pump NISSAN TERRANO 2002 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 104 of 1767

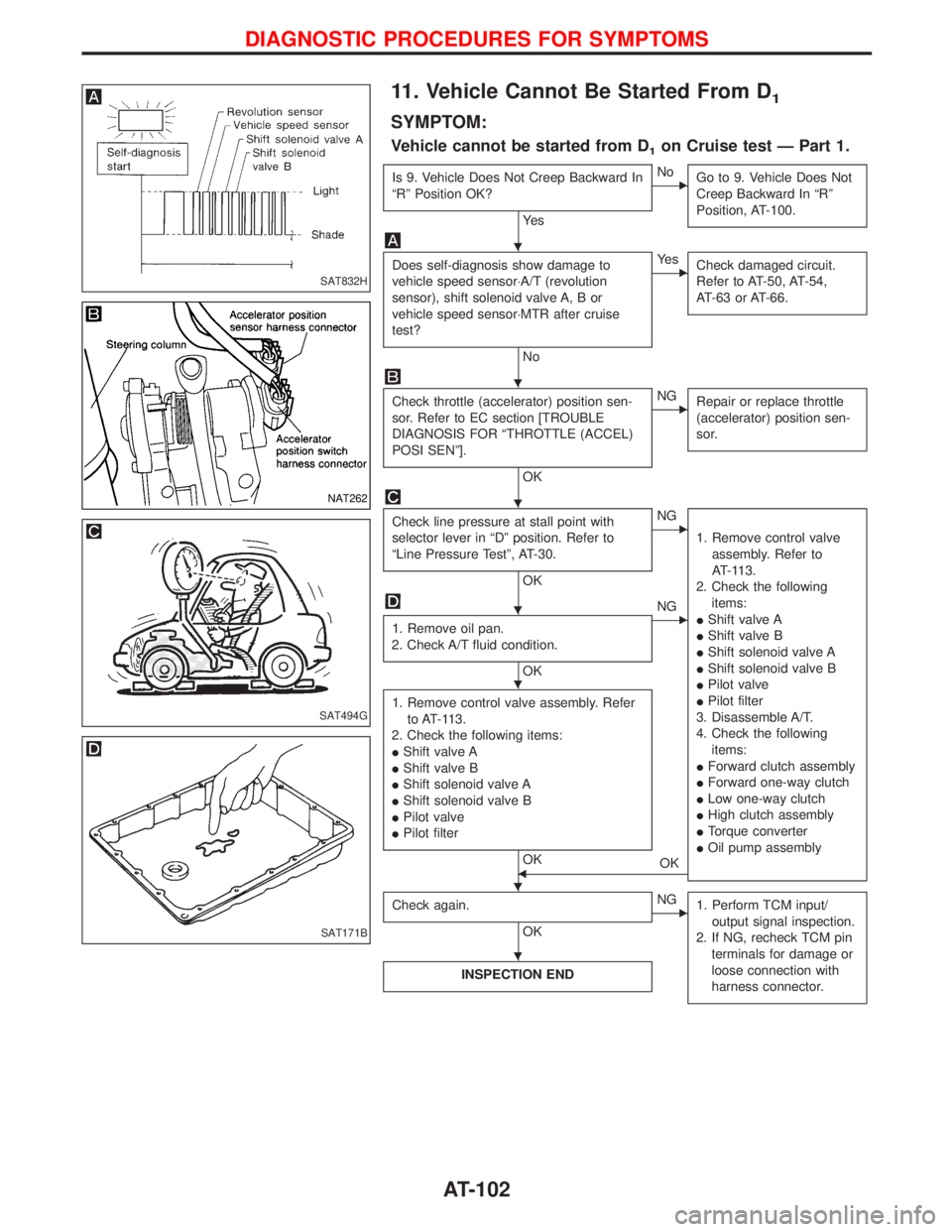

11. Vehicle Cannot Be Started From D1

SYMPTOM:

Vehicle cannot be started from D1on Cruise test Ð Part 1.

Is 9. Vehicle Does Not Creep Backward In

ªRº Position OK?

Ye s

ENo

Go to 9. Vehicle Does Not

Creep Backward In ªRº

Position, AT-100.

Does self-diagnosis show damage to

vehicle speed sensor×A/T (revolution

sensor), shift solenoid valve A, B or

vehicle speed sensor×MTR after cruise

test?

No

EYe s

Check damaged circuit.

Refer to AT-50, AT-54,

AT-63 or AT-66.

Check throttle (accelerator) position sen-

sor. Refer to EC section [TROUBLE

DIAGNOSIS FOR ªTHROTTLE (ACCEL)

POSI SENº].

OK

ENG

Repair or replace throttle

(accelerator) position sen-

sor.

Check line pressure at stall point with

selector lever in ªDº position. Refer to

ªLine Pressure Testº, AT-30.

OK

ENG

1. Remove control valve

assembly. Refer to

AT-113.

2. Check the following

items:

IShift valve A

IShift valve B

IShift solenoid valve A

IShift solenoid valve B

IPilot valve

IPilot filter

3. Disassemble A/T.

4. Check the following

items:

IForward clutch assembly

IForward one-way clutch

ILow one-way clutch

IHigh clutch assembly

ITorque converter

IOil pump assembly

1. Remove oil pan.

2. Check A/T fluid condition.

OK

ENG

1. Remove control valve assembly. Refer

to AT-113.

2. Check the following items:

IShift valve A

IShift valve B

IShift solenoid valve A

IShift solenoid valve B

IPilot valve

IPilot filter

OKFOK

Check again.

