NISSAN TEANA 2014 Service Manual

Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 3341 of 4801

PREPARATIONPB-3

< PREPARATION >

C

D E

G H

I

J

K L

M A

B

PB

N

O P

PREPARATION

PREPARATION

Commercial Service ToolINFOID:0000000009462911

Tool name Description

Brake drum clearance gauge Measuring rear rotor drum inner diameter

Power tool Loosening nuts, screws and bolts

WFIA0167E

PIIB1407E

Revision: November 20132014 Altima NAM

Page 3342 of 4801

PB-4

< BASIC INSPECTION >

PARKING BRAKE SYSTEM

BASIC INSPECTION

PARKING BRAKE SYSTEM

InspectionINFOID:0000000009462912

PEDAL STROKE

1. Operate parking brake pedal with a force of 196 N (20.0 kg-f, 44.1 lb-f), make sure pedal stroke is within

the specified number of notches. (Check it by listening and counting ratchet clicks.)

2. When brake warning lamp turns ON, check that the pedal stroke is within the specified number of notches. (Check it by listening to the clicks of the ratchet.)

INSPECT COMPONENTS

• Make sure that the mounting conditions (loosenes s, backlash, etc.) of each component are normal.

• Check the following:

- Device assembly for bend, damage and cracks. Replace if necessary.

- Cables and equalizer for wear and damage. Replace if necessary.

- Parking brake switch. Replace if necessary.

AdjustmentINFOID:0000000009462913

ADJUSTMENT

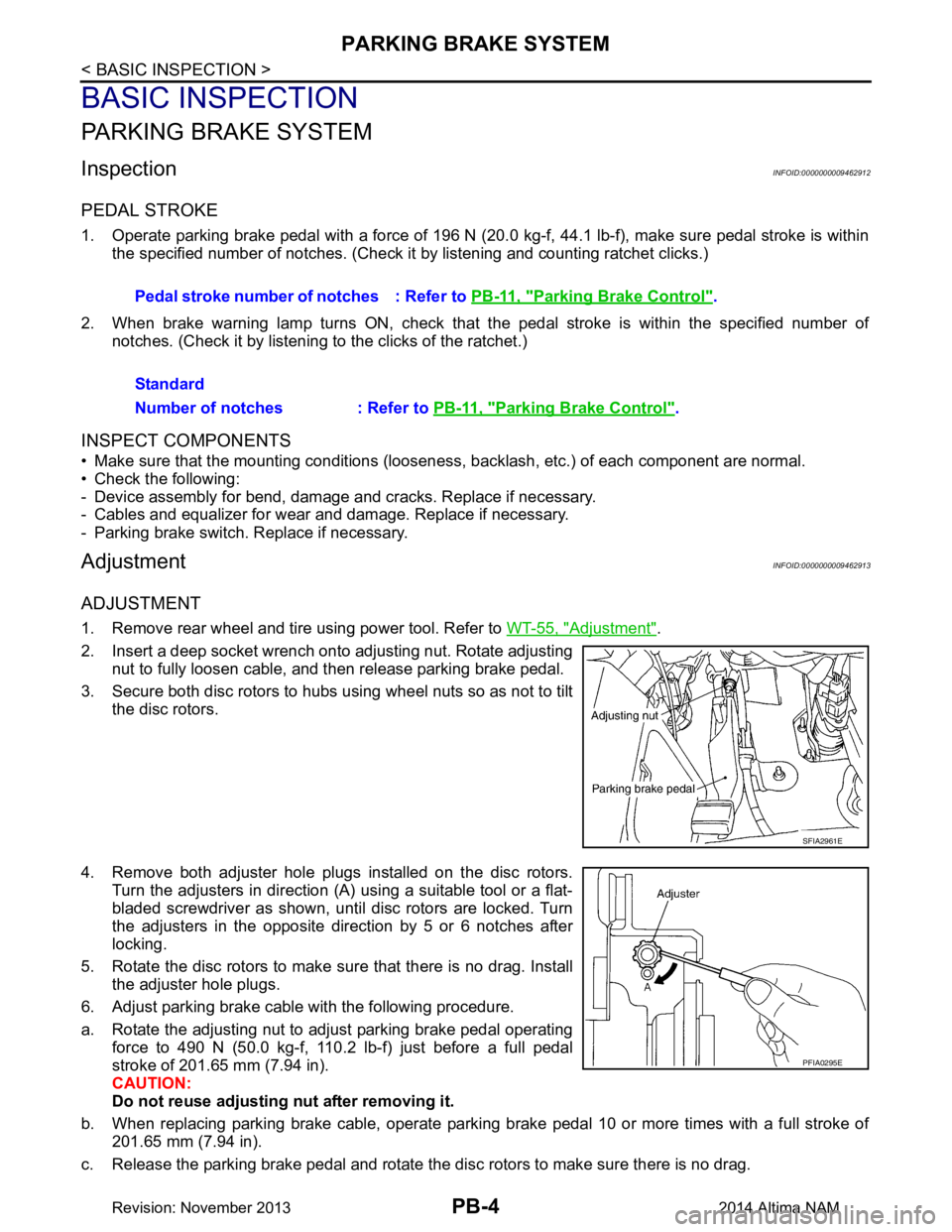

1. Remove rear wheel and tire using power tool. Refer to WT-55, "Adjustment".

2. Insert a deep socket wrench onto adjusting nut. Rotate adjusting nut to fully loosen cable, and then release parking brake pedal.

