ECU NISSAN TEANA 2014 Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 113 of 4801

REAR DISC BRAKEBR-17

< PERIODIC MAINTENANCE >

C

D E

G H

I

J

K L

M A

B

BR

N

O P

REAR DISC BRAKE

Brake BurnishingINFOID:0000000009463695

CAUTION:

• Burnish contact surfaces between brake pads and disc brake rotor according to the following proce-

dure after refinishing the disc brake rotor, replacing brake pads or if a soft pedal occurs at very low

mileage.

• Be careful of vehicle speed. Br akes do not operate firmly/securely until pads and disc rotor are

securely seated.

• Only perform this procedure under safe road and traffic conditions. Use extreme caution.

1. Drive the vehicle on straight, flat road.

2. Depress the brake pedal until the vehicle stops.

3. Release the brake pedal for a few minutes to allow the brake components to cool.

4. Repeat steps 1 to 3 until pad and disc rotor are securely seated.

Revision: November 20132014 Altima NAM

Page 119 of 4801

BRAKE PIPINGBR-23

< REMOVAL AND INSTALLATION >

C

D E

G H

I

J

K L

M A

B

BR

N

O P

3. Connect brake hose (1) to brake tube (2). Tighten flare nut (A) to specification and secure to the bracket with lock plate (3).

4. Using a suitable tool, tighten flare nut to the specified torque. Refer to BR-20, "FRONT : Exploded View"

.

5. Refill brake fluid and bleed air. Refer to BR-14, "Bleeding Brake

System".

6. Install the wheel and tire. Refer to WT-60, "Road Wheel"

.