OK

ENG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

SAT832H

NAT262

SAT494G

SAT171B

H

H

H

H

H

H H

H

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-102

Page 105 of 1767

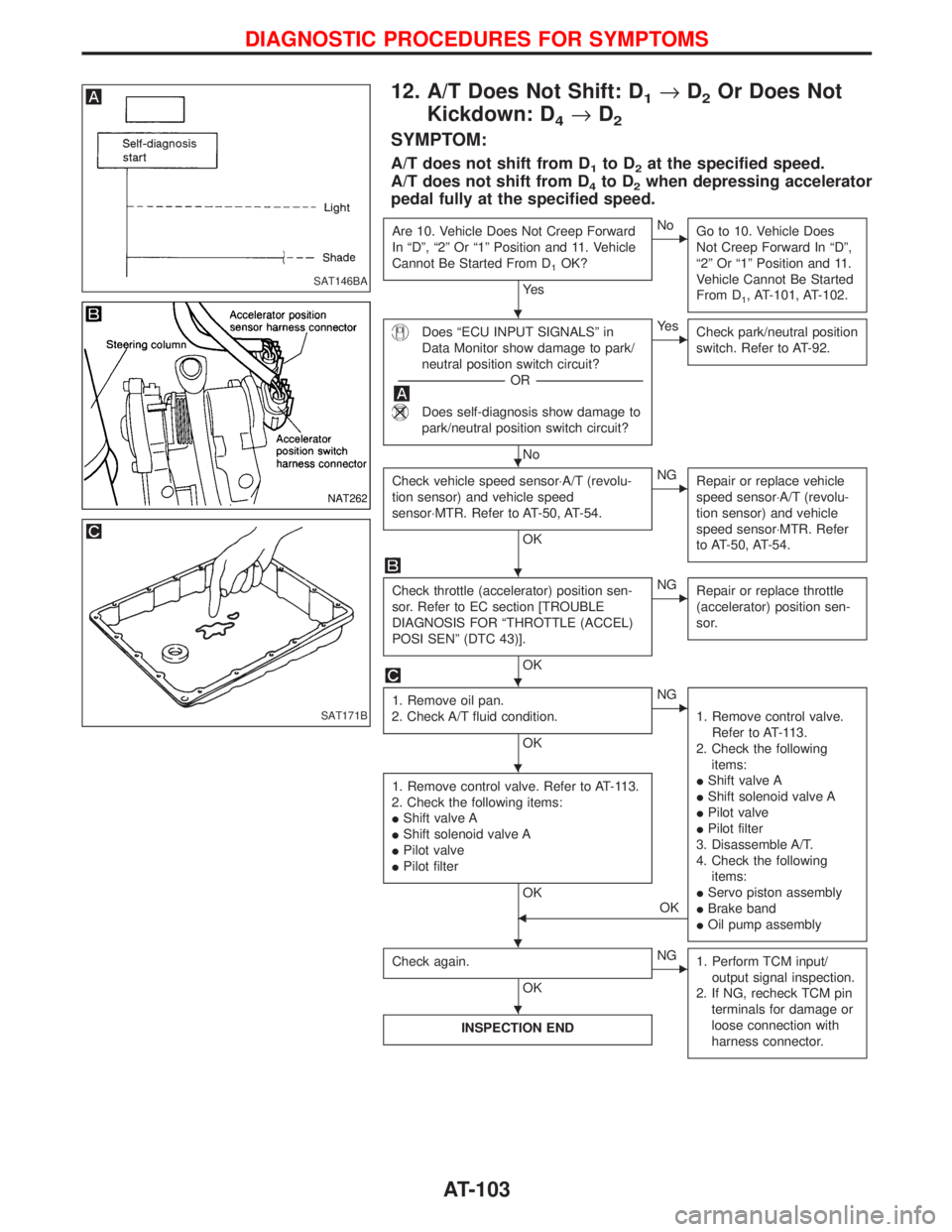

12. A/T Does Not Shift: D1®D2Or Does Not

Kickdown: D

4®D2

SYMPTOM:

A/T does not shift from D1to D2at the specified speed.

A/T does not shift from D

4to D2when depressing accelerator

pedal fully at the specified speed.

Are 10. Vehicle Does Not Creep Forward

In ªDº, ª2º Or ª1º Position and 11. Vehicle

Cannot Be Started From D

1OK?

Ye s

ENo

Go to 10. Vehicle Does

Not Creep Forward In ªDº,

ª2º Or ª1º Position and 11.

Vehicle Cannot Be Started

From D

1, AT-101, AT-102.

Does ªECU INPUT SIGNALSº in

Data Monitor show damage to park/

neutral position switch circuit?

-----------------------------------------------------------------------------------------------------------------------OR -----------------------------------------------------------------------------------------------------------------------

Does self-diagnosis show damage to

park/neutral position switch circuit?

No

EYe s

Check park/neutral position

switch. Refer to AT-92.

Check vehicle speed sensor×A/T (revolu-

tion sensor) and vehicle speed

sensor×MTR. Refer to AT-50, AT-54.

OK

ENG

Repair or replace vehicle

speed sensor×A/T (revolu-

tion sensor) and vehicle

speed sensor×MTR. Refer

to AT-50, AT-54.

Check throttle (accelerator) position sen-

sor. Refer to EC section [TROUBLE

DIAGNOSIS FOR ªTHROTTLE (ACCEL)

POSI SENº (DTC 43)].

OK

ENG

Repair or replace throttle

(accelerator) position sen-

sor.

1. Remove oil pan.

2. Check A/T fluid condition.

OK

ENG

1. Remove control valve.

Refer to AT-113.

2. Check the following

items:

IShift valve A

IShift solenoid valve A

IPilot valve

IPilot filter

3. Disassemble A/T.

4. Check the following

items:

IServo piston assembly

IBrake band

IOil pump assembly

1. Remove control valve. Refer to AT-113.

2. Check the following items:

IShift valve A

IShift solenoid valve A

IPilot valve

IPilot filter

OK

FOK

Check again.

