engine NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 1297 of 1767

Inspection and Adjustment

WHEEL ALIGNMENT (Unladen *1)

Applied model HardtopHardtop

vanWagon

Camber degree 0É30¢ 30¢

Caster degree 0É29¢ 30¢0É30¢ 30¢0É30¢ 30¢

Kingpin inclination degree 12É37¢

Total toe-in

Radial tire mm (in)3to5

(0.12 to

0.20)3.5 to 5.5

(0.14 to

0.22)3to5

(0.12 to

0.20)

Front wheel turning angle

Full turn

inside 34É27¢

outside 33É38¢

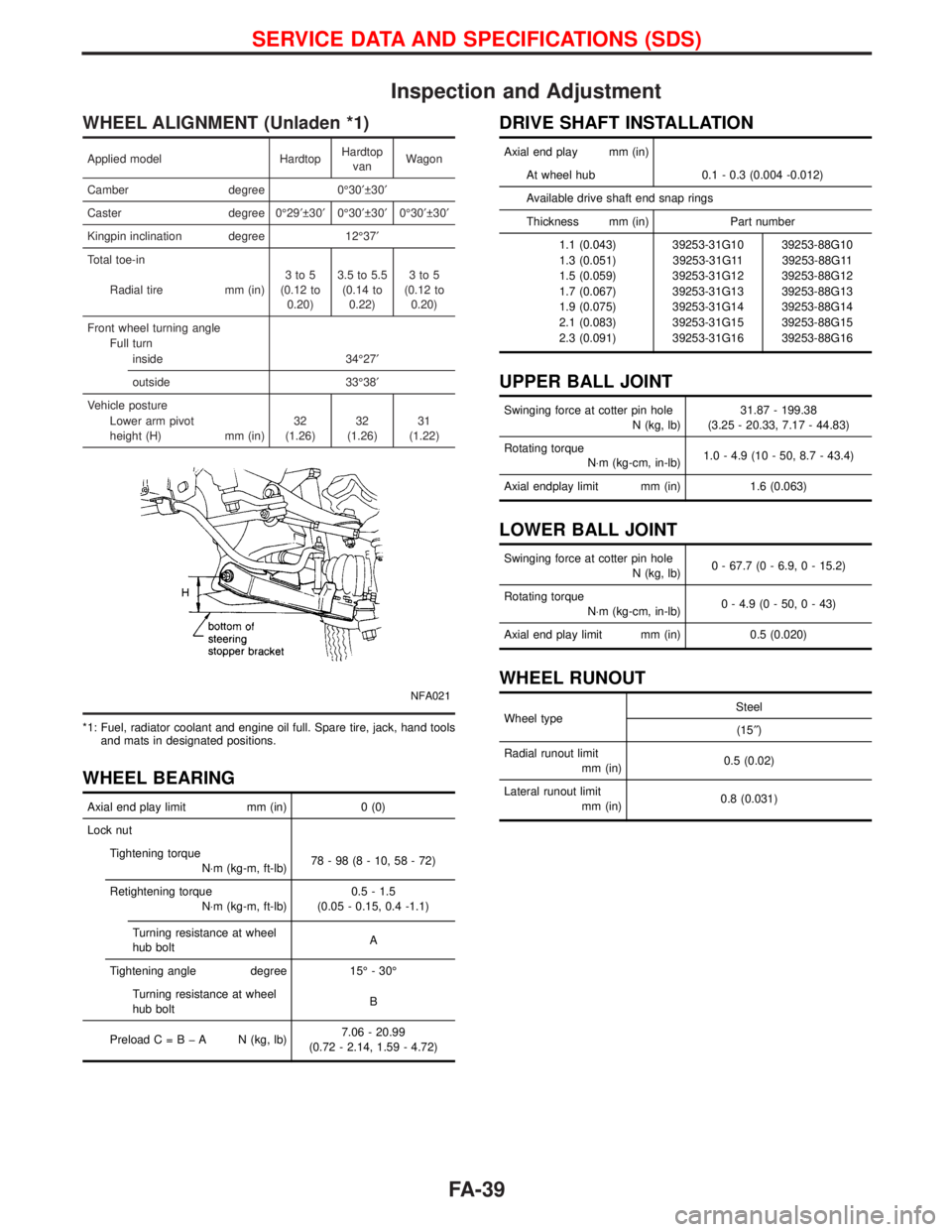

Vehicle posture

Lower arm pivot

height (H) mm (in)32

(1.26)32

(1.26)31

(1.22)

NFA021

*1: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools

and mats in designated positions.

WHEEL BEARING

Axial end play limit mm (in) 0 (0)

Lock nut

Tightening torque

N×m (kg-m, ft-lb)78-98(8-10,58-72)

Retightening torque

N×m (kg-m, ft-lb)0.5 - 1.5

(0.05 - 0.15, 0.4 -1.1)

Turning resistance at wheel

hub boltA

Tightening angle degree 15É - 30É

Turning resistance at wheel

hub boltB

PreloadC=BþA N(kg, lb)7.06 - 20.99

(0.72 - 2.14, 1.59 - 4.72)

DRIVE SHAFT INSTALLATION

Axial end play mm (in)

At wheel hub 0.1 - 0.3 (0.004 -0.012)

Available drive shaft end snap rings

Thickness mm (in) Part number

1.1 (0.043) 39253-31G10 39253-88G10

1.3 (0.051) 39253-31G11 39253-88G11

1.5 (0.059) 39253-31G12 39253-88G12

1.7 (0.067) 39253-31G13 39253-88G13

1.9 (0.075) 39253-31G14 39253-88G14

2.1 (0.083) 39253-31G15 39253-88G15

2.3 (0.091) 39253-31G16 39253-88G16

UPPER BALL JOINT

Swinging force at cotter pin hole

N (kg, lb)31.87 - 199.38

(3.25 - 20.33, 7.17 - 44.83)

Rotating torque

N×m (kg-cm, in-lb)1.0 - 4.9 (10 - 50, 8.7 - 43.4)

Axial endplay limit mm (in) 1.6 (0.063)

LOWER BALL JOINT

Swinging force at cotter pin hole

N (kg, lb)0 - 67.7 (0 - 6.9, 0 - 15.2)

Rotating torque

N×m (kg-cm, in-lb)0 - 4.9 (0 - 50, 0 - 43)

Axial end play limit mm (in) 0.5 (0.020)

WHEEL RUNOUT

Wheel typeSteel

(15²)

Radial runout limit

mm (in)0.5 (0.02)

Lateral runout limit

mm (in)0.8 (0.031)

SERVICE DATA AND SPECIFICATIONS (SDS)

FA-39

Page 1300 of 1767

Removal and Installation

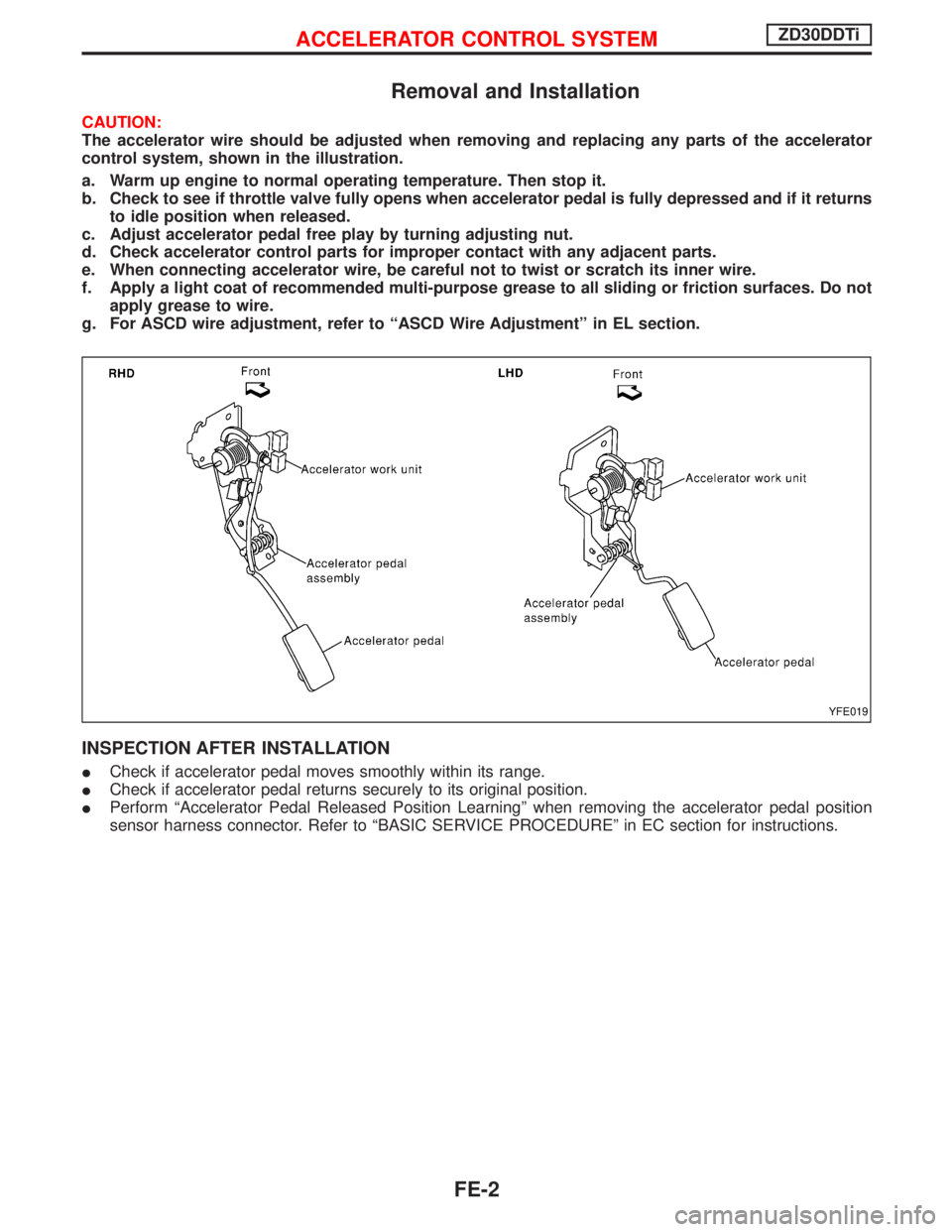

CAUTION:

The accelerator wire should be adjusted when removing and replacing any parts of the accelerator

control system, shown in the illustration.

a. Warm up engine to normal operating temperature. Then stop it.

b. Check to see if throttle valve fully opens when accelerator pedal is fully depressed and if it returns

to idle position when released.

c. Adjust accelerator pedal free play by turning adjusting nut.

d. Check accelerator control parts for improper contact with any adjacent parts.

e. When connecting accelerator wire, be careful not to twist or scratch its inner wire.

f. Apply a light coat of recommended multi-purpose grease to all sliding or friction surfaces. Do not

apply grease to wire.

g. For ASCD wire adjustment, refer to ªASCD Wire Adjustmentº in EL section.

INSPECTION AFTER INSTALLATION

ICheck if accelerator pedal moves smoothly within its range.

ICheck if accelerator pedal returns securely to its original position.

IPerform ªAccelerator Pedal Released Position Learningº when removing the accelerator pedal position

sensor harness connector. Refer to ªBASIC SERVICE PROCEDUREº in EC section for instructions.

YFE019

ACCELERATOR CONTROL SYSTEMZD30DDTi

FE-2

Page 1303 of 1767

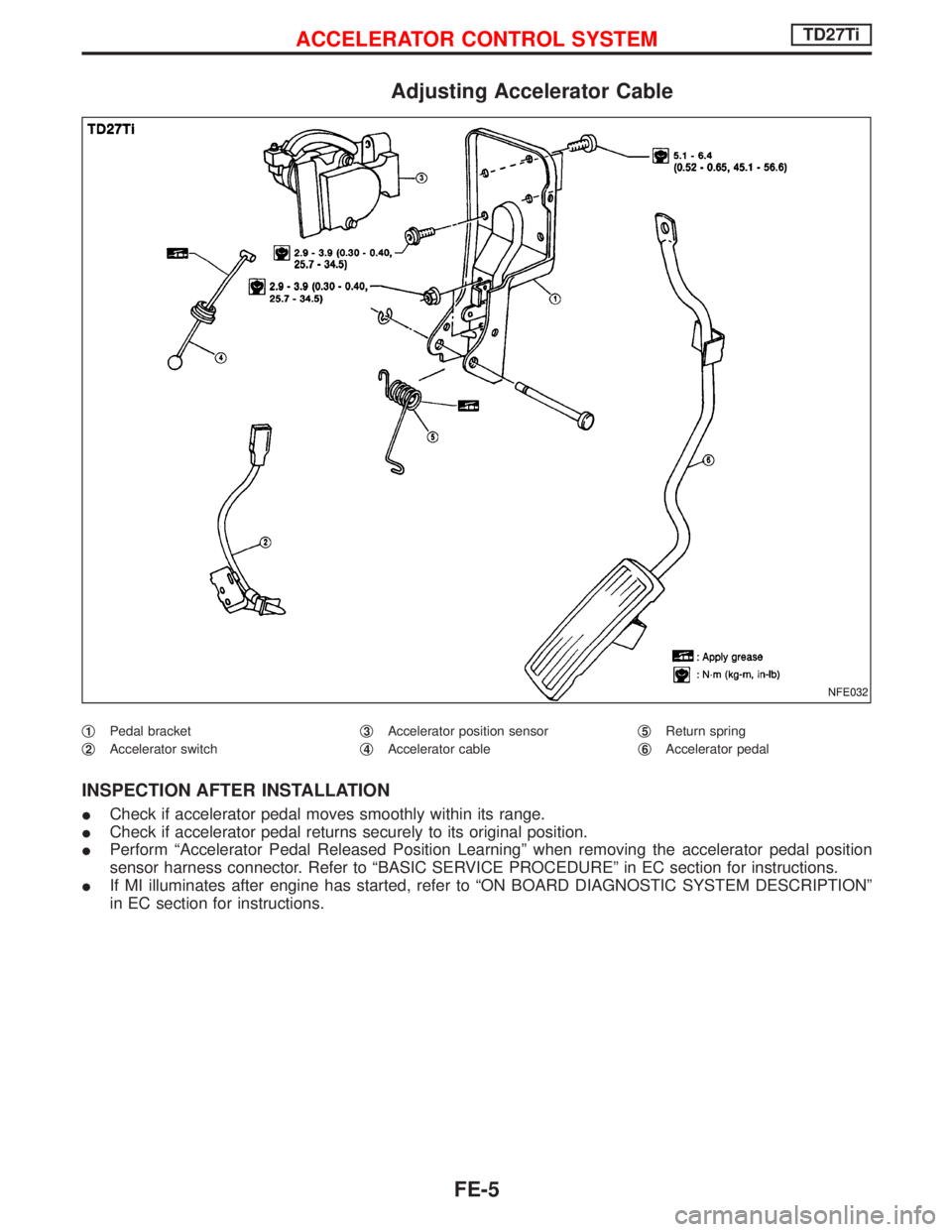

Adjusting Accelerator Cable

q1Pedal bracket

q

2Accelerator switchq

3Accelerator position sensor

q

4Accelerator cableq

5Return spring

q

6Accelerator pedal

INSPECTION AFTER INSTALLATION

ICheck if accelerator pedal moves smoothly within its range.

ICheck if accelerator pedal returns securely to its original position.

IPerform ªAccelerator Pedal Released Position Learningº when removing the accelerator pedal position

sensor harness connector. Refer to ªBASIC SERVICE PROCEDUREº in EC section for instructions.

IIf MI illuminates after engine has started, refer to ªON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONº

in EC section for instructions.

NFE032

ACCELERATOR CONTROL SYSTEMTD27Ti

FE-5

Page 1305 of 1767

WARNING:

When replacing fuel line parts, be sure to observe the following:

IDisplay a ªCAUTION:INFLAMMABLEº sign in workshop.

IBe sure to furnish workshop with a CO

2fire extinguisher service.

IDo not smoke while servicing fuel system. Keep open flames and sparks away from work area.

IBe sure to disconnect battery ground cable before conducting operations.

IPour drained fuel into an explosion-proof container, then ensure container lid is installed securely.

CAUTION:

IFor ECM models, release fuel pressure from fuel line. Refer to EC section (ªFuel Pressure Releaseº,

ªBASIC SERVICE PROCEDUREº).

IDo not disconnect any fuel line unless absolutely necessary.

IPlug hose and pipe openings to prevent entry of dust or dirt.

IAlways replace top lid seal and hose clamps with new ones.

IDo not kink or twist hoses and tubes during installation.

IDo not tighten hose clamps excessively because this could cause damage to the hose.

IEnsure fuel check valve is installed in the correct orientation.

IRefer to EC section (ªFUEL CHECK VALVEº, ªEVAPORATIVE EMISSION SYSTEMº).

IAfter installation, run engine and check for fuel leaks at connections.

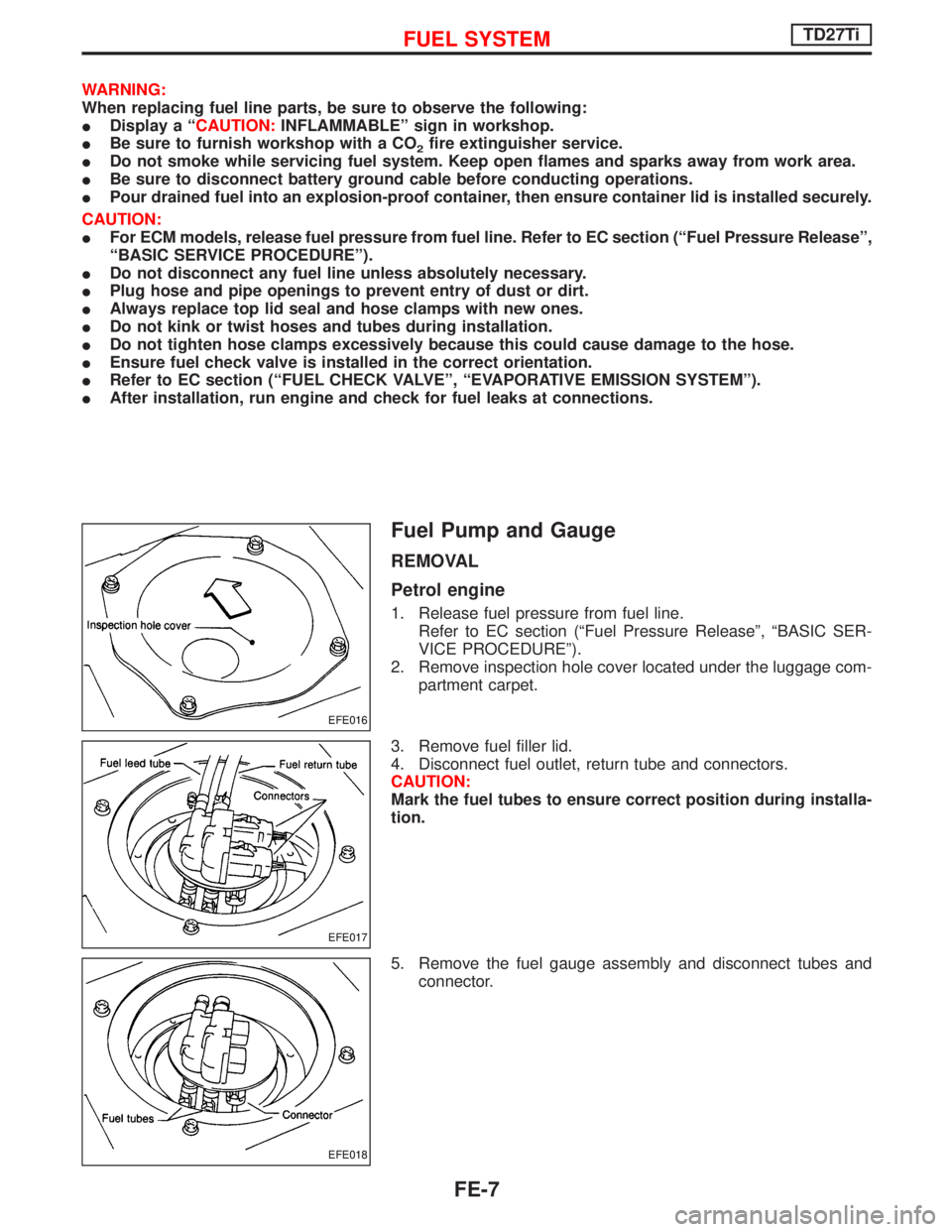

Fuel Pump and Gauge

REMOVAL

Petrol engine

1. Release fuel pressure from fuel line.

Refer to EC section (ªFuel Pressure Releaseº, ªBASIC SER-

VICE PROCEDUREº).

2. Remove inspection hole cover located under the luggage com-

partment carpet.

3. Remove fuel filler lid.

4. Disconnect fuel outlet, return tube and connectors.

CAUTION:

Mark the fuel tubes to ensure correct position during installa-

tion.

5. Remove the fuel gauge assembly and disconnect tubes and

connector.

EFE016

EFE017

EFE018

FUEL SYSTEMTD27Ti

FE-7

Page 1306 of 1767

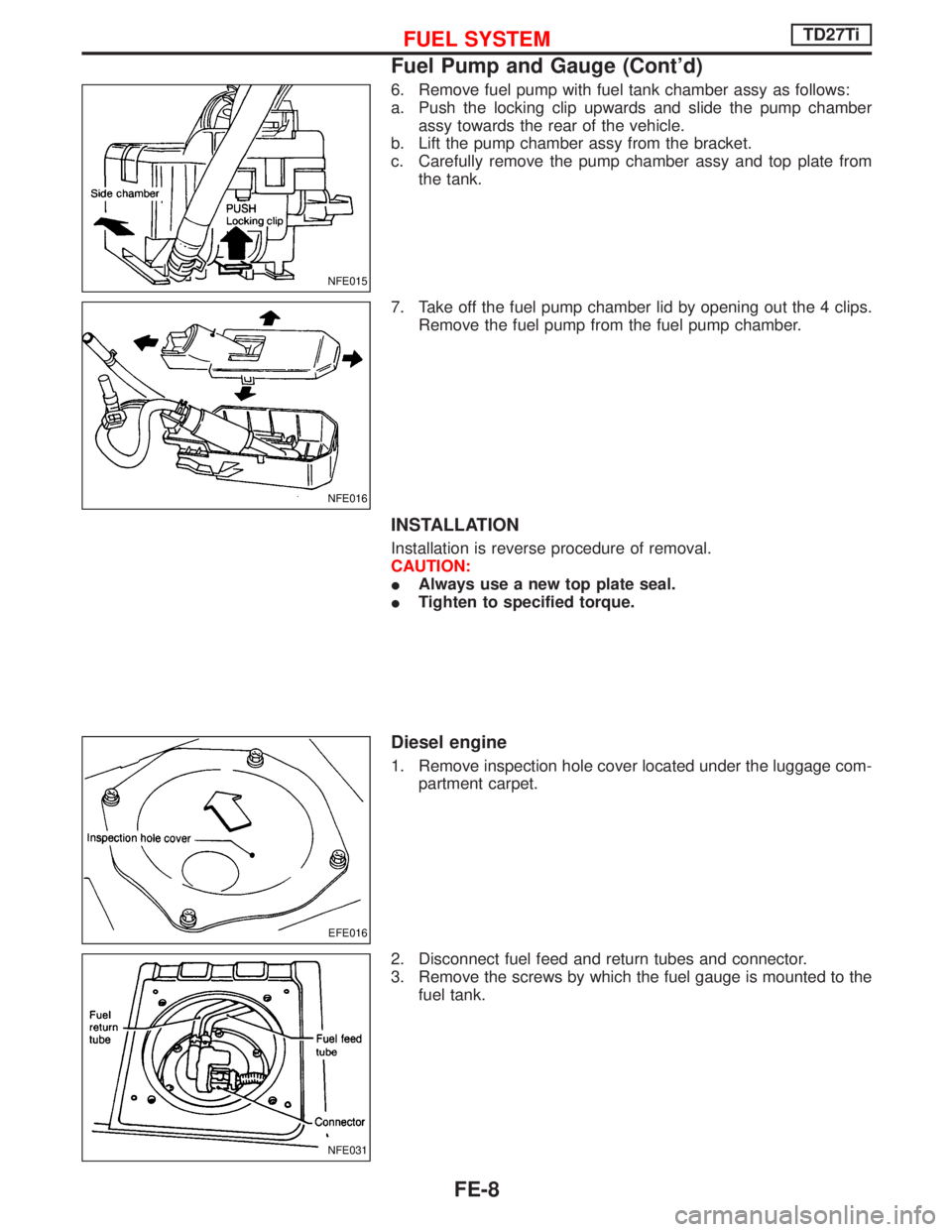

6. Remove fuel pump with fuel tank chamber assy as follows:

a. Push the locking clip upwards and slide the pump chamber

assy towards the rear of the vehicle.

b. Lift the pump chamber assy from the bracket.

c. Carefully remove the pump chamber assy and top plate from

the tank.

7. Take off the fuel pump chamber lid by opening out the 4 clips.

Remove the fuel pump from the fuel pump chamber.

INSTALLATION

Installation is reverse procedure of removal.

CAUTION:

IAlways use a new top plate seal.

ITighten to specified torque.

Diesel engine

1. Remove inspection hole cover located under the luggage com-

partment carpet.

2. Disconnect fuel feed and return tubes and connector.

3. Remove the screws by which the fuel gauge is mounted to the

fuel tank.

NFE015

NFE016

EFE016

NFE031

FUEL SYSTEMTD27Ti

Fuel Pump and Gauge (Cont'd)

FE-8

Page 1308 of 1767

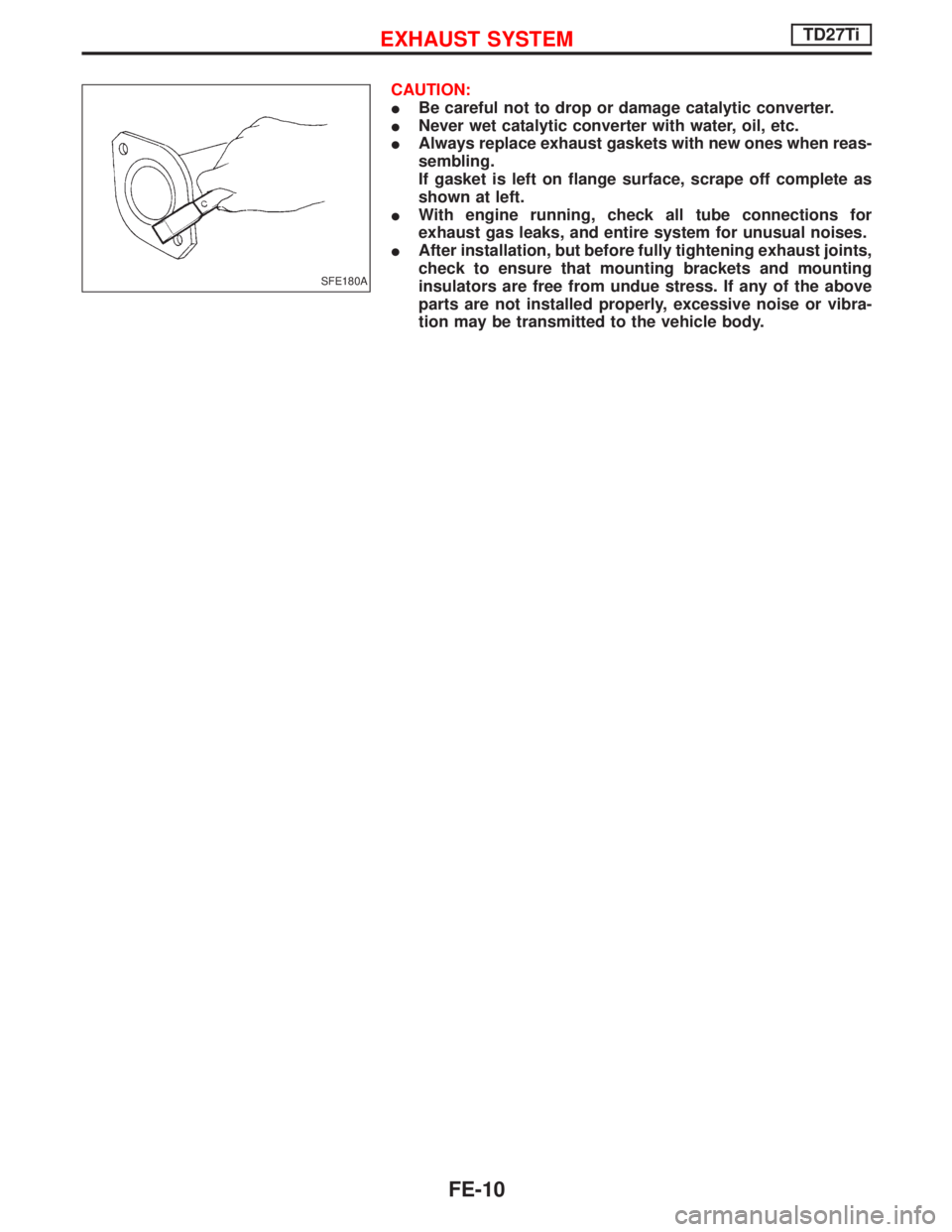

CAUTION:

IBe careful not to drop or damage catalytic converter.

INever wet catalytic converter with water, oil, etc.

IAlways replace exhaust gaskets with new ones when reas-

sembling.

If gasket is left on flange surface, scrape off complete as

shown at left.

IWith engine running, check all tube connections for

exhaust gas leaks, and entire system for unusual noises.

IAfter installation, but before fully tightening exhaust joints,

check to ensure that mounting brackets and mounting

insulators are free from undue stress. If any of the above

parts are not installed properly, excessive noise or vibra-

tion may be transmitted to the vehicle body.

SFE180A

EXHAUST SYSTEMTD27Ti

FE-10

Page 1311 of 1767

PLEASE HELP US TO IMPROVE THIS

SERVICE MANUAL ON CD!

Your comments are important to NISSAN and will help us to improve our

Service Manuals on CD. Use this form to report any issues or comments you

may have regarding this Service Manual publication.

Please print this form and type or print your comments below. Mail or fax to:

NISSANEUROP EN.V.

S320 Service Engineering

2, Avenue de Denis Papin

ZIPEC - F92350 Le Plessis Robinson

France

Fax :+ 33 (0) 1 41 07 16 81

SERVICE MANUAL: Model:Language:

Publication Number:

Please describe any issues or problems in detail:

Page number(s):

Note: Please include acopy ofeach page, marked withyour comments.

Is the organization of the manual clear and easy to follow? (circle your answer) YES NO

Please comment:

What information should be included in NISSAN Service Manuals to better support you in

servicing or repairing customer vehicles?

Date :

Your Name :Position :

Dealer :Dealer No. :

Address :

City :Country :

Telephone :

Fax :

E-mail :

Page 1316 of 1767

GENERAL INFORMATION

SECTION

GI

CONTENTS

PRECAUTIONS...............................................................2

Supplemental Restraint System (SRS)²AIR

BAG²and²SEAT BELT PRE-TENSIONER²

(Dual Air Bag System) .................................................3

Precautions for NATS ..................................................4

Precautions for Multiport Fuel Injection System

or Engine Control System ...........................................5

Precautions for Catalyst ..............................................5

Precautions for Turbocharger ......................................5

Precautions for Fuel ....................................................6

Precautions for Engine Oils .........................................6

HOW TO USE THIS MANUAL........................................8

HOW TO READ WIRING DIAGRAMS..........................10

Sample/Wiring Diagram - EXAMPL - ........................10

Description .................................................................12

HOW TO CHECK TERMINAL.......................................19

How to Probe Connectors .........................................19

How to Check Enlarged Contact Spring of

Terminal .....................................................................20

Waterproof Connector Inspection ..............................21

Terminal Lock Inspection ...........................................21

HOW TO PERFORM EFFICIENT DIAGNOSIS FOR

AN ELECTRICAL INCIDENT........................................22Work Flow ..................................................................22

Incident Simulation Tests ...........................................23

HOW TO FOLLOW FLOW CHART IN TROUBLE

DIAGNOSES..................................................................25

CONSULT-II CHECKING SYSTEM...............................26

General ......................................................................26

Function and System Application ..............................26

Nickel Metal Hydride Battery Replacement...............27

Checking Equipment..................................................27

IDENTIFICATION INFORMATION.................................28

Model Variation ..........................................................28

Identification Number .................................................29

Dimensions ................................................................31

Wheels and Tires .......................................................31

LIFTING POINTS AND TOW TRUCK TOWING...........32

Garage Jack and Safety Stand .................................32

Screw Jack ................................................................32

4-pole Lift ...................................................................33

Tow Truck Towing ......................................................33

ISO 15031-2 TERMINOLOGY LIST..............................35

ISO 15031-2 Terminology List ...................................35

TIGHTENING TORQUE OF STANDARD BOLTS........38

Page 1317 of 1767

Observe the following precautions to ensure safe and proper

servicing. These precautions are not described in each indi-

vidual section.

1. Do not operate the engine for an extended period of time with-

out proper exhaust ventilation.

Keep the work area well ventilated and free of any inflammable

materials. Special care should be taken when handling any

inflammable or poisonous materials, such as gasoline, refriger-

ant gas, etc. When working in a pit or other enclosed area, be

sure to properly ventilate the area before working with hazard-

ous materials.

Do not smoke while working on the vehicle.

2. Before jacking up the vehicle, apply wheel chocks or other tire

blocks to the wheels to prevent the vehicle from moving. After

jacking up the vehicle, support the vehicle weight with safety

stands at the points designated for proper lifting and towing

before working on the vehicle.

These operations should be done on a level surface.

3. When removing a heavy component such as the engine or

transaxle/transmission, take care not to lose your balance and

drop it. Also, do not allow it to strike adjacent parts, especially

the brake tubes and master cylinder.

4. Before starting repairs which do not require battery power,

always turn off the ignition switch, then disconnect the ground

cable from the battery to prevent accidental short circuit.

5. To prevent serious burns, avoid contact with hot metal parts

such as the radiator, exhaust manifold, tail pipe and muffler. Do

not remove the radiator cap when the engine is hot.

SGI285

SGI231

SGI232

SGI233

PRECAUTIONS

GI-2

Page 1319 of 1767

insulation (either just before the harness connectors or for

the complete harness), for easy identification.

Precautions for NATS

NATS (Nissan Anti-Theft System)

NATS will immobilize the engine if someone tries to start it without

the registered key of NATS.

Both of the originally supplied ignition key IDs have been NATS

registered.

The NATS security indicator is located on the instrument panel. The

indicator blinks when the ignition switch is in ªOFFº or ªACCº posi-

tion. Therefore, NATS warns outsiders that the vehicle is equipped

with the anti-theft system.

IWhen NATS detects trouble, the malfunction indicator lamp

(MIL) blinks.

This blinking indicates that the anti-theft is not functioning, so

prompt service is required.

IIf the malfunction indicator lamp comes on while the engine is

running, return the vehicle to the workshop before turning the

ignition switch ªOFFº.

Once the ignition switch is turned ªOFFº, the engine can not be

started.

IWhen servicing NATS (trouble diagnoses, system initialization

and additional registration of other NATS ignition key IDs) CON-

SULT-II hardware and CONSULT-II NATS software is neces-

sary.

Regarding the procedures of NATS initialization and NATS igni-

tion key ID registration, refer to CONSULT-II operation manual,

NATS.

Therefore, CONSULT-II NATS software (program card and

operation manual) must be kept strictly confidential to main-

tain the integrity of the anti-theft function.

IWhen servicing NATS (trouble diagnoses, system initialization

and additional registration of other NATS ignition key IDs), it

may be necessary to re-register original key identification.

Therefore, be sure to receive all keys from vehicle owner.

A maximum of five key IDs can be registered into NATS.

IWhen failing to start the engine first-time using the key of

NATS, starts as follows:

(1) Turn ignition key to ªOFFº.

(2) Wait approx. 5 seconds.

(3) Turn ignition key to ªSTARTº again while keeping the key

apart from any others on key-chain.

SGI916

PRECAUTIONS

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

(Dual Air Bag System) (Cont'd)

GI-4