Its control NISSAN TEANA 2014 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 3146 of 4801

![NISSAN TEANA 2014 Service Manual

LAN

AVM BRANCH LINE CIRCUITLAN-197

< DTC/CIRCUIT DIAGNOSIS > [CAN SYSTEM (TYPE 8)]

C

D E

F

G H

I

J

K L

B

A

O P

N

AVM BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000009461564

1.CHECK CONNECTOR NISSAN TEANA 2014 Service Manual

LAN

AVM BRANCH LINE CIRCUITLAN-197

< DTC/CIRCUIT DIAGNOSIS > [CAN SYSTEM (TYPE 8)]

C

D E

F

G H

I

J

K L

B

A

O P

N

AVM BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000009461564

1.CHECK CONNECTOR](/img/5/57390/w960_57390-3145.png)

LAN

AVM BRANCH LINE CIRCUITLAN-197

< DTC/CIRCUIT DIAGNOSIS > [CAN SYSTEM (TYPE 8)]

C

D E

F

G H

I

J

K L

B

A

O P

N

AVM BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000009461564

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cabl e from the negative terminal.

3. Check the terminals and connectors of the ITS c ontrol unit for damage, bend and loose connection (unit

side and connector side).

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of ITS control unit.

2. Check the resistance between the ITS control unit harness connector terminals.

Is the measurement value within the specification?

YES >> GO TO 3.

NO >> Repair the ITS control unit branch line.

3.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circui t of the ITS control unit. Refer to DAS-62, "Diagnosis Proce-

dure".

Is the inspection result normal?

YES (Present error)>>Replace the ITS control unit. Refer to DAS-68, "Removal and Installation".

YES (Past error)>>Error was detected in the ITS control unit branch line.

NO >> Repair the power supply and the ground circuit.

ITS control unit harness connector Resistance (Ω)

Connector No. Terminal No.

M58 27 7 Approx. 54 – 66

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3191 of 4801

PERIODIC MAINTENANCEMA-7

< PERIODIC MAINTENANCE >

C

D E

F

G H

I

J

K L

M B

MA

N

O A

PERIODIC MAINTENANCE

FOR USA AND CANADA

FOR USA AND CANADA : Introduc

tion of Periodic MaintenanceINFOID:0000000009889991

The following tables show the normal maintenanc e schedule. Depending upon weather and atmospheric con-

ditions, varying road surfaces, indi vidual driving habits and vehicle usage, additional or more frequent mainte-

nance may be required.

Periodic maintenance beyond th e last period shown on the tables requires similar maintenance.

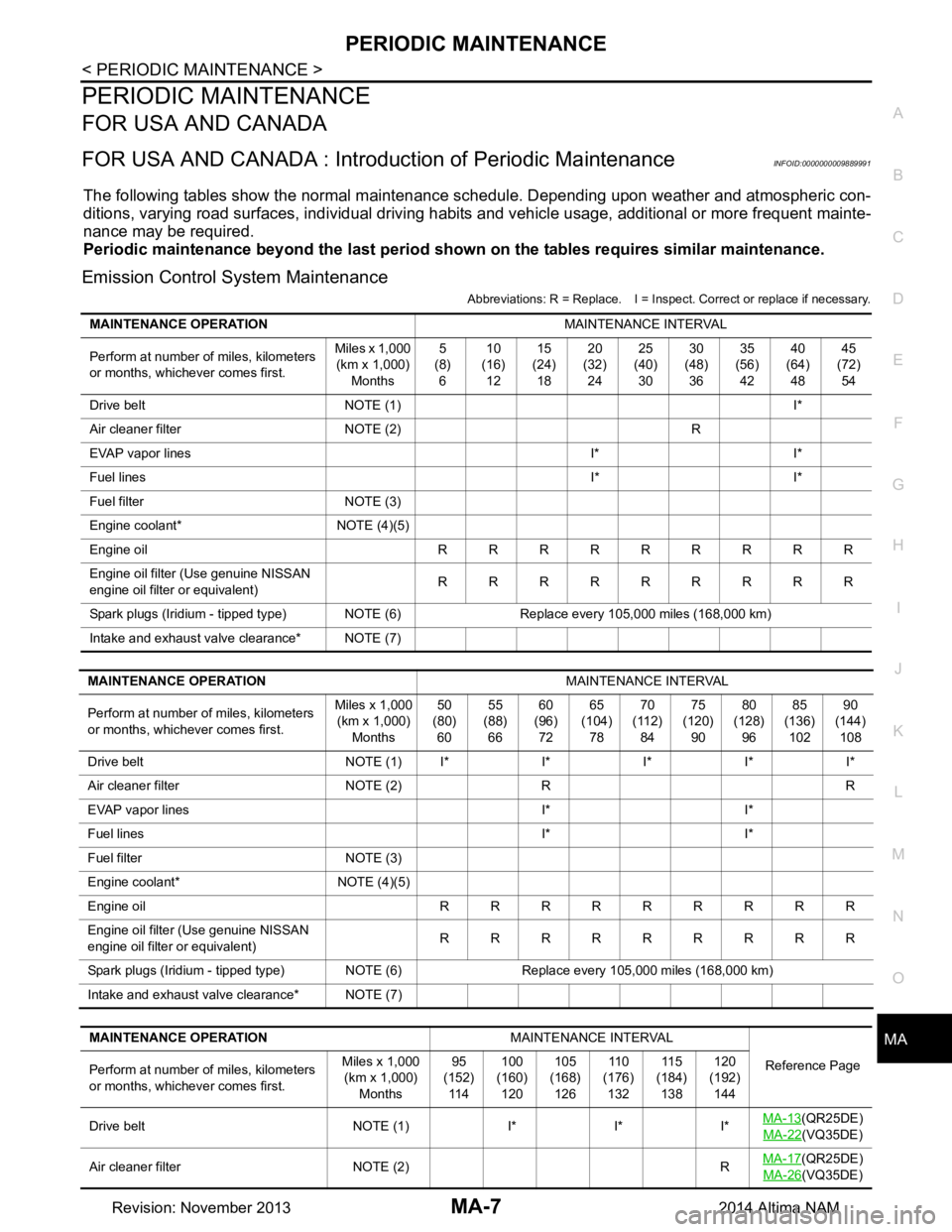

Emission Control System Maintenance

Abbreviations: R = Replace. I = Inspec t. Correct or replace if necessary.

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Perform at number of miles, kilometers

or months, whichever comes first. Miles x 1,000

(km x 1,000) Months 5

(8) 6 10

(16) 12 15

(24) 18 20

(32) 24 25

(40) 30 30

(48) 36 35

(56) 42 40

(64) 48 45

(72) 54

Drive belt NOTE (1) I*

Air cleaner filter NOTE (2) R

EVAP vapor lines I* I*

Fuel lines I* I*

Fuel filter NOTE (3)

Engine coolant* NOTE (4)(5)

Engine oil RRRRRRRRR

Engine oil filter (Use genuine NISSAN

engine oil filter or equivalent) RRRRRRRRR

Spark plugs (Iridium - tipped type) NOTE (6) Replace every 105,000 miles (168,000 km)

Intake and exhaust valve clearance* NOTE (7)

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Perform at number of miles, kilometers

or months, whichever comes first. Miles x 1,000

(km x 1,000)

Months 50

(80)

60 55

(88)

66 60

(96)

72 65

(104)

78 70

(112)

84 75

(120)

90 80

(128)

96 85

(136)

102 90

(144)

108

Drive belt NOTE (1)I*I*I*I*I*

Air cleaner filter NOTE (2) R R

EVAP vapor lines I* I*

Fuel lines I* I*

Fuel filter NOTE (3)

Engine coolant* NOTE (4)(5)