OK

ENG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

SAT146BA

NAT262

SAT171B

H

H

H

H

H

H H

H

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-103

Page 106 of 1767

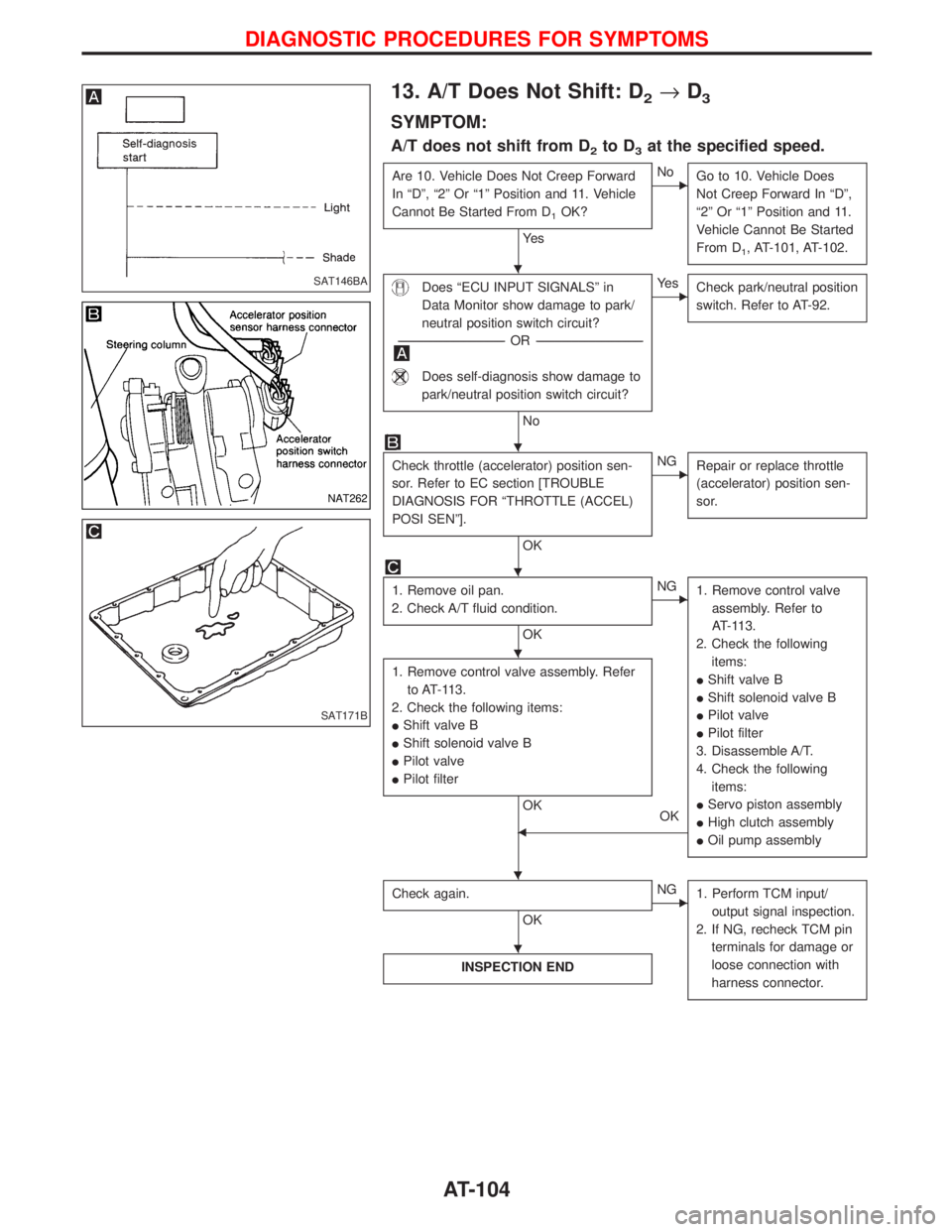

13. A/T Does Not Shift: D2®D3

SYMPTOM:

A/T does not shift from D2to D3at the specified speed.

Are 10. Vehicle Does Not Creep Forward

In ªDº, ª2º Or ª1º Position and 11. Vehicle

Cannot Be Started From D

1OK?

Ye s

ENo

Go to 10. Vehicle Does

Not Creep Forward In ªDº,

ª2º Or ª1º Position and 11.

Vehicle Cannot Be Started

From D

1, AT-101, AT-102.

Does ªECU INPUT SIGNALSº in

Data Monitor show damage to park/

neutral position switch circuit?

-----------------------------------------------------------------------------------------------------------------------OR -----------------------------------------------------------------------------------------------------------------------

Does self-diagnosis show damage to

park/neutral position switch circuit?

No

EYe s

Check park/neutral position

switch. Refer to AT-92.

Check throttle (accelerator) position sen-

sor. Refer to EC section [TROUBLE

DIAGNOSIS FOR ªTHROTTLE (ACCEL)

POSI SENº].

OK

ENG

Repair or replace throttle

(accelerator) position sen-

sor.

1. Remove oil pan.

2. Check A/T fluid condition.

OK

ENG

1. Remove control valve

assembly. Refer to

AT-113.

2. Check the following

items:

IShift valve B

IShift solenoid valve B

IPilot valve

IPilot filter

3. Disassemble A/T.

4. Check the following

items:

IServo piston assembly

IHigh clutch assembly

IOil pump assembly

1. Remove control valve assembly. Refer

to AT-113.

2. Check the following items:

IShift valve B

IShift solenoid valve B

IPilot valve

IPilot filter

OK

OK

F

Check again.