3. Secure both disc rotors to hubs using wheel nuts so as not to tilt the disc rotors.

4. Remove both adjuster hole plugs installed on the disc rotors. Turn the adjusters in direction (A) using a suitable tool or a flat-

bladed screwdriver as shown, until disc rotors are locked. Turn

the adjusters in the opposite direction by 5 or 6 notches after

locking.

5. Rotate the disc rotors to make sure that there is no drag. Install the adjuster hole plugs.

6. Adjust parking brake cable with the following procedure.

a. Rotate the adjusting nut to adjust parking brake pedal operating force to 490 N (50.0 kg-f, 110.2 lb-f) just before a full pedal

stroke of 201.65 mm (7.94 in).

CAUTION:

Do not reuse adjusting nut after removing it.

b. When replacing parking brake cable, operate parking brake pedal 10 or more times with a full stroke of 201.65 mm (7.94 in).

c. Release the parking brake pedal and rotate the disc rotors to make sure there is no drag. Pedal stroke number of notches : Refer to

PB-11, "Parking Brake Control"

.

Standard

Number of notches : Refer to PB-11, "Parking Brake Control"

.

SFIA2961E

PFIA0295E

Revision: November 20132014 Altima NAM

Page 3343 of 4801

PARKING BRAKE SYSTEMPB-5

< BASIC INSPECTION >

C

D E

G H

I

J

K L

M A

B

PB

N

O P

d. Rotate the adjusting nut to adjust the parking brak e pedal force to 196 N (20.0 kg-f, 44.1 lb-f) when the

parking brake pedal stroke is within the specified number of notches. (check it by listening and counting

the ratchet clicks).

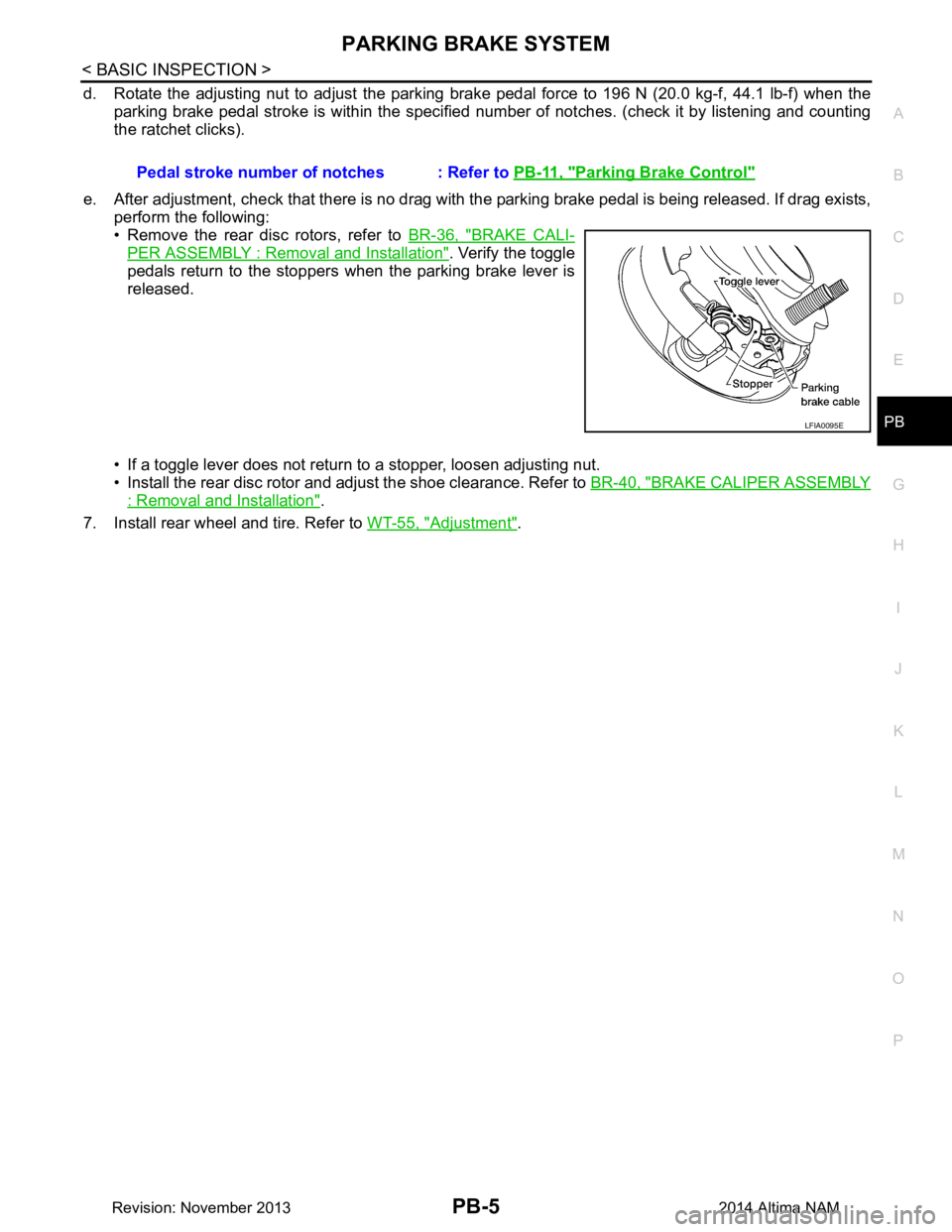

e. After adjustment, check that there is no drag with the parking brake pedal is being released. If drag exists,

perform the following:

• Remove the rear disc rotors, refer to BR-36, "BRAKE CALI-

PER ASSEMBLY : Removal and Installation". Verify the toggle

pedals return to the stoppers when the parking brake lever is

released.