Engine oil RRRRRRRRR

Engine oil filter (Use genuine NISSAN

engine oil filter or equivalent) RRRRRRRRR

Spark plugs (Iridium - tipped type) NOTE (6) Replace every 105,000 miles (168,000 km)

Intake and exhaust valve clearance* NOTE (7)

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Reference Page

Perform at number of miles, kilometers

or months, whichever comes first. Miles x 1,000

(km x 1,000)

Months 95

(152)

11 4 100

(160)

120 105

(168)

126 11 0

(176)

132 11 5

(184)

138 120

(192)

144

Drive belt NOTE (1) I* I* I* MA-13

(QR25DE)

MA-22

(VQ35DE)

Air cleaner filter NOTE (2) R MA-17

(QR25DE)

MA-26

(VQ35DE)

Revision: November 20132014 Altima NAM

Page 3263 of 4801

MWI-8

< SYSTEM DESCRIPTION >

COMPONENT PARTS

Unit Description

Combination meter Controls the following with the signals received from each unit via CAN communication and the signals

from switches and sensors:

• Speedometer

• Tachometer

• Engine coolant temperature gauge

• Fuel gauge

• Warning lamps

• Indicator lamps

• Meter illumination control

• Meter effect function

• Information display

Meter control switch Transmits the following signals to the combination meter:

• Trip reset switch signal

• Illumination control switch signal (+)

• Illumination control switch signal ( −)

ECM Transmits the following signals to the combination meter via CAN communication:

• Engine speed signal

• Engine coolant temperature signal

• Engine oil pressure warning signal

• Fuel consumption monitor signal

ABS actuator and electric unit

(control unit) Transmits the vehicle speed signal to the combination meter via CAN communication.

Power steering control module Transmits the EPS signal to the combination meter via CAN communication.

BCM Transmits the following signals to the combination meter via CAN communication:

• Tire pressure information

• Position light request signal

• Low tire pressure warning lamp signal

• Door switch signal

• Trunk lamp switch signal

TCM Receives the O/D OFF switch signal from the combination meter via CAN communication.

Transmits the O/D OFF indicator request signal to the combination meter via CAN communication.

CVT shift selector switch

(overdrive co ntrol switch)

(with QR25DE) Transmits the O/D OFF switch signal to the combination meter

Fuel level sensor unit Transmits the fuel level sensor signal to the combination meter.

Seat belt buckle switch LH

(RH similar) Transmits the seat belt buckle switch LH signal to the combination meter.

Air bag diagnosis sensor unit Transmits the following signals to the combination meter:

• Seat belt buckle switch RH signal

• Air bag warning indicator

Engine oil pressure sensor Transmits the engine oil pressure sensor signal to the ECM.

Ambient sensor Transmits the ambient sensor signal to the IPDM E/R.

A/C auto amp. • Receives the ambient sensor signal from the IPDM E/R (with auto A/C).

• Transmits the ambient sensor signal to the combination meter via CAN communication.

Parking brake switch Transmits the parking brake switch signal to the combination meter.

Washer fluid level switch Transmits the washer fluid level switch signal to the combination meter.

Steering switch Transmits the following signals to the information display:

• Display signal

• Menu up signal

• Menu down signal

• Enter signal

• Back signal

IPDM E/R • Receives the ambient sensor signal from the ambient sensor.

• Transmits the ambient sensor signal to the combination meter (without auto A/C).

• Transmits the ambient sensor signal to the A/C auto amp (with auto A/C).