OK

ENG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

SAT146BA

NAT262

SAT171B

H

H

H

H

H H

H

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-104

Page 107 of 1767

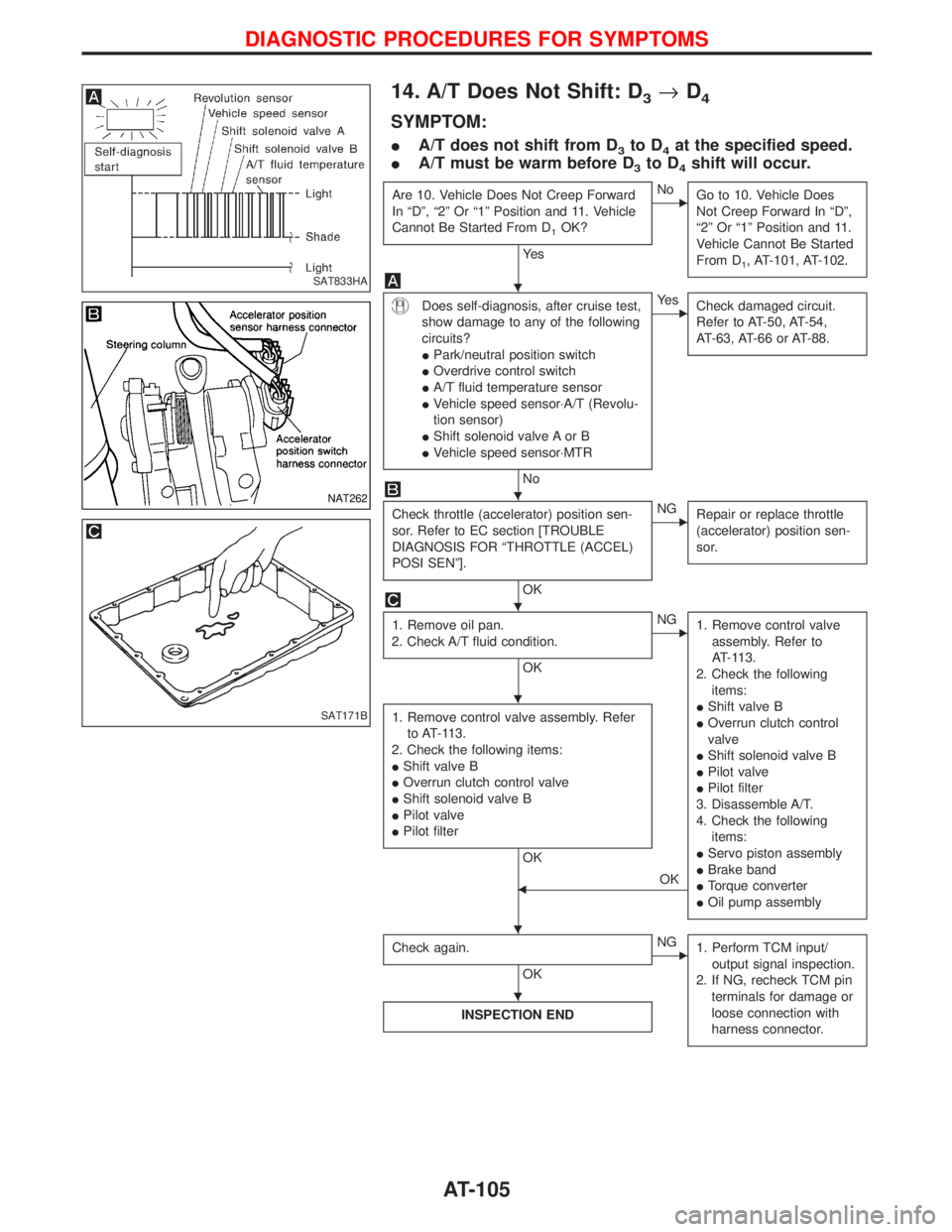

14. A/T Does Not Shift: D3®D4

SYMPTOM:

IA/T does not shift from D3to D4at the specified speed.

IA/T must be warm before D

3to D4shift will occur.

Are 10. Vehicle Does Not Creep Forward

In ªDº, ª2º Or ª1º Position and 11. Vehicle

Cannot Be Started From D

1OK?

Ye s

ENo

Go to 10. Vehicle Does

Not Creep Forward In ªDº,

ª2º Or ª1º Position and 11.

Vehicle Cannot Be Started

From D

1, AT-101, AT-102.

Does self-diagnosis, after cruise test,

show damage to any of the following

circuits?

IPark/neutral position switch

IOverdrive control switch

IA/T fluid temperature sensor

IVehicle speed sensor×A/T (Revolu-

tion sensor)

IShift solenoid valve A or B

IVehicle speed sensor×MTR

No

EYe s

Check damaged circuit.

Refer to AT-50, AT-54,

AT-63, AT-66 or AT-88.

Check throttle (accelerator) position sen-

sor. Refer to EC section [TROUBLE

DIAGNOSIS FOR ªTHROTTLE (ACCEL)

POSI SENº].

OK

ENG

Repair or replace throttle

(accelerator) position sen-

sor.

1. Remove oil pan.

2. Check A/T fluid condition.

OK

ENG

1. Remove control valve

assembly. Refer to

AT-113.

2. Check the following

items:

IShift valve B

IOverrun clutch control

valve

IShift solenoid valve B

IPilot valve

IPilot filter

3. Disassemble A/T.

4. Check the following

items:

IServo piston assembly

IBrake band

ITorque converter

IOil pump assembly

1. Remove control valve assembly. Refer

to AT-113.

2. Check the following items:

IShift valve B

IOverrun clutch control valve

IShift solenoid valve B

IPilot valve

IPilot filter

OK

FOK

Check again.

OK

ENG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

SAT833HA

NAT262

SAT171B

H

H

H

H

H H

H

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-105

Page 109 of 1767

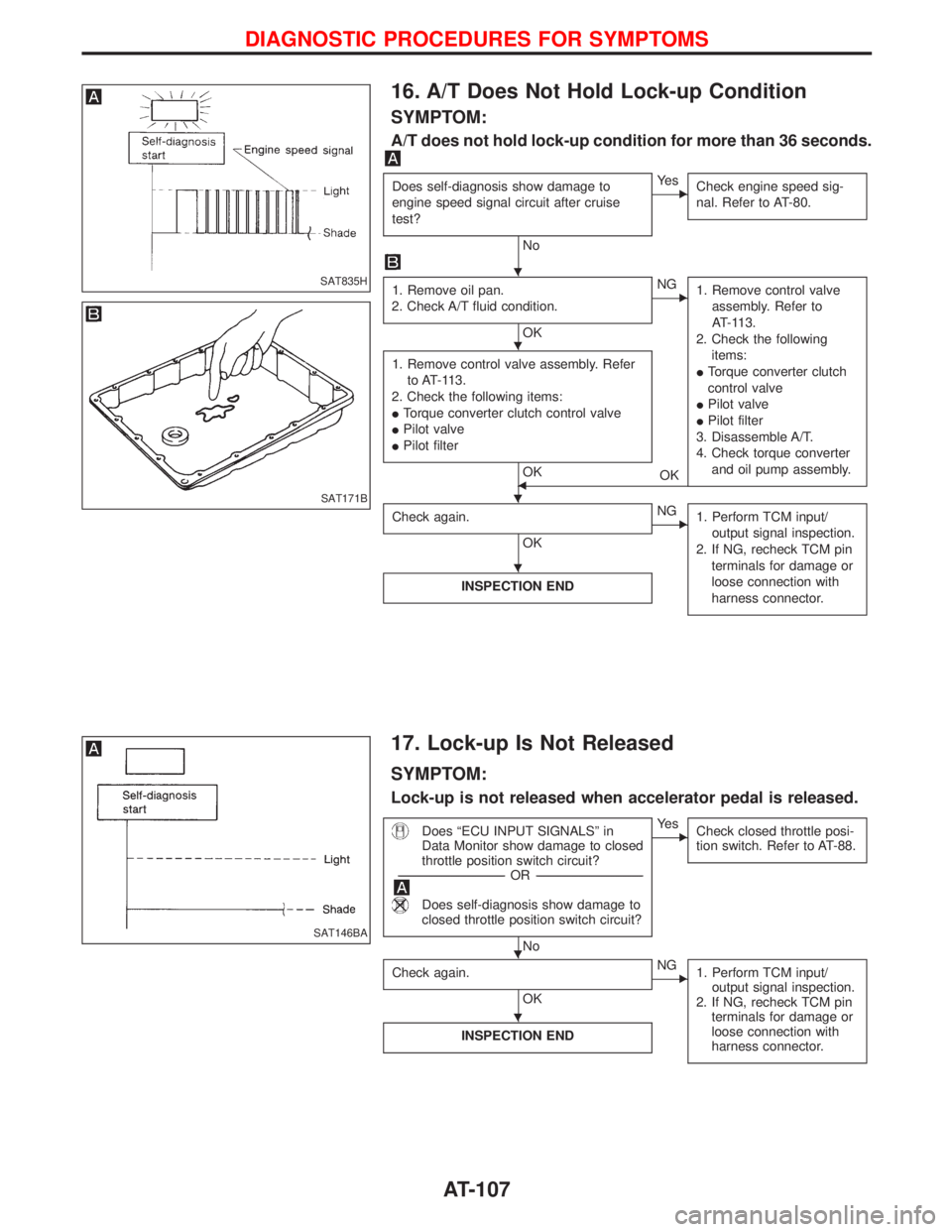

16. A/T Does Not Hold Lock-up Condition

SYMPTOM:

A/T does not hold lock-up condition for more than 36 seconds.

