engine NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 1245 of 1767

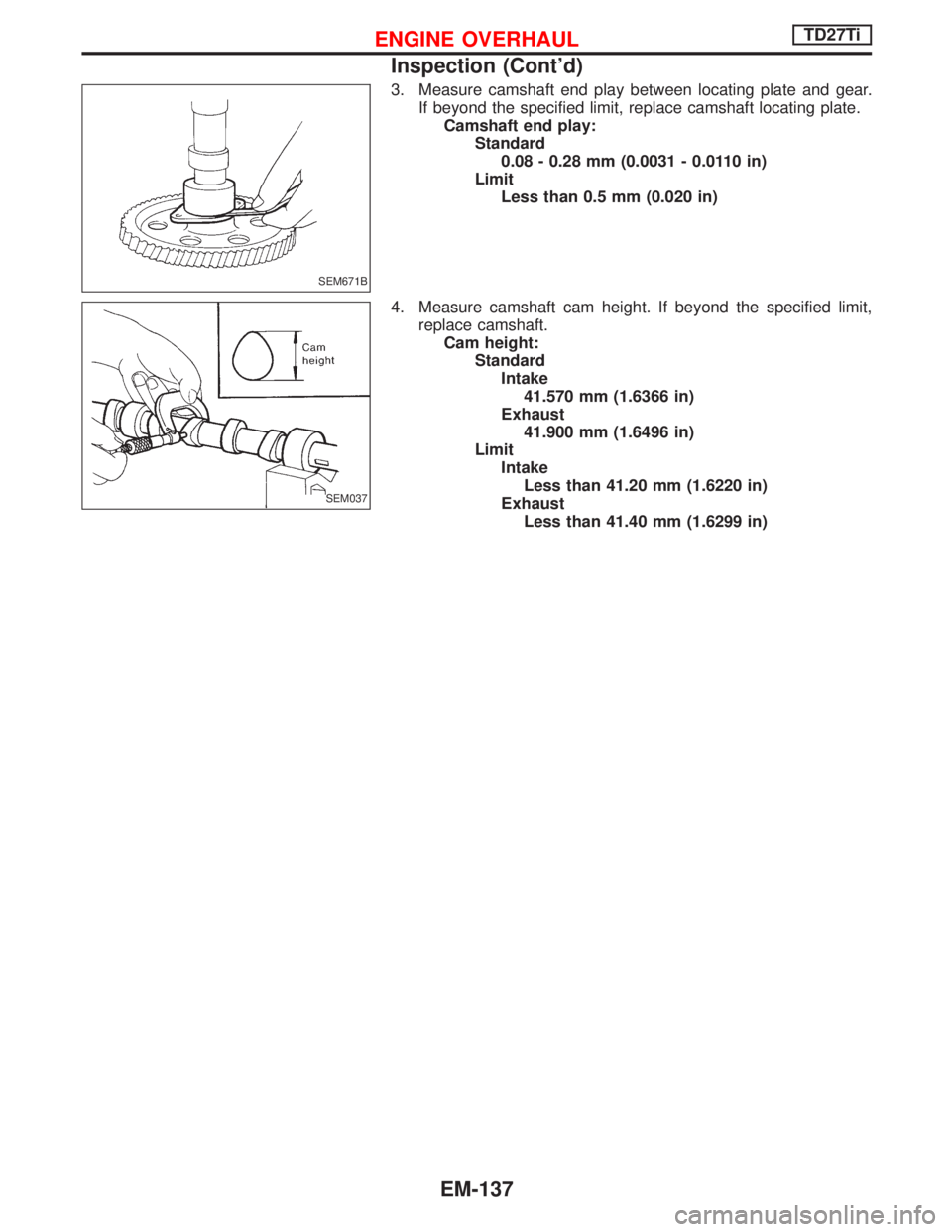

3. Measure camshaft end play between locating plate and gear.

If beyond the specified limit, replace camshaft locating plate.

Camshaft end play:

Standard

0.08 - 0.28 mm (0.0031 - 0.0110 in)

Limit

Less than 0.5 mm (0.020 in)

4. Measure camshaft cam height. If beyond the specified limit,

replace camshaft.

Cam height:

Standard

Intake

41.570 mm (1.6366 in)

Exhaust

41.900 mm (1.6496 in)

Limit

Intake

Less than 41.20 mm (1.6220 in)

Exhaust

Less than 41.40 mm (1.6299 in)

SEM671B

SEM037

ENGINE OVERHAULTD27Ti

Inspection (Cont'd)

EM-137

Page 1246 of 1767

Assembly

PISTON

1. Assemble pistons, piston pins, snap rings and connecting rods.

a. Numbers are stamped on the connecting rod and cap cor-

responding to each cylinder. Care should be taken to avoid

a wrong combination including bearing.

b. When inserting piston pin in connecting rod, heat piston

with a heater or hot water [approximately 60 to 70ÉC (140

to 158ÉF)] and apply engine oil to pin and small end of

connecting rod.

c. After assembling, ascertain that piston swings smoothly.

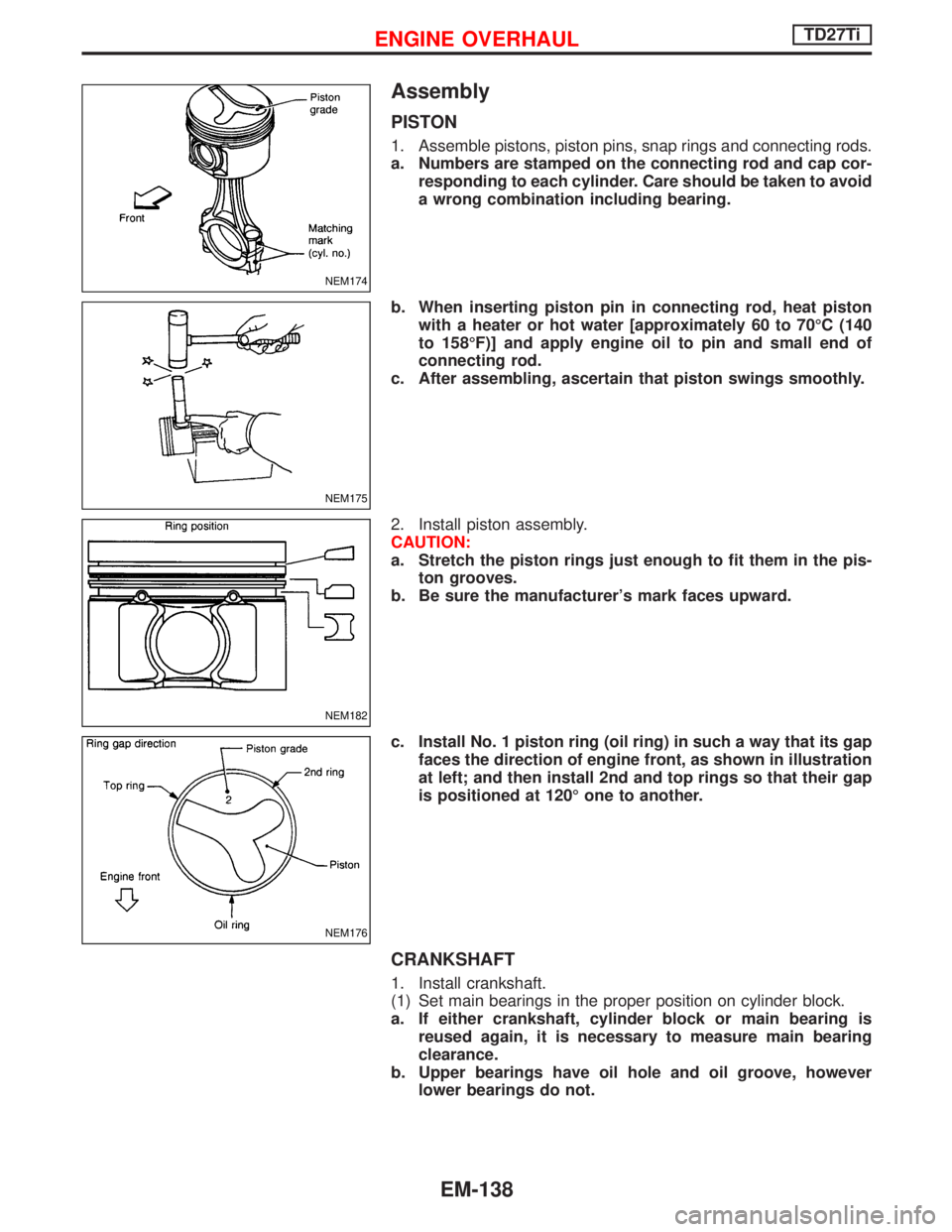

2. Install piston assembly.

CAUTION:

a. Stretch the piston rings just enough to fit them in the pis-

ton grooves.

b. Be sure the manufacturer's mark faces upward.

c. Install No. 1 piston ring (oil ring) in such a way that its gap

faces the direction of engine front, as shown in illustration

at left; and then install 2nd and top rings so that their gap

is positioned at 120É one to another.

CRANKSHAFT

1. Install crankshaft.

(1) Set main bearings in the proper position on cylinder block.

a. If either crankshaft, cylinder block or main bearing is

reused again, it is necessary to measure main bearing

clearance.

b. Upper bearings have oil hole and oil groove, however

lower bearings do not.

NEM174

NEM175

NEM182

NEM176

ENGINE OVERHAULTD27Ti

EM-138

Page 1247 of 1767

(2) Apply engine oil to crankshaft journal and pin and install crank-

shaft.

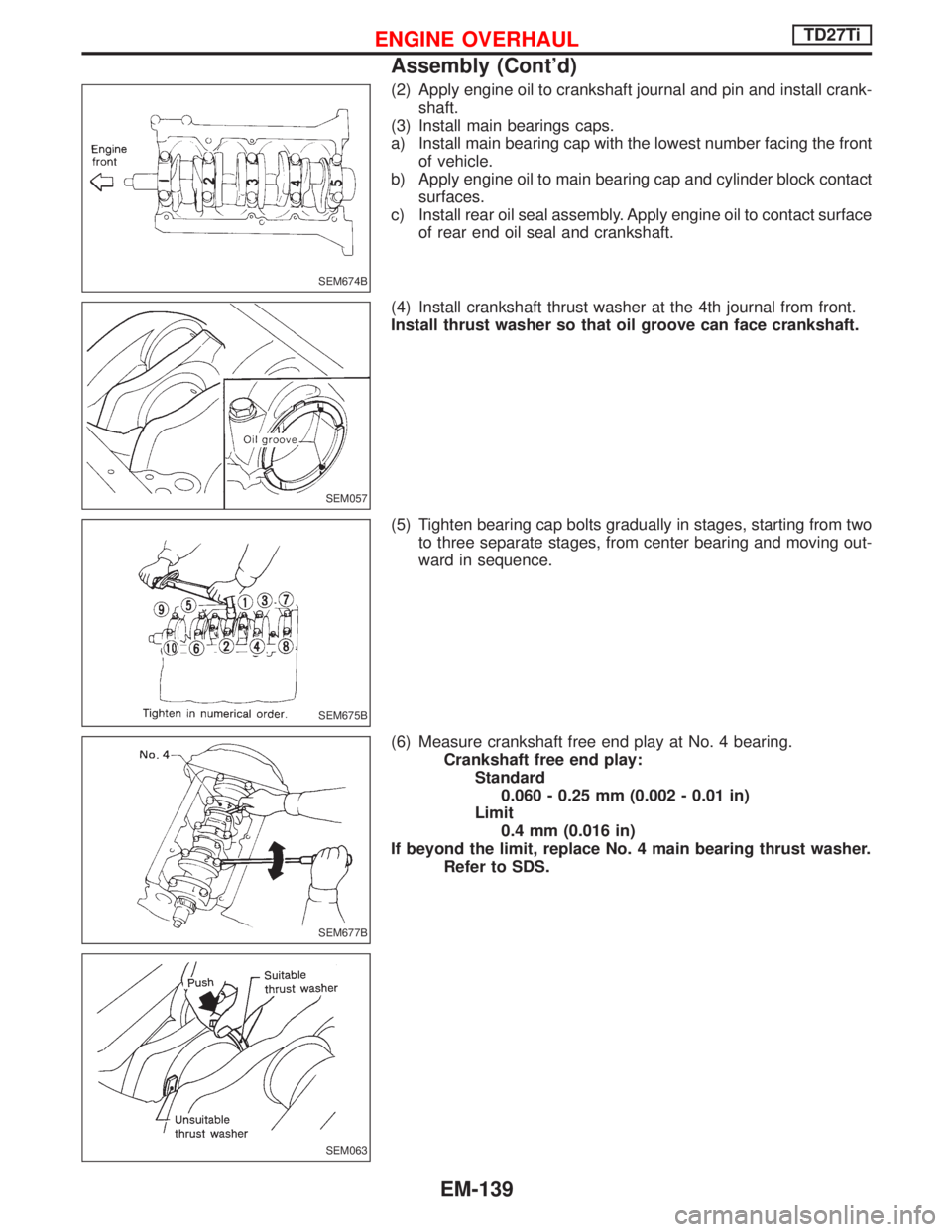

(3) Install main bearings caps.

a) Install main bearing cap with the lowest number facing the front

of vehicle.

b) Apply engine oil to main bearing cap and cylinder block contact

surfaces.

c) Install rear oil seal assembly. Apply engine oil to contact surface

of rear end oil seal and crankshaft.

(4) Install crankshaft thrust washer at the 4th journal from front.

Install thrust washer so that oil groove can face crankshaft.

(5) Tighten bearing cap bolts gradually in stages, starting from two

to three separate stages, from center bearing and moving out-

ward in sequence.

(6) Measure crankshaft free end play at No. 4 bearing.

Crankshaft free end play:

Standard

0.060 - 0.25 mm (0.002 - 0.01 in)

Limit

0.4 mm (0.016 in)

If beyond the limit, replace No. 4 main bearing thrust washer.

Refer to SDS.

SEM674B

SEM057

SEM675B

SEM677B

SEM063

ENGINE OVERHAULTD27Ti

Assembly (Cont'd)

EM-139

Page 1248 of 1767

2. Install pistons with connecting rods.

(1) Install them into corresponding cylinder using Tool.

IBe careful not to scratch cylinder wall with connecting rod.

IApply engine oil to cylinder wall, piston and bearing.

IThe leaf type combustion chamber on piston head must be

facing toward the fuel pump side.

(2) Install connecting rod bearing caps.

3. Measure connecting rod side clearance.

Connecting rod side clearance:

Standard

0.10 - 0.22 mm (0.0039 - 0.0087 in)

Limit

0.22 mm (0.0087 in)

If beyond the limit, replace connecting rod and/or crankshaft.

4. Install oil strainer and oil pan.

5. Install all removed parts.

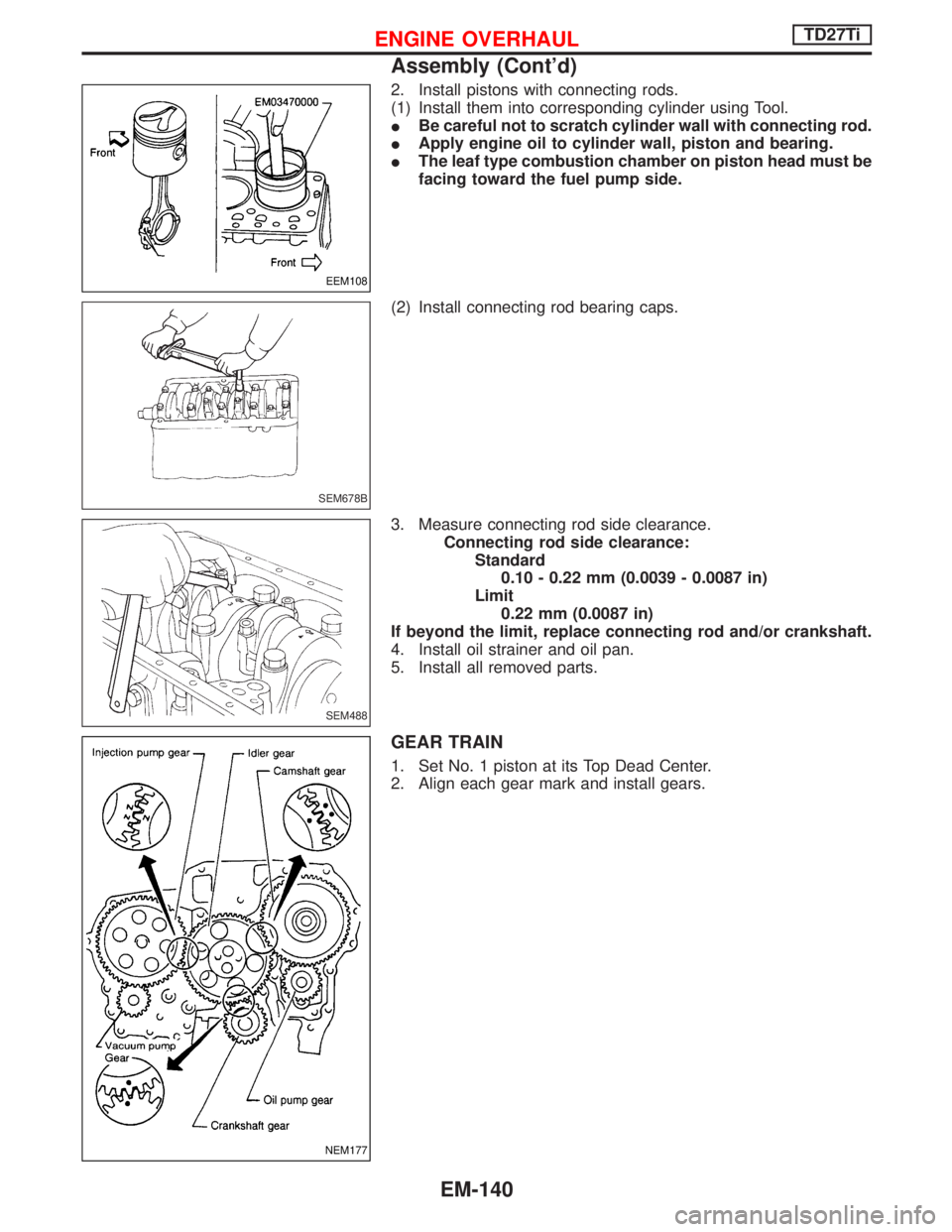

GEAR TRAIN

1. Set No. 1 piston at its Top Dead Center.

2. Align each gear mark and install gears.

EEM108

SEM678B

SEM488

NEM177

ENGINE OVERHAULTD27Ti

Assembly (Cont'd)

EM-140

Page 1249 of 1767

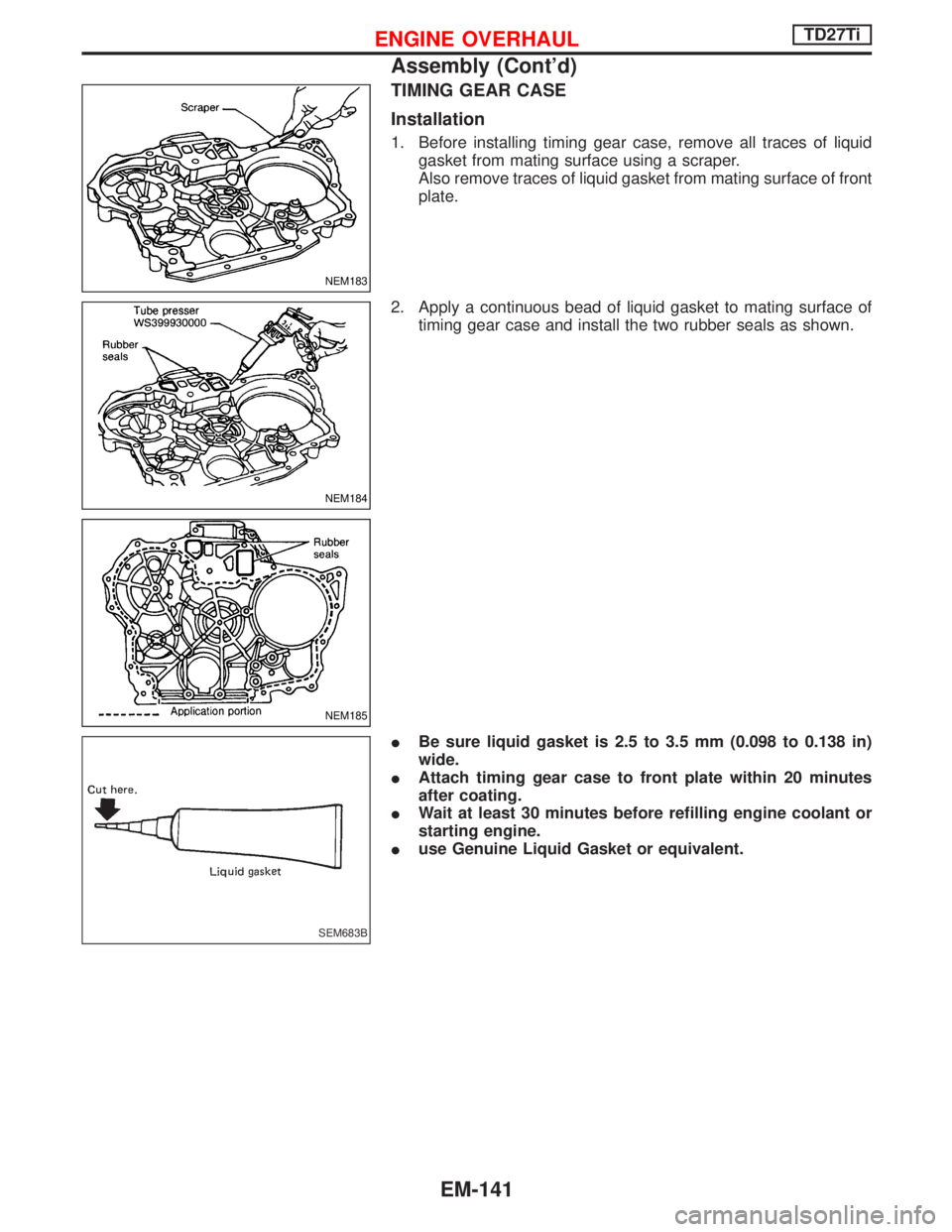

TIMING GEAR CASE

Installation

1. Before installing timing gear case, remove all traces of liquid

gasket from mating surface using a scraper.

Also remove traces of liquid gasket from mating surface of front

plate.

2. Apply a continuous bead of liquid gasket to mating surface of

timing gear case and install the two rubber seals as shown.

IBe sure liquid gasket is 2.5 to 3.5 mm (0.098 to 0.138 in)

wide.

IAttach timing gear case to front plate within 20 minutes

after coating.

IWait at least 30 minutes before refilling engine coolant or

starting engine.

Iuse Genuine Liquid Gasket or equivalent.

NEM183

NEM184

NEM185

SEM683B

ENGINE OVERHAULTD27Ti

Assembly (Cont'd)

EM-141

Page 1250 of 1767

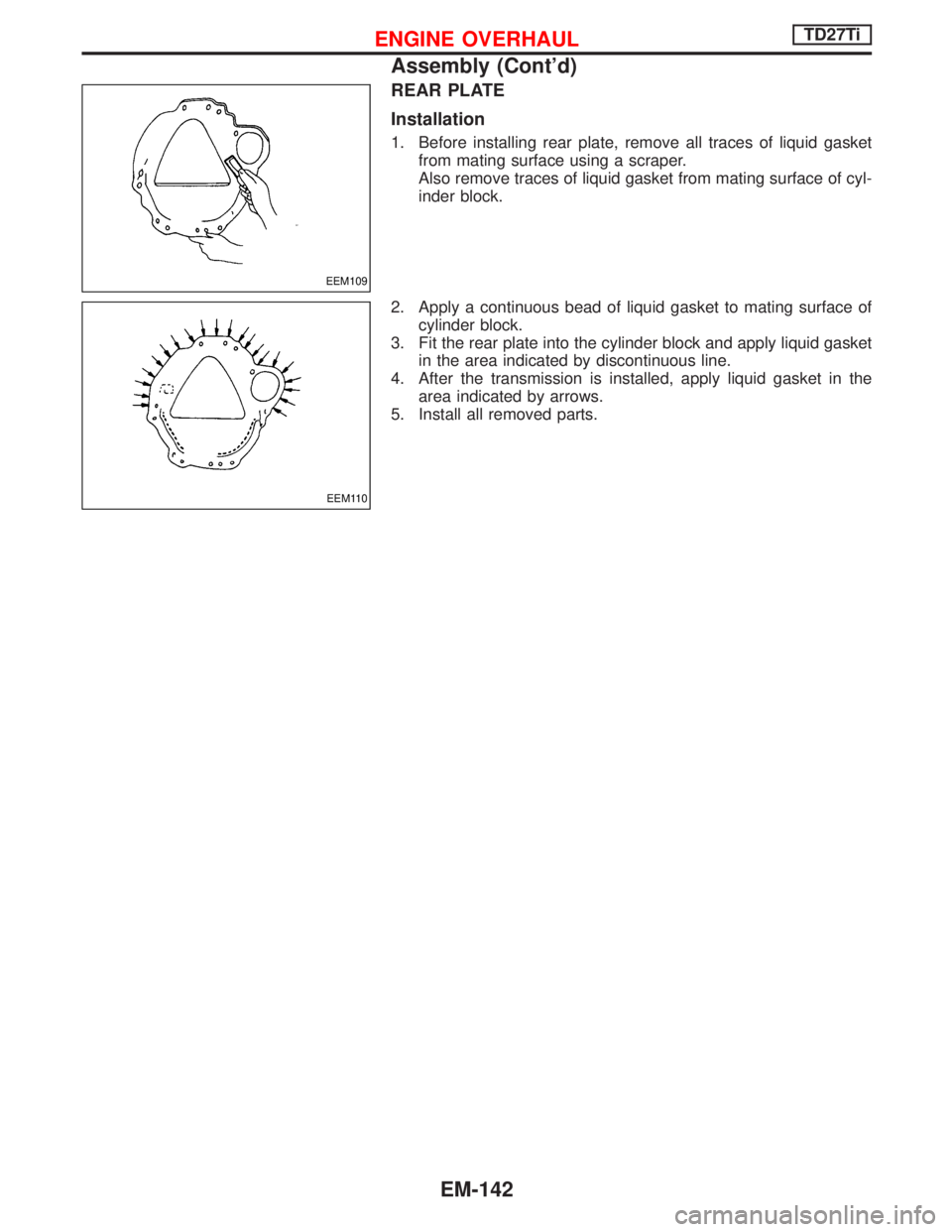

REAR PLATE

Installation

1. Before installing rear plate, remove all traces of liquid gasket

from mating surface using a scraper.

Also remove traces of liquid gasket from mating surface of cyl-

inder block.

2. Apply a continuous bead of liquid gasket to mating surface of

cylinder block.

3. Fit the rear plate into the cylinder block and apply liquid gasket

in the area indicated by discontinuous line.

4. After the transmission is installed, apply liquid gasket in the

area indicated by arrows.

5. Install all removed parts.

EEM109

EEM110

ENGINE OVERHAULTD27Ti

Assembly (Cont'd)

EM-142

Page 1251 of 1767

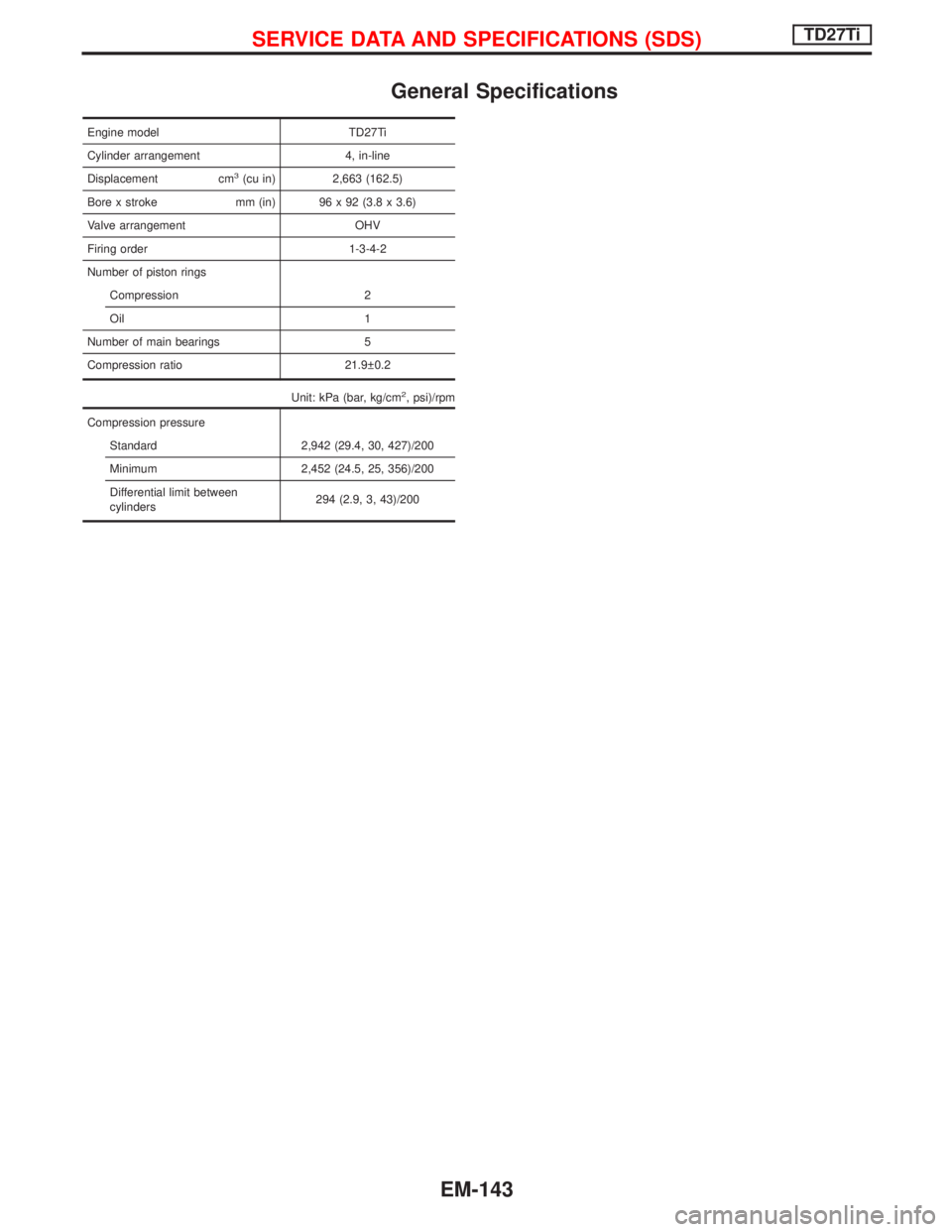

General Specifications

Engine model TD27Ti

Cylinder arrangement 4, in-line

Displacement cm

3(cu in) 2,663 (162.5)

Bore x stroke mm (in) 96 x 92 (3.8 x 3.6)

Valve arrangement OHV

Firing order 1-3-4-2

Number of piston rings

Compression 2

Oil 1

Number of main bearings 5

Compression ratio 21.9 0.2

Unit: kPa (bar, kg/cm

2, psi)/rpm

Compression pressure

Standard 2,942 (29.4, 30, 427)/200

Minimum 2,452 (24.5, 25, 356)/200

Differential limit between

cylinders294 (2.9, 3, 43)/200

SERVICE DATA AND SPECIFICATIONS (SDS)TD27Ti

EM-143

Page 1260 of 1767

(1) When installing each rubber part, final tightening must be car-

ried out under unladen condition * with tires on ground.

* Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

(2) When removing each suspension part, check wheel alignment

and adjust if necessary.

(3) Use Tool when removing or installing brake tubes.

SBR820B

PRECAUTIONS

FA-2

Page 1274 of 1767

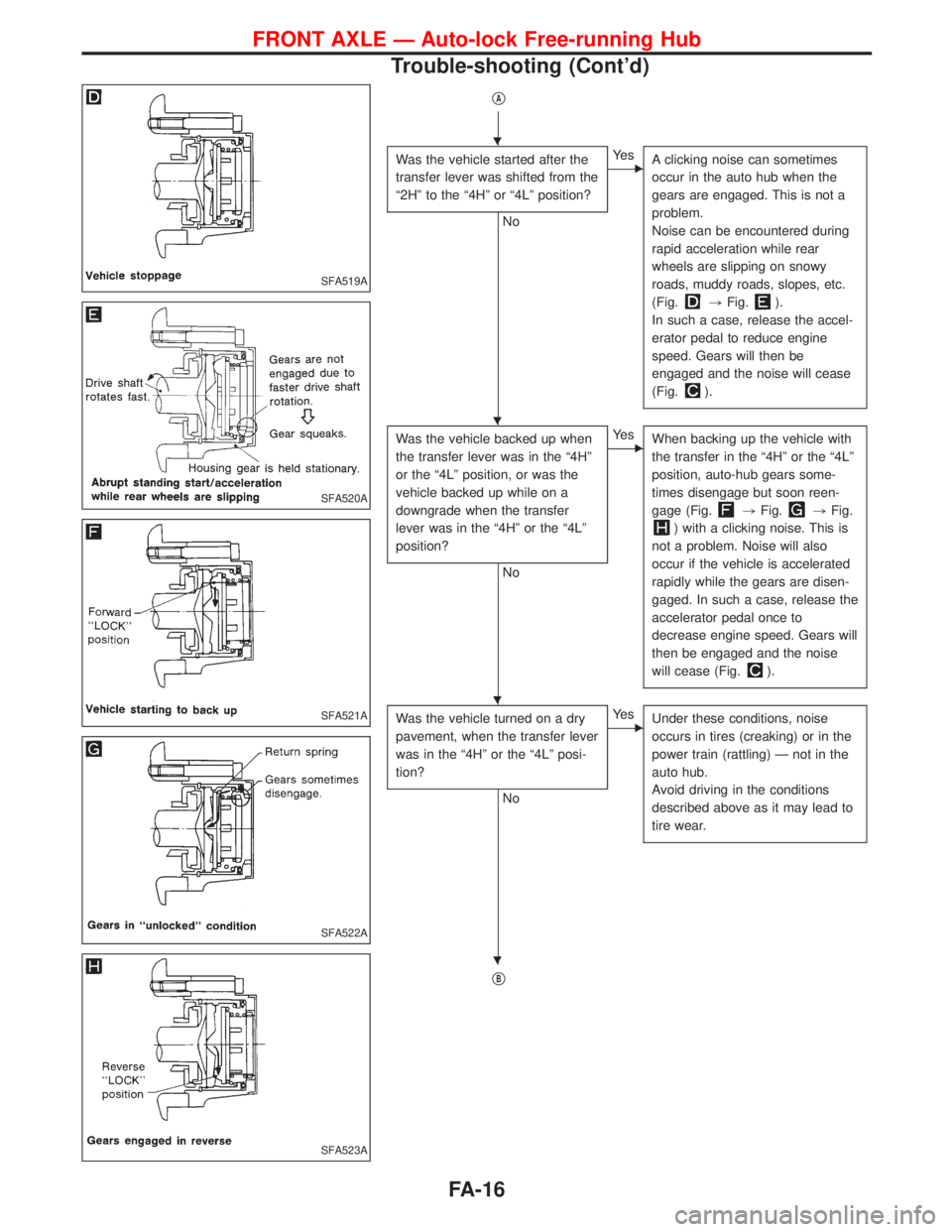

qA

Was the vehicle started after the

transfer lever was shifted from the

ª2Hº to the ª4Hº or ª4Lº position?

No

EYe s

A clicking noise can sometimes

occur in the auto hub when the

gears are engaged. This is not a

problem.

Noise can be encountered during

rapid acceleration while rear

wheels are slipping on snowy

roads, muddy roads, slopes, etc.

(Fig.

,Fig.).

In such a case, release the accel-

erator pedal to reduce engine

speed. Gears will then be

engaged and the noise will cease

(Fig.

).

Was the vehicle backed up when

the transfer lever was in the ª4Hº

or the ª4Lº position, or was the

vehicle backed up while on a

downgrade when the transfer

lever was in the ª4Hº or the ª4Lº

position?

No

EYe s

When backing up the vehicle with

the transfer in the ª4Hº or the ª4Lº

position, auto-hub gears some-

times disengage but soon reen-

gage (Fig.

,Fig.,Fig.

) with a clicking noise. This is

not a problem. Noise will also

occur if the vehicle is accelerated

rapidly while the gears are disen-

gaged. In such a case, release the

accelerator pedal once to

decrease engine speed. Gears will

then be engaged and the noise

will cease (Fig.

).

Was the vehicle turned on a dry

pavement, when the transfer lever

was in the ª4Hº or the ª4Lº posi-

tion?

No

EYe s

Under these conditions, noise

occurs in tires (creaking) or in the

power train (rattling) Ð not in the

auto hub.

Avoid driving in the conditions

described above as it may lead to

tire wear.

qB

SFA519A

SFA520A

SFA521A

SFA522A

SFA523A

H

H

H

H

FRONT AXLE Ð Auto-lock Free-running Hub

Trouble-shooting (Cont'd)

FA-16

Page 1289 of 1767

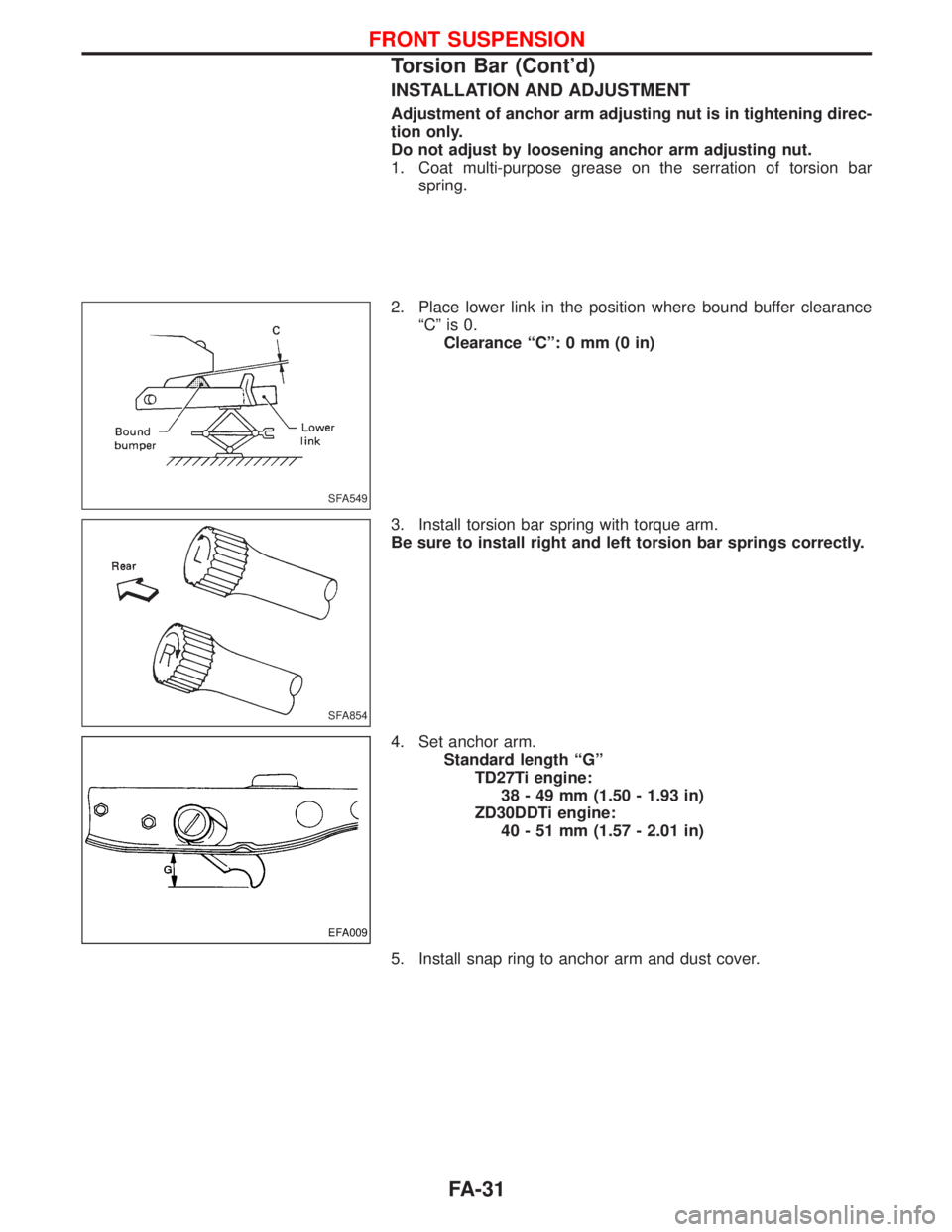

INSTALLATION AND ADJUSTMENT

Adjustment of anchor arm adjusting nut is in tightening direc-

tion only.

Do not adjust by loosening anchor arm adjusting nut.

1. Coat multi-purpose grease on the serration of torsion bar

spring.

2. Place lower link in the position where bound buffer clearance

ªCº is 0.

Clearance ªCº: 0 mm (0 in)

3. Install torsion bar spring with torque arm.

Be sure to install right and left torsion bar springs correctly.

4. Set anchor arm.

Standard length ªGº

TD27Ti engine:

38 - 49 mm (1.50 - 1.93 in)

ZD30DDTi engine:

40 - 51 mm (1.57 - 2.01 in)

5. Install snap ring to anchor arm and dust cover.

SFA549

SFA854

EFA009

FRONT SUSPENSION

Torsion Bar (Cont'd)

FA-31