NISSAN TERRANO 2002 Service Repair Manual

TERRANO 2002

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57393/w960_57393-0.png

NISSAN TERRANO 2002 Service Repair Manual

Trending: washer fluid, ECU, alternator replacement, g sensor, battery location, power steering, IDENTIFICATION INFORMATION

Page 1611 of 1767

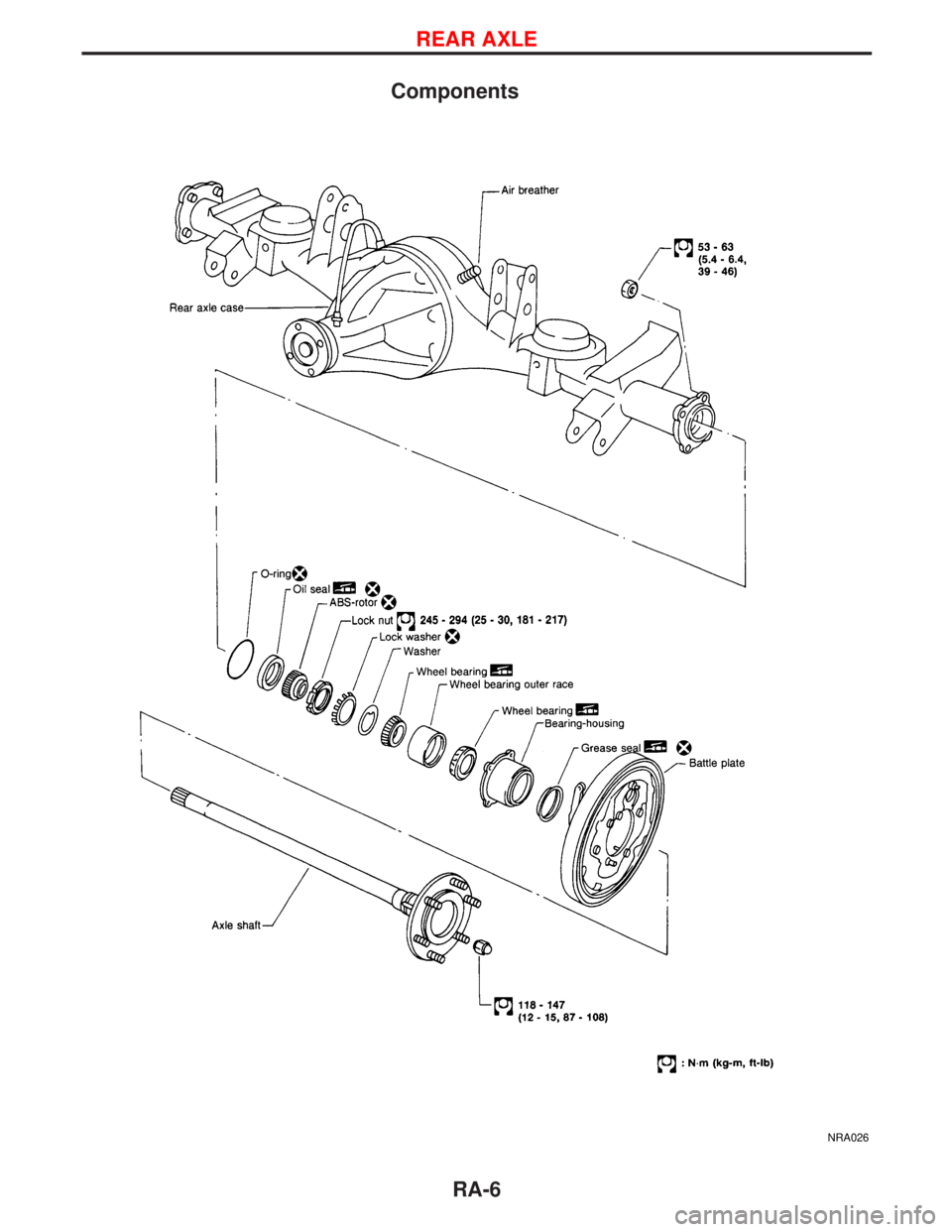

Components

NRA026

REAR AXLE

RA-6

Page 1612 of 1767

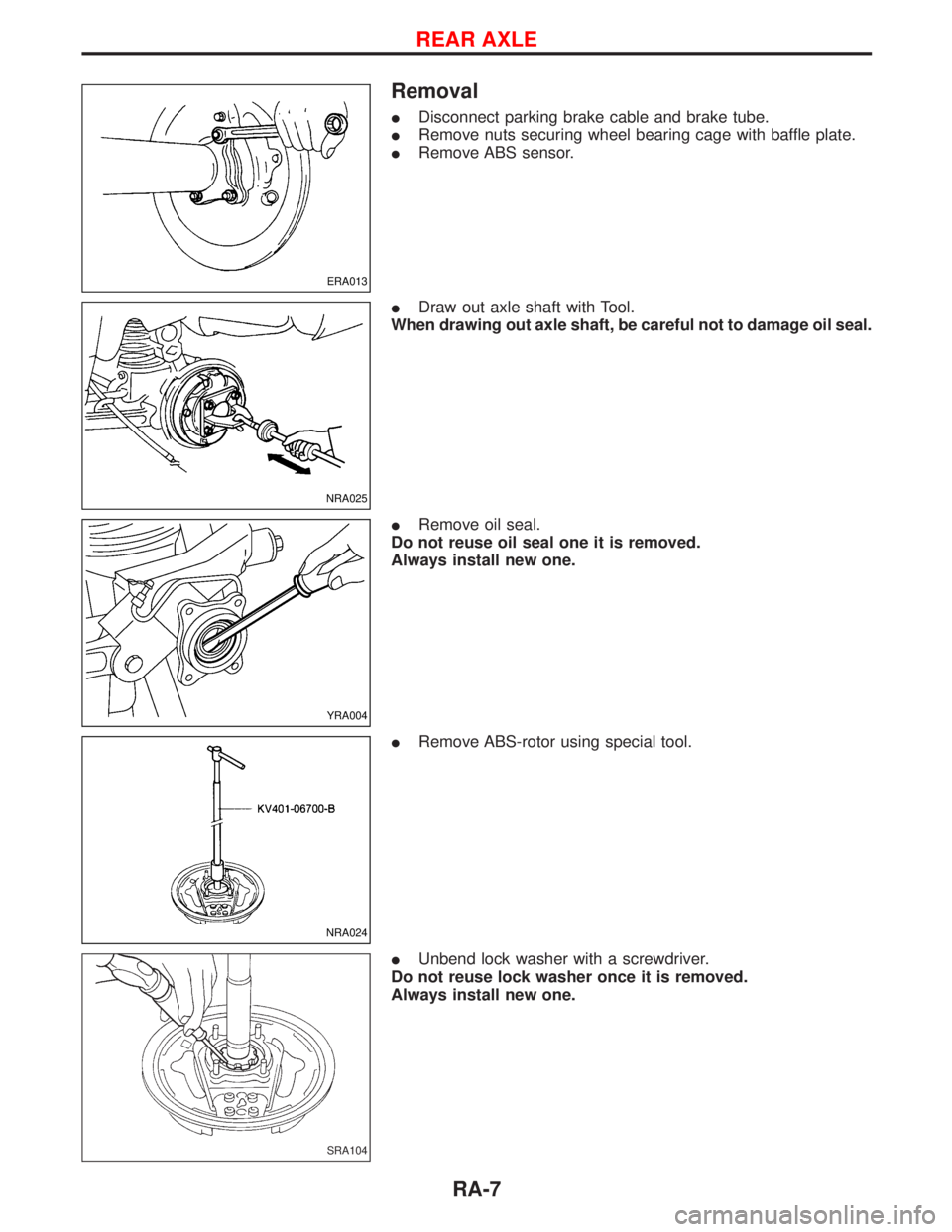

Removal

IDisconnect parking brake cable and brake tube.

