Its control NISSAN TEANA 2014 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 3433 of 4801

PG

PG-1

ELECTRICAL & POWER CONTROL

C

D E

F

G H

I

J

K L

B

SECTION PG

A

O P

N

CONTENTS

POWER SUPPLY, GROUND & CIRCUIT ELEMENTS

PRECAUTION ................

...............................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

PREPARATION ............................................3

PREPARATION .............................................. .....3

Special Service Tool ........................................... ......3

Commercial Service Tool ..........................................3

BASIC INSPECTION ....................................4

BATTERY ....................................................... .....4

How to Handle Battery ........................................ ......4

Work Flow ........................................................... ......4

INSPECTION AND ADJUSTMENT .....................7

ADDITIONAL SERVICE WHEN REMOVING BAT-

TERY NEGATIVE TERMINAL ............................... ......

7

ADDITIONAL SERVICE WHEN REMOVING

BATTERY NEGATIVE TERMINAL : Special Re-

pair Requirement ................................................. ......

7

DTC/CIRCUIT DIAGNOSIS ..........................8

POWER SUPPLY ROUTING CIRCUIT .......... .....8

Wiring Diagram — Battery Power Supply — ....... ......8

Wiring Diagram — Accessory Power Supply — .....15

Wiring Diagram — Ignition Power Supply — ..........19

Fuse ........................................................................28

Fusible Link .............................................................28

GROUND ...........................................................29

Ground Distribution .............................................. ....29

HARNESS .........................................................39

Harness Layout ................................................... ....39

ELECTRICAL UNITS LOCATION ....................61

Electrical Units Location ..........................................61

HARNESS CONNECTOR .................................65

Description ...............................................................65

STANDARDIZED RELAY .................................68

Description ...............................................................68

FUSE BLOCK - JUNCTION BOX (J/B) ............70

Terminal Arrangement .............................................70

FUSE, FUSIBLE LINK AND RELAY BOX ........71

Terminal Arrangement .............................................71

IPDM E/R (INTELLIGENT POWER DISTRI-

BUTION MODULE ENGINE ROOM) ................

72

Fuse, Connector and Terminal Arrangement ...... ....72

REMOVAL AND INSTALLATION ...............73

BATTERY ..........................................................73

Exploded View ..................................................... ....73

Removal and Installation (Battery) ..........................73

Removal and Installation (Battery Tray) ..................74

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .............................................

75

BATTERY ..........................................................75

Battery ................................................................. ....75

Revision: November 20132014 Altima NAM

Page 3474 of 4801

PG-42

< DTC/CIRCUIT DIAGNOSIS >

HARNESS

B3 M51 L/8 : Heated steering wheel switch D2 M153 W / 2 4: AV control unit (With navigation system

with BOSE audio system)

