pump NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 4 of 1767

1. SPORT Indicator Lamp Does Not Come On ........94

2. SPORT or SNOW Indicator Lamp Does Not

Come On...................................................................95

3. O/D OFF Indicator Lamp Does Not Come On......95

4. SPORT Indicator Lamp Does Not Come On ........96

5. Engine Cannot Be Started In²P²and²N²

Position......................................................................97

6. In²P²Position, Vehicle Moves Forward Or

Backward When Pushed...........................................97

7. In²N²Position, Vehicle Moves .............................98

8. Large Shock.²N²->²R²Position .........................99

9. Vehicle Does Not Creep Backward In²R²

Position....................................................................100

10. Vehicle Does Not Creep Forward In²D²,²2²

Or²1²Position.........................................................101

11. Vehicle Cannot Be Started From D

1.................102

12. A/T Does Not Shift: D

1-> D2Or Does Not

Kickdown: D

4-> D2..................................................103

13. A/T Does Not Shift: D

2-> D3............................104

14. A/T Does Not Shift: D

3-> D4.............................105

15. A/T Does Not Perform Lock-up .........................106

16. A/T Does Not Hold Lock-up Condition ..............107

17. Lock-up Is Not Released ...................................107

18. Engine Speed Does Not Return To Idle (Light

Braking D

4-> D3) .....................................................108

19. Vehicle Does Not Start From D

1.......................109

20. A/T Does Not Shift: D

2-> D1When

Depressing Accelerator Pedal................................. 110

21. A/T Does Not Shift: D

4-> D3, When

Overdrive Control Switch²ON²->²OFF²............... 111

22. A/T Does Not Shift: D

3-> 22, When Selector

Lever²D²->²2²Position......................................... 111

23. A/T Does Not Shift: 2

2-> 11, When Selector

Lever²2²->²1²Position ......................................... 112

24. Vehicle Does Not Decelerate By Engine

Brake........................................................................ 112

ON-VEHICLE SERVICE.............................................. 113Control Valve Assembly and Accumulators ............. 113

Revolution Sensor Replacement ............................. 114

Rear Oil Seal Replacement ..................................... 114

Parking Components Inspection.............................. 114

Park/neutral Position Switch Adjustment ................. 114

Manual Control Linkage Adjustment........................ 115

REMOVAL AND INSTALLATION................................ 116

Removal ................................................................... 116

Installation ................................................................ 117

MAJOR OVERHAUL................................................... 119

Oil Channel ..............................................................121

Locations of Needle Bearings, Thrust Washers

and Snap Rings .......................................................122

DISASSEMBLY............................................................123

Disassembly.............................................................123

REPAIR FOR COMPONENT PARTS..........................134

Oil Pump ..................................................................134

Control Valve Assembly ...........................................138

Control Valve Upper Body .......................................144

Control Valve Lower Body .......................................149

Reverse Clutch ........................................................151

High Clutch ..............................................................155

Forward and Overrun Clutches ...............................157

Low & Reverse Brake..............................................161

Forward Clutch Drum Assembly ..............................165

Rear Internal Gear and Forward Clutch Hub ..........168

Band Servo Piston Assembly ..................................171

Parking Pawl Components ......................................175

ASSEMBLY..................................................................177

Assembly (1) ............................................................177

Adjustment ...............................................................185

Assembly (2) ............................................................188

A/T FLUID COOLER SYSTEM...................................195

A/T Fluid Cooler.......................................................195

SERVICE DATA AND SPECIFICATIONS (SDS)........196

General Specifications .............................................196

Specifications and Adjustment.................................196

When you read wiring diagrams:

IRead GI section, ªHOW TO READ WIRING DIAGRAMSº.

ISee EL section, ªPOWER SUPPLY ROUTINGº for power distribution circuit.

When you perform trouble diagnoses, read GI section, ªHOW TO FOLLOW FLOW CHART IN

TROUBLE DIAGNOSESº and ªHOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRI-

CAL INCIDENTº.

CONTENTS(Cont'd)

AT- 2

Page 5 of 1767

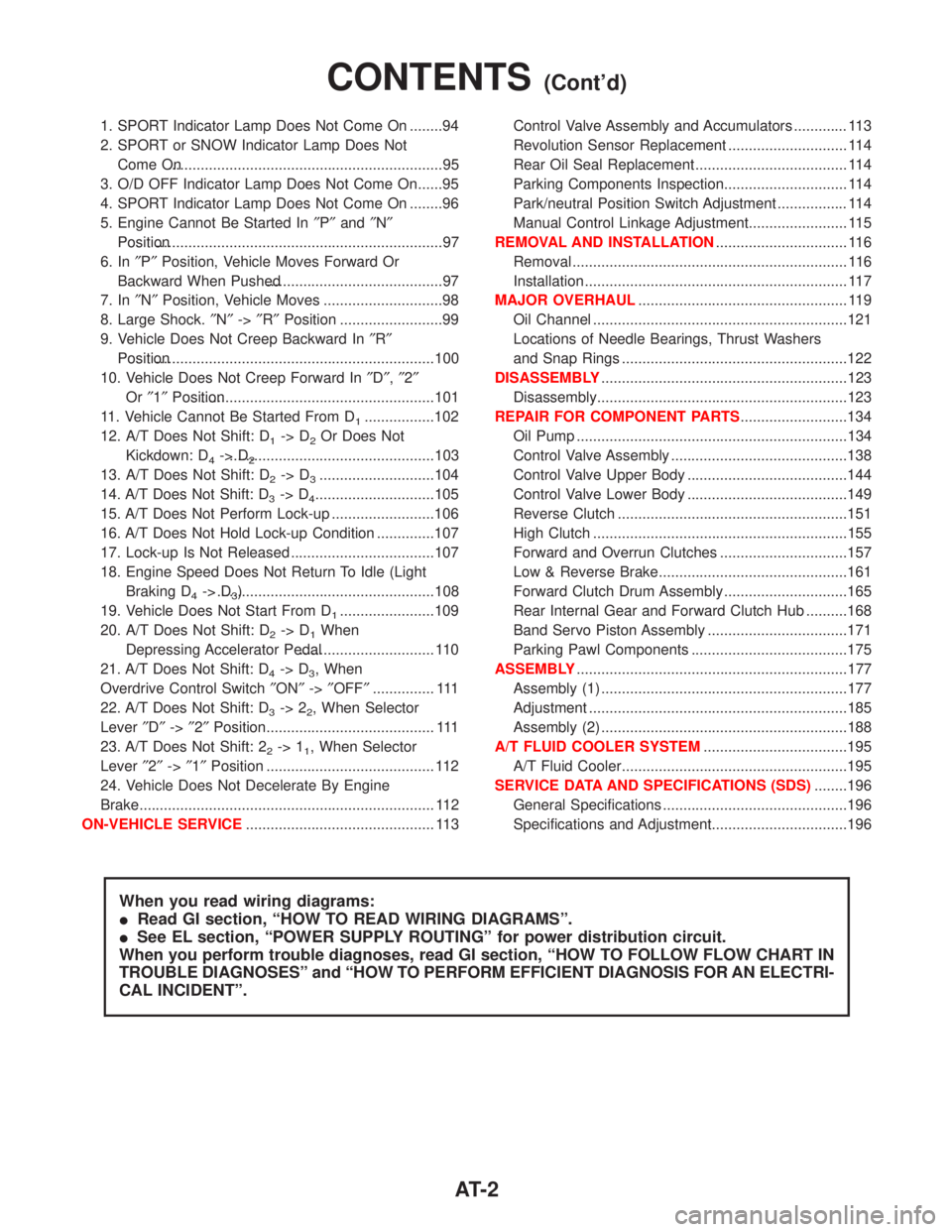

Special Service Tools

Tool number

Tool nameDescription

ST2505S001

Oil pressure gauge set

q

1ST25051001

Oil pressure gauge

q

2ST25052000

Hose

q

3ST25053000

Joint pipe

q

4ST25054000

Adapter

q

5ST25055000

Adapter

NT097

Measuring line pressure

ST07870000

Transmission case

stand

NT421

Disassembling and assembling

A/T

a: 182 mm (7.17 in)

b: 282 mm (11.10 in)

c: 230 mm (9.06 in)

d: 100 mm (3.94 in)

KV31102100

Torque converter one-

way clutch check tool

NT098

Checking one-way clutch in

torque converter

ST25850000

Sliding hammer

NT422

Removing oil pump assembly

a: 179 mm (7.05 in)

b: 70 mm (2.76 in)

c: 40 mm (1.57 in) dia.

d: M12 x 1.75P

ST33200000

Drift

NT091

Installing oil pump housing

oil seal

Installing rear oil seal

a: 60 mm (2.36 in) dia.

b: 44.5 mm (1.752 in) dia.

