NISSAN TERRANO 2002 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 1571 of 1767

13. Measure both bearing in the same way and write the left side

bearing measurement next to ªEº and the right side bearing

measurement next to ªFº.

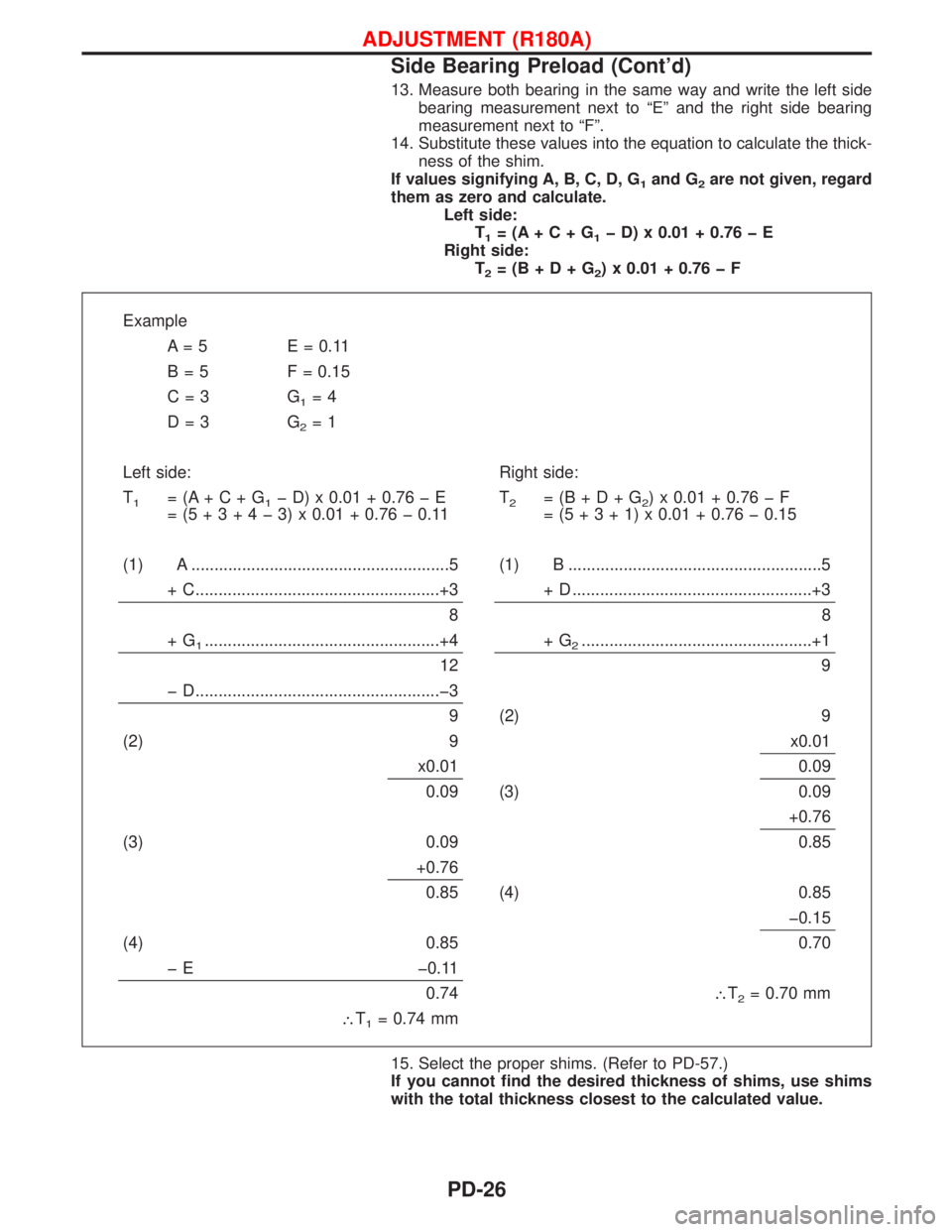

14. Substitute these values into the equation to calculate the thick-

ness of the shim.

If values signifying A, B, C, D, G

1and G2are not given, regard

them as zero and calculate.

Left side:

T

1=(A+C+G1þD)x0.01+0.76þE

Right side:

T

2=(B+D+G2)x0.01+0.76þF

Example

A = 5 E = 0.11

B = 5 F = 0.15

C=3 G

1=4

D=3 G

2=1

Left side: Right side:

T

1=(A+C+G1þD)x0.01+0.76þE

=(5+3+4þ3)x0.01 + 0.76 þ 0.11T2=(B+D+G2)x0.01+0.76þF

=(5+3+1)x0.01 + 0.76 þ 0.15

(1) A ........................................................5 (1) B .......................................................5

+ C.....................................................+3 + D ....................................................+3

88

+G

1...................................................+4 + G2..................................................+1

12 9

þ D.....................................................þ3

9 (2) 9

(2) 9 x0.01

x0.01 0.09

0.09 (3) 0.09

+0.76

(3) 0.09 0.85

+0.76

0.85 (4) 0.85

þ0.15

(4) 0.85 0.70

þ E þ0.11

0.74\T

2= 0.70 mm

\T

1= 0.74 mm

15. Select the proper shims. (Refer to PD-57.)

If you cannot find the desired thickness of shims, use shims

with the total thickness closest to the calculated value.

