Its control NISSAN TEANA 2014 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 2575 of 4801

SERVICE INFORMATION FOR ELECTRICAL INCIDENTGI-47

< BASIC INSPECTION >

C

D E

F

G H

I

J

K L

M B

GI

N

O P

no voltage; open is between fuse block and SW1 (point A).

• Close SW1 and probe at relay. voltage; open is further down the circuit than the relay.

no voltage; open is between SW1 and relay (point B).

• Close the relay and probe at the solenoid. voltage; open is further down the circuit than the solenoid.

no voltage; open is between relay and solenoid (point C).

Any powered circuit can be diagnosed using the approach in the previous example.

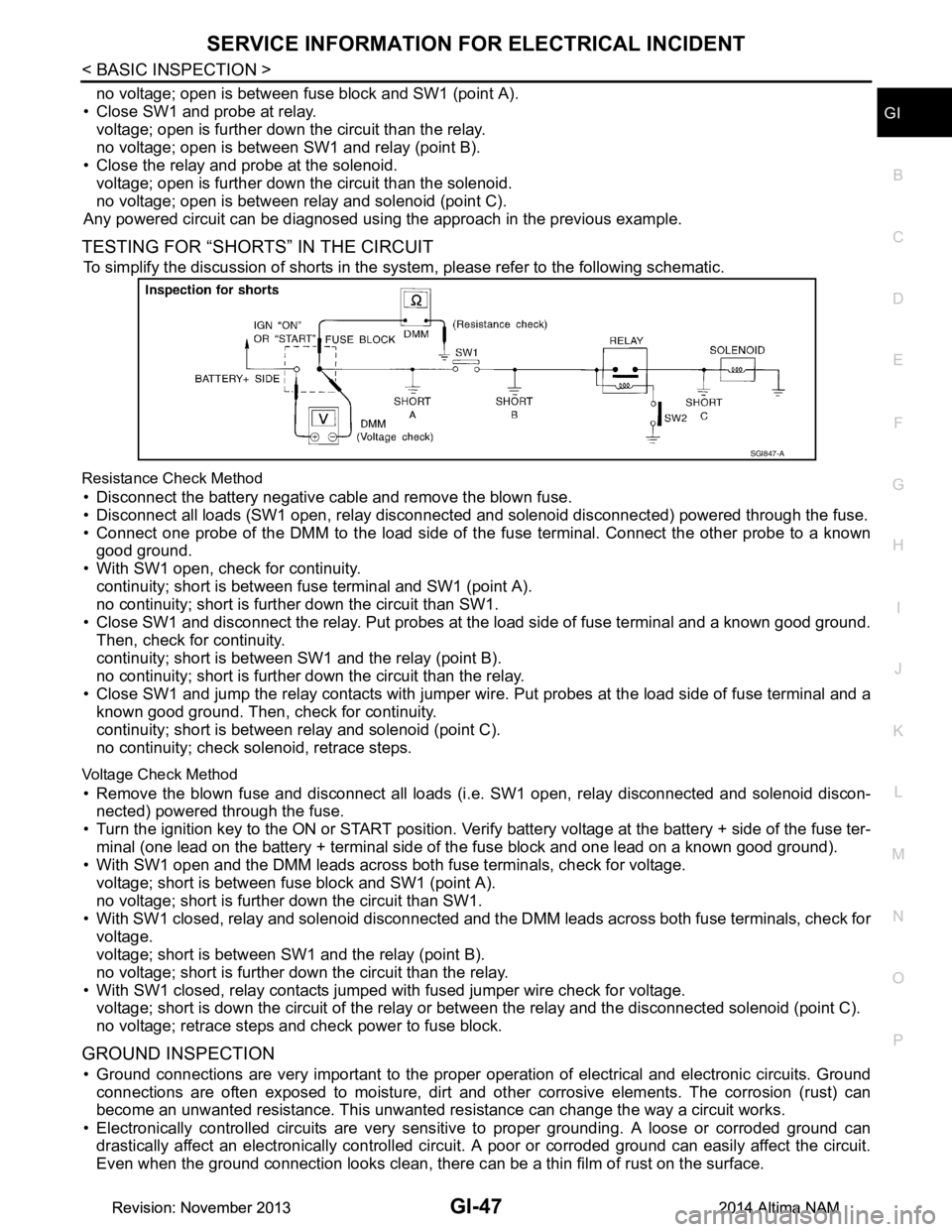

TESTING FOR “SHORTS” IN THE CIRCUIT

To simplify the discussion of shorts in the system, please refer to the following schematic.