• If a toggle lever does not return to a stopper, loosen adjusting nut.

• Install the rear disc rotor and adjust the shoe clearance. Refer to BR-40, "BRAKE CALIPER ASSEMBLY

: Removal and Installation".

7. Install rear wheel and tire. Refer to WT-55, "Adjustment"

.

Pedal stroke number of notches : Refer to

PB-11, "Parking Brake Control"

LFIA0095E

Revision: November 20132014 Altima NAM

Page 3344 of 4801

PB-6

< BASIC INSPECTION >

PARKING BRAKE SHOE

PARKING BRAKE SHOE

InspectionINFOID:0000000009462914

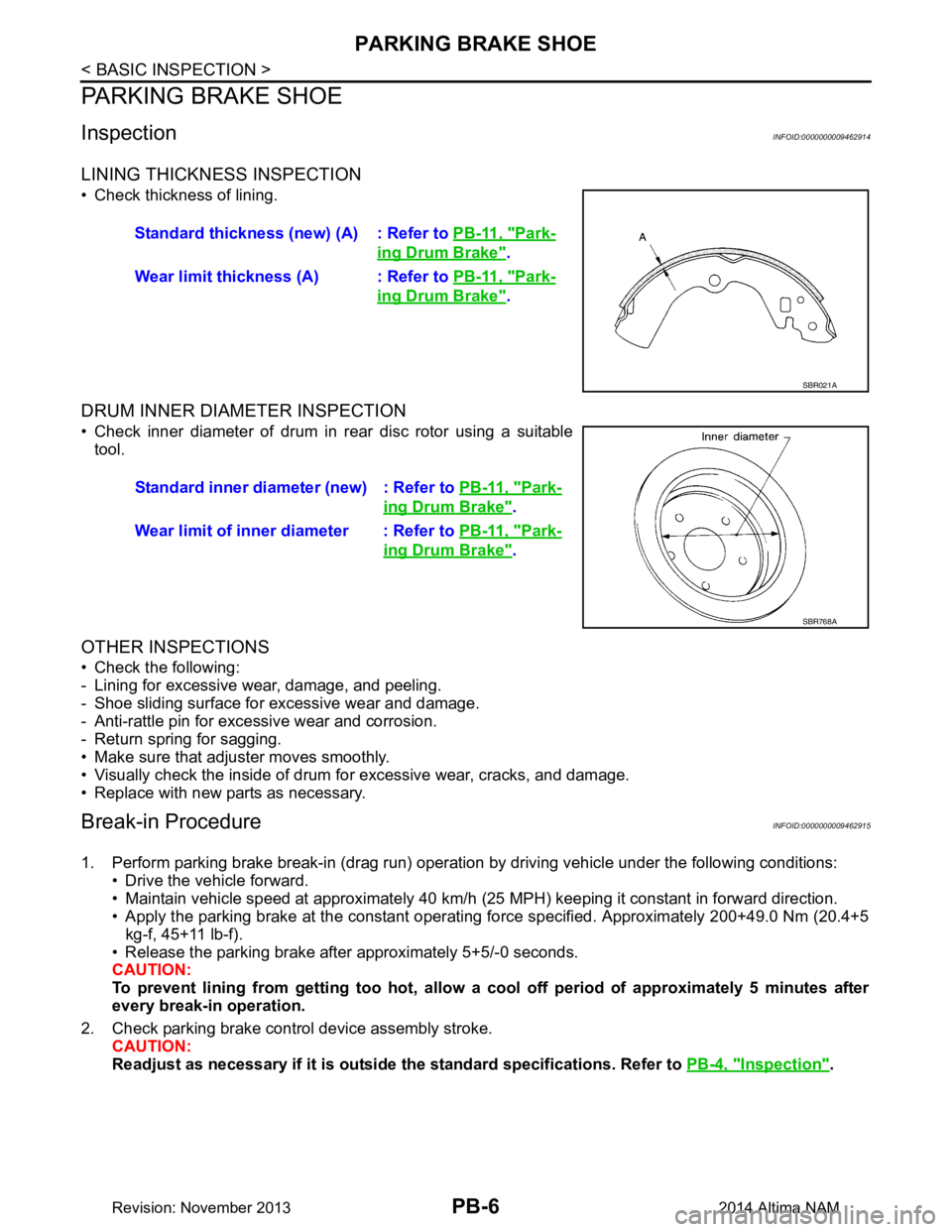

LINING THICKNESS INSPECTION

• Check thickness of lining.

DRUM INNER DIAMETER INSPECTION

• Check inner diameter of drum in rear disc rotor using a suitabletool.

OTHER INSPECTIONS

• Check the following:

- Lining for excessive wear, damage, and peeling.

- Shoe sliding surface for excessive wear and damage.

- Anti-rattle pin for excessive wear and corrosion.

- Return spring for sagging.

• Make sure that adjuster moves smoothly.

• Visually check the inside of drum for excessive wear, cracks, and damage.

• Replace with new parts as necessary.

Break-in ProcedureINFOID:0000000009462915

1. Perform parking brake break-in (drag run) operation by driving vehicle under the following conditions: • Drive the vehicle forward.

• Maintain vehicle speed at approximately 40 km/h (25 MPH) keeping it constant in forward direction.

• Apply the parking brake at the constant operating force specified. Approximately 200+49.0 Nm (20.4+5

kg-f, 45+11 lb-f).

• Release the parking brake after approximately 5+5/-0 seconds.

CAUTION:

To prevent lining from getting t oo hot, allow a cool off period of approximately 5 minutes after

every break-in operation.

