torque NISSAN TERRANO 2002 Service Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 104 of 1767

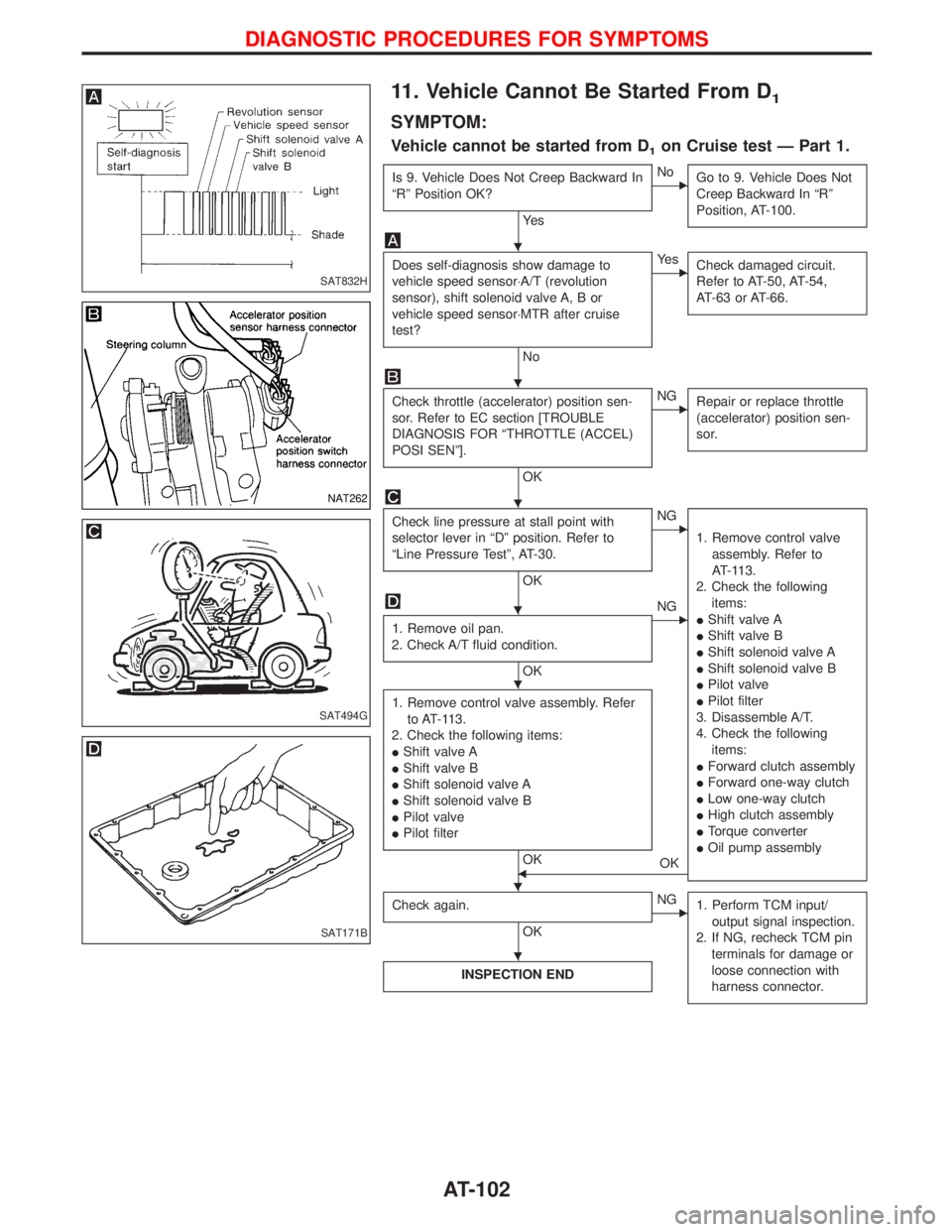

11. Vehicle Cannot Be Started From D1

SYMPTOM:

Vehicle cannot be started from D1on Cruise test Ð Part 1.

Is 9. Vehicle Does Not Creep Backward In

ªRº Position OK?

Ye s

ENo

Go to 9. Vehicle Does Not

Creep Backward In ªRº

Position, AT-100.

Does self-diagnosis show damage to

vehicle speed sensor×A/T (revolution

sensor), shift solenoid valve A, B or

vehicle speed sensor×MTR after cruise

test?

No

EYe s

Check damaged circuit.

Refer to AT-50, AT-54,

AT-63 or AT-66.

Check throttle (accelerator) position sen-

sor. Refer to EC section [TROUBLE

DIAGNOSIS FOR ªTHROTTLE (ACCEL)

POSI SENº].

OK

ENG

Repair or replace throttle

(accelerator) position sen-

sor.

Check line pressure at stall point with

selector lever in ªDº position. Refer to

ªLine Pressure Testº, AT-30.

OK

ENG

1. Remove control valve

assembly. Refer to

AT-113.

2. Check the following

items:

IShift valve A

IShift valve B

IShift solenoid valve A

IShift solenoid valve B

IPilot valve

IPilot filter

3. Disassemble A/T.

4. Check the following

items:

IForward clutch assembly

IForward one-way clutch

ILow one-way clutch

IHigh clutch assembly

ITorque converter

IOil pump assembly

1. Remove oil pan.

2. Check A/T fluid condition.

OK

ENG

1. Remove control valve assembly. Refer

to AT-113.

2. Check the following items:

IShift valve A

IShift valve B

IShift solenoid valve A

IShift solenoid valve B

IPilot valve

IPilot filter

OKFOK

Check again.