REAR

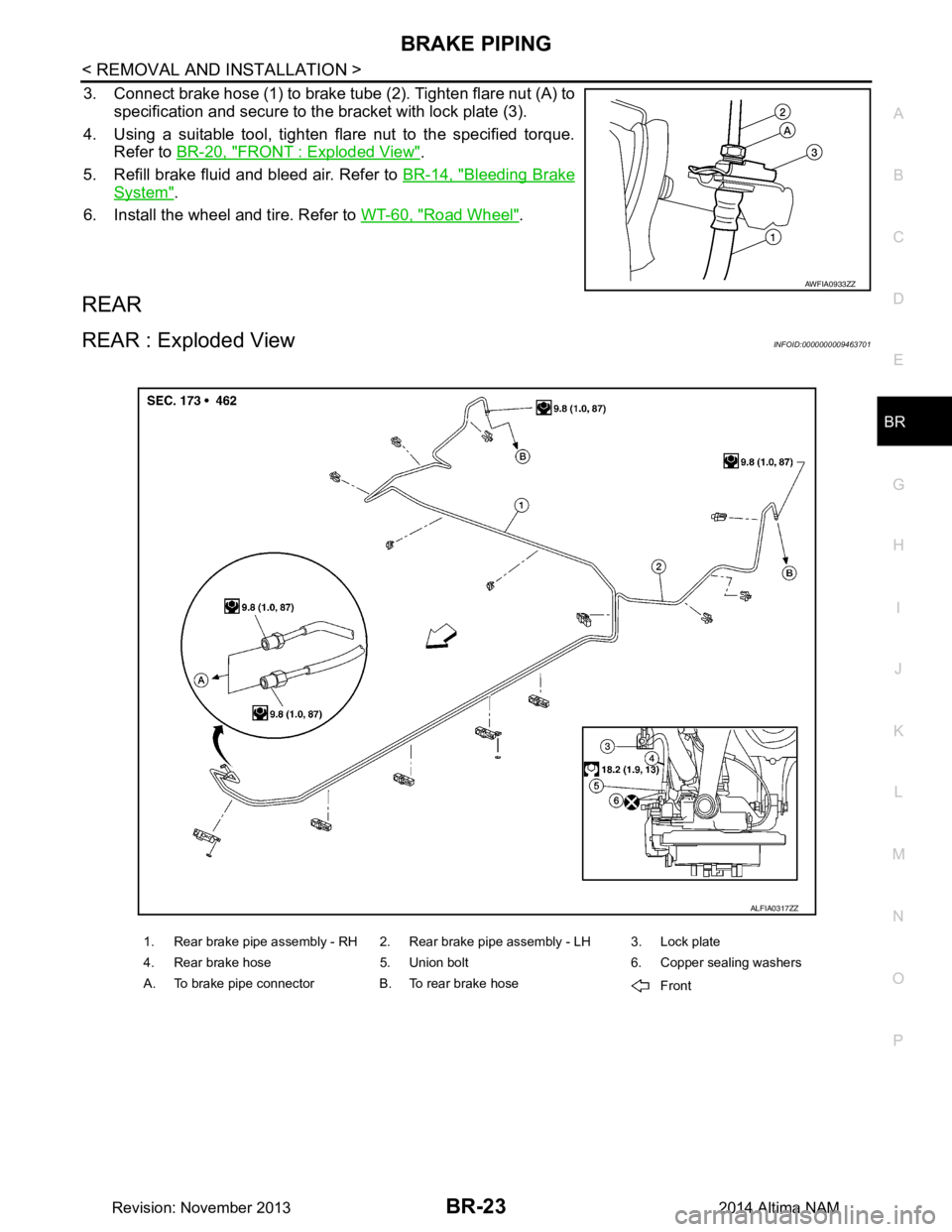

REAR : Exploded ViewINFOID:0000000009463701

AWFIA0933ZZ

1. Rear brake pipe assembly - RH 2. Rear brake pipe assembly - LH 3. Lock plate

4. Rear brake hose 5. Union bolt 6. Copper sealing washers

A. To brake pipe connector B. To rear brake hose Front

ALFIA0317ZZ

Revision: November 20132014 Altima NAM

Page 121 of 4801

BRAKE PIPINGBR-25

< REMOVAL AND INSTALLATION >

C

D E

G H

I

J

K L

M A

B

BR

N

O P

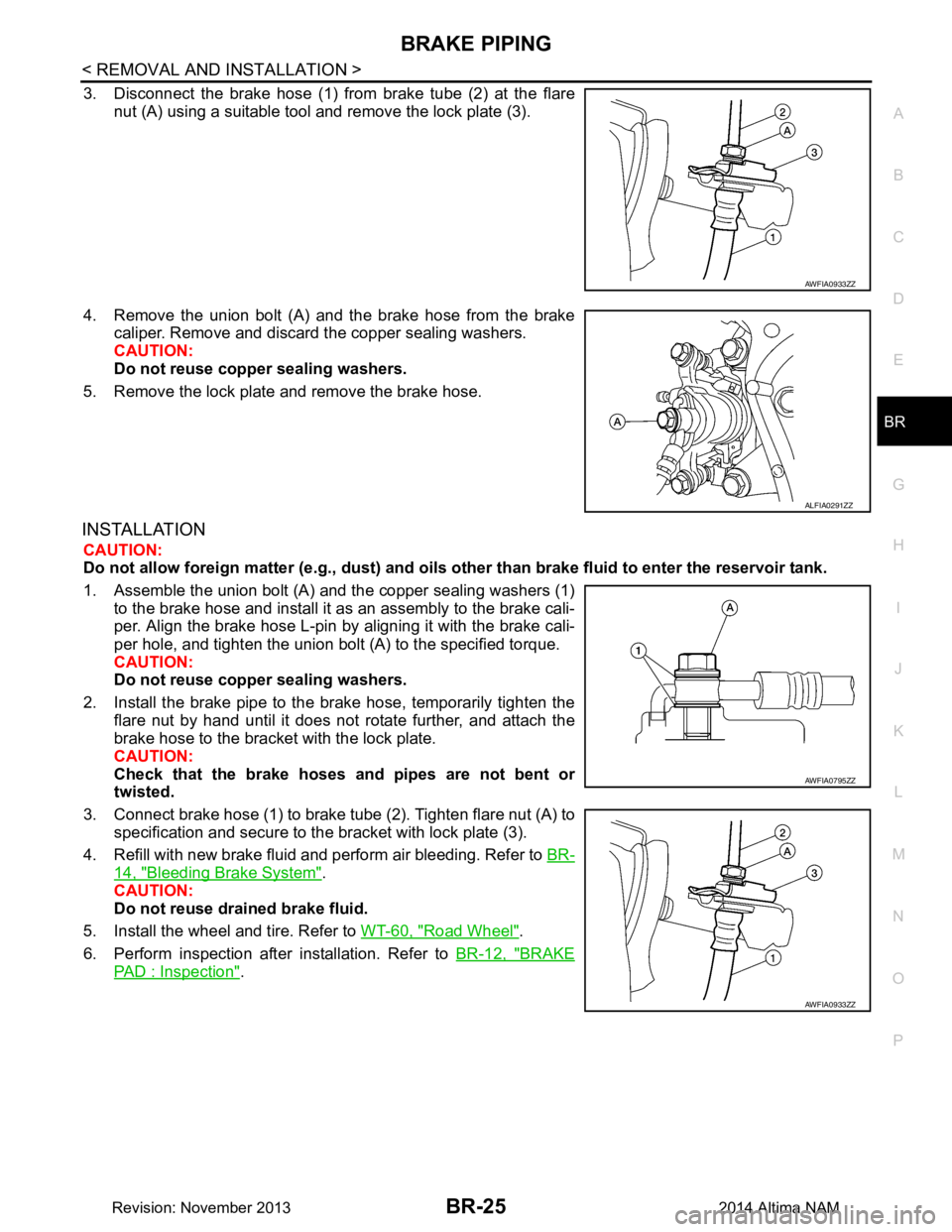

3. Disconnect the brake hose (1) from brake tube (2) at the flare nut (A) using a suitable tool and remove the lock plate (3).