Does self-diagnosis show damage to

engine speed signal circuit after cruise

test?

No

EYe s

Check engine speed sig-

nal. Refer to AT-80.

1. Remove oil pan.

2. Check A/T fluid condition.

OK

ENG

1. Remove control valve

assembly. Refer to

AT-113.

2. Check the following

items:

ITorque converter clutch

control valve

IPilot valve

IPilot filter

3. Disassemble A/T.

4. Check torque converter

and oil pump assembly.

1. Remove control valve assembly. Refer

to AT-113.

2. Check the following items:

ITorque converter clutch control valve

IPilot valve

IPilot filter

OKFOK

Check again.

OK

ENG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

17. Lock-up Is Not Released

SYMPTOM:

Lock-up is not released when accelerator pedal is released.

Does ªECU INPUT SIGNALSº in

Data Monitor show damage to closed

throttle position switch circuit?

-----------------------------------------------------------------------------------------------------------------------OR -----------------------------------------------------------------------------------------------------------------------

Does self-diagnosis show damage to

closed throttle position switch circuit?

No

EYe s

Check closed throttle posi-

tion switch. Refer to AT-88.

Check again.

OK

ENG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

SAT835H

SAT171B

SAT146BA

H

H

H H

H

H

H

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-107

Page 110 of 1767

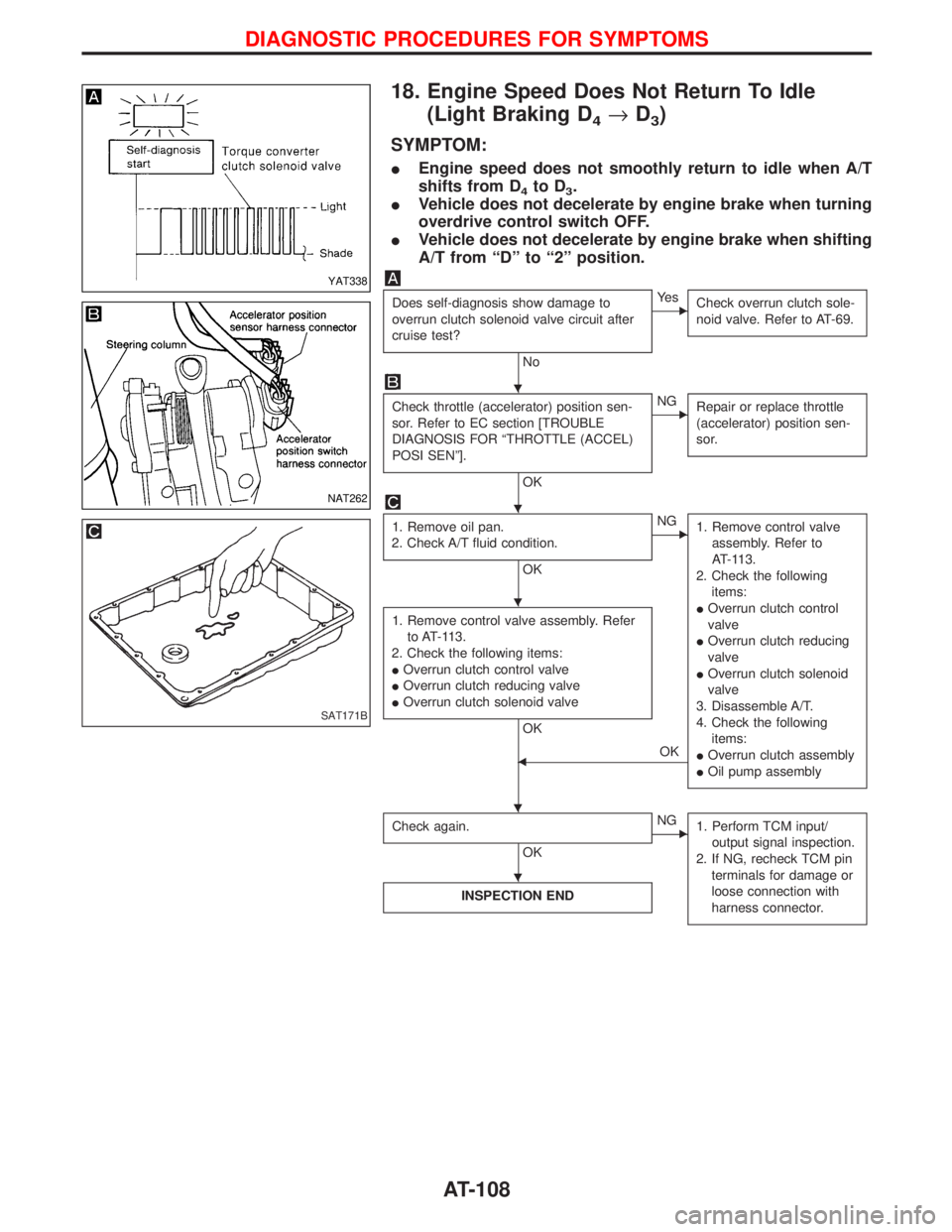

18. Engine Speed Does Not Return To Idle

(Light Braking D

4®D3)

SYMPTOM:

IEngine speed does not smoothly return to idle when A/T

shifts from D

4to D3.

IVehicle does not decelerate by engine brake when turning

overdrive control switch OFF.

IVehicle does not decelerate by engine brake when shifting

A/T from ªDº to ª2º position.

Does self-diagnosis show damage to

overrun clutch solenoid valve circuit after

cruise test?

No

EYe s

Check overrun clutch sole-

noid valve. Refer to AT-69.

Check throttle (accelerator) position sen-

sor. Refer to EC section [TROUBLE

DIAGNOSIS FOR ªTHROTTLE (ACCEL)

POSI SENº].

OK

ENG

Repair or replace throttle

(accelerator) position sen-

sor.

1. Remove oil pan.

2. Check A/T fluid condition.

OK

ENG

1. Remove control valve

assembly. Refer to

AT-113.

2. Check the following

items:

IOverrun clutch control

valve

IOverrun clutch reducing

valve

IOverrun clutch solenoid

valve

3. Disassemble A/T.

4. Check the following

items:

IOverrun clutch assembly

IOil pump assembly

1. Remove control valve assembly. Refer

to AT-113.