Brake fluid level switch Transmits the brake fluid level switch signal to the combination meter.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3273 of 4801

MWI-18

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (METER)

DIAGNOSIS SYSTEM (METER)

DescriptionINFOID:0000000009461692

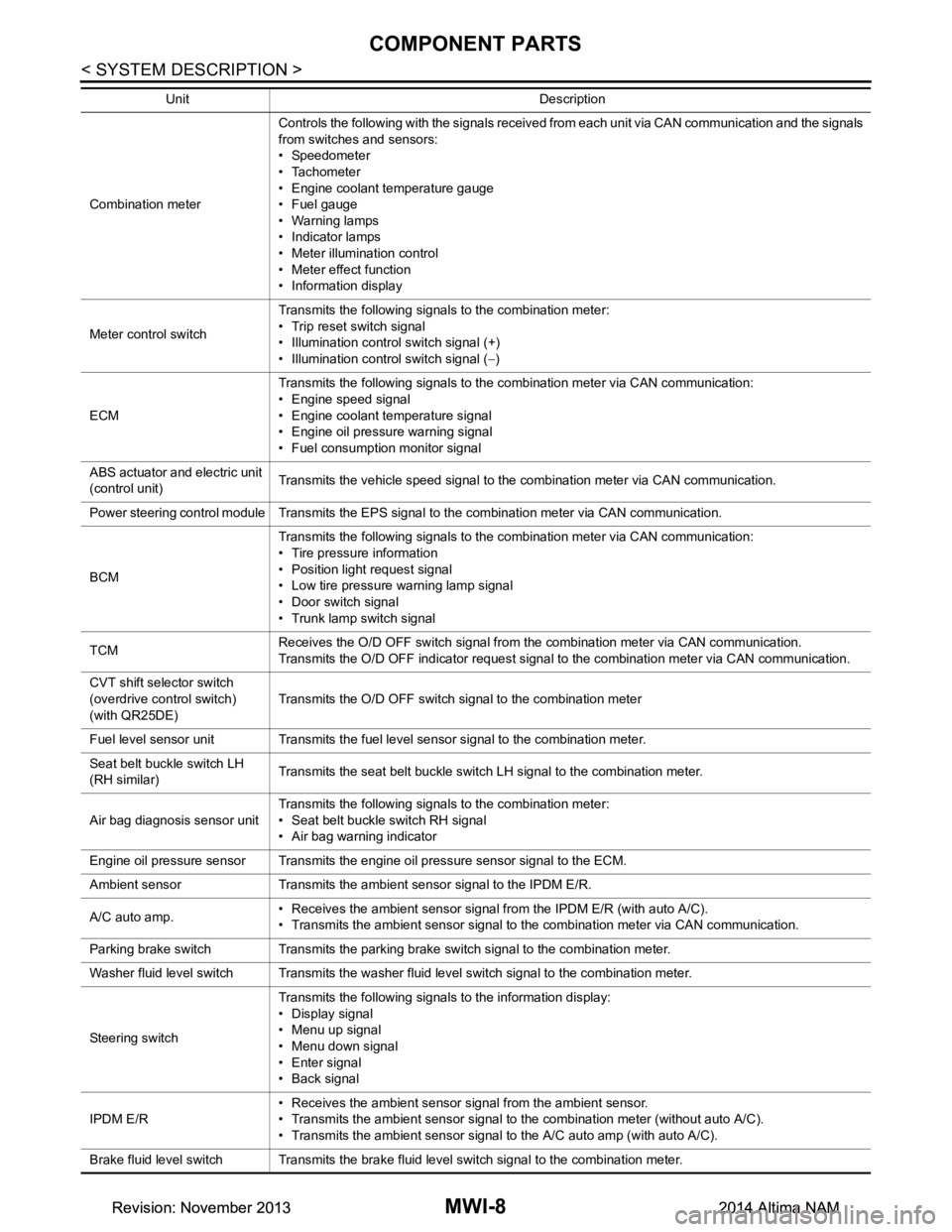

COMBINATION METER SELF-DIAGNOSIS MODE

The following meter functions can be checked during Combination Meter Self-Diagnosis Mode:

• Pointer sweep of speedometer, tachometer and gauges.

• Illumination of all LCD segments and color patterns for meter displays.

• Illumination of all lamps/LEDs that are controlled by the combination meter (regardless of switch status).

