engine NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 1371 of 1767

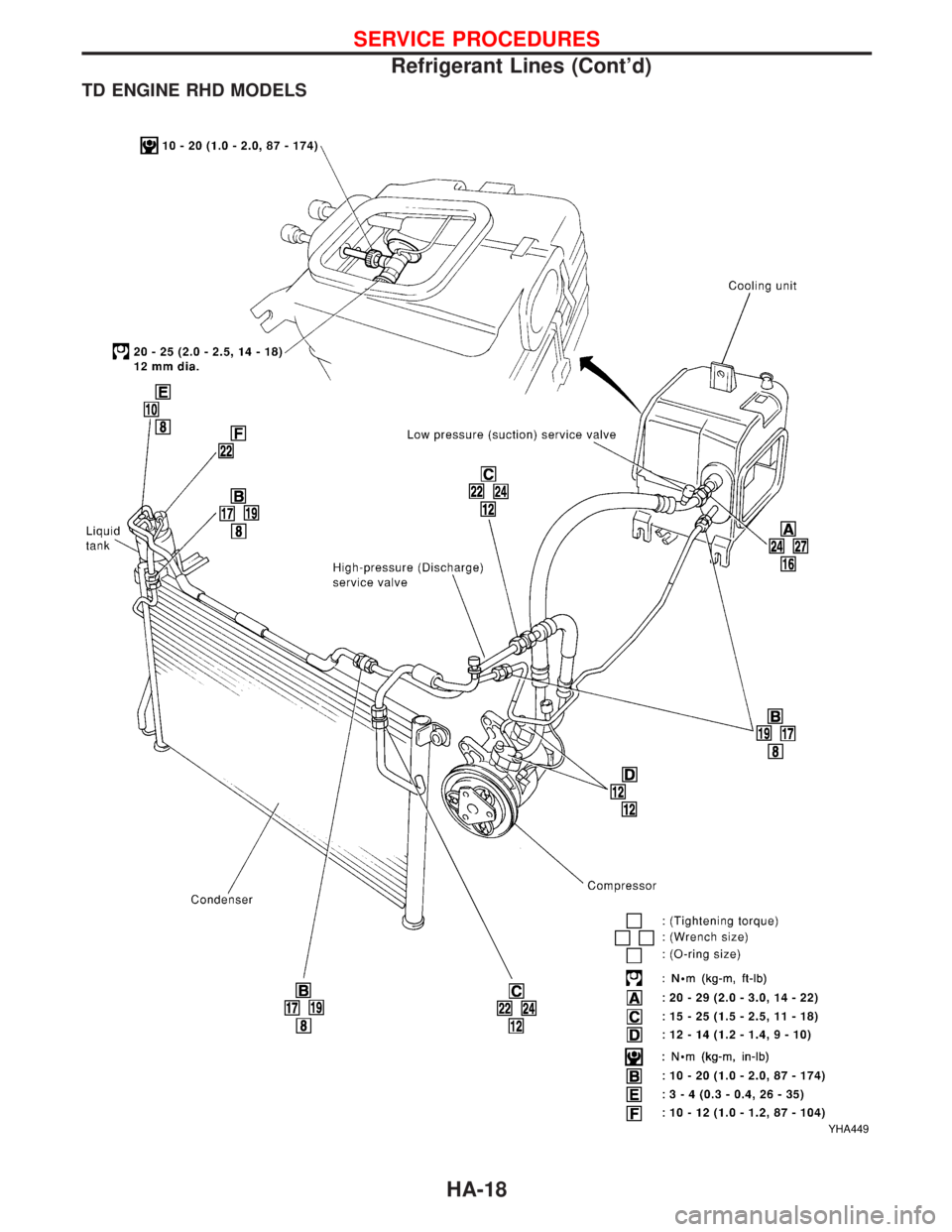

TD ENGINE RHD MODELS

YHA449

SERVICE PROCEDURES

Refrigerant Lines (Cont'd)

HA-18

Page 1372 of 1767

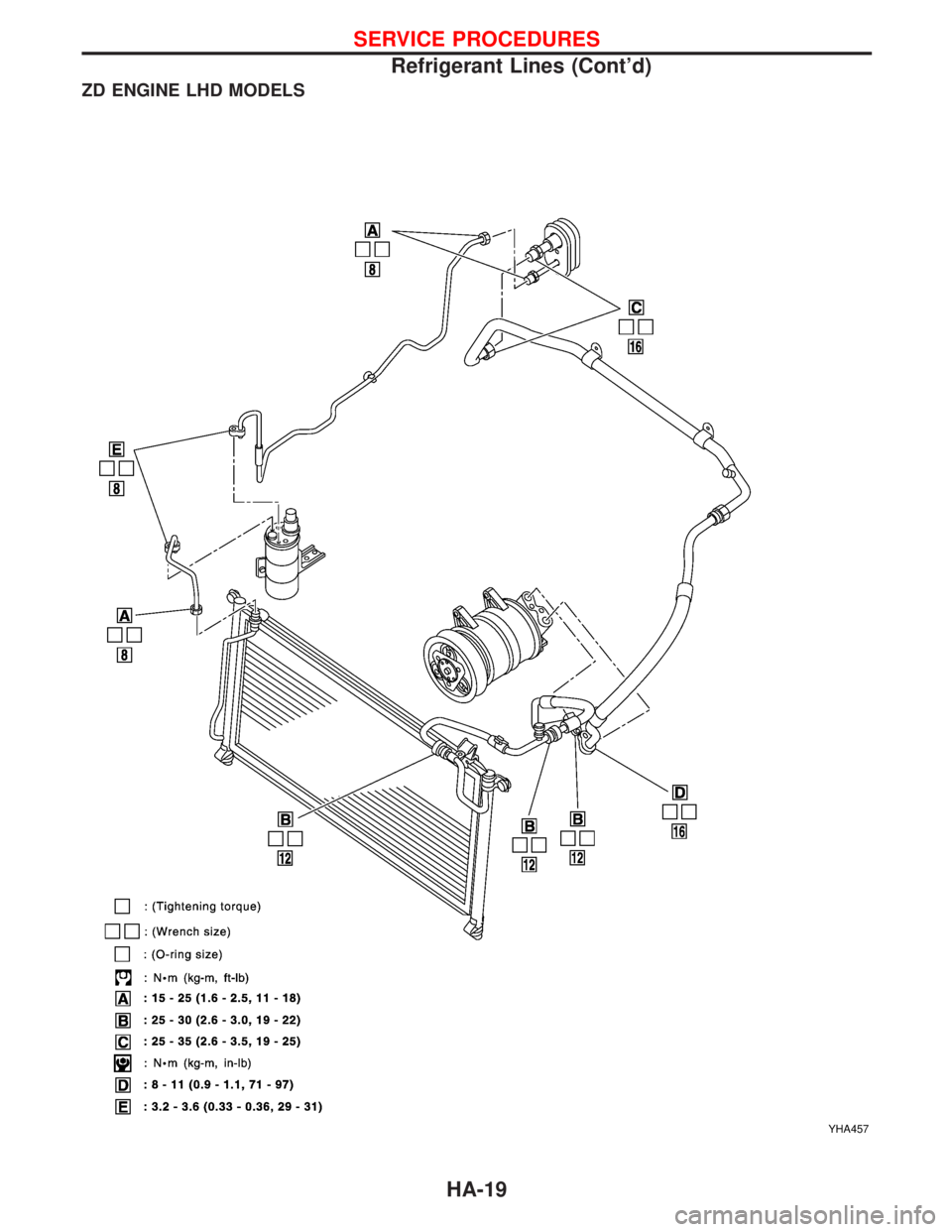

ZD ENGINE LHD MODELS

YHA457

SERVICE PROCEDURES

Refrigerant Lines (Cont'd)

HA-19

Page 1373 of 1767

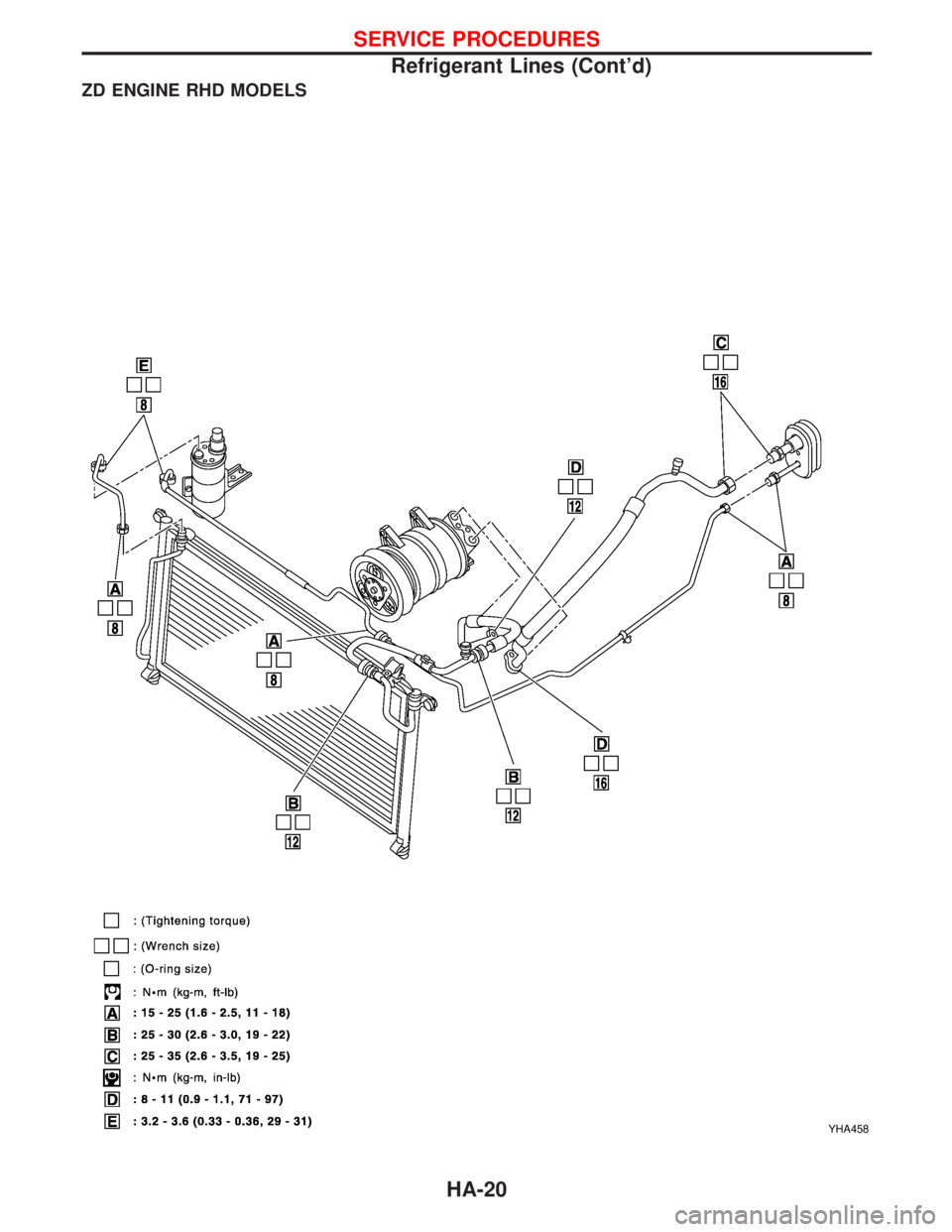

ZD ENGINE RHD MODELS

YHA458

SERVICE PROCEDURES

Refrigerant Lines (Cont'd)

HA-20

Page 1375 of 1767

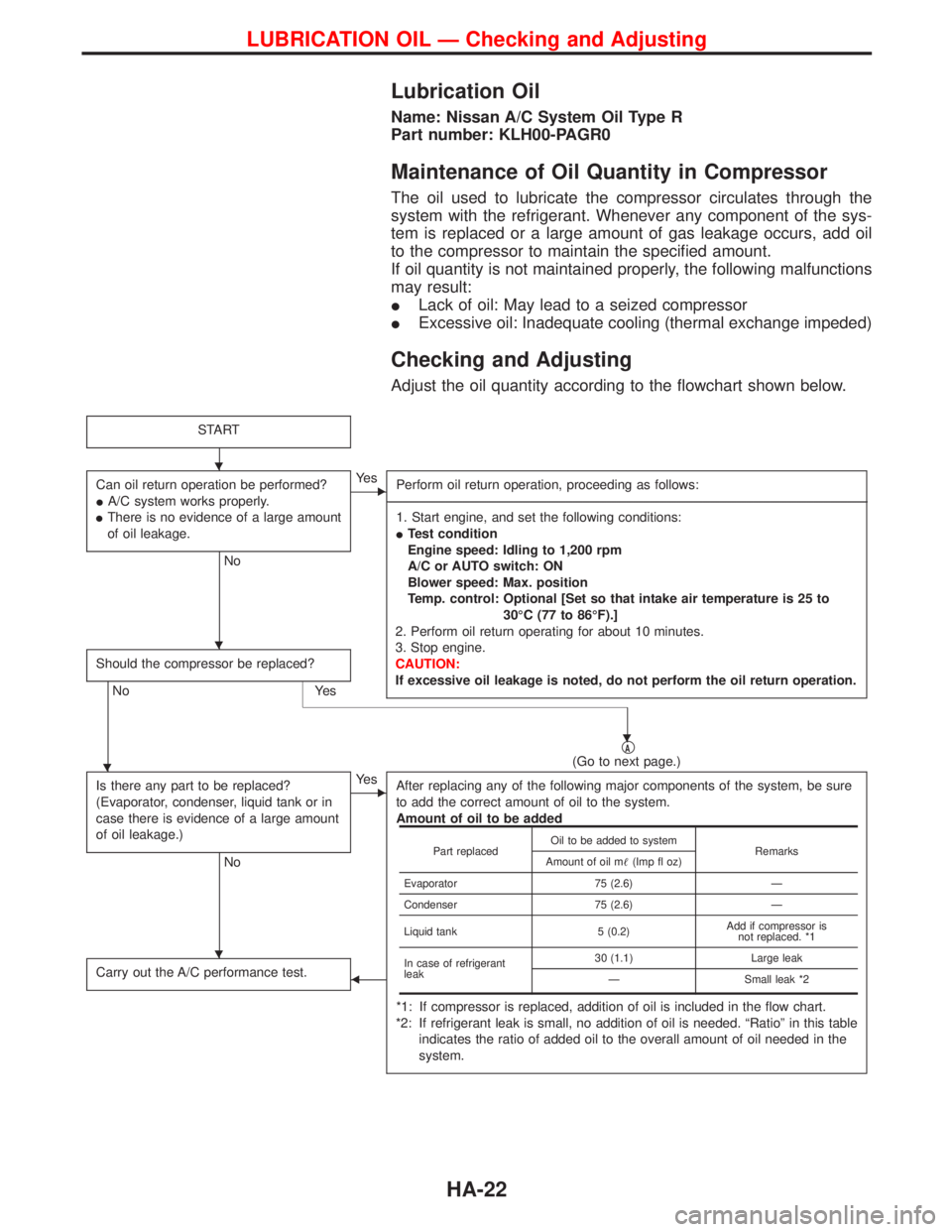

Lubrication Oil

Name: Nissan A/C System Oil Type R

Part number: KLH00-PAGR0

Maintenance of Oil Quantity in Compressor

The oil used to lubricate the compressor circulates through the

system with the refrigerant. Whenever any component of the sys-

tem is replaced or a large amount of gas leakage occurs, add oil

to the compressor to maintain the specified amount.

If oil quantity is not maintained properly, the following malfunctions

may result:

ILack of oil: May lead to a seized compressor

IExcessive oil: Inadequate cooling (thermal exchange impeded)

Checking and Adjusting

Adjust the oil quantity according to the flowchart shown below.

START

Can oil return operation be performed?

IA/C system works properly.

IThere is no evidence of a large amount

of oil leakage.

No

EYe s

Perform oil return operation, proceeding as follows:

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1. Start engine, and set the following conditions:

ITest condition

Engine speed: Idling to 1,200 rpm

A/C or AUTO switch: ON

Blower speed: Max. position

Temp. control: Optional [Set so that intake air temperature is 25 to

30ÉC (77 to 86ÉF).]

2. Perform oil return operating for about 10 minutes.

3. Stop engine.

CAUTION:

If excessive oil leakage is noted, do not perform the oil return operation.

Should the compressor be replaced?

No Yes

qA(Go to next page.)

Is there any part to be replaced?

(Evaporator, condenser, liquid tank or in

case there is evidence of a large amount

of oil leakage.)

No

EYe s

After replacing any of the following major components of the system, be sure

to add the correct amount of oil to the system.

Amount of oil to be added

*1: If compressor is replaced, addition of oil is included in the flow chart.

*2: If refrigerant leak is small, no addition of oil is needed. ªRatioº in this table

indicates the ratio of added oil to the overall amount of oil needed in the

system.

Carry out the A/C performance test.F

Part replacedOil to be added to system

Remarks

Amount of oil m(Imp fl oz)

Evaporator 75 (2.6) Ð

Condenser 75 (2.6) Ð

Liquid tank 5 (0.2)Add if compressor is

not replaced. *1

In case of refrigerant

leak30 (1.1) Large leak

Ð Small leak *2

H

H

H

H

H

LUBRICATION OIL Ð Checking and Adjusting

HA-22

Page 1381 of 1767

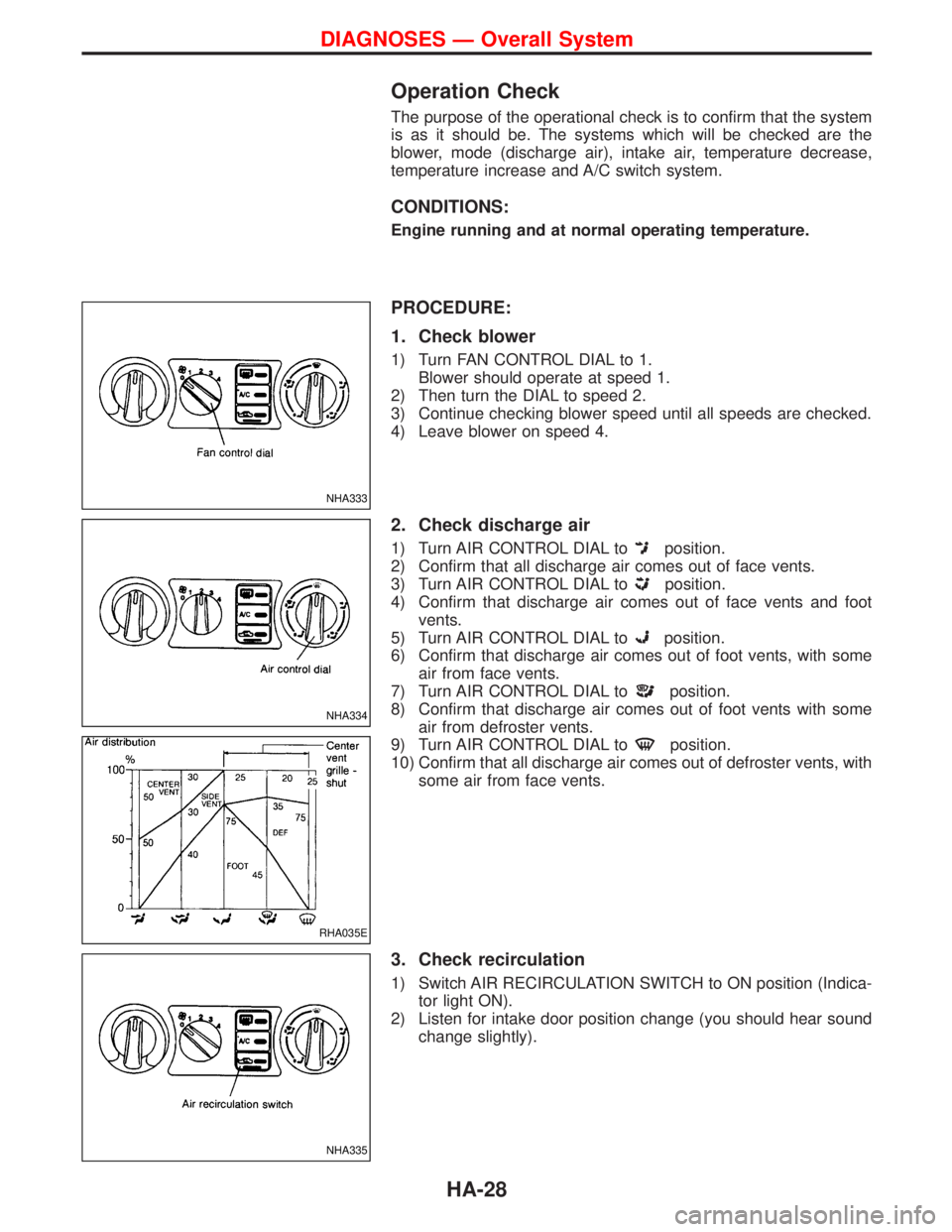

Operation Check

The purpose of the operational check is to confirm that the system

is as it should be. The systems which will be checked are the

blower, mode (discharge air), intake air, temperature decrease,

temperature increase and A/C switch system.

CONDITIONS:

Engine running and at normal operating temperature.

PROCEDURE:

1. Check blower

1) Turn FAN CONTROL DIAL to 1.

Blower should operate at speed 1.

2) Then turn the DIAL to speed 2.

3) Continue checking blower speed until all speeds are checked.

4) Leave blower on speed 4.

2. Check discharge air

1) Turn AIR CONTROL DIAL toposition.

2) Confirm that all discharge air comes out of face vents.

3) Turn AIR CONTROL DIAL to

position.

4) Confirm that discharge air comes out of face vents and foot

vents.

5) Turn AIR CONTROL DIAL to

position.

6) Confirm that discharge air comes out of foot vents, with some

air from face vents.

7) Turn AIR CONTROL DIAL to

position.

8) Confirm that discharge air comes out of foot vents with some

air from defroster vents.

9) Turn AIR CONTROL DIAL to

position.

10) Confirm that all discharge air comes out of defroster vents, with

some air from face vents.

3. Check recirculation

1) Switch AIR RECIRCULATION SWITCH to ON position (Indica-

tor light ON).

2) Listen for intake door position change (you should hear sound

change slightly).

NHA333

NHA334

RHA035E

NHA335

DIAGNOSES Ð Overall System

HA-28

Page 1383 of 1767

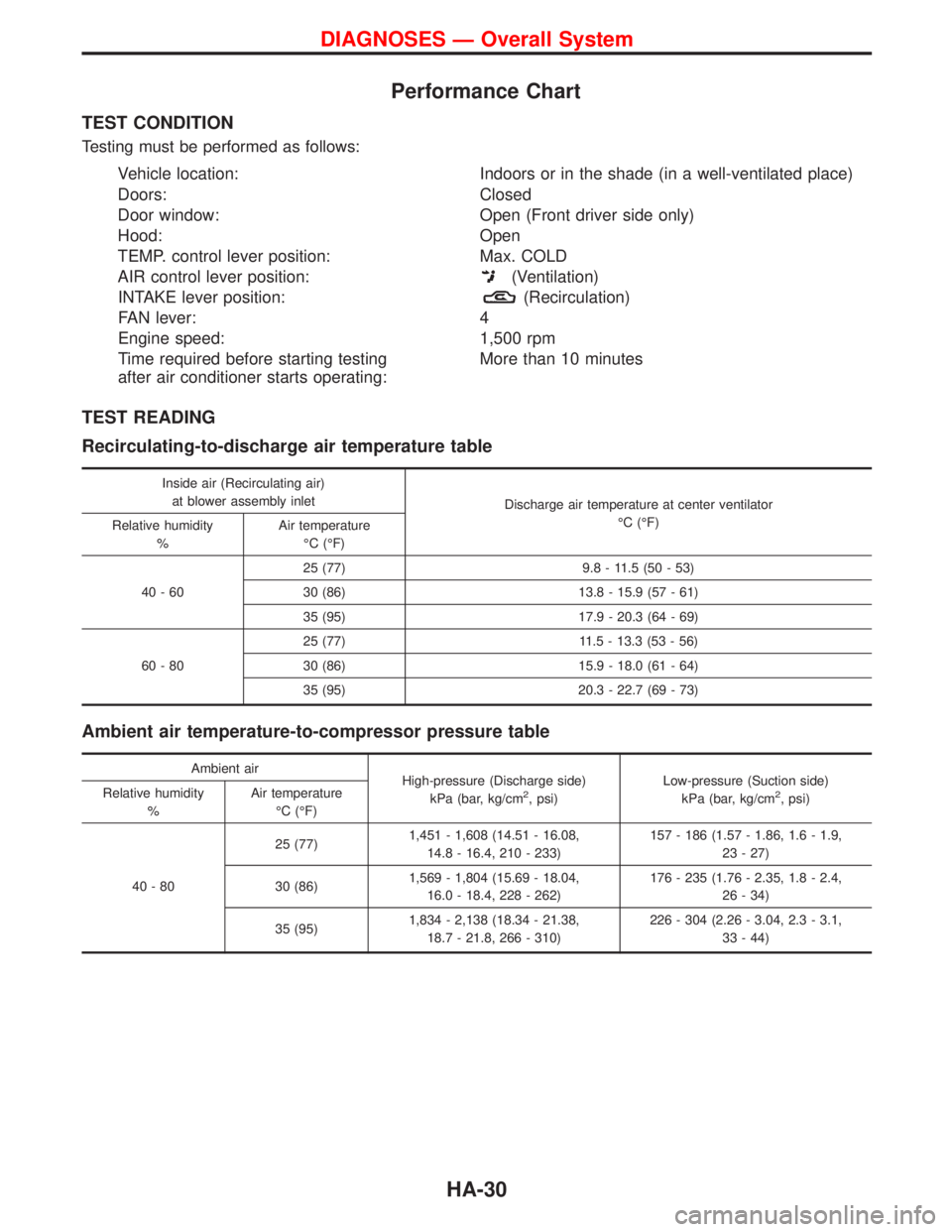

Performance Chart

TEST CONDITION

Testing must be performed as follows:

Vehicle location: Indoors or in the shade (in a well-ventilated place)

Doors: Closed

Door window: Open (Front driver side only)

Hood: Open

TEMP. control lever position: Max. COLD

AIR control lever position:

(Ventilation)

INTAKE lever position:

(Recirculation)

FAN lever: 4

Engine speed: 1,500 rpm

Time required before starting testing

after air conditioner starts operating:More than 10 minutes

TEST READING

Recirculating-to-discharge air temperature table

Inside air (Recirculating air)

at blower assembly inlet

Discharge air temperature at center ventilator

ÉC (ÉF)

Relative humidity

%Air temperature

ÉC (ÉF)

40-6025 (77) 9.8 - 11.5 (50 - 53)

30 (86) 13.8 - 15.9 (57 - 61)

35 (95) 17.9 - 20.3 (64 - 69)

60-8025 (77) 11.5 - 13.3 (53 - 56)

30 (86) 15.9 - 18.0 (61 - 64)

35 (95) 20.3 - 22.7 (69 - 73)

Ambient air temperature-to-compressor pressure table

Ambient air

High-pressure (Discharge side)

kPa (bar, kg/cm

2, psi)Low-pressure (Suction side)

kPa (bar, kg/cm2, psi) Relative humidity

%Air temperature

ÉC (ÉF)

40-8025 (77)1,451 - 1,608 (14.51 - 16.08,

14.8 - 16.4, 210 - 233)157 - 186 (1.57 - 1.86, 1.6 - 1.9,

23 - 27)

30 (86)1,569 - 1,804 (15.69 - 18.04,

16.0 - 18.4, 228 - 262)176 - 235 (1.76 - 2.35, 1.8 - 2.4,

26 - 34)

35 (95)1,834 - 2,138 (18.34 - 21.38,

18.7 - 21.8, 266 - 310)226 - 304 (2.26 - 3.04, 2.3 - 3.1,

33 - 44)

DIAGNOSES Ð Overall System

HA-30

Page 1385 of 1767

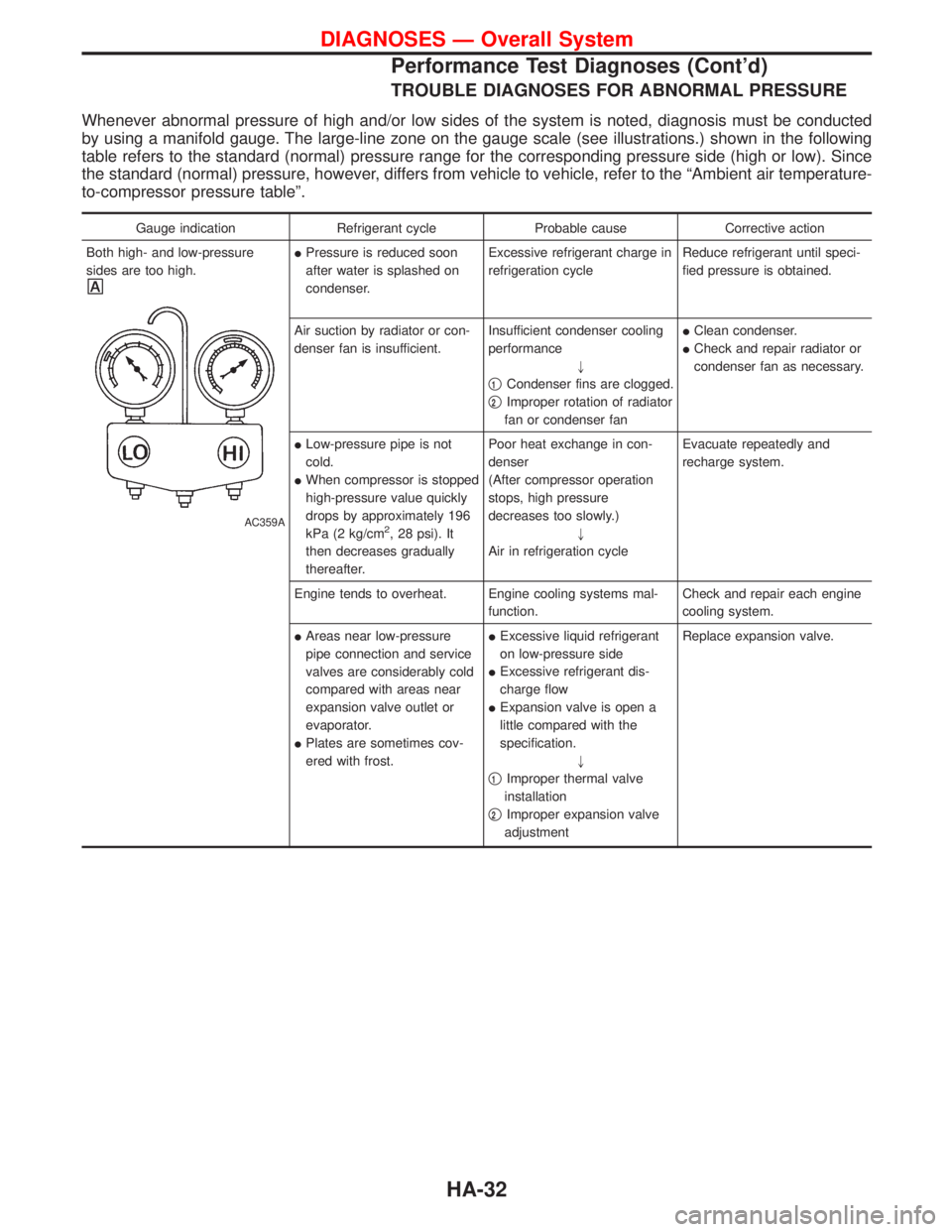

TROUBLE DIAGNOSES FOR ABNORMAL PRESSURE

Whenever abnormal pressure of high and/or low sides of the system is noted, diagnosis must be conducted

by using a manifold gauge. The large-line zone on the gauge scale (see illustrations.) shown in the following

table refers to the standard (normal) pressure range for the corresponding pressure side (high or low). Since

the standard (normal) pressure, however, differs from vehicle to vehicle, refer to the ªAmbient air temperature-

to-compressor pressure tableº.

Gauge indication Refrigerant cycle Probable cause Corrective action

Both high- and low-pressure

sides are too high.

AC359A

IPressure is reduced soon

after water is splashed on

condenser.Excessive refrigerant charge in

refrigeration cycleReduce refrigerant until speci-

fied pressure is obtained.

Air suction by radiator or con-

denser fan is insufficient.Insufficient condenser cooling

performance

"

q

1Condenser fins are clogged.

q

2Improper rotation of radiator

fan or condenser fanIClean condenser.

ICheck and repair radiator or

condenser fan as necessary.

ILow-pressure pipe is not

cold.

IWhen compressor is stopped

high-pressure value quickly

drops by approximately 196

kPa (2 kg/cm

2, 28 psi). It

then decreases gradually

thereafter.Poor heat exchange in con-

denser

(After compressor operation

stops, high pressure

decreases too slowly.)

"

Air in refrigeration cycleEvacuate repeatedly and

recharge system.

Engine tends to overheat. Engine cooling systems mal-

function.Check and repair each engine

cooling system.

IAreas near low-pressure

pipe connection and service

valves are considerably cold

compared with areas near

expansion valve outlet or

evaporator.

IPlates are sometimes cov-

ered with frost.IExcessive liquid refrigerant

on low-pressure side

IExcessive refrigerant dis-

charge flow

IExpansion valve is open a

little compared with the

specification.

"

q

1Improper thermal valve

installation

q

2Improper expansion valve

adjustmentReplace expansion valve.

DIAGNOSES Ð Overall System

Performance Test Diagnoses (Cont'd)

HA-32

Page 1391 of 1767

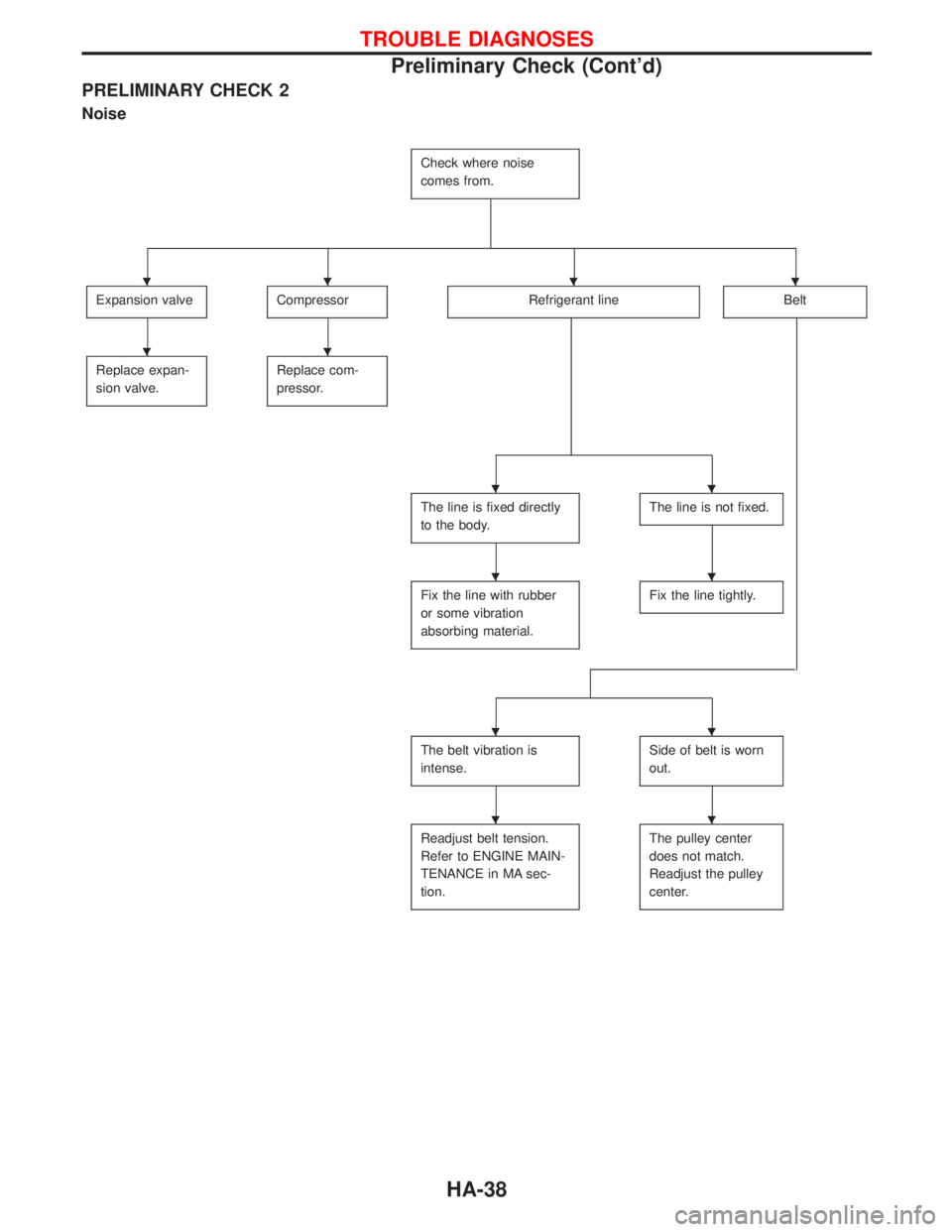

PRELIMINARY CHECK 2

Noise

Check where noise

comes from.

Expansion valveCompressorRefrigerant lineBelt

Replace expan-

sion valve.Replace com-

pressor.

The line is fixed directly

to the body.The line is not fixed.

Fix the line with rubber

or some vibration

absorbing material.Fix the line tightly.

The belt vibration is

intense.Side of belt is worn

out.

Readjust belt tension.

Refer to ENGINE MAIN-

TENANCE in MA sec-

tion.The pulley center

does not match.

Readjust the pulley

center.

HHHH

HH

HH

HH

HH

HH

TROUBLE DIAGNOSES

Preliminary Check (Cont'd)

HA-38

Page 1396 of 1767

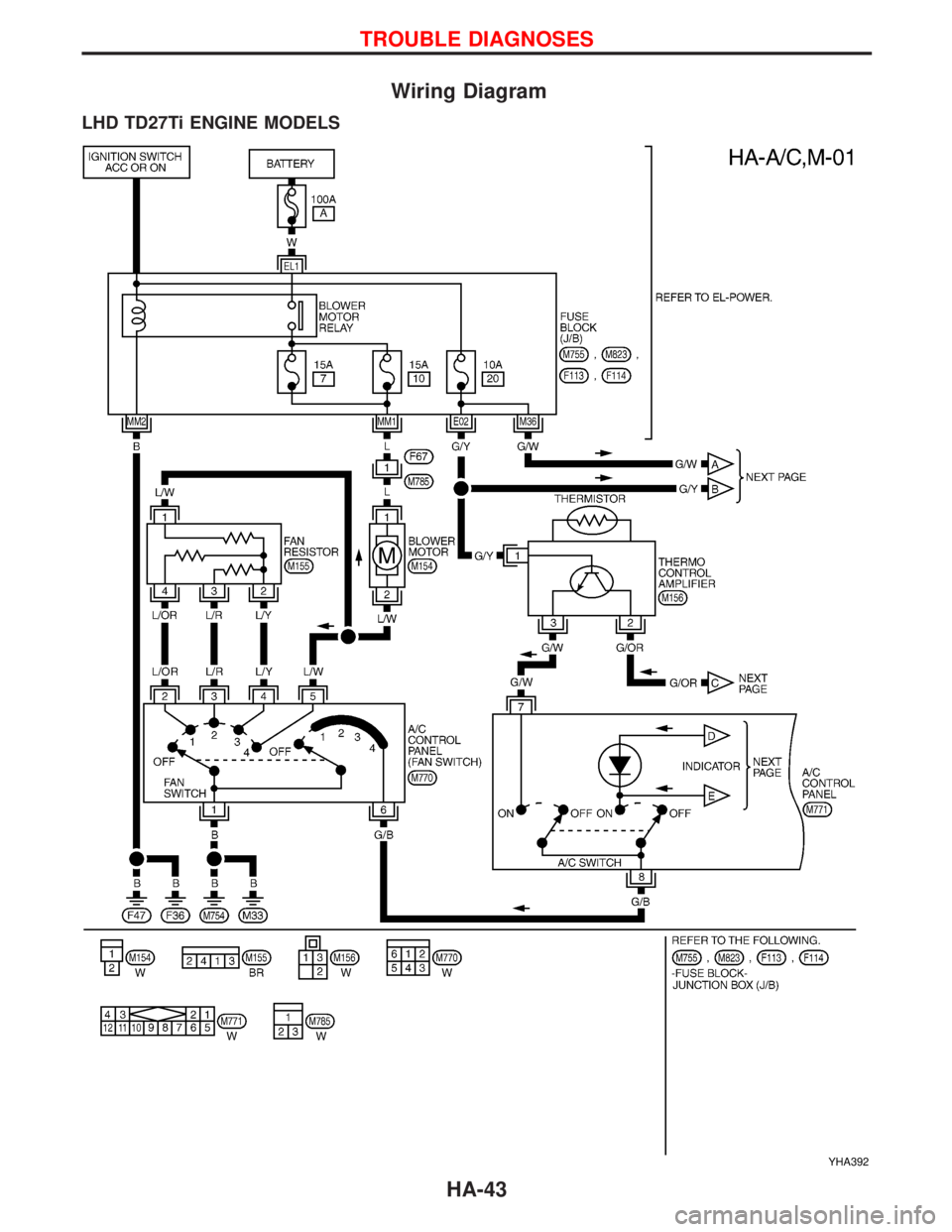

Wiring Diagram

LHD TD27Ti ENGINE MODELS

YHA392

TROUBLE DIAGNOSES

HA-43

Page 1398 of 1767

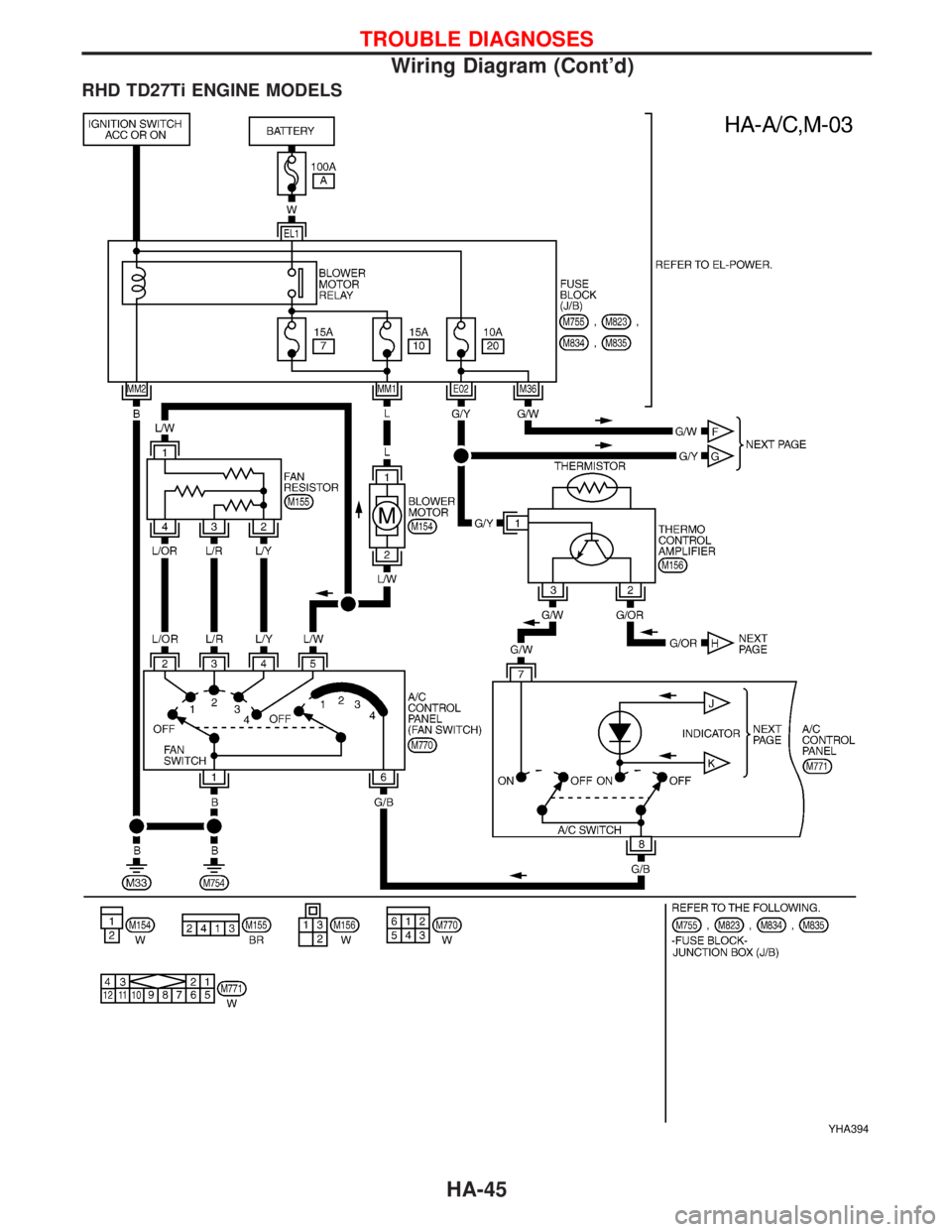

RHD TD27Ti ENGINE MODELS

YHA394

TROUBLE DIAGNOSES

Wiring Diagram (Cont'd)

HA-45