IRemove nuts securing wheel bearing cage with baffle plate.

IRemove ABS sensor.

IDraw out axle shaft with Tool.

When drawing out axle shaft, be careful not to damage oil seal.

IRemove oil seal.

Do not reuse oil seal one it is removed.

Always install new one.

IRemove ABS-rotor using special tool.

IUnbend lock washer with a screwdriver.

Do not reuse lock washer once it is removed.

Always install new one.

ERA013

NRA025

YRA004

NRA024

SRA104

REAR AXLE

RA-7

Page 1613 of 1767

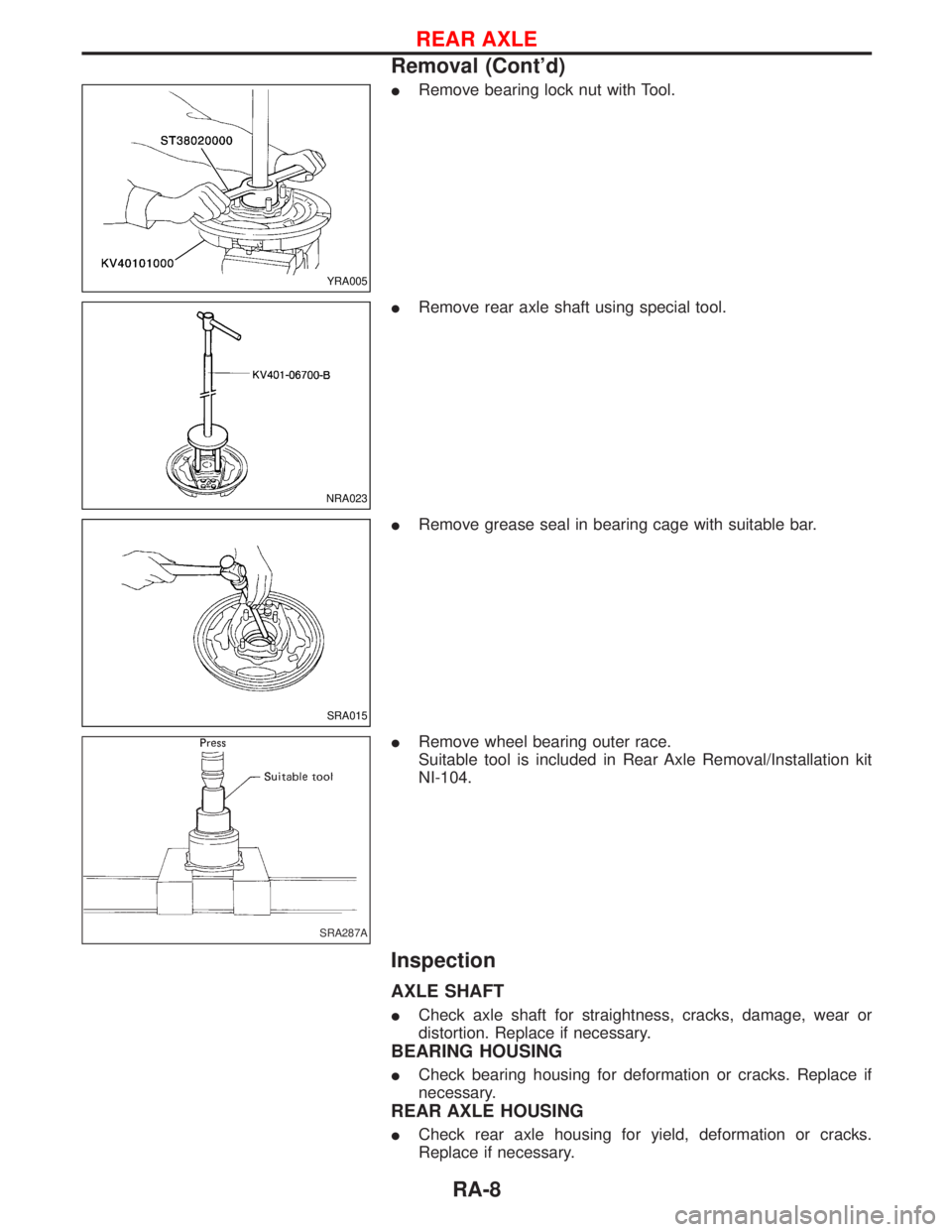

IRemove bearing lock nut with Tool.

