engine NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 1343 of 1767

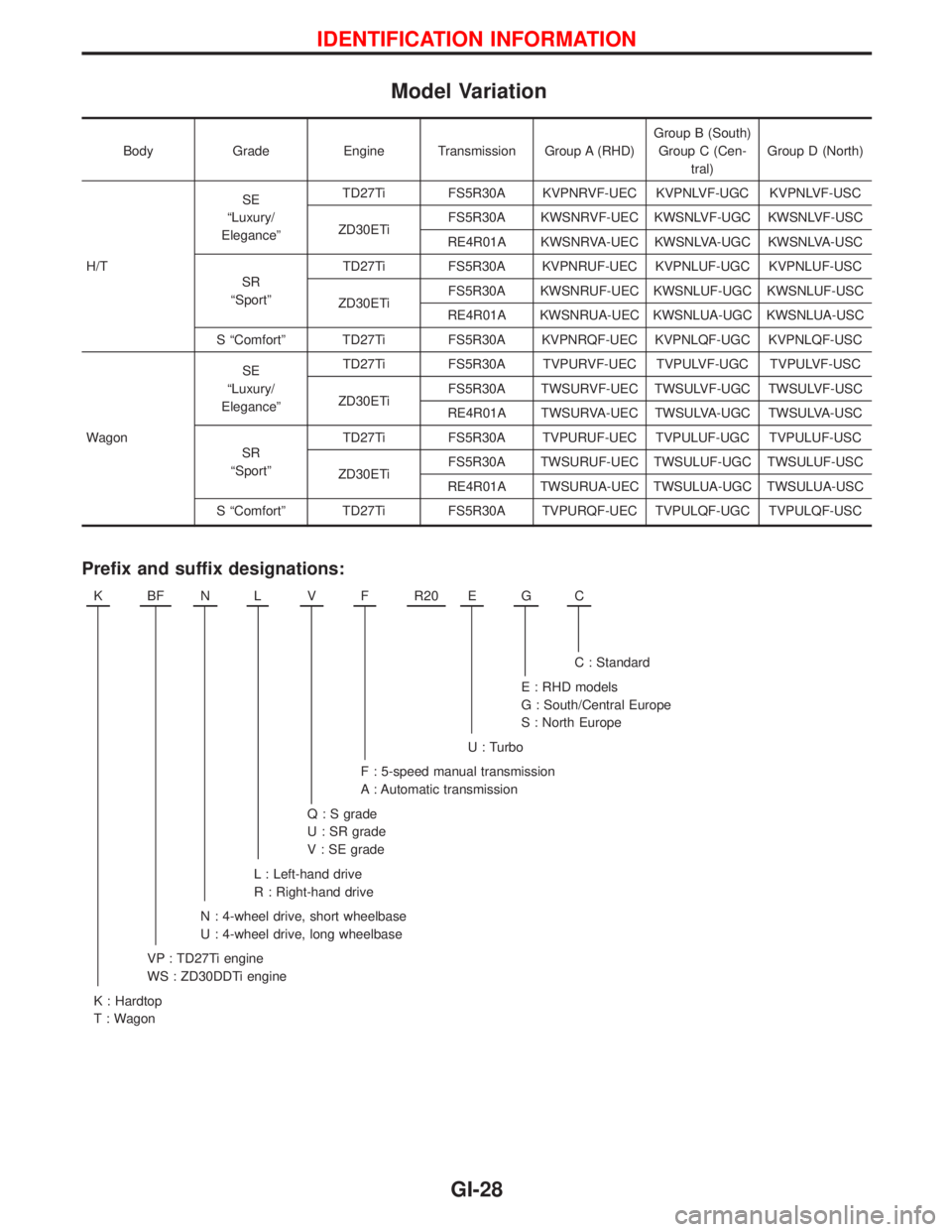

Model Variation

Body Grade Engine Transmission Group A (RHD)Group B (South)

Group C (Cen-

tral)Group D (North)

H/TSE

ªLuxury/

EleganceºTD27Ti FS5R30A KVPNRVF-UEC KVPNLVF-UGC KVPNLVF-USC

ZD30ETiFS5R30A KWSNRVF-UEC KWSNLVF-UGC KWSNLVF-USC

RE4R01A KWSNRVA-UEC KWSNLVA-UGC KWSNLVA-USC

SR

ªSportºTD27Ti FS5R30A KVPNRUF-UEC KVPNLUF-UGC KVPNLUF-USC

ZD30ETiFS5R30A KWSNRUF-UEC KWSNLUF-UGC KWSNLUF-USC

RE4R01A KWSNRUA-UEC KWSNLUA-UGC KWSNLUA-USC

S ªComfortº TD27Ti FS5R30A KVPNRQF-UEC KVPNLQF-UGC KVPNLQF-USC

WagonSE

ªLuxury/

EleganceºTD27Ti FS5R30A TVPURVF-UEC TVPULVF-UGC TVPULVF-USC

ZD30ETiFS5R30A TWSURVF-UEC TWSULVF-UGC TWSULVF-USC

RE4R01A TWSURVA-UEC TWSULVA-UGC TWSULVA-USC

SR

ªSportºTD27Ti FS5R30A TVPURUF-UEC TVPULUF-UGC TVPULUF-USC

ZD30ETiFS5R30A TWSURUF-UEC TWSULUF-UGC TWSULUF-USC

RE4R01A TWSURUA-UEC TWSULUA-UGC TWSULUA-USC

S ªComfortº TD27Ti FS5R30A TVPURQF-UEC TVPULQF-UGC TVPULQF-USC

Prefix and suffix designations:

KBFNLVFR20EGC

C : Standard

E : RHD models

G : South/Central Europe

S : North Europe

U : Turbo

F : 5-speed manual transmission

A : Automatic transmission

Q : S grade

U : SR grade

V : SE grade

L : Left-hand drive

R : Right-hand drive

N : 4-wheel drive, short wheelbase

U : 4-wheel drive, long wheelbase

VP : TD27Ti engine

WS : ZD30DDTi engine

K : Hardtop

T : Wagon

IDENTIFICATION INFORMATION

GI-28

Page 1344 of 1767

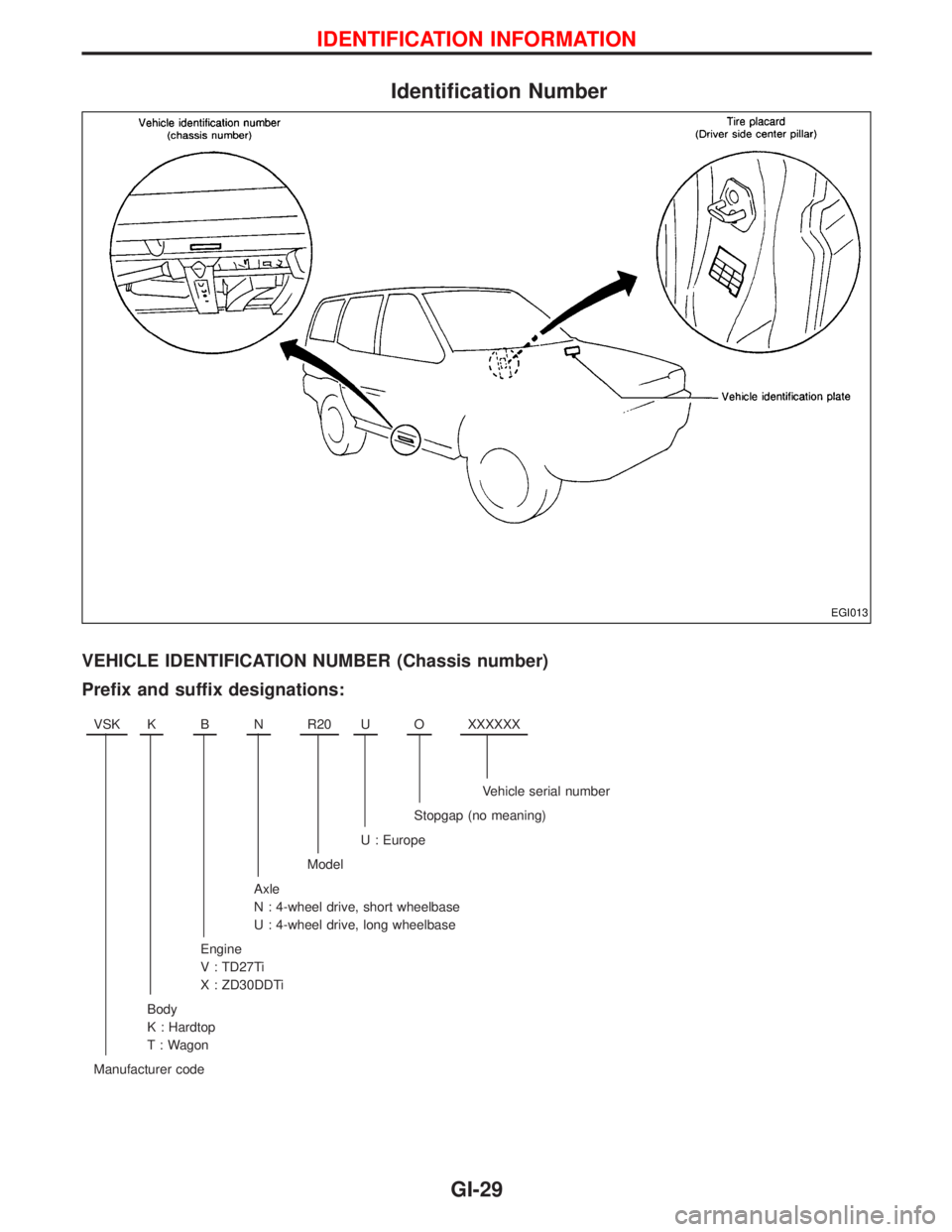

Identification Number

VEHICLE IDENTIFICATION NUMBER (Chassis number)

Prefix and suffix designations:

VSKKBNR20UOXXXXXX

Vehicle serial number

Stopgap (no meaning)

U : Europe

Model

Axle

N : 4-wheel drive, short wheelbase

U : 4-wheel drive, long wheelbase

Engine

V : TD27Ti

X : ZD30DDTi

Body

K : Hardtop

T : Wagon

Manufacturer code

EGI013

IDENTIFICATION INFORMATION

GI-29

Page 1345 of 1767

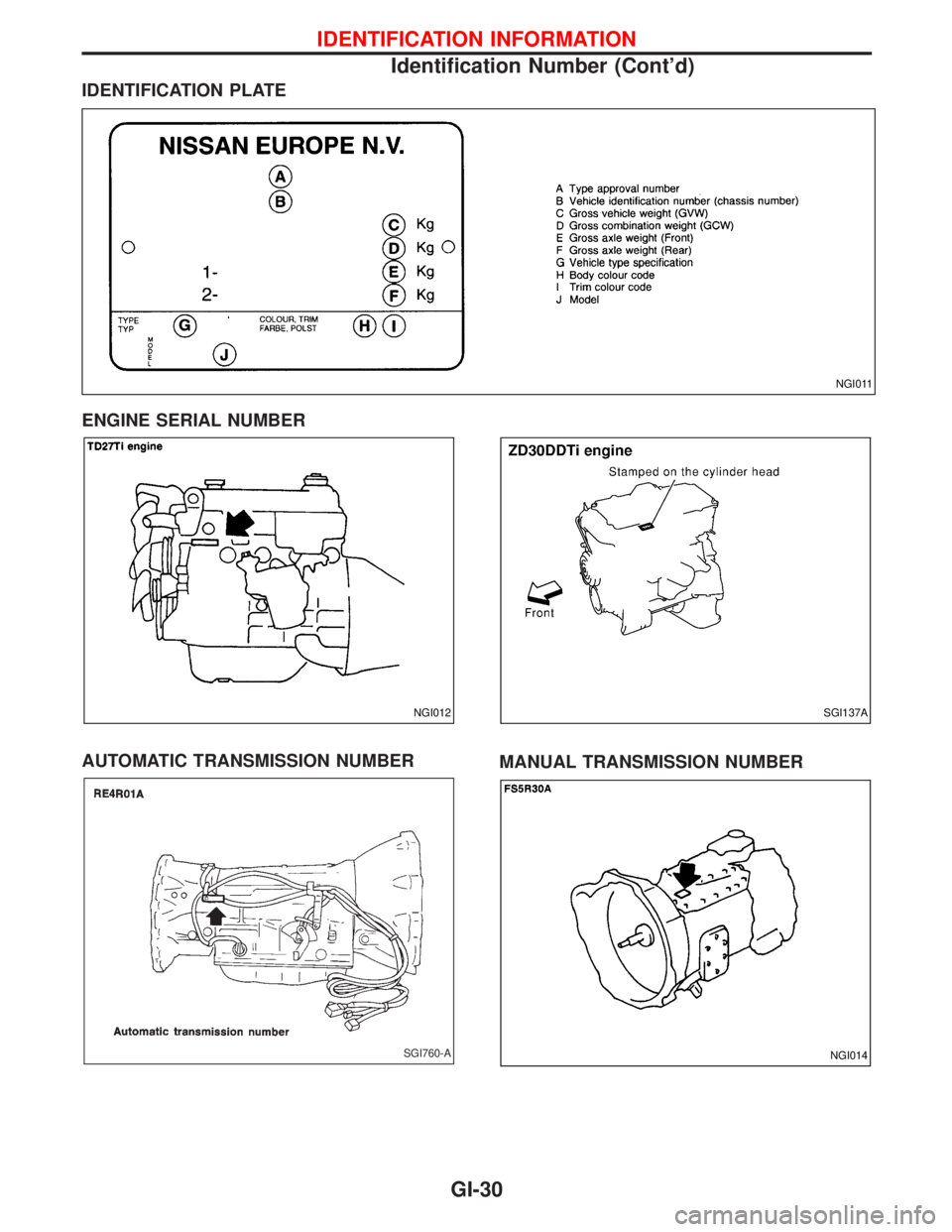

IDENTIFICATION PLATE

ENGINE SERIAL NUMBER

AUTOMATIC TRANSMISSION NUMBER

MANUAL TRANSMISSION NUMBER

NGI011

NGI012SGI137A

SGI760-ANGI014

IDENTIFICATION INFORMATION

Identification Number (Cont'd)

GI-30

Page 1347 of 1767

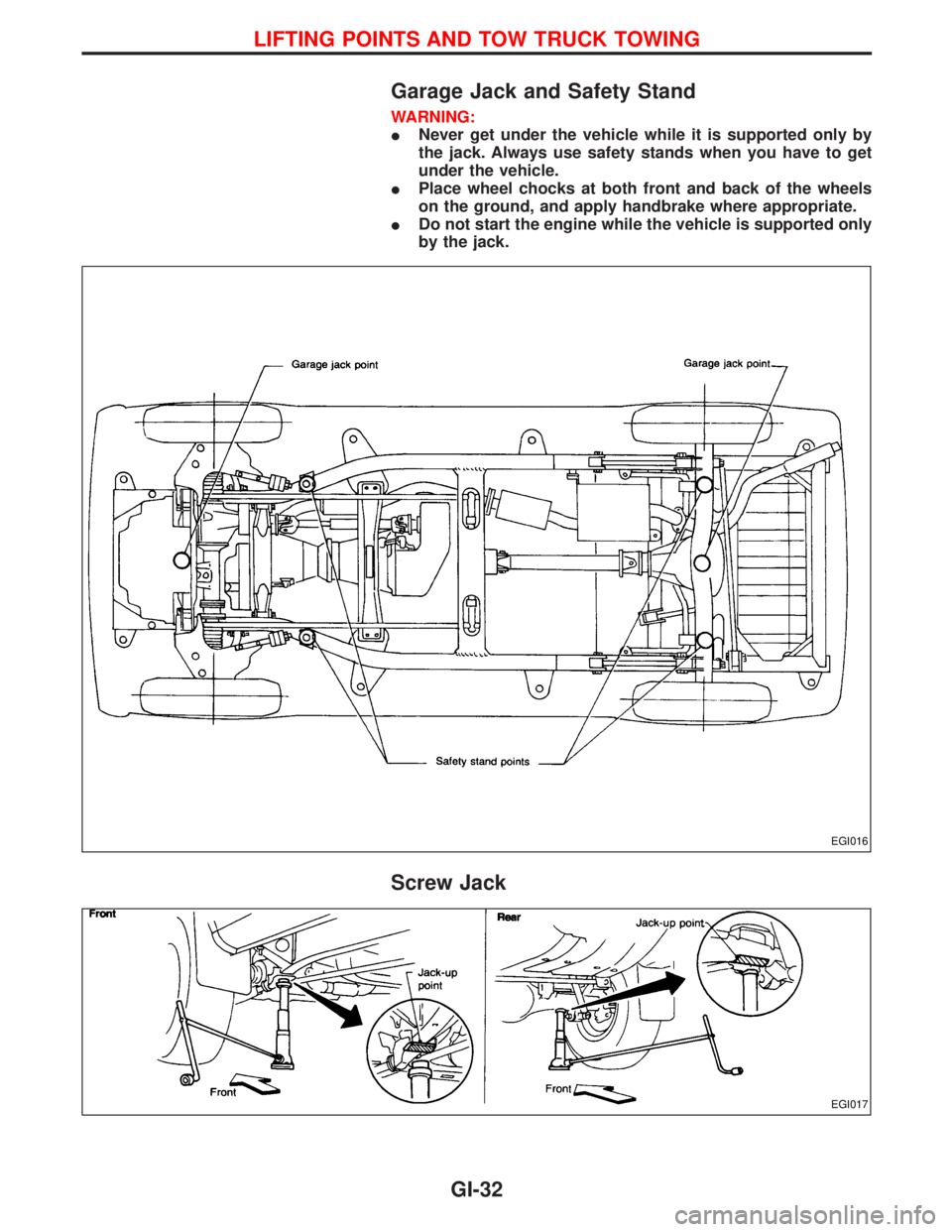

Garage Jack and Safety Stand

WARNING:

INever get under the vehicle while it is supported only by

the jack. Always use safety stands when you have to get

under the vehicle.

IPlace wheel chocks at both front and back of the wheels

on the ground, and apply handbrake where appropriate.

IDo not start the engine while the vehicle is supported only

by the jack.

Screw Jack

EGI016

EGI017

LIFTING POINTS AND TOW TRUCK TOWING

GI-32

Page 1350 of 1767

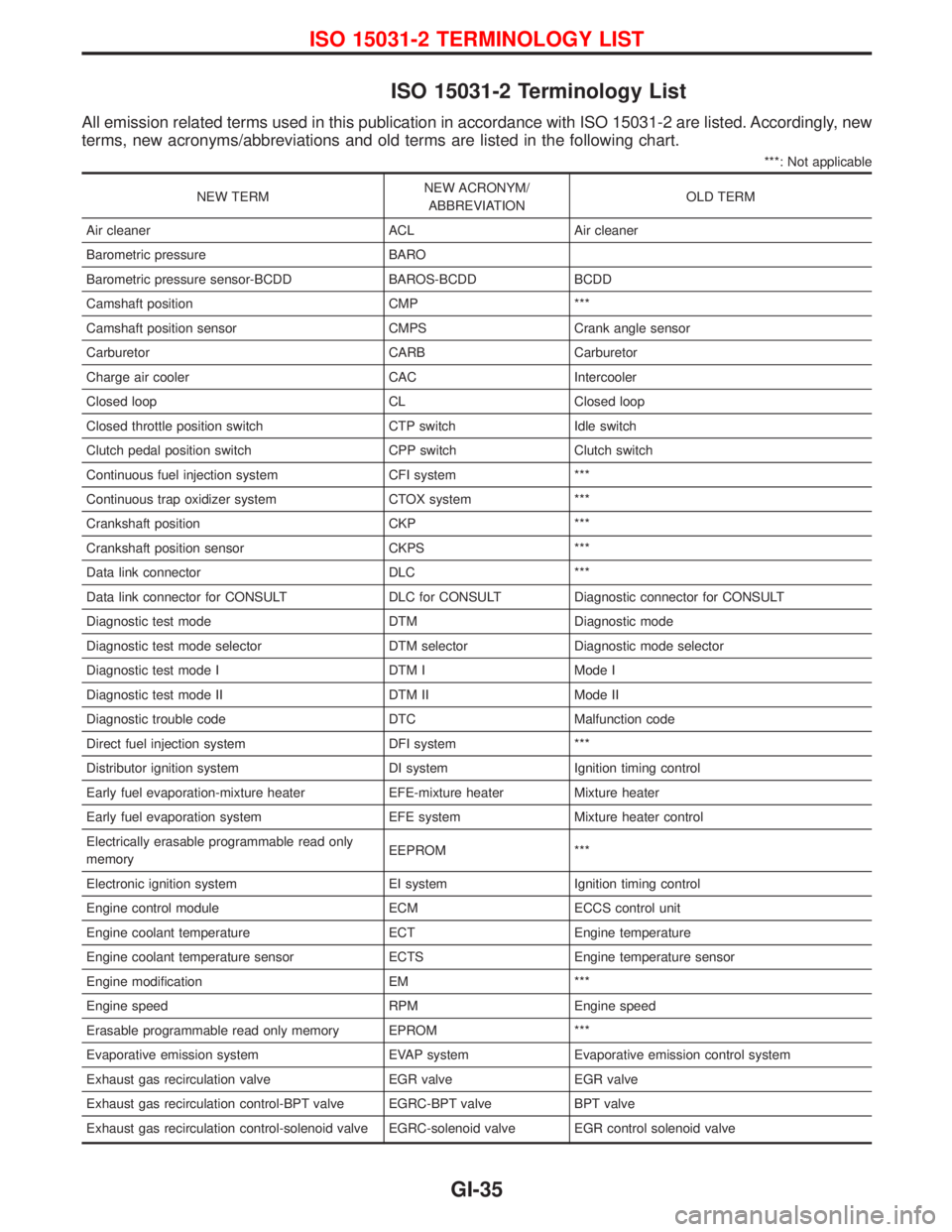

ISO 15031-2 Terminology List

All emission related terms used in this publication in accordance with ISO 15031-2 are listed. Accordingly, new

terms, new acronyms/abbreviations and old terms are listed in the following chart.

***: Not applicable

NEW TERMNEW ACRONYM/

ABBREVIATIONOLD TERM

Air cleaner ACL Air cleaner

Barometric pressure BARO

Barometric pressure sensor-BCDD BAROS-BCDD BCDD

Camshaft position CMP ***

Camshaft position sensor CMPS Crank angle sensor

Carburetor CARB Carburetor

Charge air cooler CAC Intercooler

Closed loop CL Closed loop

Closed throttle position switch CTP switch Idle switch

Clutch pedal position switch CPP switch Clutch switch

Continuous fuel injection system CFI system ***

Continuous trap oxidizer system CTOX system ***

Crankshaft position CKP ***

Crankshaft position sensor CKPS ***

Data link connector DLC ***

Data link connector for CONSULT DLC for CONSULT Diagnostic connector for CONSULT

Diagnostic test mode DTM Diagnostic mode

Diagnostic test mode selector DTM selector Diagnostic mode selector

Diagnostic test mode I DTM I Mode I

Diagnostic test mode II DTM II Mode II

Diagnostic trouble code DTC Malfunction code

Direct fuel injection system DFI system ***

Distributor ignition system DI system Ignition timing control

Early fuel evaporation-mixture heater EFE-mixture heater Mixture heater

Early fuel evaporation system EFE system Mixture heater control

Electrically erasable programmable read only

memoryEEPROM ***

Electronic ignition system EI system Ignition timing control

Engine control module ECM ECCS control unit

Engine coolant temperature ECT Engine temperature

Engine coolant temperature sensor ECTS Engine temperature sensor

Engine modification EM ***

Engine speed RPM Engine speed

Erasable programmable read only memory EPROM ***

Evaporative emission system EVAP system Evaporative emission control system

Exhaust gas recirculation valve EGR valve EGR valve

Exhaust gas recirculation control-BPT valve EGRC-BPT valve BPT valve

Exhaust gas recirculation control-solenoid valve EGRC-solenoid valve EGR control solenoid valve

ISO 15031-2 TERMINOLOGY LIST

GI-35

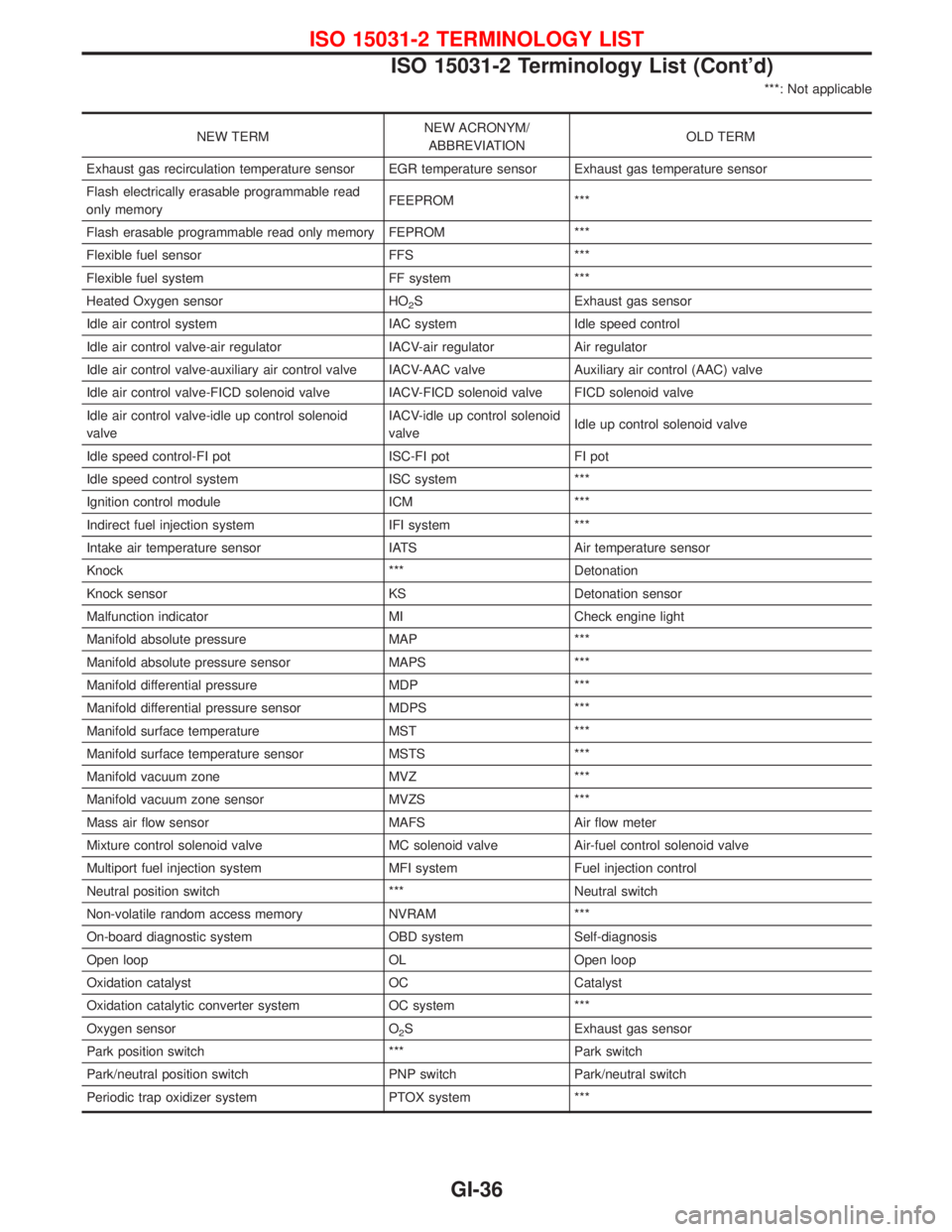

Page 1351 of 1767

***: Not applicable

NEW TERMNEW ACRONYM/

ABBREVIATIONOLD TERM

Exhaust gas recirculation temperature sensor EGR temperature sensor Exhaust gas temperature sensor

Flash electrically erasable programmable read

only memoryFEEPROM ***

Flash erasable programmable read only memory FEPROM ***

Flexible fuel sensor FFS ***

Flexible fuel system FF system ***

Heated Oxygen sensor HO

2S Exhaust gas sensor

Idle air control system IAC system Idle speed control

Idle air control valve-air regulator IACV-air regulator Air regulator

Idle air control valve-auxiliary air control valve IACV-AAC valve Auxiliary air control (AAC) valve

Idle air control valve-FICD solenoid valve IACV-FICD solenoid valve FICD solenoid valve

Idle air control valve-idle up control solenoid

valveIACV-idle up control solenoid

valveIdle up control solenoid valve

Idle speed control-FI pot ISC-FI pot FI pot

Idle speed control system ISC system ***

Ignition control module ICM ***

Indirect fuel injection system IFI system ***

Intake air temperature sensor IATS Air temperature sensor

Knock *** Detonation

Knock sensor KS Detonation sensor

Malfunction indicator MI Check engine light

Manifold absolute pressure MAP ***

Manifold absolute pressure sensor MAPS ***

Manifold differential pressure MDP ***

Manifold differential pressure sensor MDPS ***

Manifold surface temperature MST ***

Manifold surface temperature sensor MSTS ***

Manifold vacuum zone MVZ ***

Manifold vacuum zone sensor MVZS ***

Mass air flow sensor MAFS Air flow meter

Mixture control solenoid valve MC solenoid valve Air-fuel control solenoid valve

Multiport fuel injection system MFI system Fuel injection control

Neutral position switch *** Neutral switch

Non-volatile random access memory NVRAM ***

On-board diagnostic system OBD system Self-diagnosis

Open loop OL Open loop

Oxidation catalyst OC Catalyst

Oxidation catalytic converter system OC system ***

Oxygen sensor O

2S Exhaust gas sensor

Park position switch *** Park switch

Park/neutral position switch PNP switch Park/neutral switch

Periodic trap oxidizer system PTOX system ***

ISO 15031-2 TERMINOLOGY LIST

ISO 15031-2 Terminology List (Cont'd)

GI-36

Page 1358 of 1767

Precautions for Servicing Compressor

IAttach a blind plug to the suction port (low pressure) and discharge port (high pressure) of the

compressor to prevent oil from leaking out and dust from getting inside.

IWhen the compressor is removed, store it under the same condition as it is when mounted on the

car.

IWhen replacing or repairing compressor, be sure to remove oil from the compressor and check

the oil quantity extracted.

IWhen replacing with a new compressor, be sure to remove oil from the new compressor so that

the quantity of oil remaining in the new compressor is equal to the quantity collected from the

removed compressor. See the section ªLUBRICATION OILº.

IPay attention so as not to allow dirt and oil to attach on the friction surfaces between clutch and

pulley. If the surface is contaminated, with oil, wipe it off by using a clean waste cloth moistened

with thinner.

IAfter completing the compressor service operation, be sure to rotate the compressor shaft more

than five turns in both directions by hand to equalize oil distribution inside the compressor, then

run the compressor for about one hour by idling the engine.

IWhen the compressor magnet clutch has been replaced, be sure to check the magnet clutch for

normal operation by applying voltage to the clutch.

PRECAUTIONS

HA-5

Page 1359 of 1767

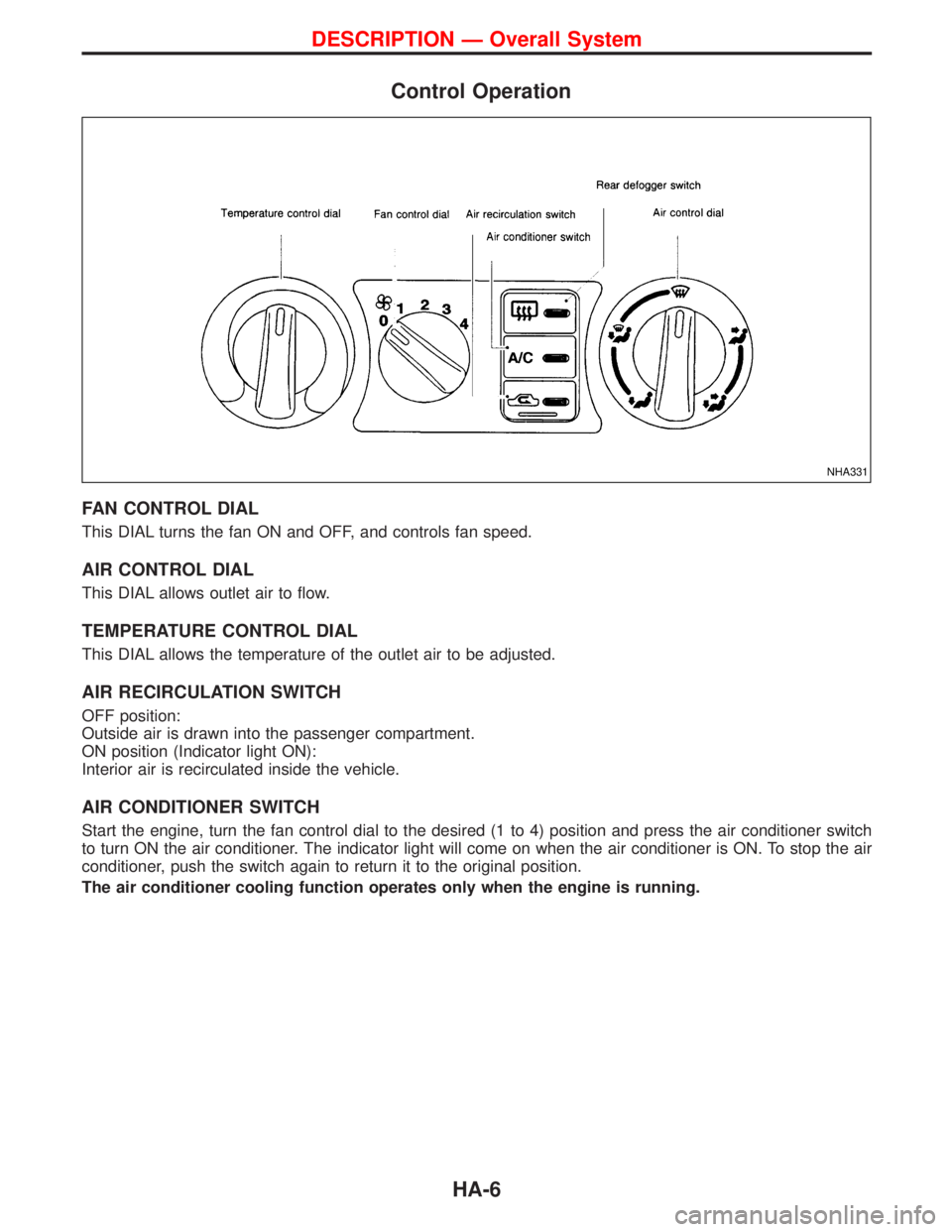

Control Operation

FAN CONTROL DIAL

This DIAL turns the fan ON and OFF, and controls fan speed.

AIR CONTROL DIAL

This DIAL allows outlet air to flow.

TEMPERATURE CONTROL DIAL

This DIAL allows the temperature of the outlet air to be adjusted.

AIR RECIRCULATION SWITCH

OFF position:

Outside air is drawn into the passenger compartment.

ON position (Indicator light ON):

Interior air is recirculated inside the vehicle.

AIR CONDITIONER SWITCH

Start the engine, turn the fan control dial to the desired (1 to 4) position and press the air conditioner switch

to turn ON the air conditioner. The indicator light will come on when the air conditioner is ON. To stop the air

conditioner, push the switch again to return it to the original position.

The air conditioner cooling function operates only when the engine is running.

NHA331

DESCRIPTION Ð Overall System

HA-6

Page 1369 of 1767

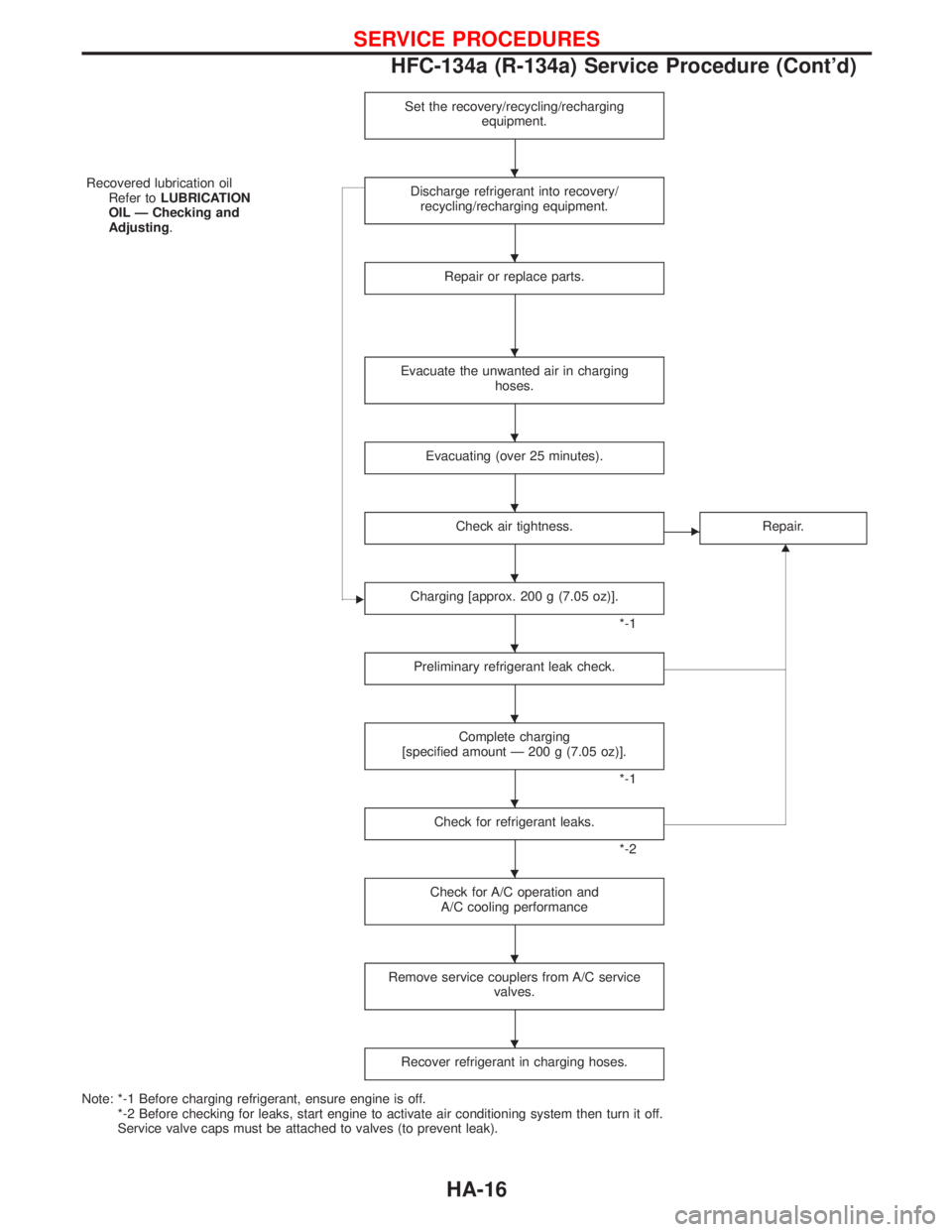

Set the recovery/recycling/recharging

equipment.

Recovered lubrication oil

Refer toLUBRICATION

OIL Ð Checking and

Adjusting.Discharge refrigerant into recovery/

recycling/recharging equipment.

Repair or replace parts.

Evacuate the unwanted air in charging

hoses.

Evacuating (over 25 minutes).

Check air tightness.ERepair.

G

ECharging [approx. 200 g (7.05 oz)].

*-1

Preliminary refrigerant leak check.

Complete charging

[specified amount Ð 200 g (7.05 oz)].

*-1

Check for refrigerant leaks.

*-2

Check for A/C operation and

A/C cooling performance

Remove service couplers from A/C service

valves.

Recover refrigerant in charging hoses.

Note: *-1 Before charging refrigerant, ensure engine is off.

*-2 Before checking for leaks, start engine to activate air conditioning system then turn it off.

Service valve caps must be attached to valves (to prevent leak).

H

H

H

H

H

H

H

H

H

H

H

H

SERVICE PROCEDURES

HFC-134a (R-134a) Service Procedure (Cont'd)

HA-16

Page 1370 of 1767

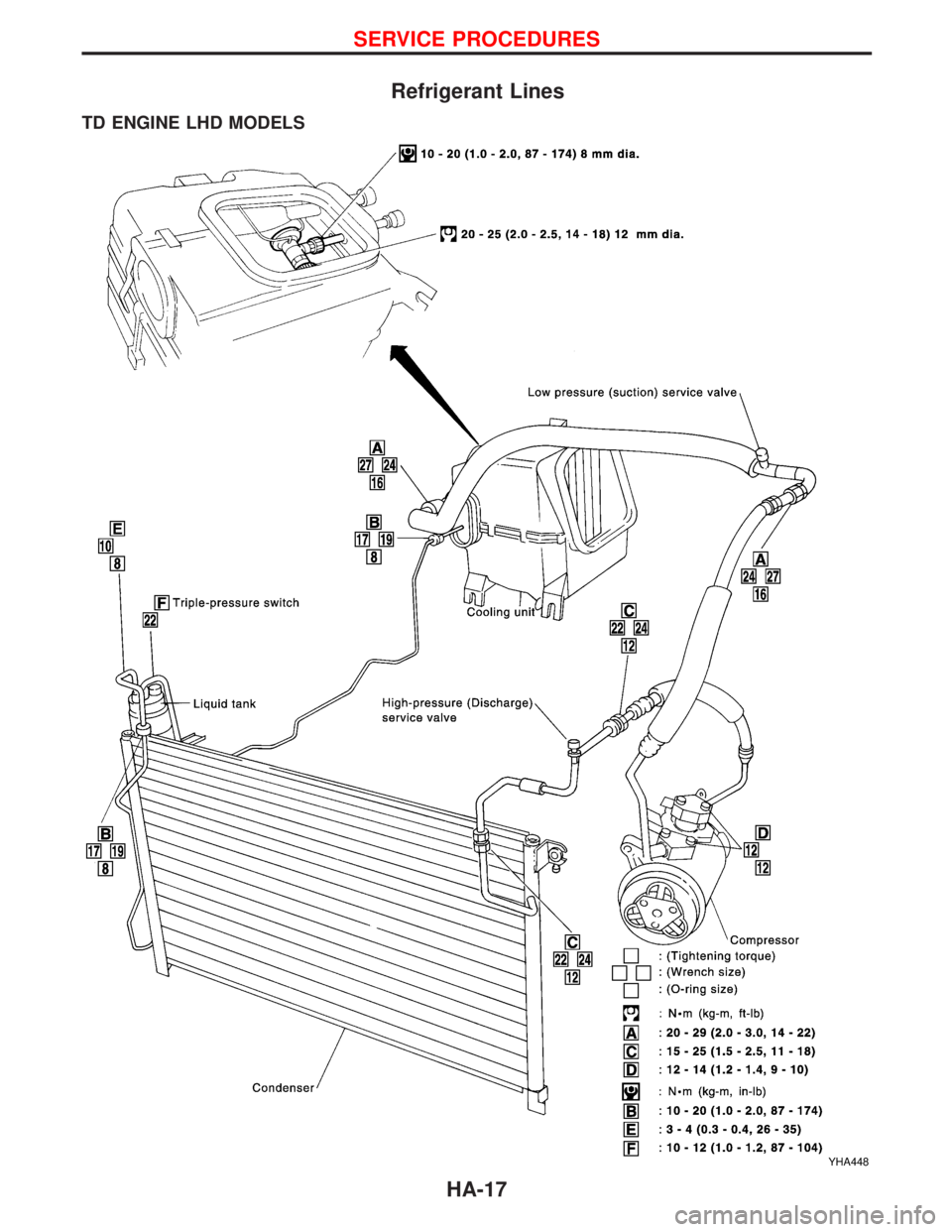

Refrigerant Lines

TD ENGINE LHD MODELS

YHA448

SERVICE PROCEDURES

HA-17