Resistance Check Method

• Disconnect the battery negative cable and remove the blown fuse.

• Disconnect all loads (SW1 open, relay disconnected and solenoid disconnected) powered through the fuse.

• Connect one probe of the DMM to the load side of the fuse terminal. Connect the other probe to a known

good ground.

• With SW1 open, check for continuity. continuity; short is between fuse terminal and SW1 (point A).

no continuity; short is further down the circuit than SW1.

• Close SW1 and disconnect the relay. Put probes at the load side of fuse terminal and a known good ground. Then, check for continuity.

continuity; short is between SW1 and the relay (point B).

no continuity; short is further down the circuit than the relay.

• Close SW1 and jump the relay contacts with jumper wir e. Put probes at the load side of fuse terminal and a

known good ground. Then, check for continuity.

continuity; short is between relay and solenoid (point C).

no continuity; check solenoid, retrace steps.

Voltage Check Method

• Remove the blown fuse and disconnect all loads (i .e. SW1 open, relay disconnected and solenoid discon-

nected) powered through the fuse.

• Turn the ignition key to the ON or START position. Veri fy battery voltage at the battery + side of the fuse ter-

minal (one lead on the battery + terminal side of the fuse block and one lead on a known good ground).

• With SW1 open and the DMM leads across both fuse terminals, check for voltage.

voltage; short is between fuse block and SW1 (point A).

no voltage; short is further down the circuit than SW1.

• With SW1 closed, relay and solenoid disconnected and t he DMM leads across both fuse terminals, check for

voltage.

voltage; short is between SW1 and the relay (point B).

no voltage; short is further down the circuit than the relay.

• With SW1 closed, relay contacts jumped with fused jumper wire check for voltage. voltage; short is down the circuit of the relay or between the relay and the disconnected solenoid (point C).

no voltage; retrace steps and check power to fuse block.

GROUND INSPECTION

• Ground connections are very important to the proper operation of electrical and electronic circuits. Ground

connections are often exposed to moisture, dirt and ot her corrosive elements. The corrosion (rust) can

become an unwanted resistance. This unwanted re sistance can change the way a circuit works.

• Electronically controlled circuits are very sens itive to proper grounding. A loose or corroded ground can

drastically affect an electronically controlled circuit. A poor or corroded ground can easily affect the circuit.

Even when the ground connection looks clean, there c an be a thin film of rust on the surface.