STARTING COMBINATION METER SELF-DIAGNOSIS MODE

NOTE:

• Check combination meter power supply and ground circuits if self-diagnosis mode does not start. Refer to

MWI-58, "COMBINATION METER : Diagnosis Procedure"

. Replace combination meter if power supply and

ground circuits are found to be normal and self-diagnosis mode does not start. Refer to MWI-82, "Removal

and Installation".

• Combination meter self-diagnosis mode will function with t he ignition switch in ON. Combination meter self-

diagnosis mode will exit upon turning the ignition switch to OFF.

How to Initiate Self-Diagnosis Mode

1. Press and hold the trip reset switch while turning the ignition switch ON. After 2 seconds release trip reset switch, then press the trip reset switch 3 times within 7 seconds after the ignition switch is turned ON.

2. When the diagnosis function is activated, the meter illuminates all of the following:

• Warning lights/indicators.

• Meter assembly.

• Information display color bars red, green, blue and white (1).

• Odometer, trip A/B odometers and CVT indicator LCD display segments (2).

3. Pressing and holding the trip reset switch performs the pointer sweep test.

CONSULT Function (METER/M&A)INFOID:0000000009461693

CAUTION:

After disconnecting the CONSULT vehicle interface (VI) from the data link connector, the ignition must

be cycled OFF → ON (for at least 5 seconds) → OFF. If this step is not performed, the BCM may not go

to ”sleep mode”, potentially causing a di scharged battery and no-start condition.

APPLICATION ITEMS

CONSULT can display each diagnostic item using the diagnostic test modes shown.

SELF DIAG RESULT

AWNIA2543GB

METER/M&A Diagnosis mode Description

SELF DIAGNOSTIC RESULT Displays combin ation meter self-diagnosis results.

DATA MONITOR Displays combination meter input/output data in real time.

WARNING HISTORY Lighting history of the warning lamp and indicator lamp can be checked.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3283 of 4801

![NISSAN TEANA 2014 Service Manual

MWI-28

< ECU DIAGNOSIS INFORMATION >

COMBINATION METER

VEHICLE SPEED CIRC

[B2205] The abnormal vehicl

e speed signal is input from the ABS actuator and electric unit (control

unit) for 2 seconds NISSAN TEANA 2014 Service Manual

MWI-28

< ECU DIAGNOSIS INFORMATION >

COMBINATION METER

VEHICLE SPEED CIRC

[B2205] The abnormal vehicl

e speed signal is input from the ABS actuator and electric unit (control

unit) for 2 seconds](/img/5/57390/w960_57390-3282.png)

MWI-28

< ECU DIAGNOSIS INFORMATION >

COMBINATION METER

VEHICLE SPEED CIRC

[B2205] The abnormal vehicl

e speed signal is input from the ABS actuator and electric unit (control

unit) for 2 seconds or more. MWI-55

TACHO METER

[B2267] If ECM continuously transmits abnormal engine speed signals for 2 seconds or more.

MWI-56

WATER TEMP METER

[B2268] If ECM continuously transmits abnormal engine coolant temperature signals for 60 sec-

onds or more. MWI-57

Display contents of CONSULT Diagnostic item is detected when... Refer to

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3346 of 4801

PB-8

< REMOVAL AND INSTALLATION >

PARKING BRAKE CONTROL

3. Disconnect the harness connector from the parking brake switch and remove parking brake switch.

4. Remove adjusting nut and discard, then loosen front cable. CAUTION:

Do not reuse adjusting nut.

5. Disconnect front cable.

6. Remove parking brake pedal assembly nuts and remove parking brake pedal assembly.

7. Remove ITS control unit. Refer to AV-436, "Removal and Installation"

.

8. Remove spring and separate rear cables (LH/ RH) from front cable, remove front cable.

9. Remove rear brake caliper and disc brake rotor. Refer to BR-40, "BRAKE CALIPER ASSEMBLY :

Removal and Installation".