KV31102400

Clutch spring

compressor

NT423

Removing and installing clutch

return springs

a: 320 mm (12.60 in)

b: 174 mm (6.85 in)

PREPARATION AND PRECAUTIONS

AT- 3

Page 12 of 1767

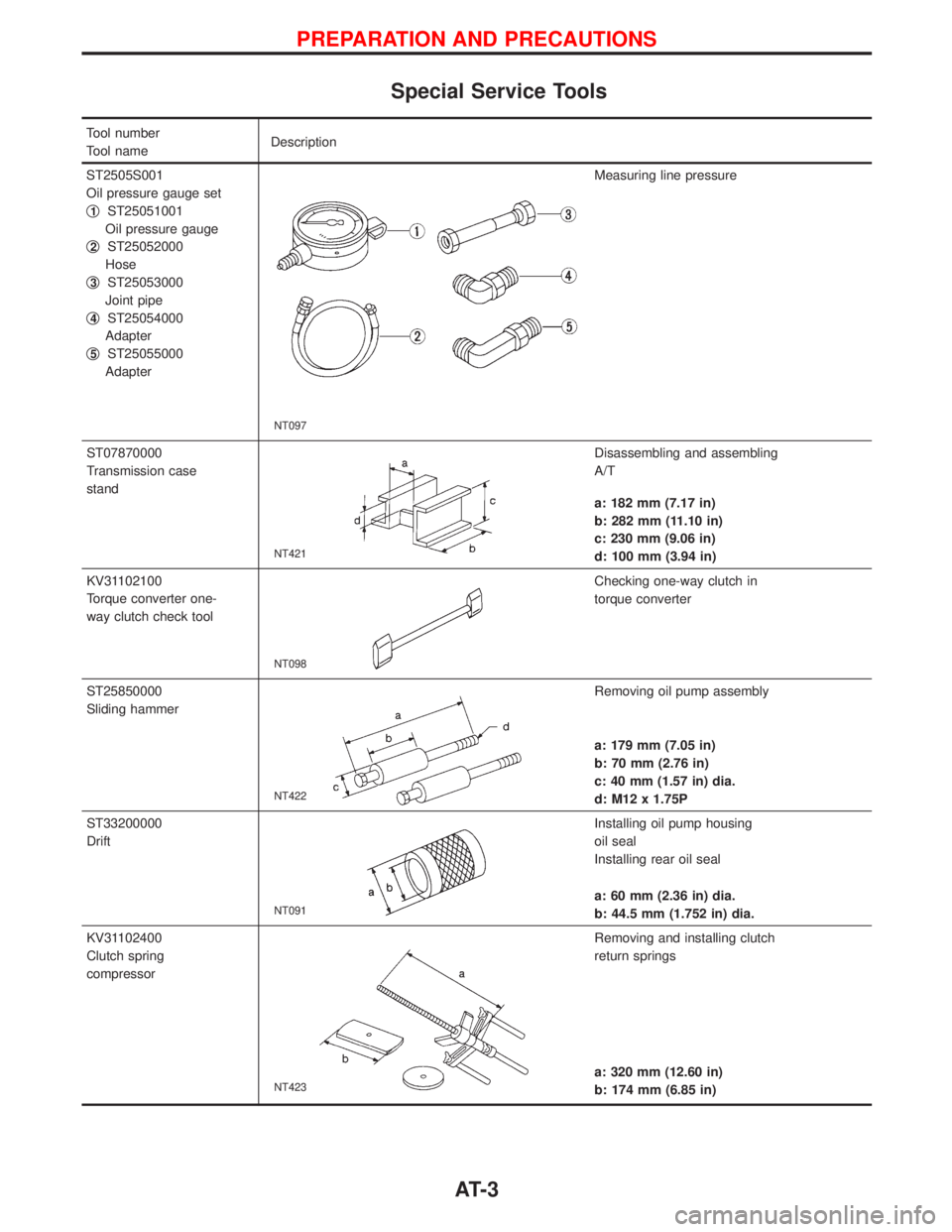

Shift Mechanism

The automatic transmission uses compact, dual planetary gear systems to improve power-transmission

efficiency, simplify construction and reduce weight.

It also employs an optimum shift control and superwide gear ratios. They improve starting performance and

acceleration during medium and high-speed operation.

Two one-way clutches are also employed: one is used for the forward clutch and the other for the low clutch.

These one-way clutches, combined with four accumulators, reduce shifting shock to a minimum.

CONSTRUCTION

q1Torque converter clutch piston

q

2Torque converter

q

3Oil pump

q

4Input shaft

q

5Brake band

q

6Reverse clutch

q

7High clutch

q

8Front pinion gearq

9Front sun gear

q

10Front internal gear

q

11Front planetary carrier

q

12Rear sun gear

q

13Rear pinion gear

q

14Rear internal gear

q

15Rear planetary carrier

q

16Forward clutchq

17Forward one-way clutch

q

18Overrun clutch

q

19Low one-way clutch

q

20Low & reverse brake

q

21Parking pawl

q

22Parking gear

q

23Output shaft

FUNCTION OF CLUTCH AND BRAKE

Control members Abbr. Function

q

6Reverse clutch R/C To transmit input power to front sun gearq9.

q

7High clutch H/C To transmit input power to front planetary carrierq11.

q

16Forward clutch F/C To connect front planetary carrierq11with forward one-way clutchq17.

q

18Overrun clutch O/C To connect front planetary carrierq11with rear internal gearq14.

q

5Brake band B/B To lock front sun gearq9.

q

17Forward one-way clutch F/O.CWhen forward clutch is engaged, to stop rear internal gearq14from rotating in opposite

direction.

q

19Low one-way clutch L/O.C At D1position, to prevent rear internal gearq14from rotating in opposite direction.

q

20Low & reverse brake L & R/BTo lock rear internal gearq14(2, 12and 11), to lock front planetary carrierq11

(R position).