2. Check the following items:

IOverrun clutch control valve

IOverrun clutch reducing valve

IOverrun clutch solenoid valve

OK

FOK

Check again.

OK

ENG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

YAT338

NAT262

SAT171B

H

H

H

H H

H

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-108

Page 112 of 1767

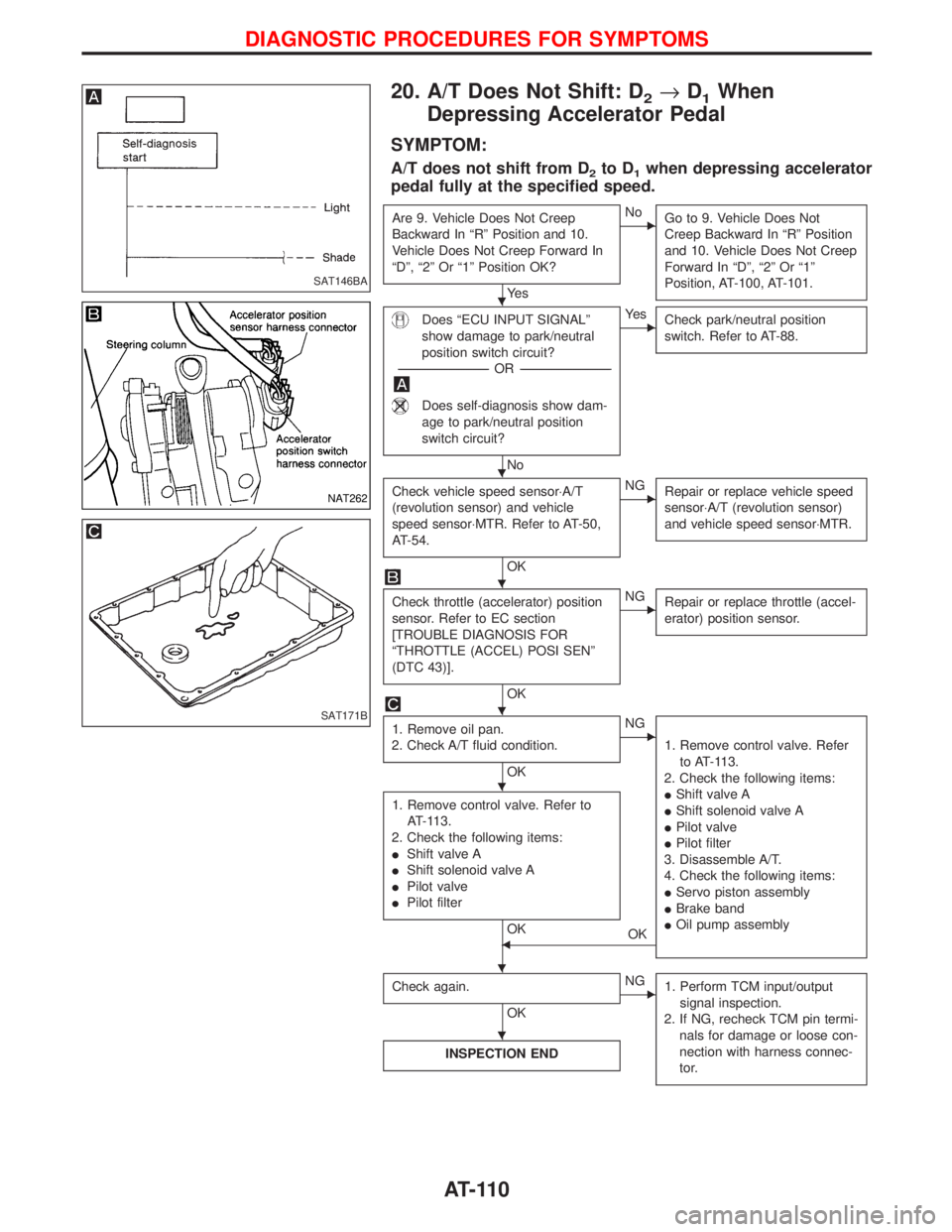

20. A/T Does Not Shift: D2®D1When

Depressing Accelerator Pedal

SYMPTOM:

A/T does not shift from D2to D1when depressing accelerator

pedal fully at the specified speed.

Are 9. Vehicle Does Not Creep

Backward In ªRº Position and 10.

Vehicle Does Not Creep Forward In

ªDº, ª2º Or ª1º Position OK?

Ye s

ENo

Go to 9. Vehicle Does Not

Creep Backward In ªRº Position

and 10. Vehicle Does Not Creep

Forward In ªDº, ª2º Or ª1º

Position, AT-100, AT-101.

Does ªECU INPUT SIGNALº

show damage to park/neutral

position switch circuit?

-----------------------------------------------------------------------------------------------------OR -----------------------------------------------------------------------------------------------------

Does self-diagnosis show dam-

age to park/neutral position

switch circuit?

No

EYe s

Check park/neutral position

switch. Refer to AT-88.

Check vehicle speed sensor×A/T

(revolution sensor) and vehicle

speed sensor×MTR. Refer to AT-50,

AT-54.

OK

ENG

Repair or replace vehicle speed

sensor×A/T (revolution sensor)

and vehicle speed sensor×MTR.

Check throttle (accelerator) position

sensor. Refer to EC section

[TROUBLE DIAGNOSIS FOR

ªTHROTTLE (ACCEL) POSI SENº

(DTC 43)].

OK

ENG

Repair or replace throttle (accel-

erator) position sensor.

1. Remove oil pan.

2. Check A/T fluid condition.

OK

ENG

1. Remove control valve. Refer

to AT-113.

2. Check the following items:

IShift valve A

IShift solenoid valve A

IPilot valve

IPilot filter

3. Disassemble A/T.

4. Check the following items:

IServo piston assembly

IBrake band

IOil pump assembly

1. Remove control valve. Refer to

AT-113.

2. Check the following items:

IShift valve A

IShift solenoid valve A

IPilot valve

IPilot filter

OKFOK

Check again.

OK

ENG

1. Perform TCM input/output

signal inspection.

2. If NG, recheck TCM pin termi-

nals for damage or loose con-

nection with harness connec-

tor.