2. Check parking brake control device assembly stroke. CAUTION:

Readjust as necessary if it is outside the standard specifications. Refer to PB-4, "Inspection"

.

Standard thickness (new) (A) : Refer to

PB-11, "Park-

ing Drum Brake".

Wear limit thickness (A) : Refer to PB-11, "Park-

ing Drum Brake".

SBR021A

Standard inner diameter (new) : Refer to PB-11, "Park-

ing Drum Brake".

Wear limit of inner diameter : Refer to PB-11, "Park-

ing Drum Brake".

SBR768A

Revision: November 20132014 Altima NAM

Page 3345 of 4801

PARKING BRAKE CONTROLPB-7

< REMOVAL AND INSTALLATION >

C

D E

G H

I

J

K L

M A

B

PB

N

O P

REMOVAL AND INSTALLATION

PARKING BRAKE CONTROL

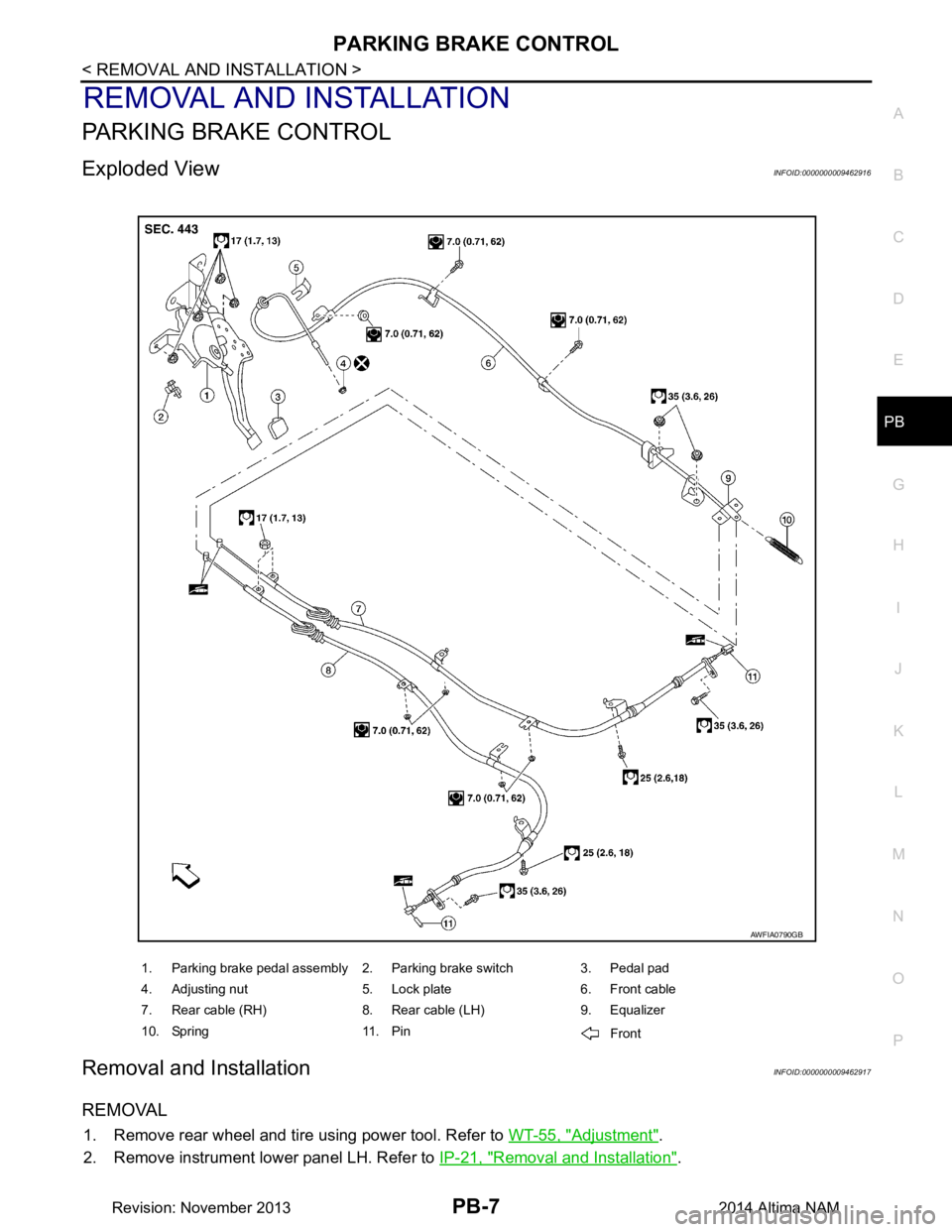

Exploded ViewINFOID:0000000009462916

Removal and InstallationINFOID:0000000009462917

REMOVAL

1. Remove rear wheel and tire using power tool. Refer to WT-55, "Adjustment".

2. Remove instrument lower panel LH. Refer to IP-21, "Removal and Installation"

.

1. Parking brake pedal assembly 2. Parking brake switch 3. Pedal pad

4. Adjusting nut 5. Lock plate 6. Front cable

7. Rear cable (RH) 8. Rear cable (LH) 9. Equalizer

10. Spring 11. Pin Front

AWFIA0790GB

Revision: November 20132014 Altima NAM

Page 3346 of 4801

PB-8

< REMOVAL AND INSTALLATION >

PARKING BRAKE CONTROL

3. Disconnect the harness connector from the parking brake switch and remove parking brake switch.

4. Remove adjusting nut and discard, then loosen front cable. CAUTION:

Do not reuse adjusting nut.

5. Disconnect front cable.

6. Remove parking brake pedal assembly nuts and remove parking brake pedal assembly.

7. Remove ITS control unit. Refer to AV-436, "Removal and Installation"

.

8. Remove spring and separate rear cables (LH/ RH) from front cable, remove front cable.

9. Remove rear brake caliper and disc brake rotor. Refer to BR-40, "BRAKE CALIPER ASSEMBLY :

Removal and Installation".

10. Remove parking brake shoe, and remove r ear cable from toggle lever. Refer to IP-14, "Exploded View"

.

11. Remove rear cable bolts and nuts, then remove rear cables.

INSTALLATION

Installation is in the reverse order of removal.

• Adjust the parking brake with new adjusting nut. Refer to WT-55, "Adjustment"

.

CAUTION:

• Do not reuse adjusting nut.

• The cables should be free from twists, damage, cracks or corrosion.

Revision: November 20132014 Altima NAM

Page 3347 of 4801

PARKING BRAKE SHOEPB-9

< REMOVAL AND INSTALLATION >

C

D E

G H

I

J

K L

M A

B

PB

N

O P

PARKING BRAKE SHOE

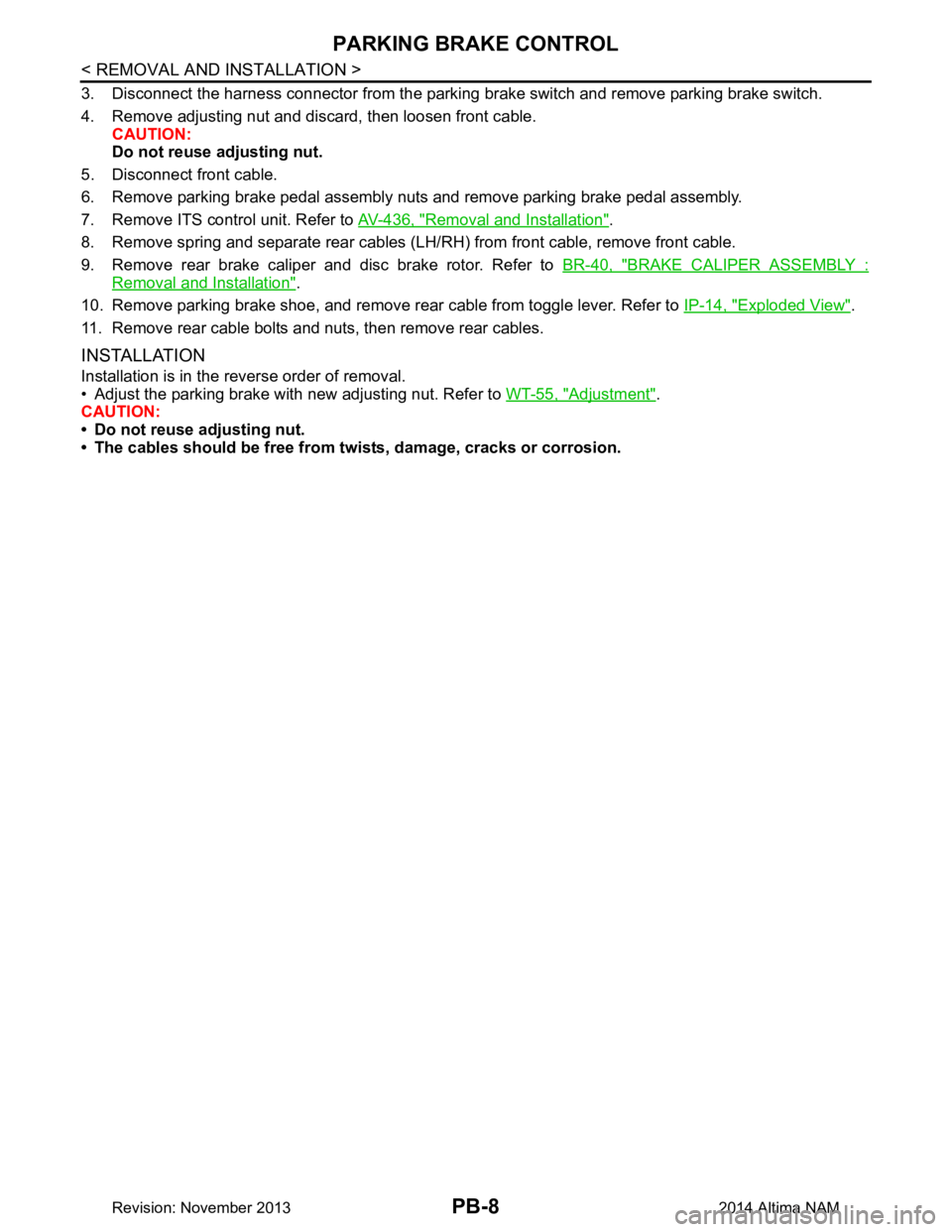

Exploded ViewINFOID:0000000009462918

Removal and InstallationINFOID:0000000009462919

WARNING:

• Clean brakes with a vacuum dust co llector to minimize the hazard of air borne particles or other

materials.

• Clean dust on disc brake rotor and back plate usin g a vacuum dust collector. Do not blow with com-

pressed air.

CAUTION:

Put matching marks on both disc brake rotor and wheel hub when removing disc rotor.

REMOVAL

1. Remove rear wheel and tire using power tool. Refer to WT-55, "Adjustment".

2. Remove rear brake caliper and disc brake rotor. Refer to BR-40, "BRAKE CALIPER ASSEMBLY :

Removal and Installation".

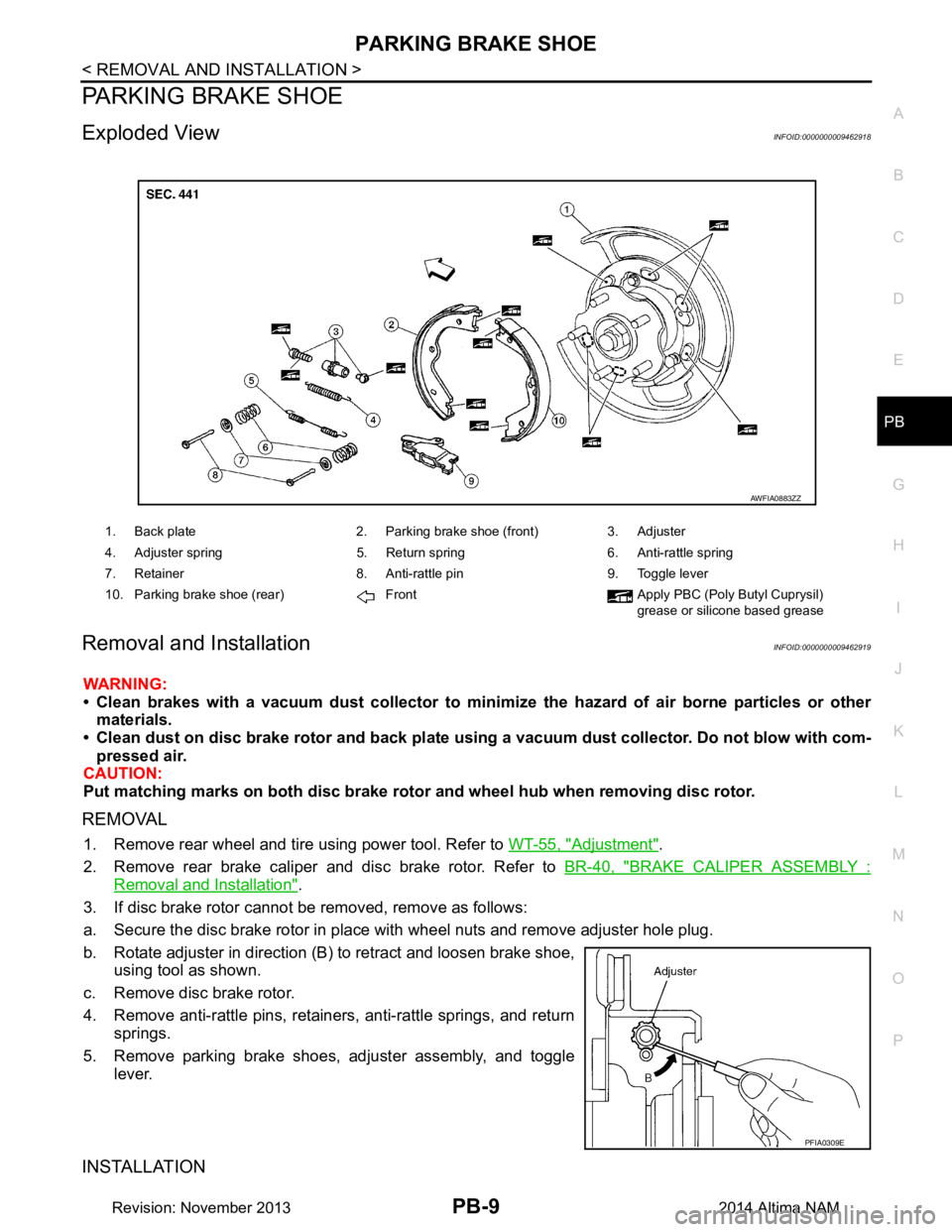

3. If disc brake rotor cannot be removed, remove as follows:

a. Secure the disc brake rotor in place with wheel nuts and remove adjuster hole plug.

b. Rotate adjuster in direction (B) to retract and loosen brake shoe, using tool as shown.

c. Remove disc brake rotor.

4. Remove anti-rattle pins, retainers, anti-rattle springs, and return springs.

5. Remove parking brake shoes, adjuster assembly, and toggle lever.

INSTALLATION

1. Back plate 2. Parking brake shoe (front) 3. Adjuster

4. Adjuster spring 5. Return spring 6. Anti-rattle spring

7. Retainer 8. Anti-rattle pin 9. Toggle lever

10. Parking brake shoe (rear) Front Apply PBC (Poly Butyl Cuprysil) grease or silicone based grease

AWFIA0883ZZ

PFIA0309E

Revision: November 20132014 Altima NAM

Page 3348 of 4801

PB-10

< REMOVAL AND INSTALLATION >

PARKING BRAKE SHOE

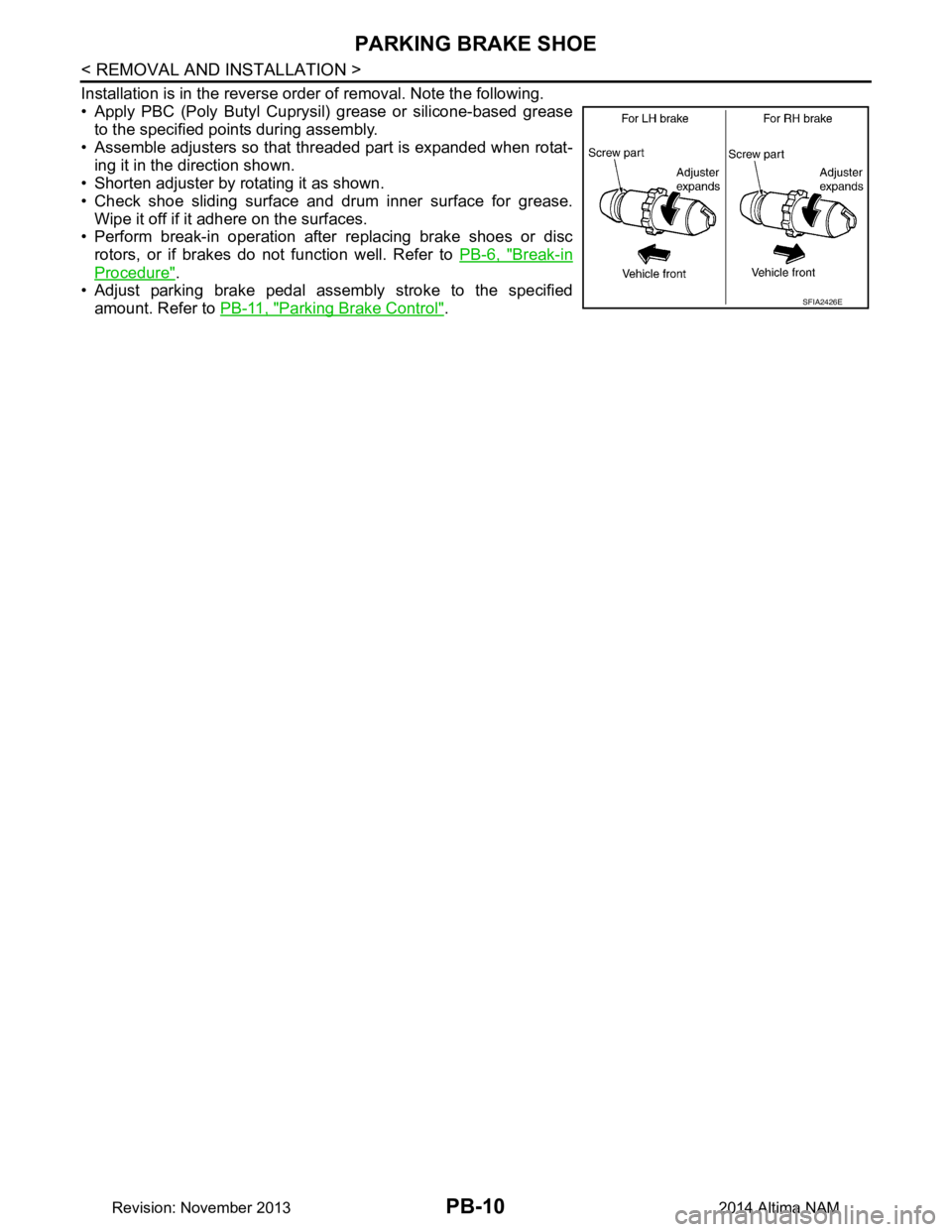

Installation is in the reverse order of removal. Note the following.

• Apply PBC (Poly Butyl Cuprysil) grease or silicone-based grease to the specified points during assembly.

• Assemble adjusters so that threaded part is expanded when rotat-

ing it in the direction shown.

• Shorten adjuster by rotating it as shown.

• Check shoe sliding surface and drum inner surface for grease. Wipe it off if it adhere on the surfaces.

• Perform break-in operation after replacing brake shoes or disc

rotors, or if brakes do not function well. Refer to PB-6, "Break-in

Procedure".

• Adjust parking brake pedal assembly stroke to the specified amount. Refer to PB-11, "Parking Brake Control"

.SFIA2426E

Revision: November 20132014 Altima NAM

Page 3349 of 4801

SERVICE DATA AND SPECIFICATIONS (SDS)PB-11

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

D E

G H

I

J

K L

M A

B

PB

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

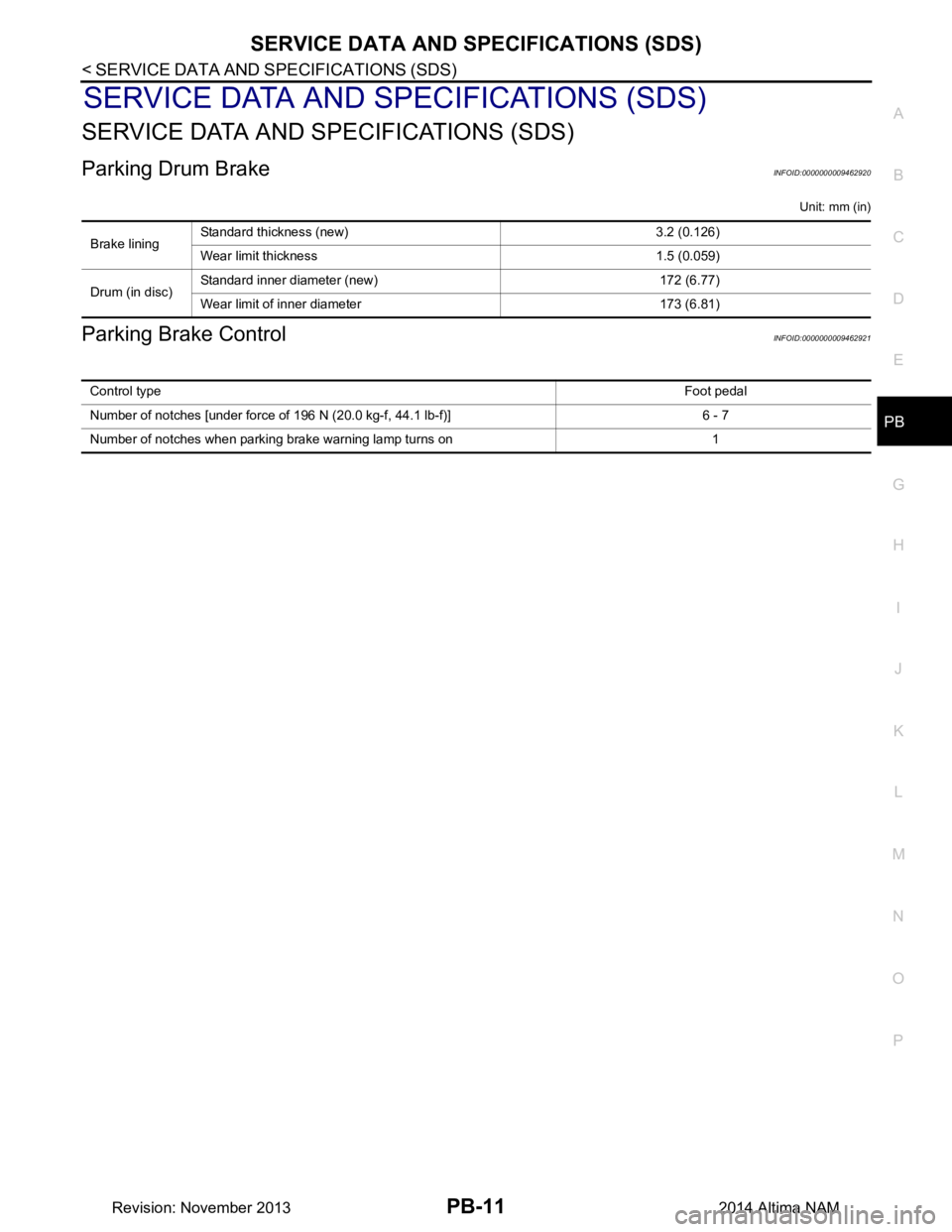

Parking Drum BrakeINFOID:0000000009462920

Unit: mm (in)

Parking Brake ControlINFOID:0000000009462921

Brake lining Standard thickness (new) 3.2 (0.126)

Wear limit thickness 1.5 (0.059)

Drum (in disc) Standard inner diameter (new) 172 (6.77)

Wear limit of inner diameter 173 (6.81)

Control type Foot pedal

Number of notches [under force of 196 N (20.0 kg-f, 44.1 lb-f)] 6 - 7

Number of notches when parking brake warning lamp turns on 1

Revision: November 20132014 Altima NAM

Page 3350 of 4801

PCS

PCS-1

ELECTRICAL & POWER CONTROL

C

D E

F

G H

I

J

K L

B

SECTION PCS

A

O P

N

CONTENTS

POWER CONTROL SYSTEM

IPDM E/R

PRECAUTION ................ ...............................

3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution for Procedure without Cowl Top Cover ......3

SYSTEM DESCRIPTION ..............................4

COMPONENT PARTS ................................... .....4

Component Parts Location .................................. ......4

SYSTEM ..............................................................5

RELAY CONTROL SYSTEM ................................ ......5

RELAY CONTROL SYSTEM : System Diagram ......5

RELAY CONTROL SYSTEM : System Descrip-

tion ...................................................................... ......

6

POWER CONSUMPTION CONTROL SYSTEM ... ......6

POWER CONSUMPTION CONTROL SYSTEM :

System Diagram .................................................. ......

7

POWER CONSUMPTION CONTROL SYSTEM :

System Description ............................................. ......

7

DIAGNOSIS SYSTEM (IPDM E/R) ......................8

Diagnosis Description ......................................... ......8

CONSULT Function (IPDM E/R) ...............................9

ECU DIAGNOSIS INFORMATION ..............12

IPDM E/R (INTELLIGENT POWER DISTRI-

BUTION MODULE ENGINE ROOM) ............. ....

12

Reference Value ................................................. ....12

Fail Safe .................................................................19

DTC Index ..............................................................20

WIRING DIAGRAM ......................................21

IPDM E/R (INTELLIGENT POWER DISTRI-

BUTION MODULE ENGINE ROOM) ................

21

Wiring Diagram .................................................... ....21

DTC/CIRCUIT DIAGNOSIS .........................27

U1000 CAN COMM CIRCUIT ...........................27

Description ........................................................... ....27

DTC Logic ................................................................27

Diagnosis Procedure ...............................................27

U1010 CONTROL UNIT (CAN) .........................28

DTC Logic ................................................................28

Diagnosis Procedure ...............................................28

B2098 IGNITION RELAY ON STUCK ..............29

DTC Logic ................................................................29

Diagnosis Procedure ...............................................29

B2099 IGNITION RELAY OFF STUCK ............30

DTC Logic ................................................................30

Diagnosis Procedure ...............................................30

POWER SUPPLY AND GROUND CIRCUIT ....31

Diagnosis Procedure ...............................................31

REMOVAL AND INSTALLATION ...............32

IPDM E/R (INTELLIGENT POWER DISTRI-

BUTION MODULE ENGINE ROOM) ................

32

Removal and Installation ..................................... ....32

POWER DISTRIBUTION SYSTEM

PRECAUTION ...... ........................................

33

PRECAUTIONS .................................................33

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ....

33

Precaution for Work .................................................33

PREPARATION ...........................................34

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM