engine NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 859 of 1767

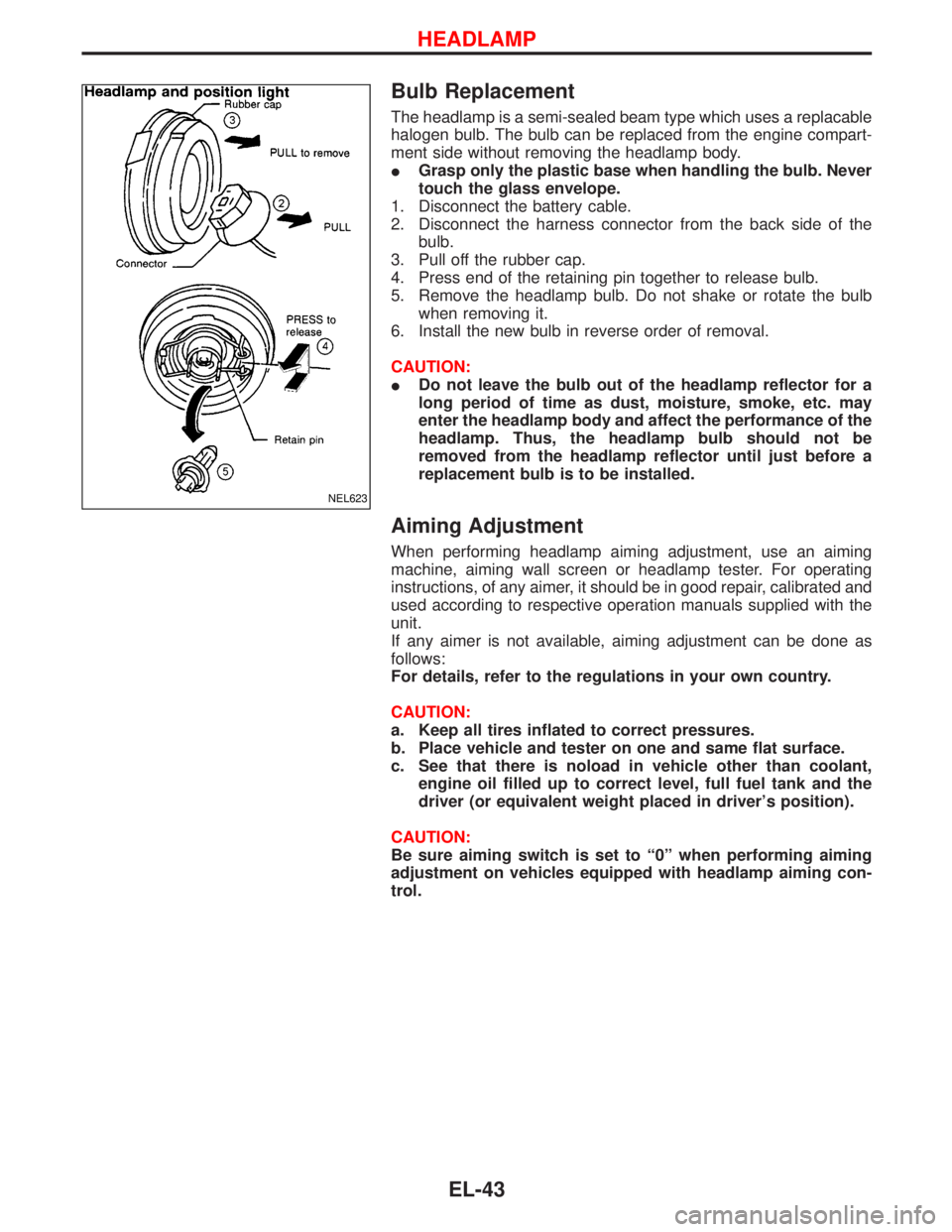

Bulb Replacement

The headlamp is a semi-sealed beam type which uses a replacable

halogen bulb. The bulb can be replaced from the engine compart-

ment side without removing the headlamp body.

IGrasp only the plastic base when handling the bulb. Never

touch the glass envelope.

1. Disconnect the battery cable.

2. Disconnect the harness connector from the back side of the

bulb.

3. Pull off the rubber cap.

4. Press end of the retaining pin together to release bulb.

5. Remove the headlamp bulb. Do not shake or rotate the bulb

when removing it.

6. Install the new bulb in reverse order of removal.

CAUTION:

IDo not leave the bulb out of the headlamp reflector for a

long period of time as dust, moisture, smoke, etc. may

enter the headlamp body and affect the performance of the

headlamp. Thus, the headlamp bulb should not be

removed from the headlamp reflector until just before a

replacement bulb is to be installed.

Aiming Adjustment

When performing headlamp aiming adjustment, use an aiming

machine, aiming wall screen or headlamp tester. For operating

instructions, of any aimer, it should be in good repair, calibrated and

used according to respective operation manuals supplied with the

unit.

If any aimer is not available, aiming adjustment can be done as

follows:

For details, refer to the regulations in your own country.

CAUTION:

a. Keep all tires inflated to correct pressures.

b. Place vehicle and tester on one and same flat surface.

c. See that there is noload in vehicle other than coolant,

engine oil filled up to correct level, full fuel tank and the

driver (or equivalent weight placed in driver's position).

CAUTION:

Be sure aiming switch is set to ª0º when performing aiming

adjustment on vehicles equipped with headlamp aiming con-

trol.

NEL623

HEADLAMP

EL-43

Page 869 of 1767

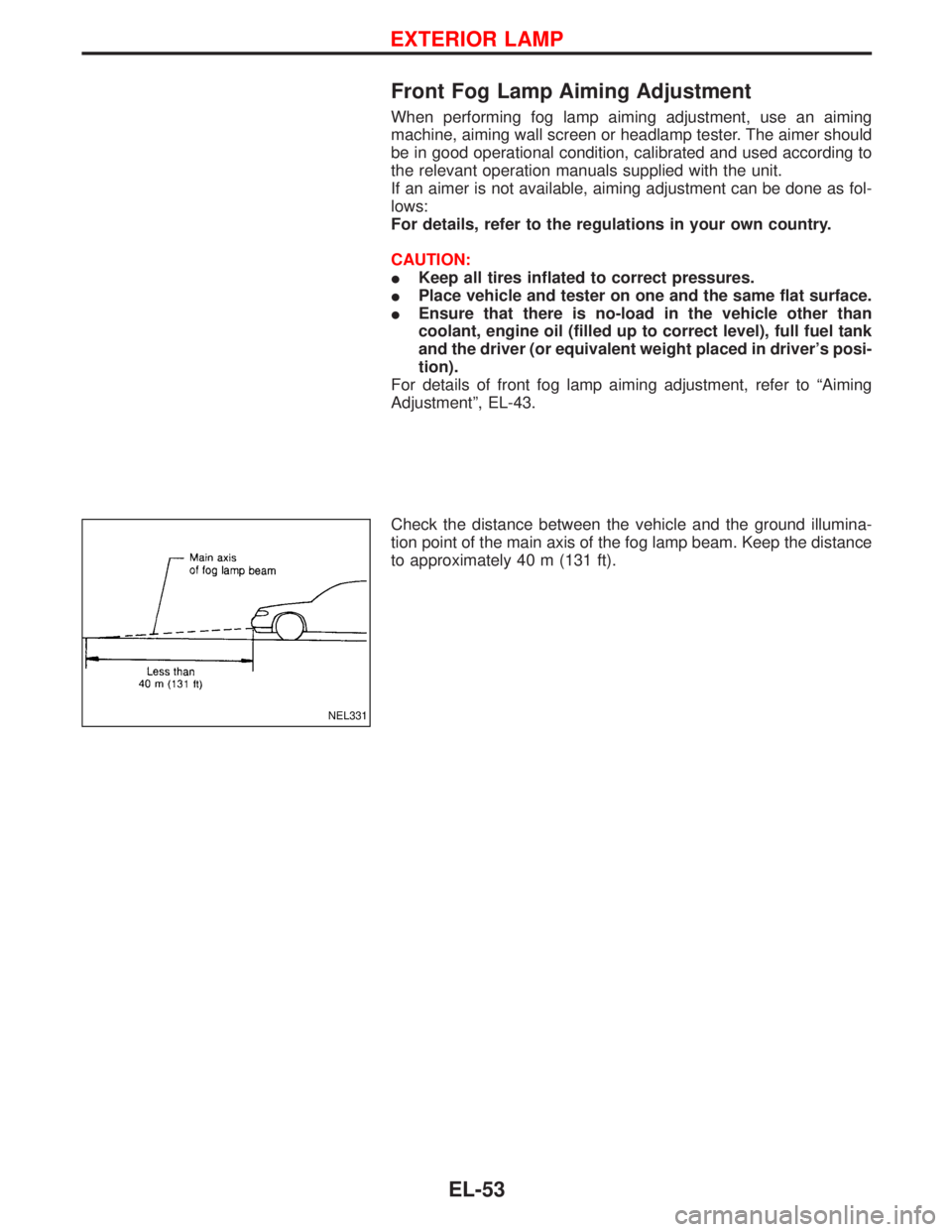

Front Fog Lamp Aiming Adjustment

When performing fog lamp aiming adjustment, use an aiming

machine, aiming wall screen or headlamp tester. The aimer should

be in good operational condition, calibrated and used according to

the relevant operation manuals supplied with the unit.

If an aimer is not available, aiming adjustment can be done as fol-

lows:

For details, refer to the regulations in your own country.

CAUTION:

IKeep all tires inflated to correct pressures.

IPlace vehicle and tester on one and the same flat surface.

IEnsure that there is no-load in the vehicle other than

coolant, engine oil (filled up to correct level), full fuel tank

and the driver (or equivalent weight placed in driver's posi-

tion).

For details of front fog lamp aiming adjustment, refer to ªAiming

Adjustmentº, EL-43.

Check the distance between the vehicle and the ground illumina-

tion point of the main axis of the fog lamp beam. Keep the distance

to approximately 40 m (131 ft).

NEL331

EXTERIOR LAMP

EL-53

Page 888 of 1767

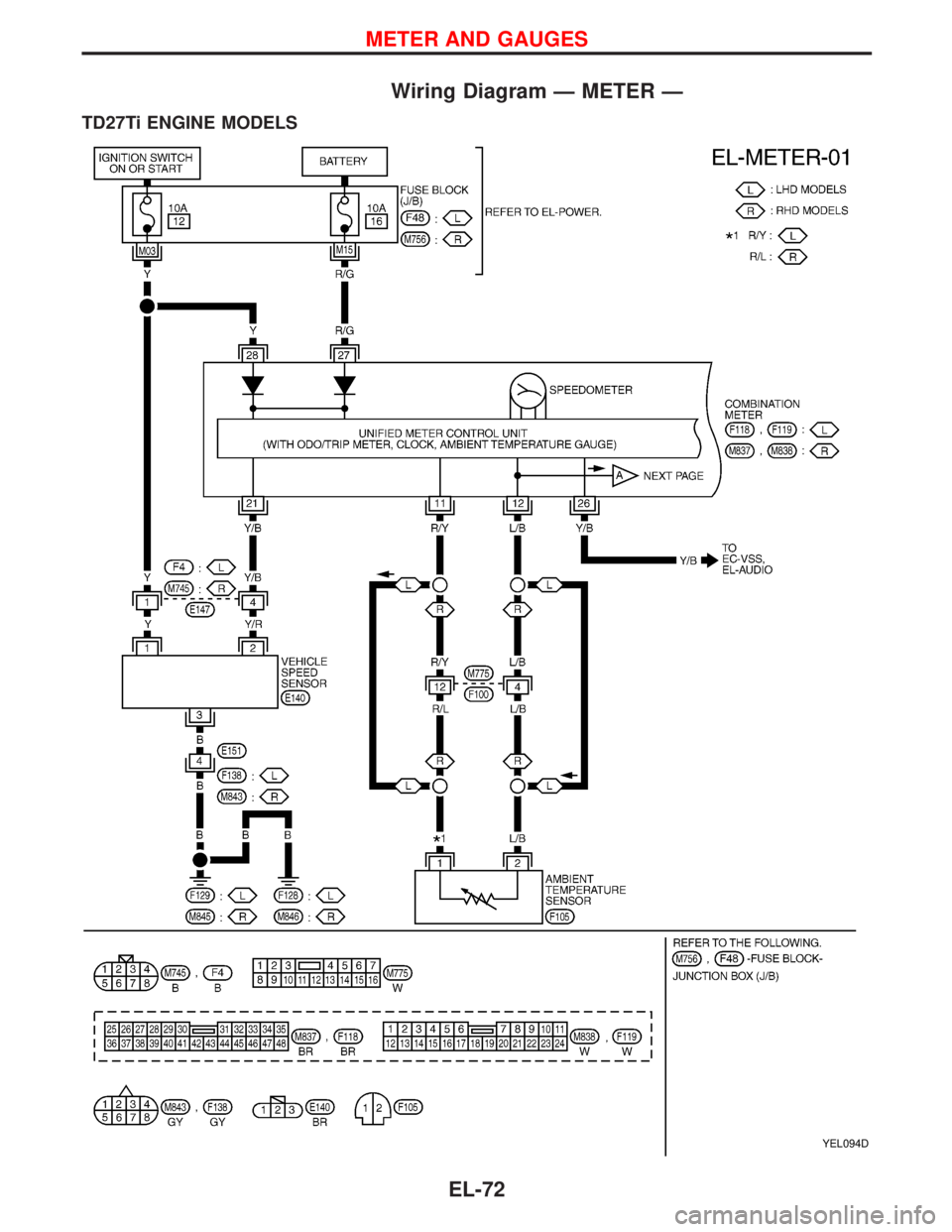

Wiring Diagram Ð METER Ð

TD27Ti ENGINE MODELS

YEL094D

METER AND GAUGES

EL-72

Page 889 of 1767

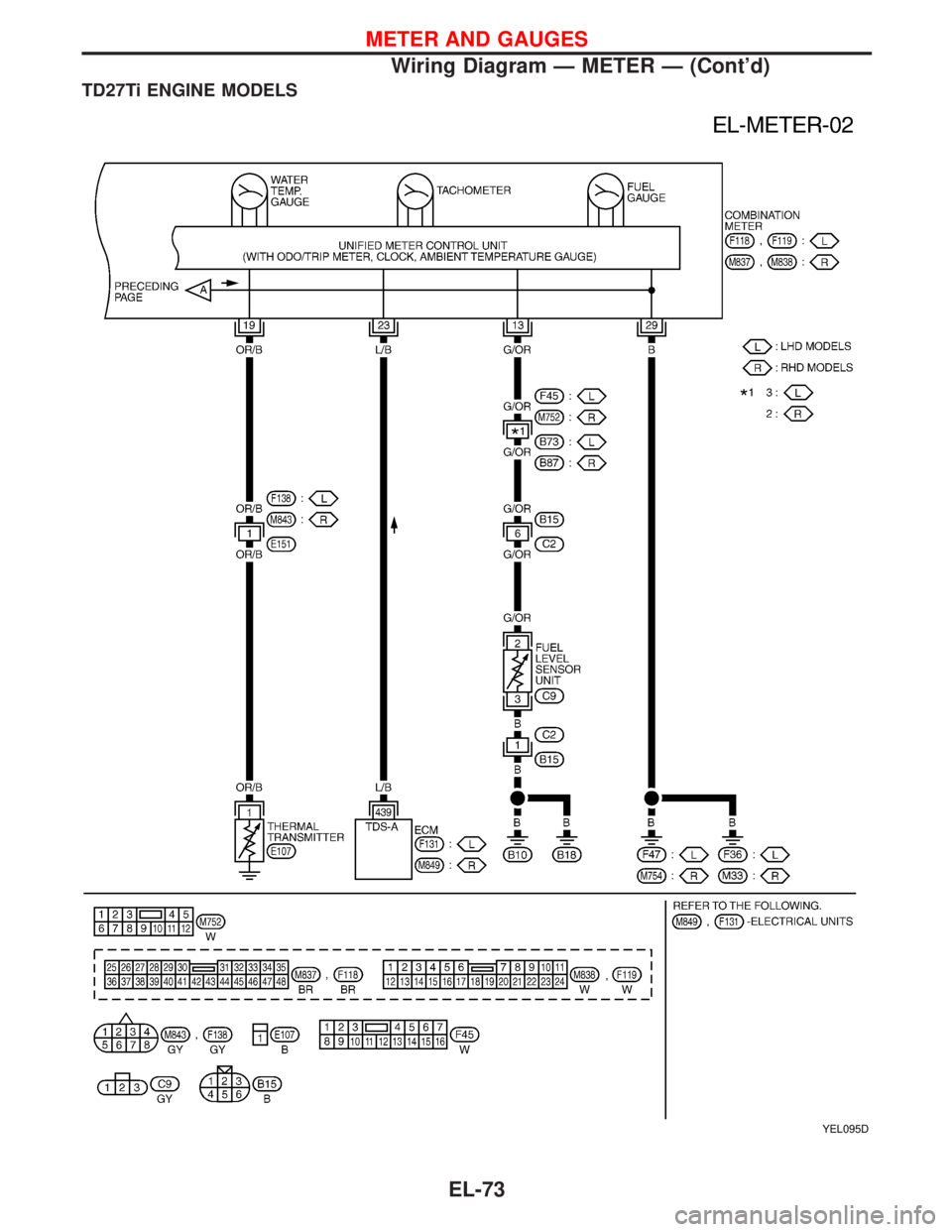

TD27Ti ENGINE MODELS

YEL095D

METER AND GAUGES

Wiring Diagram Ð METER Ð (Cont'd)

EL-73

Page 890 of 1767

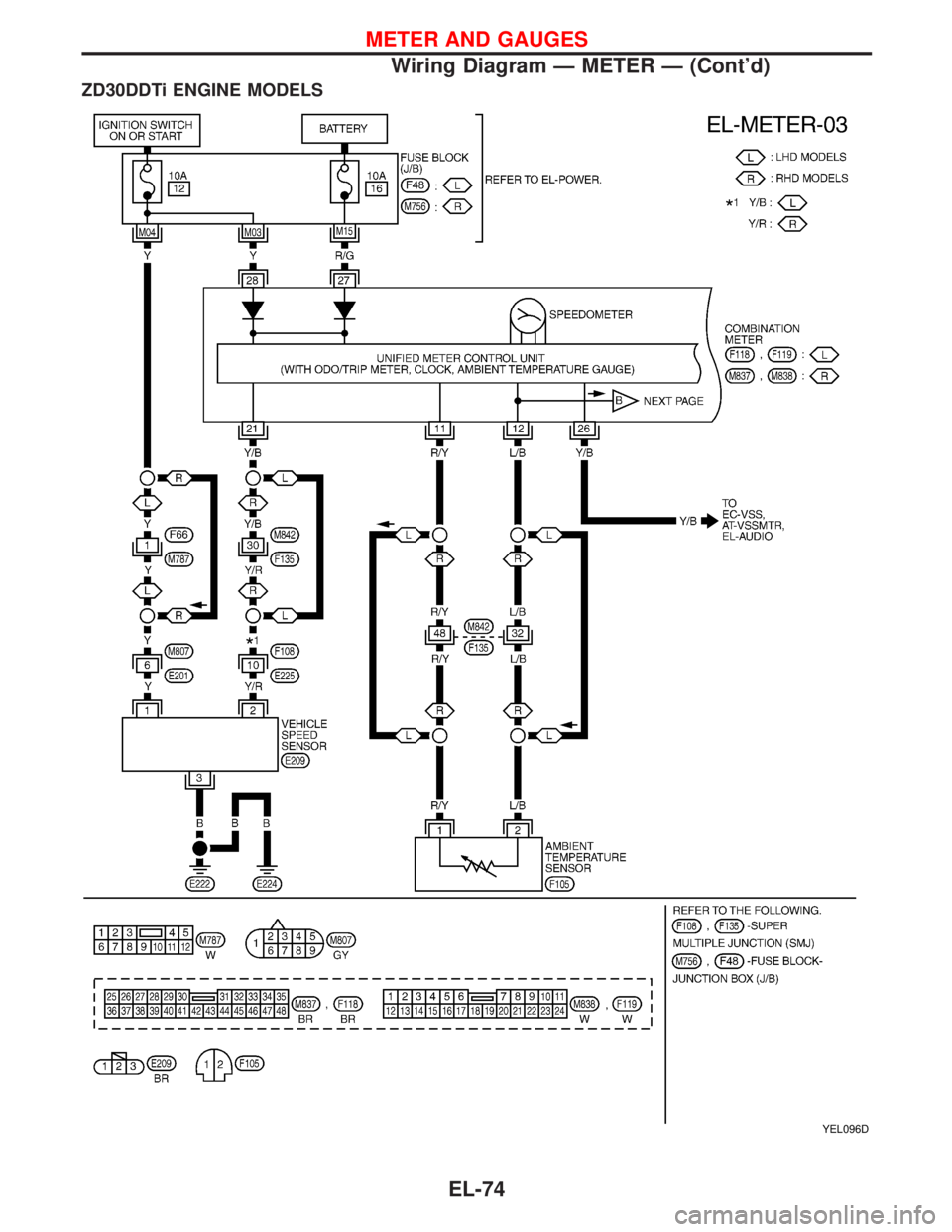

ZD30DDTi ENGINE MODELS

YEL096D

METER AND GAUGES

Wiring Diagram Ð METER Ð (Cont'd)

EL-74

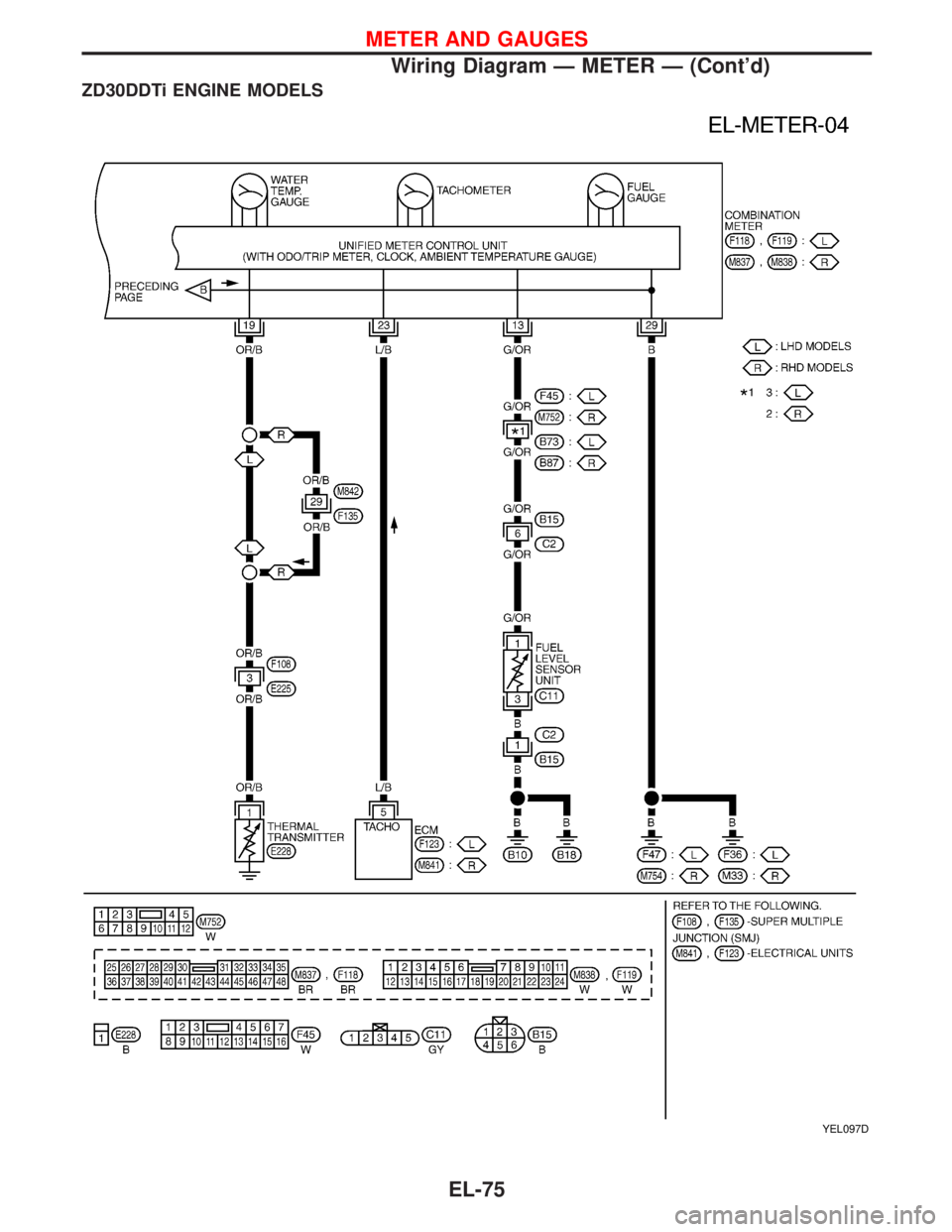

Page 891 of 1767

ZD30DDTi ENGINE MODELS

YEL097D

METER AND GAUGES

Wiring Diagram Ð METER Ð (Cont'd)

EL-75

Page 896 of 1767

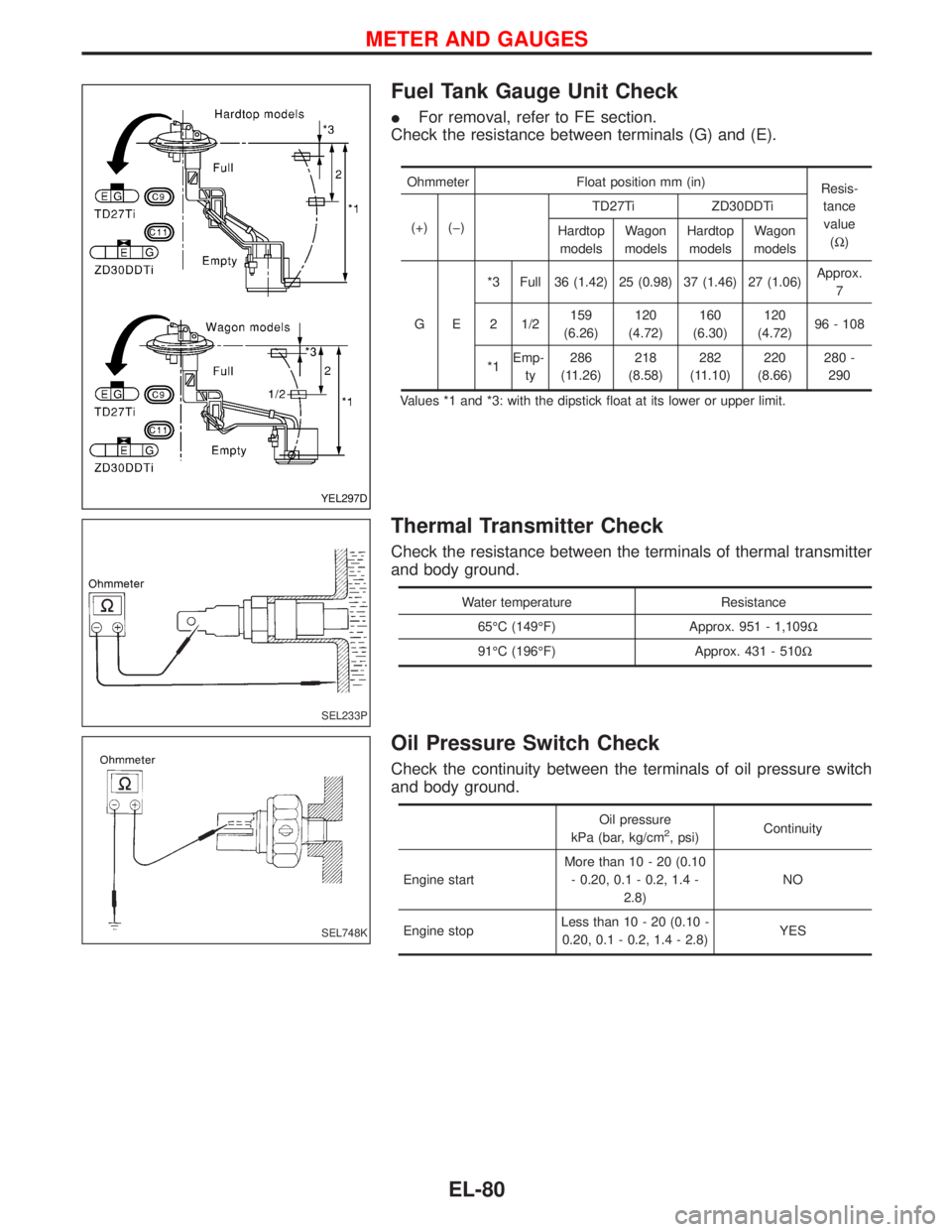

Fuel Tank Gauge Unit Check

IFor removal, refer to FE section.

Check the resistance between terminals (G) and (E).

Ohmmeter Float position mm (in)

Resis-

tance

value

(W) (+) (þ)TD27Ti ZD30DDTi

Hardtop

modelsWagon

modelsHardtop

modelsWagon

models

GE*3 Full 36 (1.42) 25 (0.98) 37 (1.46) 27 (1.06)Approx.

7

2 1/2159

(6.26)120

(4.72)160

(6.30)120

(4.72)96 - 108

*1Emp-

ty286

(11.26)218

(8.58)282

(11.10)220

(8.66)280 -

290

Values *1 and *3: with the dipstick float at its lower or upper limit.

Thermal Transmitter Check

Check the resistance between the terminals of thermal transmitter

and body ground.

Water temperature Resistance

65ÉC (149ÉF) Approx. 951 - 1,109W

91ÉC (196ÉF) Approx. 431 - 510W

Oil Pressure Switch Check

Check the continuity between the terminals of oil pressure switch

and body ground.

Oil pressure

kPa (bar, kg/cm2, psi)Continuity

Engine startMore than 10 - 20 (0.10

- 0.20, 0.1 - 0.2, 1.4 -

2.8)NO

Engine stopLess than 10 - 20 (0.10 -

0.20, 0.1 - 0.2, 1.4 - 2.8)YES

YEL297D

SEL233P

SEL748K

METER AND GAUGES

EL-80

Page 940 of 1767

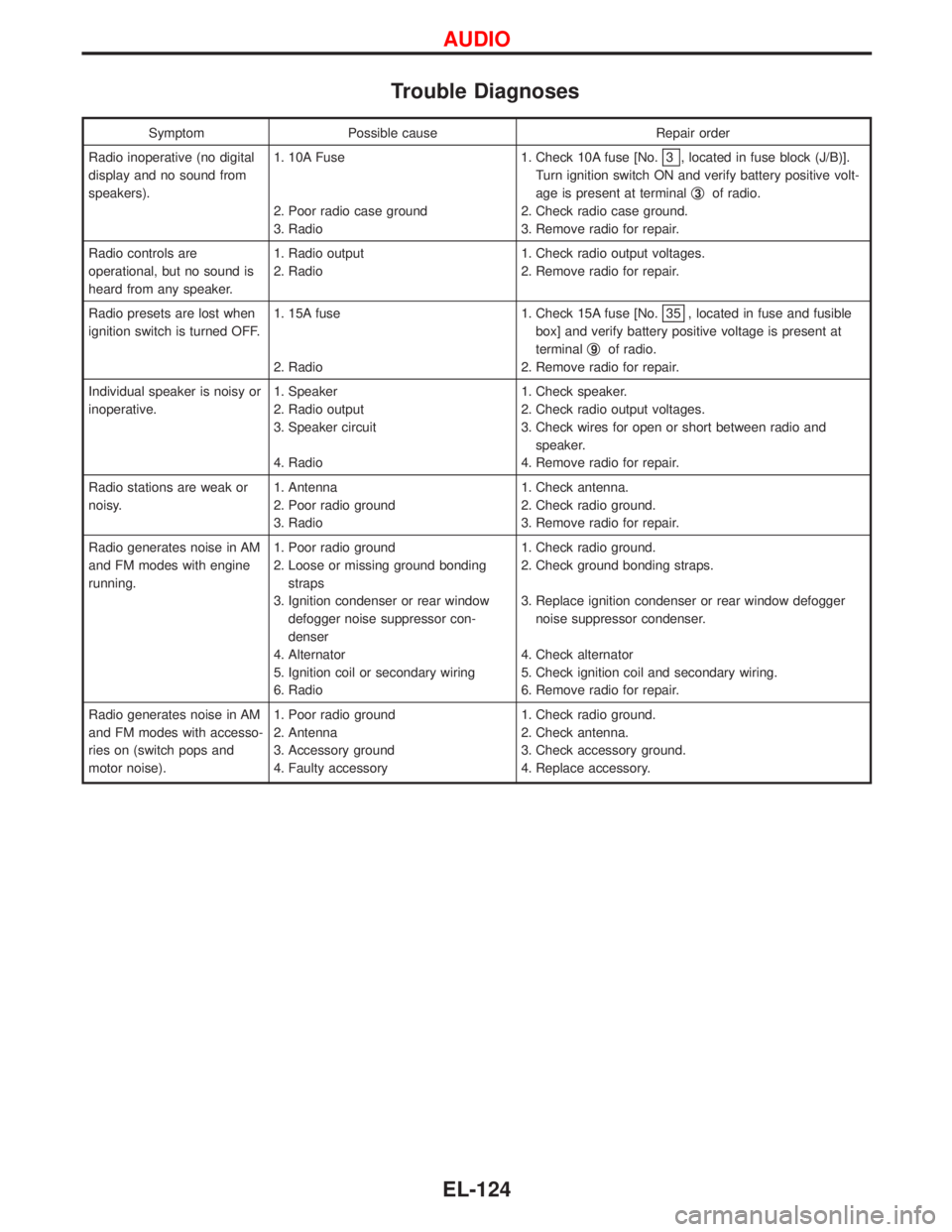

Trouble Diagnoses

Symptom Possible cause Repair order

Radio inoperative (no digital

display and no sound from

speakers).1. 10A Fuse

2. Poor radio case ground

3. Radio1. Check 10A fuse [No.

3 , located in fuse block (J/B)].

Turn ignition switch ON and verify battery positive volt-

age is present at terminalq

3of radio.

2. Check radio case ground.

3. Remove radio for repair.

Radio controls are

operational, but no sound is

heard from any speaker.1. Radio output

2. Radio1. Check radio output voltages.

2. Remove radio for repair.

Radio presets are lost when

ignition switch is turned OFF.1. 15A fuse

2. Radio1. Check 15A fuse [No.

35 , located in fuse and fusible

box] and verify battery positive voltage is present at

terminalq

9of radio.

2. Remove radio for repair.

Individual speaker is noisy or

inoperative.1. Speaker

2. Radio output

3. Speaker circuit

4. Radio1. Check speaker.

2. Check radio output voltages.

3. Check wires for open or short between radio and

speaker.

4. Remove radio for repair.

Radio stations are weak or

noisy.1. Antenna

2. Poor radio ground

3. Radio1. Check antenna.

2. Check radio ground.

3. Remove radio for repair.

Radio generates noise in AM

and FM modes with engine

running.1. Poor radio ground

2. Loose or missing ground bonding

straps

3. Ignition condenser or rear window

defogger noise suppressor con-

denser

4. Alternator

5. Ignition coil or secondary wiring

6. Radio1. Check radio ground.

2. Check ground bonding straps.

3. Replace ignition condenser or rear window defogger

noise suppressor condenser.

4. Check alternator

5. Check ignition coil and secondary wiring.

6. Remove radio for repair.

Radio generates noise in AM

and FM modes with accesso-

ries on (switch pops and

motor noise).1. Poor radio ground

2. Antenna

3. Accessory ground

4. Faulty accessory1. Check radio ground.

2. Check antenna.

3. Check accessory ground.

4. Replace accessory.

AUDIO

EL-124

Page 982 of 1767

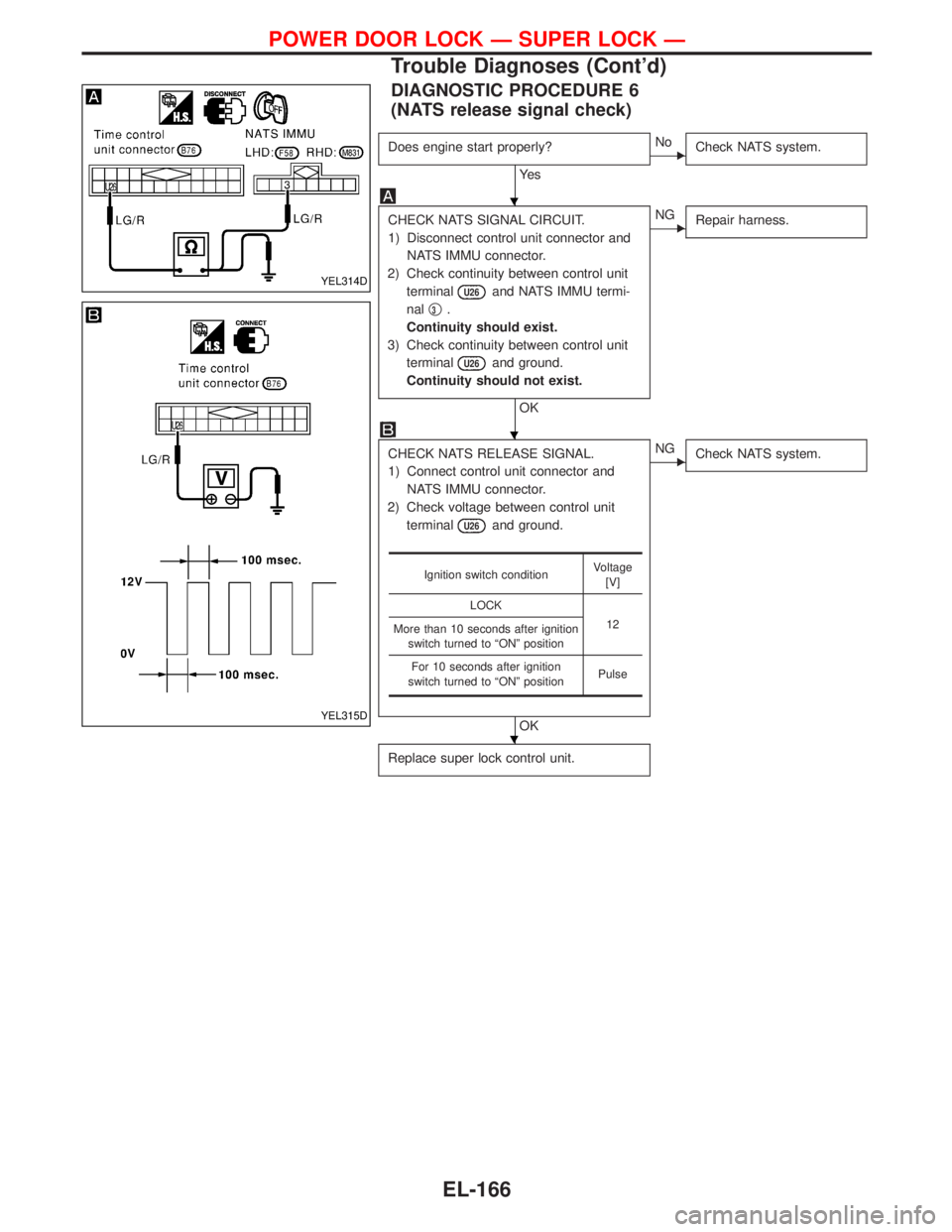

DIAGNOSTIC PROCEDURE 6

(NATS release signal check)

Does engine start properly?

Ye s

ENo

Check NATS system.

CHECK NATS SIGNAL CIRCUIT.

1) Disconnect control unit connector and

NATS IMMU connector.

2) Check continuity between control unit

terminal

U26and NATS IMMU termi-

nalq

3.

Continuity should exist.

3) Check continuity between control unit

terminal

U26and ground.

Continuity should not exist.

OK

ENG

Repair harness.

CHECK NATS RELEASE SIGNAL.

1) Connect control unit connector and

NATS IMMU connector.

2) Check voltage between control unit

terminal

U26and ground.

OK

ENG

Check NATS system.

Replace super lock control unit.

Ignition switch conditionVoltage

[V]

LOCK

12

More than 10 seconds after ignition

switch turned to ªONº position

For 10 seconds after ignition

switch turned to ªONº positionPulse

YEL314D

YEL315D

H

H

H

POWER DOOR LOCK Ð SUPER LOCK Ð

Trouble Diagnoses (Cont'd)

EL-166

Page 1002 of 1767

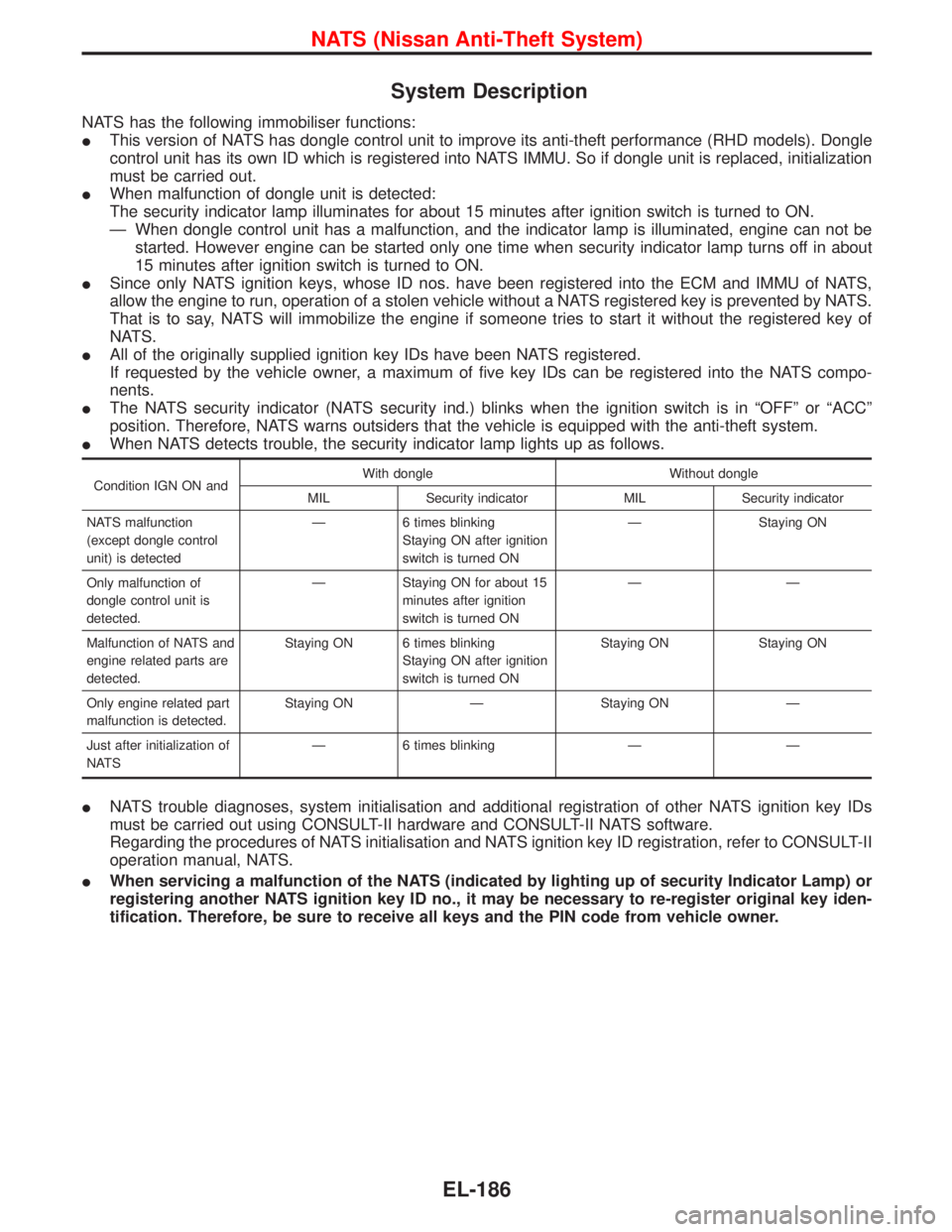

System Description

NATS has the following immobiliser functions:

IThis version of NATS has dongle control unit to improve its anti-theft performance (RHD models). Dongle

control unit has its own ID which is registered into NATS IMMU. So if dongle unit is replaced, initialization

must be carried out.

IWhen malfunction of dongle unit is detected:

The security indicator lamp illuminates for about 15 minutes after ignition switch is turned to ON.

Ð When dongle control unit has a malfunction, and the indicator lamp is illuminated, engine can not be

started. However engine can be started only one time when security indicator lamp turns off in about

15 minutes after ignition switch is turned to ON.

ISince only NATS ignition keys, whose ID nos. have been registered into the ECM and IMMU of NATS,

allow the engine to run, operation of a stolen vehicle without a NATS registered key is prevented by NATS.

That is to say, NATS will immobilize the engine if someone tries to start it without the registered key of

NATS.

IAll of the originally supplied ignition key IDs have been NATS registered.

If requested by the vehicle owner, a maximum of five key IDs can be registered into the NATS compo-

nents.

IThe NATS security indicator (NATS security ind.) blinks when the ignition switch is in ªOFFº or ªACCº

position. Therefore, NATS warns outsiders that the vehicle is equipped with the anti-theft system.

IWhen NATS detects trouble, the security indicator lamp lights up as follows.

Condition IGN ON andWith dongle Without dongle

MIL Security indicator MIL Security indicator

NATS malfunction

(except dongle control

unit) is detectedÐ 6 times blinking

Staying ON after ignition

switch is turned ONÐ Staying ON

Only malfunction of

dongle control unit is

detected.Ð Staying ON for about 15

minutes after ignition

switch is turned ONÐÐ

Malfunction of NATS and

engine related parts are

detected.Staying ON 6 times blinking

Staying ON after ignition

switch is turned ONStaying ON Staying ON

Only engine related part

malfunction is detected.Staying ON Ð Staying ON Ð

Just after initialization of

NATSÐ 6 times blinking Ð Ð

INATS trouble diagnoses, system initialisation and additional registration of other NATS ignition key IDs

must be carried out using CONSULT-II hardware and CONSULT-II NATS software.

Regarding the procedures of NATS initialisation and NATS ignition key ID registration, refer to CONSULT-II

operation manual, NATS.

IWhen servicing a malfunction of the NATS (indicated by lighting up of security Indicator Lamp) or

registering another NATS ignition key ID no., it may be necessary to re-register original key iden-

tification. Therefore, be sure to receive all keys and the PIN code from vehicle owner.

NATS (Nissan Anti-Theft System)

EL-186