SGI847-A

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2577 of 4801

SERVICE INFORMATION FOR ELECTRICAL INCIDENTGI-49

< BASIC INSPECTION >

C

D E

F

G H

I

J

K L

M B

GI

N

O P

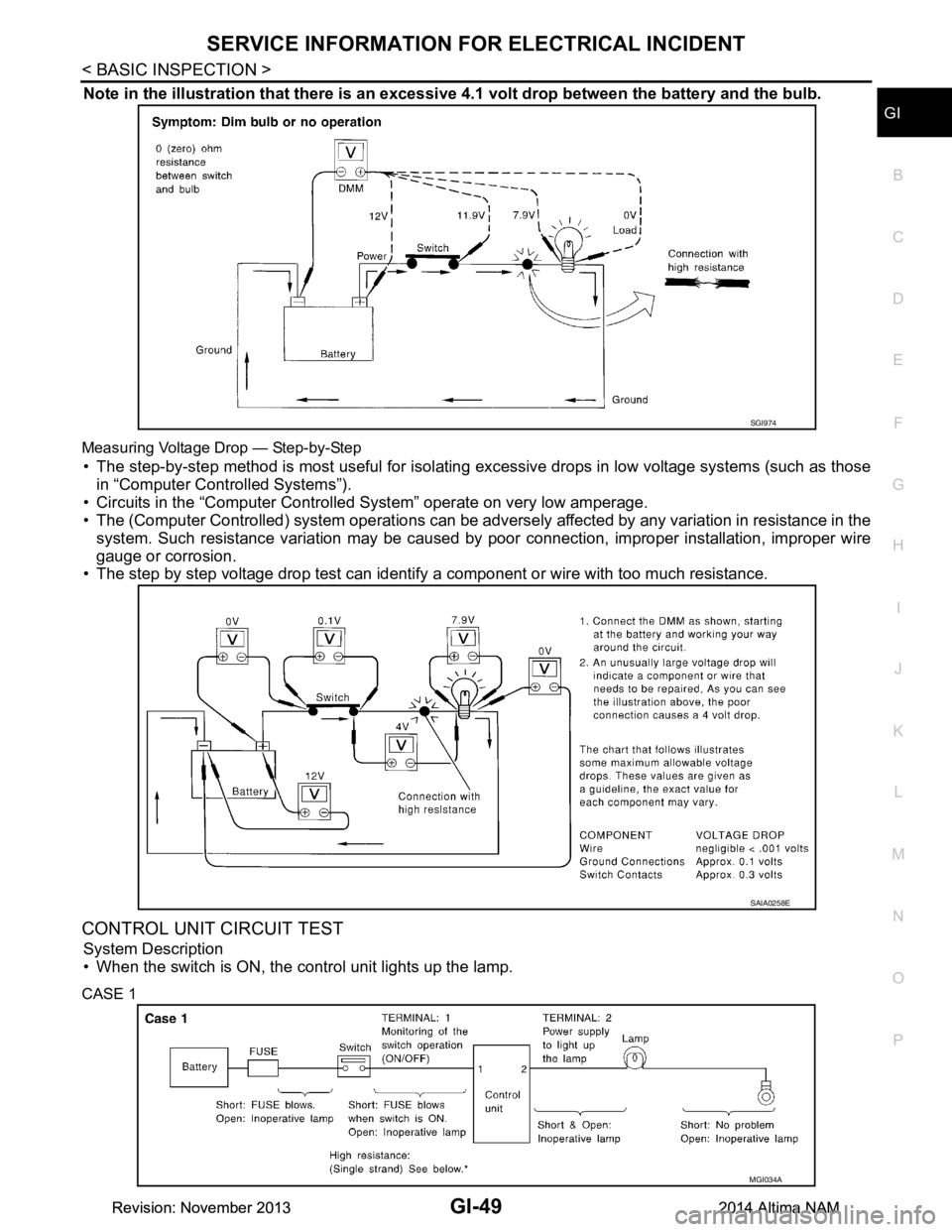

Note in the illustration that there is an excessi ve 4.1 volt drop between the battery and the bulb.

Measuring Voltage Drop — Step-by-Step

• The step-by-step method is most useful for isolating excessive drops in low voltage systems (such as those

in “Computer Controlled Systems”).

• Circuits in the “Computer Controll ed System” operate on very low amperage.

• The (Computer Controlled) system operations can be adversely affected by any variation in resistance in the

system. Such resistance variation may be caused by poor connection, improper installation, improper wire

gauge or corrosion.

• The step by step voltage drop test can identify a component or wire with too much resistance.

CONTROL UNIT CIRCUIT TEST

System Description

• When the switch is ON, the control unit lights up the lamp.

CASE 1

SGI974

SAIA0258E

MGI034A

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2580 of 4801

GI-52

< BASIC INSPECTION >

CONSULT CHECKING SYSTEM

If the CONSULT cannot diagnose the system properly, check the following items.

NOTE:

The DDL2 circuits and CAN communication lines from DLC pins 6, 7 and 14 may be connected to more than

one system. A short in a DDL circuit or CAN lines c onnected to a control unit in one system may affect CON-

SULT access to other systems. For a complete DDL circuit layout, refer to GI-38, "Wiring Diagram"

. For a com-

plete CAN line layout, refer to LAN-36, "Wiring Diagram"

.

Symptom Check item

CONSULT cannot access any

system. • CONSULT DLC power supply circuit (Terminal 8 and 16) and ground circuit (Terminal 4 and 5)

CONSULT cannot access indi-

vidual system. (Other systems

can be accessed.) • Power supply and ground circuit for the control unit of the system (For detailed circuit, refer to wiring

diagram for each system.)

• Open or short circuit between the system and CONSULT DLC (For detailed circuit, refer to wiring diagram for each system.)

• Open or short circuit CAN communication line. Refer to LAN-18, "Trouble Diagnosis Flow Chart"

.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2659 of 4801

![NISSAN TEANA 2014 Service Manual

HAC-10

< SYSTEM DESCRIPTION >[AUTOMATIC AIR CONDITIONER]

COMPONENT PARTS

Component Description

INFOID:0000000009463092

1. ECM 2. IPDM E/R 3. BCM (view with combination meter removed)

4. A/C auto amp NISSAN TEANA 2014 Service Manual

HAC-10

< SYSTEM DESCRIPTION >[AUTOMATIC AIR CONDITIONER]

COMPONENT PARTS

Component Description

INFOID:0000000009463092

1. ECM 2. IPDM E/R 3. BCM (view with combination meter removed)

4. A/C auto amp](/img/5/57390/w960_57390-2658.png)

HAC-10

< SYSTEM DESCRIPTION >[AUTOMATIC AIR CONDITIONER]