INSPECTION END

SAT146BA

NAT262

SAT171B

H

H

H

H

H

H

H

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-110

Page 126 of 1767

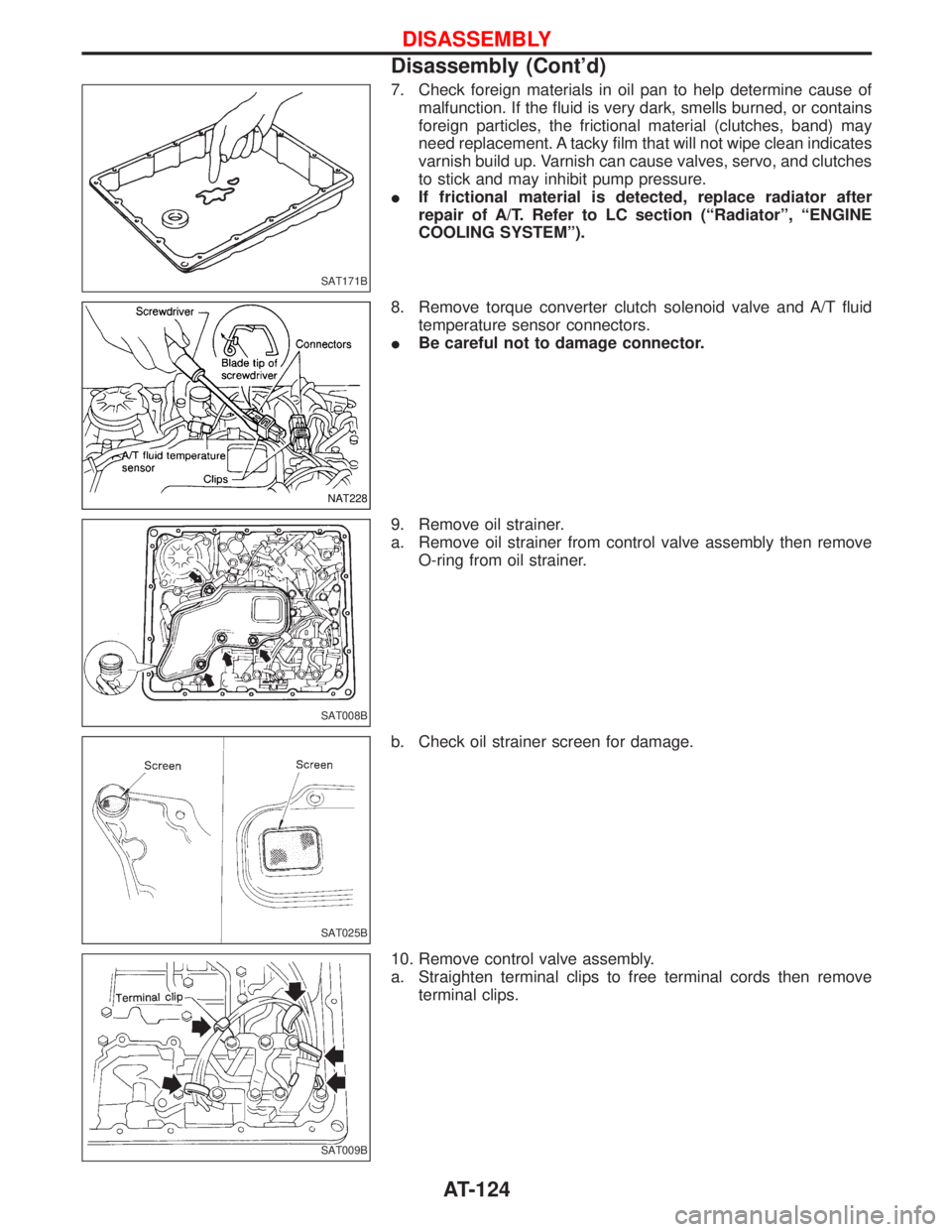

7. Check foreign materials in oil pan to help determine cause of

malfunction. If the fluid is very dark, smells burned, or contains

foreign particles, the frictional material (clutches, band) may

need replacement. A tacky film that will not wipe clean indicates

varnish build up. Varnish can cause valves, servo, and clutches

to stick and may inhibit pump pressure.

IIf frictional material is detected, replace radiator after

repair of A/T. Refer to LC section (ªRadiatorº, ªENGINE

COOLING SYSTEMº).

8. Remove torque converter clutch solenoid valve and A/T fluid

temperature sensor connectors.

IBe careful not to damage connector.

9. Remove oil strainer.

a. Remove oil strainer from control valve assembly then remove

O-ring from oil strainer.

b. Check oil strainer screen for damage.

10. Remove control valve assembly.

a. Straighten terminal clips to free terminal cords then remove

terminal clips.

SAT171B

NAT228

SAT008B

SAT025B

SAT009B

DISASSEMBLY

Disassembly (Cont'd)

AT-124

Page 128 of 1767

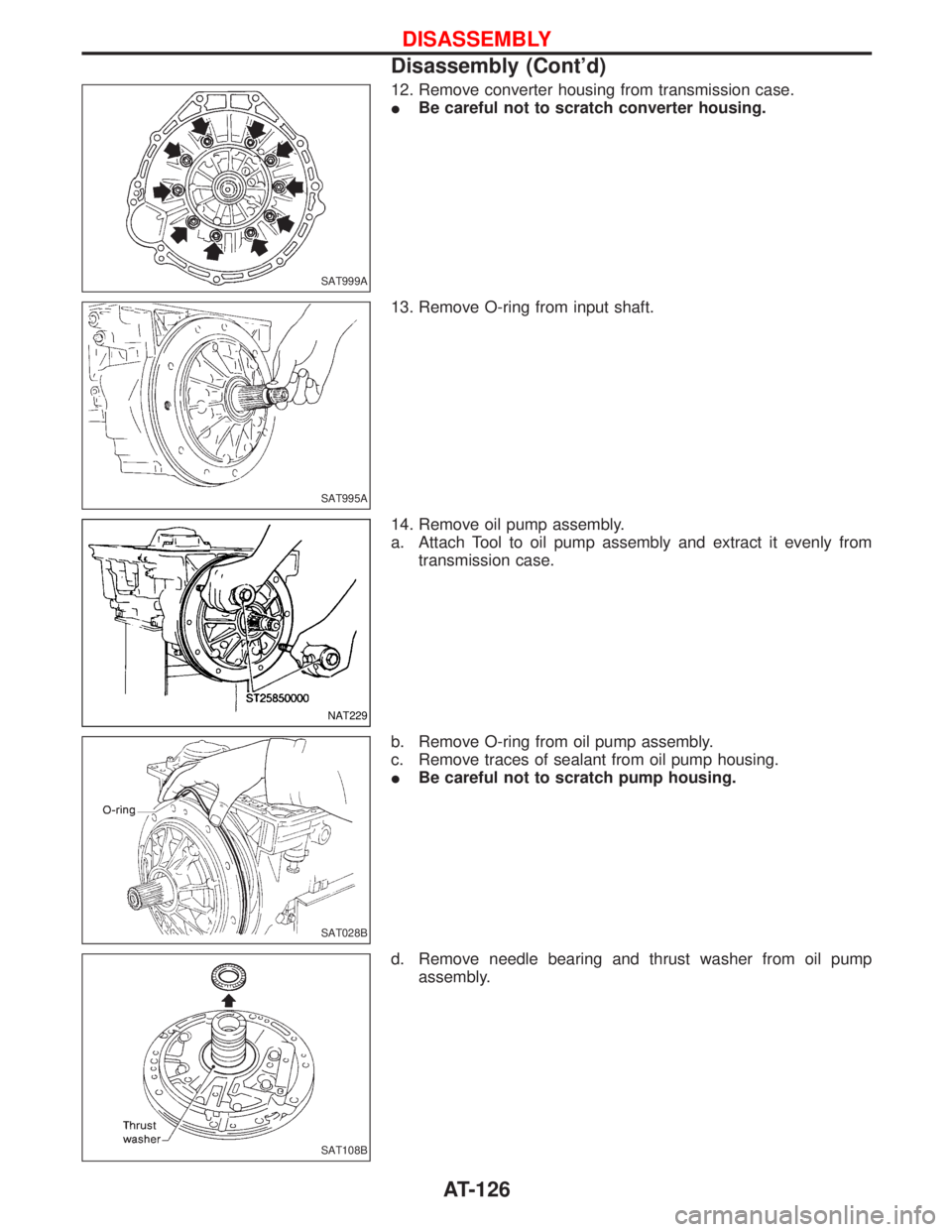

12. Remove converter housing from transmission case.

IBe careful not to scratch converter housing.

13. Remove O-ring from input shaft.

14. Remove oil pump assembly.

a. Attach Tool to oil pump assembly and extract it evenly from

transmission case.

b. Remove O-ring from oil pump assembly.

c. Remove traces of sealant from oil pump housing.

IBe careful not to scratch pump housing.

d. Remove needle bearing and thrust washer from oil pump

assembly.

SAT999A

SAT995A

NAT229

SAT028B

SAT108B

DISASSEMBLY

Disassembly (Cont'd)

AT-126

Page 129 of 1767

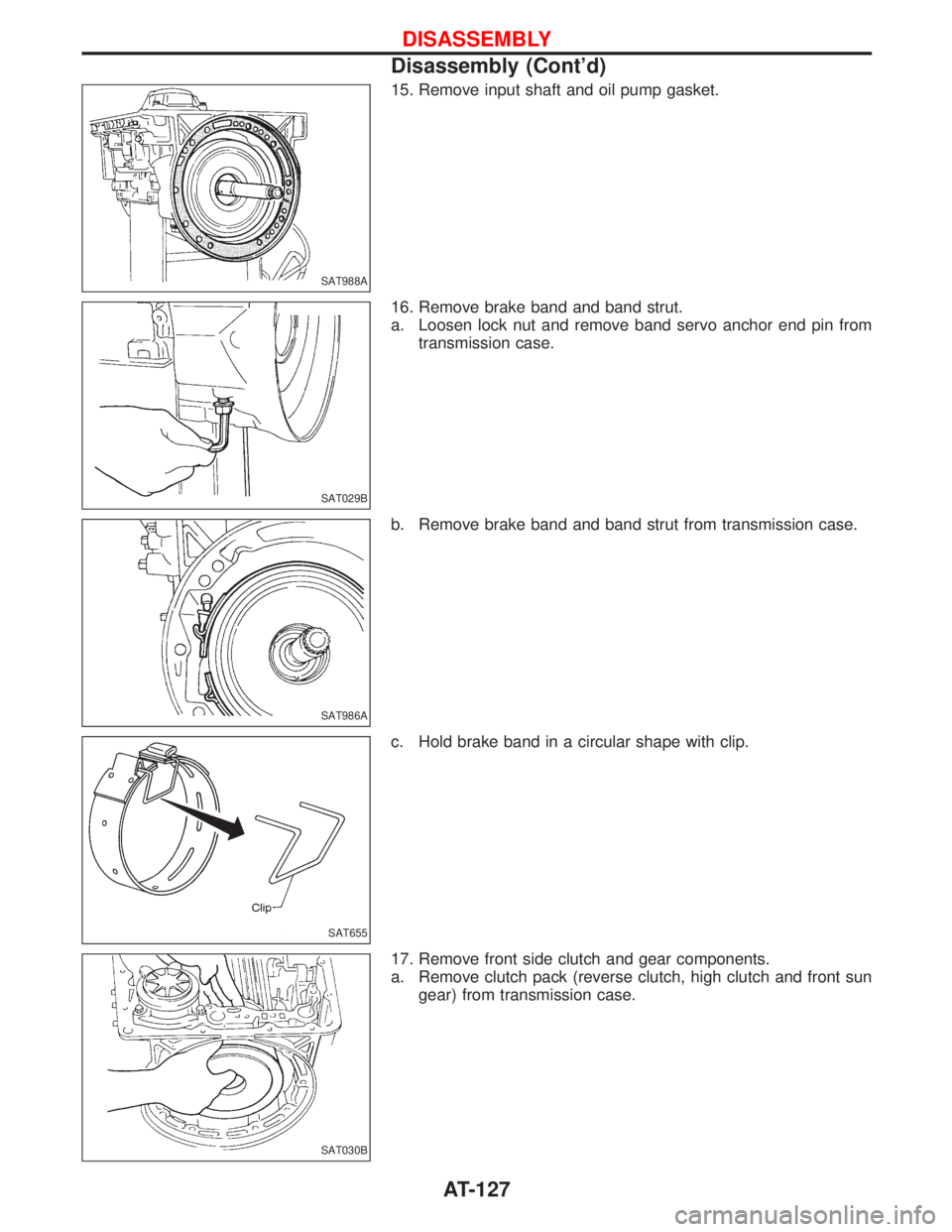

15. Remove input shaft and oil pump gasket.

16. Remove brake band and band strut.

a. Loosen lock nut and remove band servo anchor end pin from

transmission case.

b. Remove brake band and band strut from transmission case.

c. Hold brake band in a circular shape with clip.

17. Remove front side clutch and gear components.

a. Remove clutch pack (reverse clutch, high clutch and front sun

gear) from transmission case.

SAT988A

SAT029B

SAT986A

SAT655

SAT030B

DISASSEMBLY

Disassembly (Cont'd)

AT-127