ADJUSTMENT (R180A)

Side Bearing Preload (Cont'd)

PD-26

Page 1572 of 1767

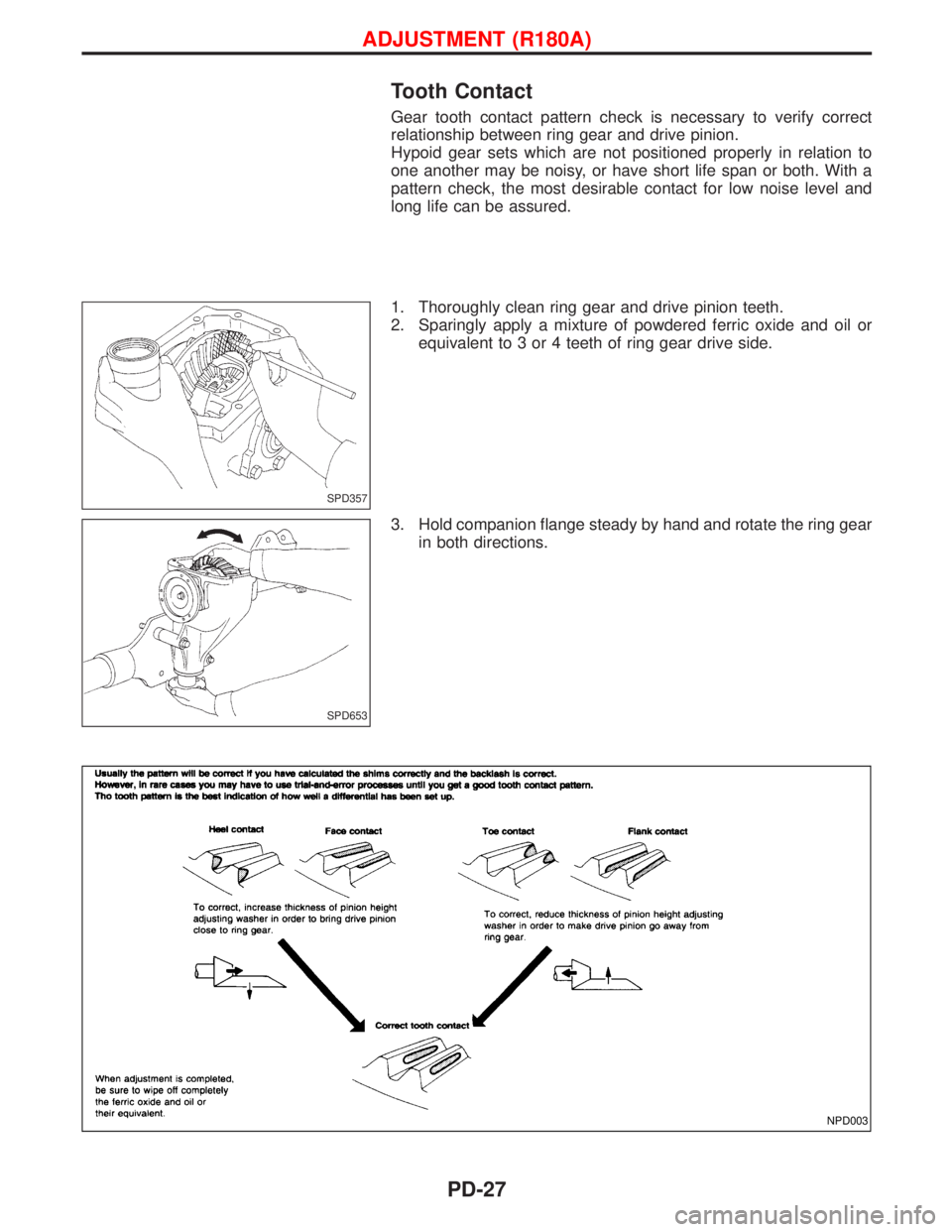

Tooth Contact

Gear tooth contact pattern check is necessary to verify correct

relationship between ring gear and drive pinion.

Hypoid gear sets which are not positioned properly in relation to

one another may be noisy, or have short life span or both. With a

pattern check, the most desirable contact for low noise level and

long life can be assured.

1. Thoroughly clean ring gear and drive pinion teeth.

2. Sparingly apply a mixture of powdered ferric oxide and oil or

equivalent to 3 or 4 teeth of ring gear drive side.

3. Hold companion flange steady by hand and rotate the ring gear

in both directions.

SPD357

SPD653

NPD003

ADJUSTMENT (R180A)