COMPONENT PARTS

Component Description

INFOID:0000000009463092

1. ECM 2. IPDM E/R 3. BCM (view with combination meter removed)

4. A/C auto amp. (view with A/C switch assembly removed) 5. A/C switch assembly 6. A/C Compressor

7. Sunload sensor 8. Refrigerant pressure sensor (view with front bumper fascia removed)9. Ambient sensor

10. Fuse Block (J/B), Front blower motor relay 11. In-vehicle sensor 12. Accessory relay-2 (view with instru-

ment panel removed)

13. Blower motor (view with front A/C as- sembly removed from vehicle) 14. Intake door motor 15. Mode door motor

16. Air mix door motor LH 17. Air mix door motor RH 18. Intake sensor

ALIIA0599ZZ

Component Description

A/C auto amp. A/C auto amp. controls front automatic air conditioning system by inputting and calculating signals

from each sensor and each switch.

A/C Compressor Vaporized refrigerant is drawn into the A/C compressor from the evaporator, where it is compressed

to a high pressure, high temperature vapor. The hot, compressed vapor is then discharged to the con-

denser.

A/C switch assembly The A/C switch assembly controls the operation of the A/C and heating system based on inputs from

the temperature control knob, the mode switches, the blower control dial, the ambient temperature

sensor, the intake sensor, and inputs received from the ECM across the CAN. Diagnosis of the A/C

switch assembly can be performed using the CONSULT. There is no self-diagnostic feature available.

Air mix door motor LH The air mix door controls the mix of hot or cold air that enters the ventilation system. It is controlled

by the A/C auto amp. based on the position of the temperature dial. The air mix door motor LH re-

ceives position commands from the A/C auto amp. and reports actual door position back via an LCU

(Local Control Unit) installed inside the motor. Commands and responses are sent across the LIN (Lo-

cal Interconnect Network) to each motor simultaneously, with each motor having its own unique ad-

dress, thereby only responding to requests sent to its specific address. The LCU reads the door

position from a Position Balanced Resistor (PBR), also part of the motor, and returns that information

to the A/C auto amp. The LCU switches the polarity of the circuits connected to the DC motor to drive

the motor forward or backward as requested by the A/C auto amp. If the air mix door moves to a po-

sition less than 5% or more than 95% of its expected or allowed positions, the A/C auto amp. will set

a DTC.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2660 of 4801

![NISSAN TEANA 2014 Service Manual

COMPONENT PARTSHAC-11

< SYSTEM DESCRIPTION > [AUTOMATIC AIR CONDITIONER]

C

D E

F

G H

J

K L

M A

B

HAC

N

O P

Air mix door motor RH The air mix door controls the mix of hot or cold air that enters th NISSAN TEANA 2014 Service Manual

COMPONENT PARTSHAC-11

< SYSTEM DESCRIPTION > [AUTOMATIC AIR CONDITIONER]

C

D E

F

G H

J

K L

M A

B

HAC

N

O P

Air mix door motor RH The air mix door controls the mix of hot or cold air that enters th](/img/5/57390/w960_57390-2659.png)

COMPONENT PARTSHAC-11

< SYSTEM DESCRIPTION > [AUTOMATIC AIR CONDITIONER]

C

D E

F

G H

J

K L

M A

B

HAC

N

O P

Air mix door motor RH The air mix door controls the mix of hot or cold air that enters the ventilation system. It is controlled

by the A/C auto amp. based on the position of the temperature dial. The air mix door motor RH re-

ceives position commands from the A/C auto amp. and reports actual door position back via an LCU

(Local Control Unit) installed inside the motor. Commands and responses are sent across the LIN (Lo-

cal Interconnect Network) to each motor simultaneously, with each motor having its own unique ad-

dress, thereby only responding to requests sent to its specific address. The LCU reads the door

position from a Position Balanced Resistor (PBR), also part of the motor, and returns that information

to the A/C auto amp. The LCU switches the polarity of the circuits connected to the DC motor to drive

the motor forward or backward as requested by the A/C auto amp. If the air mix door moves to a po-

sition less than 5% or more than 95% of its expected or allowed positions, the A/C auto amp. will set

a DTC.

Ambient sensor The ambient sensor measures the temperature of the air surrounding the vehicle. The sensor uses a

thermistor which is sensitive to the change in temperature. The electrical resistance of the thermistor

decreases as temperature increases.

BCM The BCM receives the fan ON and A/C ON signals from the A/C auto amp. and sends a compressor

ON request to the ECM.

Blower motor The blower motor varies the speed at which the air flows through the ventilation system.

