NISSAN TERRANO 2002 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 1591 of 1767

2. Measure thickness of each disc and plate.

Total thickness ªBº:

19.24 - 20.26 mm (0.7575 - 0.7976 in)

No. of discs and plates (One side):

Friction disc 5

Friction plate 6

Spring disc 1

Spring plate 1

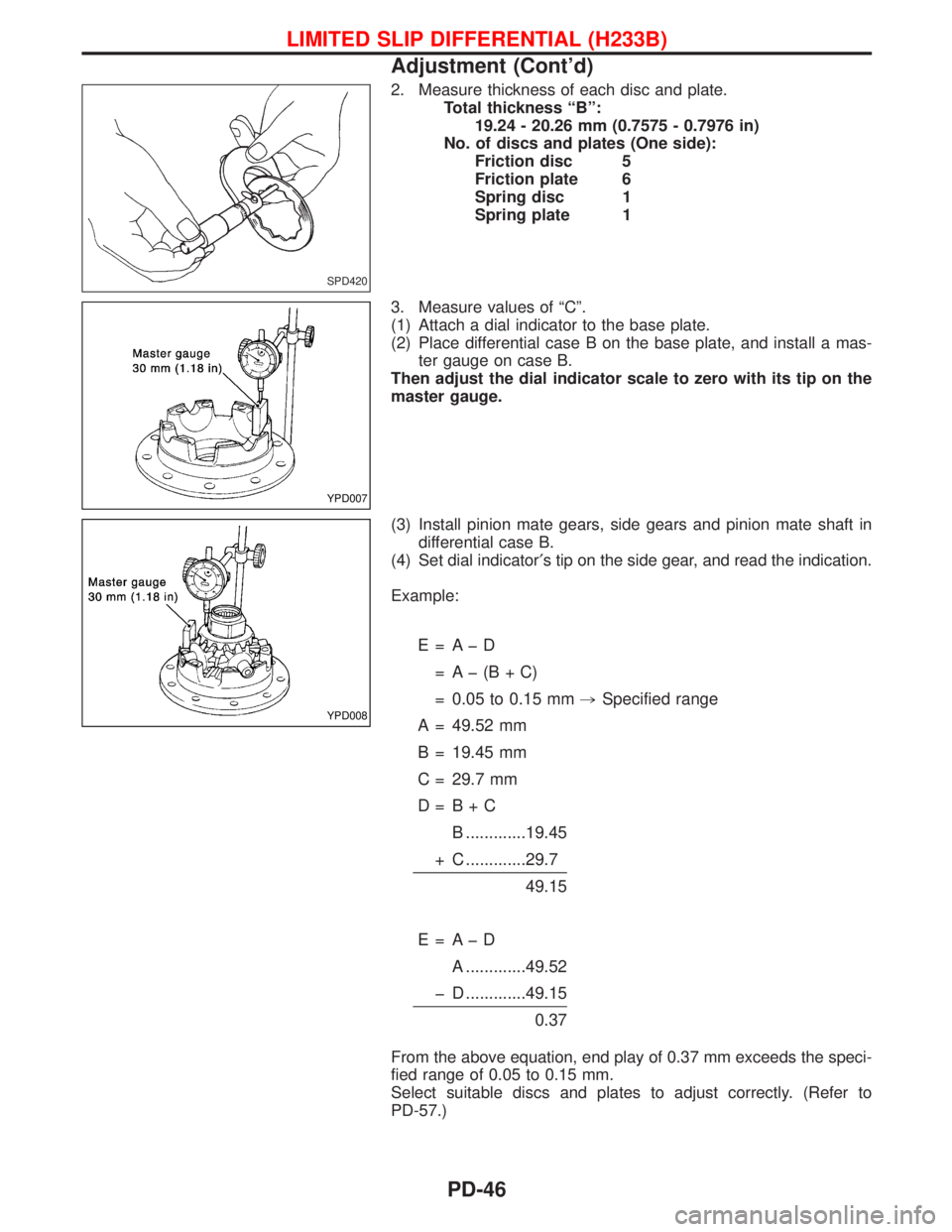

3. Measure values of ªCº.

(1) Attach a dial indicator to the base plate.

(2) Place differential case B on the base plate, and install a mas-

ter gauge on case B.

Then adjust the dial indicator scale to zero with its tip on the

master gauge.

(3) Install pinion mate gears, side gears and pinion mate shaft in

differential case B.

(4) Set dial indicator¢s tip on the side gear, and read the indication.

Example:

E= AþD

= Aþ(B+C)

= 0.05 to 0.15 mm,Specified range

A = 49.52 mm

B = 19.45 mm

C = 29.7 mm

D= B+C

B .............19.45

+ C .............29.7

49.15

E= AþD

A .............49.52

þ D .............49.15

0.37

From the above equation, end play of 0.37 mm exceeds the speci-

fied range of 0.05 to 0.15 mm.

Select suitable discs and plates to adjust correctly. (Refer to

PD-57.)

SPD420

YPD007

YPD008

LIMITED SLIP DIFFERENTIAL (H233B)

Adjustment (Cont'd)