OK

ENG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

SAT832H

NAT262

SAT494G

SAT171B

H

H

H

H

H

H H

H

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-102

Page 107 of 1767

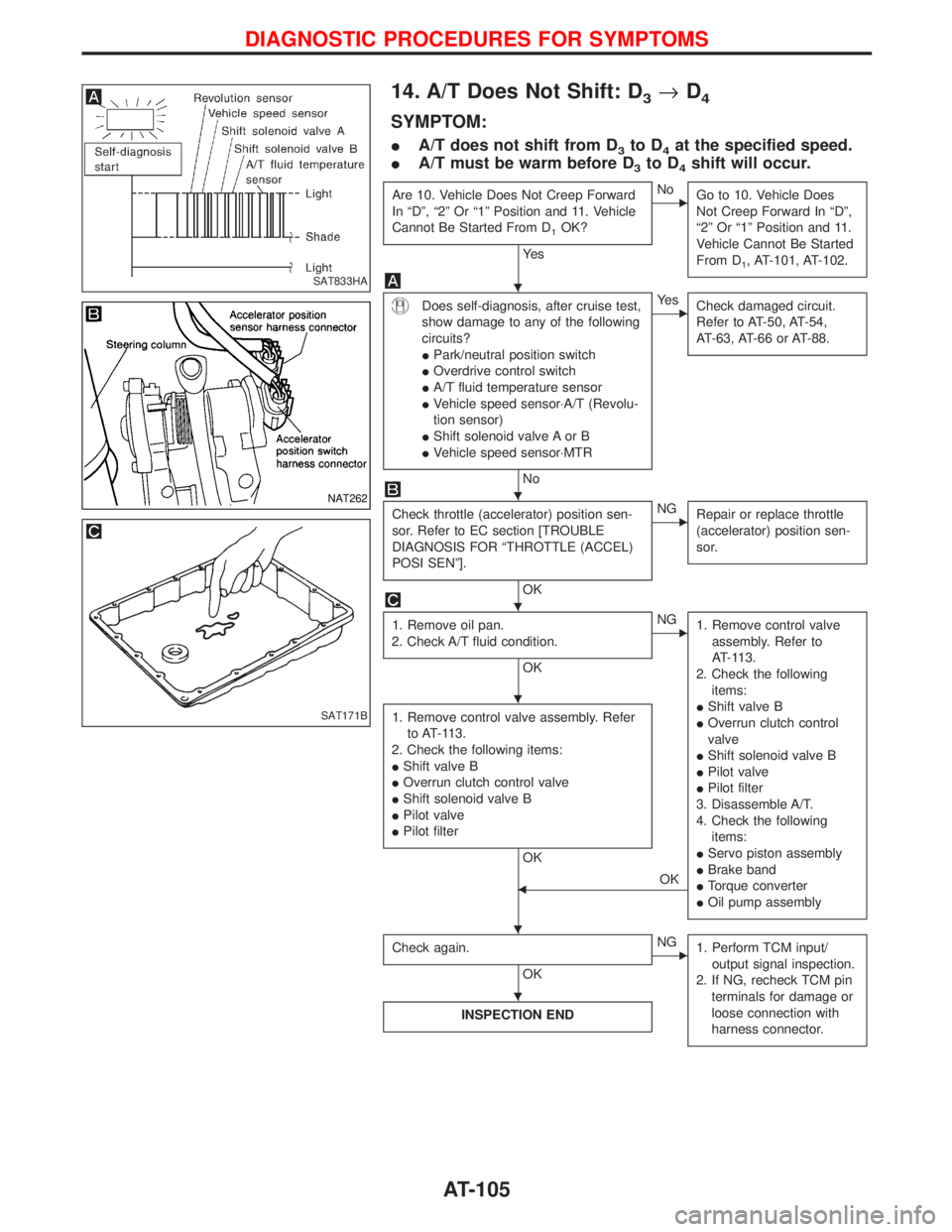

14. A/T Does Not Shift: D3®D4

SYMPTOM:

IA/T does not shift from D3to D4at the specified speed.

IA/T must be warm before D

3to D4shift will occur.

Are 10. Vehicle Does Not Creep Forward

In ªDº, ª2º Or ª1º Position and 11. Vehicle

Cannot Be Started From D

1OK?

Ye s

ENo

Go to 10. Vehicle Does

Not Creep Forward In ªDº,

ª2º Or ª1º Position and 11.

Vehicle Cannot Be Started

From D

1, AT-101, AT-102.

Does self-diagnosis, after cruise test,

show damage to any of the following

circuits?

IPark/neutral position switch

IOverdrive control switch

IA/T fluid temperature sensor

IVehicle speed sensor×A/T (Revolu-

tion sensor)

IShift solenoid valve A or B

IVehicle speed sensor×MTR

No

EYe s

Check damaged circuit.

Refer to AT-50, AT-54,

AT-63, AT-66 or AT-88.

Check throttle (accelerator) position sen-

sor. Refer to EC section [TROUBLE

DIAGNOSIS FOR ªTHROTTLE (ACCEL)

POSI SENº].

OK

ENG

Repair or replace throttle

(accelerator) position sen-

sor.

1. Remove oil pan.

2. Check A/T fluid condition.

OK

ENG

1. Remove control valve

assembly. Refer to

AT-113.

2. Check the following

items:

IShift valve B

IOverrun clutch control

valve

IShift solenoid valve B

IPilot valve

IPilot filter

3. Disassemble A/T.

4. Check the following

items:

IServo piston assembly

IBrake band

ITorque converter

IOil pump assembly

1. Remove control valve assembly. Refer

to AT-113.

2. Check the following items:

IShift valve B

IOverrun clutch control valve

IShift solenoid valve B

IPilot valve

IPilot filter

OK

FOK

Check again.