ECM The ECM sends a compressor ON request to the IPDM E/R based on the status of engine operation

and load as well as refrigerant pressure information. If all the conditions are met for A/C operation,

the ECM transmits the compressor ON request to the IPDM E/R. The ECM shares the refrigerant

pressure sensor signal, engine RPM, and engine coolant temperature with the A/C auto amp. via

CAN communication line.

Front blower motor relay The front blower motor relay controls the flow of current to fuse 17 and 27 in the Fuse Block (J/B).

The relay is connected directly to ground, and is energized when the ignition switch is in the ON or

START position.

Fuse Block (J/B) Located in the passenger compartment, behind the left lower IP, the Fuse Block (J/B) contains the

front blower motor relay and several fuses required for the air conditioner control system.

Intake door motor The intake door motor controls the position of the intake door. Fresh air is allowed to enter the cabin

in one position, and recirculated inside air is allowed to enter in the other position. At times the A/C

auto amp. may command partial fresh or recirculation based on evaporator or coolant temperatures.

The intake door motor receives position commands from the A/C auto amp. and reports actual door

position back via an LCU (Local Control Unit) installed inside the motor. Commands and responses

are sent across the LIN (Local Interconnect Network) to each motor simultaneously, with each motor

having its own unique address, thereby only responding to requests sent to its specific address. The

LCU reads the door position from a Position Balanced Resistor (PBR), also part of the motor, and re-

turns that information to the A/C auto amp. The LCU switches the polarity of the circuits connected to

the DC motor to drive the motor forward or backward as requested by the A/C auto amp. If the recir-

culation door moves to a position less than 5% or more than 95% of its expected or allowed positions,

the A/C auto amp. will set a DTC.

Intake sensor The intake sensor measures the temperature of the front evaporator fins. The sensor uses a ther-

mistor which is sensitive to the change in temperature. The electrical resistance of the thermistor de-

creases as temperature increases.

In-vehicle sensor In-vehicle sensor measures temperature of intake air that flows through aspirator to passenger room.

The sensor uses a thermistor which is sensitive to the change in temperature. The electrical resis-

tance of the thermistor decreases as temperature increases.

IPDM E/R Refer to PCS-6, "RELAY CONTROL SYSTEM : System Description"

.

Mode door motor The mode door controls the direction the conditioned air passes through the ventilation system.

Through a series of levers and gears, the mode door controls the defrost door, the foot door, and the

vent door. There are 5 preset positions: VENT, B/L, FOOT, D/F, and DEF. The FOOT position can be

set to allow some airflow through to the defroster vent, or to completely block the defroster vent using

the CONSULT. The mode door motor receives position commands from the A/C auto amp. and re-

ports actual door position back via an LCU (Local Control Unit) installed inside the motor. Commands

and responses are sent across the LIN (Local Interconnect Network) to each motor simultaneously,

with each motor having its own unique address, thereby only responding to requests sent to its spe-

cific address. The LCU reads the door position from a Position Balanced Resistor (PBR), also part of

the motor, and returns that information to the A/C auto amp. The LCU switches the polarity of the cir-

cuits connected to the DC motor to drive the motor forward or backward as requested by the A/C auto

amp. The mode door has 5 expected positions and, therefore, can set up to 5 DTCs if the expected

position is not reported back to the A/C auto amp.

Component Description

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2665 of 4801

![NISSAN TEANA 2014 Service Manual

HAC-16

< SYSTEM DESCRIPTION >[AUTOMATIC AIR CONDITIONER]

SYSTEM

Air Outlet Control

INFOID:0000000009463097

• While air outlet is in automatic control, A/C auto amp. selects the mode door position d NISSAN TEANA 2014 Service Manual

HAC-16

< SYSTEM DESCRIPTION >[AUTOMATIC AIR CONDITIONER]

SYSTEM

Air Outlet Control

INFOID:0000000009463097

• While air outlet is in automatic control, A/C auto amp. selects the mode door position d](/img/5/57390/w960_57390-2664.png)

HAC-16

< SYSTEM DESCRIPTION >[AUTOMATIC AIR CONDITIONER]

SYSTEM

Air Outlet Control

INFOID:0000000009463097

• While air outlet is in automatic control, A/C auto amp. selects the mode door position depending on a target air mix door angle and

outlet air temperature calculated from sunload.

• If ambient temperature is excessively low, D/F is selected to pre- vent windshield fogging when air outlet is set to FOOT.

Compressor ControlINFOID:0000000009463098

DESCRIPTION

• When the compressor activation condition is satisfied whil e blower motor is activated, A/C auto amp. trans-

mits A/C ON signal and blower fan ON signal to ECM via CAN communication.