PD-46

Page 1592 of 1767

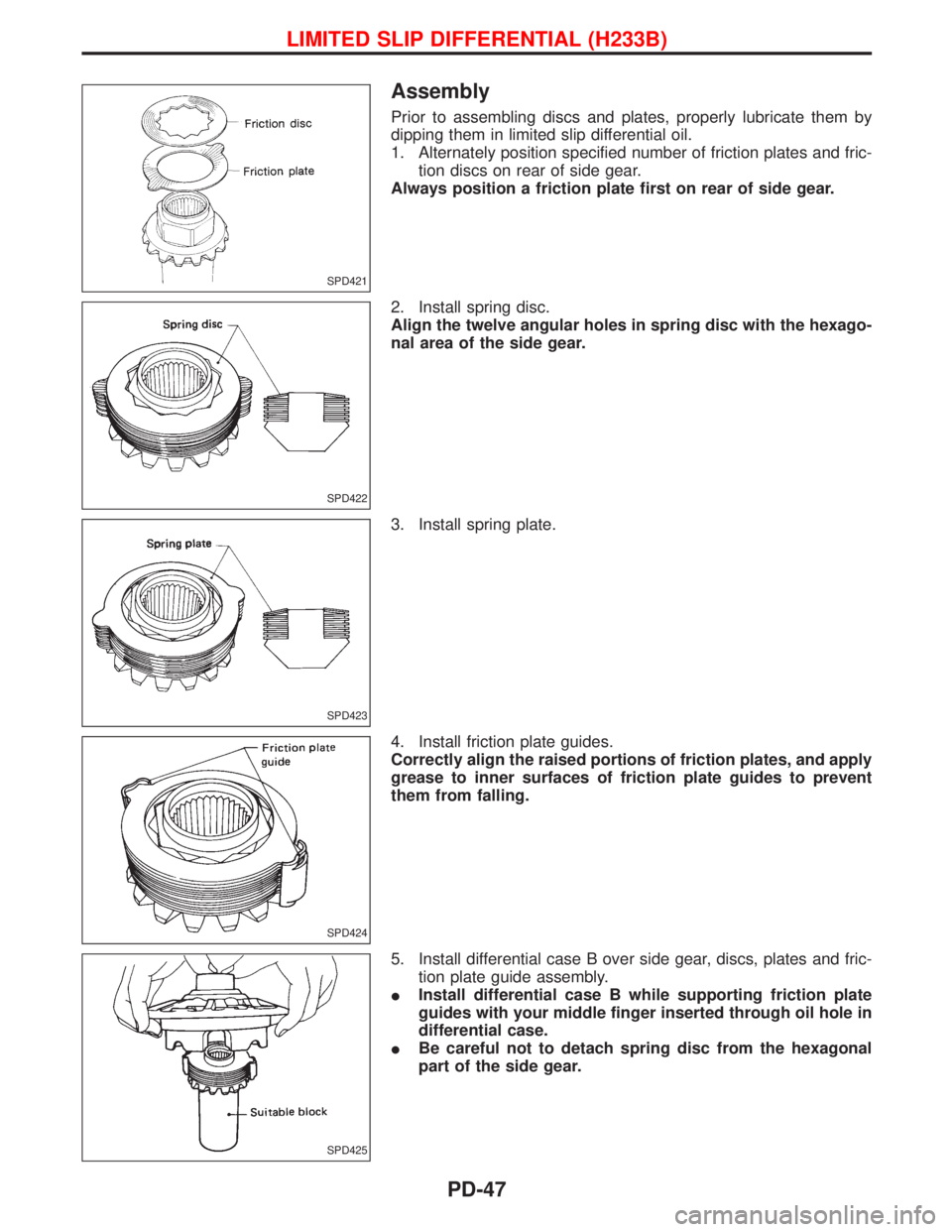

Assembly

Prior to assembling discs and plates, properly lubricate them by

dipping them in limited slip differential oil.

1. Alternately position specified number of friction plates and fric-

tion discs on rear of side gear.

Always position a friction plate first on rear of side gear.

2. Install spring disc.

Align the twelve angular holes in spring disc with the hexago-

nal area of the side gear.

3. Install spring plate.

4. Install friction plate guides.

Correctly align the raised portions of friction plates, and apply

grease to inner surfaces of friction plate guides to prevent

them from falling.

5. Install differential case B over side gear, discs, plates and fric-

tion plate guide assembly.

IInstall differential case B while supporting friction plate

guides with your middle finger inserted through oil hole in

differential case.

IBe careful not to detach spring disc from the hexagonal

part of the side gear.

SPD421

SPD422

SPD423

SPD424

SPD425

LIMITED SLIP DIFFERENTIAL (H233B)