10. Remove parking brake shoe, and remove r ear cable from toggle lever. Refer to IP-14, "Exploded View"

.

11. Remove rear cable bolts and nuts, then remove rear cables.

INSTALLATION

Installation is in the reverse order of removal.

• Adjust the parking brake with new adjusting nut. Refer to WT-55, "Adjustment"

.

CAUTION:

• Do not reuse adjusting nut.

• The cables should be free from twists, damage, cracks or corrosion.

Revision: November 20132014 Altima NAM

Page 3355 of 4801

![NISSAN TEANA 2014 Service Manual

PC S-6

< SYSTEM DESCRIPTION >[IPDM E/R]

SYSTEM

RELAY CONTROL SYSTEM : System Description

INFOID:0000000009461598

IPDM E/R activates the internal cont rol circuit to perform the relay ON-OFF control a NISSAN TEANA 2014 Service Manual

PC S-6

< SYSTEM DESCRIPTION >[IPDM E/R]

SYSTEM

RELAY CONTROL SYSTEM : System Description

INFOID:0000000009461598

IPDM E/R activates the internal cont rol circuit to perform the relay ON-OFF control a](/img/5/57390/w960_57390-3354.png)

PC S-6

< SYSTEM DESCRIPTION >[IPDM E/R]

SYSTEM

RELAY CONTROL SYSTEM : System Description

INFOID:0000000009461598

IPDM E/R activates the internal cont rol circuit to perform the relay ON-OFF control according to the input sig-

nals from various sensors and the request signals received from control units via CAN communication.

CAUTION:

IPDM E/R integrated relays cannot be removed.

POWER CONSUMPTION CONTROL SYSTEM

Control relay Input/output T ransmit unitControl partReference

page

Front fog lamp relay Front fog lamp request signal BCM (CAN) Front fog lamp EXL-101

Headlamp high relay High beam request signal BCM (CAN) Headlamp highEXL-91

Headlamp low relay Low beam request signal BCM (CAN) Headlamp lowEXL-93

(halogen)

EXL-94

(xe-

non)

Tail lamp relay Position light request signal BCM (CAN) •Parking lamp

• Side marker lamp

• License plate lamp

•Tail lamp EXL-103

• Front wiper relay

• Front wiper high relay Front wiper request signal BCM (CAN)

Front wiperWW-48

Front wiper auto stop signal Front wiper motor

Cooling fan relay-1 Cooling fan request signal ECM Cooling fan EC-499

(QR25DE)

EC-953

(VQ35DE)

A/C relay A/C compressor request signal ECM (CAN) A/C compressor HAC-87

(automatic

air condi-

tioner)

HAC-151

(manual air

conditioner)

Ignition relay-1 Ignition switch ON signal BCM (CAN)

Ignition relay-1PCS-58

Vehicle speed signal Combination meter (CAN)

Push-button ignition switch Push-button ignition switch

Fuel pump relay Fuel pump request signal ECM Fuel pump EC-508

(QR25DE)

EC-965

(VQ35DE)

ECM relay ECM relay cont rol signal ECM ECM relay EC-203

(QR25DE)

EC-709

(VQ35DE)

Throttle contro l motor relay Throttle control

motor relay sig-

nal ECMThrottle control motor re-

lay EC-475

(QR25DE)

EC-933

(VQ35DE)

Starter relay Starter relay control signal BCM Starter motor PCS-12

Starter control relay

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3356 of 4801

![NISSAN TEANA 2014 Service Manual

PCS

SYSTEMPCS-7

< SYSTEM DESCRIPTION > [IPDM E/R]

C

D E

F

G H

I

J

K L

B

A

O P

N

POWER CONSUMPTION CONTRO

L SYSTEM : System DiagramINFOID:0000000009461599

POWER CONSUMPTION CONTROL SYSTEM : System NISSAN TEANA 2014 Service Manual

PCS

SYSTEMPCS-7

< SYSTEM DESCRIPTION > [IPDM E/R]

C

D E

F

G H

I

J

K L

B

A

O P

N

POWER CONSUMPTION CONTRO

L SYSTEM : System DiagramINFOID:0000000009461599

POWER CONSUMPTION CONTROL SYSTEM : System](/img/5/57390/w960_57390-3355.png)

PCS

SYSTEMPCS-7

< SYSTEM DESCRIPTION > [IPDM E/R]

C

D E

F

G H

I

J

K L

B

A

O P

N

POWER CONSUMPTION CONTRO

L SYSTEM : System DiagramINFOID:0000000009461599

POWER CONSUMPTION CONTROL SYSTEM : System DescriptionINFOID:0000000009461600

OUTLINE

• IPDM E/R incorporates a power consumption control function that reduces the power consumption accord-

ing to the vehicle status.

• IPDM E/R changes its status (control mode) with the sleep wake up signal received from BCM via CAN com-

munication.

Normal mode (wake-up)- CAN communication is normally performed with other control units.

- Individual unit control by IPDM E/R is normally performed.

Low power consumption mode (sleep)- Low power consumption control is active.

- CAN transmission is stopped.

SLEEP MODE ACTIVATION

• IPDM E/R judges that the sleep-ready conditions are fu lfilled when the ignition switch is OFF and none of the

conditions below are present. Then it transmits a sleep-ready signal (ready) to BCM via CAN communica-

tion.

- Front wiper fail-safe operation

- Outputting signals to actuators

- Switches or relays operating

- Auto active test is starting

- Emergency OFF

- Output requests are being received from control units via CAN communication.

• IPDM E/R stops CAN communication and enters the low power consumption mode when it receives a sleep

wake up signal (sleep) from BCM and the sleep-ready conditions are fulfilled.

WAKE-UP OPERATION

• IPDM E/R changes from the low power consumption mode to the normal mode when it receives a sleep

wake-up signal (wake up) from BCM or any of the followi ng conditions is fulfilled. In addition, it transmits a

sleep-ready signal (not-ready) to BCM via CAN communication to report the CAN communication start.

- Ignition switch ON

- An output request is received from a control unit via CAN communication.

IGNITION BATTERY SAVER LOGIC

If the ignition is ON for 30 minutes with the engine OFF, the IPDM E/R and BCM turn OFF to save the battery.

ALCIA0030GB

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3419 of 4801

![NISSAN TEANA 2014 Service Manual

PCS-70

< DTC/CIRCUIT DIAGNOSIS >[POWER DISTRIBUTION SYSTEM]

B26F1 IGNITION RELAY

B26F1 IGNITION RELAY

DTC LogicINFOID:0000000009461651

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM SELF D NISSAN TEANA 2014 Service Manual

PCS-70

< DTC/CIRCUIT DIAGNOSIS >[POWER DISTRIBUTION SYSTEM]

B26F1 IGNITION RELAY

B26F1 IGNITION RELAY

DTC LogicINFOID:0000000009461651

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM SELF D](/img/5/57390/w960_57390-3418.png)

PCS-70

< DTC/CIRCUIT DIAGNOSIS >[POWER DISTRIBUTION SYSTEM]

B26F1 IGNITION RELAY

B26F1 IGNITION RELAY

DTC LogicINFOID:0000000009461651

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM SELF DIAGNOSTIC RESULT

1. Turn ignition switch ON under the following conditions, and wait for 2 seconds or more.

- CVT selector lever is in the P (park) or N (neutral) position.

- Do not depress brake pedal.

2. Perform self diagnostic result.

Is DTC B26F1detected?

YES >> Go to PCS-70, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis ProcedureINFOID:0000000009461652

Regarding Wiring Diagram information, refer to PCS-44, "Wiring Diagram".