IRemove rear axle shaft using special tool.

IRemove grease seal in bearing cage with suitable bar.

IRemove wheel bearing outer race.

Suitable tool is included in Rear Axle Removal/Installation kit

NI-104.

Inspection

AXLE SHAFT

ICheck axle shaft for straightness, cracks, damage, wear or

distortion. Replace if necessary.

BEARING HOUSING

ICheck bearing housing for deformation or cracks. Replace if

necessary.

REAR AXLE HOUSING

ICheck rear axle housing for yield, deformation or cracks.

Replace if necessary.

YRA005

NRA023

SRA015

SRA287A

REAR AXLE

Removal (Cont'd)

RA-8

Page 1614 of 1767

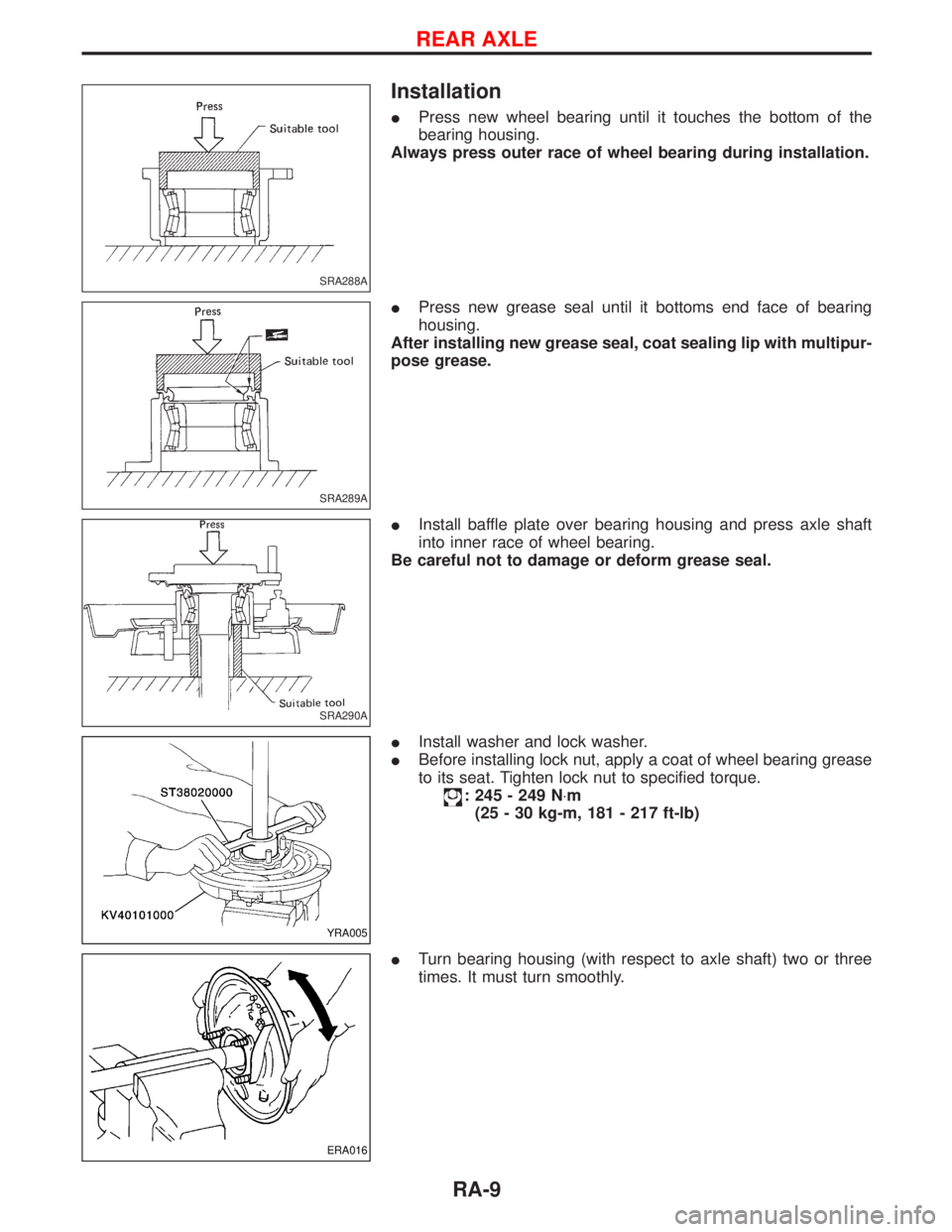

Installation

IPress new wheel bearing until it touches the bottom of the

bearing housing.

Always press outer race of wheel bearing during installation.

IPress new grease seal until it bottoms end face of bearing

housing.

After installing new grease seal, coat sealing lip with multipur-

pose grease.

IInstall baffle plate over bearing housing and press axle shaft

into inner race of wheel bearing.

Be careful not to damage or deform grease seal.

IInstall washer and lock washer.

IBefore installing lock nut, apply a coat of wheel bearing grease

to its seat. Tighten lock nut to specified torque.

: 245 - 249 N×m

(25 - 30 kg-m, 181 - 217 ft-lb)

ITurn bearing housing (with respect to axle shaft) two or three

times. It must turn smoothly.

SRA288A

SRA289A

SRA290A

YRA005

ERA016

REAR AXLE

RA-9

Page 1615 of 1767

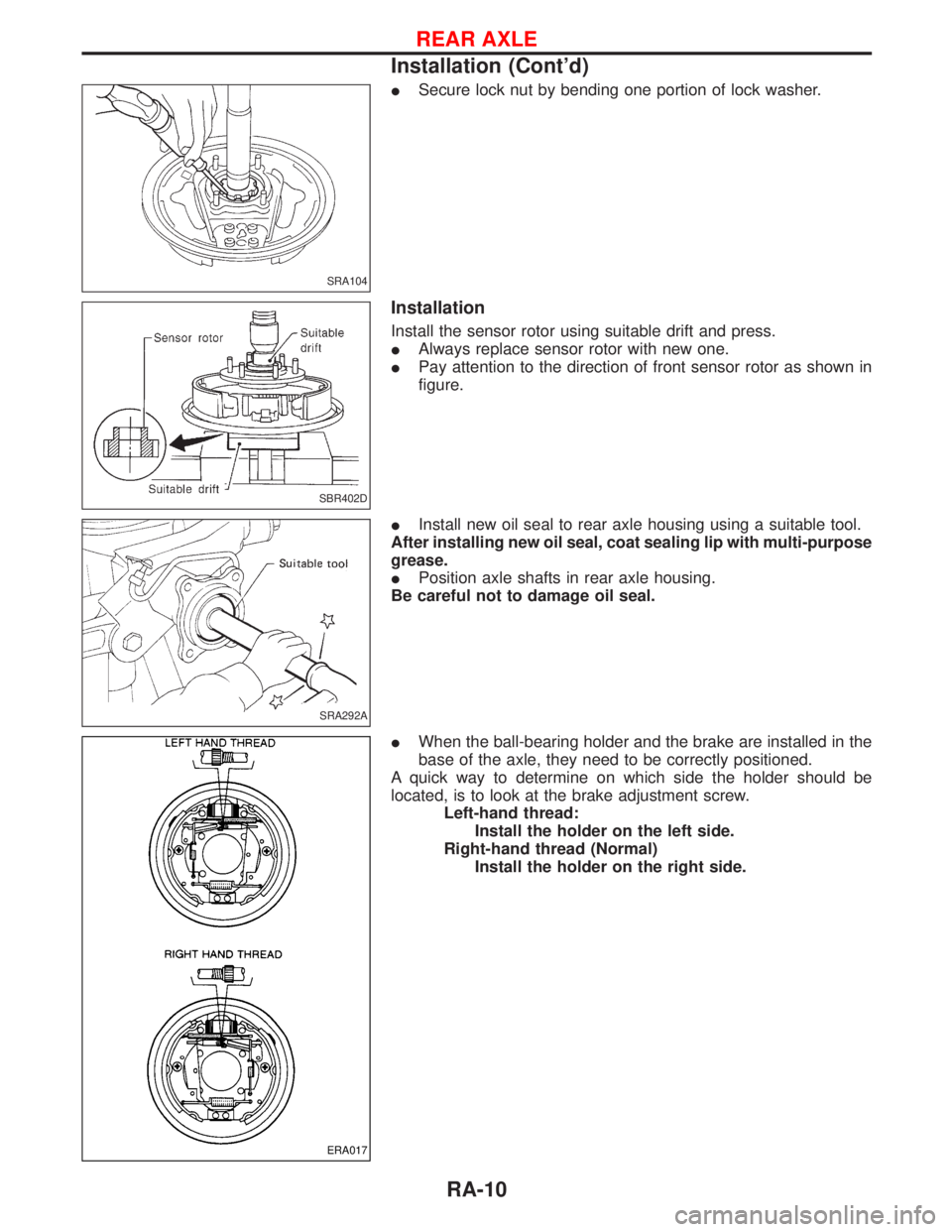

ISecure lock nut by bending one portion of lock washer.

Installation

Install the sensor rotor using suitable drift and press.

IAlways replace sensor rotor with new one.

IPay attention to the direction of front sensor rotor as shown in

figure.

IInstall new oil seal to rear axle housing using a suitable tool.

After installing new oil seal, coat sealing lip with multi-purpose

grease.

IPosition axle shafts in rear axle housing.

Be careful not to damage oil seal.

IWhen the ball-bearing holder and the brake are installed in the

base of the axle, they need to be correctly positioned.

A quick way to determine on which side the holder should be

located, is to look at the brake adjustment screw.

Left-hand thread:

Install the holder on the left side.

Right-hand thread (Normal)

Install the holder on the right side.

SRA104

SBR402D

SRA292A

ERA017

REAR AXLE

Installation (Cont'd)

RA-10

Page 1616 of 1767

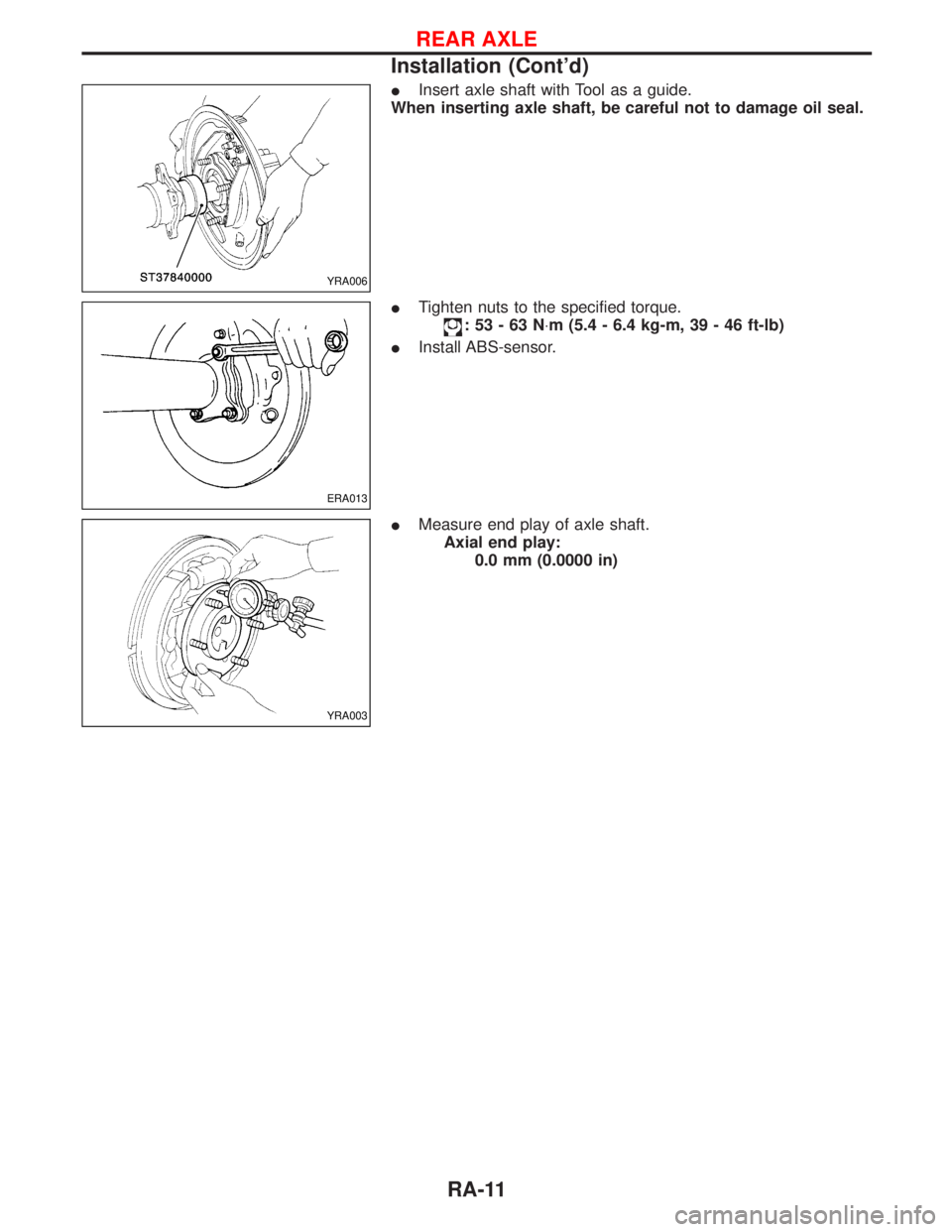

IInsert axle shaft with Tool as a guide.

When inserting axle shaft, be careful not to damage oil seal.

ITighten nuts to the specified torque.

:53-63N×m (5.4 - 6.4 kg-m, 39 - 46 ft-lb)

IInstall ABS-sensor.

IMeasure end play of axle shaft.

Axial end play:

0.0 mm (0.0000 in)

YRA006

ERA013

YRA003

REAR AXLE

Installation (Cont'd)

RA-11

Page 1617 of 1767

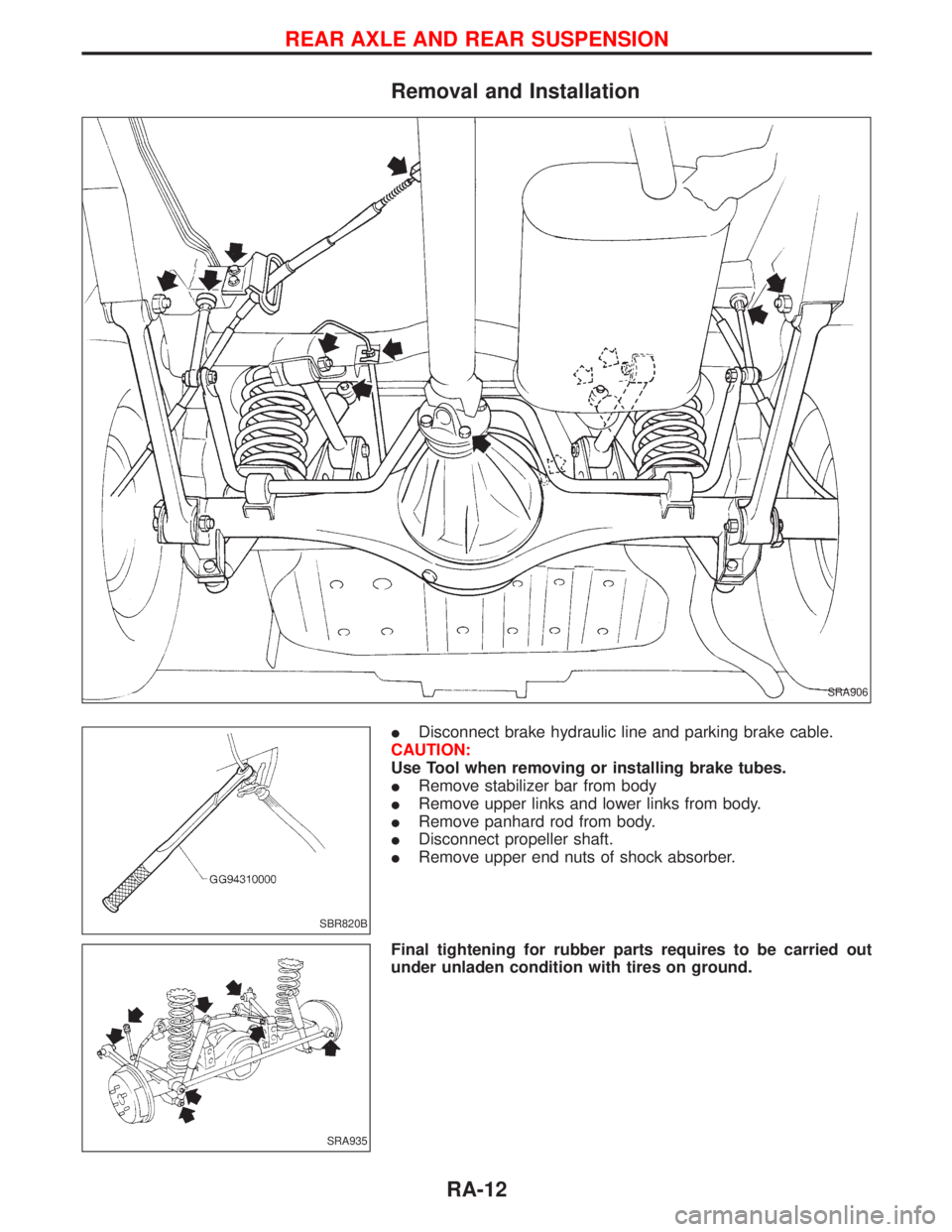

Removal and Installation

IDisconnect brake hydraulic line and parking brake cable.

CAUTION:

Use Tool when removing or installing brake tubes.

IRemove stabilizer bar from body

IRemove upper links and lower links from body.

IRemove panhard rod from body.

IDisconnect propeller shaft.

IRemove upper end nuts of shock absorber.

Final tightening for rubber parts requires to be carried out

under unladen condition with tires on ground.

SRA906

SBR820B

SRA935

REAR AXLE AND REAR SUSPENSION

RA-12

Page 1618 of 1767

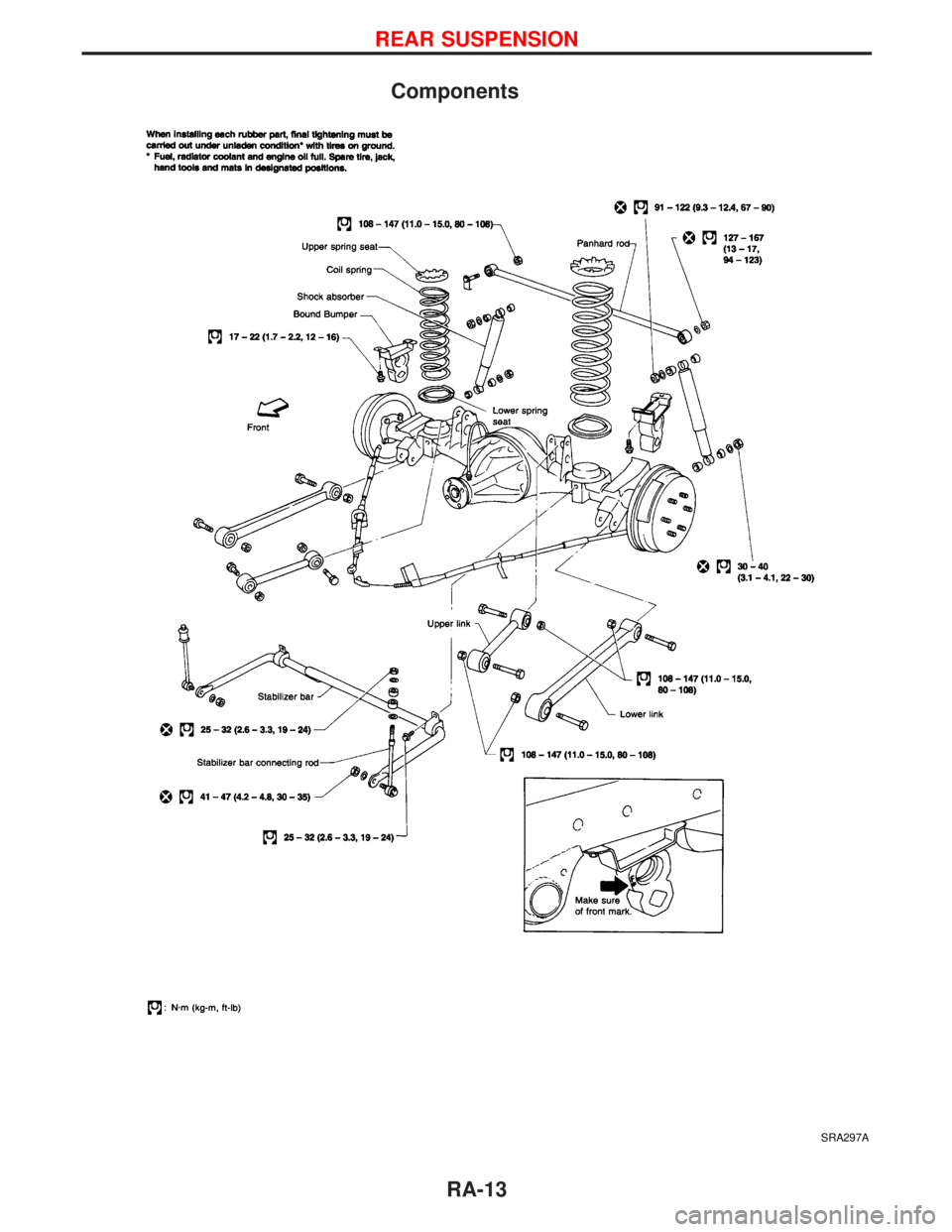

Components

SRA297A

REAR SUSPENSION

RA-13

Page 1619 of 1767

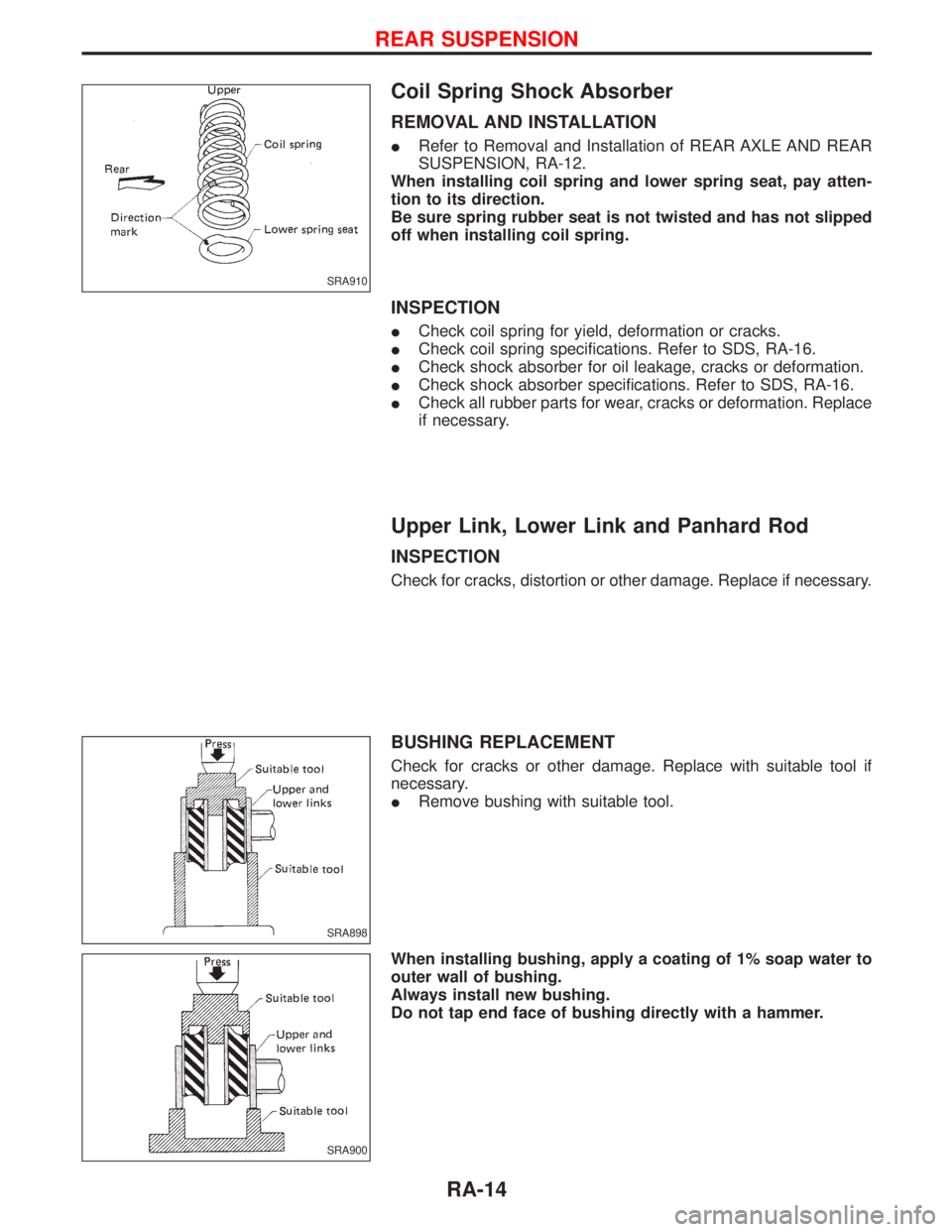

Coil Spring Shock Absorber

REMOVAL AND INSTALLATION

IRefer to Removal and Installation of REAR AXLE AND REAR

SUSPENSION, RA-12.

When installing coil spring and lower spring seat, pay atten-

tion to its direction.

Be sure spring rubber seat is not twisted and has not slipped

off when installing coil spring.

INSPECTION

ICheck coil spring for yield, deformation or cracks.

ICheck coil spring specifications. Refer to SDS, RA-16.

ICheck shock absorber for oil leakage, cracks or deformation.

ICheck shock absorber specifications. Refer to SDS, RA-16.

ICheck all rubber parts for wear, cracks or deformation. Replace

if necessary.

Upper Link, Lower Link and Panhard Rod

INSPECTION

Check for cracks, distortion or other damage. Replace if necessary.

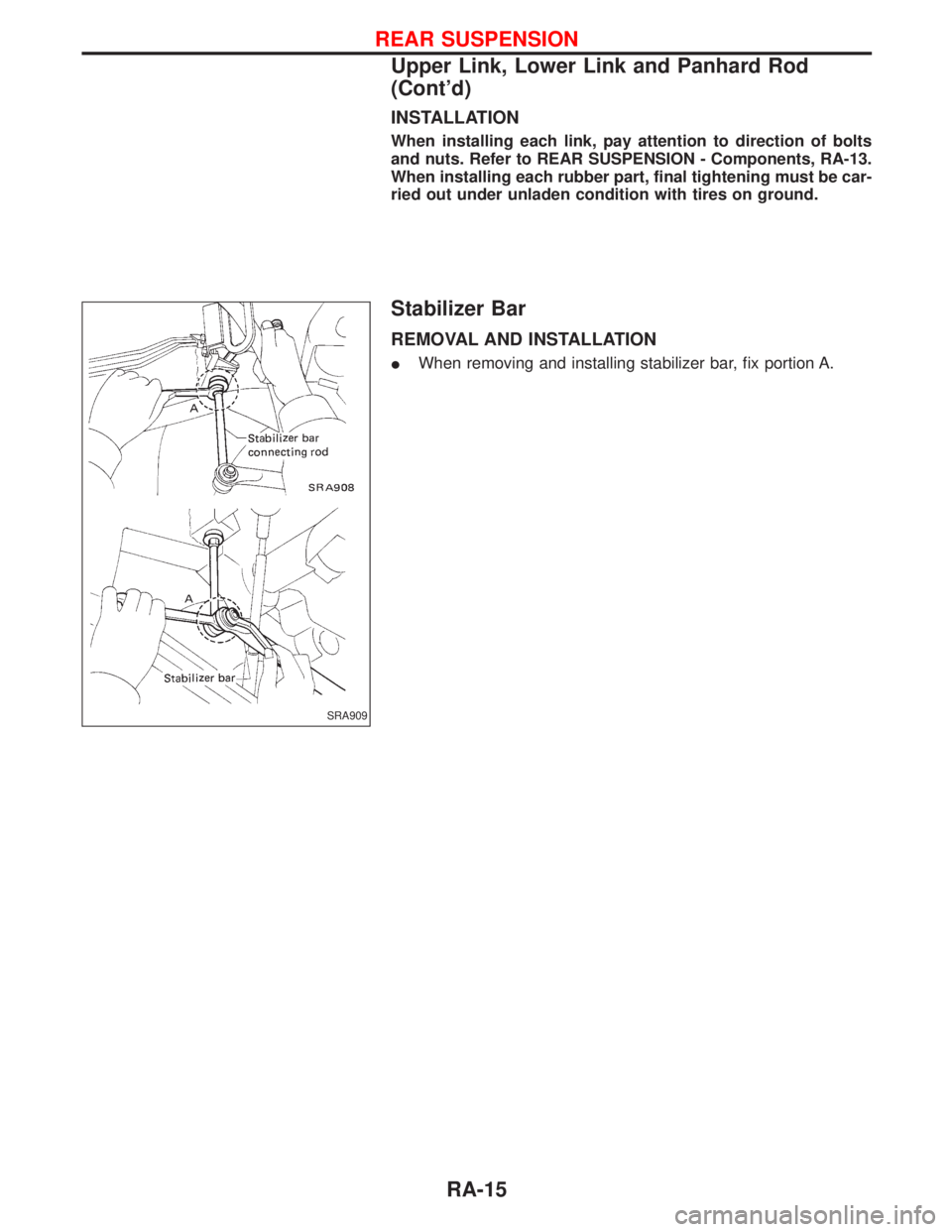

BUSHING REPLACEMENT

Check for cracks or other damage. Replace with suitable tool if

necessary.

IRemove bushing with suitable tool.

When installing bushing, apply a coating of 1% soap water to

outer wall of bushing.

Always install new bushing.

Do not tap end face of bushing directly with a hammer.

SRA910

SRA898

SRA900

REAR SUSPENSION

RA-14

Page 1620 of 1767

INSTALLATION

When installing each link, pay attention to direction of bolts

and nuts. Refer to REAR SUSPENSION - Components, RA-13.

When installing each rubber part, final tightening must be car-

ried out under unladen condition with tires on ground.

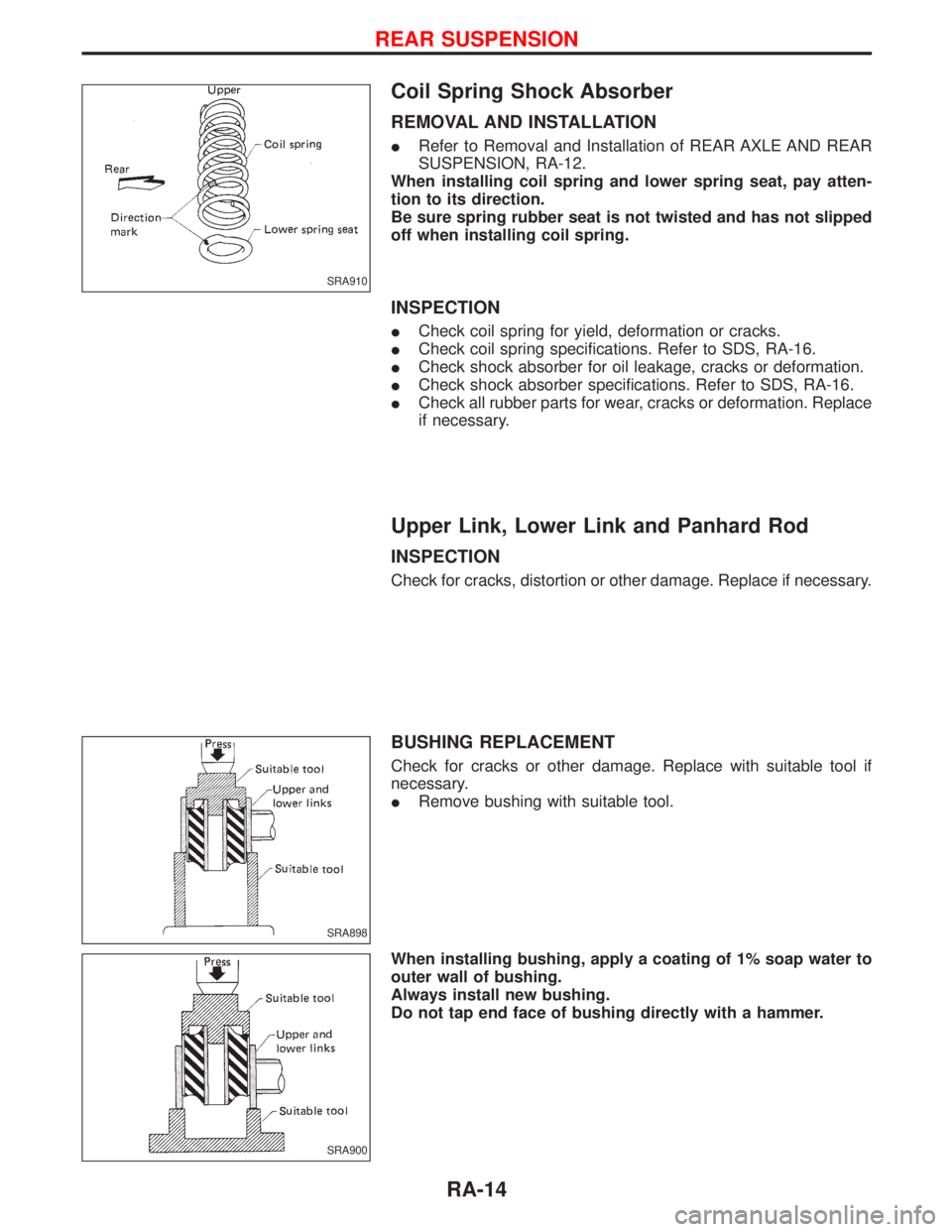

Stabilizer Bar

REMOVAL AND INSTALLATION

IWhen removing and installing stabilizer bar, fix portion A.

SRA909

REAR SUSPENSION

Upper Link, Lower Link and Panhard Rod

(Cont'd)

RA-15

Trending: wiper relay, four wheel drive, wheel bolt torque, headlamp, engine oil, trunk release, drain bolt