PD-47

Page 1593 of 1767

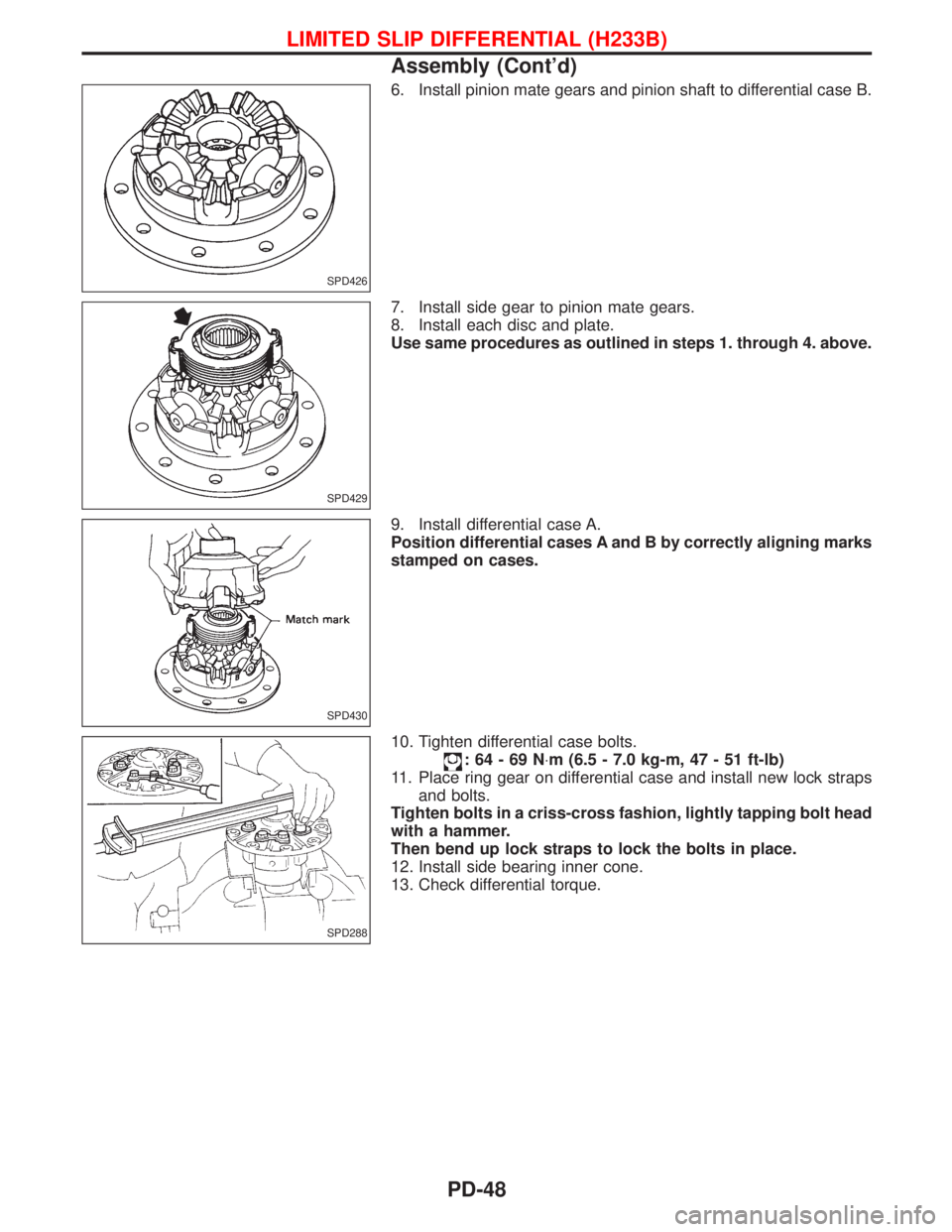

6. Install pinion mate gears and pinion shaft to differential case B.

7. Install side gear to pinion mate gears.

8. Install each disc and plate.

Use same procedures as outlined in steps 1. through 4. above.

9. Install differential case A.

Position differential cases A and B by correctly aligning marks

stamped on cases.

10. Tighten differential case bolts.

:64-69N×m (6.5 - 7.0 kg-m, 47 - 51 ft-lb)

11. Place ring gear on differential case and install new lock straps

and bolts.

Tighten bolts in a criss-cross fashion, lightly tapping bolt head

with a hammer.

Then bend up lock straps to lock the bolts in place.

12. Install side bearing inner cone.

13. Check differential torque.

SPD426

SPD429

SPD430

SPD288

LIMITED SLIP DIFFERENTIAL (H233B)

Assembly (Cont'd)

PD-48

Page 1594 of 1767

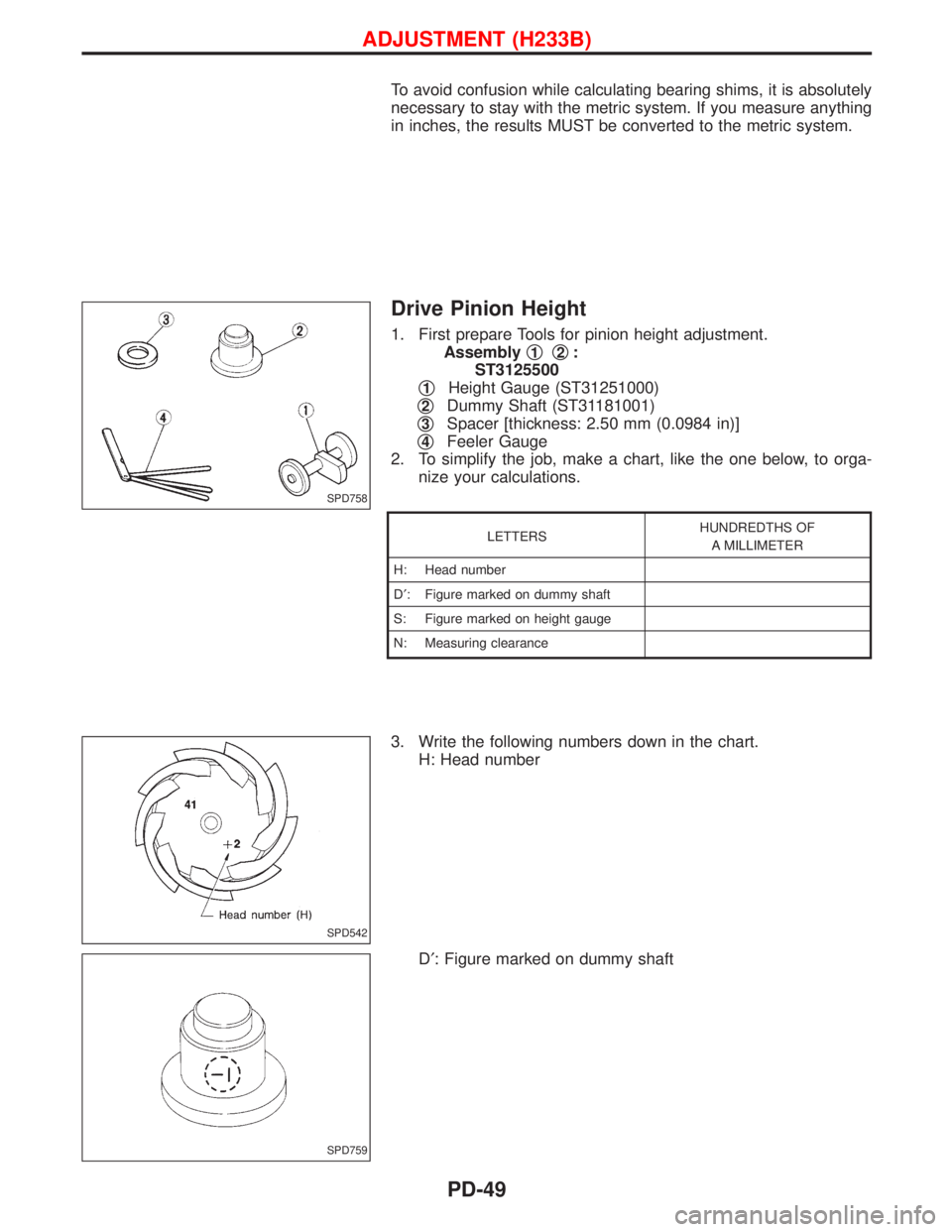

To avoid confusion while calculating bearing shims, it is absolutely

necessary to stay with the metric system. If you measure anything

in inches, the results MUST be converted to the metric system.