1. CHECK SELF DIAGNOSTIC RESULT FOR IPDM E/R

1. Perform self diagnostic result for IPDM E/R.

2. Erase DTCs.

3. Turn ignition switch OFF.

4. Turn ignition switch ON.

5. Perform self diagnostic result for IPDM E/R.

Are any DTCs detected?

YES >> Refer to PCS-20, "DTC Index".

NO >> GO TO 2.

2.CHECK IGNITION RELAY-1 CONTROL SIGNAL (IPDM E/R)

Check voltage between BCM connector M18 terminal 70 and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Replace BCM. Refer to BCS-80, "Removal and Installation"

.

3.CHECK IGNITION RELAY-1 CONTROL SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector E63 and BCM connector M18.

3. Check continuity between IPDM E/R connector E63 terminal 43 and BCM connector M18 terminal 70.

CONSULT Display DTC detecting condition Possible cause

IGN RELAY OFF

[B26F1] BCM transmits the ignition relay control signal, but

does not receive ignition switch ON signal (CAN)

from IPDM E/R. • Harness or connectors

•BCM

• IPDM E/R

BCM Ground Condition Vo l ta g e

(Approx.)

Connector Terminal

M18 70 — Ignition: OFF 0V

Ignition: ON Battery voltage

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3421 of 4801

![NISSAN TEANA 2014 Service Manual

PCS-72

< DTC/CIRCUIT DIAGNOSIS >[POWER DISTRIBUTION SYSTEM]

B26F2 IGNITION RELAY

B26F2 IGNITION RELAY

DTC LogicINFOID:0000000009461653

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM SELF D NISSAN TEANA 2014 Service Manual

PCS-72

< DTC/CIRCUIT DIAGNOSIS >[POWER DISTRIBUTION SYSTEM]

B26F2 IGNITION RELAY

B26F2 IGNITION RELAY

DTC LogicINFOID:0000000009461653

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM SELF D](/img/5/57390/w960_57390-3420.png)

PCS-72

< DTC/CIRCUIT DIAGNOSIS >[POWER DISTRIBUTION SYSTEM]

B26F2 IGNITION RELAY

B26F2 IGNITION RELAY

DTC LogicINFOID:0000000009461653

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM SELF DIAGNOSTIC RESULT

1. Turn ignition switch ON under the following conditions, and wait for 2 seconds or more.

- CVT selector lever is in the P (park) or N (neutral) position.

- Do not depress brake pedal.

2. Perform self diagnostic result.

Is DTC B26F2 detected?

YES >> Go to PCS-72, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis ProcedureINFOID:0000000009461654

Regarding Wiring Diagram information, refer to PCS-44, "Wiring Diagram".

1. CHECK SELF DIAGNOSTIC RESULT FOR IPDM E/R

1. Perform self diagnostic result for IPDM E/R.

2. Erase DTCs.

3. Turn ignition switch OFF.

4. Turn ignition switch ON.

5. Perform self diagnostic result for IPDM E/R.

Are any DTCs detected?

YES >> Refer to PCS-20, "DTC Index".

NO >> GO TO 2.

2.CHECK IGNITION RELAY-1 CONTROL SIGNAL (IPDM E/R)

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector E63.

3. Check voltage between IPDM E/R connector E63 terminal 43 and ground.

Is the inspection result normal?

YES >> Replace IPDM E/R. Refer to PCS-32, "Removal and Installation".

NO >> GO TO 3.

3.CHECK IGNITION RELAY-1 CONTROL SIGNAL CIRCUIT

1. Disconnect BCM connector M18.

2. Check voltage between IPDM E/R connector E63 terminal 43 and ground.

CONSULT Display DTC detectin g condition Possible cause

IGN RELAY ON

[B26F2] BCM transmits the ignition relay control signal, but

does not receive ignition switch ON signal (CAN)

from IPDM E/R. • Harness or connectors

•BCM

• IPDM E/R

IPDM E/R Ground Condition Vo l ta g e

(Approx.)

Connector Terminal

E63 43 — Ignition: OFF 0V

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM