engine NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 707 of 1767

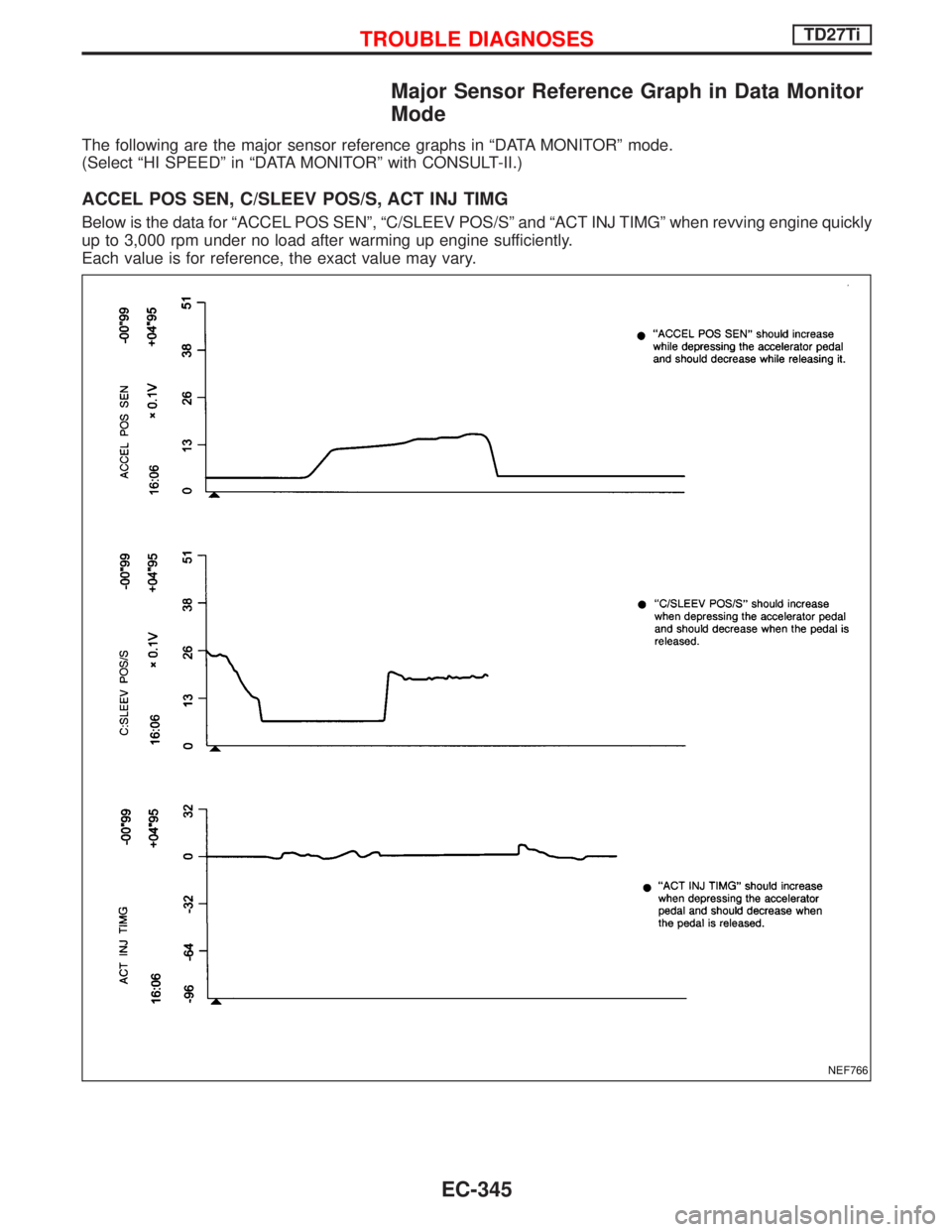

Major Sensor Reference Graph in Data Monitor

Mode

The following are the major sensor reference graphs in ªDATA MONITORº mode.

(Select ªHI SPEEDº in ªDATA MONITORº with CONSULT-II.)

ACCEL POS SEN, C/SLEEV POS/S, ACT INJ TIMG

Below is the data for ªACCEL POS SENº, ªC/SLEEV POS/Sº and ªACT INJ TIMGº when revving engine quickly

up to 3,000 rpm under no load after warming up engine sufficiently.

Each value is for reference, the exact value may vary.

NEF766

TROUBLE DIAGNOSESTD27Ti

EC-345

Page 709 of 1767

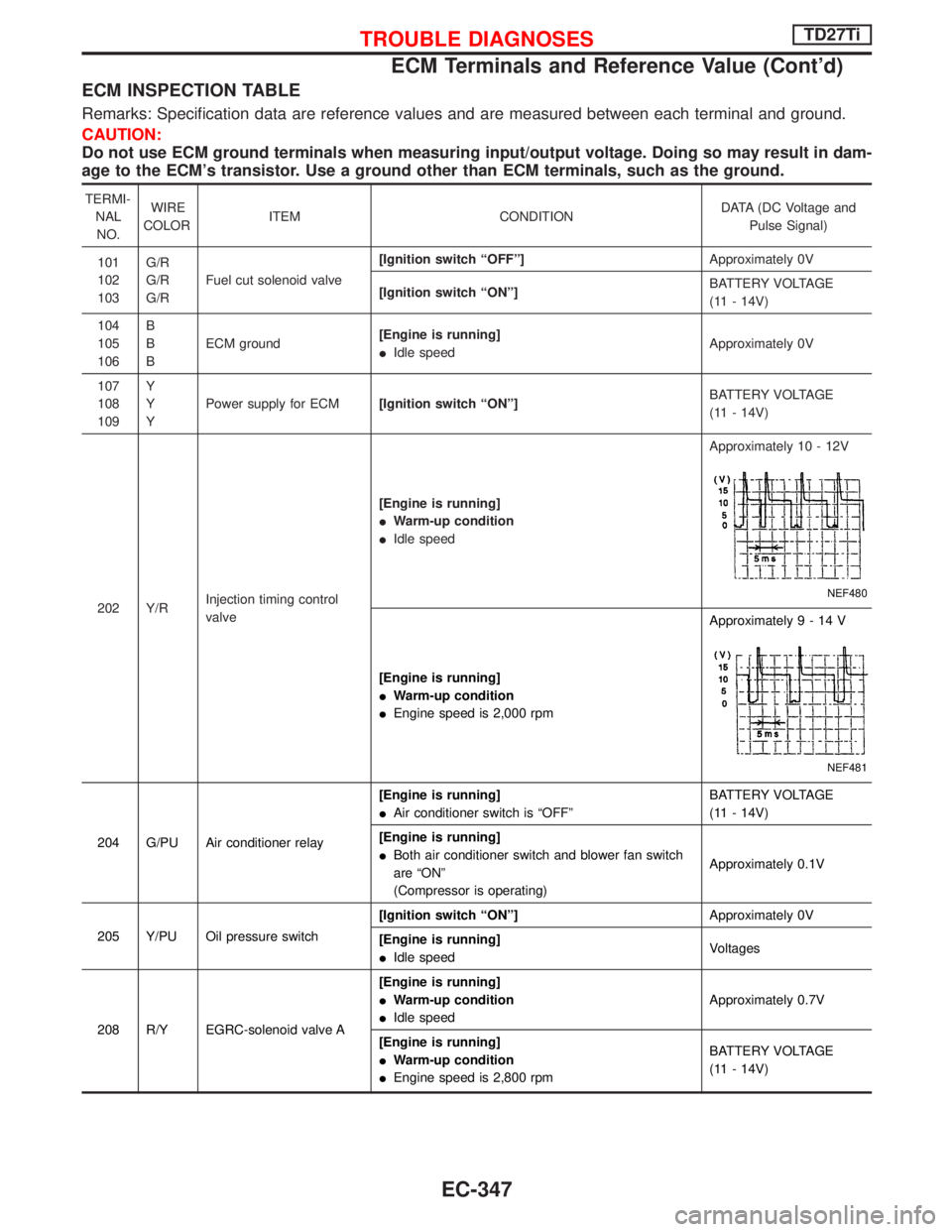

ECM INSPECTION TABLE

Remarks: Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA (DC Voltage and

Pulse Signal)

101

102

103G/R

G/R

G/RFuel cut solenoid valve[Ignition switch ªOFFº]Approximately 0V

[Ignition switch ªONº]BATTERY VOLTAGE

(11 - 14V)

104

105

106B

B

BECM ground[Engine is running]

IIdle speedApproximately 0V

107

108

109Y

Y

YPower supply for ECM[Ignition switch ªONº]BATTERY VOLTAGE

(11 - 14V)

202 Y/RInjection timing control

valve[Engine is running]

IWarm-up condition

IIdle speedApproximately 10 - 12V

NEF480

[Engine is running]

IWarm-up condition

IEngine speed is 2,000 rpmApproximately9-14V

NEF481

204 G/PU Air conditioner relay[Engine is running]

IAir conditioner switch is ªOFFºBATTERY VOLTAGE

(11 - 14V)

[Engine is running]

IBoth air conditioner switch and blower fan switch

are ªONº

(Compressor is operating)Approximately 0.1V

205 Y/PU Oil pressure switch[Ignition switch ªONº]Approximately 0V

[Engine is running]

IIdle speedVoltages

208 R/Y EGRC-solenoid valve A[Engine is running]

IWarm-up condition

IIdle speedApproximately 0.7V

[Engine is running]

IWarm-up condition

IEngine speed is 2,800 rpmBATTERY VOLTAGE

(11 - 14V)

TROUBLE DIAGNOSESTD27Ti

ECM Terminals and Reference Value (Cont'd)

EC-347

Page 710 of 1767

![NISSAN TERRANO 2002 Service Repair Manual TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA (DC Voltage and

Pulse Signal)

210 Y/B EGRC-solenoid valve B[Engine is running]

IWarm-up condition

IIdle speedApproximately 0.4V

[Engine is running]

IWarm-up NISSAN TERRANO 2002 Service Repair Manual TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA (DC Voltage and

Pulse Signal)

210 Y/B EGRC-solenoid valve B[Engine is running]

IWarm-up condition

IIdle speedApproximately 0.4V

[Engine is running]

IWarm-up](/img/5/57393/w960_57393-709.png)

TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA (DC Voltage and

Pulse Signal)

210 Y/B EGRC-solenoid valve B[Engine is running]

IWarm-up condition

IIdle speedApproximately 0.4V

[Engine is running]

IWarm-up condition

IEngine speed is 2,500 rpmBATTERY VOLTAGE

(11 - 14V)

213 G/YThrottle control solenoid

valve[Engine is running]

IWarm-up condition

ILow loadApproximately 0V

Except above condition Battery voltage (12 - 14V)

214 LG Glow relay Refer to ªGlow Control Systemº, EC-389.

215 L Malfunction indicator (MI)[Ignition switch ªONº]Approximately 1.0V

[Engine is running]

IIdle speedBATTERY VOLTAGE

(11 - 14V)

218 G/R Sensors' ground[Engine is running]

IWarm-up condition

IIdle speedApproximately 0V

219 LG/R Cooling fan relay[Engine is running]

ICooling fan is not operatingBATTERY VOLTAGE

(11 - 14V)

[Engine is running]

ICooling fan is operatingApproximately 0.1V

221 G/W Glow lamp[Ignition switch ªONº]

IGlow lamp is ªONºApproximately 1V

[Ignition switch ªONº]

IGlow lamp is ªOFFºBATTERY VOLTAGE

(11 - 14V)

223 R/LMass air flow sensor

power supply[Ignition switch ªONº]Approximately 5V

224 L/W Mass air flow sensor[Engine is running]

IWarm-up condition

IIdle speed1.5 - 2.0V

320 WControl sleeve position

sensor[Engine is running]

IIdle speedApproximately 2.6V

NEF477

321 RControl sleeve position

sensor power supply[Engine is running]

IIdle speedApproximately 2.6V

NEF476

TROUBLE DIAGNOSESTD27Ti

ECM Terminals and Reference Value (Cont'd)

EC-348

Page 711 of 1767

![NISSAN TERRANO 2002 Service Repair Manual TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA (DC Voltage and

Pulse Signal)

322 BControl sleeve position

sensor ground[Engine is running]

IIdle speedApproximately 2.6V

NEF476

325 L ECM relay (Self-shutof NISSAN TERRANO 2002 Service Repair Manual TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA (DC Voltage and

Pulse Signal)

322 BControl sleeve position

sensor ground[Engine is running]

IIdle speedApproximately 2.6V

NEF476

325 L ECM relay (Self-shutof](/img/5/57393/w960_57393-710.png)

TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA (DC Voltage and

Pulse Signal)

322 BControl sleeve position

sensor ground[Engine is running]

IIdle speedApproximately 2.6V

NEF476

325 L ECM relay (Self-shutoff)[Ignition switch ªONº]

[Ignition switch ªOFFº]

IFor a few seconds after turning ignition switch

ªOFFºApproximately 1.4V

[Ignition switch ªOFFº]

IA few seconds passed after turning ignition switch

ªOFFºBATTERY VOLTAGE

(11 - 14V)

331 L/RCrankshaft position sensor

(TDC) ground[Engine is running]

IWarm-up condition

IIdle speedApproximately 0V

333 R Needle lift sensor ground[Ignition switch ªONº]Approximately 0V

334 G/REngine coolant tempera-

ture sensor ground[Ignition switch ªONº]Approximately 0V

335 G/RFuel temperature sensor

ground[Engine is running]Approximately 0V

344 L/GCrankshaft position sensor

(TDC)[Engine is running]

IWarm-up condition

IIdle speedApproximately 0V

SEF333Y

[Engine is running]

IWarm-up condition

IEngine speed is 2,000 rpmApproximately 0V

SEF334Y

345 G Needle lift sensor[Engine is running]

IWarm-up condition

IIdle speedApproximately 3.5V

[Engine is running]

IWarm-up condition

IEngine speed is 2,000 rpmApproximately 3.5V

TROUBLE DIAGNOSESTD27Ti

ECM Terminals and Reference Value (Cont'd)

EC-349

Page 712 of 1767

![NISSAN TERRANO 2002 Service Repair Manual TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA (DC Voltage and

Pulse Signal)

347 LG/WEngine coolant tempera-

ture sensor[Engine is running]Approximately 0 - 4.8V

Output voltage varies with

engine coolant NISSAN TERRANO 2002 Service Repair Manual TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA (DC Voltage and

Pulse Signal)

347 LG/WEngine coolant tempera-

ture sensor[Engine is running]Approximately 0 - 4.8V

Output voltage varies with

engine coolant](/img/5/57393/w960_57393-711.png)

TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA (DC Voltage and

Pulse Signal)

347 LG/WEngine coolant tempera-

ture sensor[Engine is running]Approximately 0 - 4.8V

Output voltage varies with

engine coolant tempera-

ture

348 Y/B Fuel temperature sensor[Engine is running]0.6-5V

Output voltage varies with

fuel temperature.

349 G/RInjection timing control

valve ground[Ignition switch ªONº]Approximately 0V

403 G/R Air conditioner switch[Engine is running]

IAir conditioner switch is ªOFFºBATTERY VOLTAGE

(11 - 14V)

[Engine is running]

IBoth air conditioner switch and blower fan switch

are ªONº

(Compressor is operating)Approximately 0.1V

405 G/Y Stop lamp switch[Ignition switch ªONº]

IBrake pedal fully releasedApproximately 0V

[Ignition switch ªONº]

IBrake pedal depressedBATTERY VOLTAGE

(11 - 14V)

416 Y/RBrake pedal position

switch[Ignition switch ªONº]

IBrake pedal fully releasedBATTERY VOLTAGE

(11 - 14V)

[Ignition switch ªONº]

IBrake pedal depressedApproximately 0V

415 OR

Data link connector for

CONSULT-II[Engine is running]

IIdle speed (CONSULT-II is connected and turned

on)Approximately 0V

420 OR/RBATTERY VOLTAGE

(11 - 14V)

417 Y/B Vehicle speed sensor[Engine is running]

ILift up the vehicle

IIn 1st gear position

IVehicle speed is 10 km/h (6 MPH)0 - Approximately 8V

SEF891Y

[Engine is running]

ILift up the vehicle

IIn 2nd gear position

IVehicle speed is 30 km/h (19 MPH)Approximately 6V

SEF892Y

422 PU Start signal[Ignition switch ªONº]Approximately 0V

[Ignition switch ªSTARTº]BATTERY VOLTAGE

(11 - 14V)

425 R/BAccelerator position sen-

sor ground[Engine is running]

IWarm-up condition

IIdle speedApproximately 0V

TROUBLE DIAGNOSESTD27Ti

ECM Terminals and Reference Value (Cont'd)

EC-350

Page 713 of 1767

![NISSAN TERRANO 2002 Service Repair Manual TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA (DC Voltage and

Pulse Signal)

426 BAccelerator position switch

(Idle) ground[Ignition switch ªONº]Approximately 0V

433 R/WAccelerator position sen-

sor pow NISSAN TERRANO 2002 Service Repair Manual TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA (DC Voltage and

Pulse Signal)

426 BAccelerator position switch

(Idle) ground[Ignition switch ªONº]Approximately 0V

433 R/WAccelerator position sen-

sor pow](/img/5/57393/w960_57393-712.png)

TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA (DC Voltage and

Pulse Signal)

426 BAccelerator position switch

(Idle) ground[Ignition switch ªONº]Approximately 0V

433 R/WAccelerator position sen-

sor power supply[Ignition switch ªONº]Approximately 5V

434 GAccelerator position sen-

sor[Ignition switch ªONº]

IAccelerator pedal fully released0.30 - 0.50V

[Ignition switch ªONº]

IAccelerator pedal fully depressed3.0 - 4.3V

435 L/YAccelerator position switch

(Idle)[Ignition switch ªONº]

IAccelerator pedal fully releasedApproximately 0V

[Ignition switch ªONº]

IAccelerator pedal depressedBATTERY VOLTAGE

(11 - 14V)

439 L/B Tachometer[Engine is running]

IWarm-up condition

IIdle speedApproximately 3.0V

SEF325Y

[Engine is running]

IWarm-up condition

IEngine speed is 2,000 rpmApproximately 3.0V

SEF326Y

507 B/W Ignition switch[Ignition switch ªOFFº]0V

[Ignition switch ªONº]BATTERY VOLTAGE

(11 - 14V)

TROUBLE DIAGNOSESTD27Ti

ECM Terminals and Reference Value (Cont'd)

EC-351

Page 715 of 1767

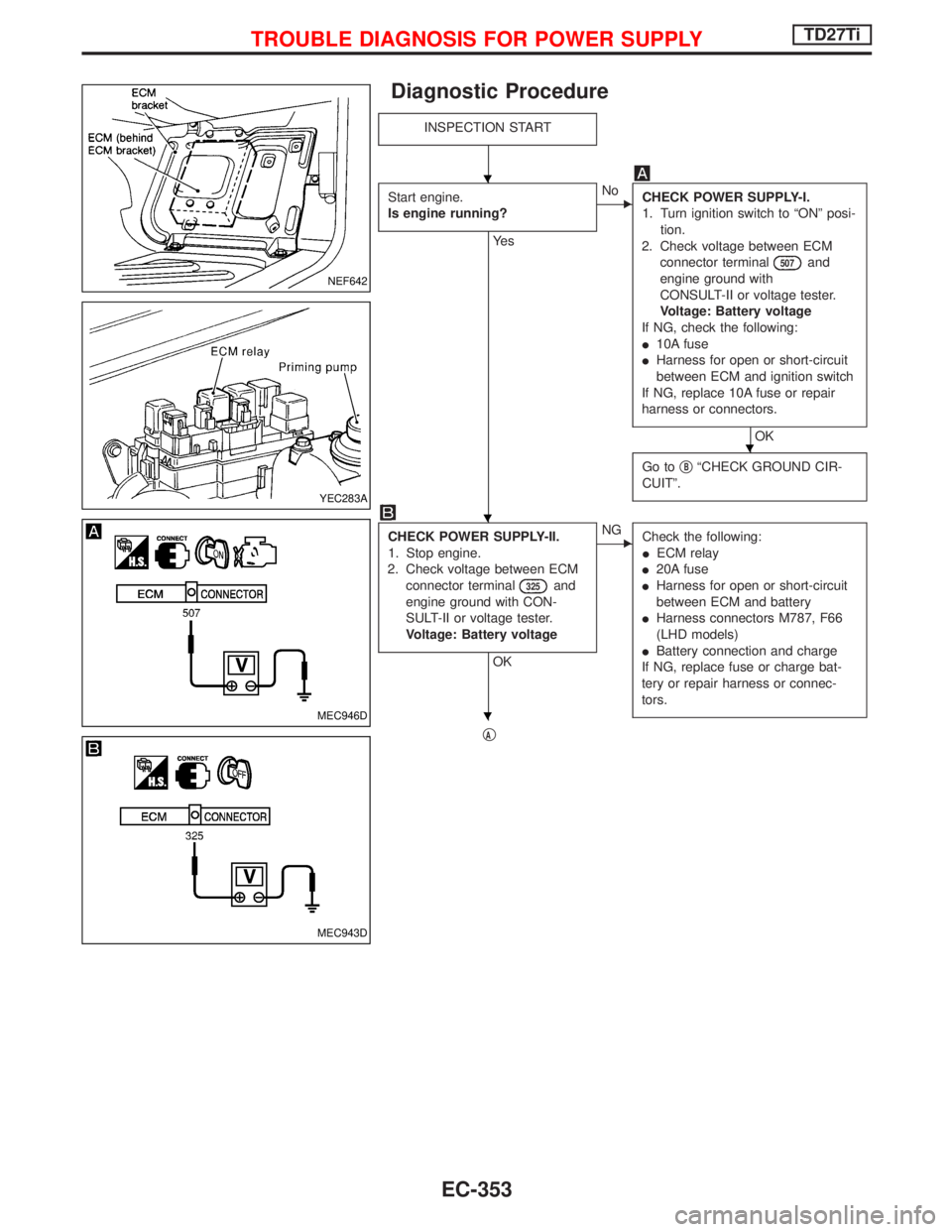

Diagnostic Procedure

INSPECTION START

Start engine.

Is engine running?

Ye s

ENo

CHECK POWER SUPPLY-I.

1. Turn ignition switch to ªONº posi-

tion.

2. Check voltage between ECM

connector terminal

507and

engine ground with

CONSULT-II or voltage tester.

Voltage: Battery voltage

If NG, check the following:

I10A fuse

IHarness for open or short-circuit

between ECM and ignition switch

If NG, replace 10A fuse or repair

harness or connectors.

OK

Go toq

BªCHECK GROUND CIR-

CUITº.

CHECK POWER SUPPLY-II.

1. Stop engine.

2. Check voltage between ECM

connector terminal

325and

engine ground with CON-

SULT-II or voltage tester.

Voltage: Battery voltage

OK

ENG

Check the following:

IECM relay

I20A fuse

IHarness for open or short-circuit

between ECM and battery

IHarness connectors M787, F66

(LHD models)

IBattery connection and charge

If NG, replace fuse or charge bat-

tery or repair harness or connec-

tors.

qA

NEF642

YEC283A

MEC946D

MEC943D

H

H

H

H

TROUBLE DIAGNOSIS FOR POWER SUPPLYTD27Ti

EC-353

Page 716 of 1767

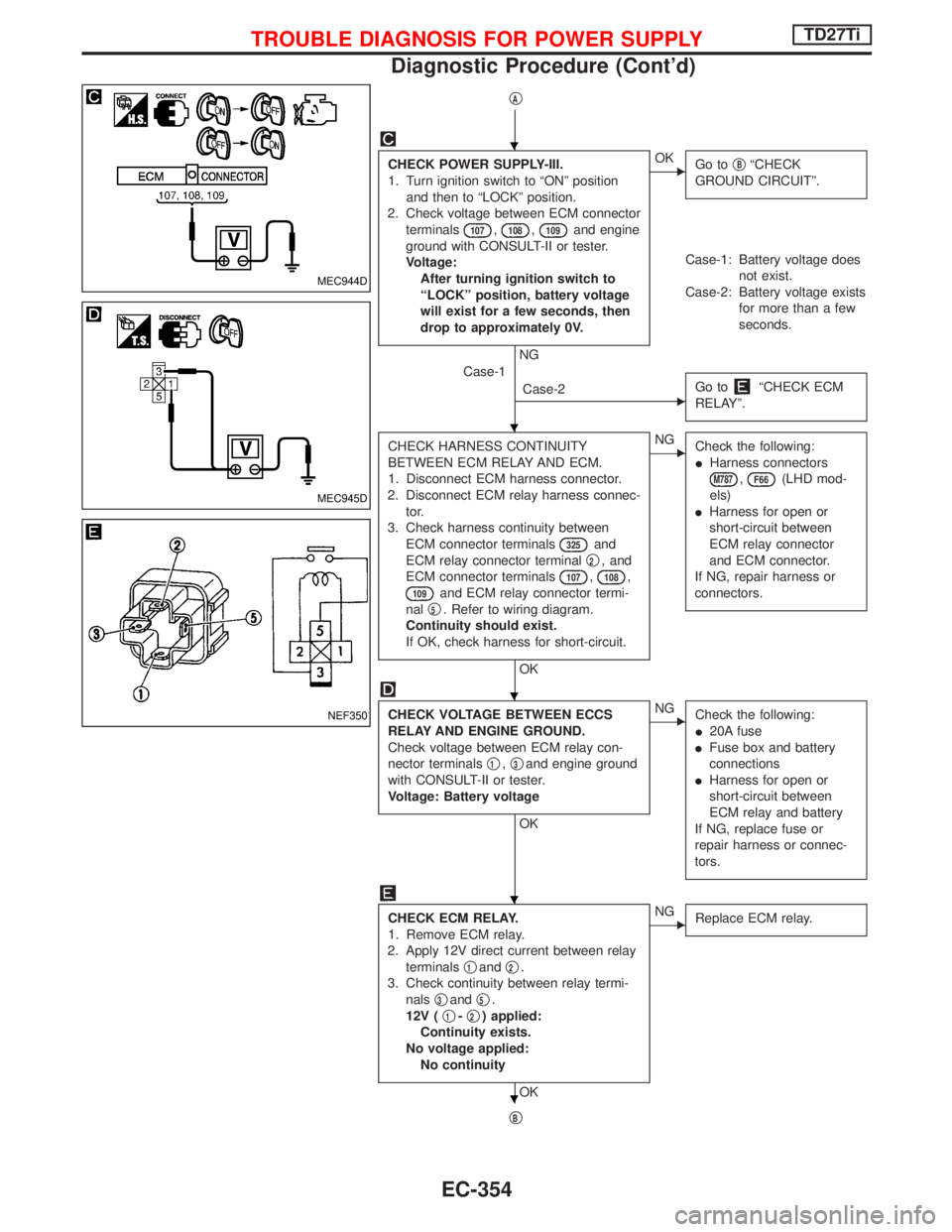

qA

CHECK POWER SUPPLY-III.

1. Turn ignition switch to ªONº position

and then to ªLOCKº position.

2. Check voltage between ECM connector

terminals

107,108,109and engine

ground with CONSULT-II or tester.

Voltage:

After turning ignition switch to

ªLOCKº position, battery voltage

will exist for a few seconds, then

drop to approximately 0V.

NG

EOK

Go toqBªCHECK

GROUND CIRCUITº.

Case-1: Battery voltage does

not exist.

Case-2: Battery voltage exists

for more than a few

seconds.

Case-1

Case-2

EGo toªCHECK ECM

RELAYº.

CHECK HARNESS CONTINUITY

BETWEEN ECM RELAY AND ECM.

1. Disconnect ECM harness connector.

2. Disconnect ECM relay harness connec-

tor.

3. Check harness continuity between

ECM connector terminals

325and

ECM relay connector terminalq

2, and

ECM connector terminals

107,108,

109and ECM relay connector termi-

nalq

5. Refer to wiring diagram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG

Check the following:

IHarness connectors

M787,F66(LHD mod-

els)

IHarness for open or

short-circuit between

ECM relay connector

and ECM connector.

If NG, repair harness or

connectors.

CHECK VOLTAGE BETWEEN ECCS

RELAY AND ENGINE GROUND.

Check voltage between ECM relay con-

nector terminalsq

1,q3and engine ground

with CONSULT-II or tester.

Voltage: Battery voltage

OK

ENG

Check the following:

I20A fuse

IFuse box and battery

connections

IHarness for open or

short-circuit between

ECM relay and battery

If NG, replace fuse or

repair harness or connec-

tors.

CHECK ECM RELAY.

1. Remove ECM relay.

2. Apply 12V direct current between relay

terminalsq

1andq2.

3. Check continuity between relay termi-

nalsq

3andq5.

12V (q

1-q2) applied:

Continuity exists.

No voltage applied:

No continuity

OK

ENG

Replace ECM relay.

qB

MEC944D

MEC945D

NEF350

H

H

H

H

H

TROUBLE DIAGNOSIS FOR POWER SUPPLYTD27Ti

Diagnostic Procedure (Cont'd)

EC-354

Page 717 of 1767

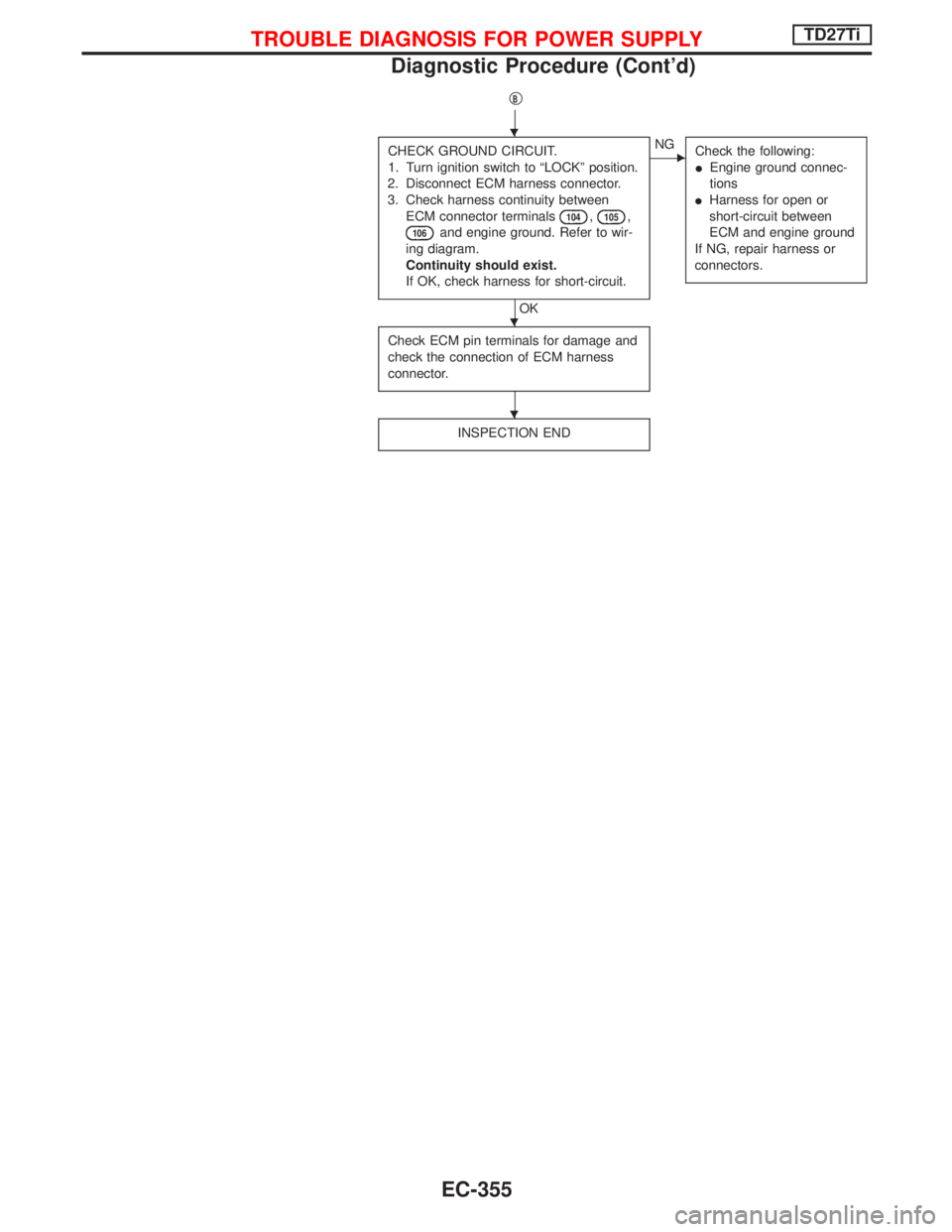

qB

CHECK GROUND CIRCUIT.

1. Turn ignition switch to ªLOCKº position.

2. Disconnect ECM harness connector.

3. Check harness continuity between

ECM connector terminals

104,105,

106and engine ground. Refer to wir-

ing diagram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG

Check the following:

IEngine ground connec-

tions

IHarness for open or

short-circuit between

ECM and engine ground

If NG, repair harness or

connectors.

Check ECM pin terminals for damage and

check the connection of ECM harness

connector.

INSPECTION END

H

H

H

TROUBLE DIAGNOSIS FOR POWER SUPPLYTD27Ti

Diagnostic Procedure (Cont'd)

EC-355

Page 718 of 1767

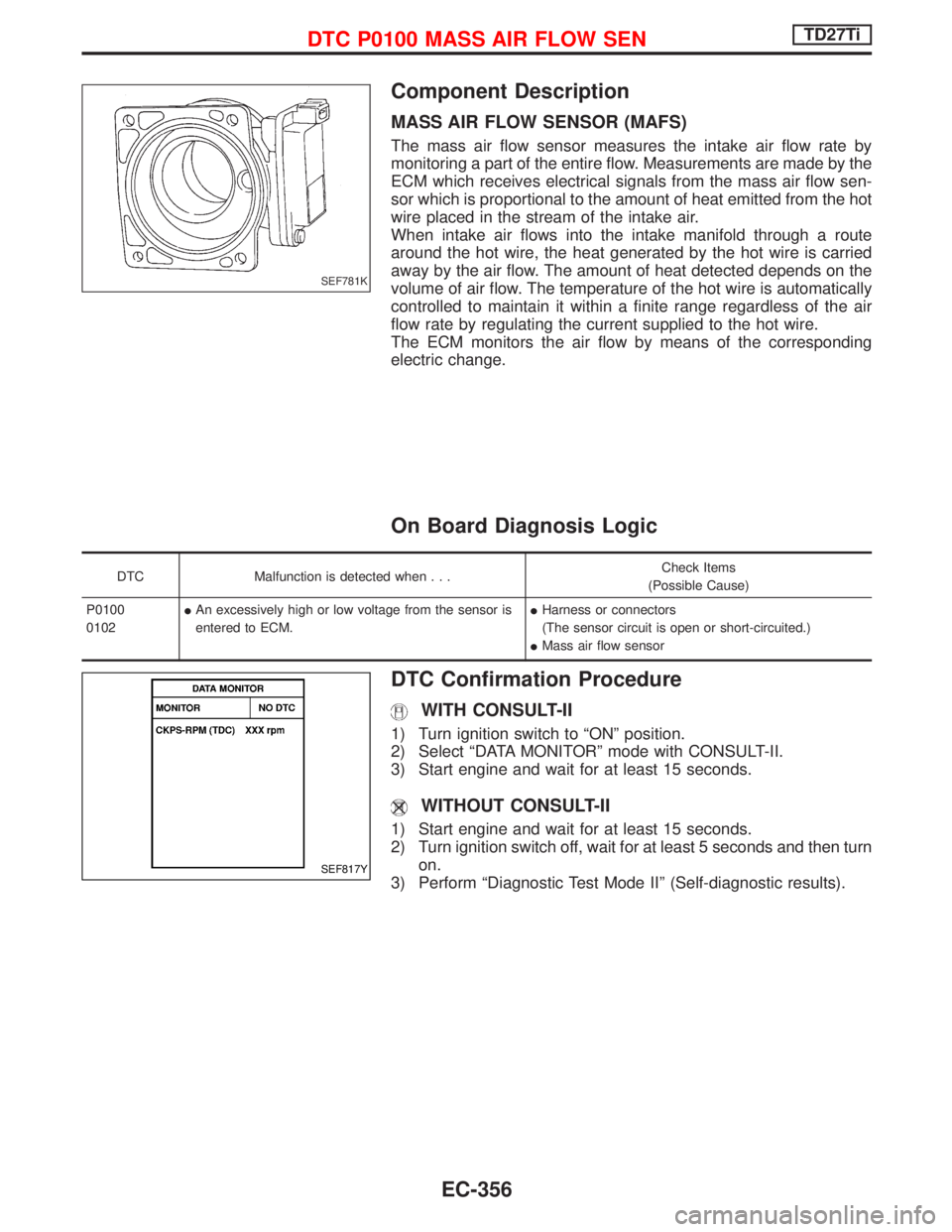

Component Description

MASS AIR FLOW SENSOR (MAFS)

The mass air flow sensor measures the intake air flow rate by

monitoring a part of the entire flow. Measurements are made by the

ECM which receives electrical signals from the mass air flow sen-

sor which is proportional to the amount of heat emitted from the hot

wire placed in the stream of the intake air.

When intake air flows into the intake manifold through a route

around the hot wire, the heat generated by the hot wire is carried

away by the air flow. The amount of heat detected depends on the

volume of air flow. The temperature of the hot wire is automatically

controlled to maintain it within a finite range regardless of the air

flow rate by regulating the current supplied to the hot wire.

The ECM monitors the air flow by means of the corresponding

electric change.

On Board Diagnosis Logic

DTC Malfunction is detected when...Check Items

(Possible Cause)

P0100

0102IAn excessively high or low voltage from the sensor is

entered to ECM.IHarness or connectors

(The sensor circuit is open or short-circuited.)

IMass air flow sensor

DTC Confirmation Procedure

WITH CONSULT-II

1) Turn ignition switch to ªONº position.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and wait for at least 15 seconds.

WITHOUT CONSULT-II

1) Start engine and wait for at least 15 seconds.

2) Turn ignition switch off, wait for at least 5 seconds and then turn

on.

3) Perform ªDiagnostic Test Mode IIº (Self-diagnostic results).

SEF781K

SEF817Y

DTC P0100 MASS AIR FLOW SENTD27Ti

EC-356