Drive Pinion Height

1. First prepare Tools for pinion height adjustment.

Assemblyq

1q2:

ST3125500

q

1Height Gauge (ST31251000)

q

2Dummy Shaft (ST31181001)

q

3Spacer [thickness: 2.50 mm (0.0984 in)]

q

4Feeler Gauge

2. To simplify the job, make a chart, like the one below, to orga-

nize your calculations.

LETTERSHUNDREDTHS OF

A MILLIMETER

H: Head number

D¢: Figure marked on dummy shaft

S: Figure marked on height gauge

N: Measuring clearance

3. Write the following numbers down in the chart.

H: Head number

D¢: Figure marked on dummy shaft

SPD758

SPD542

SPD759

ADJUSTMENT (H233B)

PD-49

Page 1595 of 1767

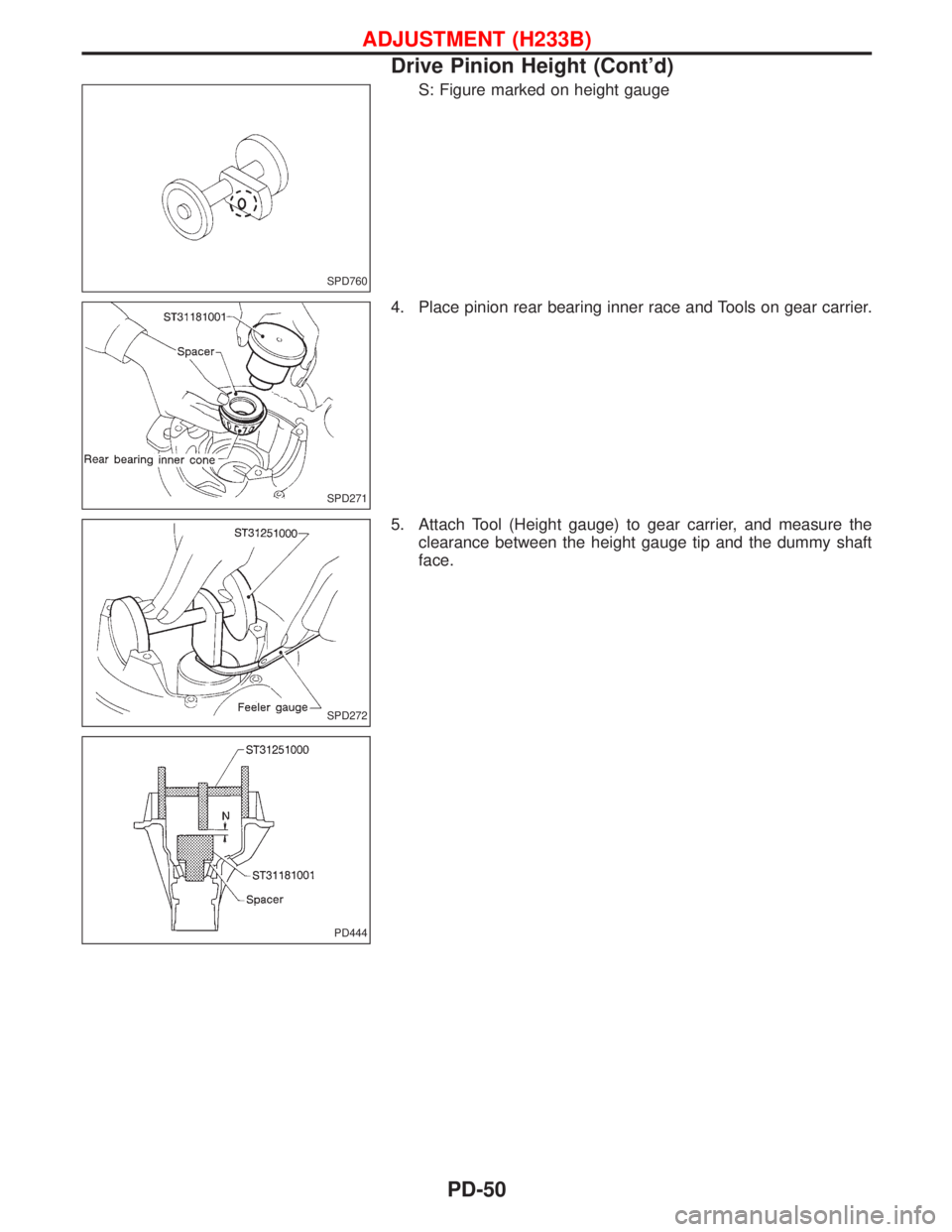

S: Figure marked on height gauge

4. Place pinion rear bearing inner race and Tools on gear carrier.

5. Attach Tool (Height gauge) to gear carrier, and measure the

clearance between the height gauge tip and the dummy shaft

face.