SAT509I

OVERALL SYSTEM

AT-10

Page 33 of 1767

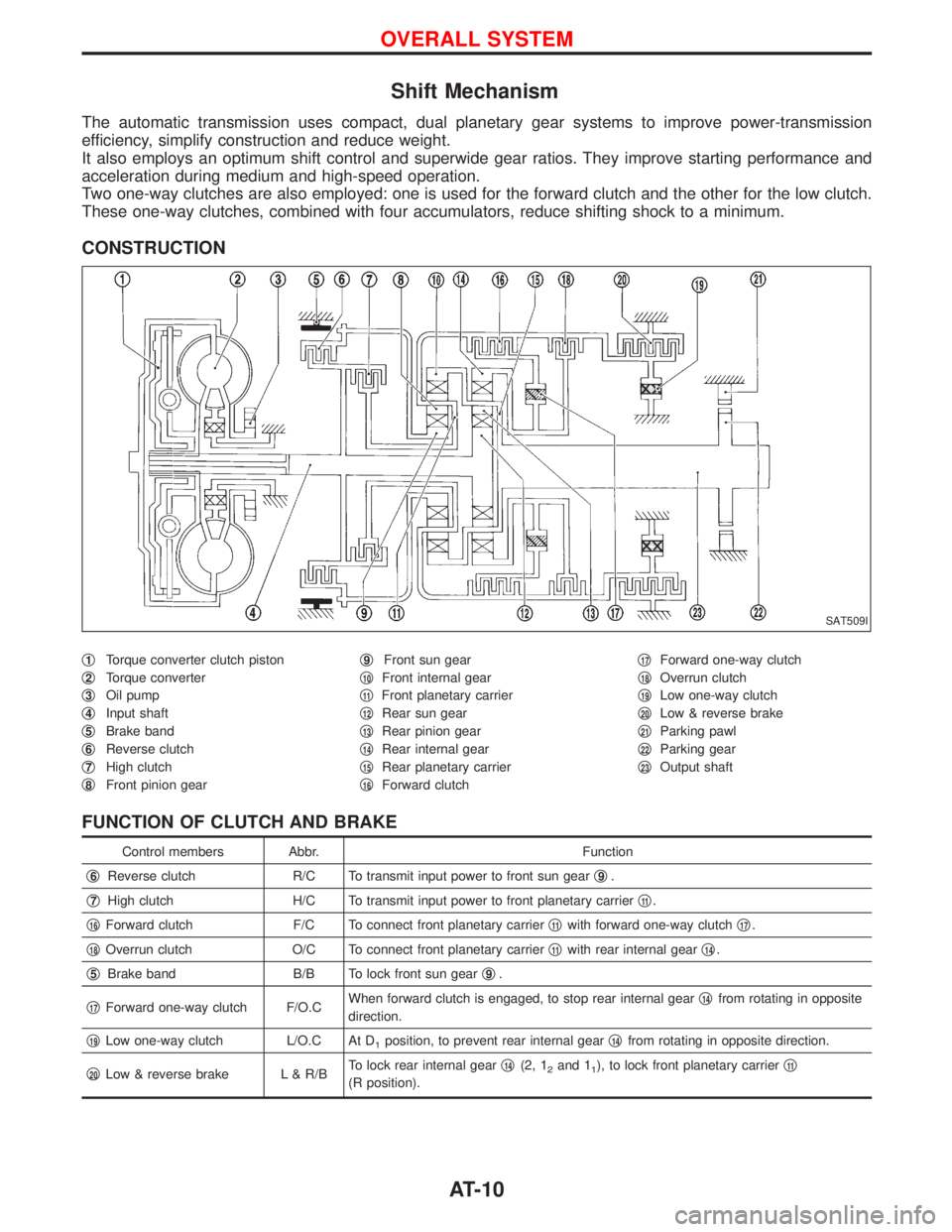

4. Set parking brake and block wheels.

IContinue to depress brake pedal fully while line pressure

test is being performed at stall speed.

5. Start engine and measure line pressure at idle and stall speed.

IWhen measuring line pressure at stall speed, follow the

stall test procedure.

Line pressure:

Refer to SDS, AT-196.

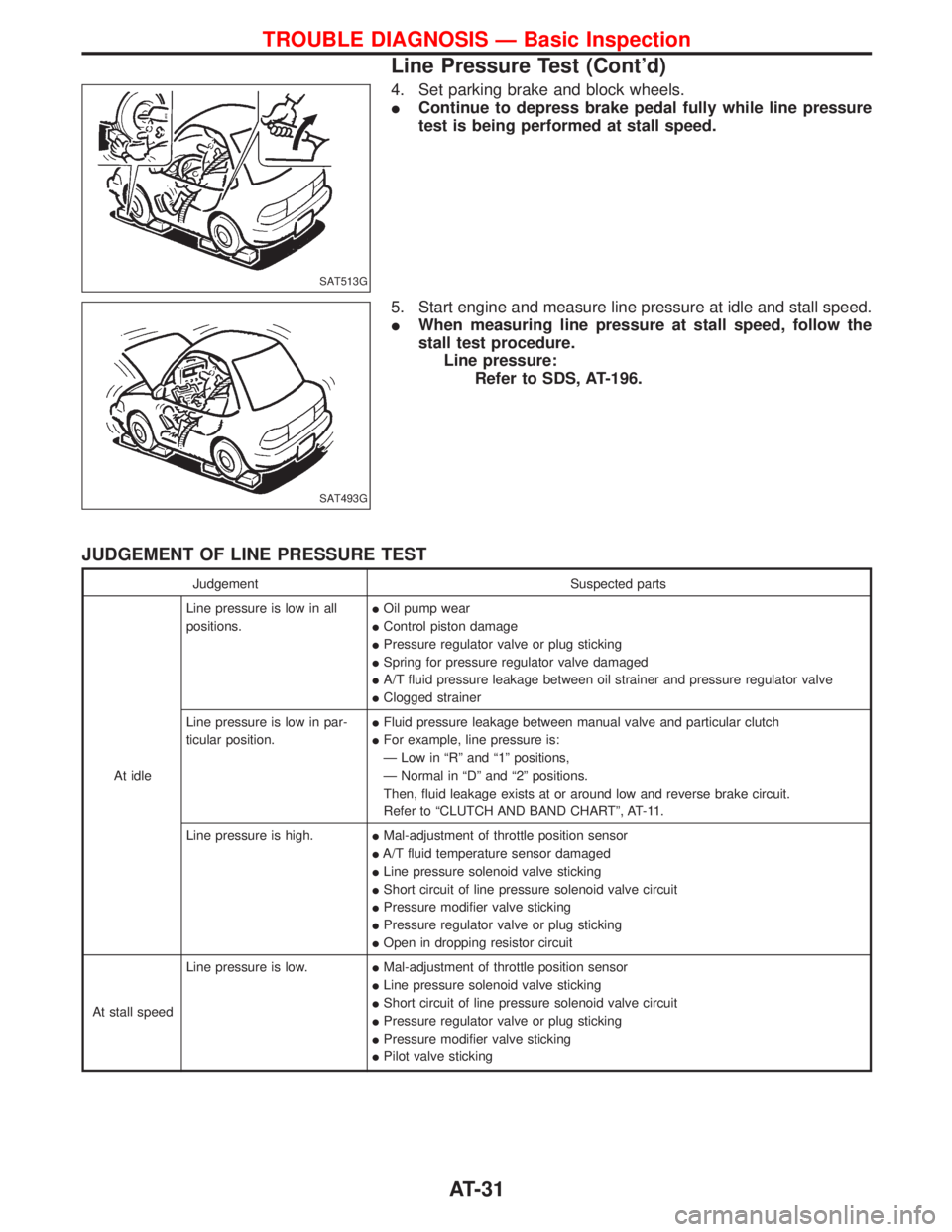

JUDGEMENT OF LINE PRESSURE TEST

Judgement Suspected parts

At idleLine pressure is low in all

positions.IOil pump wear

IControl piston damage

IPressure regulator valve or plug sticking

ISpring for pressure regulator valve damaged

IA/T fluid pressure leakage between oil strainer and pressure regulator valve

IClogged strainer

Line pressure is low in par-

ticular position.IFluid pressure leakage between manual valve and particular clutch

IFor example, line pressure is:

Ð Low in ªRº and ª1º positions,

Ð Normal in ªDº and ª2º positions.

Then, fluid leakage exists at or around low and reverse brake circuit.

Refer to ªCLUTCH AND BAND CHARTº, AT-11.

Line pressure is high.IMal-adjustment of throttle position sensor

IA/T fluid temperature sensor damaged

ILine pressure solenoid valve sticking

IShort circuit of line pressure solenoid valve circuit

IPressure modifier valve sticking

IPressure regulator valve or plug sticking

IOpen in dropping resistor circuit

At stall speedLine pressure is low.IMal-adjustment of throttle position sensor

ILine pressure solenoid valve sticking

IShort circuit of line pressure solenoid valve circuit

IPressure regulator valve or plug sticking

IPressure modifier valve sticking

IPilot valve sticking

SAT513G

SAT493G

TROUBLE DIAGNOSIS Ð Basic Inspection

Line Pressure Test (Cont'd)

AT-31

Page 45 of 1767

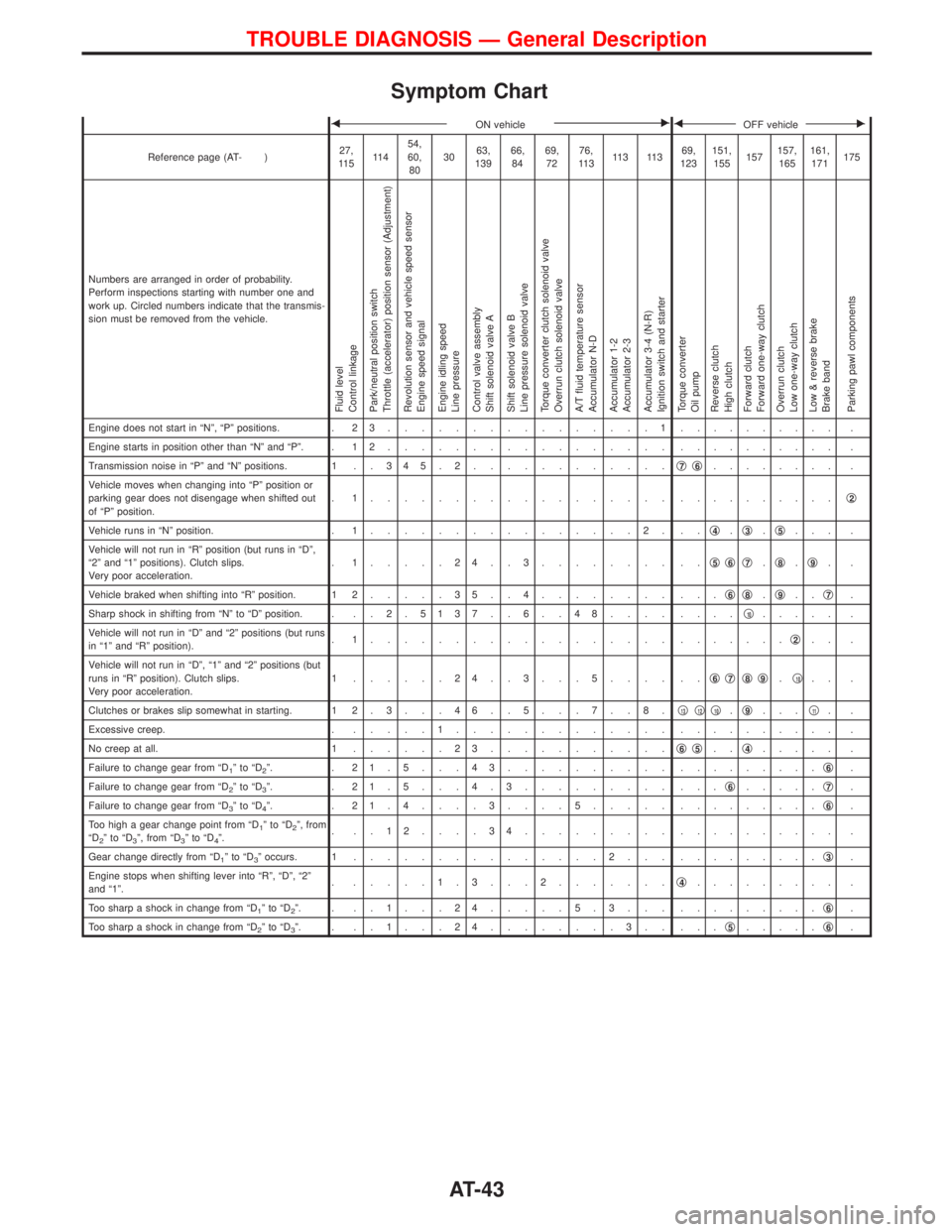

Symptom Chart

FON vehicleEFOFF vehicleE

Reference page (AT- )27,

11 511 454,

60,

803063,

13966,

8469,

7276,

11 311 3 11 369,

123151,

155157157,

165161,

171175

Numbers are arranged in order of probability.

Perform inspections starting with number one and

work up. Circled numbers indicate that the transmis-

sion must be removed from the vehicle.

Fluid level

Control linkage

Park/neutral position switch

Throttle (accelerator) position sensor (Adjustment)

Revolution sensor and vehicle speed sensor

Engine speed signal

Engine idling speed

Line pressure

Control valve assembly

Shift solenoid valve A

Shift solenoid valve B

Line pressure solenoid valve

Torque converter clutch solenoid valve

Overrun clutch solenoid valve

A/T fluid temperature sensor

Accumulator N-D

Accumulator 1-2

Accumulator 2-3

Accumulator 3-4 (N-R)

Ignition switch and starter

Torque converter

Oil pump

Reverse clutch

High clutch

Forward clutch

Forward one-way clutch

Overrun clutch

Low one-way clutch

Low & reverse brake

Brake band

Parking pawl components

Engine does not start in ªNº, ªPº positions. . 2 3................1.......... .

Engine starts in position other than ªNº and ªPº. . 1 2................. .......... .

Transmission noise in ªPº and ªNº positions. 1 . . 3 4 5 . 2............q

7q6........ .

Vehicle moves when changing into ªPº position or

parking gear does not disengage when shifted out

of ªPº position.. 1.................. ..........q

2

Vehicle runs in ªNº position. . 1................2. ..q4.q3.q5... .

Vehicle will not run in ªRº position (but runs in ªDº,

ª2º and ª1º positions). Clutch slips.

Very poor acceleration.. 1.....24..3........ ..q

5q6q7.q8.q9..

Vehicle braked when shifting into ªRº position. 1 2.....35..4........ ...q

6q8.q9..q7.

Sharp shock in shifting from ªNº to ªDº position. . . . 2 .5137 . . 6 . . 48.... ....q

10..... .

Vehicle will not run in ªDº and ª2º positions (but runs

in ª1º and ªRº position).. 1.................. .......q

2.. .

Vehicle will not run in ªDº, ª1º and ª2º positions (but

runs in ªRº position). Clutch slips.

Very poor acceleration.1 ......24..3...5.... ..q

6q7q8q9.q10.. .

Clutches or brakes slip somewhat in starting. 1 2 . 3 . . . 4 6 . . 5 . . . 7 . . 8 .q

13q12q10.q9...q11..

Excessive creep. ......1............. .......... .

No creep at all. 1......23...........q

6q5..q4..... .

Failure to change gear from ªD

1ºtoªD2º. . 21.5...43.......... .........q6.

Failure to change gear from ªD

2ºtoªD3º. . 21.5...4.3......... ...q6.....q7.

Failure to change gear from ªD

3ºtoªD4º. . 21.4....3....5..... .........q6.

Too high a gear change point from ªD

1ºtoªD2º, from

ªD2ºtoªD3º, from ªD3ºtoªD4º.. ..12....34......... .......... .

Gear change directly from ªD

1ºtoªD3º occurs. 1...............2... .........q3.

Engine stops when shifting lever into ªRº, ªDº, ª2º

and ª1º.. .....1.3...2.......q

4......... .

Too sharp a shock in change from ªD

1ºtoªD2º. . ..1...24.....5.3... .........q6.

Too sharp a shock in change from ªD

2ºtoªD3º. . ..1...24........3.. ...q5.....q6.

TROUBLE DIAGNOSIS Ð General Description

AT-43

Page 46 of 1767

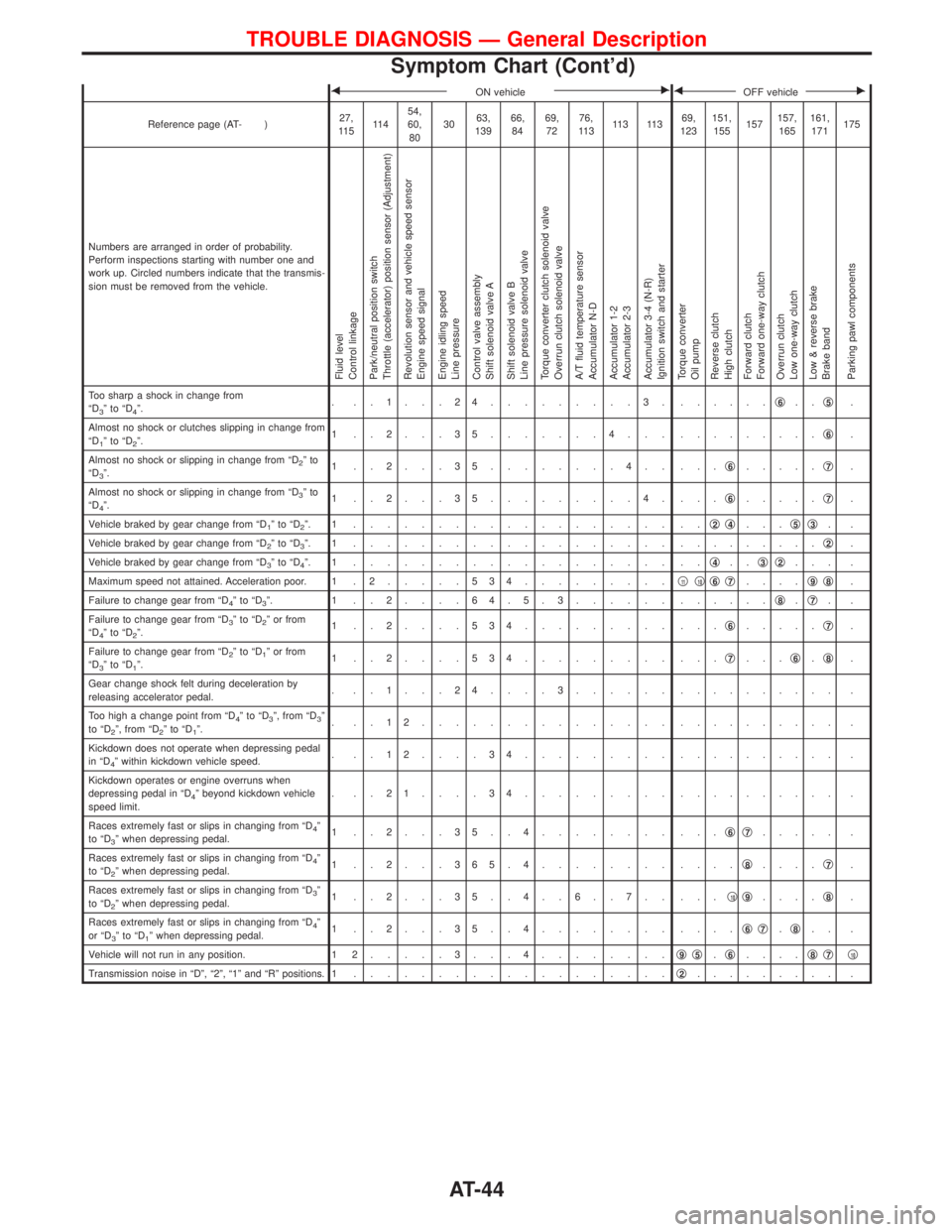

FON vehicleEFOFF vehicleE

Reference page (AT- )27,

11 511 454,

60,

803063,

13966,

8469,

7276,

11 311 3 11 369,

123151,

155157157,

165161,

171175

Numbers are arranged in order of probability.

Perform inspections starting with number one and

work up. Circled numbers indicate that the transmis-

sion must be removed from the vehicle.

Fluid level

Control linkage

Park/neutral position switch

Throttle (accelerator) position sensor (Adjustment)

Revolution sensor and vehicle speed sensor

Engine speed signal

Engine idling speed

Line pressure

Control valve assembly

Shift solenoid valve A

Shift solenoid valve B

Line pressure solenoid valve

Torque converter clutch solenoid valve

Overrun clutch solenoid valve

A/T fluid temperature sensor

Accumulator N-D

Accumulator 1-2

Accumulator 2-3

Accumulator 3-4 (N-R)

Ignition switch and starter

Torque converter

Oil pump

Reverse clutch

High clutch

Forward clutch

Forward one-way clutch

Overrun clutch

Low one-way clutch

Low & reverse brake

Brake band

Parking pawl components

Too sharp a shock in change from

ªD3ºtoªD4º.. ..1...24.........3. ......q6..q5.

Almost no shock or clutches slipping in change from

ªD

1ºtoªD2º.1 ..2...35.......4... .........q6.

Almost no shock or slipping in change from ªD

2ºto

ªD3º.1 ..2...35........4.. ...q6.....q7.

Almost no shock or slipping in change from ªD

3ºto

ªD4º.1 ..2...35.........4. ...q6.....q7.

Vehicle braked by gear change from ªD

1ºtoªD2º. 1 ................... ..q2q4...q5q3..

Vehicle braked by gear change from ªD

2ºtoªD3º. 1 ................... .........q2.

Vehicle braked by gear change from ªD

3ºtoªD4º. 1 ................... ..q4..q3q2... .

Maximum speed not attained. Acceleration poor. 1 . 2.....534.........q

11q10q6q7....q9q8.

Failure to change gear from ªD

4ºtoªD3º. 1 ..2....64.5.3...... ......q8.q7..

Failure to change gear from ªD

3ºtoªD2º or from

ªD4ºtoªD2º.1 ..2....534......... ...q6.....q7.

Failure to change gear from ªD

2ºtoªD1º or from

ªD3ºtoªD1º.1 ..2....534......... ...q7...q6.q8.

Gear change shock felt during deceleration by

releasing accelerator pedal.. ..1...24....3...... .......... .

Too high a change point from ªD

4ºtoªD3º, from ªD3º

to ªD2º, from ªD2ºtoªD1º.. ..12............... .......... .

Kickdown does not operate when depressing pedal

in ªD

4º within kickdown vehicle speed.. ..12....34......... .......... .

Kickdown operates or engine overruns when

depressing pedal in ªD

4º beyond kickdown vehicle

speed limit.. ..21....34......... .......... .

Races extremely fast or slips in changing from ªD

4º

to ªD3º when depressing pedal.1 ..2...35..4........ ...q6q7..... .

Races extremely fast or slips in changing from ªD

4º

to ªD2º when depressing pedal.1 ..2...365.4........ ....q8....q7.

Races extremely fast or slips in changing from ªD

3º

to ªD2º when depressing pedal.1 ..2...35..4..6..7.. ...q10q9....q8.

Races extremely fast or slips in changing from ªD

4º

or ªD3ºtoªD1º when depressing pedal.1 ..2...35..4........ ....q6q7.q8.. .

Vehicle will not run in any position. 1 2.....3...4........q

9q5.q6....q8q7q10

Transmission noise in ªDº, ª2º, ª1º and ªRº positions. 1...................q2......... .

TROUBLE DIAGNOSIS Ð General Description

Symptom Chart (Cont'd)

AT-44

Page 47 of 1767

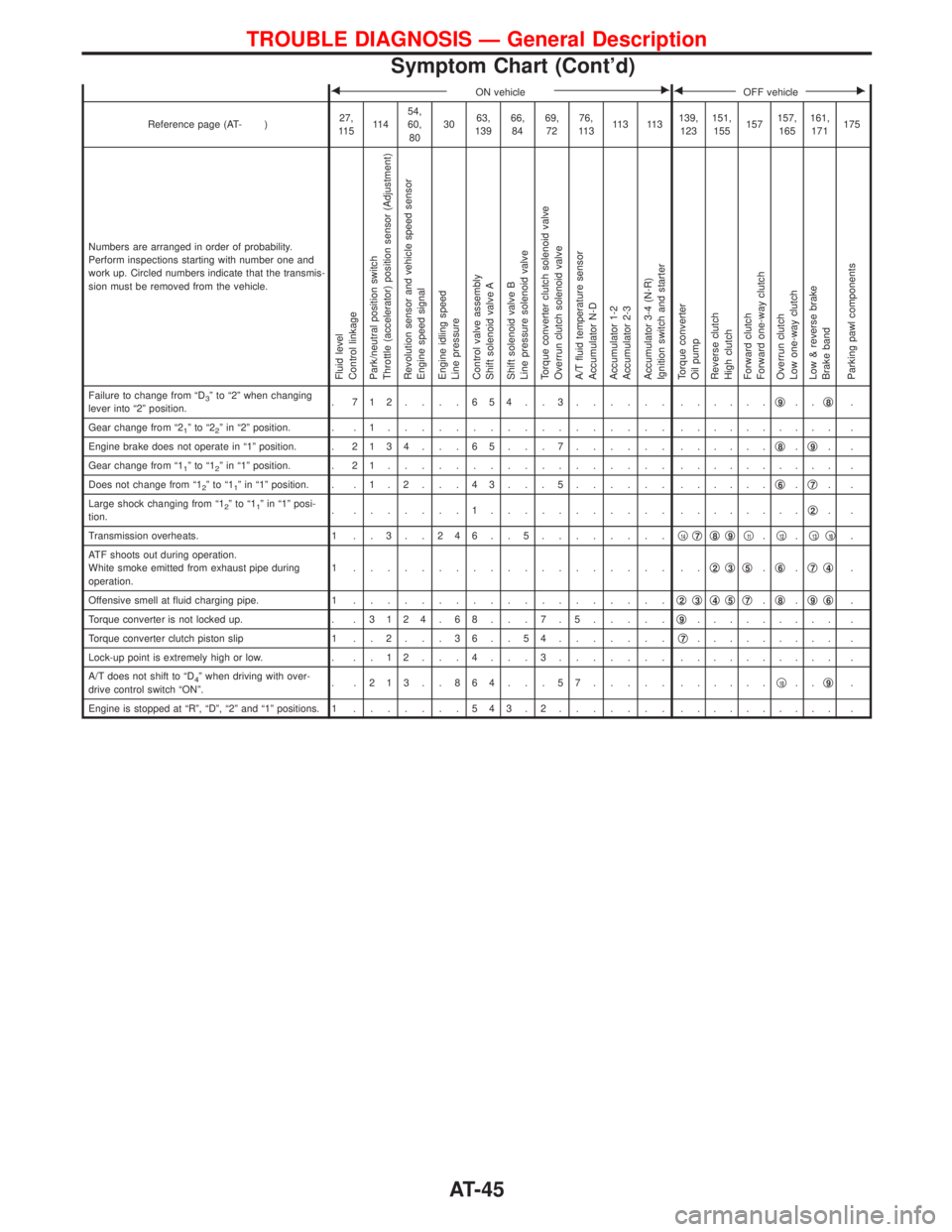

FON vehicleEFOFF vehicleE

Reference page (AT- )27,

11 511 454,

60,

803063,

13966,

8469,

7276,

11 311 3 11 3139,

123151,

155157157,

165161,

171175

Numbers are arranged in order of probability.

Perform inspections starting with number one and

work up. Circled numbers indicate that the transmis-

sion must be removed from the vehicle.

Fluid level

Control linkage

Park/neutral position switch

Throttle (accelerator) position sensor (Adjustment)

Revolution sensor and vehicle speed sensor

Engine speed signal

Engine idling speed

Line pressure

Control valve assembly

Shift solenoid valve A

Shift solenoid valve B

Line pressure solenoid valve

Torque converter clutch solenoid valve

Overrun clutch solenoid valve

A/T fluid temperature sensor

Accumulator N-D

Accumulator 1-2

Accumulator 2-3

Accumulator 3-4 (N-R)

Ignition switch and starter

Torque converter

Oil pump

Reverse clutch

High clutch

Forward clutch

Forward one-way clutch

Overrun clutch

Low one-way clutch

Low & reverse brake

Brake band

Parking pawl components

Failure to change from ªD3º to ª2º when changing

lever into ª2º position.. 712....654..3...... ......q9..q8.

Gear change from ª2

1ºtoª22º in ª2º position. . . 1................. .......... .

Engine brake does not operate in ª1º position. .2134 . . . 65 . . . 7...... ......q

8.q9..

Gear change from ª1

1ºtoª12º in ª1º position. . 2 1................. .......... .

Does not change from ª1

2ºtoª11º in ª1º position. . . 1 . 2 . . . 4 3 . . . 5...... ......q6.q7..

Large shock changing from ª1

2ºtoª11º in ª1º posi-

tion.. .......1........... ........q2..

Transmission overheats. 1 . . 3 . . 2 4 6 . . 5........q

14q7q8q9q11.q12.q13q10.

ATF shoots out during operation.

White smoke emitted from exhaust pipe during

operation.1 ................... ..q

2q3q5.q6.q7q4.

Offensive smell at fluid charging pipe. 1...................q

2q3q4q5q7.q8.q9q6.

Torque converter is not locked up. . .3124 . 68 . . . 7 . 5.....q

9......... .

Torque converter clutch piston slip 1 . . 2 . . . 3 6 . . 5 4.......q

7......... .

Lock-up point is extremely high or low. . . . 1 2 . . . 4 . . . 3....... .......... .

A/T does not shift to ªD

4º when driving with over-

drive control switch ªONº.. .213..864...57..... ......q10..q9.

Engine is stopped at ªRº, ªDº, ª2º and ª1º positions. 1.......543.2....... .......... .

TROUBLE DIAGNOSIS Ð General Description

Symptom Chart (Cont'd)

AT-45

Page 86 of 1767

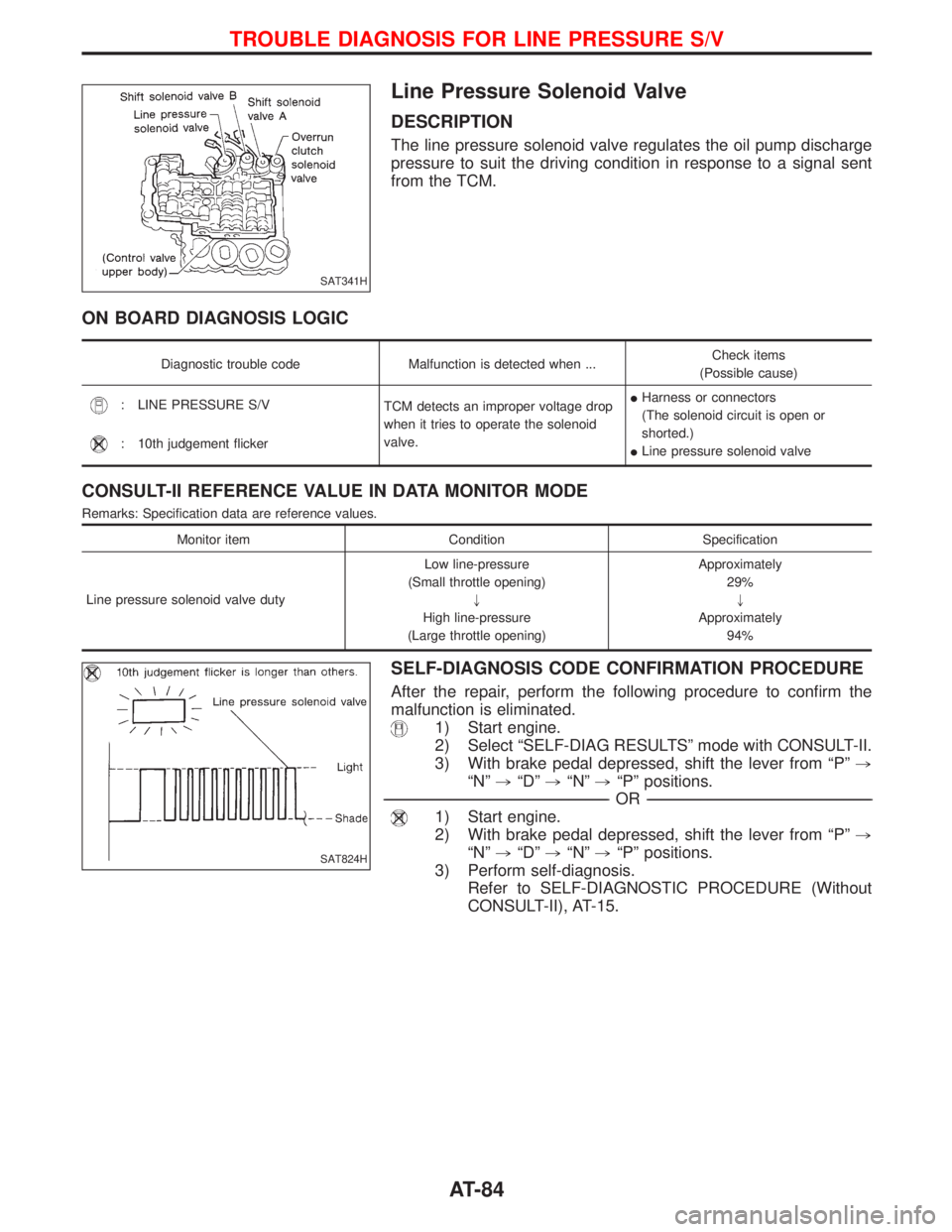

Line Pressure Solenoid Valve

DESCRIPTION

The line pressure solenoid valve regulates the oil pump discharge

pressure to suit the driving condition in response to a signal sent

from the TCM.

ON BOARD DIAGNOSIS LOGIC

Diagnostic trouble code Malfunction is detected when ...Check items

(Possible cause)

: LINE PRESSURE S/V

TCM detects an improper voltage drop

when it tries to operate the solenoid

valve.IHarness or connectors

(The solenoid circuit is open or

shorted.)

ILine pressure solenoid valve

: 10th judgement flicker

CONSULT-II REFERENCE VALUE IN DATA MONITOR MODE

Remarks: Specification data are reference values.

Monitor item Condition Specification

Line pressure solenoid valve dutyLow line-pressure

(Small throttle opening)

"

High line-pressure

(Large throttle opening)Approximately

29%

"

Approximately

94%

SELF-DIAGNOSIS CODE CONFIRMATION PROCEDURE

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

1) Start engine.

2) Select ªSELF-DIAG RESULTSº mode with CONSULT-II.

3) With brake pedal depressed, shift the lever from ªPº,

ªNº,ªDº,ªNº,ªPº positions.

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------OR------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1) Start engine.

2) With brake pedal depressed, shift the lever from ªPº,

ªNº,ªDº,ªNº,ªPº positions.

3) Perform self-diagnosis.

Refer to SELF-DIAGNOSTIC PROCEDURE (Without

CONSULT-II), AT-15.

SAT341H

SAT824H

TROUBLE DIAGNOSIS FOR LINE PRESSURE S/V

AT-84

Page 102 of 1767

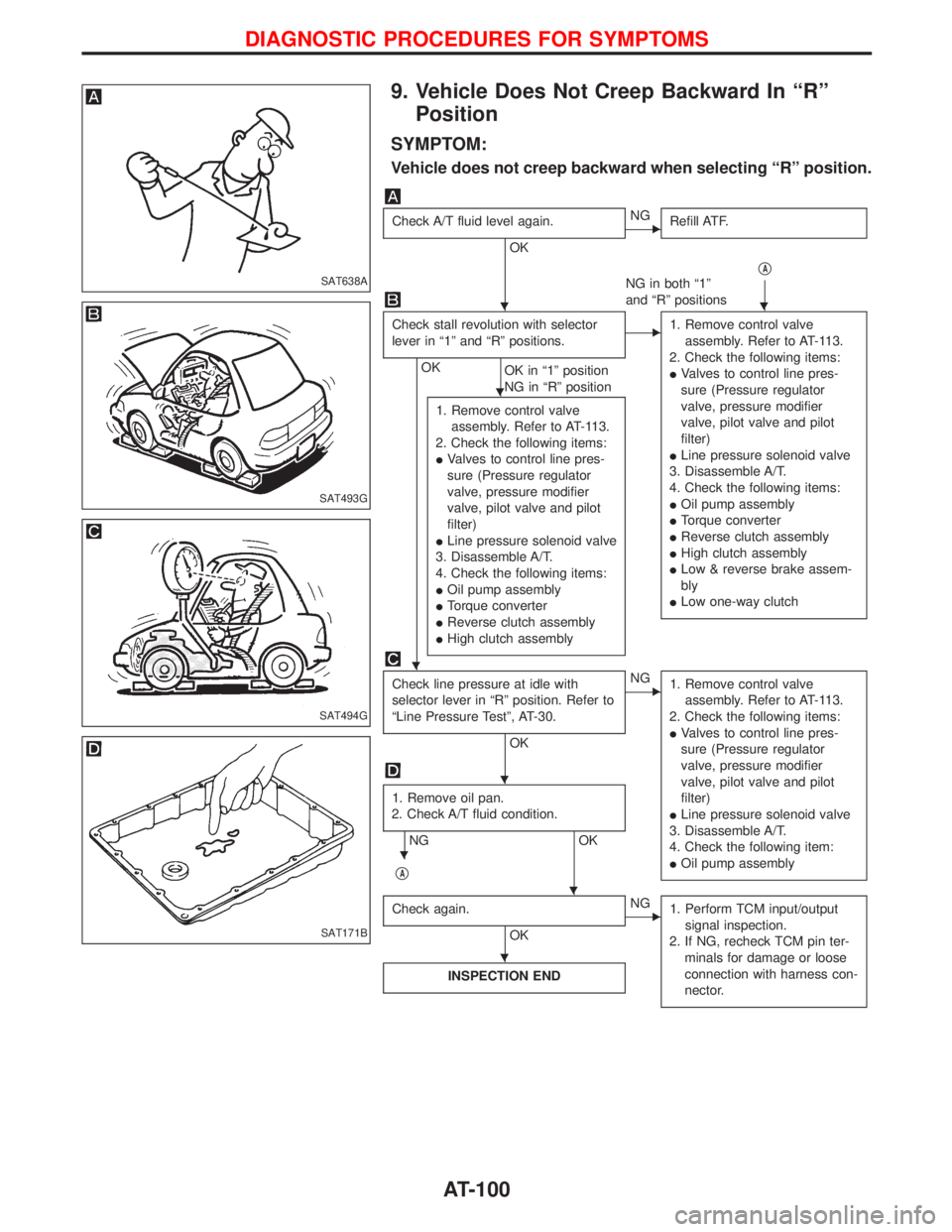

9. Vehicle Does Not Creep Backward In ªRº

Position

SYMPTOM:

Vehicle does not creep backward when selecting ªRº position.

Check A/T fluid level again.

OK

ENG

Refill ATF.

qA

NG in both ª1º

and ªRº positions

Check stall revolution with selector

lever in ª1º and ªRº positions.

OK

OK in ª1º position

NG in ªRº position

E1. Remove control valve

assembly. Refer to AT-113.

2. Check the following items:

IValves to control line pres-

sure (Pressure regulator

valve, pressure modifier

valve, pilot valve and pilot

filter)

ILine pressure solenoid valve

3. Disassemble A/T.

4. Check the following items:

IOil pump assembly

ITorque converter

IReverse clutch assembly

IHigh clutch assembly

ILow & reverse brake assem-

bly

ILow one-way clutch

1. Remove control valve

assembly. Refer to AT-113.

2. Check the following items:

IValves to control line pres-

sure (Pressure regulator

valve, pressure modifier

valve, pilot valve and pilot

filter)

ILine pressure solenoid valve

3. Disassemble A/T.

4. Check the following items:

IOil pump assembly

ITorque converter

IReverse clutch assembly

IHigh clutch assembly

Check line pressure at idle with

selector lever in ªRº position. Refer to

ªLine Pressure Testº, AT-30.

OK

ENG

1. Remove control valve

assembly. Refer to AT-113.

2. Check the following items:

IValves to control line pres-

sure (Pressure regulator

valve, pressure modifier

valve, pilot valve and pilot

filter)

ILine pressure solenoid valve

3. Disassemble A/T.

4. Check the following item:

IOil pump assembly

1. Remove oil pan.

2. Check A/T fluid condition.

NG OK

q

A

Check again.

OK

ENG

1. Perform TCM input/output

signal inspection.

2. If NG, recheck TCM pin ter-

minals for damage or loose

connection with harness con-

nector.

INSPECTION END

SAT638A

SAT493G

SAT494G

SAT171B

HH

H

H

H

H

H

H

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-100

Page 103 of 1767

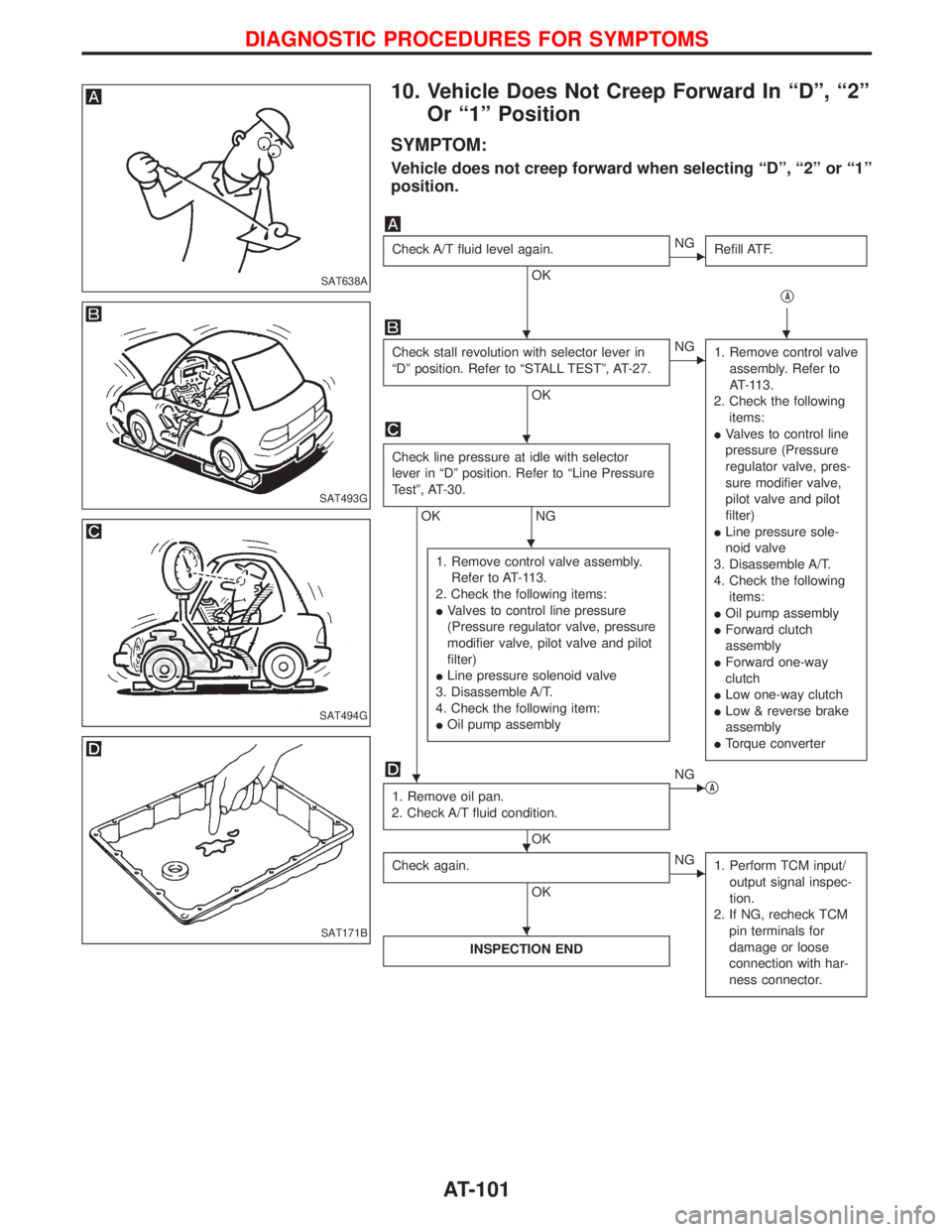

10. Vehicle Does Not Creep Forward In ªDº, ª2º

Or ª1º Position

SYMPTOM:

Vehicle does not creep forward when selecting ªDº, ª2º or ª1º

position.

Check A/T fluid level again.

OK

ENG

Refill ATF.

qA

Check stall revolution with selector lever in

ªDº position. Refer to ªSTALL TESTº, AT-27.

OK

ENG

1. Remove control valve

assembly. Refer to

AT-113.

2. Check the following

items:

IValves to control line

pressure (Pressure

regulator valve, pres-

sure modifier valve,

pilot valve and pilot

filter)

ILine pressure sole-

noid valve

3. Disassemble A/T.

4. Check the following

items:

IOil pump assembly

IForward clutch

assembly

IForward one-way

clutch

ILow one-way clutch

ILow & reverse brake

assembly

ITorque converter

Check line pressure at idle with selector

lever in ªDº position. Refer to ªLine Pressure

Testº, AT-30.

OK NG

1. Remove control valve assembly.

Refer to AT-113.

2. Check the following items:

IValves to control line pressure

(Pressure regulator valve, pressure

modifier valve, pilot valve and pilot

filter)

ILine pressure solenoid valve

3. Disassemble A/T.

4. Check the following item:

IOil pump assembly

1. Remove oil pan.

2. Check A/T fluid condition.

OK

ENG

qA

Check again.

OK

ENG

1. Perform TCM input/

output signal inspec-

tion.

2. If NG, recheck TCM

pin terminals for

damage or loose

connection with har-

ness connector.

INSPECTION END

SAT638A

SAT493G

SAT494G

SAT171B

HH

H

H

H

H H

H

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-101