4. Remove the union bolt (A) and the brake hose from the brake caliper. Remove and discard the copper sealing washers.

CAUTION:

Do not reuse copper sealing washers.

5. Remove the lock plate and remove the brake hose.

INSTALLATION

CAUTION:

Do not allow foreign matte r (e.g., dust) and oils other than brake fluid to enter the reservoir tank.

1. Assemble the union bolt (A) and the copper sealing washers (1) to the brake hose and install it as an assembly to the brake cali-

per. Align the brake hose L-pin by aligning it with the brake cali-

per hole, and tighten the union bolt (A) to the specified torque.

CAUTION:

Do not reuse copper sealing washers.

2. Install the brake pipe to the brake hose, temporarily tighten the flare nut by hand until it does not rotate further, and attach the

brake hose to the bracket with the lock plate.

CAUTION:

Check that the brake hoses and pipes are not bent or

twisted.

3. Connect brake hose (1) to brake tube (2). Tighten flare nut (A) to specification and secure to the bracket with lock plate (3).

4. Refill with new brake fluid and perform air bleeding. Refer to BR-

14, "Bleeding Brake System".

CAUTION:

Do not reuse drained brake fluid.

5. Install the wheel and tire. Refer to WT-60, "Road Wheel"

.

6. Perform inspection after installation. Refer to BR-12, "BRAKE

PAD : Inspection".