• ECM judges that the compressor can be activated depending on the state of each sensor (refrigerant pres-

sure sensor signal and others) and transmits A/C comp ressor request signal to IPDM E/R via CAN commu-

nication.

• IPDM E/R turns A/C relay ON and activate s the compressor depending on request from ECM.

COMPRESSOR PROTECTION CONTROL AT PRESSURE MALFUNCTION

When high-pressure side value that is detected by refrigerant pressure sensor is as per the following state,

ECM requests IPDM E/R to turn A/C relay OFF and stops the compressor.

• 3.12 MPa (31.82 kg/cm

2, 452.4 psi) or more (When the engine speed is less than 1,500 rpm)

• 2.74 MPa (27.95 kg/cm

2, 397.3 psi) or more (When the engine speed is 1,500 rpm or more)

• 0.14 MPa (1.43 kg/cm

2, 20.3 psi) or less

COMPRESSOR OIL CIRCULATION CONTROL

When the engine starts while the engine coolant temperature is 56 °C (133 °F) or less, ECM activates the com-

pressor for approximately 6 seconds and circulates the compressor lubricant once.

LOW TEMPERATURE PROTECTION CONTROL

• When intake sensor detects that front evaporator fin temperature is 2.5 °C (37 °F) or less, A/C auto amp. requests ECM to turn com-

pressor OFF, and stops the compressor.

• When the front evaporator fin temperature returns to 5.0 °C (41 °F)

or more, the compressor is activated.

OPERATING RATE CONTROL

When set temperature is other than fully cold or air out let is “VENT”, “B/L” or “FOOT” A/C auto amp. controls

the compressor activation depending on ambient temperature.

AIR CONDITIONING CUT CONTROL

When set engine is running is excessively high load conditi on, ECM requests IPDM E/R to turn A/C relay OFF,

and stops the compressor. Refer to EC-56, "AIR CONDITIONING CUT CONT ROL : System Description (with

automatic air conditioner)" (QR25DE) or EC-573, "AIR CONDITIONING CUT CONTROL : System Descrip-

tion" (VQ35DE) for details.

JMIIA0730GB

JMIIA0742GB

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2666 of 4801

![NISSAN TEANA 2014 Service Manual

SYSTEMHAC-17

< SYSTEM DESCRIPTION > [AUTOMATIC AIR CONDITIONER]

C

D E

F

G H

J

K L

M A

B

HAC

N

O P

Door ControlINFOID:0000000009463099

DOOR MOTOR CONTROL

• LCU (Local Control Unit) is built into e NISSAN TEANA 2014 Service Manual

SYSTEMHAC-17

< SYSTEM DESCRIPTION > [AUTOMATIC AIR CONDITIONER]

C

D E

F

G H

J

K L

M A

B

HAC

N

O P

Door ControlINFOID:0000000009463099

DOOR MOTOR CONTROL

• LCU (Local Control Unit) is built into e](/img/5/57390/w960_57390-2665.png)

SYSTEMHAC-17

< SYSTEM DESCRIPTION > [AUTOMATIC AIR CONDITIONER]

C

D E

F

G H

J

K L

M A

B

HAC

N

O P

Door ControlINFOID:0000000009463099

DOOR MOTOR CONTROL

• LCU (Local Control Unit) is built into each door moto r, and detects door position by PBR (Potentio Balance

Resistor).

• A/C auto amp. communicates with each LCU via communication line and receives each door position feed- back signal from each LCU.

• Each LCU controls each door to the appropriate posit ion depending on the control signal from A/C auto amp.

• Each LCU transmits the signal of door movement completion to A/C auto amp., when the door movement is completed.

SWITCHES AND THEIR CONTROL FUNCTION

ALIIA0602GB

JMIIA1778ZZ

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2675 of 4801

![NISSAN TEANA 2014 Service Manual

HAC-26

< SYSTEM DESCRIPTION >[AUTOMATIC AIR CONDITIONER]

DIAGNOSIS SYSTEM

(A/C AUTO AMP.)

WORK SUPPORT

NOTE:

When the battery cable is disconnected from the negative terminal or when the battery vo NISSAN TEANA 2014 Service Manual

HAC-26

< SYSTEM DESCRIPTION >[AUTOMATIC AIR CONDITIONER]

DIAGNOSIS SYSTEM

(A/C AUTO AMP.)

WORK SUPPORT

NOTE:

When the battery cable is disconnected from the negative terminal or when the battery vo](/img/5/57390/w960_57390-2674.png)

HAC-26

< SYSTEM DESCRIPTION >[AUTOMATIC AIR CONDITIONER]

DIAGNOSIS SYSTEM

(A/C AUTO AMP.)