C3 M52 W/2 : Combination switch (Spiral cable) A3 M155 W/4 : Joint connector-M06

C3 M53 W/8 : Steering angle sensor C3 M156 W/4 : Joint connector-M07

D2 M54 W/4 : Hazard switch D3 M157 W/4 : Joint connector-M08

A1 M55 BR/2 : Front speaker LH B3 M158 W/8 : Meter control switch

B1 M56 B/2 : Sunload sensor D1 M159 W/4 : Dongle unit

B2 M57 — : Body ground Console sub-harness

E3 M58 W/40 : ITS control unit D4 M201 W/6 : Front heated seat switch LH

E3 M59 W/32 : ITS control unit E4 M202 BR/6 : Front heated seat switch RH

F2 M60 O/2 : Front passenger air bag module D4 M204 BR/2 : CVT shift selector

F1 M61 — : Body ground E3 M205 W / 1 6 : T o M 1 6

B3 M62 GR/8 : Warning system switch D5 M209 GR/3 : Front console power socket

F1 M63 BR/2 : Front speaker RH Speaker sub-harness

A3 M64 W/4 : Joint connector-M01 D1 M300 W / 2 : T o M 5 0

F1 M66 W/3 : Optical sensor D1 M301 BR/2 : Center speaker

Revision: November 20132014 Altima NAM

Page 3498 of 4801

PG-66

< DTC/CIRCUIT DIAGNOSIS >

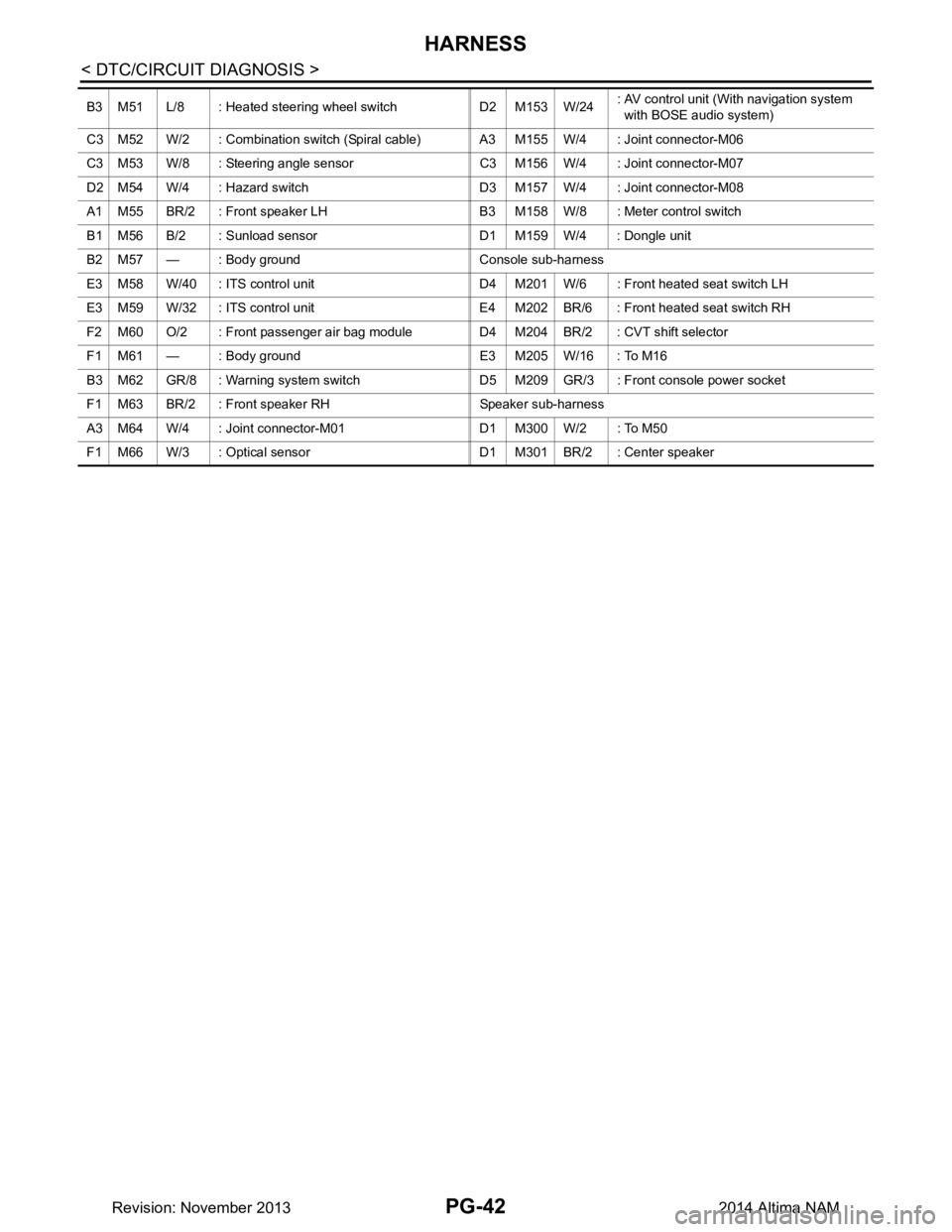

HARNESS CONNECTOR

• The slide-locking type connectors are disconnected by pushing or pulling the slider. Refer to the figure

below.