AWFIA0933ZZ

ALFIA0291ZZ

AWFIA0795ZZ

AWFIA0933ZZ

Revision: November 20132014 Altima NAM

Page 139 of 4801

FRONT DISC BRAKEBR-43

< UNIT DISASSEMBLY AND ASSEMBLY >

C

D E

G H

I

J

K L

M A

B

BR

N

O P

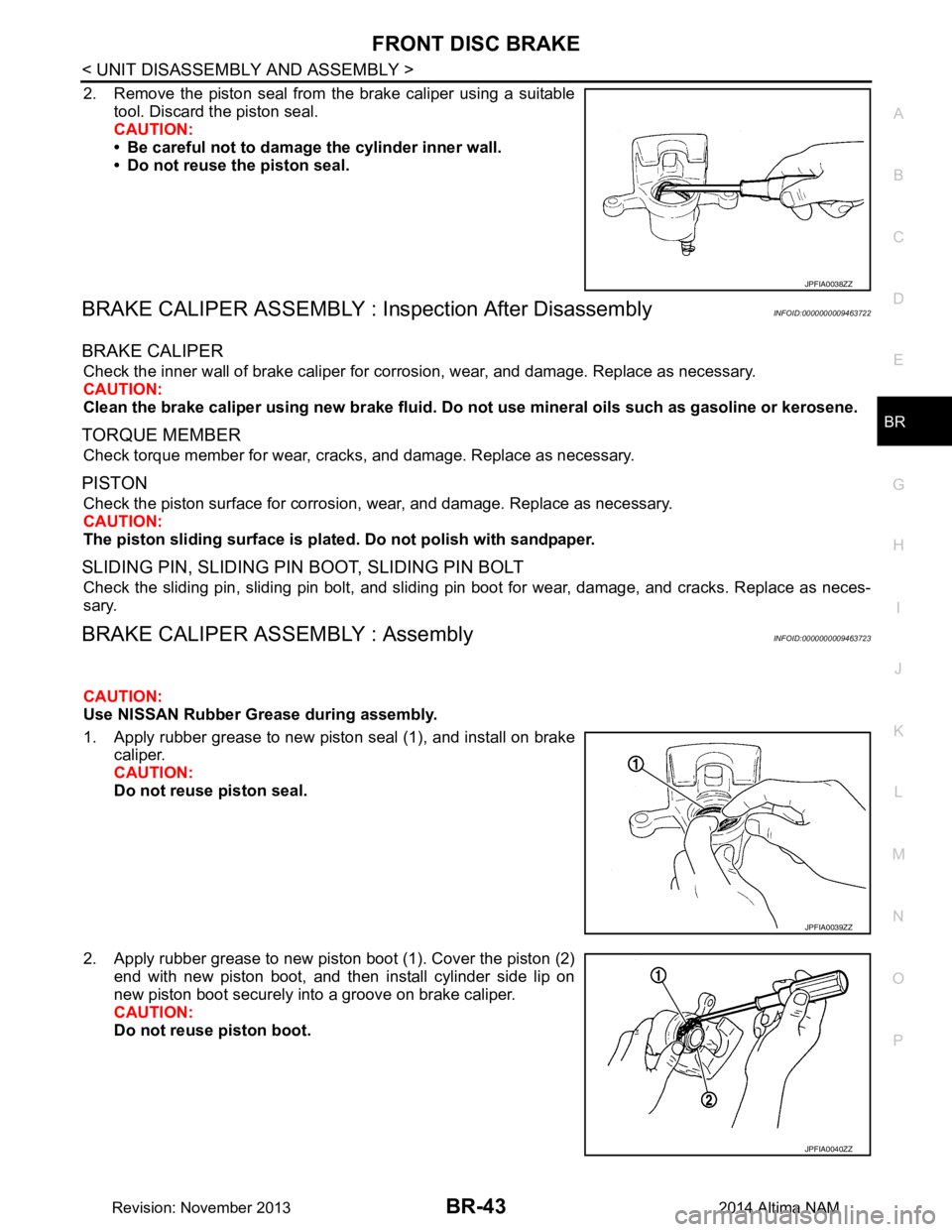

2. Remove the piston seal from the brake caliper using a suitable tool. Discard the piston seal.

CAUTION:

• Be careful not to damage the cylinder inner wall.

• Do not reuse the piston seal.

BRAKE CALIPER ASSEMBLY : In spection After DisassemblyINFOID:0000000009463722

BRAKE CALIPER

Check the inner wall of brake caliper for co rrosion, wear, and damage. Replace as necessary.

CAUTION:

Clean the brake caliper using new br ake fluid. Do not use mineral oils such as gasoline or kerosene.

TORQUE MEMBER

Check torque member for wear, cracks, and damage. Replace as necessary.

PISTON

Check the piston surface for corrosion, wear, and damage. Replace as necessary.

CAUTION:

The piston sliding surface is plated . Do not polish with sandpaper.

SLIDING PIN, SLIDING PIN BOOT, SLIDING PIN BOLT

Check the sliding pin, sliding pin bolt, and sliding pin boot for wear, damage, and cracks. Replace as neces-

sary.

BRAKE CALIPER ASSEMBLY : AssemblyINFOID:0000000009463723

CAUTION:

Use NISSAN Rubber Grease during assembly.

1. Apply rubber grease to new piston seal (1), and install on brake caliper.

CAUTION:

Do not reuse piston seal.

2. Apply rubber grease to new piston boot (1). Cover the piston (2) end with new piston boot, and then install cylinder side lip on

new piston boot securely into a groove on brake caliper.

CAUTION:

Do not reuse piston boot.