WORK SUPPORT

NOTE:

When the battery cable is disconnected from the negative terminal or when the battery voltage becomes 10V or less, the setting of

WORK SUPPORT may be cancelled.

ACTIVE TEST

HVAC TEST

FAN REQ SIG [On/Off] Displays blower switch ON/OFF status transmitted to other units via CAN communica-

tion

FAN DUTY [%] Duty ratio of blower motor judged by A/C auto amp.

XM Target discharge air temperature judged by A/C auto amp. according to the tempera-

ture setting and the value from each sensor

PA TARGET A/TEMP Target discharge front air temperature (passenger side) judged by A/C auto amp. de-

pending on the temperature setting and the value from each sensor.

ENG COOL TEMP [ °C] Water temperature signal value received from ECM via CAN communication

VEHICLE SPEED [km/h

(mph)] Vehicle speed signal value received from meter via CAN communication

Monitor item [Unit] Description

Work item Description Reference

TEMP SET CORRECT

(Setting of difference between tem-

perature setting and control tempera-

ture) If the temperature felt by the customer is different than the airflow

temperature controlled by the temperature setting, the auto ampli-

fier control temperature can be adjusted to compensate for the

temperature setting. HAC-50, "Temperature

Setting Trimmer"

REC MEMORY SET

(REC memory function setting) • If the ignition switch is turned to the OFF position while the REC

switch is set to ON (recirculation), “With” or “Without” of the REC

switch ON (recirculation) condition can be selected.

• If “” was set, the REC switch will be ON (recirculation) when turn-

ing the ignition switch to the ON position again.

• If “Without” was set, the air inlets will be controlled automatically when turning the ignition switch to the ON position again. HAC-51, "Inlet Port

Memory Function (REC)"

FRE MEMORY SET

(FRE memory function setting) • If the ignition switch is turned to the OFF position while the FRE

switch is set to ON (fresh air intake), “With” or “” of the FRE

switch ON (fresh air intake) condition can be selected.

• If “With” was set, the FRE switch will be ON (fresh air intake) when turning the ignition switch to the ON position again.

• If “Without” was set, the air inlets will be controlled automatically when turning the ignition switch to the ON position again. HAC-50, "Inlet Port

Memory Function (FRE)"

BLOW SET

(Blow setting to DEF in FOOT mode) In the FOOT mode, the air blowing to the DEF can change ON/

OFF. HAC-50, "Foot Position

Setting Trimmer"

TARGET EVAPORATOR TEMP UP-

PER LIMIT SETTING Set the target evaporator upper temperature limit.

HAC-51, "Target Evapo-

rator Temp Upper Limit"

Test item Description

HVAC TEST The operation check of A/C system can be performed by selecting the mode. Refer to the fol-

lowing table for the conditions of each mode.

Te s t i t e m

MODE 1 MODE 2 MODE 3 MODE 4 MODE 5 MODE 6 MODE 7

Mode door position VENT VENT B/L D/F1 D/F2 DEF DEF

Intake door position REC REC 20%FRE FRE FRE FRE FRE

Air mix door position

(driver & passenger

side) FULL COLD FULL COLD FULL COLD FULL HOT FULL HOT FULL HOT FULL HOT

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2697 of 4801

![NISSAN TEANA 2014 Service Manual

HAC-48

< BASIC INSPECTION >[AUTOMATIC AIR CONDITIONER]

OPERATION INSPECTION

OPERATION INSPECTION

Work ProcedureINFOID:0000000009463110

DESCRIPTION

The purpose of the operational check is to che

ck th NISSAN TEANA 2014 Service Manual

HAC-48

< BASIC INSPECTION >[AUTOMATIC AIR CONDITIONER]

OPERATION INSPECTION

OPERATION INSPECTION

Work ProcedureINFOID:0000000009463110

DESCRIPTION

The purpose of the operational check is to che

ck th](/img/5/57390/w960_57390-2696.png)

HAC-48

< BASIC INSPECTION >[AUTOMATIC AIR CONDITIONER]

OPERATION INSPECTION

OPERATION INSPECTION

Work ProcedureINFOID:0000000009463110

DESCRIPTION

The purpose of the operational check is to che

ck that the individual system operates normally.