SPD760

SPD271

SPD272

PD444

ADJUSTMENT (H233B)

Drive Pinion Height (Cont'd)

PD-50

Page 1596 of 1767

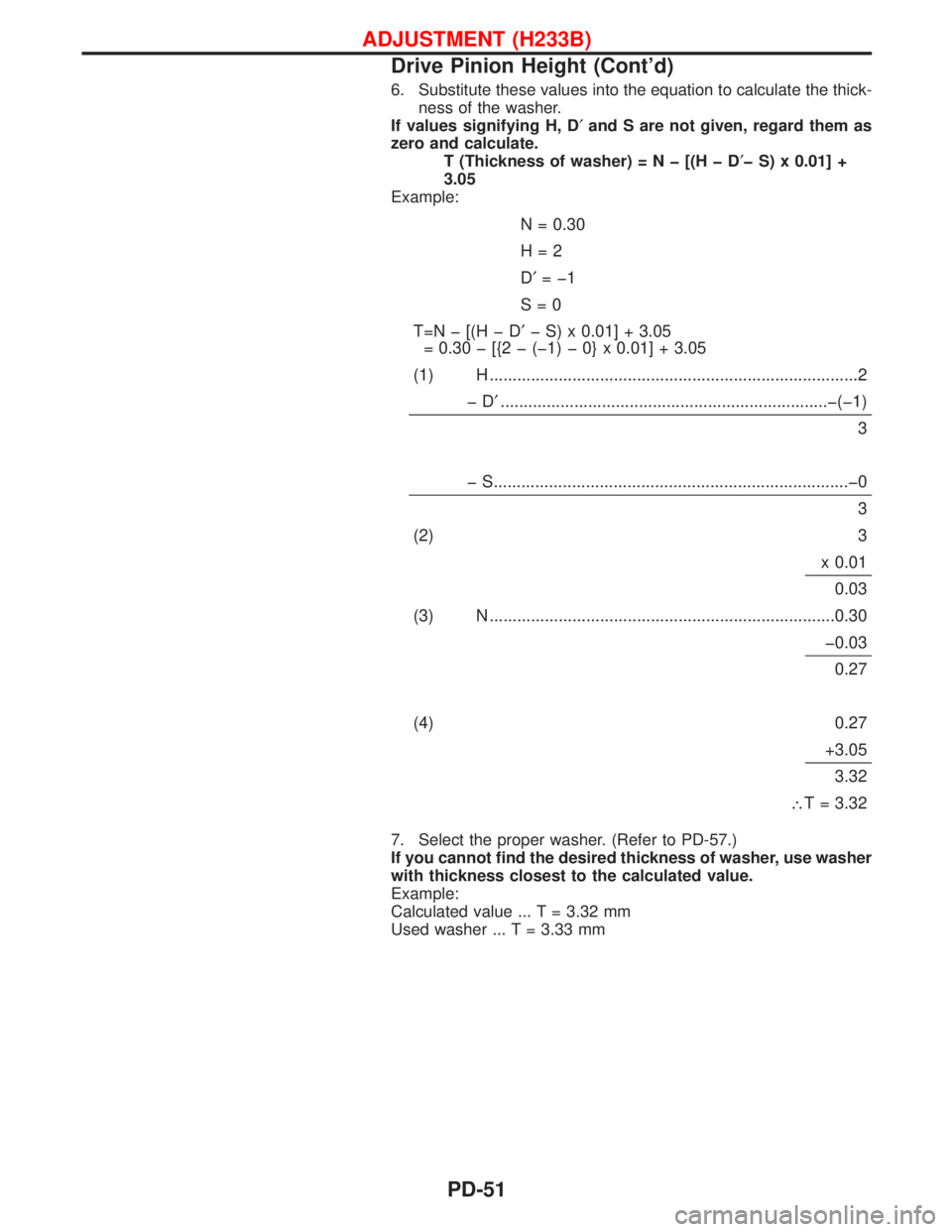

6. Substitute these values into the equation to calculate the thick-

ness of the washer.

If values signifying H, D¢and S are not given, regard them as

zero and calculate.

T (Thickness of washer)=Nþ[(HþD¢þ S) x 0.01] +

3.05

Example:

N = 0.30

H=2

D¢=þ1

S=0

T=Nþ[(HþD¢þ S) x 0.01] + 3.05

= 0.30 þ [{2 þ (þ1) þ 0} x 0.01] + 3.05

(1) H ................................................................................2

þD¢.......................................................................þ(þ1)

3

þ S.............................................................................þ0

3

(2) 3

x 0.01

0.03

(3) N ...........................................................................0.30

þ0.03

0.27

(4) 0.27

+3.05

3.32

\T = 3.32

7. Select the proper washer. (Refer to PD-57.)

If you cannot find the desired thickness of washer, use washer

with thickness closest to the calculated value.

Example:

Calculated value ... T = 3.32 mm

Used washer ... T = 3.33 mm

ADJUSTMENT (H233B)

Drive Pinion Height (Cont'd)

