NISSAN TERRANO 2002 Service Repair Manual

TERRANO 2002

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57393/w960_57393-0.png

NISSAN TERRANO 2002 Service Repair Manual

Trending: air filter, warning light, steering, display, rear view mirror, wheel, trunk

Page 451 of 1767

DTC Confirmation Procedure

WITH CONSULT-II

1) Turn ignition switch ªONº, and wait at least 6 seconds.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and wait at least 3 seconds.

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-92.

WITHOUT CONSULT-II

1) Turn ignition switch ªONº, and wait at least 6 seconds.

2) Start engine and wait at least 3 seconds.

3) Turn ignition switch ªOFFº, wait at least 5 seconds and then turn

ªONº.

4) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with

ECM.

5) If DTC is detected, go to ªDiagnostic Procedureº, EC-92.

SEF817Y

DTC 0102 MASS AIR FLOW SENZD30DDTi

EC-89

Page 452 of 1767

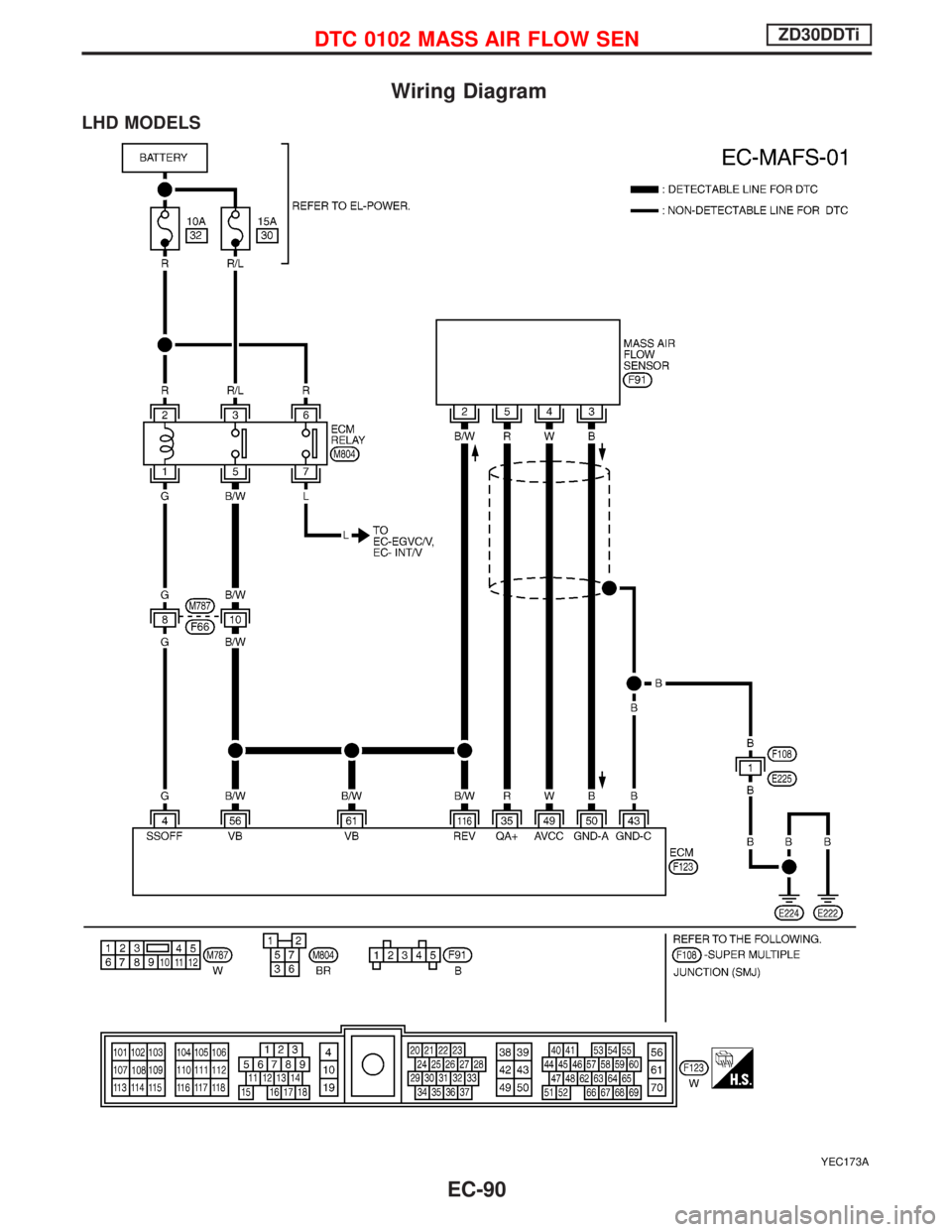

Wiring Diagram

LHD MODELS

YEC173A

DTC 0102 MASS AIR FLOW SENZD30DDTi

EC-90

Page 453 of 1767

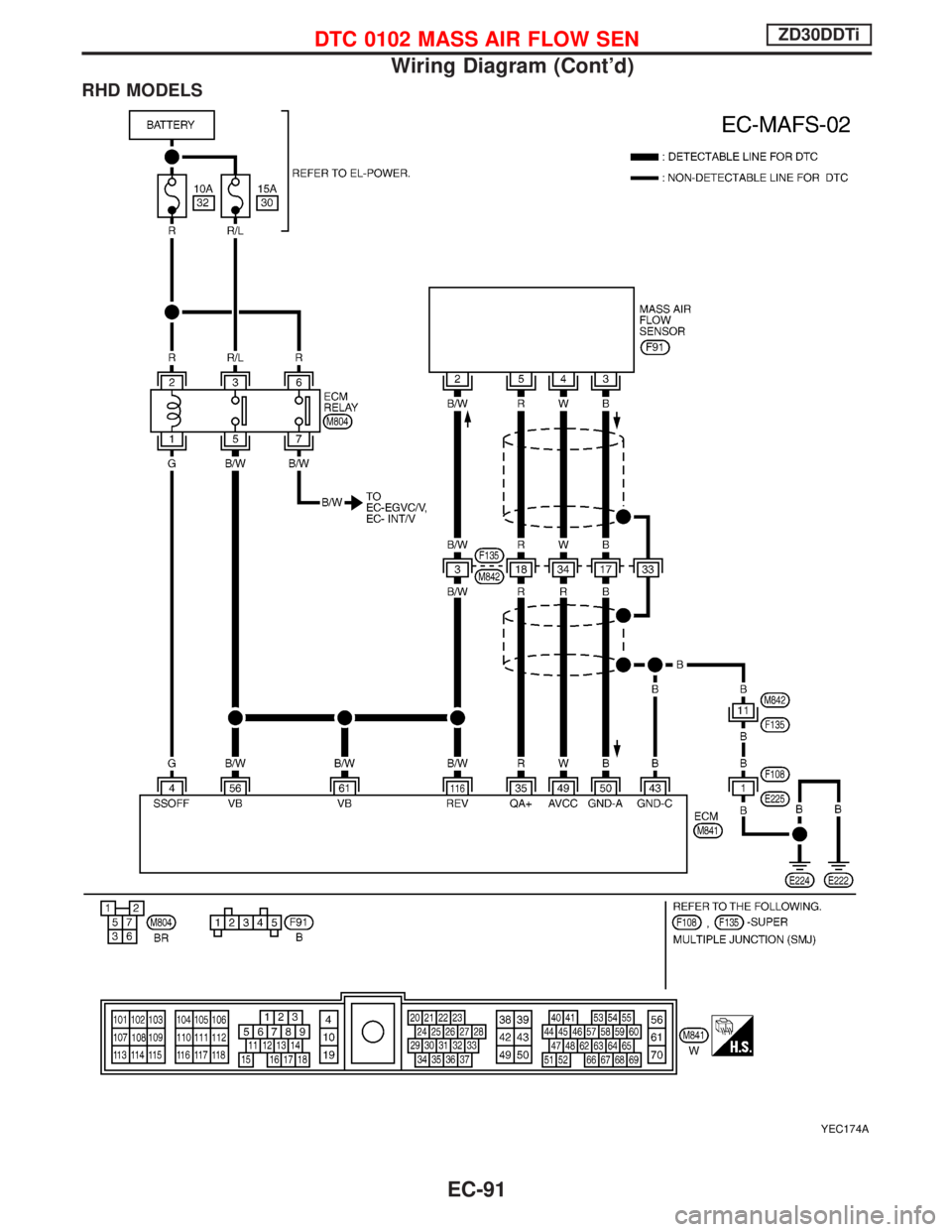

RHD MODELS

YEC174A

DTC 0102 MASS AIR FLOW SENZD30DDTi

Wiring Diagram (Cont'd)

EC-91

Page 454 of 1767

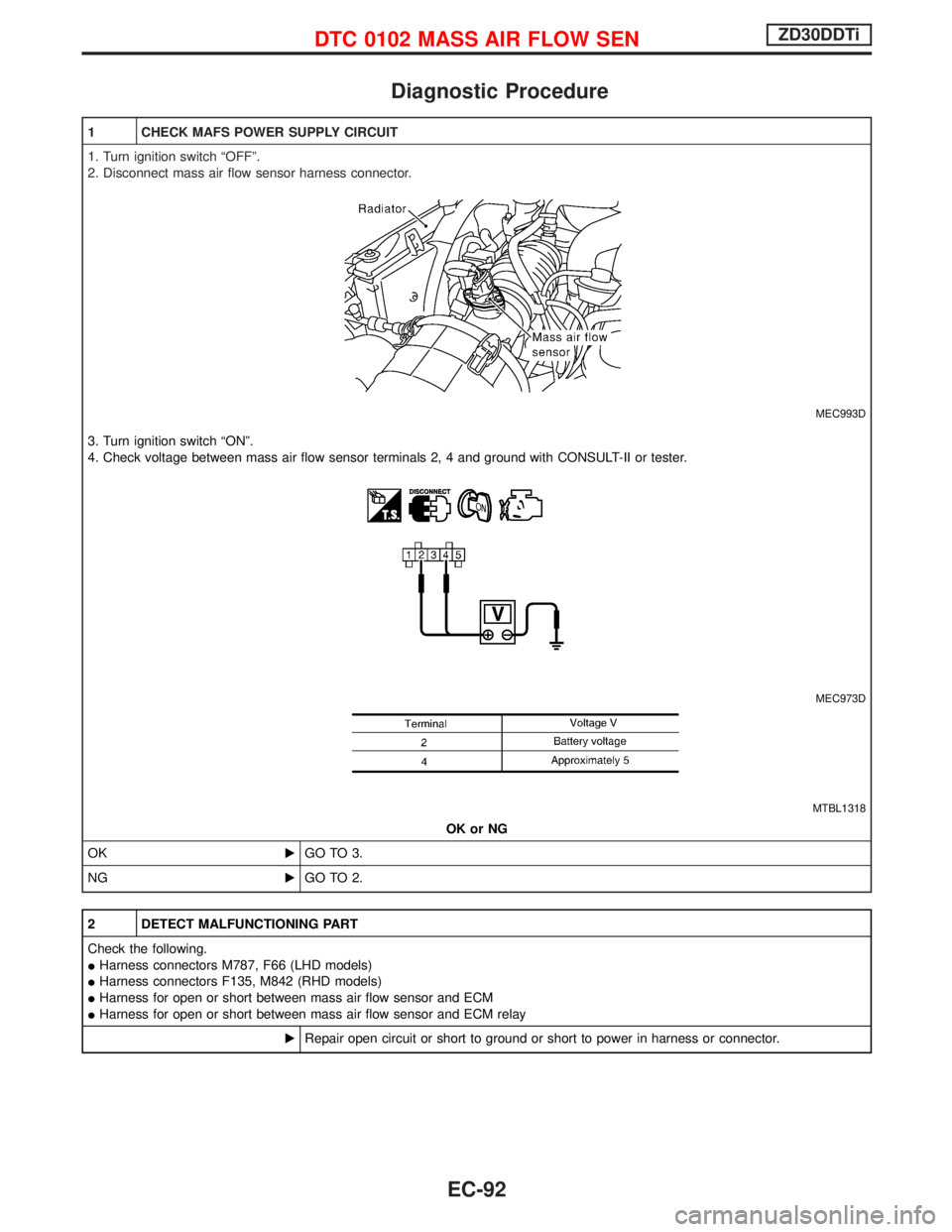

Diagnostic Procedure

1 CHECK MAFS POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect mass air flow sensor harness connector.

MEC993D

3. Turn ignition switch ªONº.

4. Check voltage between mass air flow sensor terminals 2, 4 and ground with CONSULT-II or tester.

MEC973D

MTBL1318

OK or NG

OKEGO TO 3.

NGEGO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors M787, F66 (LHD models)

IHarness connectors F135, M842 (RHD models)

IHarness for open or short between mass air flow sensor and ECM

IHarness for open or short between mass air flow sensor and ECM relay

ERepair open circuit or short to ground or short to power in harness or connector.

DTC 0102 MASS AIR FLOW SENZD30DDTi

EC-92

Page 455 of 1767

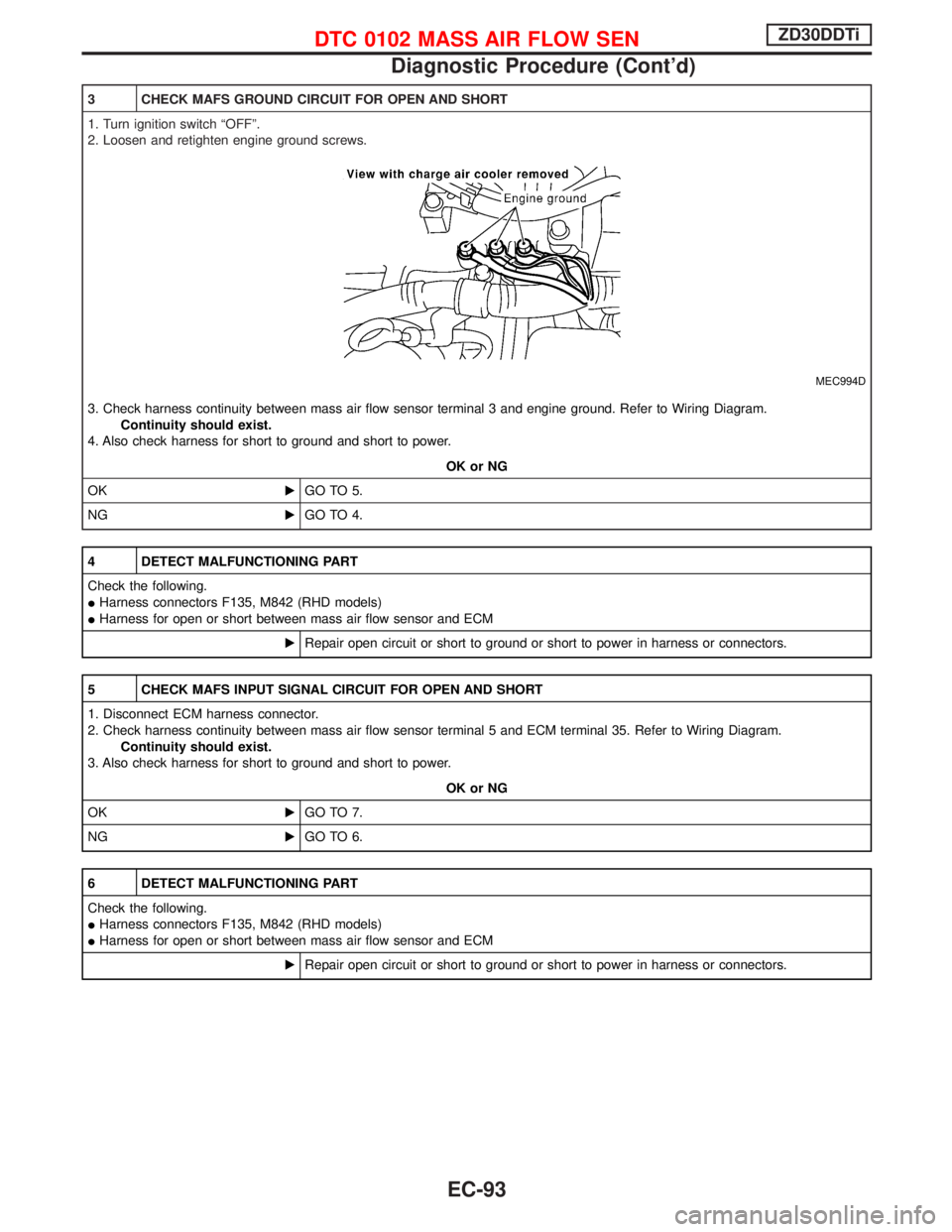

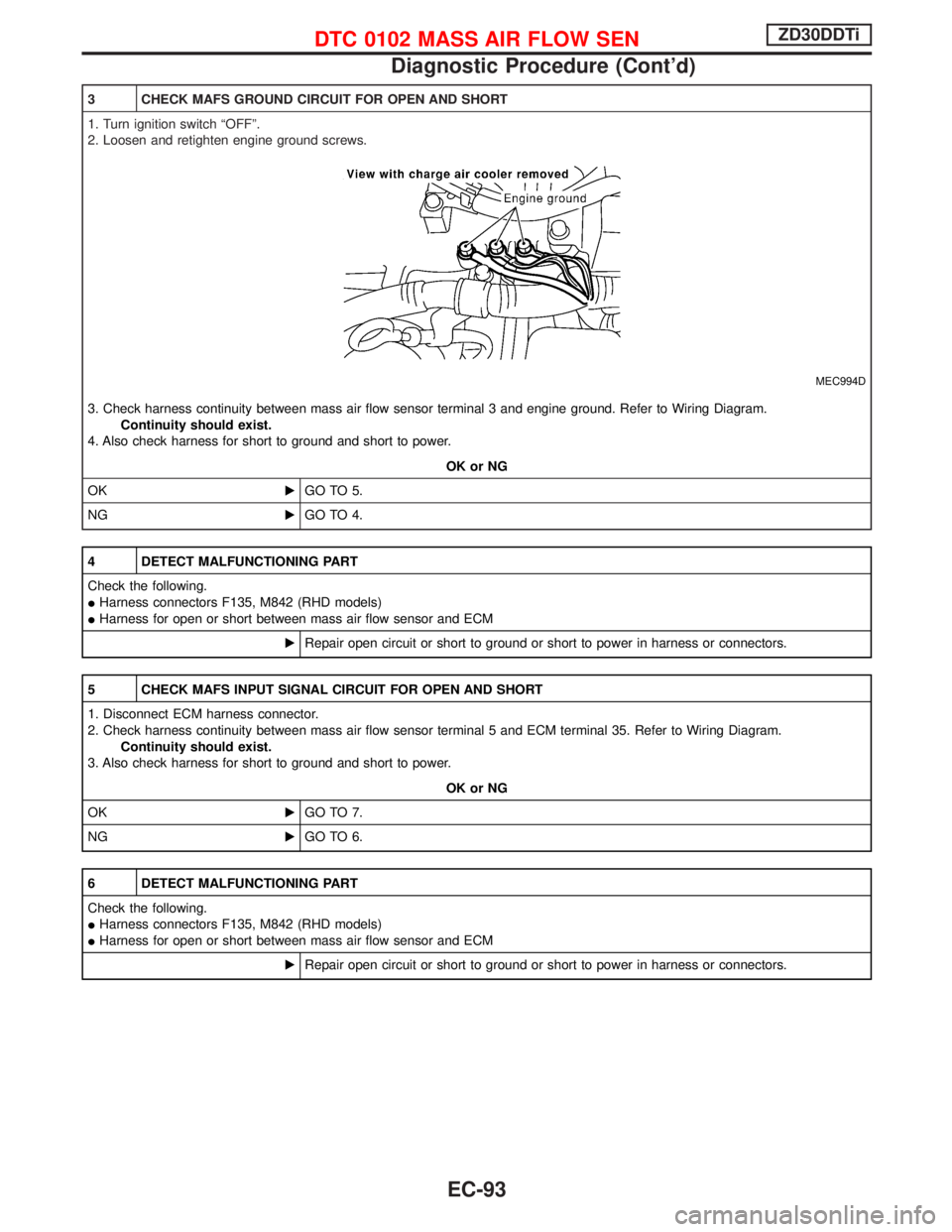

3 CHECK MAFS GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Loosen and retighten engine ground screws.

MEC994D

3. Check harness continuity between mass air flow sensor terminal 3 and engine ground. Refer to Wiring Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OKEGO TO 5.

NGEGO TO 4.

4 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors F135, M842 (RHD models)

IHarness for open or short between mass air flow sensor and ECM

ERepair open circuit or short to ground or short to power in harness or connectors.

5 CHECK MAFS INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between mass air flow sensor terminal 5 and ECM terminal 35. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OKEGO TO 7.

NGEGO TO 6.

6 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors F135, M842 (RHD models)

IHarness for open or short between mass air flow sensor and ECM

ERepair open circuit or short to ground or short to power in harness or connectors.

DTC 0102 MASS AIR FLOW SENZD30DDTi

Diagnostic Procedure (Cont'd)

EC-93

Page 456 of 1767

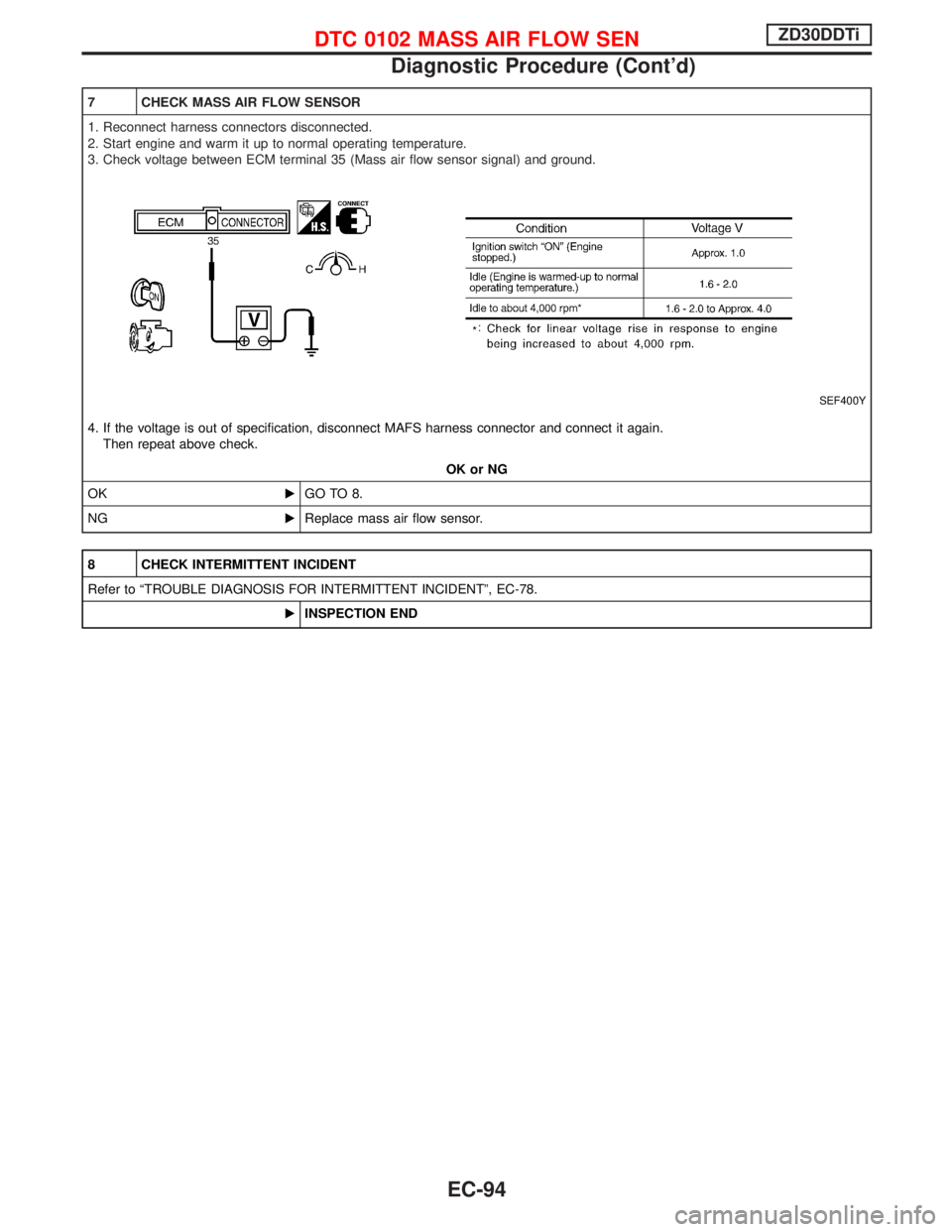

7 CHECK MASS AIR FLOW SENSOR

1. Reconnect harness connectors disconnected.

2. Start engine and warm it up to normal operating temperature.

3. Check voltage between ECM terminal 35 (Mass air flow sensor signal) and ground.

SEF400Y

4. If the voltage is out of specification, disconnect MAFS harness connector and connect it again.

Then repeat above check.

OK or NG

OKEGO TO 8.

NGEReplace mass air flow sensor.

8 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-78.

EINSPECTION END

DTC 0102 MASS AIR FLOW SENZD30DDTi

Diagnostic Procedure (Cont'd)

EC-94

Page 457 of 1767

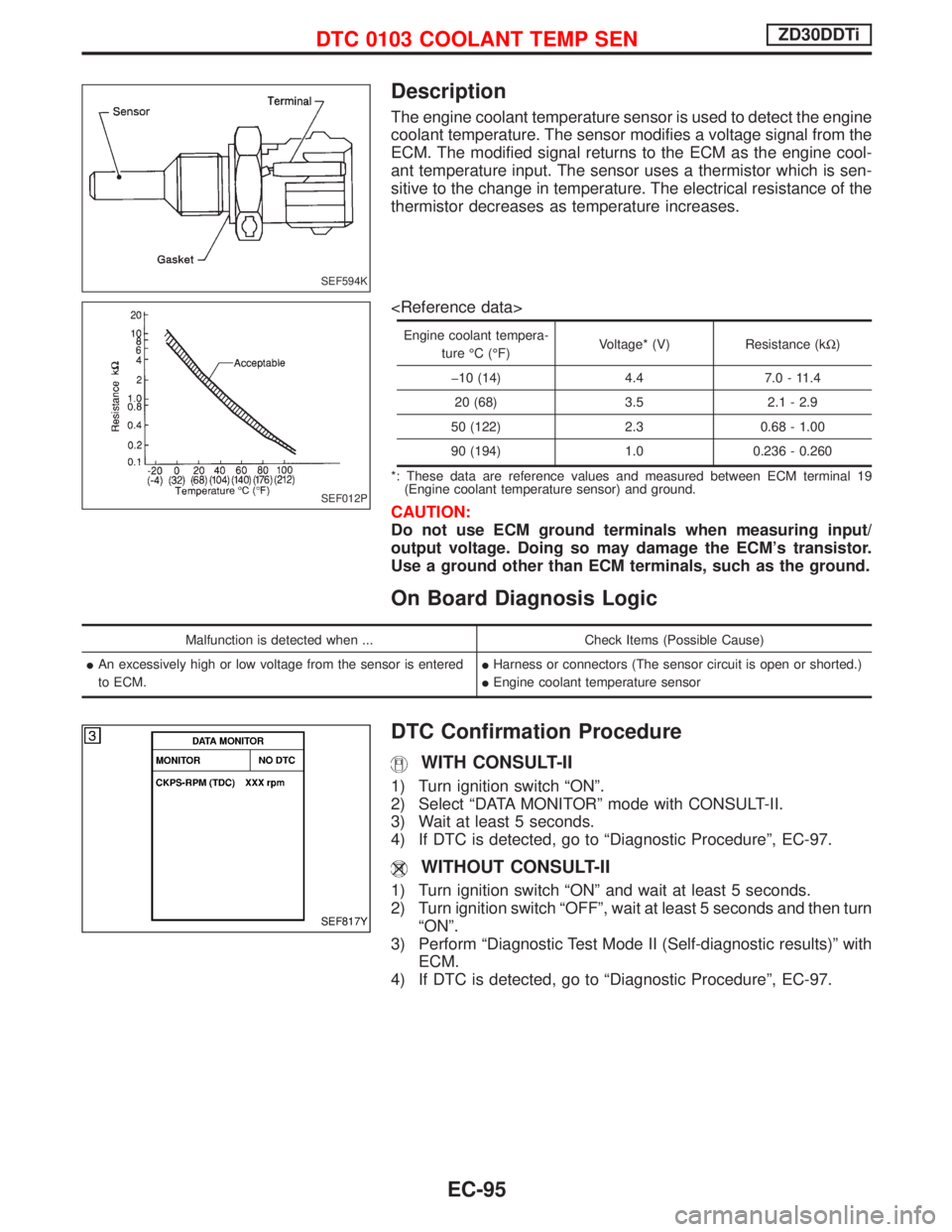

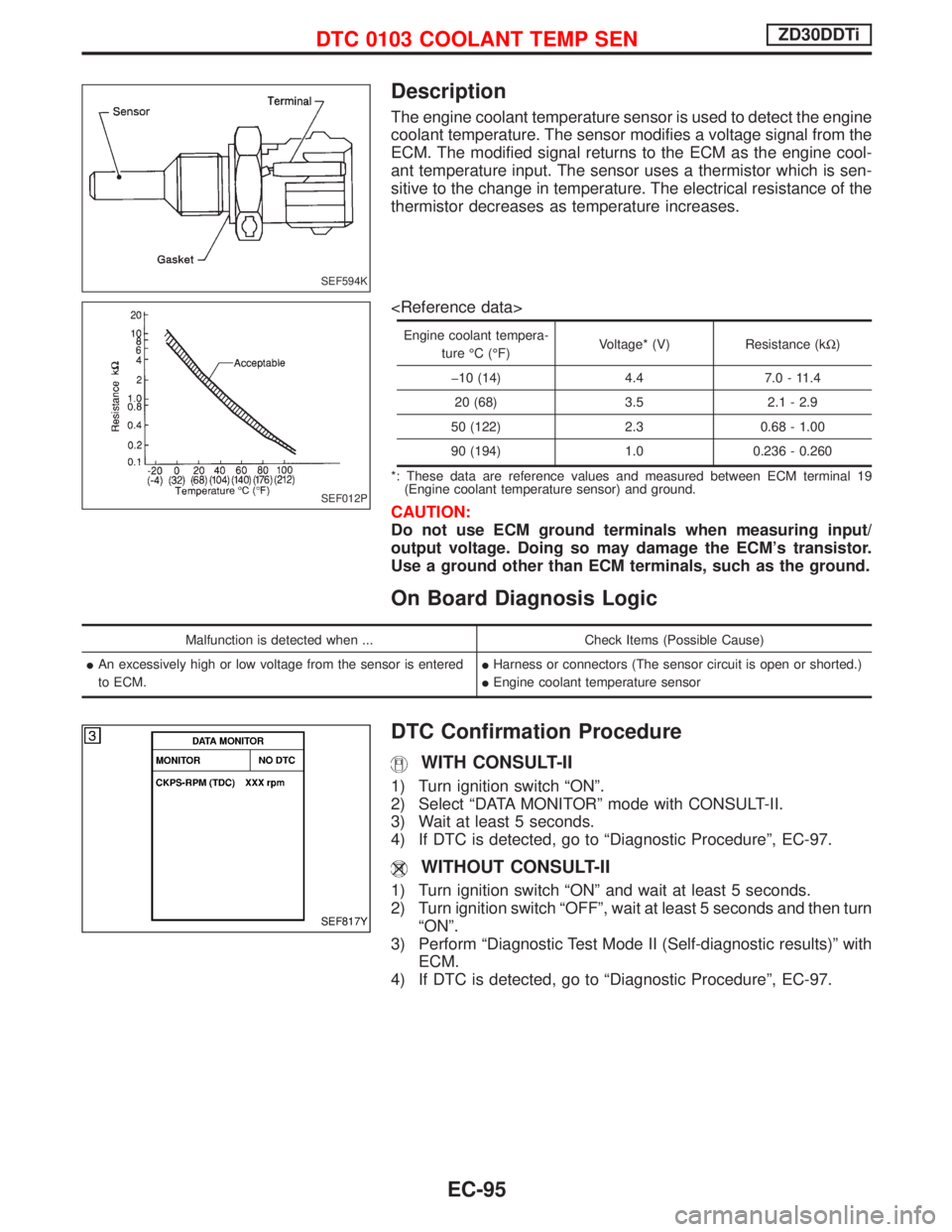

Description

The engine coolant temperature sensor is used to detect the engine

coolant temperature. The sensor modifies a voltage signal from the

ECM. The modified signal returns to the ECM as the engine cool-

ant temperature input. The sensor uses a thermistor which is sen-

sitive to the change in temperature. The electrical resistance of the

thermistor decreases as temperature increases.

Engine coolant tempera-

ture ÉC (ÉF)Voltage* (V) Resistance (kW)

þ10 (14) 4.4 7.0 - 11.4

20 (68) 3.5 2.1 - 2.9

50 (122) 2.3 0.68 - 1.00

90 (194) 1.0 0.236 - 0.260

*: These data are reference values and measured between ECM terminal 19

(Engine coolant temperature sensor) and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/

output voltage. Doing so may damage the ECM's transistor.

Use a ground other than ECM terminals, such as the ground.

On Board Diagnosis Logic

Malfunction is detected when ... Check Items (Possible Cause)

IAn excessively high or low voltage from the sensor is entered

to ECM.IHarness or connectors (The sensor circuit is open or shorted.)

IEngine coolant temperature sensor

DTC Confirmation Procedure

WITH CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Wait at least 5 seconds.

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-97.

WITHOUT CONSULT-II

1) Turn ignition switch ªONº and wait at least 5 seconds.

2) Turn ignition switch ªOFFº, wait at least 5 seconds and then turn

ªONº.

3) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with

ECM.

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-97.

SEF594K

SEF012P

SEF817Y

DTC 0103 COOLANT TEMP SENZD30DDTi

EC-95

Page 458 of 1767

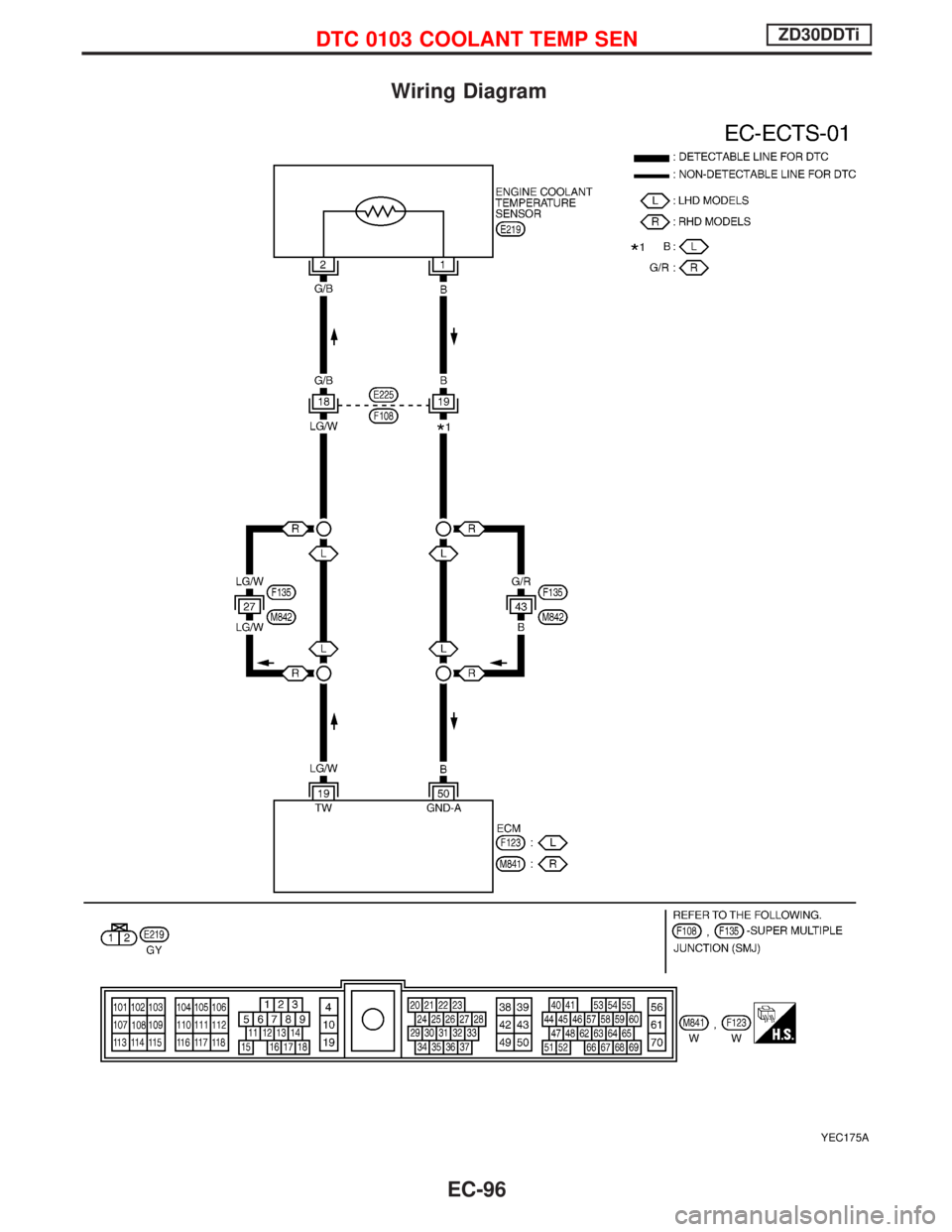

Wiring Diagram

YEC175A

DTC 0103 COOLANT TEMP SENZD30DDTi

EC-96

Page 459 of 1767

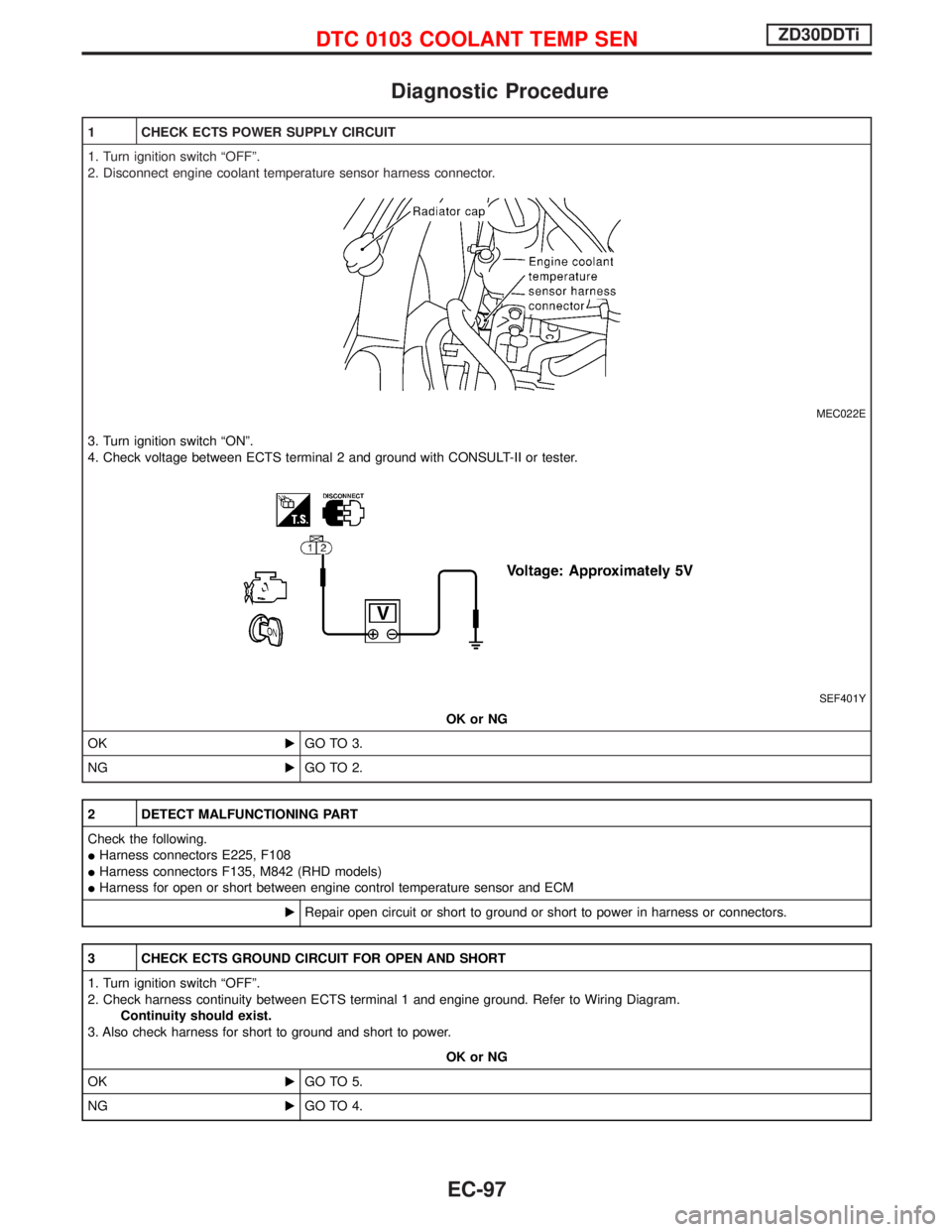

Diagnostic Procedure

1 CHECK ECTS POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect engine coolant temperature sensor harness connector.

MEC022E

3. Turn ignition switch ªONº.

4. Check voltage between ECTS terminal 2 and ground with CONSULT-II or tester.

SEF401Y

OK or NG

OKEGO TO 3.

NGEGO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors E225, F108

IHarness connectors F135, M842 (RHD models)

IHarness for open or short between engine control temperature sensor and ECM

ERepair open circuit or short to ground or short to power in harness or connectors.

3 CHECK ECTS GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Check harness continuity between ECTS terminal 1 and engine ground. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OKEGO TO 5.

NGEGO TO 4.

DTC 0103 COOLANT TEMP SENZD30DDTi

EC-97

Page 460 of 1767

4 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors E225, F108

IHarness connectors F135, M842 (RHD models)

IHarness for open or short between engine coolant temperature sensor and ECM

ERepair open circuit or short to ground or short to power in harness or connectors.

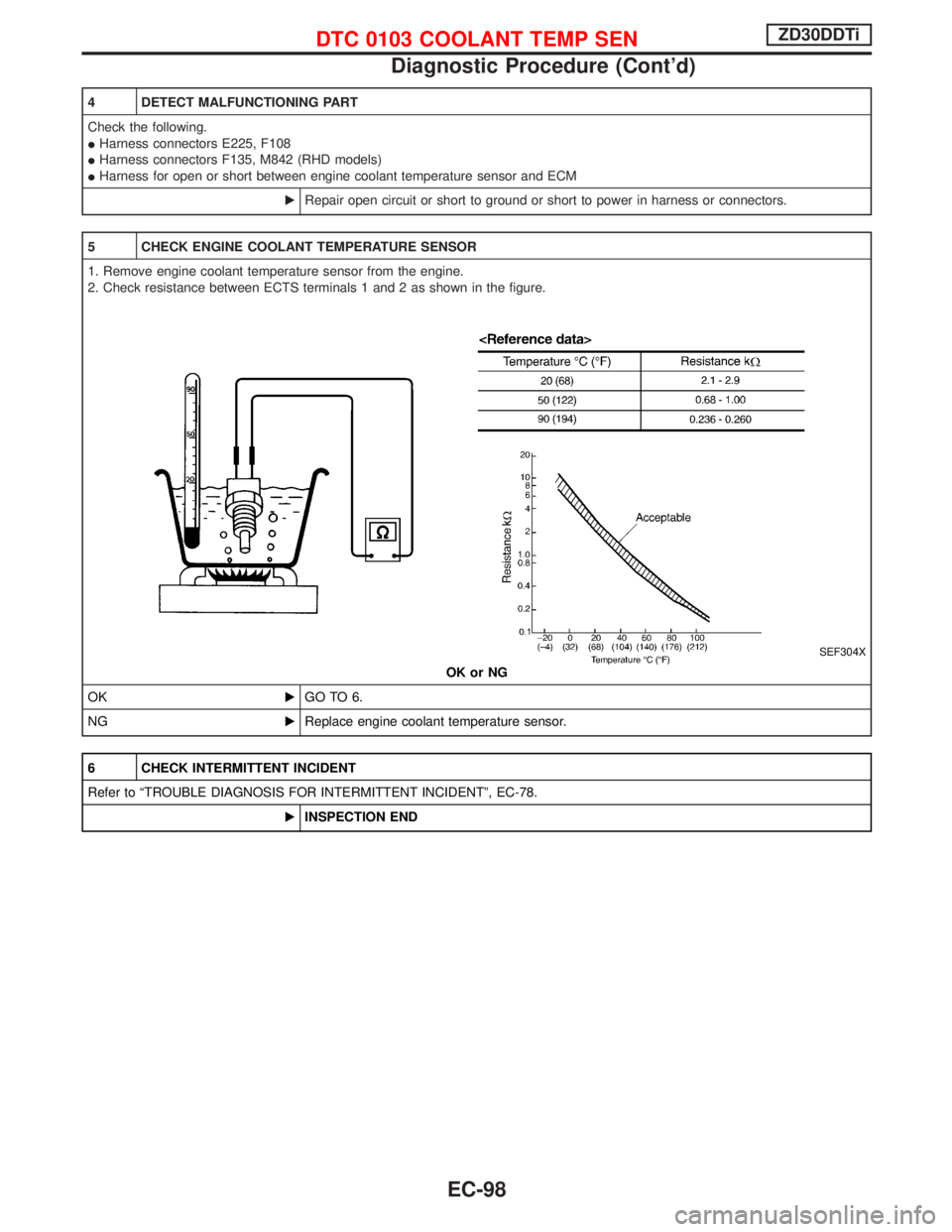

5 CHECK ENGINE COOLANT TEMPERATURE SENSOR

1. Remove engine coolant temperature sensor from the engine.

2. Check resistance between ECTS terminals 1 and 2 as shown in the figure.

SEF304X

OK or NG

OKEGO TO 6.

NGEReplace engine coolant temperature sensor.

6 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-78.

EINSPECTION END

DTC 0103 COOLANT TEMP SENZD30DDTi

Diagnostic Procedure (Cont'd)

EC-98

Trending: check oil, recommended oil, remote, clutch, low beam, spare wheel, headrest