INSPECTION PROCEDURE

1.CHECK MEMORY FUNCTION

1. Start the engine.

2. Operate the temperature control switch (drive r side) and raise the temperature setting to 32°C (90 °F).

3. Press the OFF switch.

4. Turn the ignition switch OFF.

5. Turn the ignition switch ON.

6. Press the AUTO switch.

7. Check that the temperature setting, before turning the ignition switch OFF, is stored.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Check power and ground circuits for A/C auto amp. Refer to HAC-78, "A/C AUTO AMP. : Diagno-

sis Procedure".

2.CHECK BLOWER MOTOR SPEED

1. Operate the fan control dial. Check that the fan speed changes.

2. Check the operation for all fan speeds.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Check blower motor system. Refer to HAC-84, "Diagnosis Procedure"

.

3.CHECK DISCHARGE AIR (MODE SWITCH AND DEF SWITCH)

1. Press the MODE switch and the DEF switch.

2. Check that the air outlets change according to each i ndicated air outlet by placing a hand in front of the

outlets. Refer to HAC-13, "System Description"

.

NOTE:

Confirm that the A/C compressor clutch is engaged (sound or visual inspection) and intake door position is at

FRE ( ) when the D/F ( ) or DEF ( ) is selected.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Check mode door system. Refer to HAC-80, "MODE DOOR MOTOR : Diagnosis Procedure"

.

4.CHECK INTAKE AIR

1. Press the REC ( ) switch. Indicator is turned ON.

2. Press the FRE ( ) switch. Indicator is turned ON.

3. Listen for the intake door position change. (Slight change of blower sound can be heard.)

NOTE:

Confirm that the A/C compressor clutch is engaged (sound or visual inspection) and the FRE ( ) switch is

pressed when the D/F ( ) or DEF ( ) is selected.

Is the inspection result normal?

YES >> GO TO 5.

NO >> Check intake door system. Refer to HAC-81, "INTAKE DOOR MOTOR : Diagnosis Procedure"

.

5.CHECK A/C SWITCH

1. Press the A/C switch.

2. The A/C switch indicator is turned ON.

Confirm that the A/C compressor clutch engages (sound or visual inspection).

Is the inspection result normal?

Conditions : Engine running at normal operating temperature

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2704 of 4801

![NISSAN TEANA 2014 Service Manual

U1000 CAN COMM CIRCUITHAC-55

< DTC/CIRCUIT DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D E

F

G H

J

K L

M A

B

HAC

N

O P

DTC/CIRCUIT DIAGNOSIS

U1000 CAN COMM CIRCUIT

DescriptionINFOID:0000000009463121

NISSAN TEANA 2014 Service Manual

U1000 CAN COMM CIRCUITHAC-55

< DTC/CIRCUIT DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D E

F

G H

J

K L

M A

B

HAC

N

O P

DTC/CIRCUIT DIAGNOSIS

U1000 CAN COMM CIRCUIT

DescriptionINFOID:0000000009463121](/img/5/57390/w960_57390-2703.png)

U1000 CAN COMM CIRCUITHAC-55

< DTC/CIRCUIT DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D E

F

G H

J

K L

M A

B

HAC

N

O P

DTC/CIRCUIT DIAGNOSIS

U1000 CAN COMM CIRCUIT

DescriptionINFOID:0000000009463121

CAN (Controller Area Network) is a serial communication system for real time application. It is an on-vehicle

multiplex communication system with high data communication speed and excellent error detection ability.

Many electronic control units are equipped onto vehicl es, and each control unit shares information and links

with other control units during operation (not independent ). In CAN communication, control units are con-

nected with two communication lines (CAN-H line, CAN-L line) allowing a high rate of information transmission

with less wiring. Each control unit transmits/receives data but selectively reads required data only. Refer to

LAN-32, "CAN COMMUNICATION SYSTEM : CAN Communication Signal Chart"

.

DTC LogicINFOID:0000000009463122

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM SELF-DIAGNOSIS

With CONSULT

1. Turn ignition switch ON and wait for 2 seconds or more.

2. Using CONSULT, perform “SELF- DIAGNOSIS RESULTS” of HVAC.

3. Check if any DTC No. is displayed in the self-diagnosis results.

Is DTC detected?

YES >> Refer to HAC-55, "Diagnosis Procedure".

NO >> Refer to GI-43, "Intermittent Incident"

.

Diagnosis ProcedureINFOID:0000000009463123

1.CHECK CAN COMMUNICATION SYSTEM

Check CAN communication system. Refer to LAN-18, "Trouble Diagnosis Flow Chart"

.

>> Inspection End.

DTC Items

(CONSULT screen terms) DTC detection condition Possible cause

U1000 CAN COMM CIRCUIT When A/C auto amp. is not transmitting

or receiving CAN communication signal

for 2 or more seconds. CAN communication system

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM