display NISSAN TERRANO 2002 Service Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 699 of 1767

Description for Work Flow

STEP DESCRIPTION

STEP IGet detailed information about the conditions and the environment when the incident/symptom occurred using the

ªDIAGNOSTIC WORKSHEETº as shown on the next page.

STEP IIBefore confirming the concern, check and write down (print out using CONSULT-II) the Diagnostic Trouble Code

(DTC), then erase the code. (Refer to EC-321). The DTC can be used when duplicating the incident at STEP III &

IV.

Study the relationship between the cause, specified by DTC, and the symptom described by the customer. (The

ªSymptom Matrix Chartº will be useful. Refer to EC-340.)

STEP IIITry to confirm the symptom and under what conditions the incident occurs.

The ªDIAGNOSTIC WORK SHEETº is useful to verify the incident. Connect CONSULT-II to the vehicle in DATA

MONITOR (AUTO TRIG) mode and check real time diagnosis results.

If the malfunction code is detected, skip STEP IV and perform STEP V.

STEP IVTry to detect the Diagnostic Trouble Code (DTC) by driving in (or performing) the ªDTC CONFIRMATION PROCE-

DUREº. Check and read the DTC by using CONSULT-II.

During the DTC verification, be sure to connect CONSULT-II to the vehicle in DATA MONITOR (AUTO TRIG) mode

and check real time diagnosis results.

In case the ªDTC CONFIRMATION PROCEDUREº is not available, perform the ªOVERALL FUNCTION CHECKº

instead. The DTC cannot be displayed by this check, however, this simplified ªcheckº is an effective alternative.

The ªNGº result of the ªOVERALL FUNCTION CHECKº is the same as the DTC detection.

STEP VTake the appropriate action based on the results of STEP I through IV.

If the malfunction code is indicated, proceed to TROUBLE DIAGNOSIS FOR DTC.

If the normal code is indicated, proceed to the BASIC INSPECTION. Refer to EC-338. Then perform inspections

according to the Symptom Matrix Chart. Refer to EC-340.

STEP VIIdentify where to begin diagnosis based on the relationship study between symptom and possible causes. Inspect

the system for mechanical binding, loose connectors or wiring damage using (tracing) ªHarness Layoutsº.

Gently shake the related connectors, components or wiring harness with CONSULT-II set in ªDATA MONITOR

(AUTO TRIG)º mode.

Check the voltage of the related ECM terminals or monitor the output data from the related sensors with CON-

SULT-II. Refer to EC-346.

The ªDIAGNOSTIC PROCEDUREº in EC section contains a description based on open circuit inspection. A short

circuit inspection is also required for the circuit check in the DIAGNOSTIC PROCEDURE.

Repair or replace the malfunctioning parts.

STEP VIIOnce you have repaired the circuit or replaced a component, you need to run the engine in the same conditions

and circumstances which resulted in the customer's initial complaint.

Perform the ªDTC CONFIRMATION PROCEDUREº and confirm the normal code (Diagnostic trouble code No. 55)

is detected. If the incident is still detected in the final check, perform STEP VI by using a different method from the

previous one.

Before returning the vehicle to the customer, be sure to erase the unnecessary (already fixed) DTC in ECM. (Refer

to EC-321.)

TROUBLE DIAGNOSESTD27Ti

EC-337

Page 701 of 1767

qA

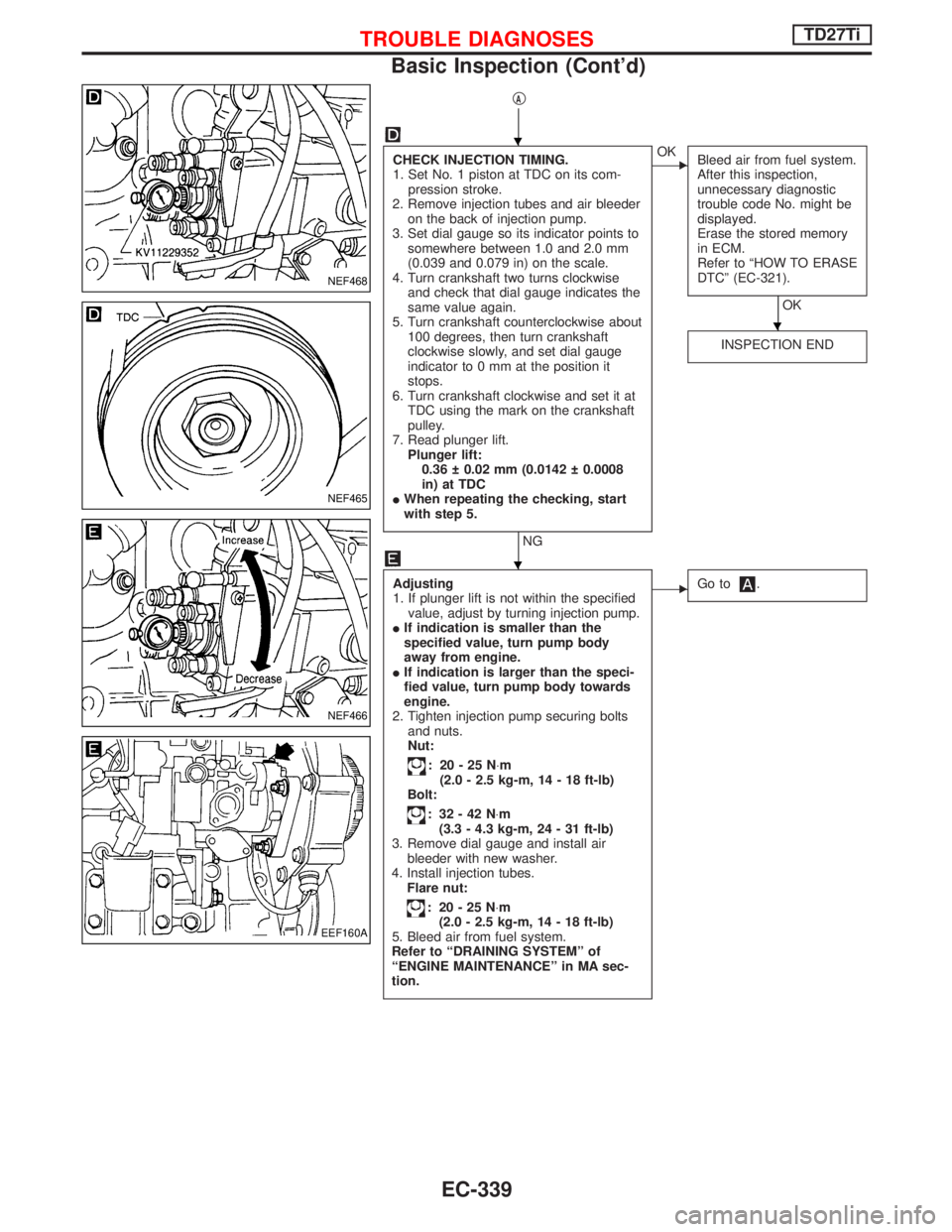

CHECK INJECTION TIMING.

1. Set No. 1 piston at TDC on its com-

pression stroke.

2. Remove injection tubes and air bleeder

on the back of injection pump.

3. Set dial gauge so its indicator points to

somewhere between 1.0 and 2.0 mm

(0.039 and 0.079 in) on the scale.

4. Turn crankshaft two turns clockwise

and check that dial gauge indicates the

same value again.

5. Turn crankshaft counterclockwise about

100 degrees, then turn crankshaft

clockwise slowly, and set dial gauge

indicator to 0 mm at the position it

stops.

6. Turn crankshaft clockwise and set it at

TDC using the mark on the crankshaft

pulley.

7. Read plunger lift.

Plunger lift:

0.36 0.02 mm (0.0142 0.0008

in) at TDC

IWhen repeating the checking, start

with step 5.

NG

EOK

Bleed air from fuel system.

After this inspection,

unnecessary diagnostic

trouble code No. might be

displayed.

Erase the stored memory

in ECM.

Refer to ªHOW TO ERASE

DTCº (EC-321).

OK

INSPECTION END

Adjusting

1. If plunger lift is not within the specified

value, adjust by turning injection pump.

IIf indication is smaller than the

specified value, turn pump body

away from engine.

IIf indication is larger than the speci-

fied value, turn pump body towards

engine.

2. Tighten injection pump securing bolts

and nuts.

Nut:

: 20-25N×m

(2.0 - 2.5 kg-m, 14 - 18 ft-lb)

Bolt:

: 32-42N×m

(3.3 - 4.3 kg-m, 24 - 31 ft-lb)

3. Remove dial gauge and install air

bleeder with new washer.

4. Install injection tubes.

Flare nut:

: 20-25N×m

(2.0 - 2.5 kg-m, 14 - 18 ft-lb)

5. Bleed air from fuel system.

Refer to ªDRAINING SYSTEMº of

ªENGINE MAINTENANCEº in MA sec-

tion.

EGo to.

NEF468

NEF465

NEF466

EEF160A

H

H

H

TROUBLE DIAGNOSESTD27Ti

Basic Inspection (Cont'd)

EC-339

Page 728 of 1767

DTC Confirmation Procedure B (For

Accelerator Sticking)

If DTC P0571 is displayed same time, cure it at first.

WITH CONSULT-II

1) Turn ignition switch to ªONº position.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and rev it up to above 1,300 rpm.

4) Depress brake pedal immediately after releasing accelerator

pedal and keep it at least 5 seconds.

WITHOUT CONSULT-II

1) Start engine and rev it up to above 1,300 rpm.

2) Depress brake pedal immediately after releasing accelerator

pedal and keep it at least 5 seconds.

3) Turn ignition switch to ªLOCKº position, wait at least 5 seconds

and then turn to ªONº position.

4) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with

ECM.

DTC P0120 ACCEL POS SENSORTD27Ti

EC-366

Page 738 of 1767

Component Description

FUEL CUT SOLENOID VALVE

When the ignition switch is off, the ECM turns the fuel cut solenoid

valve OFF (under this condition, no current flows through the fuel

cut solenoid valve), shutting off fuel supply.

When the engine is not operating due to trouble, the fuel cut sole-

noid valve may or may not be OFF even when the ignition switch

is ON.

On Board Diagnosis Logic

DTC Malfunction is detected when ...Check Items

(Possible Cause)

P0125

0306IFuel cut solenoid valve circuit is malfunctioning.IHarness or connectors

(The solenoid valve circuit is open or shorted.)

IFuel cut solenoid valve

DTC Confirmation Procedure

NOTE:

If DTC P0115 or P0335 is displayed same time, perform trouble

diagnosis for P0115 or P0335 first.

WITH CONSULT-II

1) Turn ignition switch to ªONº position.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine. (If no start, circuit is open.)

4) Warm it up sufficiently.

5) Turn ignition switch to ªLOCKº position, wait at least 5 seconds.

6) Start engine and rev it up to above 1,300 rpm. Release pedal

and wait at least 3 seconds.

WITHOUT CONSULT-II

1) Start engine. (If no start, circuit is open.)

2) Warm it up sufficiently.

3) Turn ignition switch to ªLOCKº position, wait at least 5 seconds.

4) Start engine and rev it up to above 1,300 rpm. Release pedal

and wait at least 3 seconds.

5) Turn ignition switch to ªLOCKº position, wait at least 5 seconds

and then turn to ªONº position.

6) Perform ªDiagnostic Test Mode IIº (Self-diagnostic results).

SEF667S

DTC P0215 FUEL CUT S/V 1TD27Ti

EC-376

Page 743 of 1767

DTC P1246 Confirmation Procedure

NOTE:

If both DTC P1246 and P1240 or P0335 are displayed, perform

TROUBLE DIAGNOSIS FOR DTC P1240 or P0335. (See EC-427

or EC-385.)

WITH CONSULT-II

1) Turn ignition switch to ªONº position and select ªDATA MONI-

TORº mode with CONSULT-II.

2) Start engine. Run it for 10 seconds at idle.

WITHOUT CONSULT-II

1) Start engine. Run it for 10 seconds at idle.

2) Turn ignition switch to ªLOCKº position, wait at least 5 seconds

and then turn to ªONº position.

3) Perform ªDiagnostic Test Mode IIº (Self-diagnostic results).

NOTE:

If a malfunction occurs intermittently, conduct suitable driving

pattern for 10 minutes. This makes it possible to determine

DTC.

DTC P0216 INJ TIMING CONT/V, DTC P1246 F/INJ TIMG F/BTD27Ti

EC-381

Page 747 of 1767

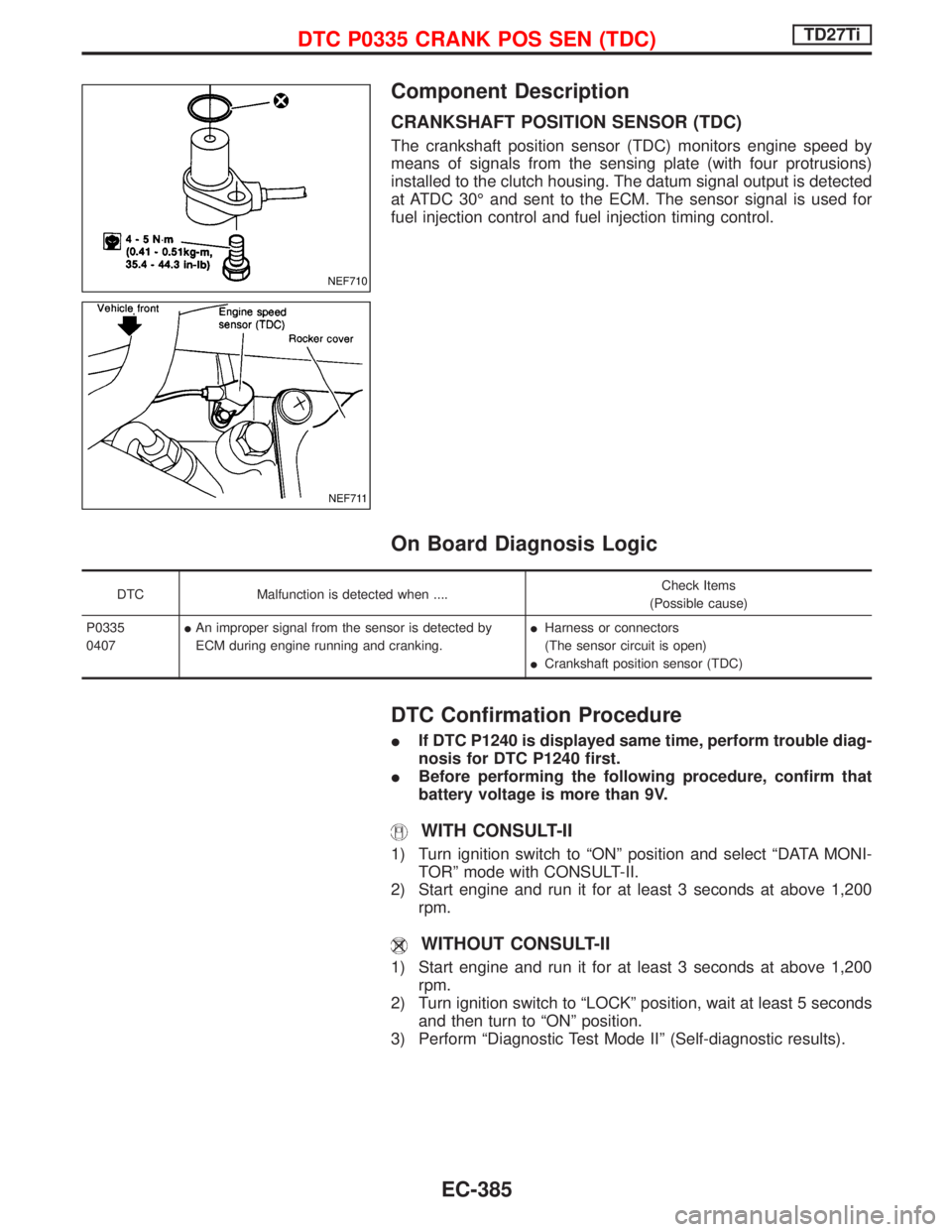

Component Description

CRANKSHAFT POSITION SENSOR (TDC)

The crankshaft position sensor (TDC) monitors engine speed by

means of signals from the sensing plate (with four protrusions)

installed to the clutch housing. The datum signal output is detected

at ATDC 30É and sent to the ECM. The sensor signal is used for

fuel injection control and fuel injection timing control.

On Board Diagnosis Logic

DTC Malfunction is detected when ....Check Items

(Possible cause)

P0335

0407IAn improper signal from the sensor is detected by

ECM during engine running and cranking.IHarness or connectors

(The sensor circuit is open)

ICrankshaft position sensor (TDC)

DTC Confirmation Procedure

IIf DTC P1240 is displayed same time, perform trouble diag-

nosis for DTC P1240 first.

IBefore performing the following procedure, confirm that

battery voltage is more than 9V.

WITH CONSULT-II

1) Turn ignition switch to ªONº position and select ªDATA MONI-

TORº mode with CONSULT-II.

2) Start engine and run it for at least 3 seconds at above 1,200

rpm.

WITHOUT CONSULT-II

1) Start engine and run it for at least 3 seconds at above 1,200

rpm.

2) Turn ignition switch to ªLOCKº position, wait at least 5 seconds

and then turn to ªONº position.

3) Perform ªDiagnostic Test Mode IIº (Self-diagnostic results).

NEF710

NEF711

DTC P0335 CRANK POS SEN (TDC)TD27Ti

EC-385

Page 770 of 1767

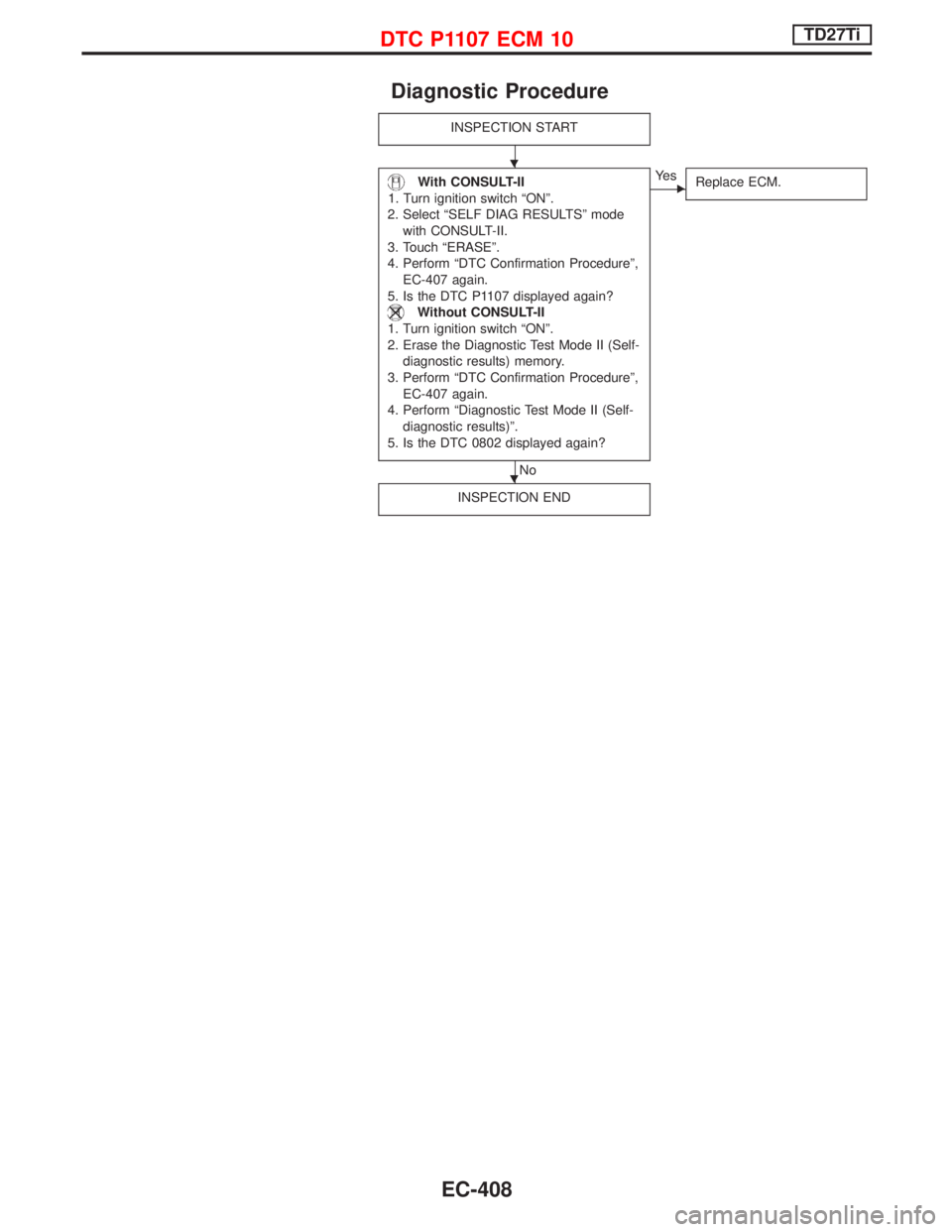

Diagnostic Procedure

INSPECTION START

With CONSULT-II

1. Turn ignition switch ªONº.

2. Select ªSELF DIAG RESULTSº mode

with CONSULT-II.

3. Touch ªERASEº.

4. Perform ªDTC Confirmation Procedureº,

EC-407 again.

5. Is the DTC P1107 displayed again?

Without CONSULT-II

1. Turn ignition switch ªONº.

2. Erase the Diagnostic Test Mode II (Self-

diagnostic results) memory.

3. Perform ªDTC Confirmation Procedureº,

EC-407 again.

4. Perform ªDiagnostic Test Mode II (Self-

diagnostic results)º.

5. Is the DTC 0802 displayed again?

No

EYe s

Replace ECM.

INSPECTION END

H

H

DTC P1107 ECM 10TD27Ti

EC-408

Page 798 of 1767

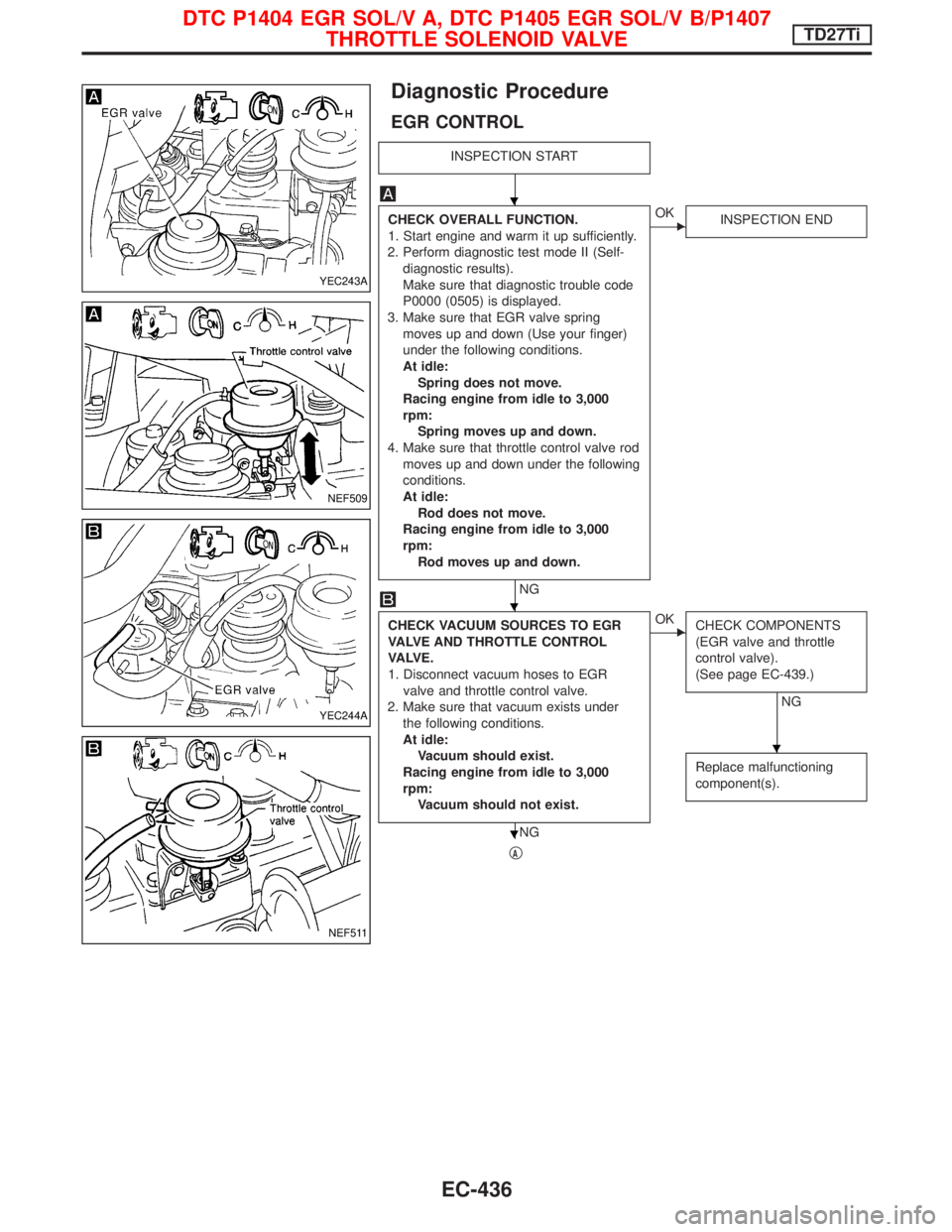

Diagnostic Procedure

EGR CONTROL

INSPECTION START

CHECK OVERALL FUNCTION.

1. Start engine and warm it up sufficiently.

2. Perform diagnostic test mode II (Self-

diagnostic results).

Make sure that diagnostic trouble code

P0000 (0505) is displayed.

3. Make sure that EGR valve spring

moves up and down (Use your finger)

under the following conditions.

At idle:

Spring does not move.

Racing engine from idle to 3,000

rpm:

Spring moves up and down.

4. Make sure that throttle control valve rod

moves up and down under the following

conditions.

At idle:

Rod does not move.

Racing engine from idle to 3,000

rpm:

Rod moves up and down.

NG

EOK

INSPECTION END

CHECK VACUUM SOURCES TO EGR

VALVE AND THROTTLE CONTROL

VA LV E .

1. Disconnect vacuum hoses to EGR

valve and throttle control valve.

2. Make sure that vacuum exists under

the following conditions.

At idle:

Vacuum should exist.

Racing engine from idle to 3,000

rpm:

Vacuum should not exist.

NG

EOK

CHECK COMPONENTS

(EGR valve and throttle

control valve).

(See page EC-439.)

NG

Replace malfunctioning

component(s).

qA

YEC243A

NEF509

YEC244A

NEF511

H

H

H

H

DTC P1404 EGR SOL/V A, DTC P1405 EGR SOL/V B/P1407

THROTTLE SOLENOID VALVETD27Ti

EC-436

Page 807 of 1767

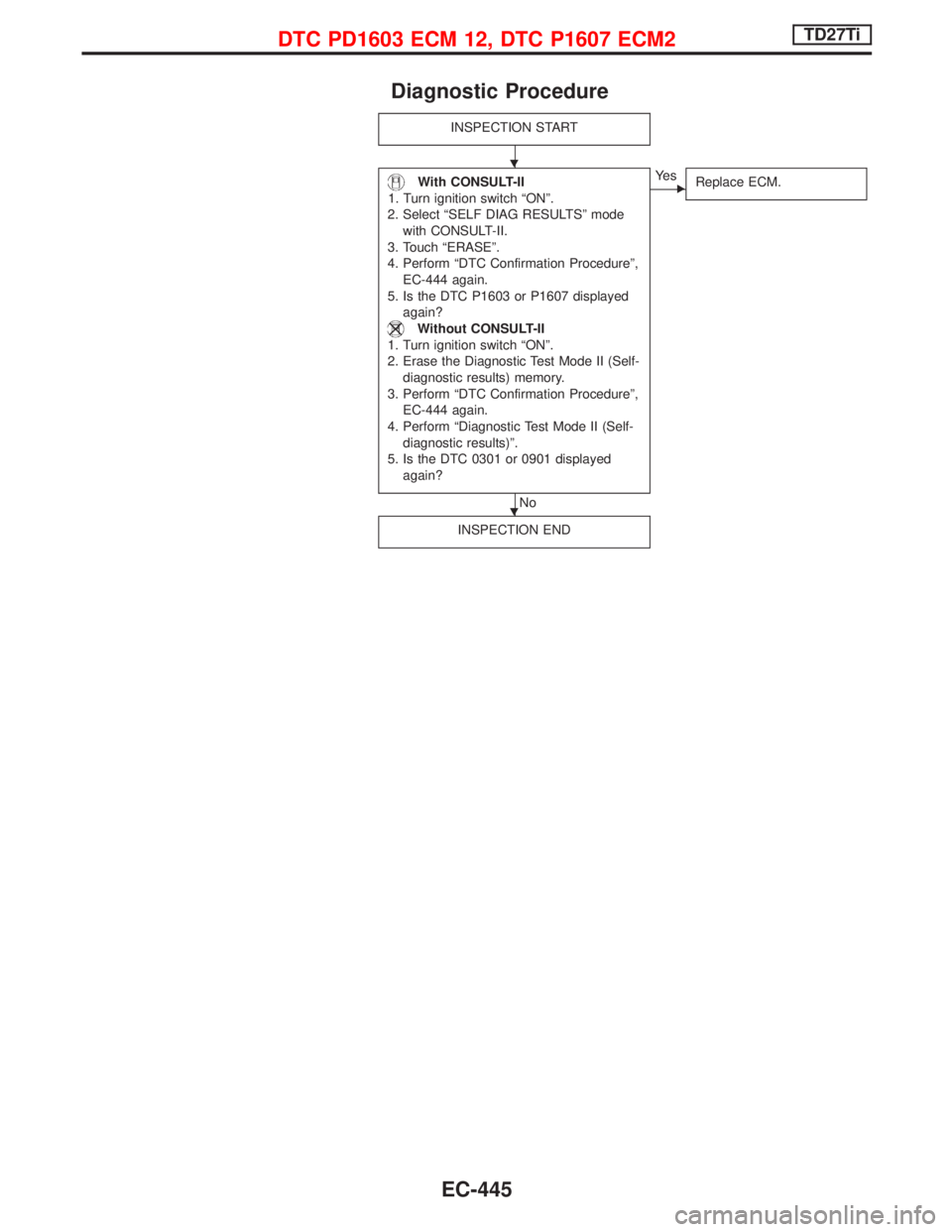

Diagnostic Procedure

INSPECTION START

With CONSULT-II

1. Turn ignition switch ªONº.

2. Select ªSELF DIAG RESULTSº mode

with CONSULT-II.

3. Touch ªERASEº.

4. Perform ªDTC Confirmation Procedureº,

EC-444 again.

5. Is the DTC P1603 or P1607 displayed

again?

Without CONSULT-II

1. Turn ignition switch ªONº.

2. Erase the Diagnostic Test Mode II (Self-

diagnostic results) memory.

3. Perform ªDTC Confirmation Procedureº,

EC-444 again.

4. Perform ªDiagnostic Test Mode II (Self-

diagnostic results)º.

5. Is the DTC 0301 or 0901 displayed

again?

No

EYe s

Replace ECM.

INSPECTION END

H

H

DTC PD1603 ECM 12, DTC P1607 ECM2TD27Ti

EC-445

Page 892 of 1767

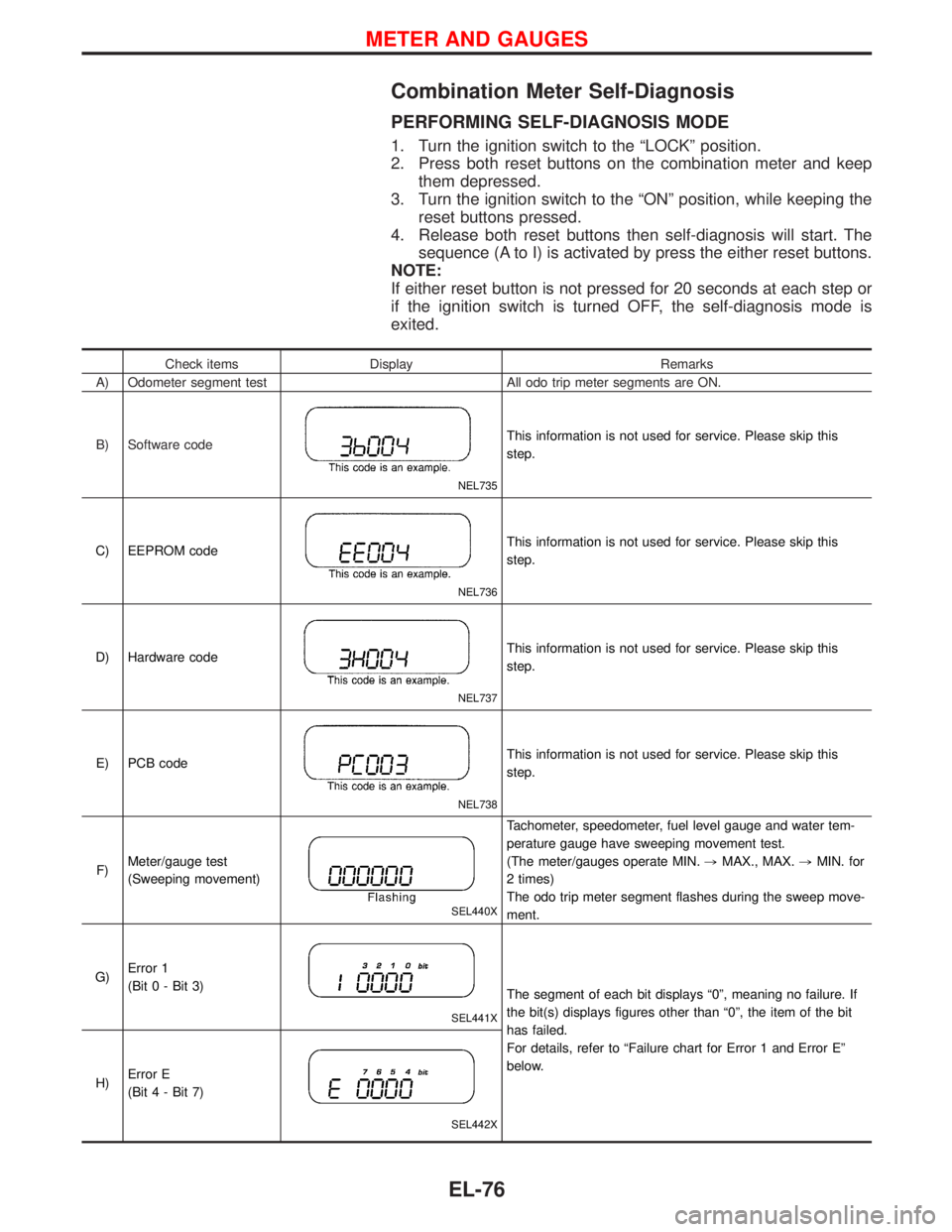

Combination Meter Self-Diagnosis

PERFORMING SELF-DIAGNOSIS MODE

1. Turn the ignition switch to the ªLOCKº position.

2. Press both reset buttons on the combination meter and keep

them depressed.

3. Turn the ignition switch to the ªONº position, while keeping the

reset buttons pressed.

4. Release both reset buttons then self-diagnosis will start. The

sequence (A to I) is activated by press the either reset buttons.

NOTE:

If either reset button is not pressed for 20 seconds at each step or

if the ignition switch is turned OFF, the self-diagnosis mode is

exited.

Check items Display Remarks

A) Odometer segment test All odo trip meter segments are ON.

B) Software code

NEL735

This information is not used for service. Please skip this

step.

C) EEPROM code

NEL736

This information is not used for service. Please skip this

step.

D) Hardware code

NEL737

This information is not used for service. Please skip this

step.

E) PCB code

NEL738

This information is not used for service. Please skip this

step.

F)Meter/gauge test

(Sweeping movement)

SEL440X

Tachometer, speedometer, fuel level gauge and water tem-

perature gauge have sweeping movement test.

(The meter/gauges operate MIN.,MAX., MAX.,MIN. for

2 times)

The odo trip meter segment flashes during the sweep move-

ment.

G)Error 1

(Bit 0 - Bit 3)

SEL441X

The segment of each bit displays ª0º, meaning no failure. If

the bit(s) displays figures other than ª0º, the item of the bit

has failed.

For details, refer to ªFailure chart for Error 1 and Error Eº

below.

H)Error E

(Bit 4 - Bit 7)

SEL442X

METER AND GAUGES

EL-76