PD-51

Page 1597 of 1767

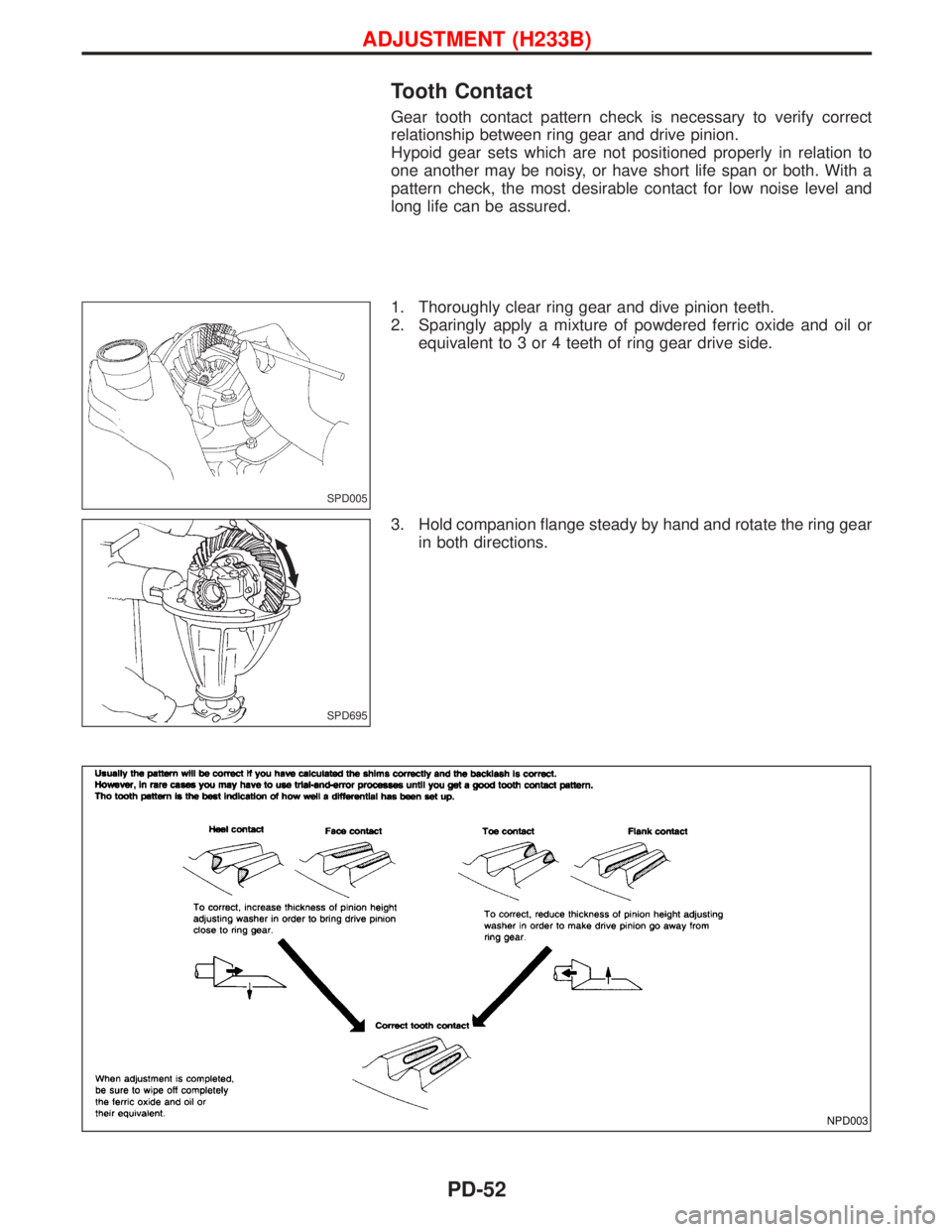

Tooth Contact

Gear tooth contact pattern check is necessary to verify correct

relationship between ring gear and drive pinion.

Hypoid gear sets which are not positioned properly in relation to

one another may be noisy, or have short life span or both. With a

pattern check, the most desirable contact for low noise level and

long life can be assured.

1. Thoroughly clear ring gear and dive pinion teeth.

2. Sparingly apply a mixture of powdered ferric oxide and oil or

equivalent to 3 or 4 teeth of ring gear drive side.

3. Hold companion flange steady by hand and rotate the ring gear

in both directions.

SPD005

SPD695

NPD003

ADJUSTMENT (H233B)