OK

ENG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

SAT833HA

NAT262

SAT171B

H

H

H

H

H H

H

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-105

Page 108 of 1767

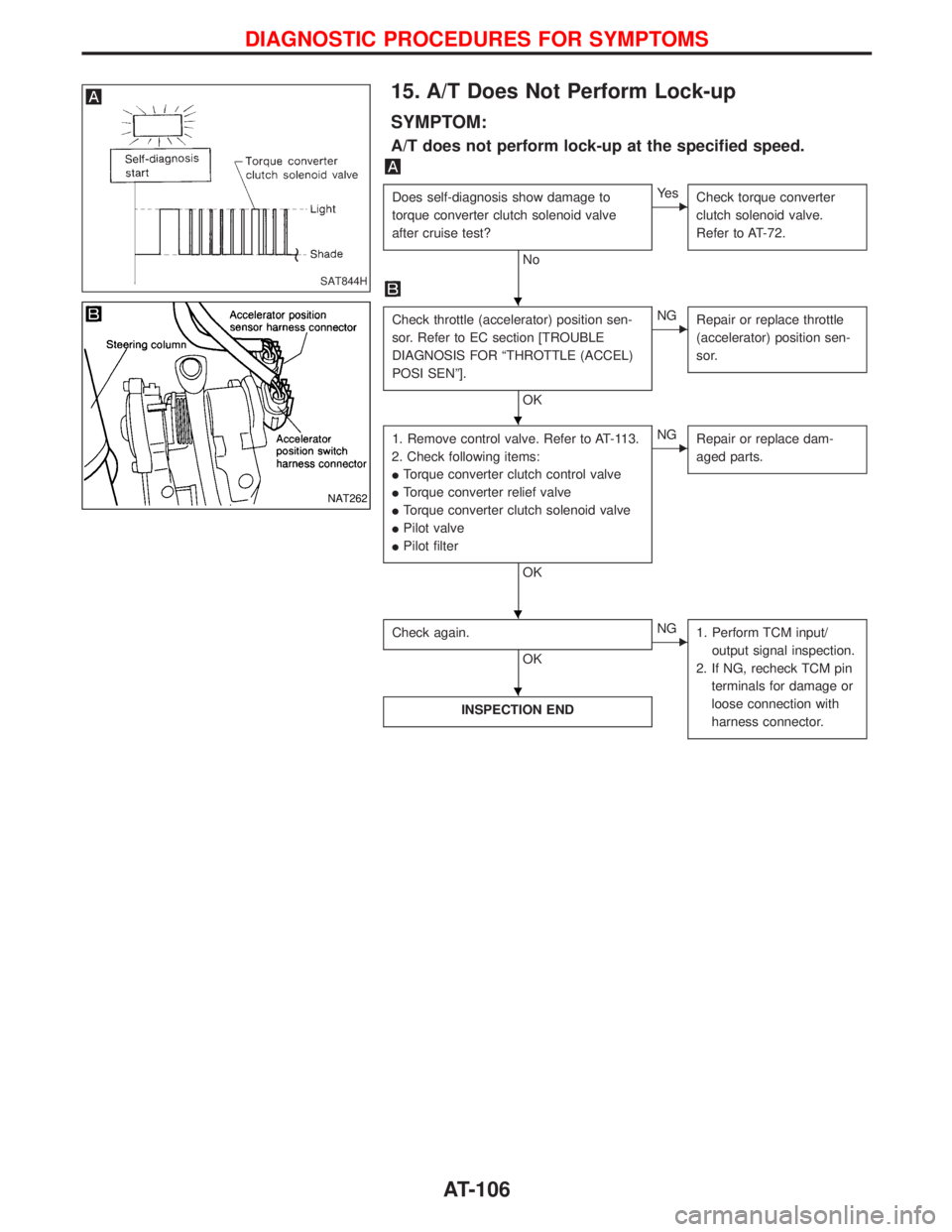

15. A/T Does Not Perform Lock-up

SYMPTOM:

A/T does not perform lock-up at the specified speed.

Does self-diagnosis show damage to

torque converter clutch solenoid valve

after cruise test?

No

EYe s

Check torque converter

clutch solenoid valve.

Refer to AT-72.

Check throttle (accelerator) position sen-

sor. Refer to EC section [TROUBLE

DIAGNOSIS FOR ªTHROTTLE (ACCEL)

POSI SENº].

OK

ENG

Repair or replace throttle

(accelerator) position sen-

sor.

1. Remove control valve. Refer to AT-113.

2. Check following items:

ITorque converter clutch control valve

ITorque converter relief valve

ITorque converter clutch solenoid valve

IPilot valve

IPilot filter

OK

ENG

Repair or replace dam-

aged parts.

Check again.

OK

ENG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

SAT844H

NAT262

H

H

H H

H

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-106

Page 109 of 1767

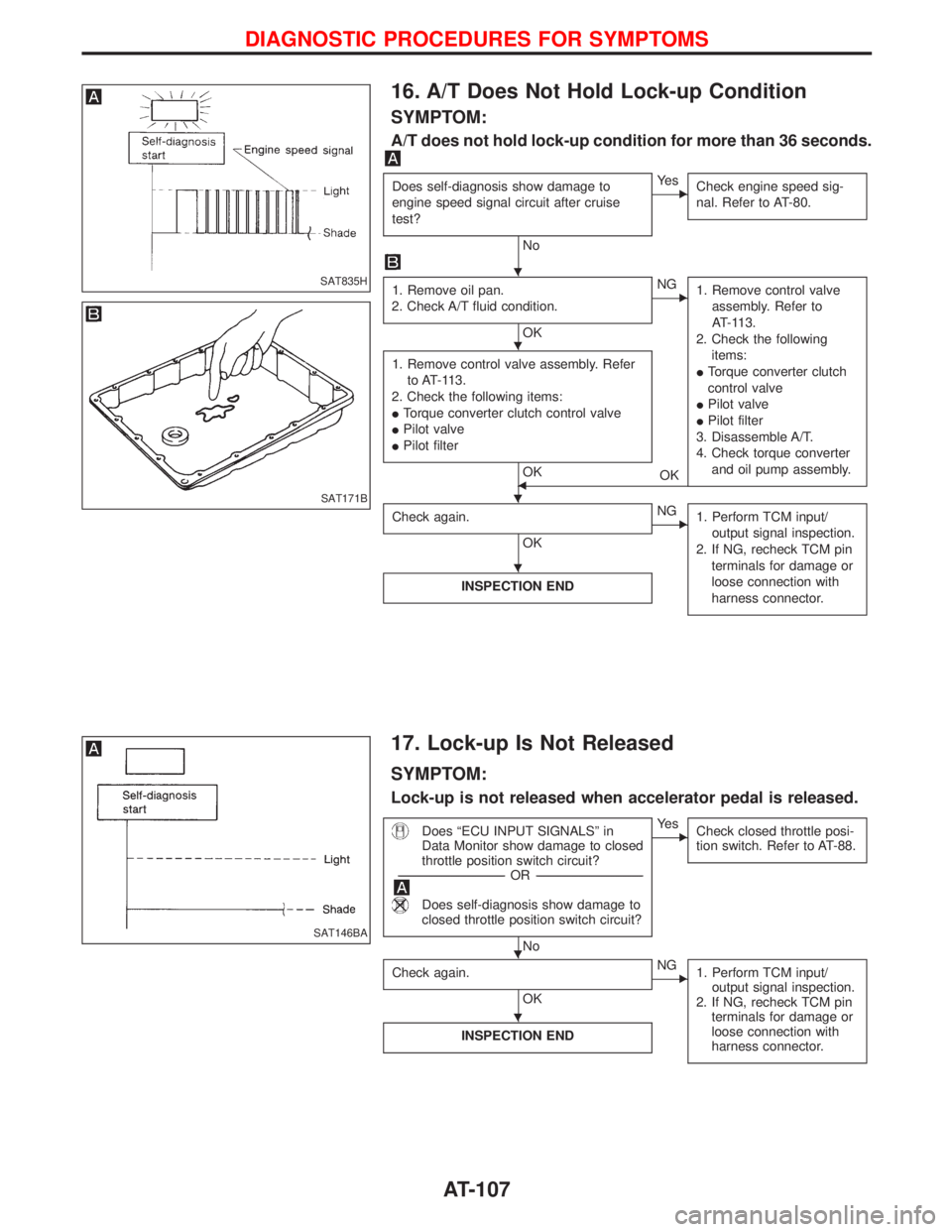

16. A/T Does Not Hold Lock-up Condition

SYMPTOM:

A/T does not hold lock-up condition for more than 36 seconds.

Does self-diagnosis show damage to

engine speed signal circuit after cruise

test?

No

EYe s

Check engine speed sig-

nal. Refer to AT-80.

1. Remove oil pan.

2. Check A/T fluid condition.

OK

ENG

1. Remove control valve

assembly. Refer to

AT-113.

2. Check the following

items:

ITorque converter clutch

control valve

IPilot valve

IPilot filter

3. Disassemble A/T.

4. Check torque converter

and oil pump assembly.

1. Remove control valve assembly. Refer

to AT-113.

2. Check the following items:

ITorque converter clutch control valve

IPilot valve

IPilot filter

OKFOK

Check again.

OK

ENG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

17. Lock-up Is Not Released

SYMPTOM:

Lock-up is not released when accelerator pedal is released.

Does ªECU INPUT SIGNALSº in

Data Monitor show damage to closed

throttle position switch circuit?

-----------------------------------------------------------------------------------------------------------------------OR -----------------------------------------------------------------------------------------------------------------------

Does self-diagnosis show damage to

closed throttle position switch circuit?

No

EYe s

Check closed throttle posi-

tion switch. Refer to AT-88.

Check again.

OK

ENG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

SAT835H

SAT171B

SAT146BA

H

H

H H

H

H

H

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-107

Page 116 of 1767

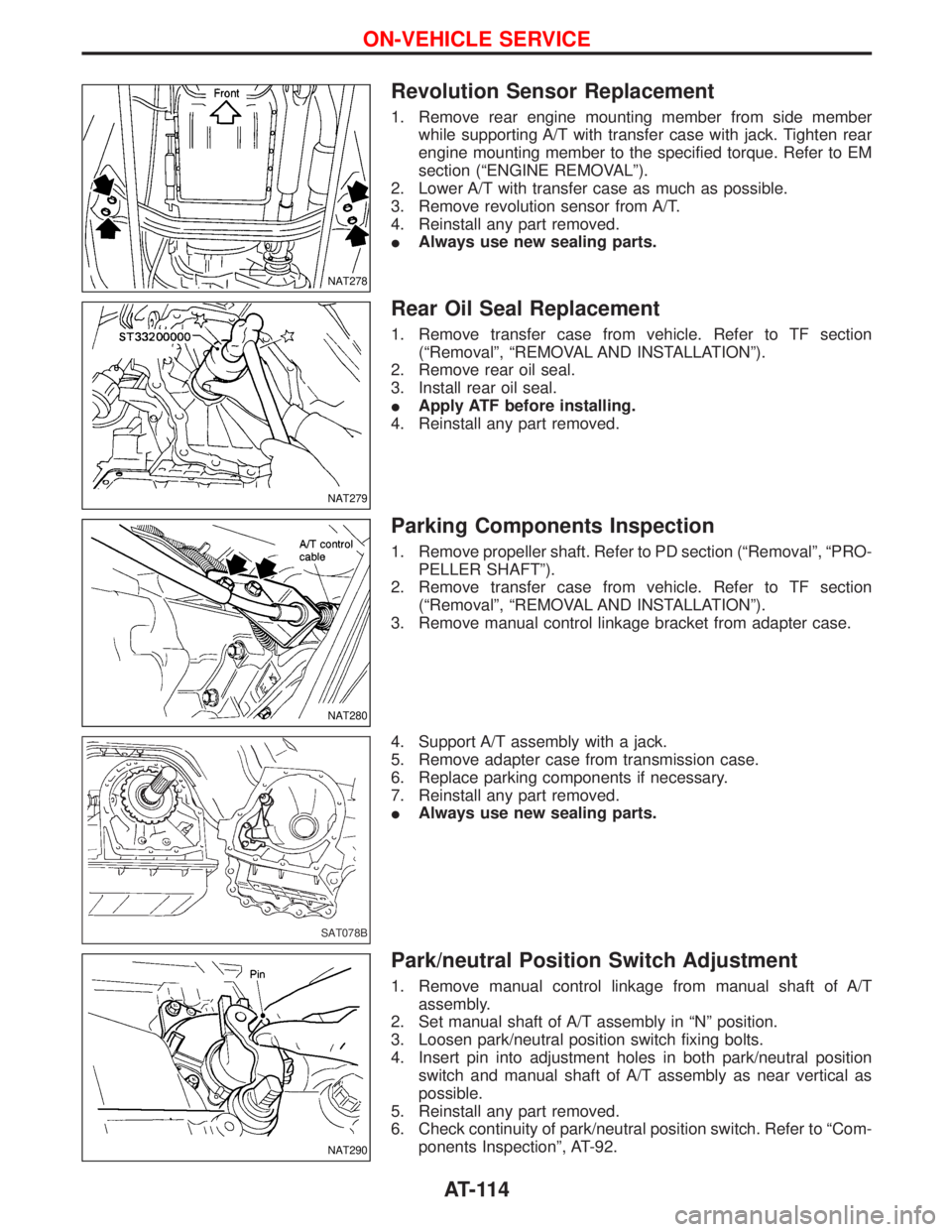

Revolution Sensor Replacement

1. Remove rear engine mounting member from side member

while supporting A/T with transfer case with jack. Tighten rear

engine mounting member to the specified torque. Refer to EM

section (ªENGINE REMOVALº).

2. Lower A/T with transfer case as much as possible.

3. Remove revolution sensor from A/T.

4. Reinstall any part removed.

IAlways use new sealing parts.

Rear Oil Seal Replacement

1. Remove transfer case from vehicle. Refer to TF section

(ªRemovalº, ªREMOVAL AND INSTALLATIONº).

2. Remove rear oil seal.

3. Install rear oil seal.

IApply ATF before installing.

4. Reinstall any part removed.

Parking Components Inspection

1. Remove propeller shaft. Refer to PD section (ªRemovalº, ªPRO-

PELLER SHAFTº).

2. Remove transfer case from vehicle. Refer to TF section

(ªRemovalº, ªREMOVAL AND INSTALLATIONº).

3. Remove manual control linkage bracket from adapter case.

4. Support A/T assembly with a jack.

5. Remove adapter case from transmission case.

6. Replace parking components if necessary.

7. Reinstall any part removed.

IAlways use new sealing parts.

Park/neutral Position Switch Adjustment

1. Remove manual control linkage from manual shaft of A/T

assembly.

2. Set manual shaft of A/T assembly in ªNº position.

3. Loosen park/neutral position switch fixing bolts.

4. Insert pin into adjustment holes in both park/neutral position

switch and manual shaft of A/T assembly as near vertical as

possible.

5. Reinstall any part removed.

6. Check continuity of park/neutral position switch. Refer to ªCom-

ponents Inspectionº, AT-92.

NAT278

NAT279

NAT280

SAT078B

NAT290

ON-VEHICLE SERVICE

AT-114

Page 117 of 1767

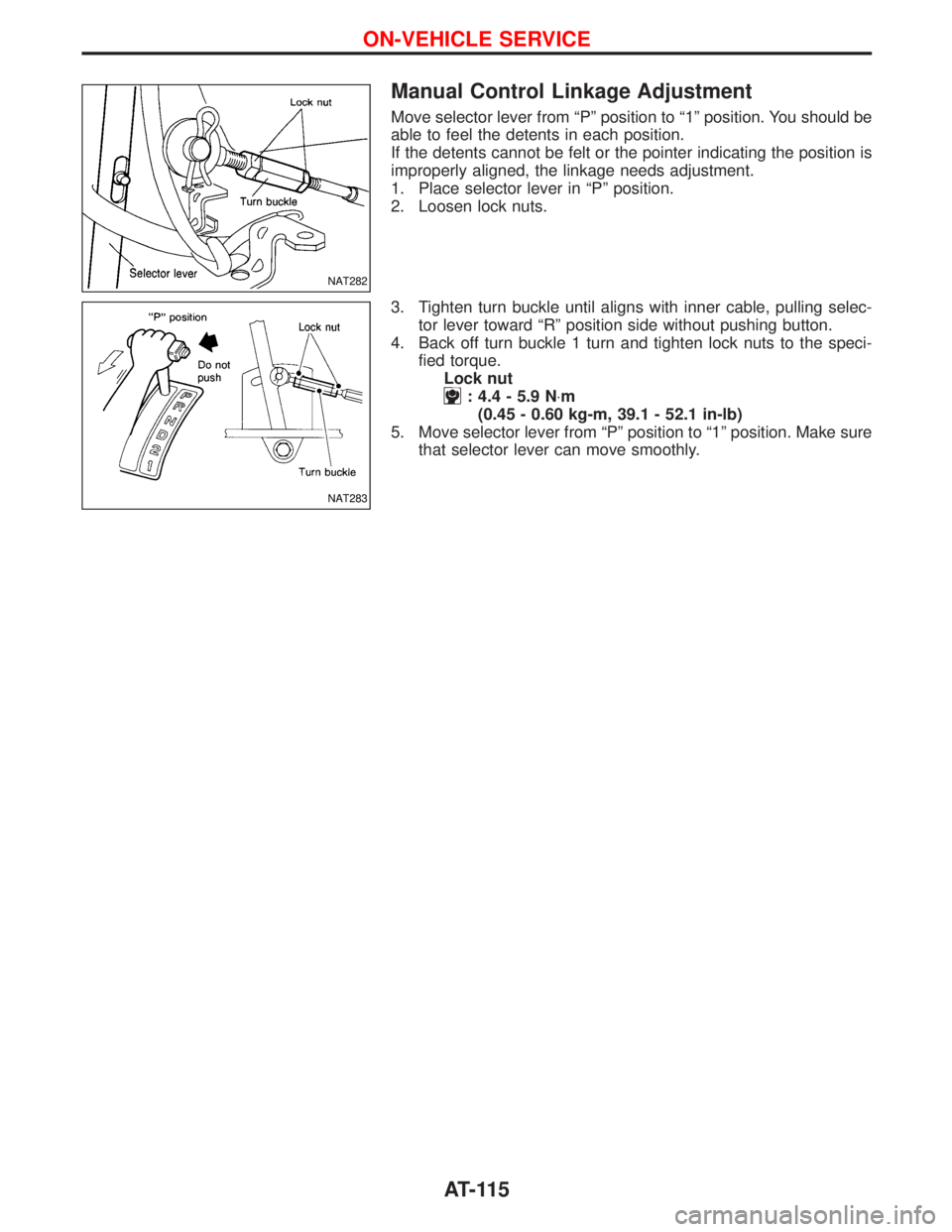

Manual Control Linkage Adjustment

Move selector lever from ªPº position to ª1º position. You should be

able to feel the detents in each position.

If the detents cannot be felt or the pointer indicating the position is

improperly aligned, the linkage needs adjustment.

1. Place selector lever in ªPº position.

2. Loosen lock nuts.

3. Tighten turn buckle until aligns with inner cable, pulling selec-

tor lever toward ªRº position side without pushing button.

4. Back off turn buckle 1 turn and tighten lock nuts to the speci-

fied torque.

Lock nut

: 4.4 - 5.9 N×m

(0.45 - 0.60 kg-m, 39.1 - 52.1 in-lb)

5. Move selector lever from ªPº position to ª1º position. Make sure

that selector lever can move smoothly.

NAT282

NAT283

ON-VEHICLE SERVICE

AT-115

Page 119 of 1767

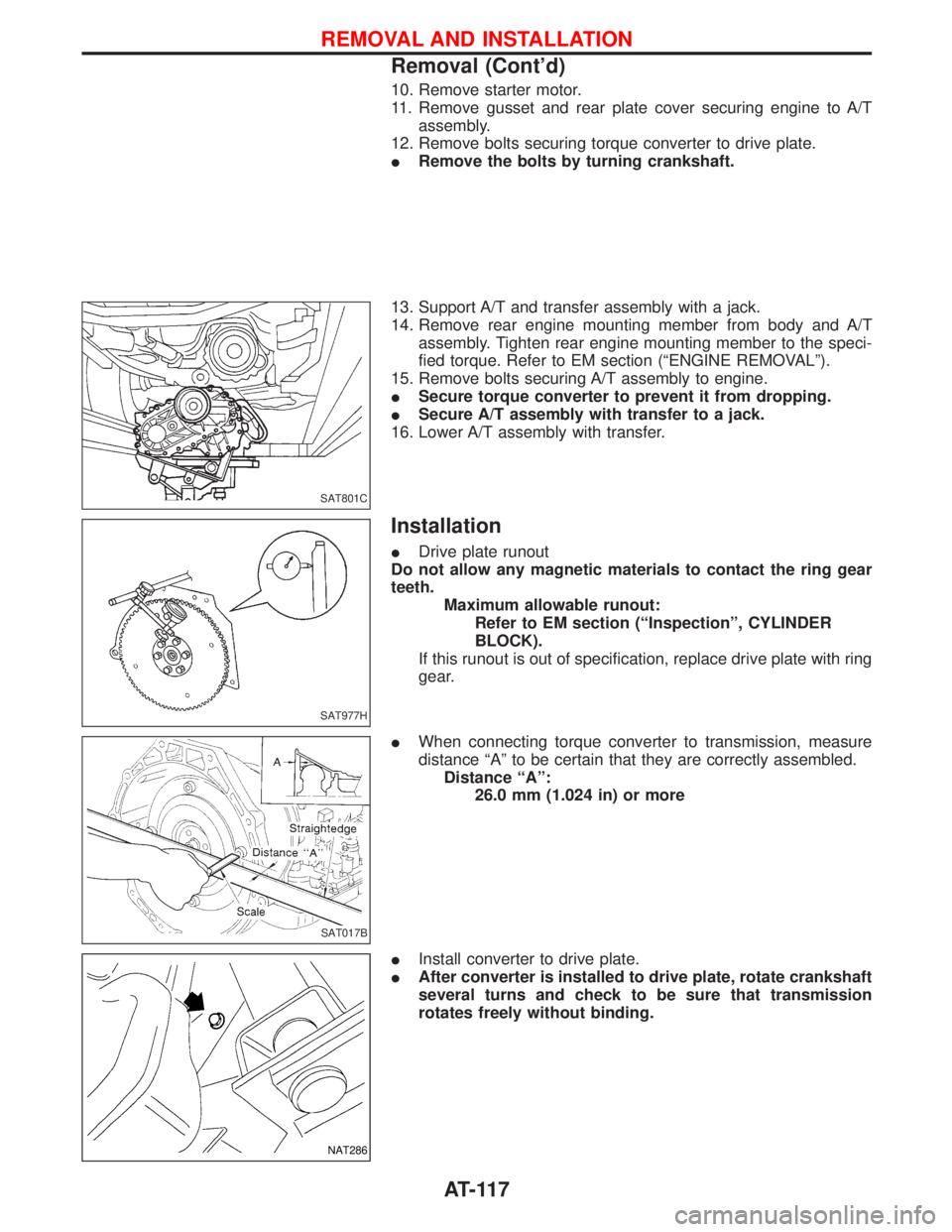

10. Remove starter motor.

11. Remove gusset and rear plate cover securing engine to A/T

assembly.

12. Remove bolts securing torque converter to drive plate.

IRemove the bolts by turning crankshaft.

13. Support A/T and transfer assembly with a jack.

14. Remove rear engine mounting member from body and A/T

assembly. Tighten rear engine mounting member to the speci-

fied torque. Refer to EM section (ªENGINE REMOVALº).

15. Remove bolts securing A/T assembly to engine.

ISecure torque converter to prevent it from dropping.

ISecure A/T assembly with transfer to a jack.

16. Lower A/T assembly with transfer.

Installation

IDrive plate runout

Do not allow any magnetic materials to contact the ring gear

teeth.

Maximum allowable runout:

Refer to EM section (ªInspectionº, CYLINDER

BLOCK).

If this runout is out of specification, replace drive plate with ring

gear.

IWhen connecting torque converter to transmission, measure

distance ªAº to be certain that they are correctly assembled.

Distance ªAº:

26.0 mm (1.024 in) or more

IInstall converter to drive plate.

IAfter converter is installed to drive plate, rotate crankshaft

several turns and check to be sure that transmission

rotates freely without binding.

SAT801C

SAT977H

SAT017B

NAT286

REMOVAL AND INSTALLATION

Removal (Cont'd)

AT-117

Page 120 of 1767

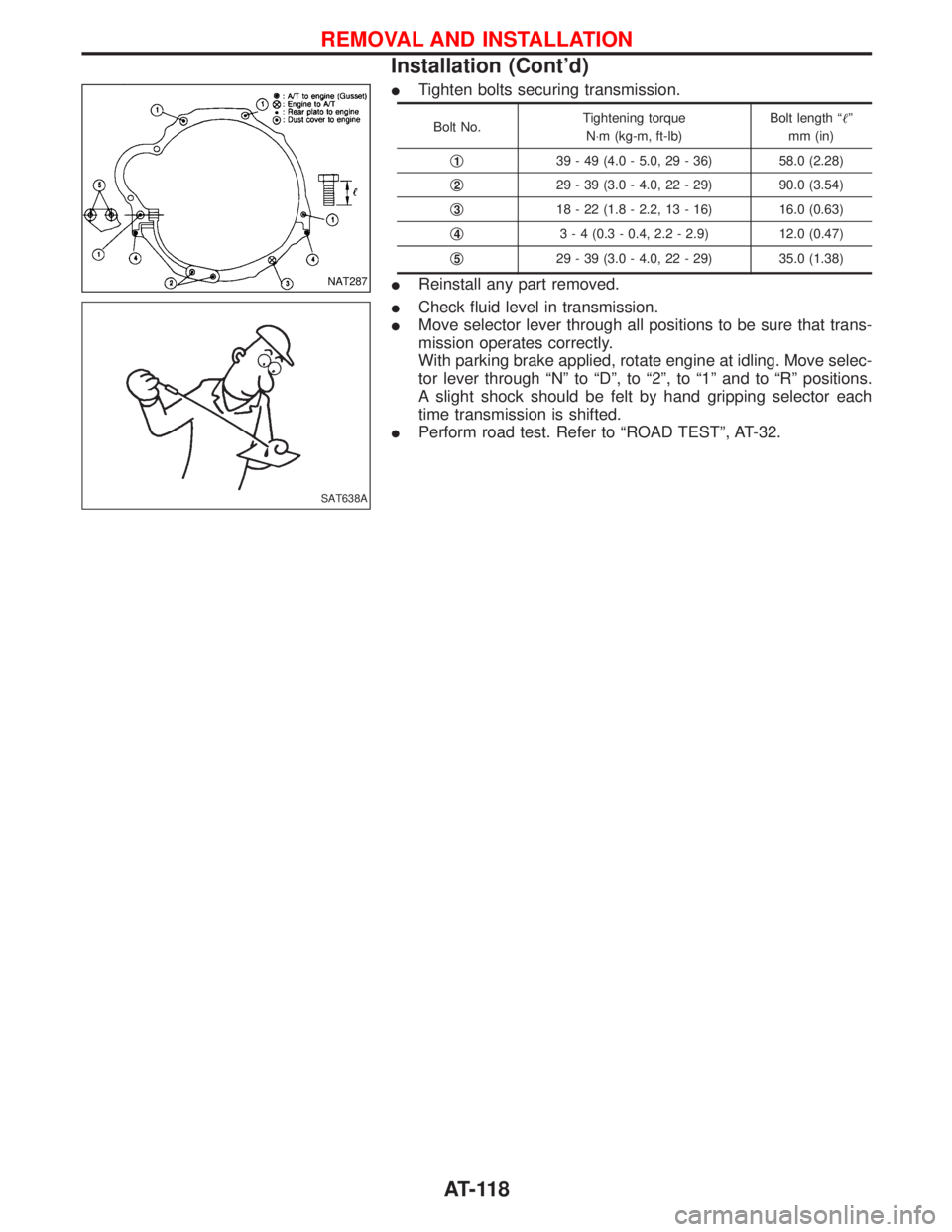

ITighten bolts securing transmission.

Bolt No.Tightening torque

N×m (kg-m, ft-lb)Bolt length ªº

mm (in)

q

139 - 49 (4.0 - 5.0, 29 - 36) 58.0 (2.28)

q

229 - 39 (3.0 - 4.0, 22 - 29) 90.0 (3.54)

q

318 - 22 (1.8 - 2.2, 13 - 16) 16.0 (0.63)

q

43 - 4 (0.3 - 0.4, 2.2 - 2.9) 12.0 (0.47)

q

529 - 39 (3.0 - 4.0, 22 - 29) 35.0 (1.38)

IReinstall any part removed.

ICheck fluid level in transmission.

IMove selector lever through all positions to be sure that trans-

mission operates correctly.

With parking brake applied, rotate engine at idling. Move selec-

tor lever through ªNº to ªDº, to ª2º, to ª1º and to ªRº positions.

A slight shock should be felt by hand gripping selector each

time transmission is shifted.

IPerform road test. Refer to ªROAD TESTº, AT-32.NAT287

SAT638A

REMOVAL AND INSTALLATION

Installation (Cont'd)

AT-118

Page 125 of 1767

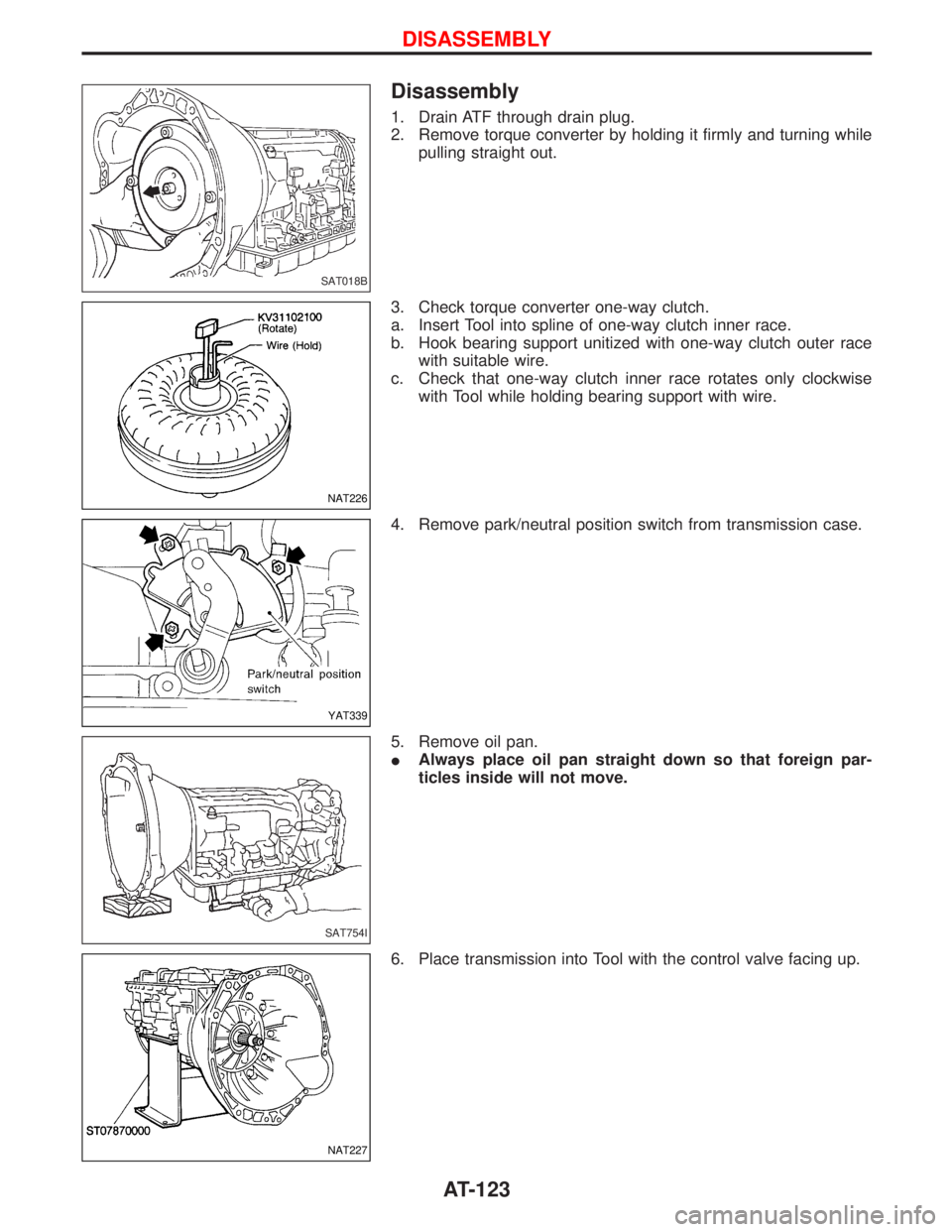

Disassembly

1. Drain ATF through drain plug.

2. Remove torque converter by holding it firmly and turning while

pulling straight out.

3. Check torque converter one-way clutch.

a. Insert Tool into spline of one-way clutch inner race.

b. Hook bearing support unitized with one-way clutch outer race

with suitable wire.

c. Check that one-way clutch inner race rotates only clockwise

with Tool while holding bearing support with wire.

4. Remove park/neutral position switch from transmission case.

5. Remove oil pan.

IAlways place oil pan straight down so that foreign par-

ticles inside will not move.

6. Place transmission into Tool with the control valve facing up.

SAT018B

NAT226

YAT339

SAT754I

NAT227

DISASSEMBLY

AT-123

Page 126 of 1767

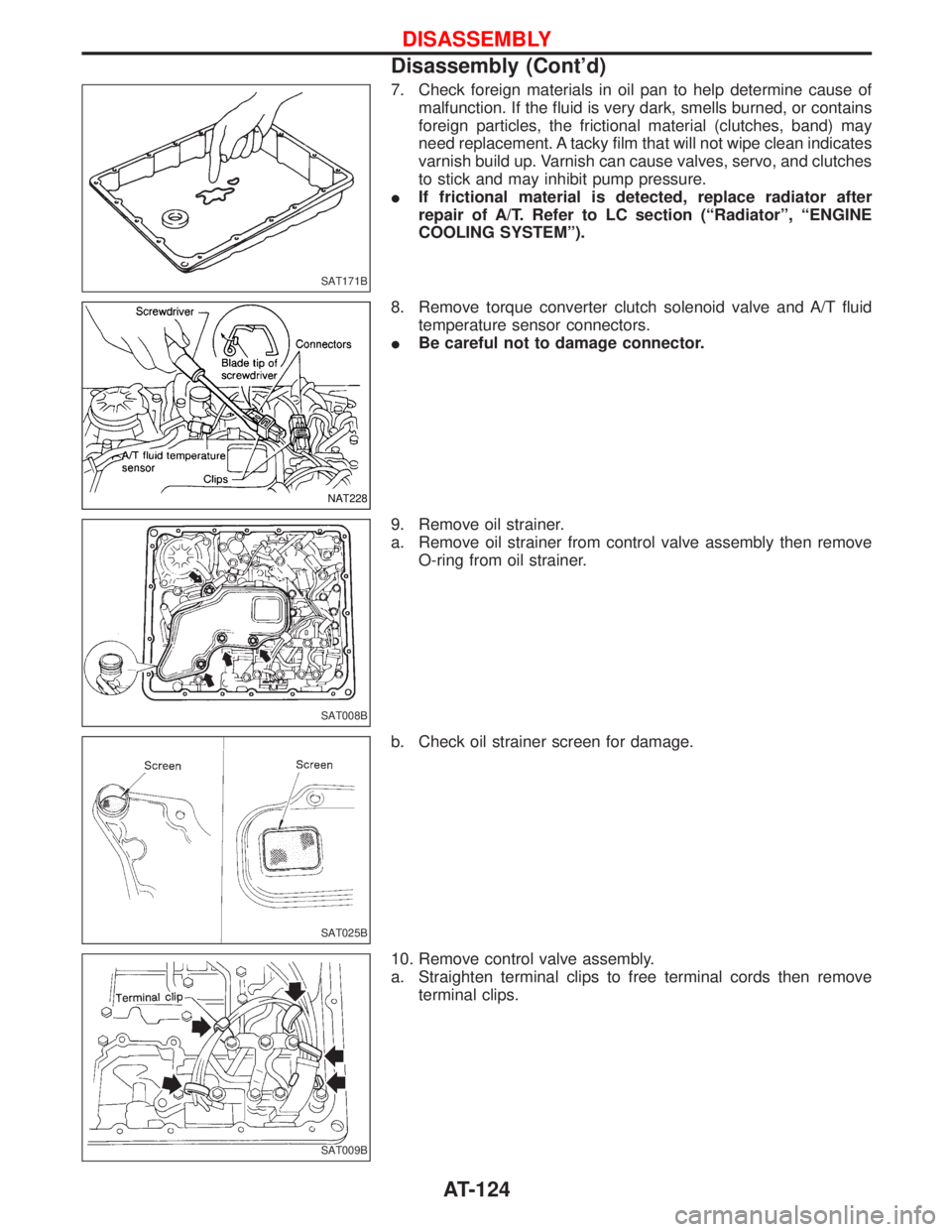

7. Check foreign materials in oil pan to help determine cause of

malfunction. If the fluid is very dark, smells burned, or contains

foreign particles, the frictional material (clutches, band) may

need replacement. A tacky film that will not wipe clean indicates

varnish build up. Varnish can cause valves, servo, and clutches

to stick and may inhibit pump pressure.

IIf frictional material is detected, replace radiator after

repair of A/T. Refer to LC section (ªRadiatorº, ªENGINE

COOLING SYSTEMº).

8. Remove torque converter clutch solenoid valve and A/T fluid

temperature sensor connectors.

IBe careful not to damage connector.

9. Remove oil strainer.

a. Remove oil strainer from control valve assembly then remove

O-ring from oil strainer.

b. Check oil strainer screen for damage.

10. Remove control valve assembly.

a. Straighten terminal clips to free terminal cords then remove

terminal clips.

SAT171B

NAT228

SAT008B

SAT025B

SAT009B

DISASSEMBLY

Disassembly (Cont'd)

AT-124