PD-27

Page 1573 of 1767

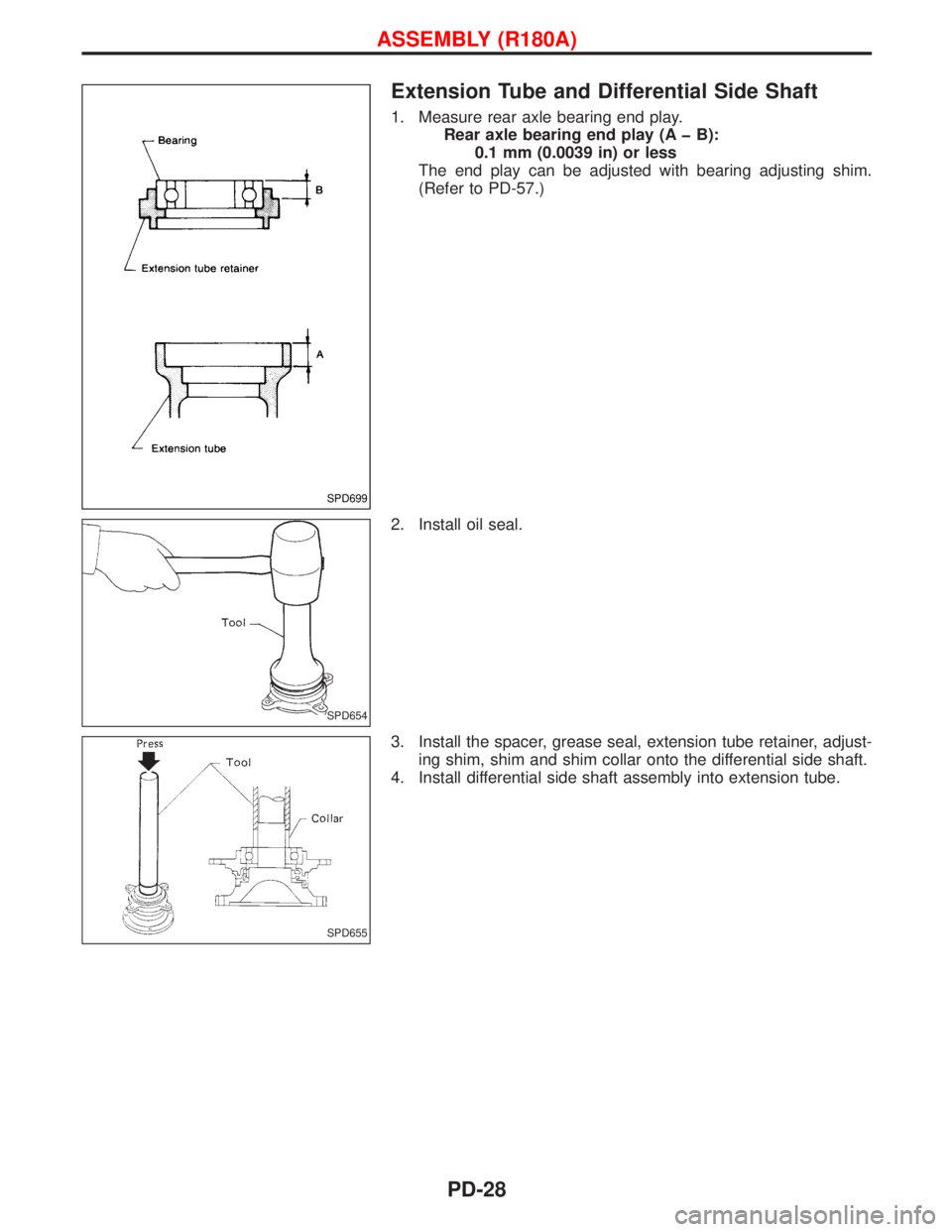

Extension Tube and Differential Side Shaft

1. Measure rear axle bearing end play.

Rear axle bearing end play (A þ B):

0.1 mm (0.0039 in) or less

The end play can be adjusted with bearing adjusting shim.

(Refer to PD-57.)

2. Install oil seal.

3. Install the spacer, grease seal, extension tube retainer, adjust-

ing shim, shim and shim collar onto the differential side shaft.

4. Install differential side shaft assembly into extension tube.

SPD699

SPD654

SPD655

ASSEMBLY (R180A)