CAUTION:

• Do not pull the harness or wires when disconnecting the connector.

• Be careful not to damage the connector su pport bracket when disconnecting the connector.

[Example]

HARNESS CONNECTOR (LEVER LOCKING TYPE)

• Lever locking type harness connectors are used on certain control units and control modules such as ECM, ABS actuator and electric unit (control unit), etc.

• Lever locking type harness connectors are also used on super multiple junction (SMJ) connectors.

• Always confirm the lever is fully locked in place by moving the lever as far as it will go to ensure full connec-

tion.

CAUTION:

SEL769V

Revision: November 20132014 Altima NAM

Page 3516 of 4801

![NISSAN TEANA 2014 Service Manual

COMPONENT PARTSPWC-9

< SYSTEM DESCRIPTION > [LH FRONT ONLY ANTI-PINCH]

C

D E

F

G H

I

J

L

M A

B

PWC

N

O P

Component Function

BCM • Supplies power to power window switches.

• Controls retained p NISSAN TEANA 2014 Service Manual

COMPONENT PARTSPWC-9

< SYSTEM DESCRIPTION > [LH FRONT ONLY ANTI-PINCH]

C

D E

F

G H

I

J

L

M A

B

PWC

N

O P

Component Function

BCM • Supplies power to power window switches.

• Controls retained p](/img/5/57390/w960_57390-3515.png)

COMPONENT PARTSPWC-9

< SYSTEM DESCRIPTION > [LH FRONT ONLY ANTI-PINCH]

C

D E

F

G H

I

J

L

M A

B

PWC

N

O P

Component Function

BCM • Supplies power to power window switches.

• Controls retained power.

Front power window motor LH • Integrates the ENCODER POWER and WINDOW MOTOR.

• Starts operating with signals from main power window and door lock/unlock switch.

• Transmits power window motor rotation as a pulse signal to main power window and door lock/unlock switch.

Front power window motor RH Starts operating with signals from main power window and door lock/unlock switch &

power window and door lock/unlock switch RH.

Main power window and door lock/un-

lock switch • Directly controls all power window motor of all doors.

• Controls anti-pinch operation of front power window LH.

Power window and door lock/unlock

switch RH • Controls front power window motor RH.

Rear power window switch • Controls rear power window motors LH and RH.

Rear power window motor Starts operating with signals from main power window and door lock/unlock switch &

rear power window switch.

Front door switch LH or RH Detects door open/close condition and transmits to BCM.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3518 of 4801

![NISSAN TEANA 2014 Service Manual

SYSTEMPWC-11

< SYSTEM DESCRIPTION > [LH FRONT ONLY ANTI-PINCH]

C

D E

F

G H

I

J

L

M A

B

PWC

N

O P

• AUTO UP/DOWN operation can be performed when main power window and door lock/unlock switch turns NISSAN TEANA 2014 Service Manual

SYSTEMPWC-11

< SYSTEM DESCRIPTION > [LH FRONT ONLY ANTI-PINCH]

C

D E

F

G H

I

J

L

M A

B

PWC

N

O P

• AUTO UP/DOWN operation can be performed when main power window and door lock/unlock switch turns](/img/5/57390/w960_57390-3517.png)

SYSTEMPWC-11

< SYSTEM DESCRIPTION > [LH FRONT ONLY ANTI-PINCH]

C

D E

F

G H

I

J

L

M A

B

PWC

N

O P

• AUTO UP/DOWN operation can be performed when main power window and door lock/unlock switch turns to AUTO.

• Encoder continues detecting the movement of power window motor and transmits to main power window

and door lock/unlock switch as the encoder pulse signal while power window motor is operating.

• Main power window and door lock/unlock switch reads the changes of encoder signal and stops AUTO oper-

ation when door glass is at fully opened/closed position.

• Power window motor is operable in case encoder is malfunctioning.

RETAINED POWER OPERATION

• Retained power operation is an additional power supply function that enables power window system to oper-

ate during the 45 seconds even when ignition switch is turned OFF

Retained power function cancel conditions

• Front door CLOSE (door switch OFF) →OPEN (door switch ON).

• When ignition switch is ON.

• When timer time passes. (45 seconds)

• AUTO function does not operate if encoder is malfunctioning.

POWER WINDOW LOCK FUNCTION

Ground circuit inside main power window and door lock/unlock switch shuts off when power window lock

switch is ON. This inhibits power window switch operation except with the main power window and door lock/

unlock switch.

ANTI-PINCH OPERATION (FRONT LH)

• Pinch foreign material in the door glass during AUTO-U P operation, and it is the anti-pinch function that low-

ers the door glass 150mm. (5.9 in .) or 2 seconds when detected.

• Encoder continues detecting the movement of power window motor and transmits to main power window and door lock/unlock switch as the encoder pulse signal while power window motor is operating.

• Resistance is applied to the power window motor ro tation that changes the frequency of encoder pulse sig-

nal if foreign material is trapped in the door glass.

• Power window switch controls to lower the window gla ss for 150 mm. (5.9 in.) or 2 seconds after it detects

encoder pulse signal frequency change.

OPERATION CONDITION

• When door glass AUTO-UP operation is performed (anti- pinch function does not operate just before the door

glass closes and is fully closed)

NOTE:

Depending on environment and driving conditions, if a similar impact or load is applied to the door glass, it

may lower.

KEYLESS POWER WINDOW DOWN FUNCTION

All power windows open when the unlock button on Intelligent Key is activated and pressed for more than 3

seconds with the ignition switch OFF. The windows keep opening if the unlock button is continuously pressed.

The power window opening stops when the following operations are performed:

• When the unlock button is pressed for more than 15 seconds.

• When the ignition switch is turned ON while the power window opening is operated.

• When the unlock button is released.

While retained power operation activate, keyless power window down function cannot be operated.

Fail-safeINFOID:0000000009460823

FAIL-SAFE CONTROL

Switches to fail-safe control when malfunction is det ected in the encoder signal that detects UP/DOWN speed

and direction of door glass. Switches to fail-safe control when an error beyond the regulation value is detected

between the fully closed position and the actual position of the glass.

Malfunction Malfunction condition

Pulse sensor malfunction When only one side of pulse signal is being detected for more than the specified value.

Both pulse sensors mal-

function When both pulse signals have not been detected for more than the specified value during glass

open/close operation.

Pulse direction malfunc-

tion When the pulse signal that is detected during glass open/close operation detects the opposite con-

dition of power window motor operating direction.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3578 of 4801

![NISSAN TEANA 2014 Service Manual

COMPONENT PARTSPWC-71

< SYSTEM DESCRIPTION > [LH & RH FRONT ANTI-PINCH]

C

D E

F

G H

I

J

L

M A

B

PWC

N

O P

Component Function

BCM • Supplies power to power window switches.

• Controls retained NISSAN TEANA 2014 Service Manual

COMPONENT PARTSPWC-71

< SYSTEM DESCRIPTION > [LH & RH FRONT ANTI-PINCH]

C

D E

F

G H

I

J

L

M A

B

PWC

N

O P

Component Function

BCM • Supplies power to power window switches.

• Controls retained](/img/5/57390/w960_57390-3577.png)

COMPONENT PARTSPWC-71

< SYSTEM DESCRIPTION > [LH & RH FRONT ANTI-PINCH]

C

D E

F

G H

I

J

L

M A

B

PWC

N

O P

Component Function

BCM • Supplies power to power window switches.

• Controls retained power.

Front power window motor LH • Integrates the ENCODER POWER and WINDOW MOTOR.

• Starts operating with signals from main power window and door lock/unlock switch.

• Transmits power window motor rotation as a pulse signal to main power window and door lock/unlock switch.

Front power window motor RH • Integrates the ENCODER POWER and WINDOW MOTOR.

• Starts operating with signals from main power window and door lock/unlock switch &

power window and door lock/unlock switch RH.

• Transmits power window motor rotation as a pulse signal to main power window and door lock/unlock switch.

Main power window and door lock/un-

lock switch • Directly controls all power window motor of all doors.

• Controls anti-pinch operation of front power window LH.

Power window and door lock/unlock

switch RH • Controls front power window motor RH.

• Controls anti-pinch operation of front power window RH.

Rear power window switch • Controls rear power window motors LH and RH.

Rear power window motor Starts operating with signals from main power window and door lock/unlock switch &

rear power window switch.

Front door lock assembly LH (key cylin-

der switch) Transmits operation condition of key cylinder switch to power window main switch.

Front door switch LH or RH Detects door open/close condition and transmits to BCM.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3580 of 4801

![NISSAN TEANA 2014 Service Manual

SYSTEMPWC-73

< SYSTEM DESCRIPTION > [LH & RH FRONT ANTI-PINCH]

C

D E

F

G H

I

J

L

M A

B

PWC

N

O P

POWER WINDOW OPERATION

• Power window system activated by the power window swit ch when the igniti NISSAN TEANA 2014 Service Manual

SYSTEMPWC-73

< SYSTEM DESCRIPTION > [LH & RH FRONT ANTI-PINCH]

C

D E

F

G H

I

J

L

M A

B

PWC

N

O P

POWER WINDOW OPERATION

• Power window system activated by the power window swit ch when the igniti](/img/5/57390/w960_57390-3579.png)

SYSTEMPWC-73

< SYSTEM DESCRIPTION > [LH & RH FRONT ANTI-PINCH]

C

D E

F

G H

I

J

L

M A

B

PWC

N

O P

POWER WINDOW OPERATION

• Power window system activated by the power window swit ch when the ignition switch is in the ON position

or during the retained power operation after ignition switch turns OFF.

• Power window main switch (driver side) can open/close all windows.

• Front & rear power window switch can open/close the corresponding windows.

• If door glass receives resistance that is more than the specified value and the power window is in the AUTO-

UP operation (Front LH & RH), power window will move in the reverse direction (Anti-Pinch Function).

POWER WINDOW AUTO-OPERATION (FRONT LH & RH)

• AUTO UP/DOWN operation can be performed when main power window and door lock/unlock switch &

power window and door lock/unlock switch RH turns to AUTO.

• Encoder continues detecting the movement of power window motor and transmits to power window switch

as the encoder pulse signal while power window motor is operating.

• Power window switch reads the changes of encoder signal and stops AUTO operation when door glass is at fully opened/closed position.

• Power window motor is operable in case encoder is malfunctioning.

• AUTO function does not operate if encoder is malfunctioning.

RETAINED POWER OPERATION

• Retained power operation is an additional power supply function that enables power window system to oper-

ate during the 45 seconds even when ignition switch is turned OFF

Retained power function cancel conditions • Front door CLOSE (door switch OFF) →OPEN (door switch ON).

• When ignition switch is ON.

• When timer time passes. (45 seconds)

POWER WINDOW LOCK FUNCTION

Ground circuit inside power window main switch shuts off when power window lock switch is ON. This inhibits

power window switch operation except with the power window switch.

ANTI-PINCH OPERATION (FRONT LH & RH)

• Pinch foreign material in the door glass during AUTO-U P operation, and it is the anti-pinch function that low-

ers the door glass 150 mm (5.9 in.) or 2 seconds when detected.

• Encoder continues detecting the movement of power window motor and transmits to power window switch

as the encoder pulse signal while power window motor is operating.

• Resistance is applied to the power window motor ro tation that changes the frequency of encoder pulse sig-

nal if foreign material is trapped in the door glass.

• Power window switch controls to lower the window glas s for 150 mm (5.9 in.) or 2 seconds after it detects

encoder pulse signal frequency change.

OPERATION CONDITION

• When all door glass AUTO-UP operation is performed ( anti-pinch function does not operate just before the

door glass closes and is fully closed)

NOTE:

Depending on environment and driving conditions, if a similar impact or load is applied to the door glass, it

may lower.

KEY CYLINDER SWITCH OPERATION

Hold the door key cylinder to the LOCK or UNLOCK dire ction for more than 1 second to OPEN or CLOSE front

power windows when ignition switch is OFF. In addition, it stops when key position is moved to NEUTRAL

when operating.

OPERATION CONDITION

• Ignition switch OFF

Item Input signal to front power window

switch Front power window switch

function Actuator

Power window and

door lock/unlock

switch RH Front power window motor RH UP/

DOWN signal Power window control Front power window motor RH

Encoder Encoder pulse signal

BCM RAP signal

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3622 of 4801

![NISSAN TEANA 2014 Service Manual

ENCODERPWC-115

< DTC/CIRCUIT DIAGNOSIS > [LH & RH FRONT ANTI-PINCH]

C

D E

F

G H

I

J

L

M A

B

PWC

N

O P

1. Disconnect main power window and door lock/unlock switch.

2. Check continuity between main NISSAN TEANA 2014 Service Manual

ENCODERPWC-115

< DTC/CIRCUIT DIAGNOSIS > [LH & RH FRONT ANTI-PINCH]

C

D E

F

G H

I

J

L

M A

B

PWC

N

O P

1. Disconnect main power window and door lock/unlock switch.

2. Check continuity between main](/img/5/57390/w960_57390-3621.png)

ENCODERPWC-115

< DTC/CIRCUIT DIAGNOSIS > [LH & RH FRONT ANTI-PINCH]

C

D E

F

G H

I

J

L

M A

B

PWC

N

O P

1. Disconnect main power window and door lock/unlock switch.

2. Check continuity between main power window and door lock/unlock switch connector D7 and front power

window motor LH connector D9.

3. Check continuity between main power window and door lock/unlock switch connector D7 and ground.

Is the inspection result normal?

YES >> Replace front power window motor LH. Refer to GW-16, "Removal and Installation - Front Regula-

tor". After that, refer to PWC-93, "ADDITIONAL SERVICE WH EN REPLACING CONTROL UNIT :

Special Repair Requirement".

NO >> Repair or replace the harness or connectors.

PASSENGER SIDE

PASSENGER SIDE : DescriptionINFOID:0000000009460947

Detects condition of the front power window motor RH operation and transmits to power window and door

lock/unlock switch RH as pulse signal.

PASSENGER SIDE : Comp onent Function CheckINFOID:0000000009460948

1.CHECK ENCODER OPERATION

Check front door glass RH perform AUTO open/close operation normally when operating power window and

door lock/unlock switch RH.

Is the inspection result normal?

YES >> Encoder operation is OK.

NO >> Refer to PWC-115, "PASSENGER SIDE : Diagnosis Procedure"

.

PASSENGER SIDE : Dia gnosis ProcedureINFOID:0000000009460949

Regarding Wiring Diagram information, refer to PWC-83, "Wiring Diagram - With Left And Right Front Power

Window Anti-Pinch".

1. CHECK ENCODER SIGNAL

1. Connect front power window motor RH.

2. Turn ignition switch ON.

3. Check signal between power window and door lock/unlock switch RH connector D105 and ground with oscilloscope.

Main power window and door lock/un-

lock switch connector Te r m i n a lFront power window motor LH

connector Terminal Continuity

D7 5

D9 5

Ye s

46

Main power window and door lock/unlock switch connector Te r m i n a l

GroundContinuity

D7 5

No

4

Te r m i n a l s

Signal

(Reference value)

(+)

(–)

Power window and door lock/unlock

switch RH

connector Te r m i n a l

D105 9

Ground Refer to following signal

10

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3634 of 4801

![NISSAN TEANA 2014 Service Manual

POWER WINDOW LOCK SWITCHPWC-127

< DTC/CIRCUIT DIAGNOSIS > [LH & RH FRONT ANTI-PINCH]

C

D E

F

G H

I

J

L

M A

B

PWC

N

O P

POWER WINDOW LOCK SWITCH

DescriptionINFOID:0000000009460965

Ground circuit of NISSAN TEANA 2014 Service Manual

POWER WINDOW LOCK SWITCHPWC-127

< DTC/CIRCUIT DIAGNOSIS > [LH & RH FRONT ANTI-PINCH]

C

D E

F

G H

I

J

L

M A

B

PWC

N

O P

POWER WINDOW LOCK SWITCH

DescriptionINFOID:0000000009460965

Ground circuit of](/img/5/57390/w960_57390-3633.png)

POWER WINDOW LOCK SWITCHPWC-127

< DTC/CIRCUIT DIAGNOSIS > [LH & RH FRONT ANTI-PINCH]

C

D E

F

G H

I

J

L

M A

B

PWC

N

O P

POWER WINDOW LOCK SWITCH

DescriptionINFOID:0000000009460965

Ground circuit of main power window and door lock/unlock switch shuts off if power window lock switch of

main power window and door lock/unlock switch is operated. This inhibits all operation, except for the main

switch.

Component Function CheckINFOID:0000000009460966

1. CHECK POWER WINDOW LOCK SIGNAL

Exchanges for a normal main power window and door lock/unlock switch, and operation is checked.

Does power window lock operate?

YES >> Replace main power window and door lock/unlock switch. Refer to PWC-142, "Removal and

Installation". After that, refer to PWC-127, "Special Repair Requirement".

NO >> Check condition of harness and connector.

Special Repair RequirementINFOID:0000000009460967

1. PERFORM INITIALIZATION PROCEDURE

Perform initialization procedure.

Refer to PWC-93, "ADDITIONAL SERVICE WHEN REPLACIN G CONTROL UNIT : Special Repair Require-

ment".

Is the inspection result normal?

YES >> Inspection end.

NO >> Check intermittent incident. Refer to GI-43, "Intermittent Incident"