PD-52

Page 1598 of 1767

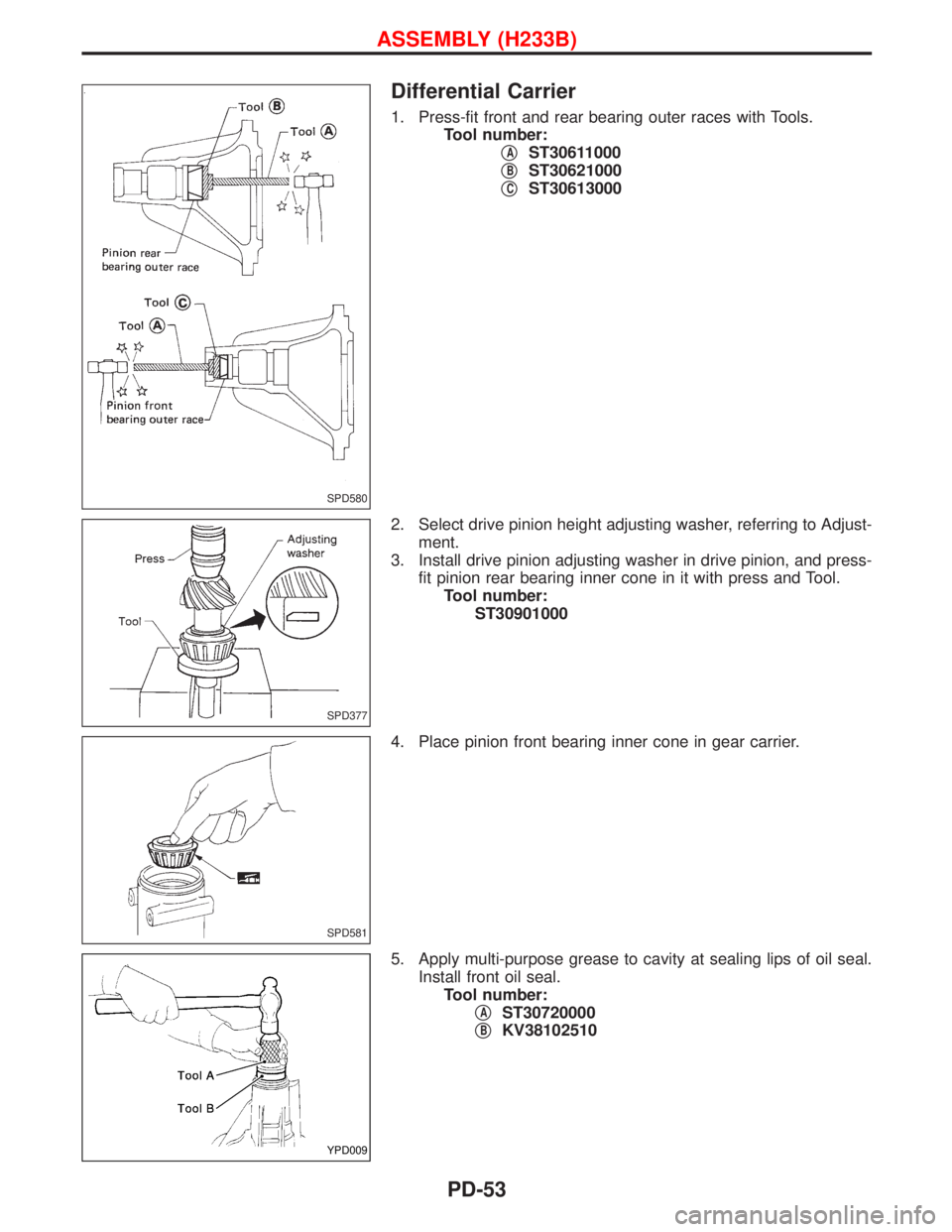

Differential Carrier

1. Press-fit front and rear bearing outer races with Tools.

Tool number:

q

AST30611000

q

BST30621000

q

CST30613000

2. Select drive pinion height adjusting washer, referring to Adjust-

ment.

3. Install drive pinion adjusting washer in drive pinion, and press-

fit pinion rear bearing inner cone in it with press and Tool.

Tool number:

ST30901000

4. Place pinion front bearing inner cone in gear carrier.

5. Apply multi-purpose grease to cavity at sealing lips of oil seal.

Install front oil seal.

Tool number:

q

AST30720000

q

BKV38102510

SPD580

SPD377

SPD581

YPD009

ASSEMBLY (H233B)

PD-53

Page 1599 of 1767

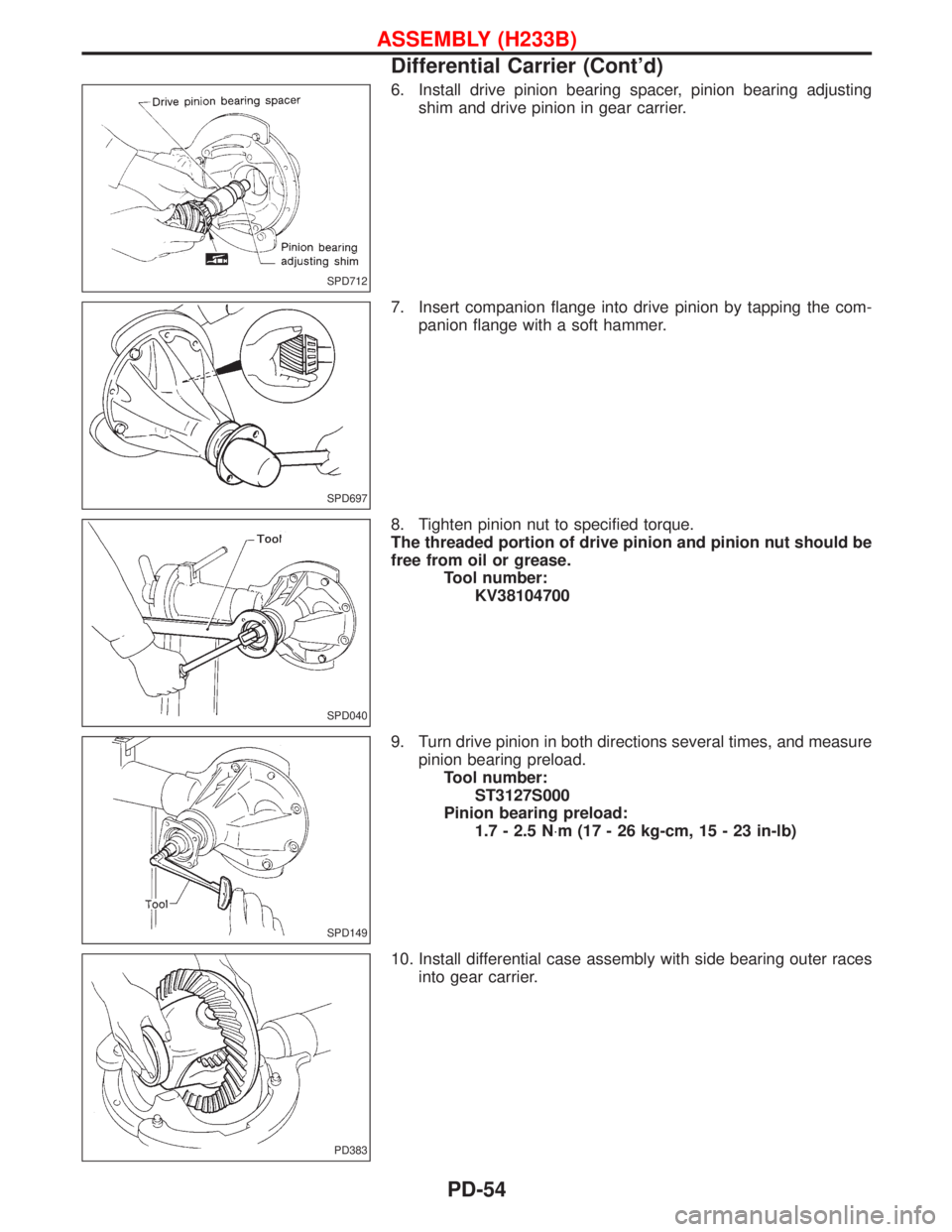

6. Install drive pinion bearing spacer, pinion bearing adjusting

shim and drive pinion in gear carrier.

7. Insert companion flange into drive pinion by tapping the com-

panion flange with a soft hammer.

8. Tighten pinion nut to specified torque.

The threaded portion of drive pinion and pinion nut should be

free from oil or grease.

Tool number:

KV38104700

9. Turn drive pinion in both directions several times, and measure

pinion bearing preload.

Tool number:

ST3127S000

Pinion bearing preload:

1.7 - 2.5 N×m (17 - 26 kg-cm, 15 - 23 in-lb)

10. Install differential case assembly with side bearing outer races

into gear carrier.

SPD712

SPD697

SPD040

SPD149

PD383

ASSEMBLY (H233B)

Differential Carrier (Cont'd)

PD-54

Page 1600 of 1767

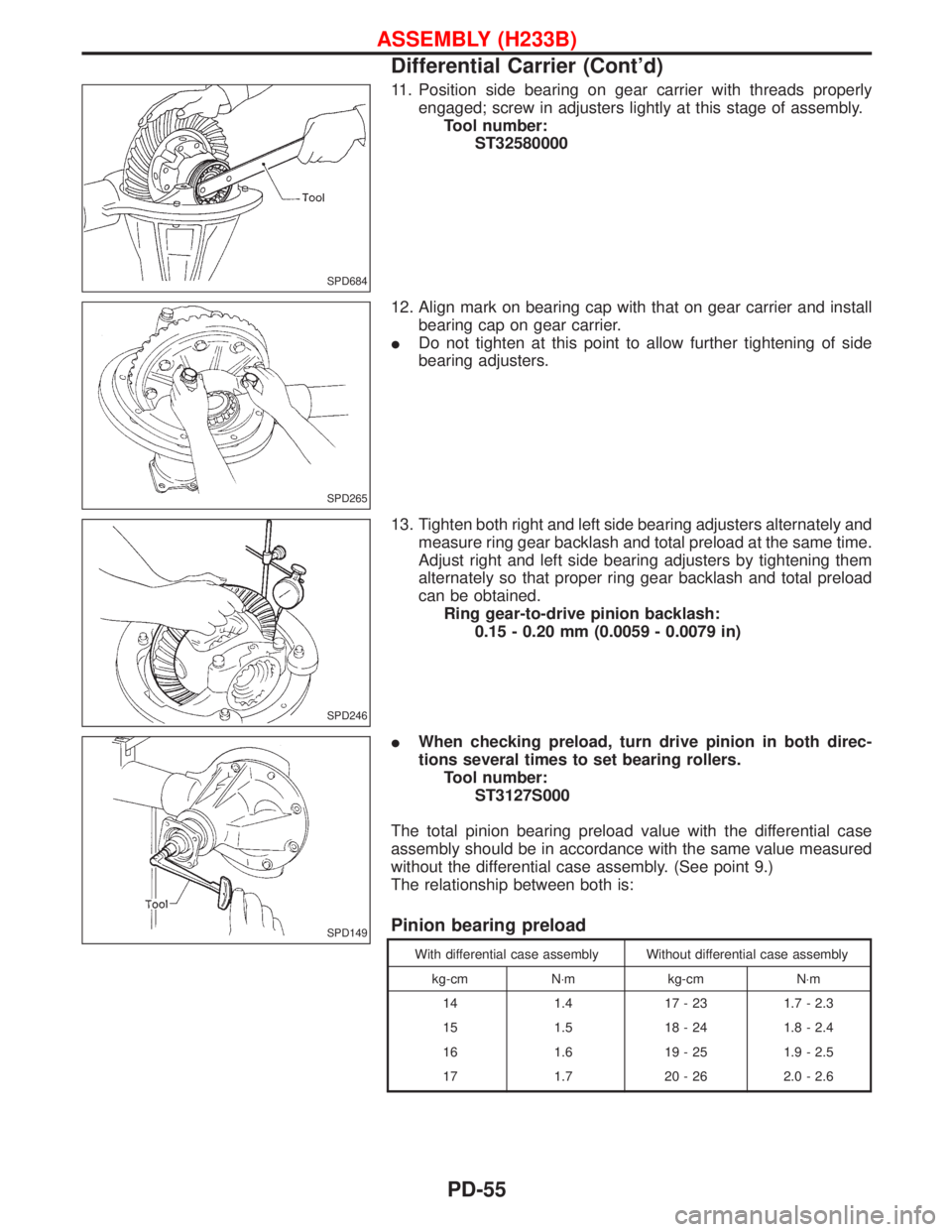

11. Position side bearing on gear carrier with threads properly

engaged; screw in adjusters lightly at this stage of assembly.

Tool number:

ST32580000

12. Align mark on bearing cap with that on gear carrier and install

bearing cap on gear carrier.

IDo not tighten at this point to allow further tightening of side

bearing adjusters.

13. Tighten both right and left side bearing adjusters alternately and

measure ring gear backlash and total preload at the same time.

Adjust right and left side bearing adjusters by tightening them

alternately so that proper ring gear backlash and total preload

can be obtained.

Ring gear-to-drive pinion backlash:

0.15 - 0.20 mm (0.0059 - 0.0079 in)

IWhen checking preload, turn drive pinion in both direc-

tions several times to set bearing rollers.

Tool number:

ST3127S000

The total pinion bearing preload value with the differential case

assembly should be in accordance with the same value measured

without the differential case assembly. (See point 9.)

The relationship between both is:

Pinion bearing preload

With differential case assembly Without differential case assembly

kg-cm N×m kg-cm N×m

14 1.4 17 - 23 1.7 - 2.3

15 1.5 18 - 24 1.8 - 2.4

16 1.6 19 - 25 1.9 - 2.5

17 1.7 20 - 26 2.0 - 2.6

SPD684

SPD265

SPD246

SPD149

ASSEMBLY (H233B)

Differential Carrier (Cont'd)

PD-55