engine NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 671 of 1767

Fuel Injection Timing System

SYSTEM DESCRIPTION

The fuel injection timing system determines the optimal fuel injection timing, based on engine speed, injection

quantity, engine coolant temperature and atmospheric pressure. The timing is formed by a basic value (Basic

Control) and two correction values. By performing a duty cycle signal on the timing control valve, the ECM

allows the valve to provide optimal injection timing. The ECM also performs feedback control on the timing

control valve using the signal from the needle lift sensor which detects the actual fuel injection timing.

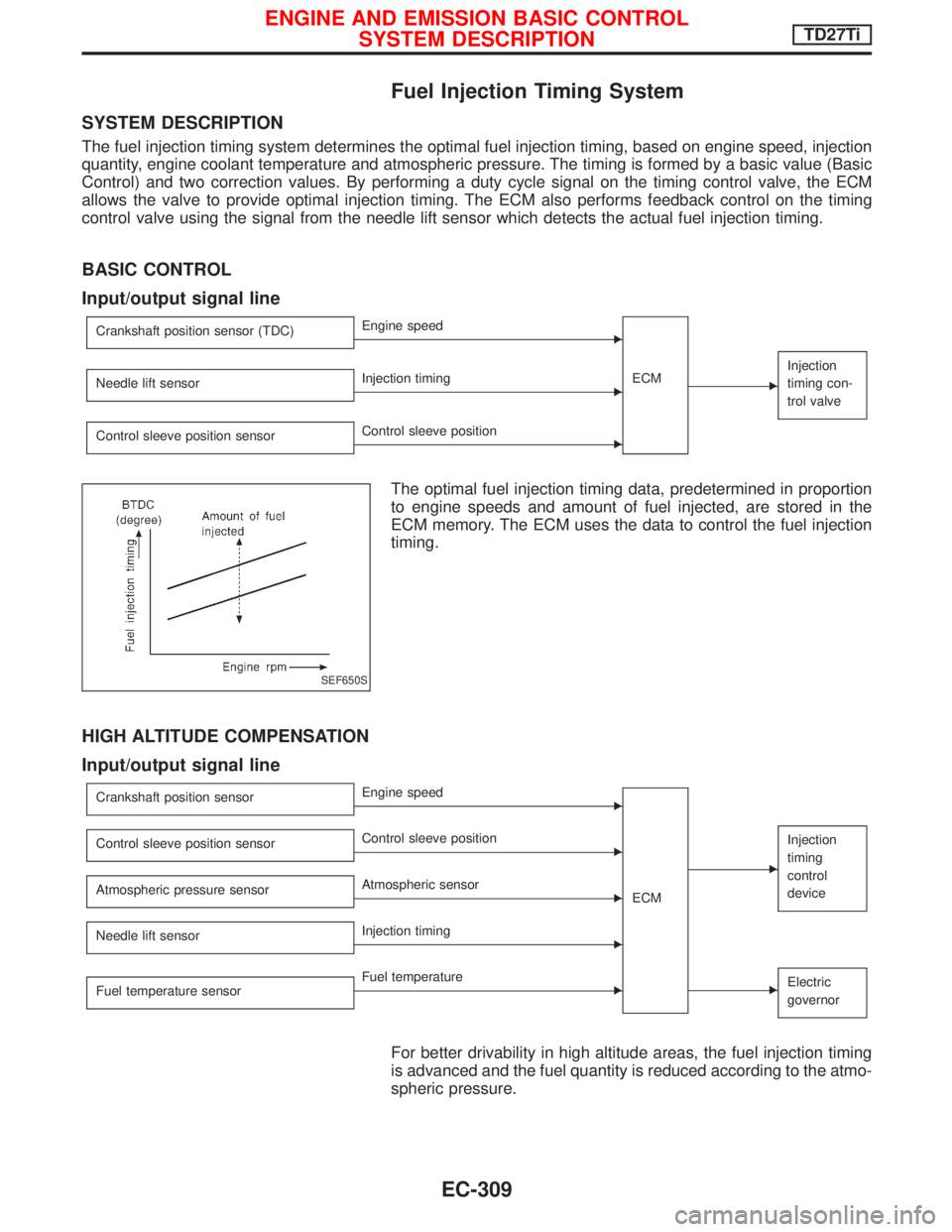

BASIC CONTROL

Input/output signal line

Crankshaft position sensor (TDC)EEngine speed

ECM

E

Injection

timing con-

trol valve

Needle lift sensorEInjection timing

Control sleeve position sensor

EControl sleeve position

The optimal fuel injection timing data, predetermined in proportion

to engine speeds and amount of fuel injected, are stored in the

ECM memory. The ECM uses the data to control the fuel injection

timing.

HIGH ALTITUDE COMPENSATION

Input/output signal line

Crankshaft position sensorEEngine speed

ECM

E

Injection

timing

control

deviceControl sleeve position sensorEControl sleeve position

Atmospheric pressure sensor

EAtmospheric sensor

Needle lift sensor

EInjection timing

Fuel temperature sensor

EFuel temperatureEElectric

governor

For better drivability in high altitude areas, the fuel injection timing

is advanced and the fuel quantity is reduced according to the atmo-

spheric pressure.

SEF650S

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTIONTD27Ti

EC-309

Page 672 of 1767

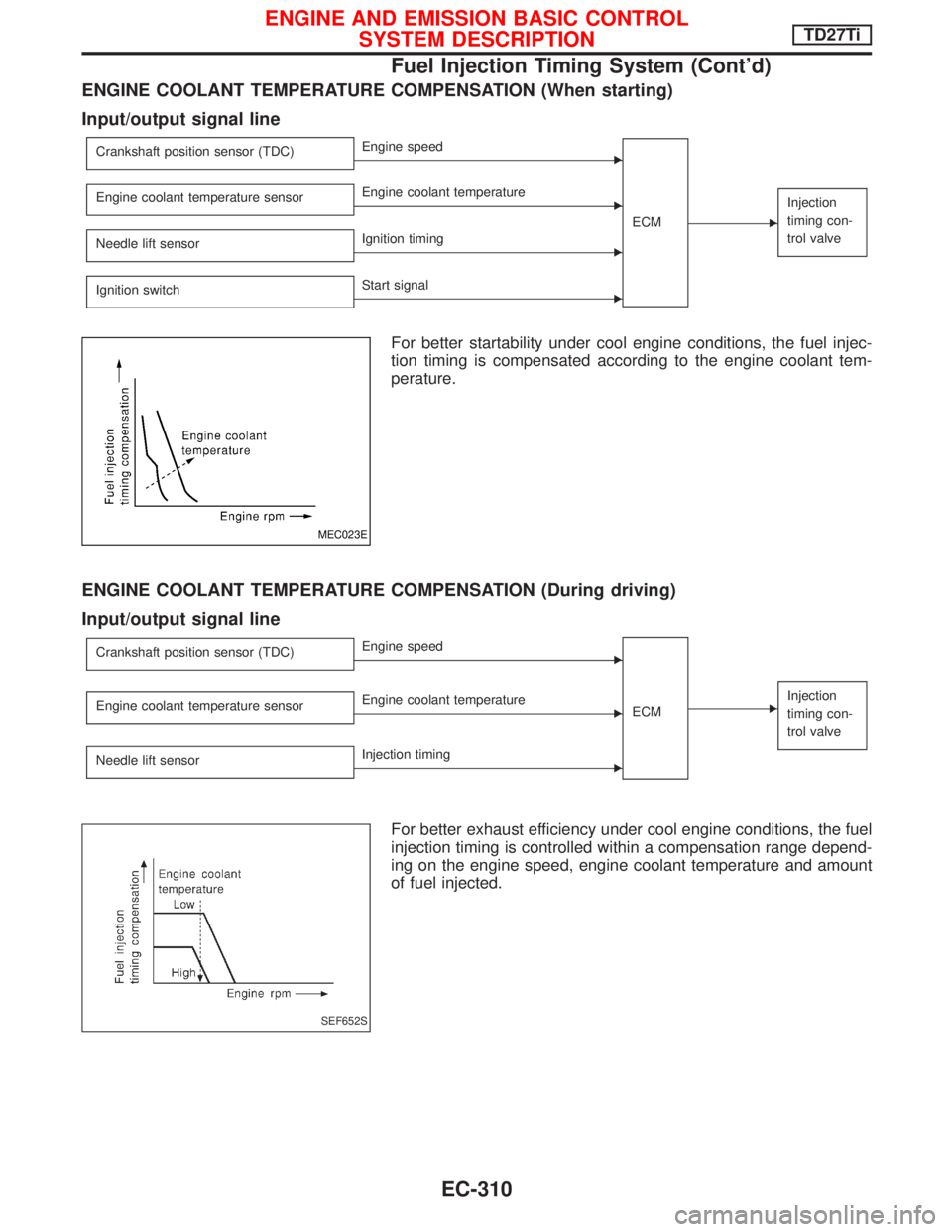

ENGINE COOLANT TEMPERATURE COMPENSATION (When starting)

Input/output signal line

Crankshaft position sensor (TDC)EEngine speed

ECM

E

Injection

timing con-

trol valveEngine coolant temperature sensorEEngine coolant temperature

Needle lift sensor

EIgnition timing

Ignition switch

EStart signal

For better startability under cool engine conditions, the fuel injec-

tion timing is compensated according to the engine coolant tem-

perature.

ENGINE COOLANT TEMPERATURE COMPENSATION (During driving)

Input/output signal line

Crankshaft position sensor (TDC)EEngine speed

ECM

EInjection

timing con-

trol valveEngine coolant temperature sensorEEngine coolant temperature

Needle lift sensor

EInjection timing

For better exhaust efficiency under cool engine conditions, the fuel

injection timing is controlled within a compensation range depend-

ing on the engine speed, engine coolant temperature and amount

of fuel injected.

MEC023E

SEF652S

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTIONTD27Ti

Fuel Injection Timing System (Cont'd)

EC-310

Page 673 of 1767

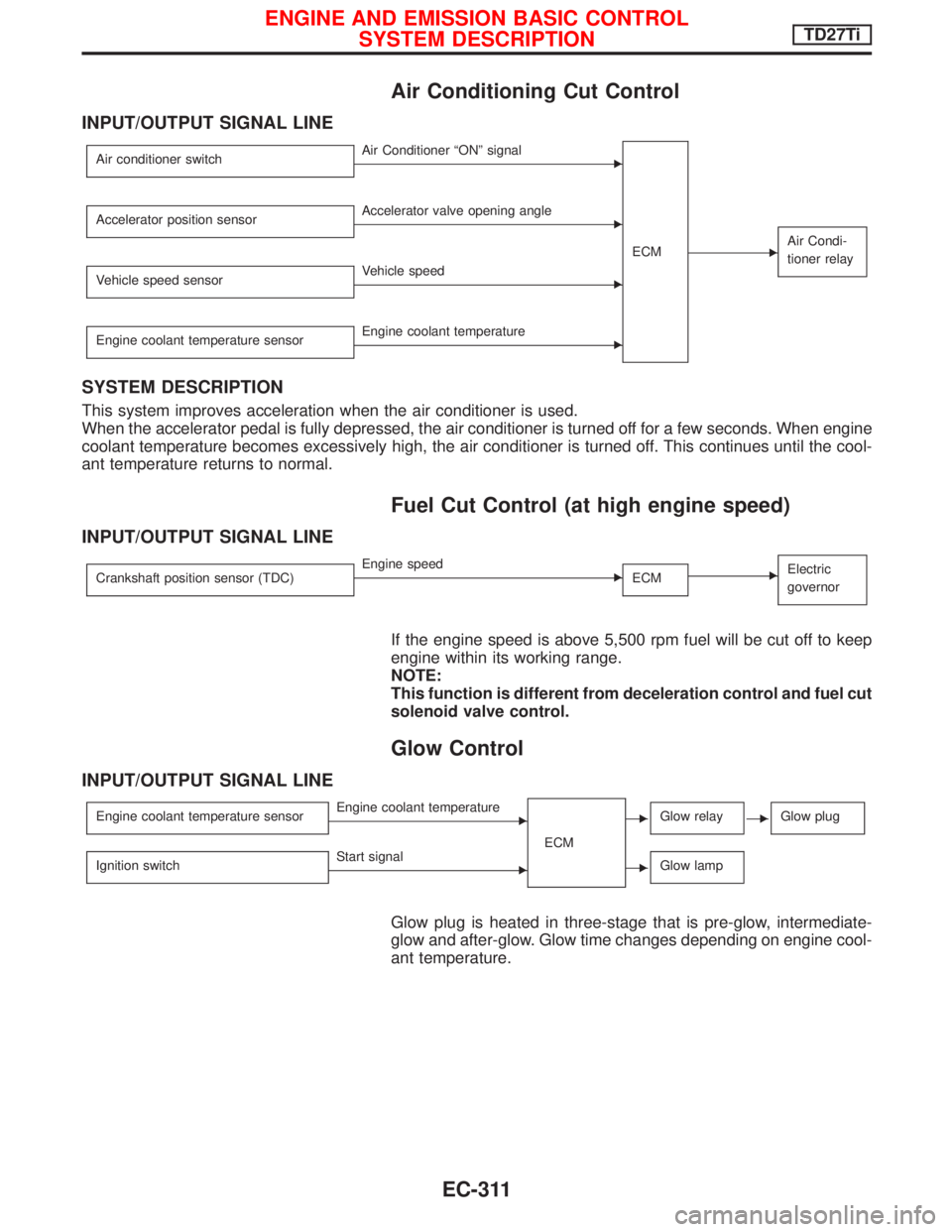

Air Conditioning Cut Control

INPUT/OUTPUT SIGNAL LINE

Air conditioner switchEAir Conditioner ªONº signal

ECM

EAir Condi-

tioner relay

Accelerator position sensorEAccelerator valve opening angle

Vehicle speed sensor

EVehicle speed

Engine coolant temperature sensor

EEngine coolant temperature

SYSTEM DESCRIPTION

This system improves acceleration when the air conditioner is used.

When the accelerator pedal is fully depressed, the air conditioner is turned off for a few seconds. When engine

coolant temperature becomes excessively high, the air conditioner is turned off. This continues until the cool-

ant temperature returns to normal.

Fuel Cut Control (at high engine speed)

INPUT/OUTPUT SIGNAL LINE

Crankshaft position sensor (TDC)EEngine speed

ECMEElectric

governor

If the engine speed is above 5,500 rpm fuel will be cut off to keep

engine within its working range.

NOTE:

This function is different from deceleration control and fuel cut

solenoid valve control.

Glow Control

INPUT/OUTPUT SIGNAL LINE

Engine coolant temperature sensorEEngine coolant temperature

ECMEGlow relayEGlow plug

Ignition switchEStart signalEGlow lamp

Glow plug is heated in three-stage that is pre-glow, intermediate-

glow and after-glow. Glow time changes depending on engine cool-

ant temperature.

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTIONTD27Ti

EC-311

Page 675 of 1767

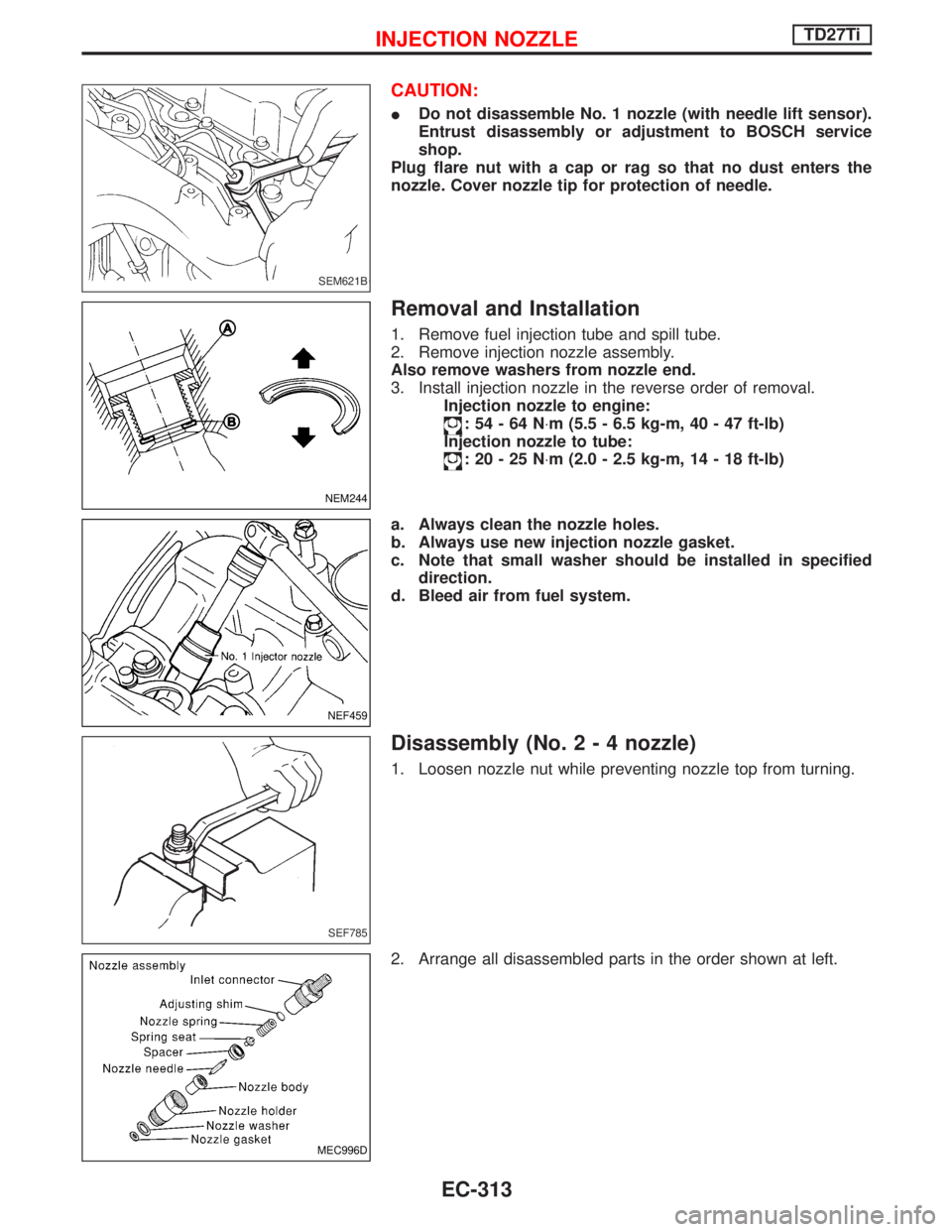

CAUTION:

IDo not disassemble No. 1 nozzle (with needle lift sensor).

Entrust disassembly or adjustment to BOSCH service

shop.

Plug flare nut with a cap or rag so that no dust enters the

nozzle. Cover nozzle tip for protection of needle.

Removal and Installation

1. Remove fuel injection tube and spill tube.

2. Remove injection nozzle assembly.

Also remove washers from nozzle end.

3. Install injection nozzle in the reverse order of removal.

Injection nozzle to engine:

:54-64N×m (5.5 - 6.5 kg-m, 40 - 47 ft-lb)

Injection nozzle to tube:

:20-25N×m (2.0 - 2.5 kg-m, 14 - 18 ft-lb)

a. Always clean the nozzle holes.

b. Always use new injection nozzle gasket.

c. Note that small washer should be installed in specified

direction.

d. Bleed air from fuel system.

Disassembly (No.2-4nozzle)

1. Loosen nozzle nut while preventing nozzle top from turning.

2. Arrange all disassembled parts in the order shown at left.

SEM621B

NEM244

NEF459

SEF785

MEC996D

INJECTION NOZZLETD27Ti

EC-313

Page 683 of 1767

DTC and MI Detection Logic

When a malfunction is detected for the first time, the malfunction (DTC) is stored in the ECM memory.

The MI will light up each time the ECM detects a malfunction. However, if the same malfunction is experienced

in two consecutive driving patterns and the engine is still running, the MI will stay lit up. For a description of

diagnostic items causing the MI to light up, refer to ªTROUBLE DIAGNOSIS Ð INDEXº, EC-293.

Diagnostic Trouble Code (DTC)

HOW TO READ DTC

The DTC can be read by the following methods.

Without CONSULT-II

ECM displays the DTC by a set of four digit numbers with MI illumination in the diagnostic test mode II (Self-

diagnostic results). Example: 0102, 0103, 0104, etc.

With CONSULT-II

CONSULT-II displays the DTC in ªSELF-DIAG RESULTSº mode. Examples: P0100, P0115, P0500, etc.

These DTCs are prescribed by ISO15031-6.

(CONSULT-II also displays the malfunctioning component or system.)

IOutput of the trouble code means that the indicated circuit has a malfunction. However, in the Mode

II it does not indicate whether the malfunction is still occurring or occurred in the past and returned

to normal.

CONSULT-II can identify them. Therefore, using CONSULT-II (if available) is recommended.

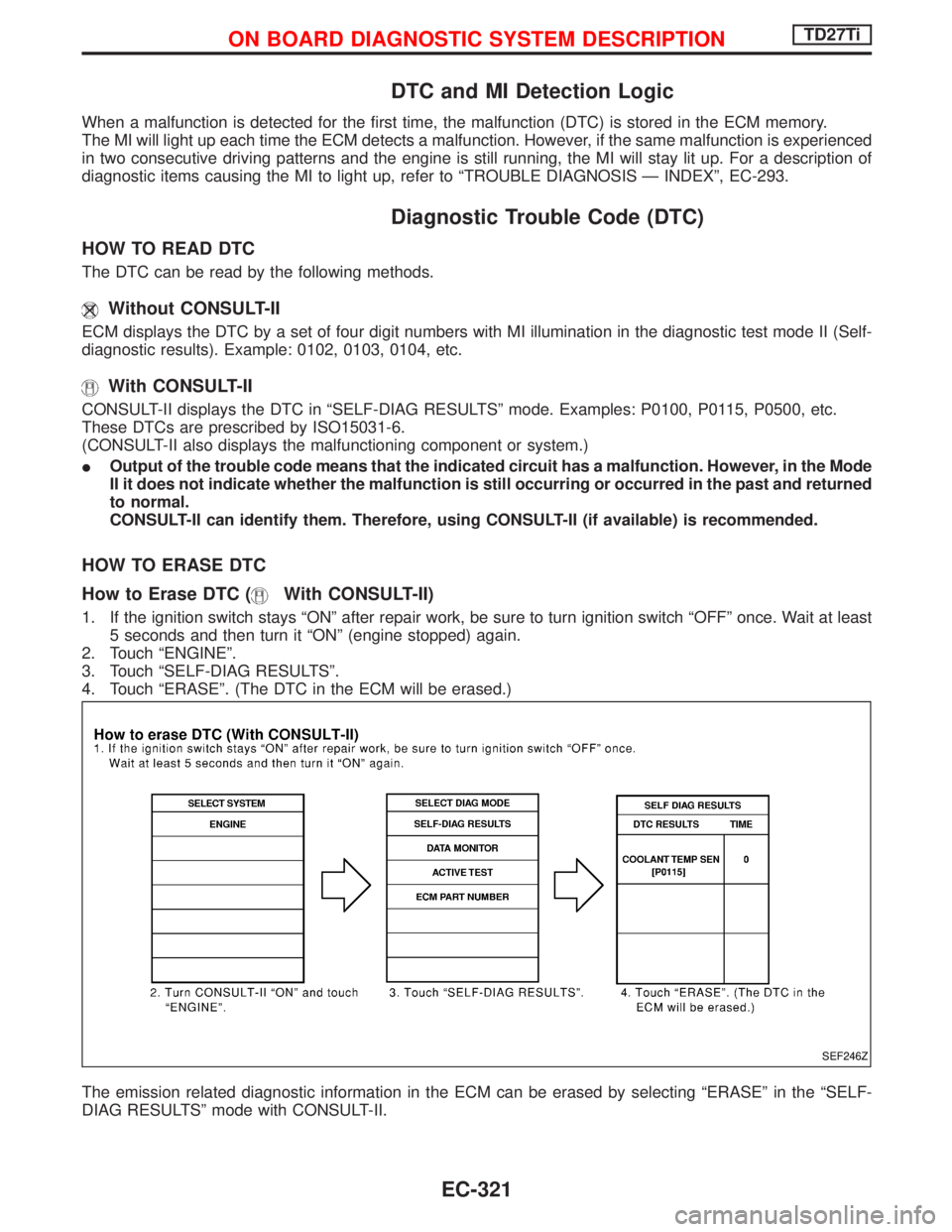

HOW TO ERASE DTC

How to Erase DTC (

With CONSULT-II)

1. If the ignition switch stays ªONº after repair work, be sure to turn ignition switch ªOFFº once. Wait at least

5 seconds and then turn it ªONº (engine stopped) again.

2. Touch ªENGINEº.

3. Touch ªSELF-DIAG RESULTSº.

4. Touch ªERASEº. (The DTC in the ECM will be erased.)

The emission related diagnostic information in the ECM can be erased by selecting ªERASEº in the ªSELF-

DIAG RESULTSº mode with CONSULT-II.

SEF246Z

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONTD27Ti

EC-321

Page 684 of 1767

How to Erase DTC (Without CONSULT-II)

1. If the ignition switch stays ªONº after repair work, be sure to turn ignition switch ªOFFº once. Wait at least

5 seconds and then turn it ªONº (engine stopped) again.

2. Change the diagnostic test mode from Mode II to Mode I by using the data link connector. (See EC-323.)

The emission related diagnostic information in the ECM can be erased by changing the diagnostic test mode.

IIf the battery is disconnected, the emission-related diagnostic information will be lost after approx.

24 hours.

IErasing the emission-related diagnostic information using CONSULT-II is easier and quicker than

switching the diagnostic test mode using the data link connector.

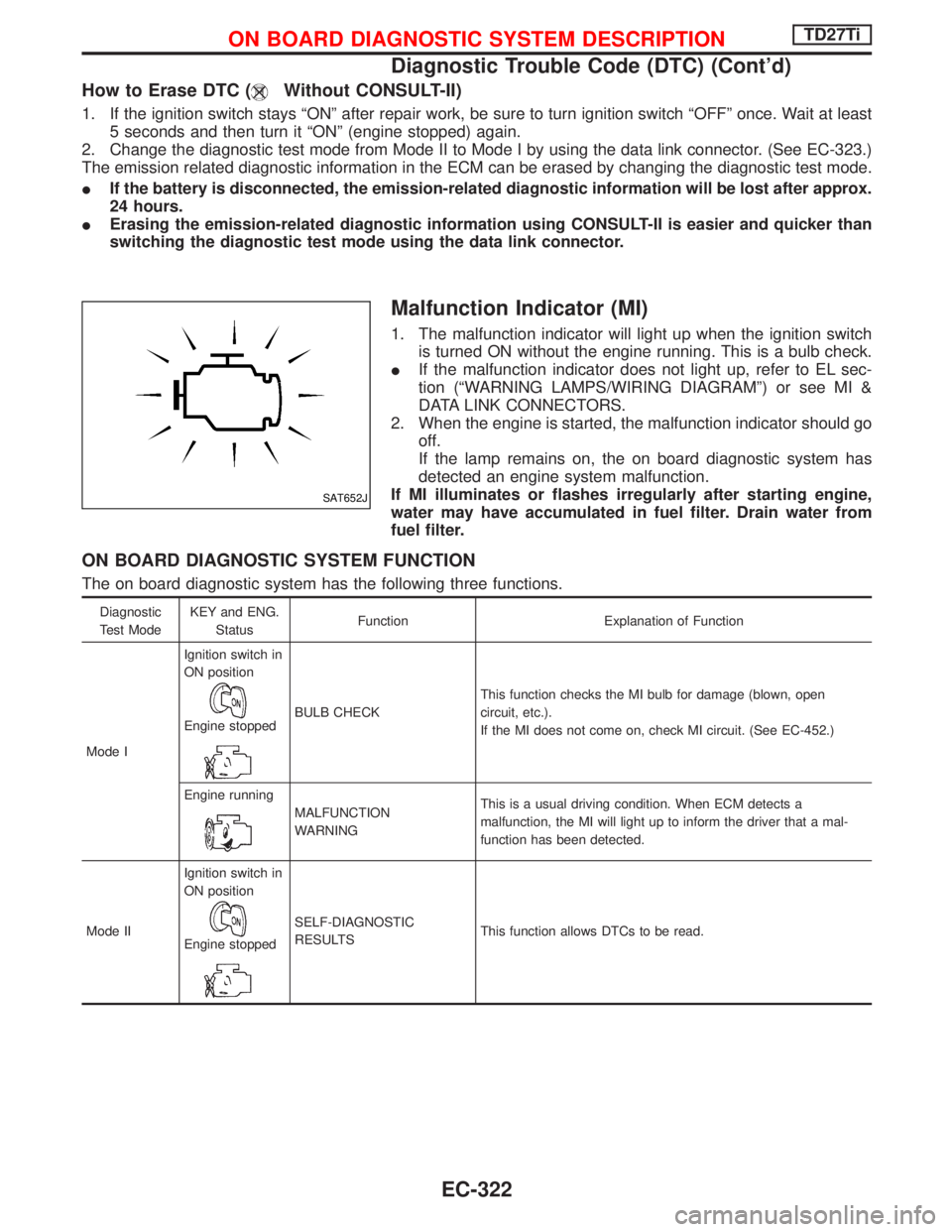

Malfunction Indicator (MI)

1. The malfunction indicator will light up when the ignition switch

is turned ON without the engine running. This is a bulb check.

IIf the malfunction indicator does not light up, refer to EL sec-

tion (ªWARNING LAMPS/WIRING DIAGRAMº) or see MI &

DATA LINK CONNECTORS.

2. When the engine is started, the malfunction indicator should go

off.

If the lamp remains on, the on board diagnostic system has

detected an engine system malfunction.

If MI illuminates or flashes irregularly after starting engine,

water may have accumulated in fuel filter. Drain water from

fuel filter.

ON BOARD DIAGNOSTIC SYSTEM FUNCTION

The on board diagnostic system has the following three functions.

Diagnostic

Test ModeKEY and ENG.

StatusFunction Explanation of Function

Mode IIgnition switch in

ON position

Engine stoppedBULB CHECKThis function checks the MI bulb for damage (blown, open

circuit, etc.).

If the MI does not come on, check MI circuit. (See EC-452.)

Engine running

MALFUNCTION

WARNINGThis is a usual driving condition. When ECM detects a

malfunction, the MI will light up to inform the driver that a mal-

function has been detected.

Mode IIIgnition switch in

ON position

Engine stopped

SELF-DIAGNOSTIC

RESULTSThis function allows DTCs to be read.

SAT652J

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONTD27Ti

Diagnostic Trouble Code (DTC) (Cont'd)

EC-322

Page 689 of 1767

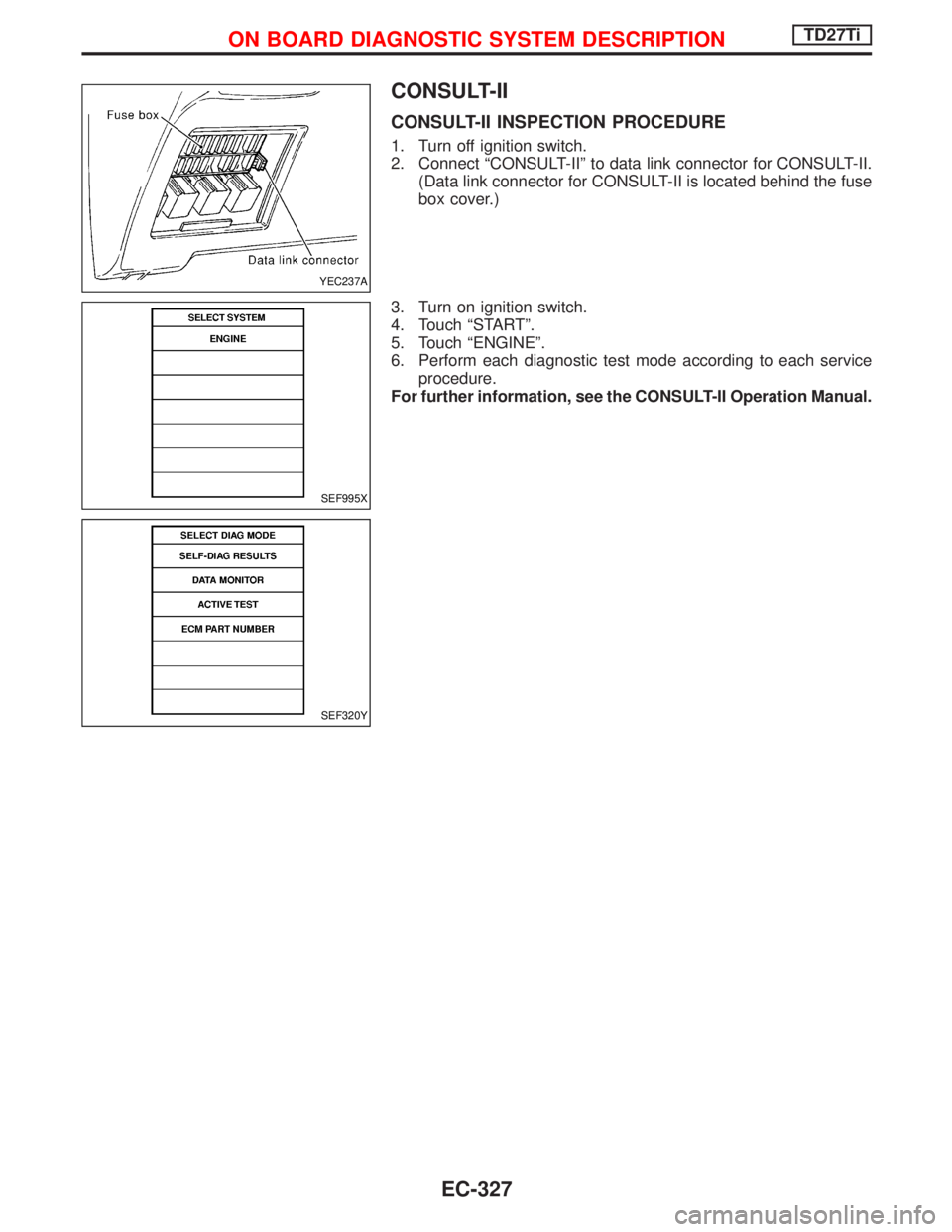

CONSULT-II

CONSULT-II INSPECTION PROCEDURE

1. Turn off ignition switch.

2. Connect ªCONSULT-IIº to data link connector for CONSULT-II.

(Data link connector for CONSULT-II is located behind the fuse

box cover.)

3. Turn on ignition switch.

4. Touch ªSTARTº.

5. Touch ªENGINEº.

6. Perform each diagnostic test mode according to each service

procedure.

For further information, see the CONSULT-II Operation Manual.

YEC237A

SEF995X

SEF320Y

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONTD27Ti

EC-327

Page 690 of 1767

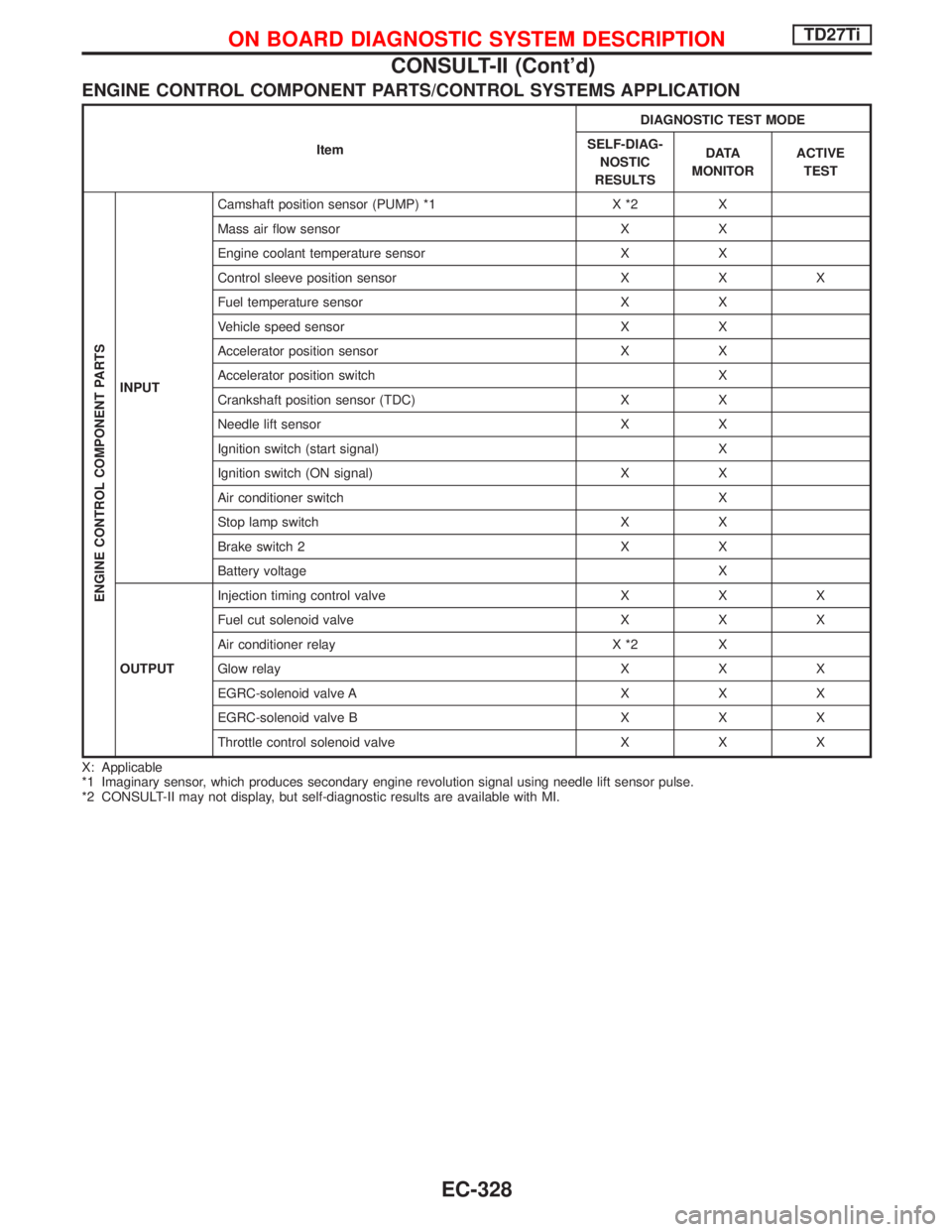

ENGINE CONTROL COMPONENT PARTS/CONTROL SYSTEMS APPLICATION

ItemDIAGNOSTIC TEST MODE

SELF-DIAG-

NOSTIC

RESULTSD ATA

MONITORACTIVE

TEST

ENGINE CONTROL COMPONENT PARTS

INPUTCamshaft position sensor (PUMP) *1 X *2 X

Mass air flow sensor X X

Engine coolant temperature sensor X X

Control sleeve position sensor X X X

Fuel temperature sensor X X

Vehicle speed sensor X X

Accelerator position sensor X X

Accelerator position switch X

Crankshaft position sensor (TDC) X X

Needle lift sensor X X

Ignition switch (start signal) X

Ignition switch (ON signal) X X

Air conditioner switch X

Stop lamp switch X X

Brake switch 2 X X

Battery voltage X

OUTPUTInjection timing control valve X X X

Fuel cut solenoid valve X X X

Air conditioner relay X *2 X

Glow relay X X X

EGRC-solenoid valve A X X X

EGRC-solenoid valve B X X X

Throttle control solenoid valve X X X

X: Applicable

*1 Imaginary sensor, which produces secondary engine revolution signal using needle lift sensor pulse.

*2 CONSULT-II may not display, but self-diagnostic results are available with MI.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONTD27Ti

CONSULT-II (Cont'd)

EC-328

Page 691 of 1767

![NISSAN TERRANO 2002 Service Repair Manual SELF-DIAGNOSTIC MODE

Regarding items detected in ªSELF-DIAG RESULTSº mode, refer to ªTROUBLE DIAGNOSIS Ð INDEXº,

EC-293.

DATA MONITOR MODE

Monitored item

[Unit]ECM

input

signalsMain

signalsDescri NISSAN TERRANO 2002 Service Repair Manual SELF-DIAGNOSTIC MODE

Regarding items detected in ªSELF-DIAG RESULTSº mode, refer to ªTROUBLE DIAGNOSIS Ð INDEXº,

EC-293.

DATA MONITOR MODE

Monitored item

[Unit]ECM

input

signalsMain

signalsDescri](/img/5/57393/w960_57393-690.png)

SELF-DIAGNOSTIC MODE

Regarding items detected in ªSELF-DIAG RESULTSº mode, refer to ªTROUBLE DIAGNOSIS Ð INDEXº,

EC-293.

DATA MONITOR MODE

Monitored item

[Unit]ECM

input

signalsMain

signalsDescription Remarks

CKPS×RPM

(TDC) [rpm]

qq

IThe engine speed computed from the

crankshaft position sensor (TDC) signal

is displayed.

CMPS×RPM -

PUMP [rpm]

qqIThe engine speed computed from the

needle lift sensor signal is displayed.

COOLAN TEMP/S

[ÉC] or [ÉF]

qq

IThe engine coolant temperature (deter-

mined by the signal voltage of the engine

coolant temperature sensor) is displayed.IWhen the engine coolant temperature

sensor is open or short-circuited, ECM

enters fail-safe mode. The same data as

the fuel temperature is displayed.

VHCL SPEED SE

[km/h] or [mph]

qqIThe vehicle speed computed from the

vehicle speed sensor signal is displayed.

FUEL TEMP SEN

[ÉC] or [ÉF]

qq

IThe fuel temperature (determined by the

signal voltage of the fuel temperature

sensor) is displayed.

ACCEL POS SEN [V]

qqIThe accelerator position sensor signal

voltage is displayed.

OFF ACCEL POS

[ON/OFF]

qqIIndicates [ON/OFF] condition from the

accelerator position switch signal.ISignal at approximately 9É opened.

C/SLEEV POS/S [V]

qqIThe control sleeve position sensor signal

voltage is displayed.

BATTERY VOLT [V]

qqIThe power supply voltage of ECM is dis-

played.

START SIGNAL

[ON/OFF]

qqIIndicates [ON/OFF] condition from the

starter signal.IAfter starting the engine, [OFF] is dis-

played regardless of the starter signal.

AIR COND SIG

[ON/OFF]

qq

IIndicates [ON/OFF] condition of the air

conditioner switch as determined by the

air conditioner signal.

BRAKE SW

[ON/OFF]

qIIndicates [ON/OFF] condition of the stop

lamp switch.

BRAKE SW2

[ON/OFF]

qIIndicates [ON/OFF] condition of the

brake switch 2.

IGN SW

[ON/OFF]

qqIIndicates [ON/OFF] condition from igni-

tion switch.

MAS AIR/FL SE [V]

qqIThe signal voltage of the mass air flow

sensor is displayed.IWhen the engine is stopped, a certain

value is indicated.

ACT INJ TIMG [É]

q

IThe actual injection timing angle deter-

mined by the ECM (an approximate aver-

age angle between injection start and

end from TDC) is displayed.

TARGET F/INJ

[mm

3/stroke]qIThe target fuel injection quantity (deter-

mined by the ECM according to the input

signal) is indicated.

NOTE:

Any monitored item that does not match the vehicle being diagnosed is deleted from the display automatically.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONTD27Ti

CONSULT-II (Cont'd)

EC-329

Page 693 of 1767

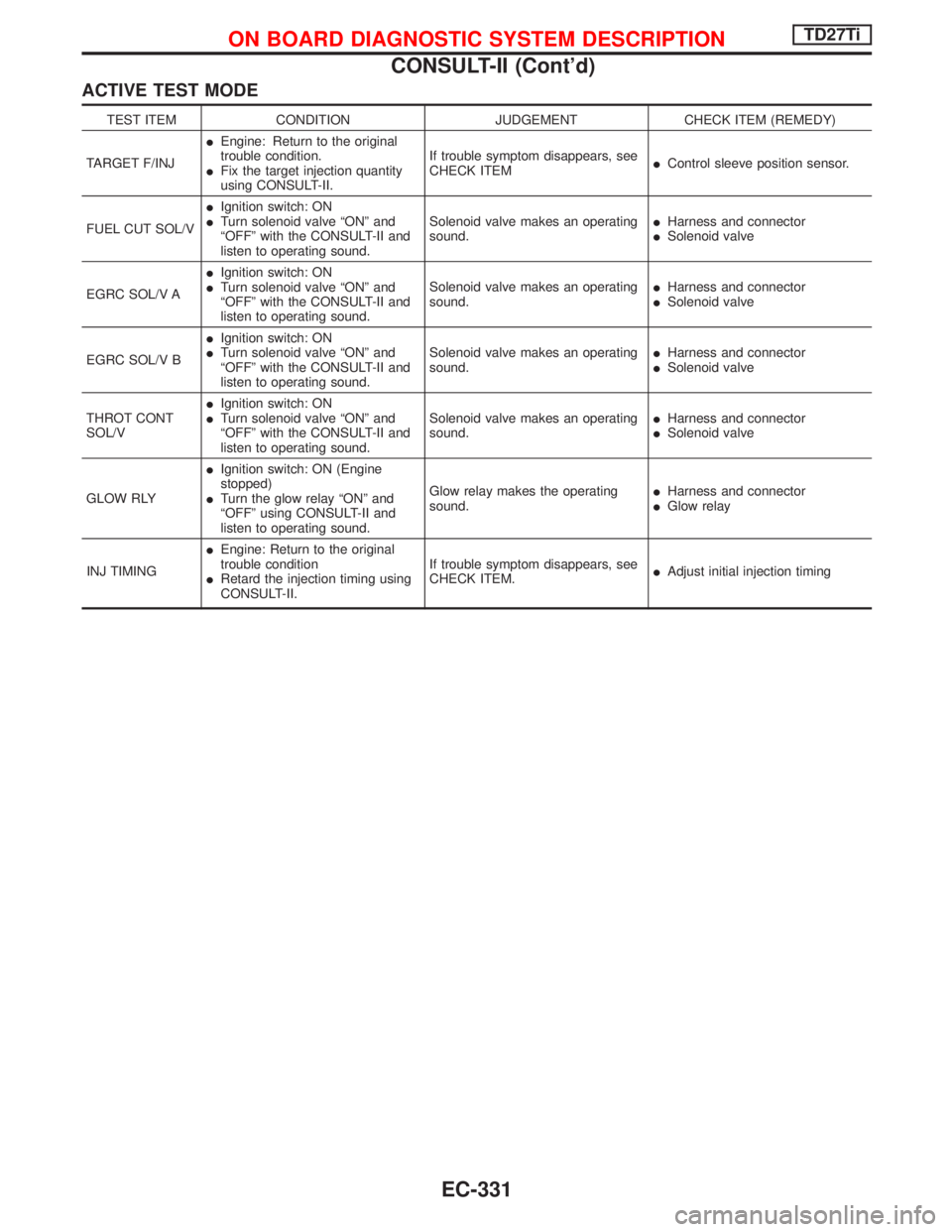

ACTIVE TEST MODE

TEST ITEM CONDITION JUDGEMENT CHECK ITEM (REMEDY)

TARGET F/INJIEngine: Return to the original

trouble condition.

IFix the target injection quantity

using CONSULT-II.If trouble symptom disappears, see

CHECK ITEMIControl sleeve position sensor.

FUEL CUT SOL/VIIgnition switch: ON

ITurn solenoid valve ªONº and

ªOFFº with the CONSULT-II and

listen to operating sound.Solenoid valve makes an operating

sound.IHarness and connector

ISolenoid valve

EGRC SOL/V AIIgnition switch: ON

ITurn solenoid valve ªONº and

ªOFFº with the CONSULT-II and

listen to operating sound.Solenoid valve makes an operating

sound.IHarness and connector

ISolenoid valve

EGRC SOL/V BIIgnition switch: ON

ITurn solenoid valve ªONº and

ªOFFº with the CONSULT-II and

listen to operating sound.Solenoid valve makes an operating

sound.IHarness and connector

ISolenoid valve

THROT CONT

SOL/VIIgnition switch: ON

ITurn solenoid valve ªONº and

ªOFFº with the CONSULT-II and

listen to operating sound.Solenoid valve makes an operating

sound.IHarness and connector

ISolenoid valve

GLOW RLYIIgnition switch: ON (Engine

stopped)

ITurn the glow relay ªONº and

ªOFFº using CONSULT-II and

listen to operating sound.Glow relay makes the operating

sound.IHarness and connector

IGlow relay

INJ TIMINGIEngine: Return to the original

trouble condition

IRetard the injection timing using

CONSULT-II.If trouble symptom disappears, see

CHECK ITEM.IAdjust initial injection timing

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONTD27Ti

CONSULT-II (Cont'd)

EC-331