PD-28

Page 1574 of 1767

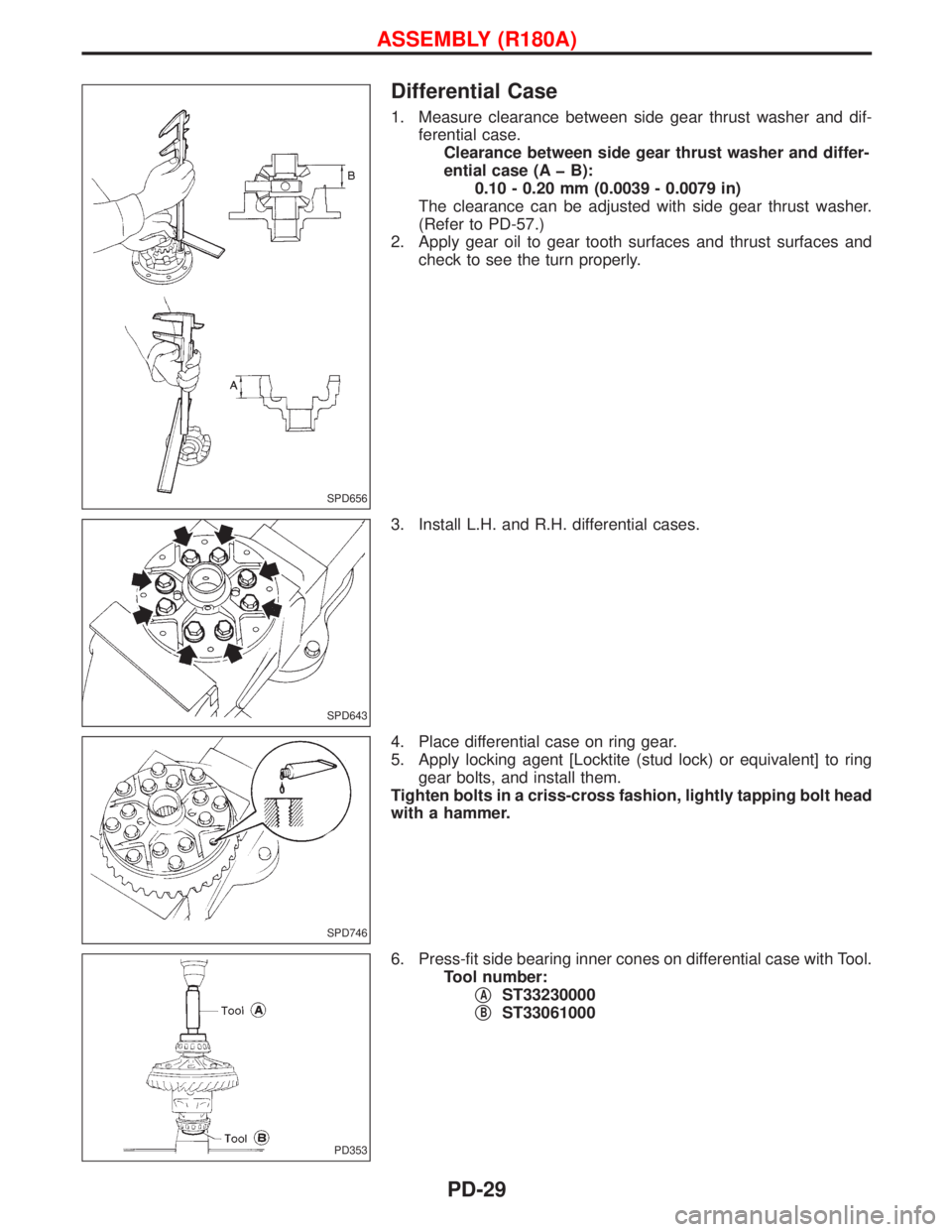

Differential Case

1. Measure clearance between side gear thrust washer and dif-

ferential case.

Clearance between side gear thrust washer and differ-

ential case (A þ B):

0.10 - 0.20 mm (0.0039 - 0.0079 in)

The clearance can be adjusted with side gear thrust washer.

(Refer to PD-57.)

2. Apply gear oil to gear tooth surfaces and thrust surfaces and

check to see the turn properly.

3. Install L.H. and R.H. differential cases.

4. Place differential case on ring gear.

5. Apply locking agent [Locktite (stud lock) or equivalent] to ring

gear bolts, and install them.

Tighten bolts in a criss-cross fashion, lightly tapping bolt head

with a hammer.

6. Press-fit side bearing inner cones on differential case with Tool.

Tool number:

q

AST33230000

q

BST33061000

SPD656

SPD643

SPD746

PD353

ASSEMBLY (R180A)

