock unit status: Lock/Unlock

Handle position

Combination meter / ABS actuator and

electric unit (control unit)Transmits the vehicle speed signal to the driver seat control unit via CAN commu-

nication

AV control unit The setting change of auto drive positioner system can be performed on the display

TCMTransmits the shift position signal (P range) to the driver seat control unit via CAN

communication

Item Function

Key slot The key switch is installed to detect the key inserted/removed status

Front door switch (driver side) Detects front door (driver side) open/close status

Control device (detention switch) Detects the P range position of selector lever

Set switch The registration and system setting can be performed with its operation

Memory switch 1/2 The registration and operation can be performed with its operation

Power seat switchThe following switches are installed

Reclining switch

Lifting switch (front)

Lifting switch (rear)

Sliding switch

Item Function

Lifting sensor (front) Detects the up/down position of seat lifting (front)

Lifting sensor (rear) Detects the up/down position of seat lifting (rear)

Reclining sensor Detects the tilt of seatback

Sliding sensor Detects the front/rear position of seat

Page 22 of 5121

ADP-16

< FUNCTION DIAGNOSIS >

AUTOMATIC DRIVE POSITIONER SYSTEM

MANUAL FUNCTION

MANUAL FUNCTION : System DiagramINFOID:0000000003759072

MANUAL FUNCTION : System DescriptionINFOID:0000000003759073

OUTLINE

The driving position (seat) can be adjusted manually with power seat switch.

DETAIL FLOW

Seat

Item Function

Lifting motor (front) Moves the seat lifting (front) upward/downward

Lifting motor (rear) Moves the seat lifting (rear) upward/downward

Reclining motor Tilts and raises up the seatback

Sliding motor Slides the seat frontward/rearward

Memory indicator Illuminates or blinks according to the registration/operation status

JMJIA1813GB

Order Input Output Control unit condition

1Power seat switch

(sliding, lifting, reclin-

ing)—The power seat switch signal is inputted to the driver seat control

unit when the power seat switch is operated

2—Motors

(sliding, lifting, reclin-

ing)The driver seat control unit outputs signals to each motor accord-

ing to the power seat switch input signal