.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3779 of 4801

SE-30

< REMOVAL AND INSTALLATION >

FRONT SEAT

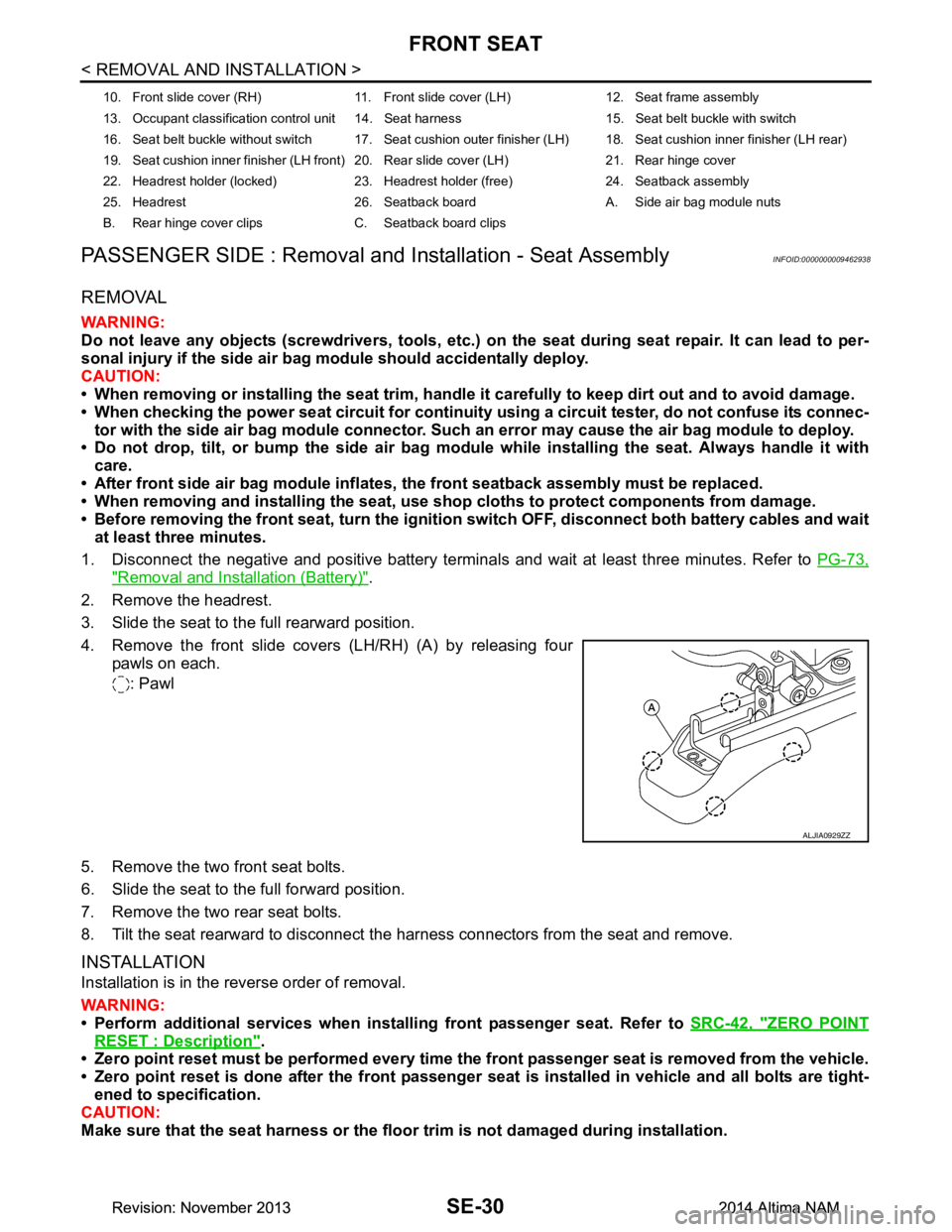

PASSENGER SIDE : Removal and Installation - Seat Assembly

INFOID:0000000009462938

REMOVAL

WARNING:

Do not leave any objects (screwdriver s, tools, etc.) on the seat during seat repair. It can lead to per-

sonal injury if the side air bag module should accidentally deploy.

CAUTION:

• When removing or installing the seat trim, handle it carefully to keep dirt out and to avoid damage.

• When checking the power seat circuit for continuity using a circuit tester, do not confuse its connec-

tor with the side air bag module connector. Such an error may cau se the air bag module to deploy.

• Do not drop, tilt, or bump the si de air bag module while installing the seat. Always handle it with

care.

• After front side air bag module inflates, the front seatback assembly must be replaced.

• When removing and installing the seat, use shop cloths to protect components from damage.

• Before removing the front seat, turn the ignition switch OFF, disconnect both battery cables and wait

at least three minutes.

1. Disconnect the negative and positive battery terminal s and wait at least three minutes. Refer to PG-73,

"Removal and Installation (Battery)".

2. Remove the headrest.

3. Slide the seat to the full rearward position.

4. Remove the front slide covers (LH/RH) (A) by releasing four pawls on each.

: Pawl

5. Remove the two front seat bolts.

6. Slide the seat to the full forward position.

7. Remove the two rear seat bolts.

8. Tilt the seat rearward to disconnect the harness connectors from the seat and remove.

INSTALLATION

Installation is in the reverse order of removal.

WARNING:

• Perform additional services when instal ling front passenger seat. Refer to SRC-42, "ZERO POINT

RESET : Description".

• Zero point reset must be performed every time th e front passenger seat is removed from the vehicle.

• Zero point reset is done after the front passenger seat is installed in vehicle and all bolts are tight-

ened to specification.

CAUTION:

Make sure that the seat harness or the floor trim is not damaged during installation.

10. Front slide cover (RH) 11. Front sl ide cover (LH) 12. Seat frame assembly

13. Occupant classification control unit 14. Seat harness 15. Seat belt buckle with switch

16. Seat belt buckle without switch 17. Seat cushion outer finisher (LH) 18. Seat cushion inner finisher (LH rear)

19. Seat cushion inner finisher (LH front) 20. Rear slide cover (LH) 21. Rear hinge cover

22. Headrest holder (locked) 23. Headrest holder (free) 24. Seatback assembly

25. Headrest 26. Seatback board A. Side air bag module nuts

B. Rear hinge cover clips C. Seatback board clips

ALJIA0929ZZ

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM