torque NISSAN TERRANO 2002 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 30 of 1767

8. Move selector lever to ªNº position.

9. Cool off ATF.

IRun engine at idle for at least one minute.

10. Repeat steps 5 through 9 with selector lever in ª2º, ª1º and ªRº

positions.

JUDGEMENT OF STALL TEST

The test result and possible damaged components relating to each result are shown in the illustration.

In order to pinpoint the possible damaged components, follow the WORK FLOW as shown in AT-26.

Note

Stall revolution is too high in ªDº or ª2º position:

ISlippage occurs in 1st gear but not in 2nd and 3rd gears. ..... Low one-way clutch slippage

ISlippage occurs at the following gears:

1st through 3rd gears in ªDº position and engine brake functions.

1st and 2nd gears in ª2º position and engine brake functions with accelerator pedal released (fully closed

throttle). ..... Forward clutch or forward one-way clutch slippage

Stall revolution is too high in ªRº position:

IEngine brake does not function in ª1º position. ..... Low & reverse brake slippage

IEngine brake functions in ª1º position. ..... Reverse clutch slippage

Stall revolution within specifications:

IVehicle does not achieve speed of more than 80 km/h (50 MPH). ..... One-way clutch seizure in torque

converter housing

CAUTION:

Be careful since automatic fluid temperature increases abnormally.

ISlippage occurs in 3rd and 4th gears in ªDº position. ..... High clutch slippage

ISlippage occurs in 2nd and 4th gears in ªDº position. ..... Brake band slippage

Stall revolution less than specifications:

IPoor acceleration during starts. ..... One-way clutch seizure in torque converter

SAT771B

TROUBLE DIAGNOSIS Ð Basic Inspection

Stall Test (Cont'd)

AT-28

Page 45 of 1767

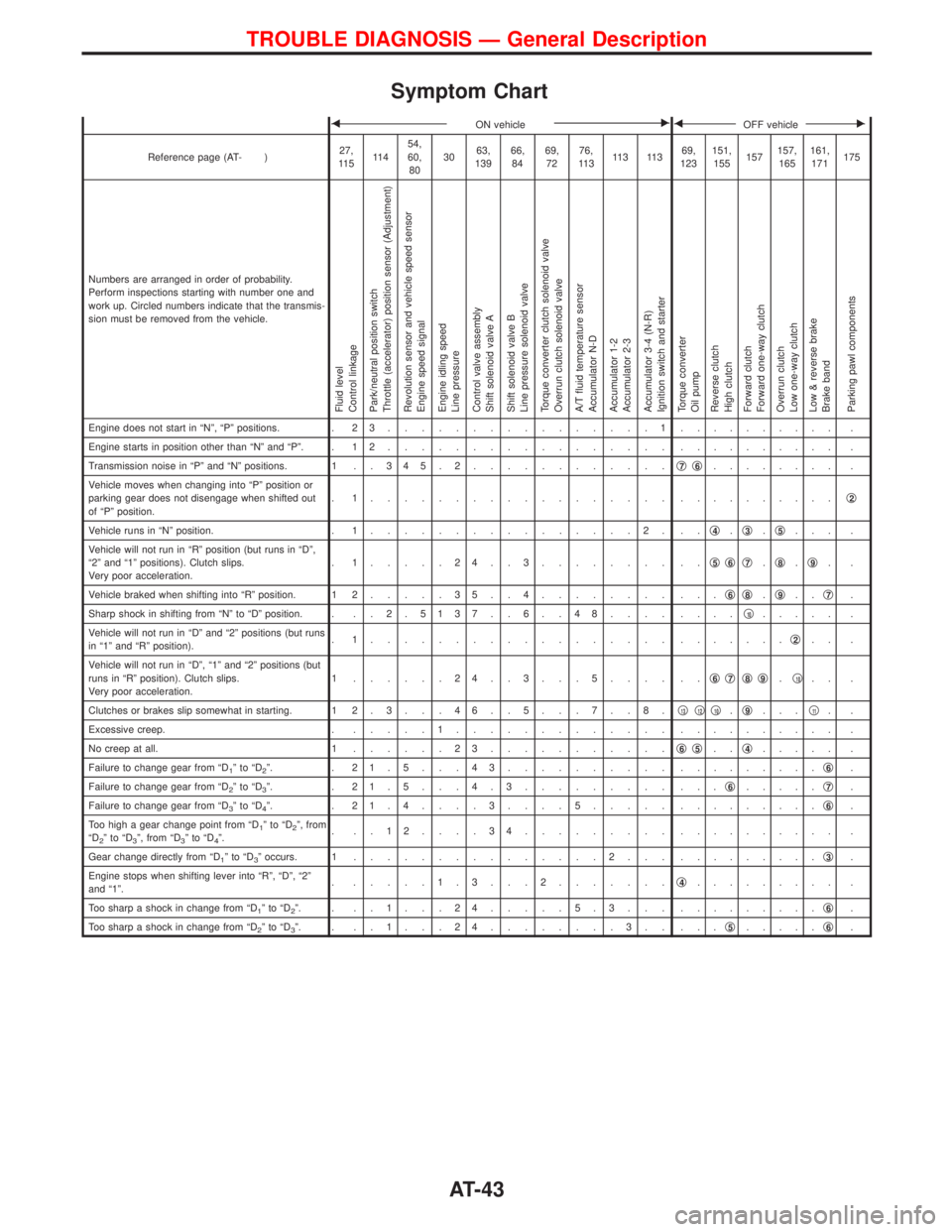

Symptom Chart

FON vehicleEFOFF vehicleE

Reference page (AT- )27,

11 511 454,

60,

803063,

13966,

8469,

7276,

11 311 3 11 369,

123151,

155157157,

165161,

171175

Numbers are arranged in order of probability.

Perform inspections starting with number one and

work up. Circled numbers indicate that the transmis-

sion must be removed from the vehicle.

Fluid level

Control linkage

Park/neutral position switch

Throttle (accelerator) position sensor (Adjustment)

Revolution sensor and vehicle speed sensor

Engine speed signal

Engine idling speed

Line pressure

Control valve assembly

Shift solenoid valve A

Shift solenoid valve B

Line pressure solenoid valve

Torque converter clutch solenoid valve

Overrun clutch solenoid valve

A/T fluid temperature sensor

Accumulator N-D

Accumulator 1-2

Accumulator 2-3

Accumulator 3-4 (N-R)

Ignition switch and starter

Torque converter

Oil pump

Reverse clutch

High clutch

Forward clutch

Forward one-way clutch

Overrun clutch

Low one-way clutch

Low & reverse brake

Brake band

Parking pawl components

Engine does not start in ªNº, ªPº positions. . 2 3................1.......... .

Engine starts in position other than ªNº and ªPº. . 1 2................. .......... .

Transmission noise in ªPº and ªNº positions. 1 . . 3 4 5 . 2............q

7q6........ .

Vehicle moves when changing into ªPº position or

parking gear does not disengage when shifted out

of ªPº position.. 1.................. ..........q

2

Vehicle runs in ªNº position. . 1................2. ..q4.q3.q5... .

Vehicle will not run in ªRº position (but runs in ªDº,

ª2º and ª1º positions). Clutch slips.

Very poor acceleration.. 1.....24..3........ ..q

5q6q7.q8.q9..

Vehicle braked when shifting into ªRº position. 1 2.....35..4........ ...q

6q8.q9..q7.

Sharp shock in shifting from ªNº to ªDº position. . . . 2 .5137 . . 6 . . 48.... ....q

10..... .

Vehicle will not run in ªDº and ª2º positions (but runs

in ª1º and ªRº position).. 1.................. .......q

2.. .

Vehicle will not run in ªDº, ª1º and ª2º positions (but

runs in ªRº position). Clutch slips.

Very poor acceleration.1 ......24..3...5.... ..q

6q7q8q9.q10.. .

Clutches or brakes slip somewhat in starting. 1 2 . 3 . . . 4 6 . . 5 . . . 7 . . 8 .q

13q12q10.q9...q11..

Excessive creep. ......1............. .......... .

No creep at all. 1......23...........q

6q5..q4..... .

Failure to change gear from ªD

1ºtoªD2º. . 21.5...43.......... .........q6.

Failure to change gear from ªD

2ºtoªD3º. . 21.5...4.3......... ...q6.....q7.

Failure to change gear from ªD

3ºtoªD4º. . 21.4....3....5..... .........q6.

Too high a gear change point from ªD

1ºtoªD2º, from

ªD2ºtoªD3º, from ªD3ºtoªD4º.. ..12....34......... .......... .

Gear change directly from ªD

1ºtoªD3º occurs. 1...............2... .........q3.

Engine stops when shifting lever into ªRº, ªDº, ª2º

and ª1º.. .....1.3...2.......q

4......... .

Too sharp a shock in change from ªD

1ºtoªD2º. . ..1...24.....5.3... .........q6.

Too sharp a shock in change from ªD

2ºtoªD3º. . ..1...24........3.. ...q5.....q6.

TROUBLE DIAGNOSIS Ð General Description

AT-43

Page 46 of 1767

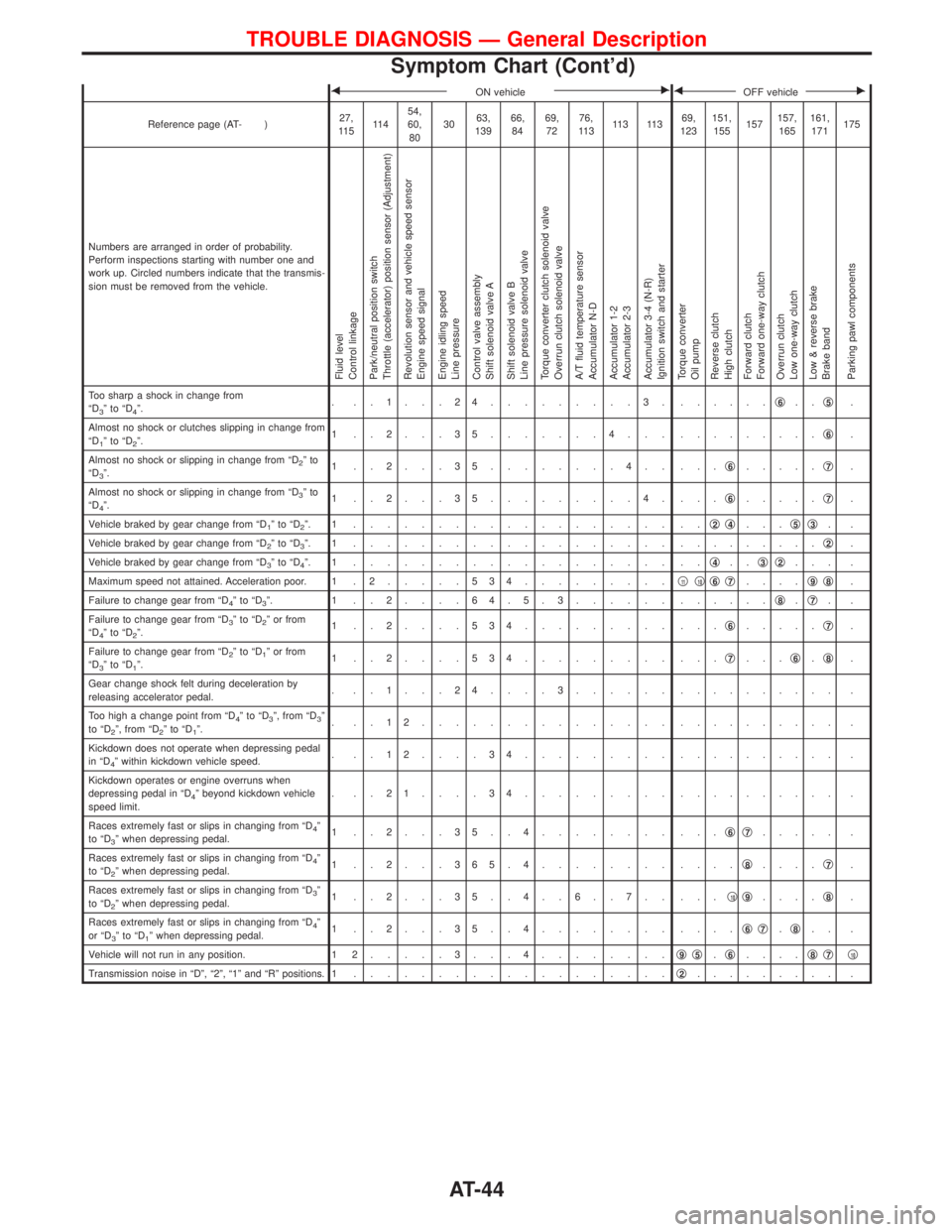

FON vehicleEFOFF vehicleE

Reference page (AT- )27,

11 511 454,

60,

803063,

13966,

8469,

7276,

11 311 3 11 369,

123151,

155157157,

165161,

171175

Numbers are arranged in order of probability.

Perform inspections starting with number one and

work up. Circled numbers indicate that the transmis-

sion must be removed from the vehicle.

Fluid level

Control linkage

Park/neutral position switch

Throttle (accelerator) position sensor (Adjustment)

Revolution sensor and vehicle speed sensor

Engine speed signal

Engine idling speed

Line pressure

Control valve assembly

Shift solenoid valve A

Shift solenoid valve B

Line pressure solenoid valve

Torque converter clutch solenoid valve

Overrun clutch solenoid valve

A/T fluid temperature sensor

Accumulator N-D

Accumulator 1-2

Accumulator 2-3

Accumulator 3-4 (N-R)

Ignition switch and starter

Torque converter

Oil pump

Reverse clutch

High clutch

Forward clutch

Forward one-way clutch

Overrun clutch

Low one-way clutch

Low & reverse brake

Brake band

Parking pawl components

Too sharp a shock in change from

ªD3ºtoªD4º.. ..1...24.........3. ......q6..q5.

Almost no shock or clutches slipping in change from

ªD

1ºtoªD2º.1 ..2...35.......4... .........q6.

Almost no shock or slipping in change from ªD

2ºto

ªD3º.1 ..2...35........4.. ...q6.....q7.

Almost no shock or slipping in change from ªD

3ºto

ªD4º.1 ..2...35.........4. ...q6.....q7.

Vehicle braked by gear change from ªD

1ºtoªD2º. 1 ................... ..q2q4...q5q3..

Vehicle braked by gear change from ªD

2ºtoªD3º. 1 ................... .........q2.

Vehicle braked by gear change from ªD

3ºtoªD4º. 1 ................... ..q4..q3q2... .

Maximum speed not attained. Acceleration poor. 1 . 2.....534.........q

11q10q6q7....q9q8.

Failure to change gear from ªD

4ºtoªD3º. 1 ..2....64.5.3...... ......q8.q7..

Failure to change gear from ªD

3ºtoªD2º or from

ªD4ºtoªD2º.1 ..2....534......... ...q6.....q7.

Failure to change gear from ªD

2ºtoªD1º or from

ªD3ºtoªD1º.1 ..2....534......... ...q7...q6.q8.

Gear change shock felt during deceleration by

releasing accelerator pedal.. ..1...24....3...... .......... .

Too high a change point from ªD

4ºtoªD3º, from ªD3º

to ªD2º, from ªD2ºtoªD1º.. ..12............... .......... .

Kickdown does not operate when depressing pedal

in ªD

4º within kickdown vehicle speed.. ..12....34......... .......... .

Kickdown operates or engine overruns when

depressing pedal in ªD

4º beyond kickdown vehicle

speed limit.. ..21....34......... .......... .

Races extremely fast or slips in changing from ªD

4º

to ªD3º when depressing pedal.1 ..2...35..4........ ...q6q7..... .

Races extremely fast or slips in changing from ªD

4º

to ªD2º when depressing pedal.1 ..2...365.4........ ....q8....q7.

Races extremely fast or slips in changing from ªD

3º

to ªD2º when depressing pedal.1 ..2...35..4..6..7.. ...q10q9....q8.

Races extremely fast or slips in changing from ªD

4º

or ªD3ºtoªD1º when depressing pedal.1 ..2...35..4........ ....q6q7.q8.. .

Vehicle will not run in any position. 1 2.....3...4........q

9q5.q6....q8q7q10

Transmission noise in ªDº, ª2º, ª1º and ªRº positions. 1...................q2......... .

TROUBLE DIAGNOSIS Ð General Description

Symptom Chart (Cont'd)

AT-44

Page 47 of 1767

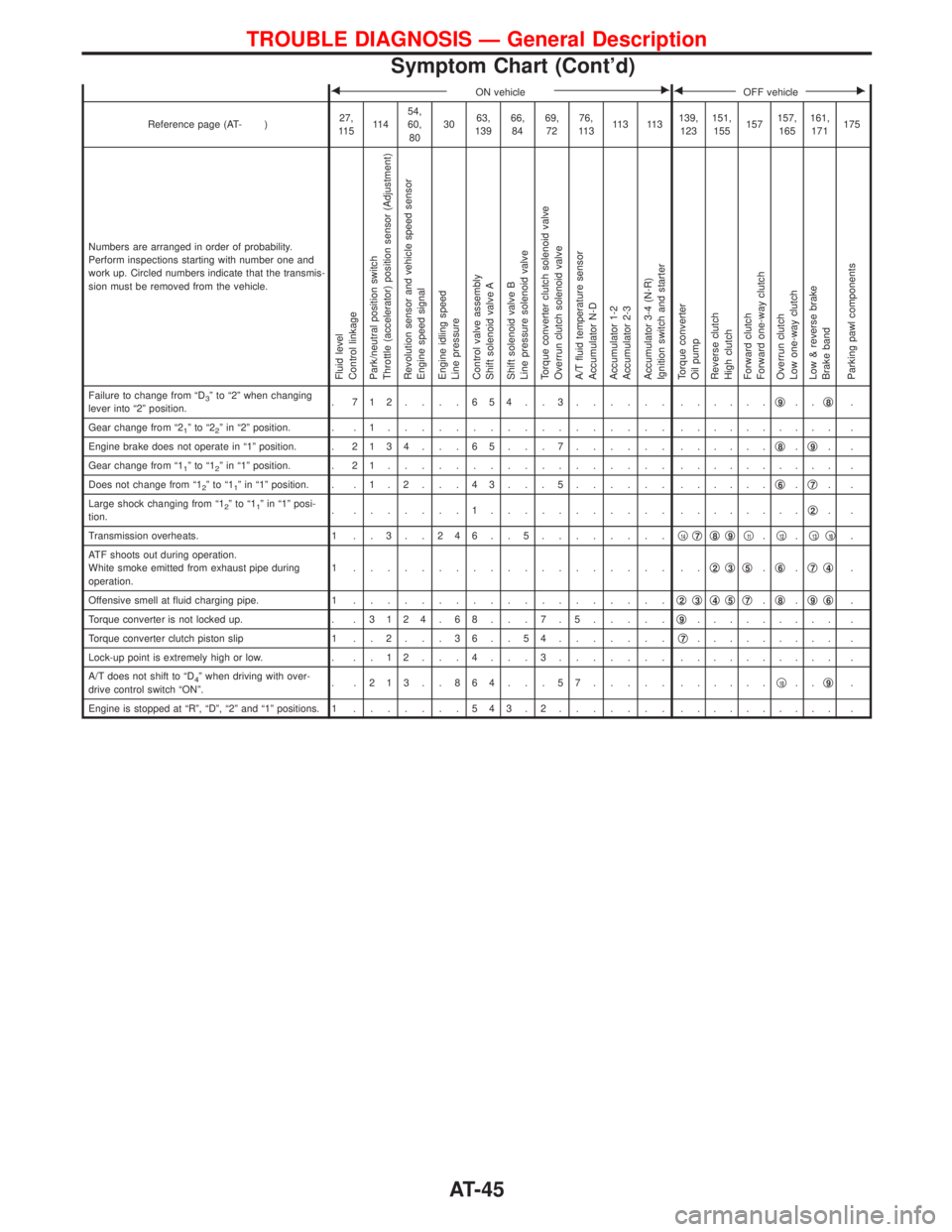

FON vehicleEFOFF vehicleE

Reference page (AT- )27,

11 511 454,

60,

803063,

13966,

8469,

7276,

11 311 3 11 3139,

123151,

155157157,

165161,

171175

Numbers are arranged in order of probability.

Perform inspections starting with number one and

work up. Circled numbers indicate that the transmis-

sion must be removed from the vehicle.

Fluid level

Control linkage

Park/neutral position switch

Throttle (accelerator) position sensor (Adjustment)

Revolution sensor and vehicle speed sensor

Engine speed signal

Engine idling speed

Line pressure

Control valve assembly

Shift solenoid valve A

Shift solenoid valve B

Line pressure solenoid valve

Torque converter clutch solenoid valve

Overrun clutch solenoid valve

A/T fluid temperature sensor

Accumulator N-D

Accumulator 1-2

Accumulator 2-3

Accumulator 3-4 (N-R)

Ignition switch and starter

Torque converter

Oil pump

Reverse clutch

High clutch

Forward clutch

Forward one-way clutch

Overrun clutch

Low one-way clutch

Low & reverse brake

Brake band

Parking pawl components

Failure to change from ªD3º to ª2º when changing

lever into ª2º position.. 712....654..3...... ......q9..q8.

Gear change from ª2

1ºtoª22º in ª2º position. . . 1................. .......... .

Engine brake does not operate in ª1º position. .2134 . . . 65 . . . 7...... ......q

8.q9..

Gear change from ª1

1ºtoª12º in ª1º position. . 2 1................. .......... .

Does not change from ª1

2ºtoª11º in ª1º position. . . 1 . 2 . . . 4 3 . . . 5...... ......q6.q7..

Large shock changing from ª1

2ºtoª11º in ª1º posi-

tion.. .......1........... ........q2..

Transmission overheats. 1 . . 3 . . 2 4 6 . . 5........q

14q7q8q9q11.q12.q13q10.

ATF shoots out during operation.

White smoke emitted from exhaust pipe during

operation.1 ................... ..q

2q3q5.q6.q7q4.

Offensive smell at fluid charging pipe. 1...................q

2q3q4q5q7.q8.q9q6.

Torque converter is not locked up. . .3124 . 68 . . . 7 . 5.....q

9......... .

Torque converter clutch piston slip 1 . . 2 . . . 3 6 . . 5 4.......q

7......... .

Lock-up point is extremely high or low. . . . 1 2 . . . 4 . . . 3....... .......... .

A/T does not shift to ªD

4º when driving with over-

drive control switch ªONº.. .213..864...57..... ......q10..q9.

Engine is stopped at ªRº, ªDº, ª2º and ª1º positions. 1.......543.2....... .......... .

TROUBLE DIAGNOSIS Ð General Description

Symptom Chart (Cont'd)

AT-45

Page 48 of 1767

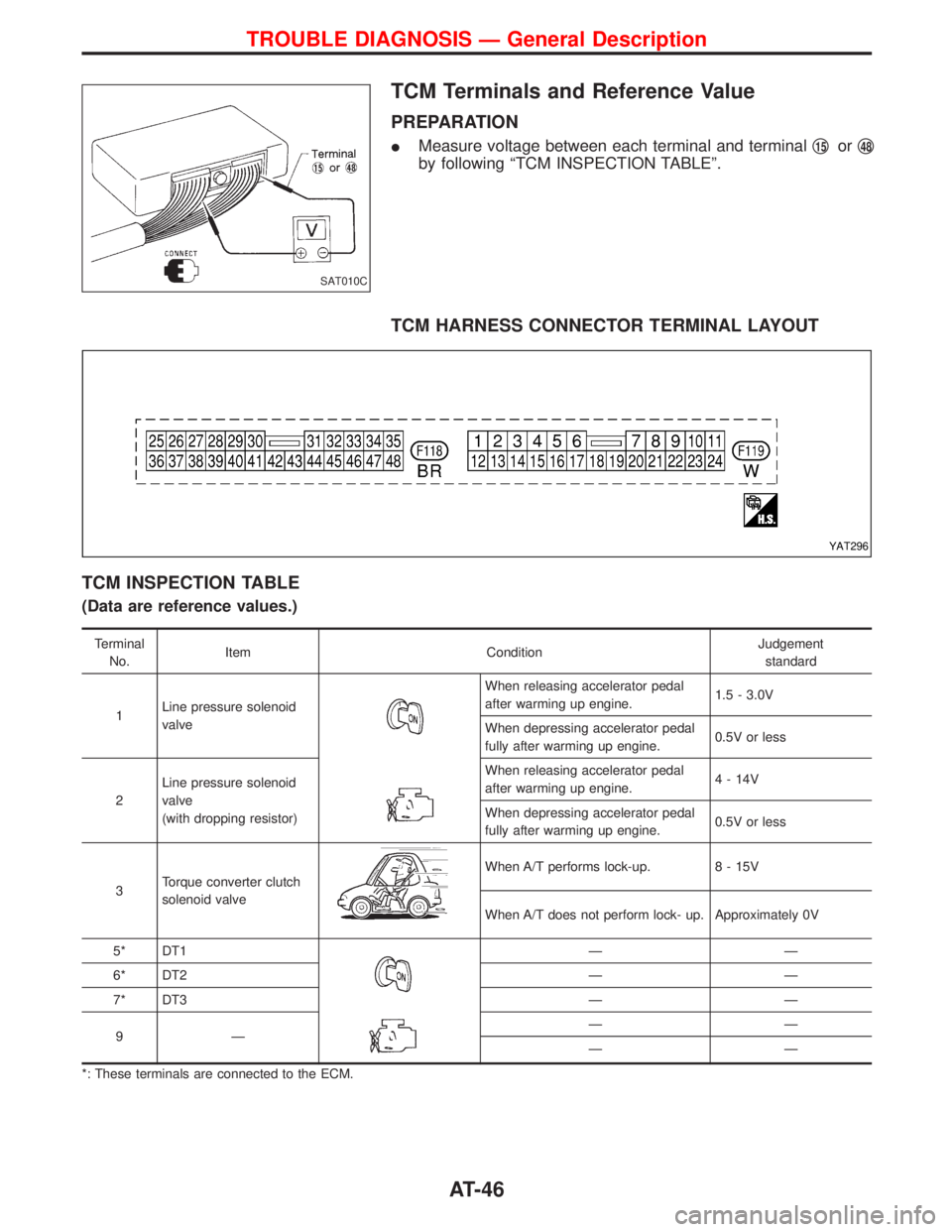

TCM Terminals and Reference Value

PREPARATION

IMeasure voltage between each terminal and terminalq15orq48

by following ªTCM INSPECTION TABLEº.

TCM HARNESS CONNECTOR TERMINAL LAYOUT

TCM INSPECTION TABLE

(Data are reference values.)

Terminal

No.Item ConditionJudgement

standard

1Line pressure solenoid

valve

When releasing accelerator pedal

after warming up engine.1.5 - 3.0V

When depressing accelerator pedal

fully after warming up engine.0.5V or less

2Line pressure solenoid

valve

(with dropping resistor)When releasing accelerator pedal

after warming up engine.4 - 14V

When depressing accelerator pedal

fully after warming up engine.0.5V or less

3Torque converter clutch

solenoid valve

When A/T performs lock-up. 8 - 15V

When A/T does not perform lock- up. Approximately 0V

5* DT1

ÐÐ

6* DT2 Ð Ð

7* DT3 Ð Ð

9ÐÐÐ

ÐÐ

*: These terminals are connected to the ECM.

SAT010C

YAT296

TROUBLE DIAGNOSIS Ð General Description

AT-46

Page 74 of 1767

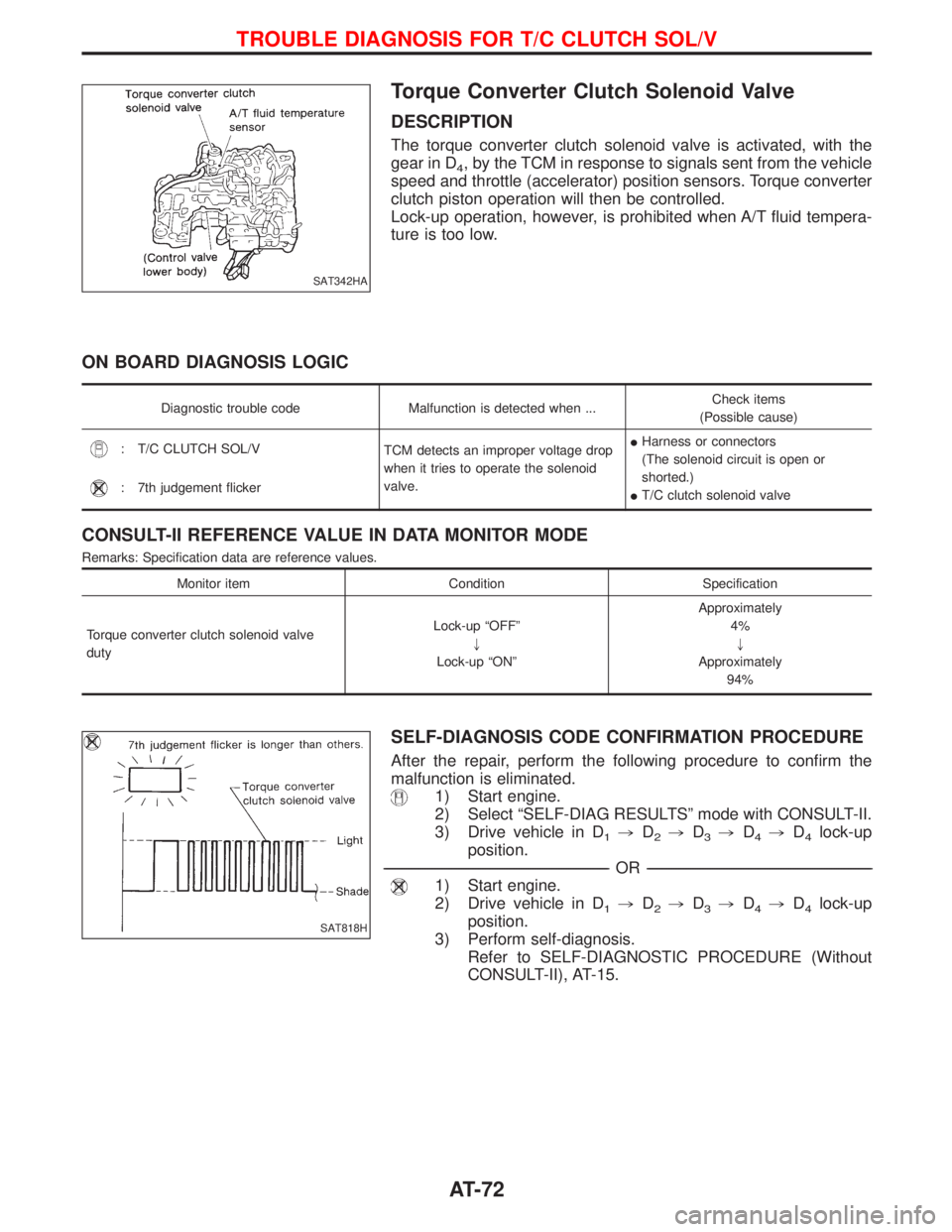

Torque Converter Clutch Solenoid Valve

DESCRIPTION

The torque converter clutch solenoid valve is activated, with the

gear in D

4, by the TCM in response to signals sent from the vehicle

speed and throttle (accelerator) position sensors. Torque converter

clutch piston operation will then be controlled.

Lock-up operation, however, is prohibited when A/T fluid tempera-

ture is too low.

ON BOARD DIAGNOSIS LOGIC

Diagnostic trouble code Malfunction is detected when ...Check items

(Possible cause)

: T/C CLUTCH SOL/V

TCM detects an improper voltage drop

when it tries to operate the solenoid

valve.IHarness or connectors

(The solenoid circuit is open or

shorted.)

IT/C clutch solenoid valve

: 7th judgement flicker

CONSULT-II REFERENCE VALUE IN DATA MONITOR MODE

Remarks: Specification data are reference values.

Monitor item Condition Specification

Torque converter clutch solenoid valve

dutyLock-up ªOFFº

"

Lock-up ªONºApproximately

4%

"

Approximately

94%

SELF-DIAGNOSIS CODE CONFIRMATION PROCEDURE

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

1) Start engine.

2) Select ªSELF-DIAG RESULTSº mode with CONSULT-II.

3) Drive vehicle in D

1,D2,D3,D4,D4lock-up

position.

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------OR------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1) Start engine.

2) Drive vehicle in D

1,D2,D3,D4,D4lock-up

position.

3) Perform self-diagnosis.

Refer to SELF-DIAGNOSTIC PROCEDURE (Without

CONSULT-II), AT-15.

SAT342HA

SAT818H

TROUBLE DIAGNOSIS FOR T/C CLUTCH SOL/V

AT-72

Page 75 of 1767

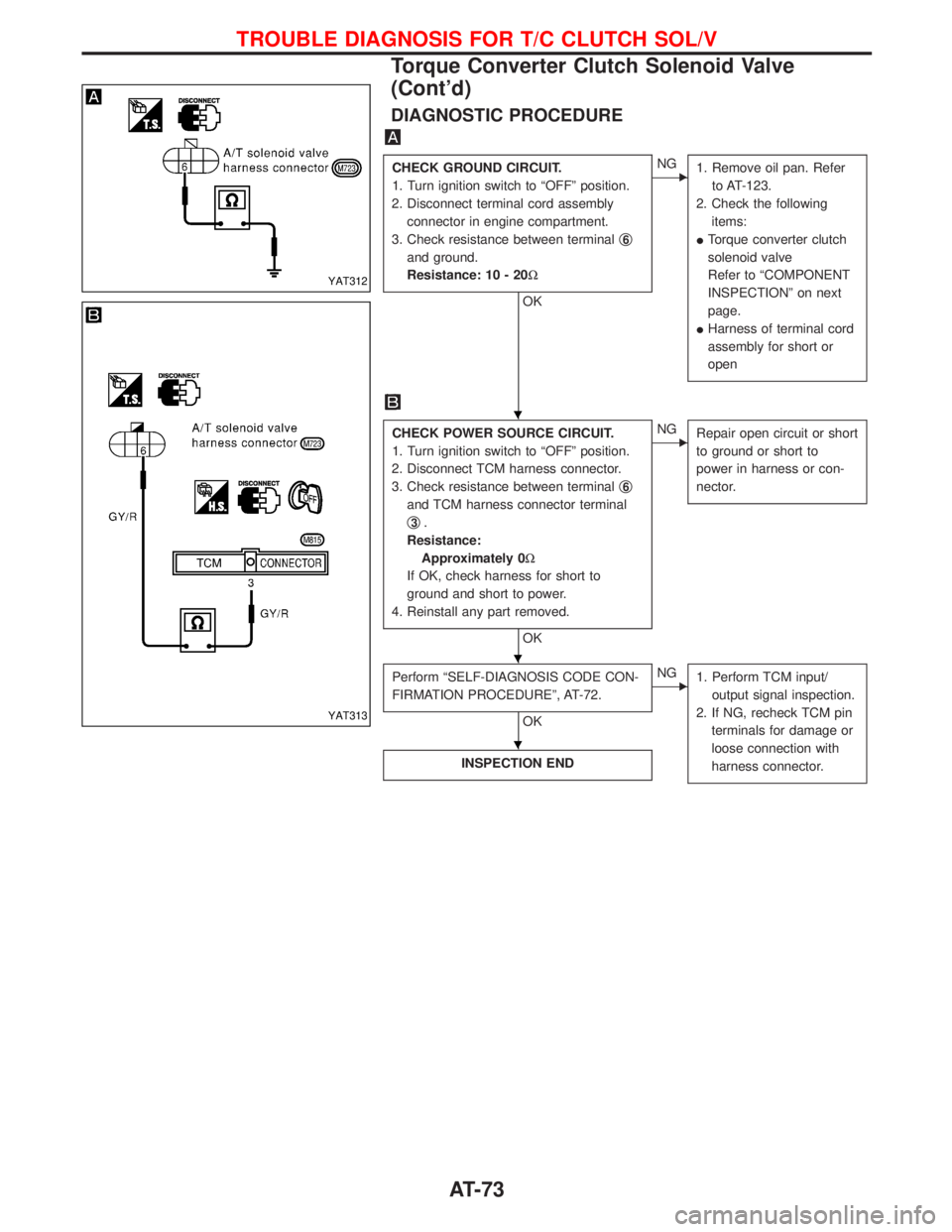

DIAGNOSTIC PROCEDURE

CHECK GROUND CIRCUIT.

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly

connector in engine compartment.

3. Check resistance between terminalq

6

and ground.

Resistance: 10 - 20W

OK

ENG

1. Remove oil pan. Refer

to AT-123.

2. Check the following

items:

ITorque converter clutch

solenoid valve

Refer to ªCOMPONENT

INSPECTIONº on next

page.

IHarness of terminal cord

assembly for short or

open

CHECK POWER SOURCE CIRCUIT.

1. Turn ignition switch to ªOFFº position.

2. Disconnect TCM harness connector.

3. Check resistance between terminalq

6

and TCM harness connector terminal

q

3.

Resistance:

Approximately 0W

If OK, check harness for short to

ground and short to power.

4. Reinstall any part removed.

OK

ENG

Repair open circuit or short

to ground or short to

power in harness or con-

nector.

Perform ªSELF-DIAGNOSIS CODE CON-

FIRMATION PROCEDUREº, AT-72.

OK

ENG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

YAT312

YAT313

H

H

H

TROUBLE DIAGNOSIS FOR T/C CLUTCH SOL/V

Torque Converter Clutch Solenoid Valve

(Cont'd)

AT-73

Page 76 of 1767

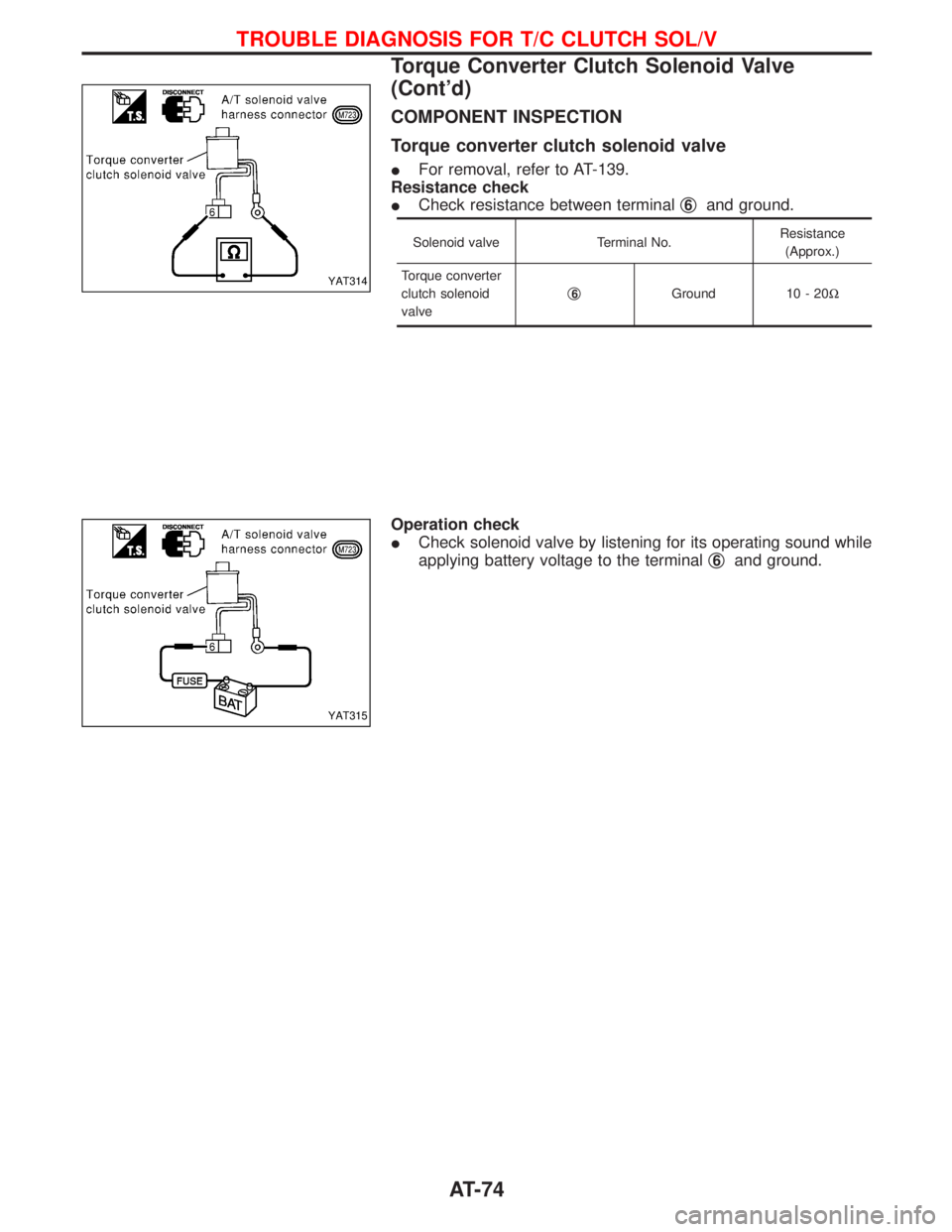

COMPONENT INSPECTION

Torque converter clutch solenoid valve

IFor removal, refer to AT-139.

Resistance check

ICheck resistance between terminalq

6and ground.

Solenoid valve Terminal No.Resistance

(Approx.)

Torque converter

clutch solenoid

valveq

6Ground 10 - 20W

Operation check

ICheck solenoid valve by listening for its operating sound while

applying battery voltage to the terminalq

6and ground.

YAT314

YAT315

TROUBLE DIAGNOSIS FOR T/C CLUTCH SOL/V

Torque Converter Clutch Solenoid Valve

(Cont'd)

AT-74

Page 102 of 1767

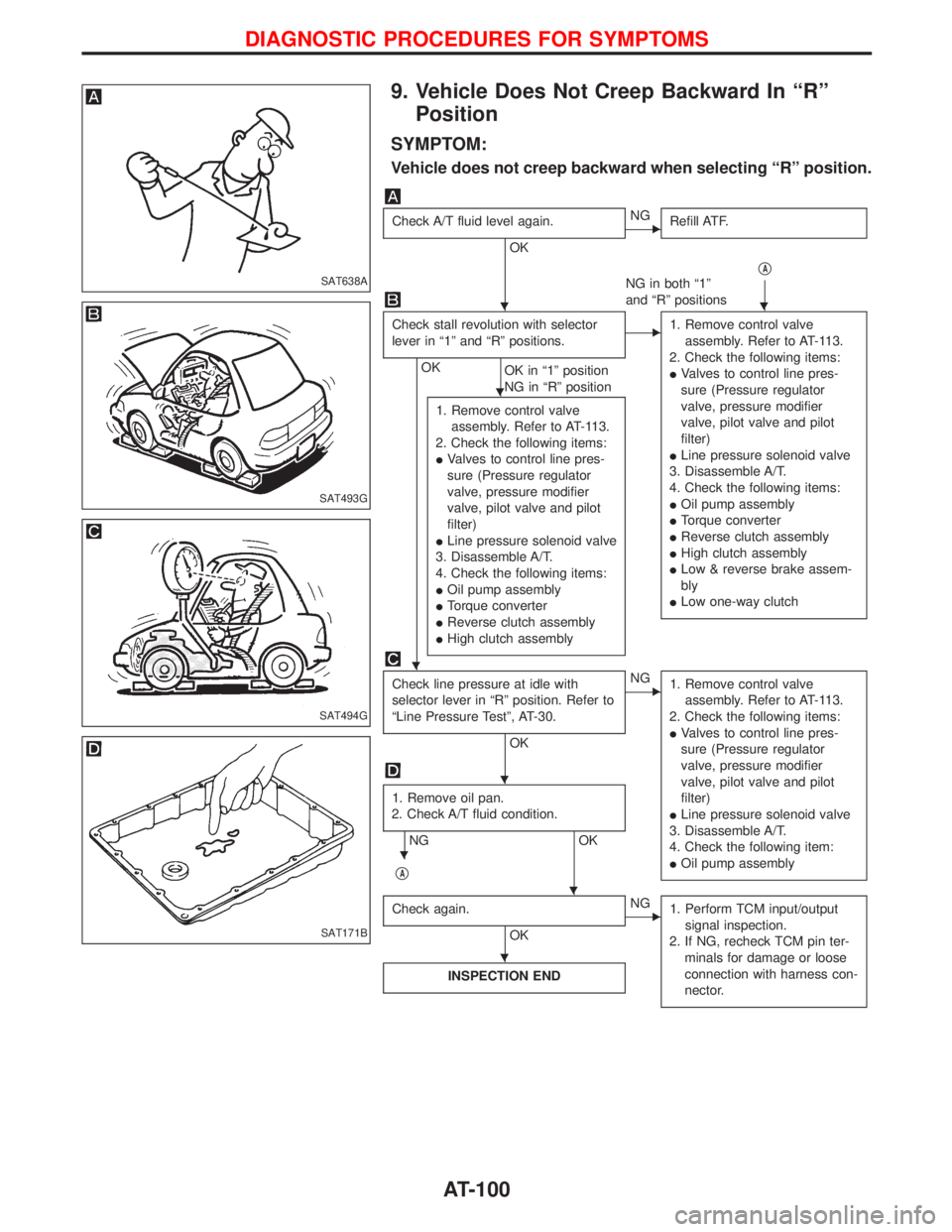

9. Vehicle Does Not Creep Backward In ªRº

Position

SYMPTOM:

Vehicle does not creep backward when selecting ªRº position.

Check A/T fluid level again.

OK

ENG

Refill ATF.

qA

NG in both ª1º

and ªRº positions

Check stall revolution with selector

lever in ª1º and ªRº positions.

OK

OK in ª1º position

NG in ªRº position

E1. Remove control valve

assembly. Refer to AT-113.

2. Check the following items:

IValves to control line pres-

sure (Pressure regulator

valve, pressure modifier

valve, pilot valve and pilot

filter)

ILine pressure solenoid valve

3. Disassemble A/T.

4. Check the following items:

IOil pump assembly

ITorque converter

IReverse clutch assembly

IHigh clutch assembly

ILow & reverse brake assem-

bly

ILow one-way clutch

1. Remove control valve

assembly. Refer to AT-113.

2. Check the following items:

IValves to control line pres-

sure (Pressure regulator

valve, pressure modifier

valve, pilot valve and pilot

filter)

ILine pressure solenoid valve

3. Disassemble A/T.

4. Check the following items:

IOil pump assembly

ITorque converter

IReverse clutch assembly

IHigh clutch assembly

Check line pressure at idle with

selector lever in ªRº position. Refer to

ªLine Pressure Testº, AT-30.

OK

ENG

1. Remove control valve

assembly. Refer to AT-113.

2. Check the following items:

IValves to control line pres-

sure (Pressure regulator

valve, pressure modifier

valve, pilot valve and pilot

filter)

ILine pressure solenoid valve

3. Disassemble A/T.

4. Check the following item:

IOil pump assembly

1. Remove oil pan.

2. Check A/T fluid condition.

NG OK

q

A

Check again.

OK

ENG

1. Perform TCM input/output

signal inspection.

2. If NG, recheck TCM pin ter-

minals for damage or loose

connection with harness con-

nector.

INSPECTION END

SAT638A

SAT493G

SAT494G

SAT171B

HH

H

H

H

H

H

H

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-100

Page 103 of 1767

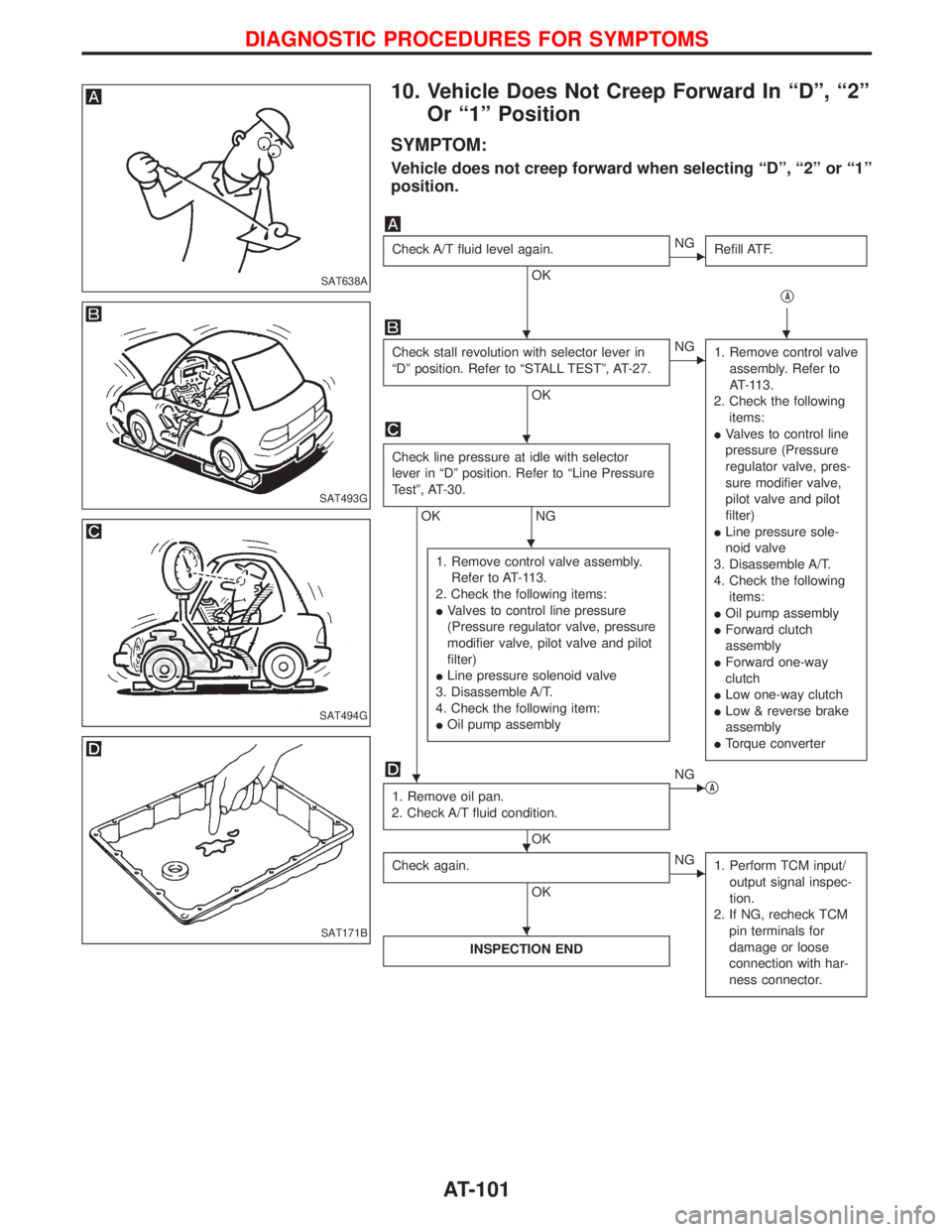

10. Vehicle Does Not Creep Forward In ªDº, ª2º

Or ª1º Position

SYMPTOM:

Vehicle does not creep forward when selecting ªDº, ª2º or ª1º

position.

Check A/T fluid level again.

OK

ENG

Refill ATF.

qA

Check stall revolution with selector lever in

ªDº position. Refer to ªSTALL TESTº, AT-27.

OK

ENG

1. Remove control valve

assembly. Refer to

AT-113.

2. Check the following

items:

IValves to control line

pressure (Pressure

regulator valve, pres-

sure modifier valve,

pilot valve and pilot

filter)

ILine pressure sole-

noid valve

3. Disassemble A/T.

4. Check the following

items:

IOil pump assembly

IForward clutch

assembly

IForward one-way

clutch

ILow one-way clutch

ILow & reverse brake

assembly

ITorque converter

Check line pressure at idle with selector

lever in ªDº position. Refer to ªLine Pressure

Testº, AT-30.

OK NG

1. Remove control valve assembly.

Refer to AT-113.

2. Check the following items:

IValves to control line pressure

(Pressure regulator valve, pressure

modifier valve, pilot valve and pilot

filter)

ILine pressure solenoid valve

3. Disassemble A/T.

4. Check the following item:

IOil pump assembly

1. Remove oil pan.

2. Check A/T fluid condition.

OK

ENG

qA

Check again.

OK

ENG

1. Perform TCM input/

output signal inspec-

tion.

2. If NG, recheck TCM

pin terminals for

damage or loose

connection with har-

ness connector.

INSPECTION END

SAT638A

SAT493G

SAT494G

SAT171B

HH

H

H

H

H H

H

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-101