PD-29

Page 1575 of 1767

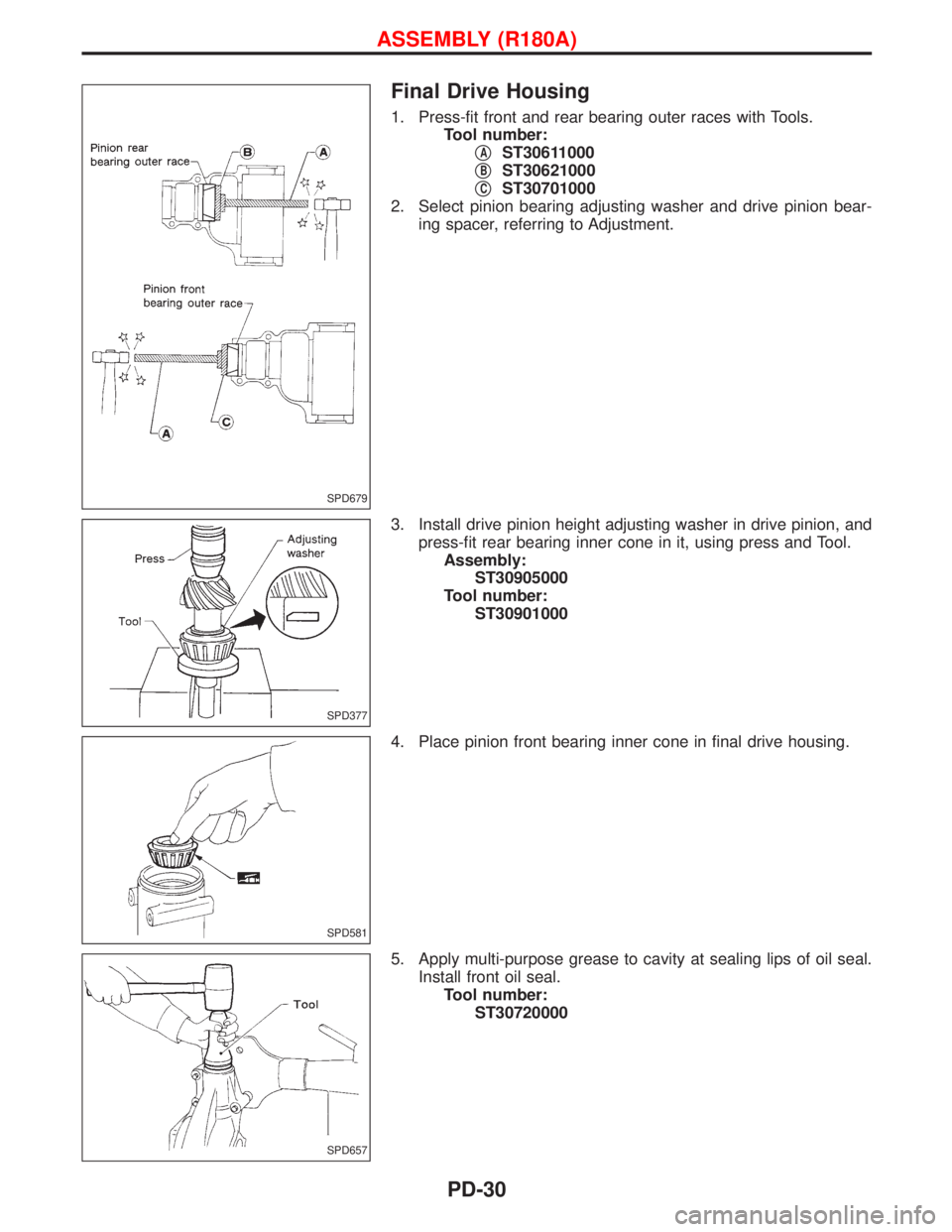

Final Drive Housing

1. Press-fit front and rear bearing outer races with Tools.

Tool number:

q

AST30611000

q

BST30621000

q

CST30701000

2. Select pinion bearing adjusting washer and drive pinion bear-

ing spacer, referring to Adjustment.

3. Install drive pinion height adjusting washer in drive pinion, and

press-fit rear bearing inner cone in it, using press and Tool.

Assembly:

ST30905000

Tool number:

ST30901000

4. Place pinion front bearing inner cone in final drive housing.

5. Apply multi-purpose grease to cavity at sealing lips of oil seal.

Install front oil seal.

Tool number:

ST30720000

SPD679

SPD377

SPD581

SPD657

ASSEMBLY (R180A)

PD-30

Page 1576 of 1767

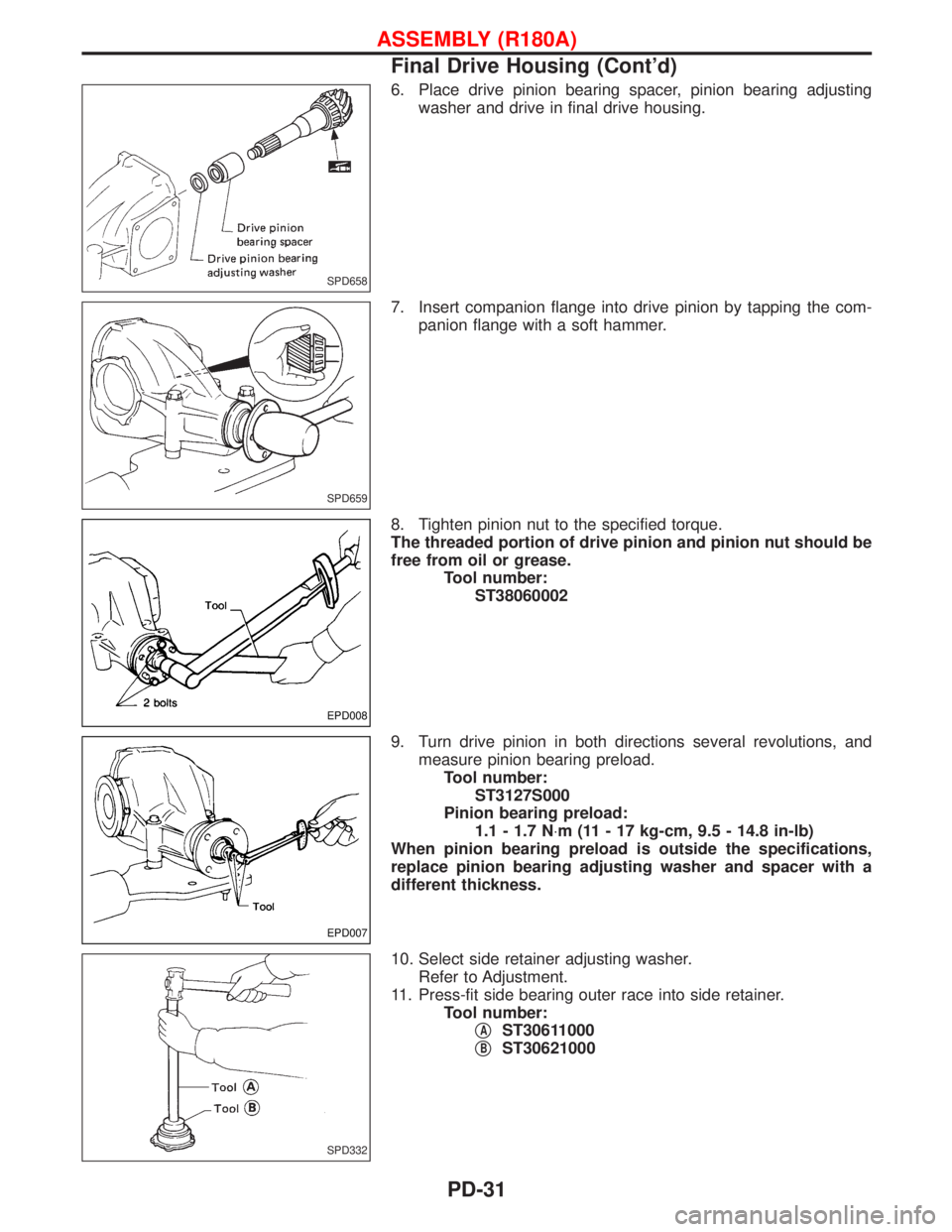

6. Place drive pinion bearing spacer, pinion bearing adjusting

washer and drive in final drive housing.

7. Insert companion flange into drive pinion by tapping the com-

panion flange with a soft hammer.

8. Tighten pinion nut to the specified torque.

The threaded portion of drive pinion and pinion nut should be

free from oil or grease.

Tool number:

ST38060002

9. Turn drive pinion in both directions several revolutions, and

measure pinion bearing preload.

Tool number:

ST3127S000

Pinion bearing preload:

1.1 - 1.7 N×m (11 - 17 kg-cm, 9.5 - 14.8 in-lb)

When pinion bearing preload is outside the specifications,

replace pinion bearing adjusting washer and spacer with a

different thickness.

10. Select side retainer adjusting washer.

Refer to Adjustment.

11. Press-fit side bearing outer race into side retainer.

Tool number:

q

AST30611000

q

BST30621000

SPD658

SPD659

EPD008

EPD007

SPD332

ASSEMBLY (R180A)

Final Drive Housing (Cont'd)

PD-31

Page 1577 of 1767

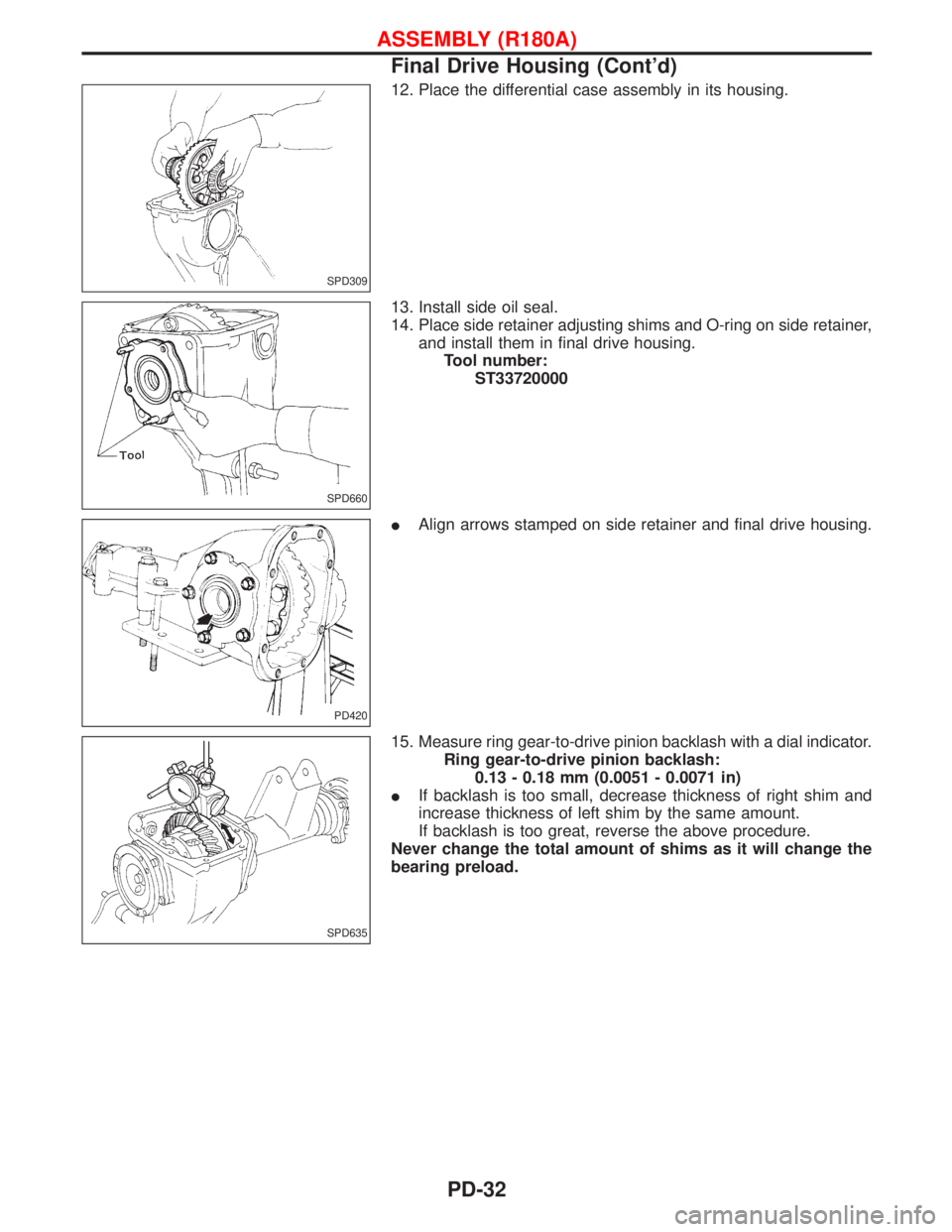

12. Place the differential case assembly in its housing.

13. Install side oil seal.

14. Place side retainer adjusting shims and O-ring on side retainer,

and install them in final drive housing.

Tool number:

ST33720000

IAlign arrows stamped on side retainer and final drive housing.

15. Measure ring gear-to-drive pinion backlash with a dial indicator.

Ring gear-to-drive pinion backlash:

0.13 - 0.18 mm (0.0051 - 0.0071 in)

IIf backlash is too small, decrease thickness of right shim and

increase thickness of left shim by the same amount.

If backlash is too great, reverse the above procedure.

Never change the total amount of shims as it will change the

bearing preload.

SPD309

SPD660

PD420

SPD635

ASSEMBLY (R180A)

Final Drive Housing (Cont'd)

PD-32

Page 1578 of 1767

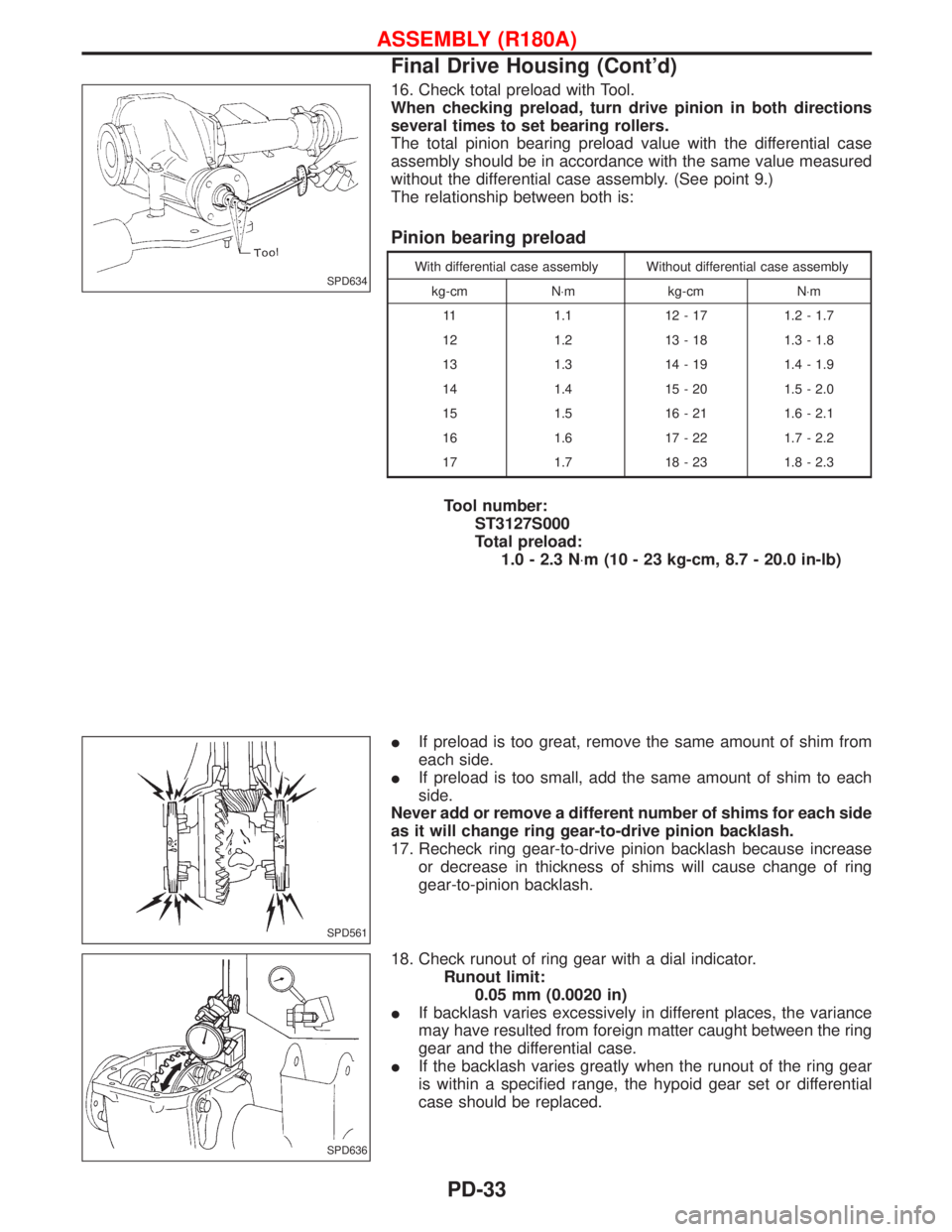

16. Check total preload with Tool.

When checking preload, turn drive pinion in both directions

several times to set bearing rollers.

The total pinion bearing preload value with the differential case

assembly should be in accordance with the same value measured

without the differential case assembly. (See point 9.)

The relationship between both is:

Pinion bearing preload

With differential case assembly Without differential case assembly

kg-cm N×m kg-cm N×m

11 1.1 12 - 17 1.2 - 1.7

12 1.2 13 - 18 1.3 - 1.8

13 1.3 14 - 19 1.4 - 1.9

14 1.4 15 - 20 1.5 - 2.0

15 1.5 16 - 21 1.6 - 2.1

16 1.6 17 - 22 1.7 - 2.2

17 1.7 18 - 23 1.8 - 2.3

Tool number:

ST3127S000

Total preload:

1.0 - 2.3 N×m (10 - 23 kg-cm, 8.7 - 20.0 in-lb)

IIf preload is too great, remove the same amount of shim from

each side.

IIf preload is too small, add the same amount of shim to each

side.

Never add or remove a different number of shims for each side

as it will change ring gear-to-drive pinion backlash.

17. Recheck ring gear-to-drive pinion backlash because increase

or decrease in thickness of shims will cause change of ring

gear-to-pinion backlash.

18. Check runout of ring gear with a dial indicator.

Runout limit:

0.05 mm (0.0020 in)

IIf backlash varies excessively in different places, the variance

may have resulted from foreign matter caught between the ring

gear and the differential case.

IIf the backlash varies greatly when the runout of the ring gear

is within a specified range, the hypoid gear set or differential

case should be replaced.

SPD634

SPD561

SPD636

ASSEMBLY (R180A)

Final Drive Housing (Cont'd)

PD-33

Page 1579 of 1767

19. Check tooth contact.

Refer to Adjustment.

20. Install rear cover and gasket.

21. Install extension tube and differential side shaft assembly.

SPD661

ASSEMBLY (R180A)

Final Drive Housing (Cont'd)

PD-34

Page 1580 of 1767

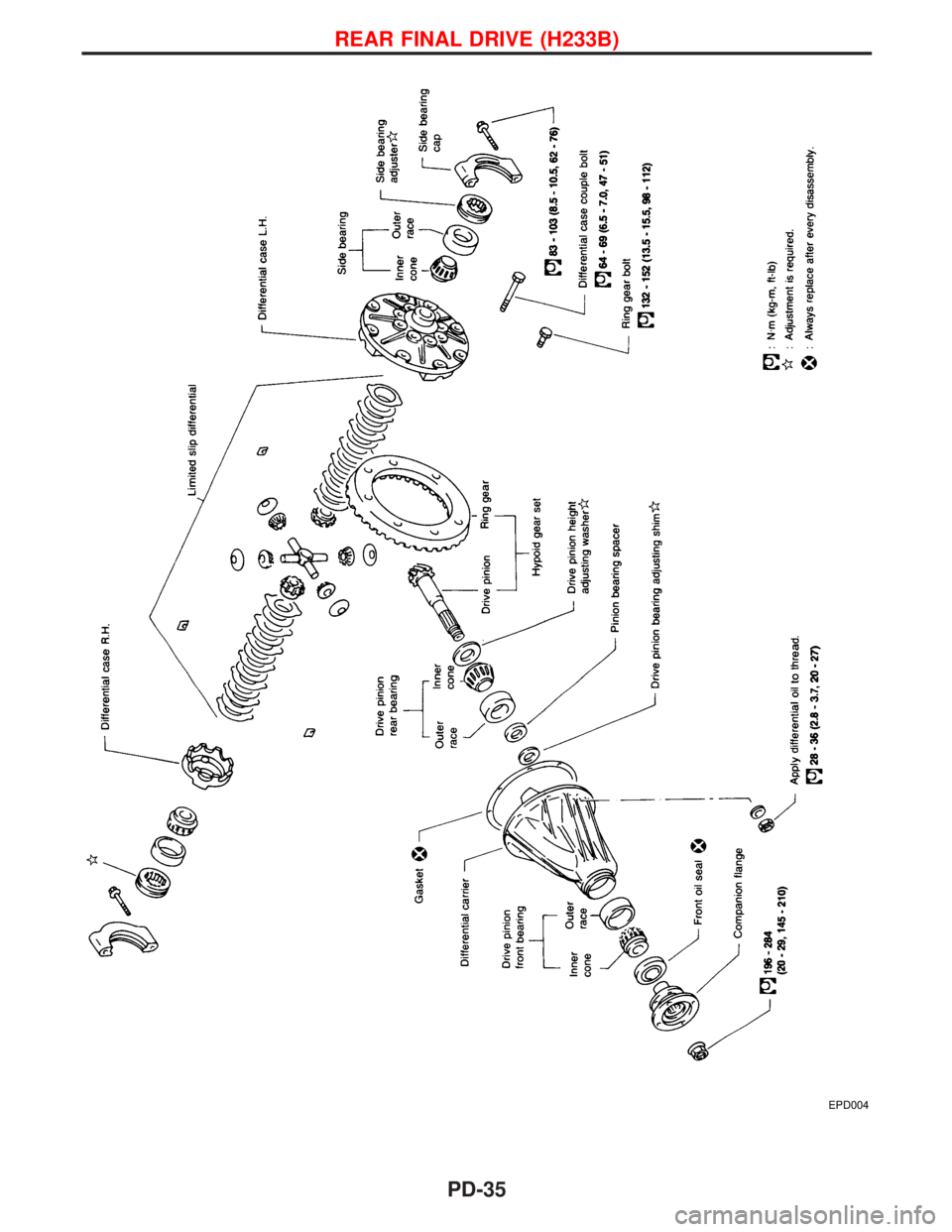

EPD004

REAR FINAL DRIVE (H233B)

PD-35