JPFIA0038ZZ

JPFIA0039ZZ

JPFIA0040ZZ

Revision: November 20132014 Altima NAM

Page 143 of 4801

REAR DISC BRAKEBR-47

< UNIT DISASSEMBLY AND ASSEMBLY >

C

D E

G H

I

J

K L

M A

B

BR

N

O P

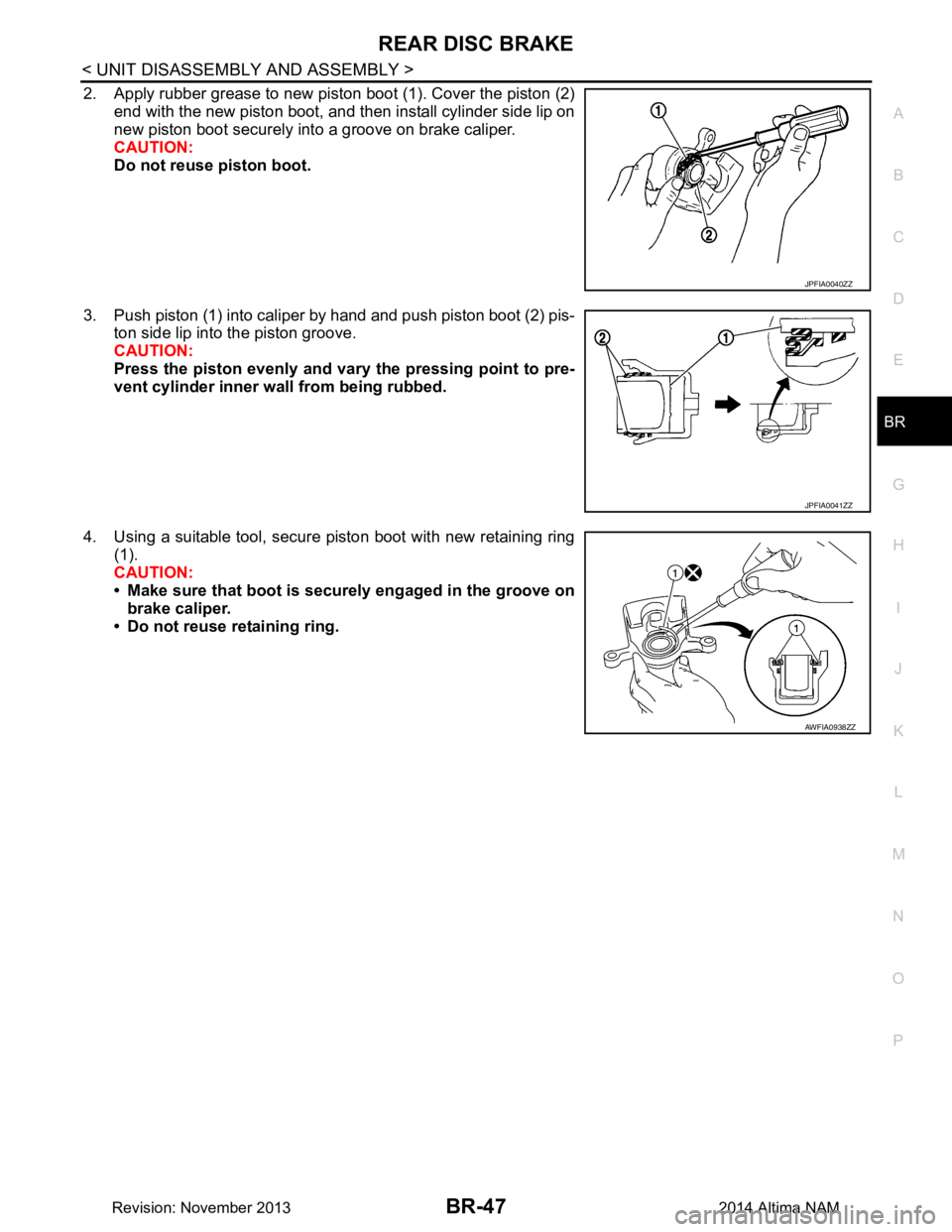

2. Apply rubber grease to new piston boot (1). Cover the piston (2) end with the new piston boot, and then install cylinder side lip on

new piston boot securely into a groove on brake caliper.

CAUTION:

Do not reuse piston boot.

3. Push piston (1) into caliper by hand and push piston boot (2) pis- ton side lip into the piston groove.

CAUTION:

Press the piston evenly and var y the pressing point to pre-

vent cylinder inner wall from being rubbed.

4. Using a suitable tool, secure piston boot with new retaining ring (1).

CAUTION:

• Make sure that boot is securely engaged in the groove on

brake caliper.

• Do not reuse retaining ring.

JPFIA0040ZZ

JPFIA0041ZZ

AWFIA0938ZZ

Revision: November 20132014 Altima NAM

Page 147 of 4801

BRC-1

BRAKES

C

D E

G H

I

J

K L

M

SECTION BRC

A

B

BRC

N

O P

CONTENTS

BRAKE CONTROL SYSTEM

VDC/TCS/ABS

PRECAUTION ................ ...............................

4

PRECAUTIONS .............................................. .....4

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

4

Precaution for Brake System ....................................4

Precaution for Brake Control .....................................5

Precaution for CAN System ................................ ......5

Precaution for Work ..................................................6

PREPARATION ............................................7

PREPARATION .............................................. .....7

Special Service Tool ........................................... ......7

Commercial Service Tool ..........................................7

SYSTEM DESCRIPTION ..............................8

COMPONENT PARTS ................................... .....8

Component Parts Location .................................. ......8

Component Description .............................................9

ABS Actuator and Electric Unit (Control Unit) ...........9

Wheel Sensor and Sensor Rotor ............................10

Stop Lamp Switch ...................................................10

Steering Angle Sensor ............................................10

Brake Fluid Level Switch .........................................10

Vacuum Sensor .......................................................10

Parking Brake Switch ..............................................11

VDC OFF Switch .....................................................11

SYSTEM .............................................................12

VDC/TCS/ABS ....................................................... ....12

VDC/TCS/ABS : System Diagram ...........................12

VDC/TCS/ABS : System De scription ......................12

VDC/TCS/ABS : VDC Functi on ...............................23

VDC/TCS/ABS : TCS Functi on ...............................25

VDC/TCS/ABS : ABS Function ........................... ....27

VDC/TCS/ABS : EBD Functi on ...............................28

VDC/TCS/ABS : Fail-safe ... .....................................29

DIAGNOSIS SYSTEM [ABS ACTUATOR

AND ELECTRIC UNIT (CONTROL UNIT)] .......

33

CONSULT Function (ABS) .................................. ....33

ECU DIAGNOSIS INFORMATION ..............38

ABS ACTUATOR AND ELECTRIC UNIT

(CONTROL UNIT) .............................................

38

Reference Value .................................................. ....38

Fail-safe ...................................................................41

DTC Inspection Priority Chart ..................................44

DTC Index ...............................................................45

WIRING DIAGRAM ......................................47

BRAKE CONTROL SYSTEM ...........................47

Wiring Diagram .................................................... ....47

BASIC INSPECTION ...................................55

DIAGNOSIS AND REPAIR WORK FLOW .......55

Work Flow ............................................................ ....55

Diagnostic Work Sheet ............................................56

ADDITIONAL SERVICE WHEN REPLACING

ABS ACTUATOR AND ELECTRIC UNIT

(CONTROL UNIT) .............................................

57

Description ........................................................... ....57

ADJUSTMENT OF STEERING ANGLE SEN-

SOR NEUTRAL POSITION ...............................

58

Description ........................................................... ....58

Work Procedure .......................................................58

CONFIGURATION [ABS ACTUATOR AND

ELECTRIC UNIT (CONTROL UNIT)] ................

60

Work Procedure ................................................... ....60

CALIBRATION OF DECEL G SENSOR ...........62

Description ...............................................................62

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 152 of 4801

![NISSAN TEANA 2014 Workshop Manual

BRC-6

< PRECAUTION >[VDC/TCS/ABS]

PRECAUTIONS

• Do not make a bypass connection to repaired area. (If the circuit is

bypassed, characteristics of twisted wire will be lost.)

Precaution for WorkINFO NISSAN TEANA 2014 Workshop Manual

BRC-6

< PRECAUTION >[VDC/TCS/ABS]

PRECAUTIONS

• Do not make a bypass connection to repaired area. (If the circuit is

bypassed, characteristics of twisted wire will be lost.)

Precaution for WorkINFO](/img/5/57390/w960_57390-151.png)

BRC-6

< PRECAUTION >[VDC/TCS/ABS]

PRECAUTIONS

• Do not make a bypass connection to repaired area. (If the circuit is

bypassed, characteristics of twisted wire will be lost.)

Precaution for WorkINFOID:0000000009463738

• When removing or disassembling each component, be careful not to damage or deform it. If a component

may be subject to interference, be sure to protect it with a shop cloth.

• When removing (disengaging) components with a screwdriver or similar tool, be sure to wrap the component with a shop cloth or vinyl tape to protect it.

• Protect the removed parts with a s hop cloth and prevent them from being dropped.

• Replace a deformed or damaged clip.

• If a part is specified as a non-reusable part, always replace it with a new one.

• Be sure to tighten bolts and nuts securely to the specified torque.

• After installation is complete, be sure to check that each part works properly.

• Follow the steps below to clean components:

- Water soluble dirt:

• Dip a soft cloth into lukewarm water, wring the water out of the cloth and wipe the dirty area.

• Then rub with a soft, dry cloth.

- Oily dirt:

• Dip a soft cloth into lukewarm water with mild detergent (concentration: within 2 to 3%) and wipe the dirty area.

• Then dip a cloth into fresh water, wring the water out of the cloth and wipe the detergent off.

• Then rub with a soft, dry cloth.

- Do not use organic solvent such as thinner, benzene, alcohol or gasoline.

- For genuine leather seats, use a genuine leather seat cleaner.

PKIA0307E

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 179 of 4801

![NISSAN TEANA 2014 Workshop Manual

DIAGNOSIS SYSTEM [ABS ACTUATOR AND ELECTRIC UNIT (CONTROL

UNIT)]

BRC-33

< SYSTEM DESCRIPTION > [VDC/TCS/ABS]

C

D E

G H

I

J

K L

M A

B

BRC

N

O P

DIAGNOSIS SYSTEM [ABS ACTUATOR AND ELECTRIC UNIT (CO NISSAN TEANA 2014 Workshop Manual

DIAGNOSIS SYSTEM [ABS ACTUATOR AND ELECTRIC UNIT (CONTROL

UNIT)]

BRC-33

< SYSTEM DESCRIPTION > [VDC/TCS/ABS]

C

D E

G H

I

J

K L

M A

B

BRC

N

O P

DIAGNOSIS SYSTEM [ABS ACTUATOR AND ELECTRIC UNIT (CO](/img/5/57390/w960_57390-178.png)

DIAGNOSIS SYSTEM [ABS ACTUATOR AND ELECTRIC UNIT (CONTROL

UNIT)]

BRC-33

< SYSTEM DESCRIPTION > [VDC/TCS/ABS]

C

D E

G H

I

J

K L

M A

B

BRC

N

O P

DIAGNOSIS SYSTEM [ABS ACTUATOR AND ELECTRIC UNIT (CONTROL

UNIT)]

CONSULT Function (ABS)INFOID:0000000009463758

CAUTION:

After disconnecting the CONSULT vehicle interface (VI) from the data link connector, the ignition must

be cycled OFF → ON (for at least 5 seconds) → OFF. If this step is not performed, the BCM may not go

to ”sleep mode”, potentiall y causing a discharged battery and a no-start condition.

FUNCTION

CONSULT can display each diagnostic item us ing the following direct diagnostic modes.

ECU IDENTIFICATION

ABS actuator and electric unit (control unit) part number is displayed.

SELF DIAGNOSTIC RESULT

Operation Procedure

1. Before performing the self-diagnosis, start engine and drive vehicle at 30 km/h (19 MPH) or more for

approximately 1 minute.

How To Erase Self Diagnostic Result

1. After erasing DTC memory, start engine and drive vehicle at 30 km/h (19 MPH) or more for approximately 1 minute as the final inspection, and make sure t hat the ABS warning lamp, VDC OFF indicator lamp,

SLIP indicator lamp and brake warning lamp turn OFF.

CAUTION:

If memory cannot be erased, perform applicable diagnosis.

NOTE:

• When the wheel sensor malfunctions, after inspecting the wheel sensor system, the ABS warning lamp,

SLIP indicator lamp and brake warning lamp will not turn OFF even when the system is normal, unless

the vehicle is driven at approximately 30 km/h (19 MPH) or more for approximately 1 minute.

• Brake warning lamp will turn ON in case of parking brake operation (when switch is ON) or of brake fluid

level switch operation (when brake fluid is insufficient).

• VDC OFF switch should not stay in ON position.

Display Item List

Refer to BRC-45, "DTC Index".

DATA MONITOR

Direct Diagnostic Mode Description

ECU identification The ABS actuator and electric un it (control unit) part number is displayed.

Self Diagnostic Result The ABS actuator and electric unit (control unit) self diagnostic results are displayed.

Data Monitor The ABS actuator and elec tric unit (control unit) input/output data is displayed in real time.

Active Test The ABS actuator and elec tric unit (control unit) activates outputs to test components.

Work support The settings for ABS actuator and electric unit (control unit) functions can be changed.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication is displayed.

Configuration • Read and save the vehicle specification (TYPE ID).

• Write the vehicle specification (TYPE ID) when replacing ABS actu ator and electric unit (con-

trol unit).

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 180 of 4801

![NISSAN TEANA 2014 Workshop Manual

BRC-34

< SYSTEM DESCRIPTION >[VDC/TCS/ABS]

DIAGNOSIS SYSTEM [

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL

UNIT)]

Item

(Unit) Data monitor item selection

Remarks

ECU INPUT

SIGNALS MAIN

SIGNALS SELECTION

NISSAN TEANA 2014 Workshop Manual

BRC-34

< SYSTEM DESCRIPTION >[VDC/TCS/ABS]

DIAGNOSIS SYSTEM [

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL

UNIT)]

Item

(Unit) Data monitor item selection

Remarks

ECU INPUT

SIGNALS MAIN

SIGNALS SELECTION](/img/5/57390/w960_57390-179.png)

BRC-34

< SYSTEM DESCRIPTION >[VDC/TCS/ABS]

DIAGNOSIS SYSTEM [

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL

UNIT)]

Item

(Unit) Data monitor item selection

Remarks

ECU INPUT

SIGNALS MAIN

SIGNALS SELECTION

FROM MENU

FR LH SENSOR

(km/h, mph) ×× × Wheel speed (km/h, mph) calculated by front wheel

sensor LH signal is displayed.

FR RH SENSOR

(km/h, mph) ×× × Wheel speed (km/h, mph) calculated by front wheel

sensor RH signal is displayed.

RR LH SENSOR

(km/h, mph) ×× ×

Wheel speed (km/h, mph) calculated by rear wheel

sensor LH signal is displayed.

RR RH SENSOR

(km/h, mph) ×× × Wheel speed (km/h, mph) calculated by rear wheel

sensor RH signal is displayed.

DECEL G-SEN

(G) ×× × Longitudinal acceleration (G) detected by decel G-

sensor is displayed.

FR RH IN SOL

(On/Off) –

×× Front RH IN ABS solenoid (On/Off) status is dis-

played.

FR RH OUT SOL

(On/Off) –

×× Front RH OUT ABS solenoid (On/Off) status is dis-

played.

FR LH IN SOL

(On/Off) –

×× Front LH IN ABS solenoid (On/Off) status is displayed.

FR LH OUT SOL

(On/Off) –

×× Front LH OUT ABS solenoid (On/Off) status is dis-

played.

RR RH IN SOL

(On/Off) –

×× Rear RH IN ABS solenoid (On/ Off) status is displayed.

RR RH OUT SOL

(On/Off) –

×× Rear RH OUT ABS solenoid (On/Off) status is dis-

played.

RR LH IN SOL

(On/Off) –

×× Rear LH IN ABS solenoid (On/ Off) status is displayed.

RR LH OUT SOL

(On/Off) –

×× Rear LH OUT ABS solenoid (On/Off) status is dis-

played.

EBD WARN LAMP

(On/Off) ––

×Brake warning lamp (On/Off) status is displayed.

STOP LAMP SW

(On/Off) ×× ×

Stop lamp switch (On/Off) status is displayed.

MOTOR RELAY

(On/Off) –

×× ABS motor relay signal (On/Of f) status is displayed.

ACTUATOR RLY

(On/Off) –

×× ABS actuator relay signal (On/ Off) status is displayed.

ABS WARN LAMP

(On/Off) –

×× ABS warning lamp (On/Off) status is displayed.

OFF LAMP

(On/Off) –

×× VDC OFF Lamp (On/Off) status is displayed.

SLIP/VDC LAMP

(On/Off) –

×× SLIP indicator lamp (On/Off) status is displayed.

BATTERY VOLT

(V) ×× × Voltage (V) supplied to ABS actuator and electric unit

(control unit) is displayed.

GEAR

(1, 2, 3, 4, 5) ×× ×

Gear position (1, 2, 3, 4, 5) judged by transmission

range switch signal is displayed.

SLCT LVR POSI ×× × Current gear position judged from current gear posi-

tion signal is displayed.

YAW R AT E S E N

(d/s) ×× × Yaw rate (d/s) detected by yaw rate sensor is dis-

played.

R POSI SIG

(On/Off) ––

×Reverse shift position (On/Off) judged by transmis-

sion range switch signal.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 181 of 4801

![NISSAN TEANA 2014 Workshop Manual

DIAGNOSIS SYSTEM [ABS ACTUATOR AND ELECTRIC UNIT (CONTROL

UNIT)]

BRC-35

< SYSTEM DESCRIPTION > [VDC/TCS/ABS]

C

D E

G H

I

J

K L

M A

B

BRC

N

O P

× : Applicable

–: Not applicable N POSI SIG

(On/O NISSAN TEANA 2014 Workshop Manual

DIAGNOSIS SYSTEM [ABS ACTUATOR AND ELECTRIC UNIT (CONTROL

UNIT)]

BRC-35

< SYSTEM DESCRIPTION > [VDC/TCS/ABS]

C

D E

G H

I

J

K L

M A

B

BRC

N

O P

× : Applicable

–: Not applicable N POSI SIG

(On/O](/img/5/57390/w960_57390-180.png)

DIAGNOSIS SYSTEM [ABS ACTUATOR AND ELECTRIC UNIT (CONTROL

UNIT)]

BRC-35

< SYSTEM DESCRIPTION > [VDC/TCS/ABS]

C

D E

G H

I

J

K L

M A

B

BRC

N

O P

× : Applicable

–: Not applicable N POSI SIG

(On/Off) ––

×Neutral position (On/Off) judged by transmission

range switch signal.

P POSI SIG

(On/Off) ––

×Park position (On/Off) judged by transmission range

switch signal.

ACCEL POS SIG

(%) ×

– ×Throttle valve open/close status judged by CAN com-

munication signal is displayed.

SIDE G-SENSOR

(m/s

2) ×

– ×Transverse acceleration detected by side G-sensor is

displayed.

STR ANGLE SIG

(deg) ×

– ×Steering angle detected by steering angle sensor is

displayed.

PRESS SENSOR

(bar) ×

– ×Brake pressure detected by pressure sensor is dis-

played.

EBD SIGNAL

(On/Off) ––

×EBD operation (On/Off) status is displayed.

ABS SIGNAL

(On/Off) ––

×ABS operation (On/Off) status is displayed.

TCS SIGNAL

(On/Off) ––

×TCS operation (On/Off) status is displayed.

VDC SIGNAL

(On/Off) ––

×VDC operation (On/Off) status is displayed.

EBD FAIL SIG

(On/Off) ––

×EBD fail signal (On/Off) status is displayed.

ABS FAIL SIG

(On/Off) ––

×ABS fail signal (On/Off) status is displayed.

TCS FAIL SIG

(On/Off) ––

×TCS fail signal (On/Off) status is displayed.

VDC FAIL SIG

(On/Off) ––

×VDC fail signal (On/Off) status is displayed.

CRANKING SIG

(On/Off) ––

×The input state of the key SW START position signal

is displayed.

FLUID LEV SW

(On/Off) ×

– ×Brake fluid level switch (On/Off) status is displayed.

PARK BRAKE SW

(On/Off) ×

– ×Park brake switch (On/Off) status is displayed.

USV[FL-RR]

(On/Off) ——

×Primary side USV solenoid valve (On/Off) status is

displayed.

USV[FR-RL]

(On/Off) ——

×Secondary side USV solenoid valve (On/Off) status is

displayed.

HSV[FL-RR]

(On/Off) ——

×Primary side HSV solenoid valve (On/Off) status is

displayed.

HSV[FR-RL]

(On/Off) ——

×Secondary side HSV solenoid valve (On/Off) status is

displayed.

V/R OUTPUT

(On/Off) ——

×Valve relay operation signal (On/Off) status is dis-

played.

M/R OUTPUT

(On/Off) ——

×Motor relay operation signal (On/Off) status is dis-

played.

ENGINE RPM

(tr/min) ×

– ×Engine speed judged by CAN communication signal

is displayed.

Item

(Unit) Data monitor item selection

Remarks

ECU INPUT

SIGNALS MAIN

SIGNALS SELECTION

FROM MENU

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM