NISSAN TERRANO 2002 Service Repair Manual

TERRANO 2002

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57393/w960_57393-0.png

NISSAN TERRANO 2002 Service Repair Manual

Page 1439 of 1767

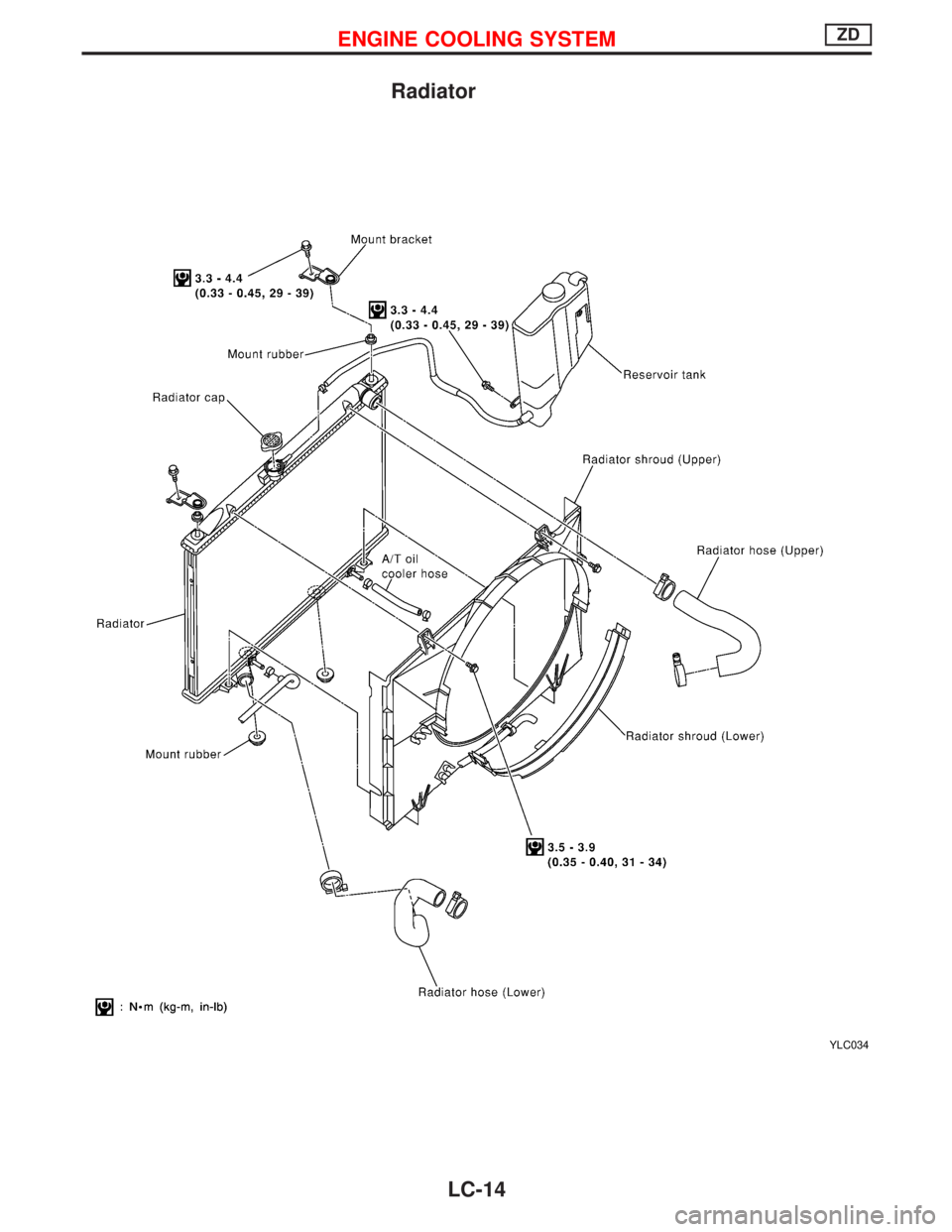

Radiator

YLC034

ENGINE COOLING SYSTEMZD

LC-14

Page 1440 of 1767

REMOVAL AND INSTALLATION

1. Remove under cover.

2. Drain engine coolant. Refer to MA section, ªChanging Engine

Coolantº.

3. Remove air cleaner case, air duct and resonator.

4. Remove battery (right side).

5. Remove radiator shroud (lower).

6. Remove radiator shroud (front).

7. Disconnect radiator hose (upper and lower).

8. Disconnect reservoir tank hose.

9. Disconnect A/T oil cooler hose (Only A/T models).

10. Remove radiator.

11. After repairing or replacing radiator, install all removed parts in

reverse order of removal.

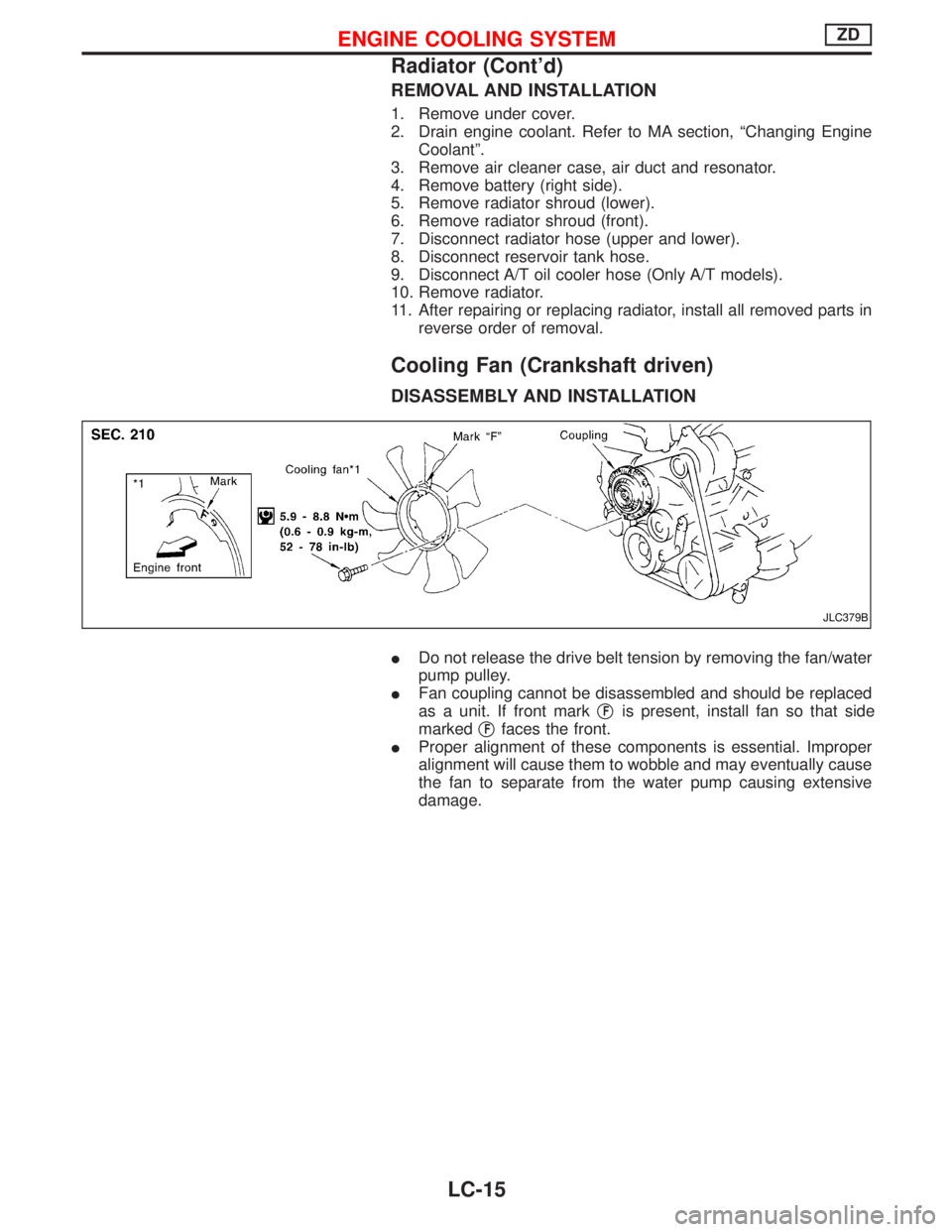

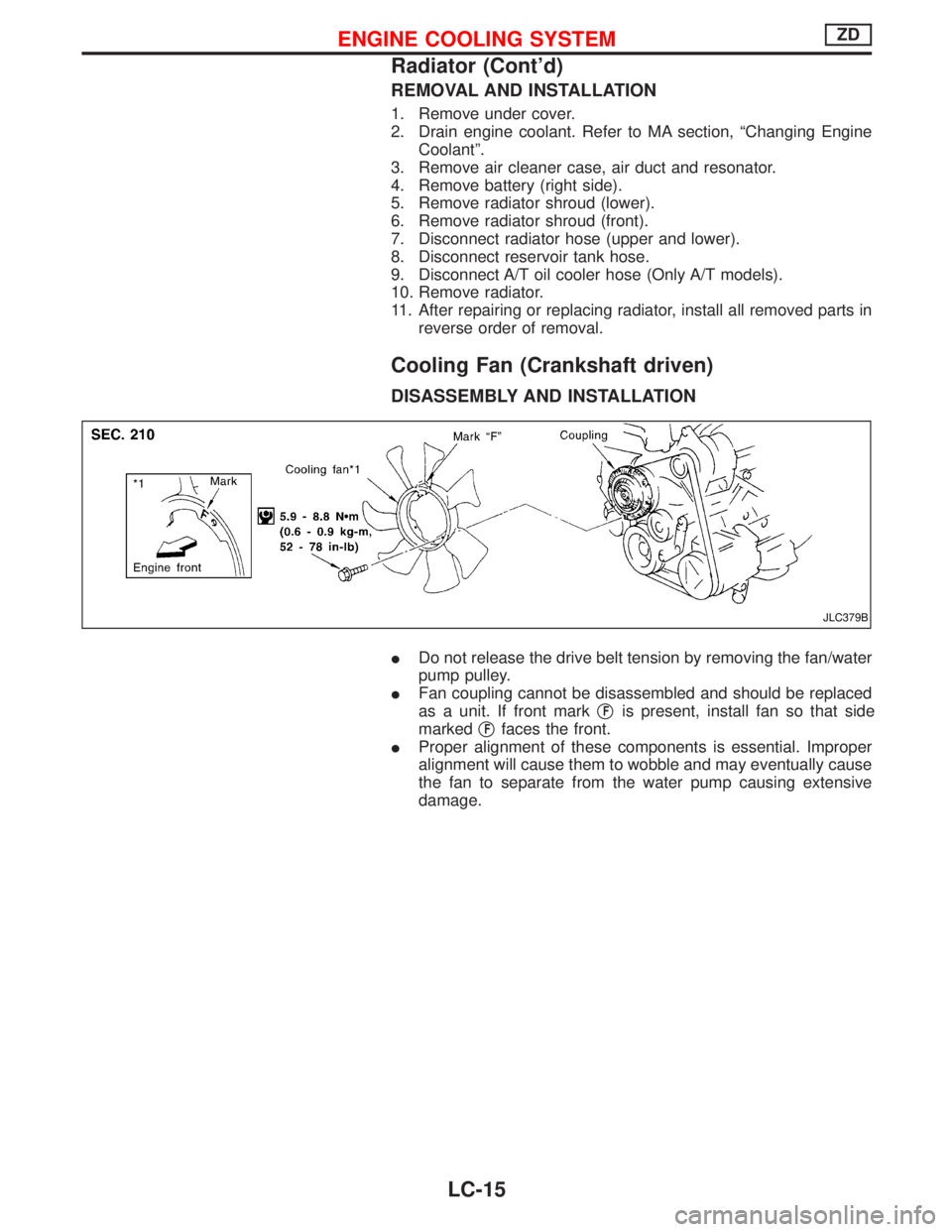

Cooling Fan (Crankshaft driven)

DISASSEMBLY AND INSTALLATION

IDo not release the drive belt tension by removing the fan/water

pump pulley.

IFan coupling cannot be disassembled and should be replaced

as a unit. If front markq

Fis present, install fan so that side

markedq

Ffaces the front.

IProper alignment of these components is essential. Improper

alignment will cause them to wobble and may eventually cause

the fan to separate from the water pump causing extensive

damage.

JLC379B

ENGINE COOLING SYSTEMZD

Radiator (Cont'd)

LC-15

Page 1441 of 1767

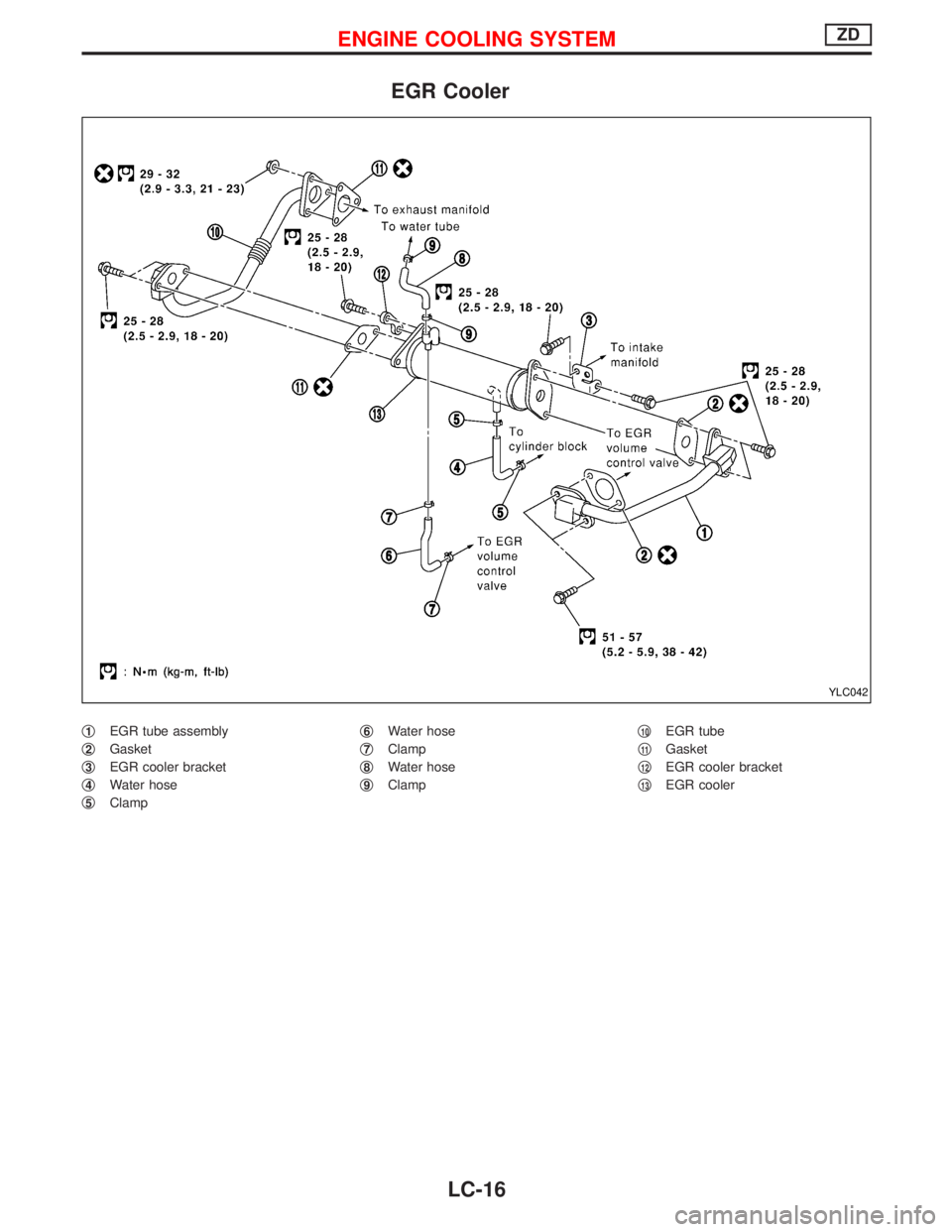

EGR Cooler

q1EGR tube assembly

q

2Gasket

q

3EGR cooler bracket

q

4Water hose

q

5Clampq

6Water hose

q

7Clamp

q

8Water hose

q

9Clampq

10EGR tube

q

11Gasket

q

12EGR cooler bracket

q

13EGR cooler

YLC042

ENGINE COOLING SYSTEMZD

LC-16

Page 1442 of 1767

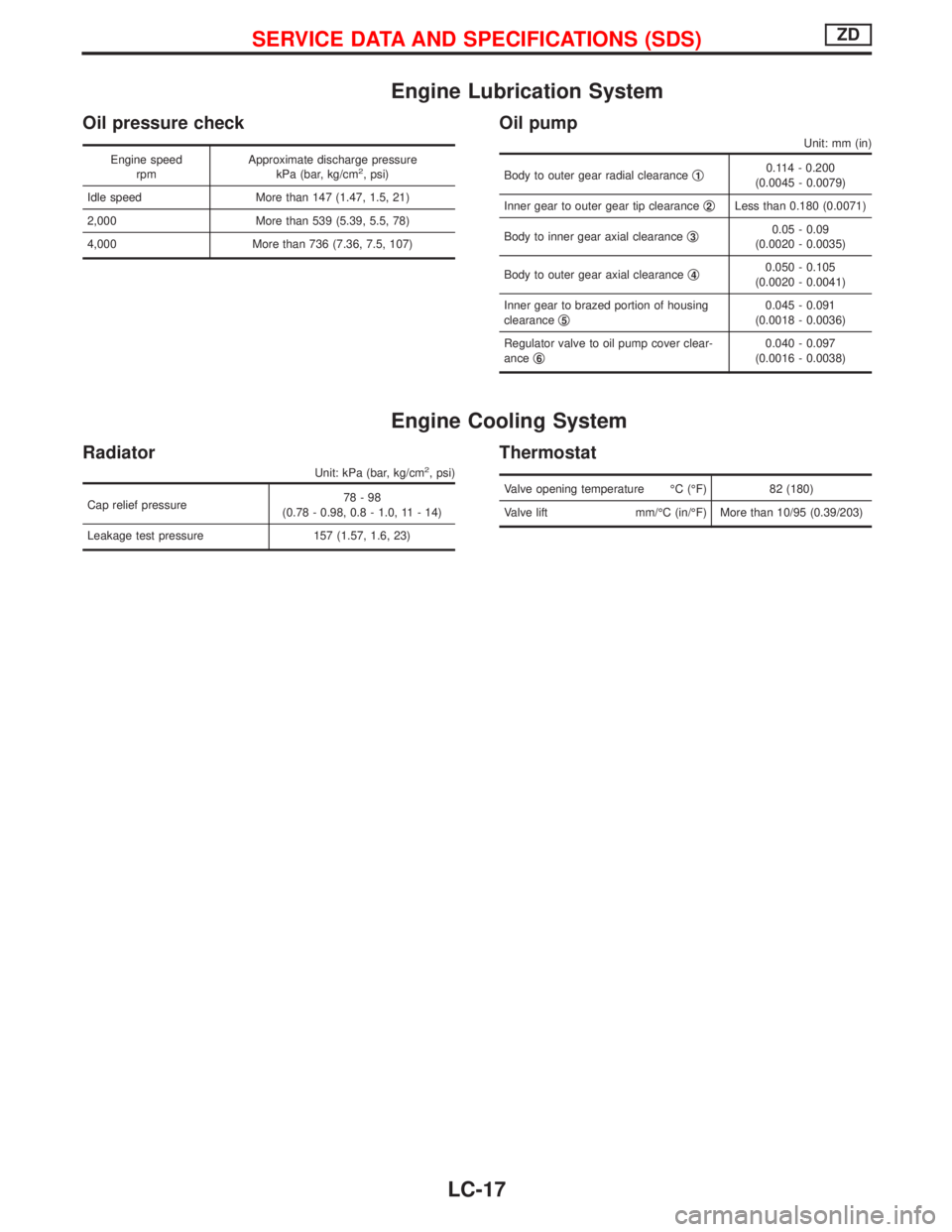

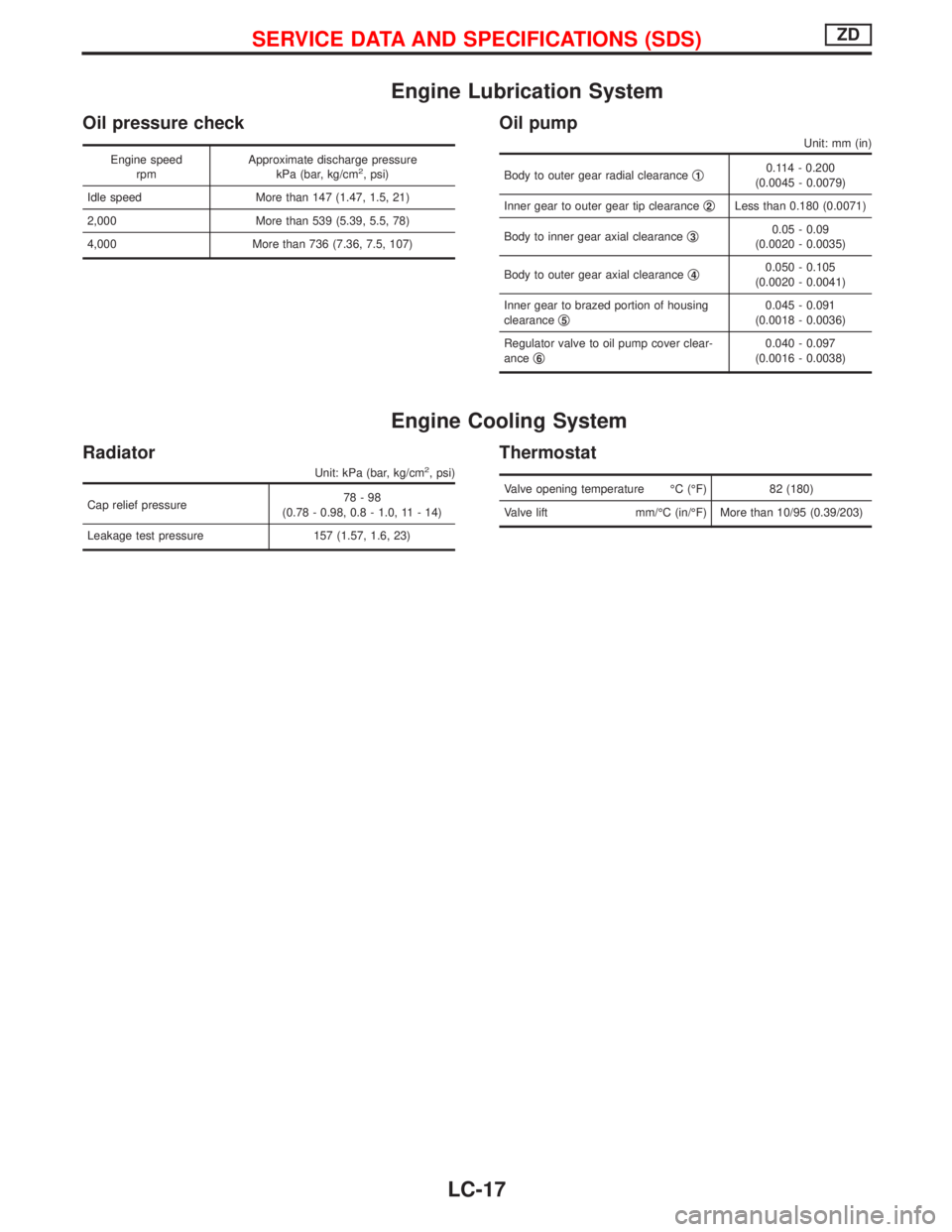

Engine Lubrication System

Oil pressure check

Engine speed

rpmApproximate discharge pressure

kPa (bar, kg/cm2, psi)

Idle speed More than 147 (1.47, 1.5, 21)

2,000 More than 539 (5.39, 5.5, 78)

4,000 More than 736 (7.36, 7.5, 107)

Oil pump

Unit: mm (in)

Body to outer gear radial clearanceq10.114 - 0.200

(0.0045 - 0.0079)

Inner gear to outer gear tip clearanceq

2Less than 0.180 (0.0071)

Body to inner gear axial clearanceq

30.05 - 0.09

(0.0020 - 0.0035)

Body to outer gear axial clearanceq

40.050 - 0.105

(0.0020 - 0.0041)

Inner gear to brazed portion of housing

clearanceq

50.045 - 0.091

(0.0018 - 0.0036)

Regulator valve to oil pump cover clear-

anceq

60.040 - 0.097

(0.0016 - 0.0038)

Engine Cooling System

Radiator

Unit: kPa (bar, kg/cm2, psi)

Cap relief pressure78-98

(0.78 - 0.98, 0.8 - 1.0, 11 - 14)

Leakage test pressure 157 (1.57, 1.6, 23)

Thermostat

Valve opening temperature ÉC (ÉF) 82 (180)

Valve lift mm/ÉC (in/ÉF) More than 10/95 (0.39/203)

SERVICE DATA AND SPECIFICATIONS (SDS)ZD

LC-17

Page 1444 of 1767

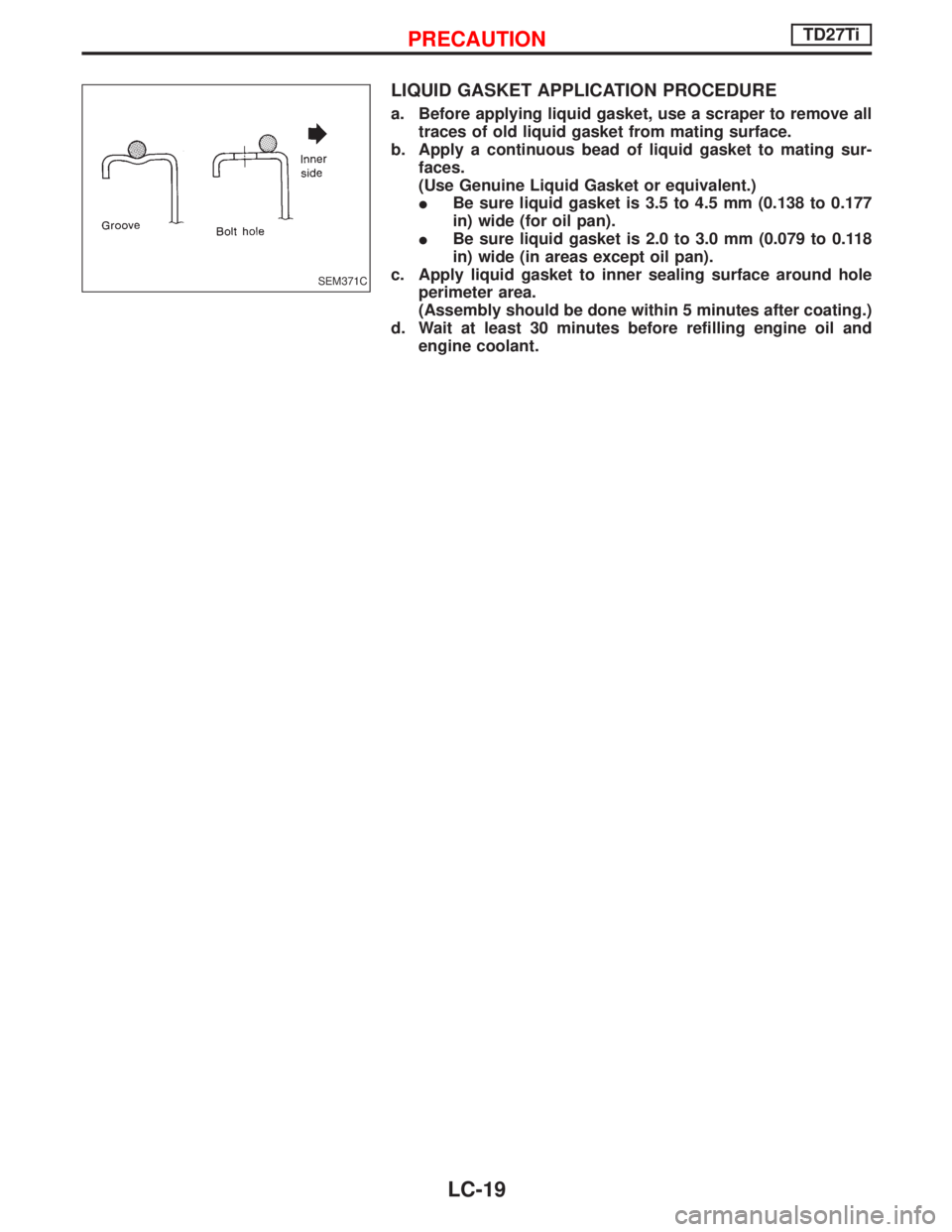

LIQUID GASKET APPLICATION PROCEDURE

a. Before applying liquid gasket, use a scraper to remove all

traces of old liquid gasket from mating surface.

b. Apply a continuous bead of liquid gasket to mating sur-

faces.

(Use Genuine Liquid Gasket or equivalent.)

IBe sure liquid gasket is 3.5 to 4.5 mm (0.138 to 0.177

in) wide (for oil pan).

IBe sure liquid gasket is 2.0 to 3.0 mm (0.079 to 0.118

in) wide (in areas except oil pan).

c. Apply liquid gasket to inner sealing surface around hole

perimeter area.

(Assembly should be done within 5 minutes after coating.)

d. Wait at least 30 minutes before refilling engine oil and

engine coolant.

SEM371C

PRECAUTIONTD27Ti

LC-19

Page 1445 of 1767

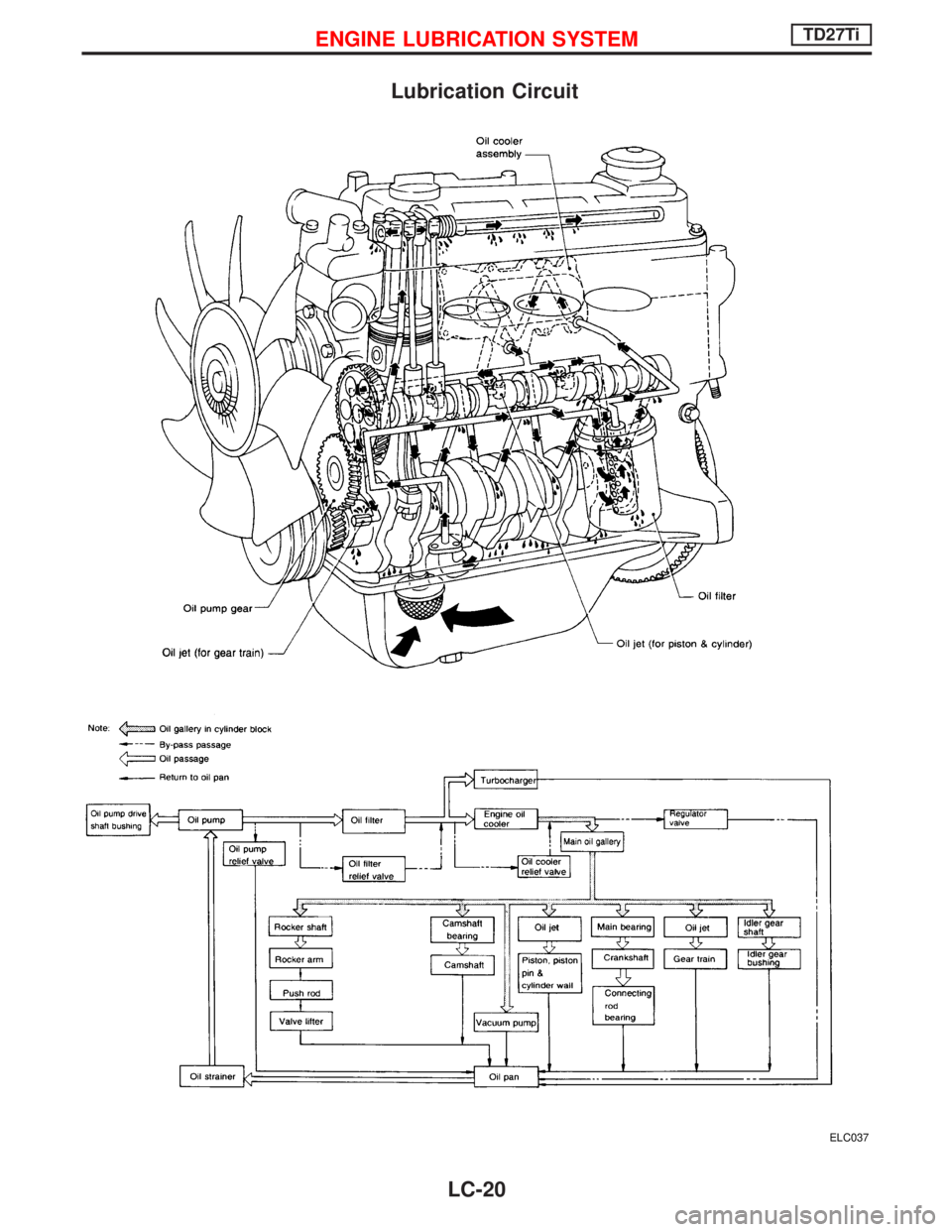

Lubrication Circuit

ELC037

ENGINE LUBRICATION SYSTEMTD27Ti

LC-20

Page 1446 of 1767

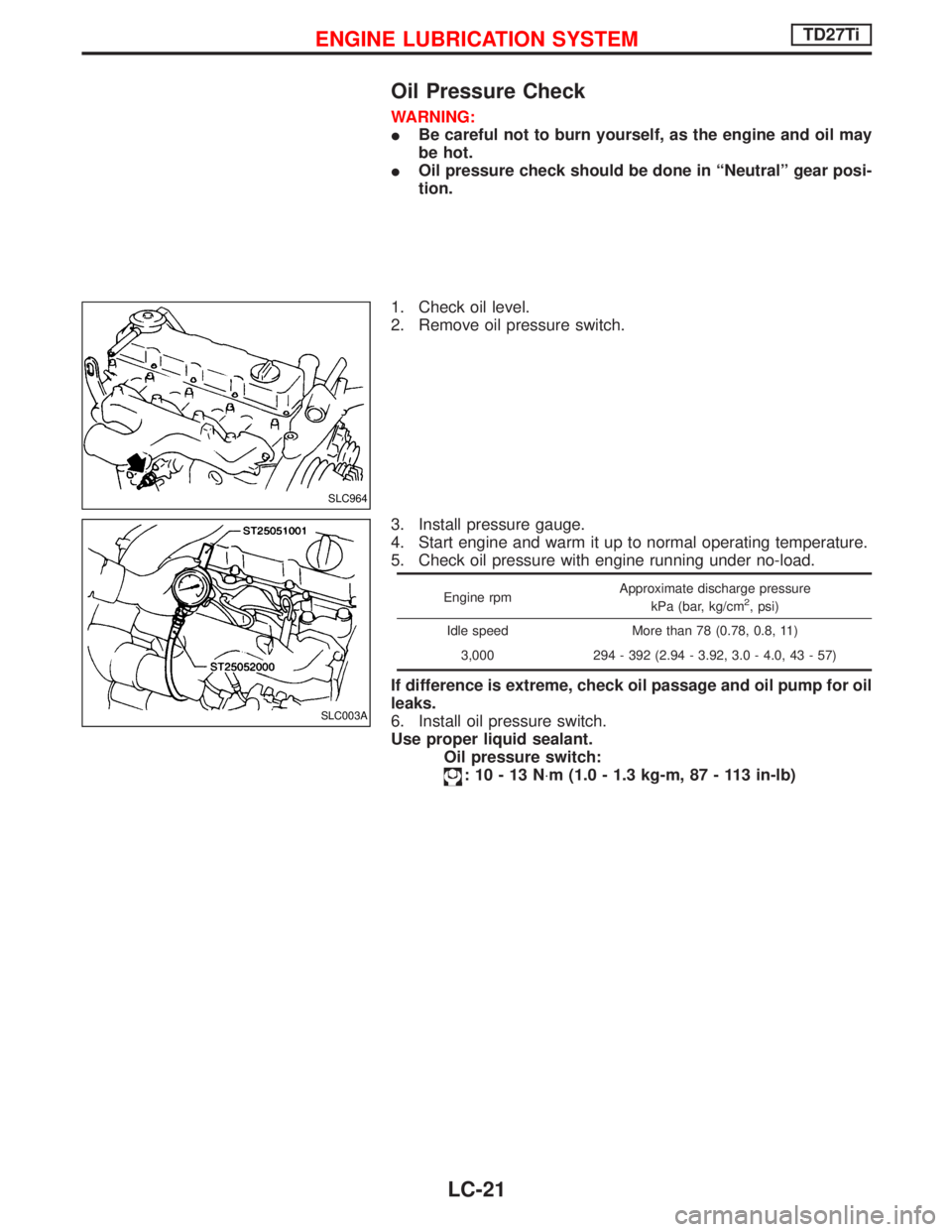

Oil Pressure Check

WARNING:

IBe careful not to burn yourself, as the engine and oil may

be hot.

IOil pressure check should be done in ªNeutralº gear posi-

tion.

1. Check oil level.

2. Remove oil pressure switch.

3. Install pressure gauge.

4. Start engine and warm it up to normal operating temperature.

5. Check oil pressure with engine running under no-load.

Engine rpmApproximate discharge pressure

kPa (bar, kg/cm2, psi)

Idle speed More than 78 (0.78, 0.8, 11)

3,000 294 - 392 (2.94 - 3.92, 3.0 - 4.0, 43 - 57)

If difference is extreme, check oil passage and oil pump for oil

leaks.

6. Install oil pressure switch.

Use proper liquid sealant.

Oil pressure switch:

:10-13N×m (1.0 - 1.3 kg-m, 87 - 113 in-lb)

SLC964

SLC003A

ENGINE LUBRICATION SYSTEMTD27Ti

LC-21

Page 1447 of 1767

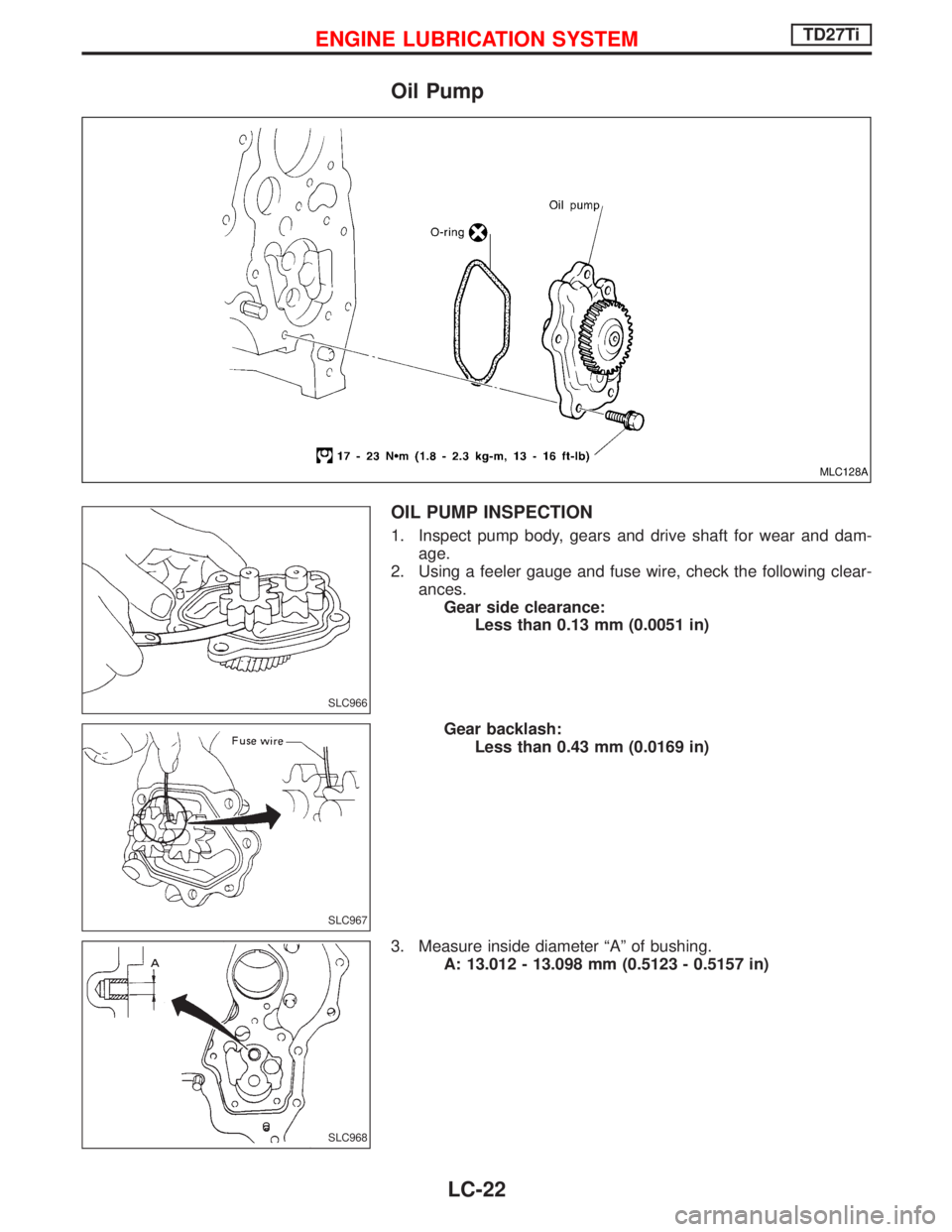

Oil Pump

OIL PUMP INSPECTION

1. Inspect pump body, gears and drive shaft for wear and dam-

age.

2. Using a feeler gauge and fuse wire, check the following clear-

ances.

Gear side clearance:

Less than 0.13 mm (0.0051 in)

Gear backlash:

Less than 0.43 mm (0.0169 in)

3. Measure inside diameter ªAº of bushing.

A: 13.012 - 13.098 mm (0.5123 - 0.5157 in)

MLC128A

SLC966

SLC967

SLC968

ENGINE LUBRICATION SYSTEMTD27Ti

LC-22

Page 1448 of 1767

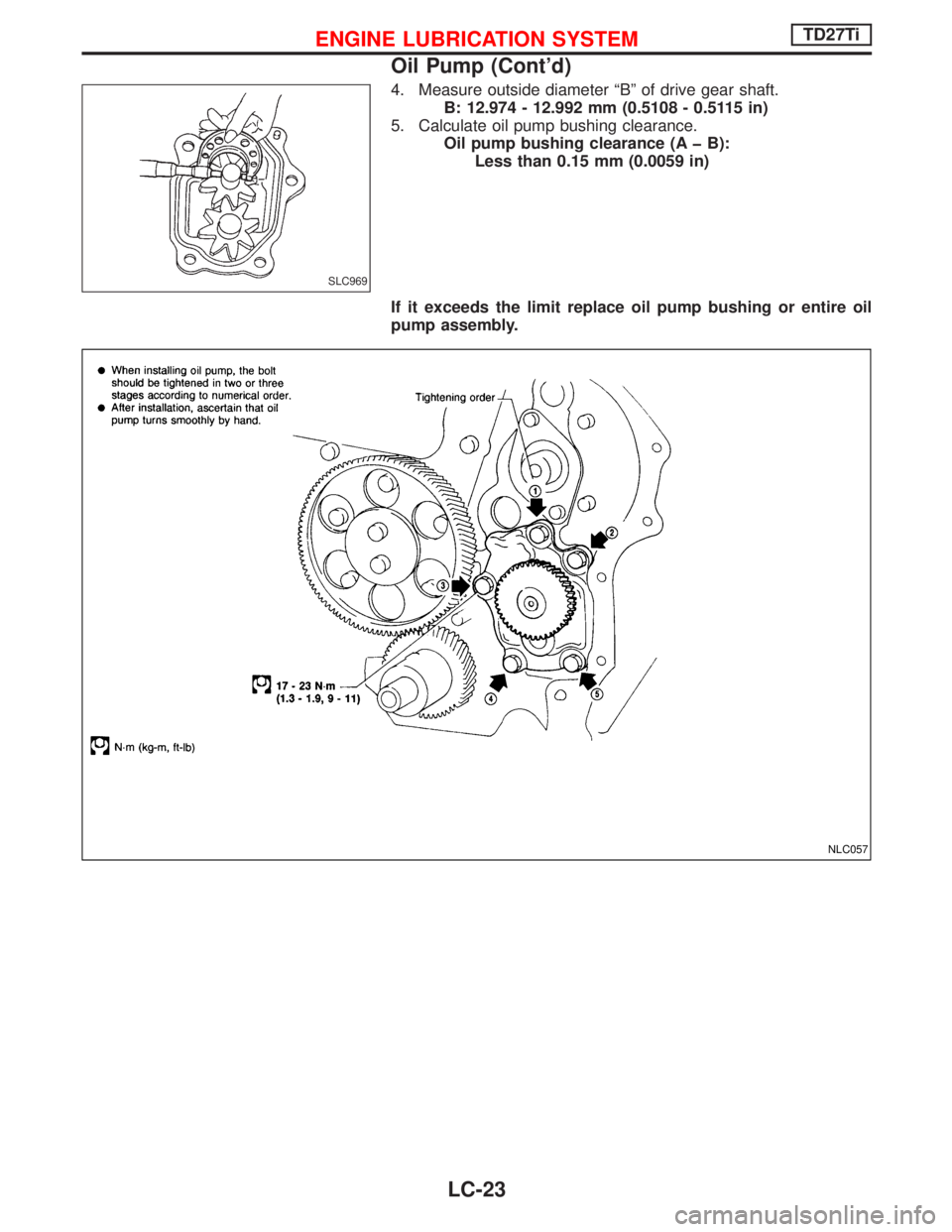

4. Measure outside diameter ªBº of drive gear shaft.

B: 12.974 - 12.992 mm (0.5108 - 0.5115 in)

5. Calculate oil pump bushing clearance.

Oil pump bushing clearance (A þ B):

Less than 0.15 mm (0.0059 in)

If it exceeds the limit replace oil pump bushing or entire oil

pump assembly.

SLC969

NLC057

ENGINE LUBRICATION SYSTEMTD27Ti

Oil Pump (Cont'd)

LC-23

Page 1449 of 1767

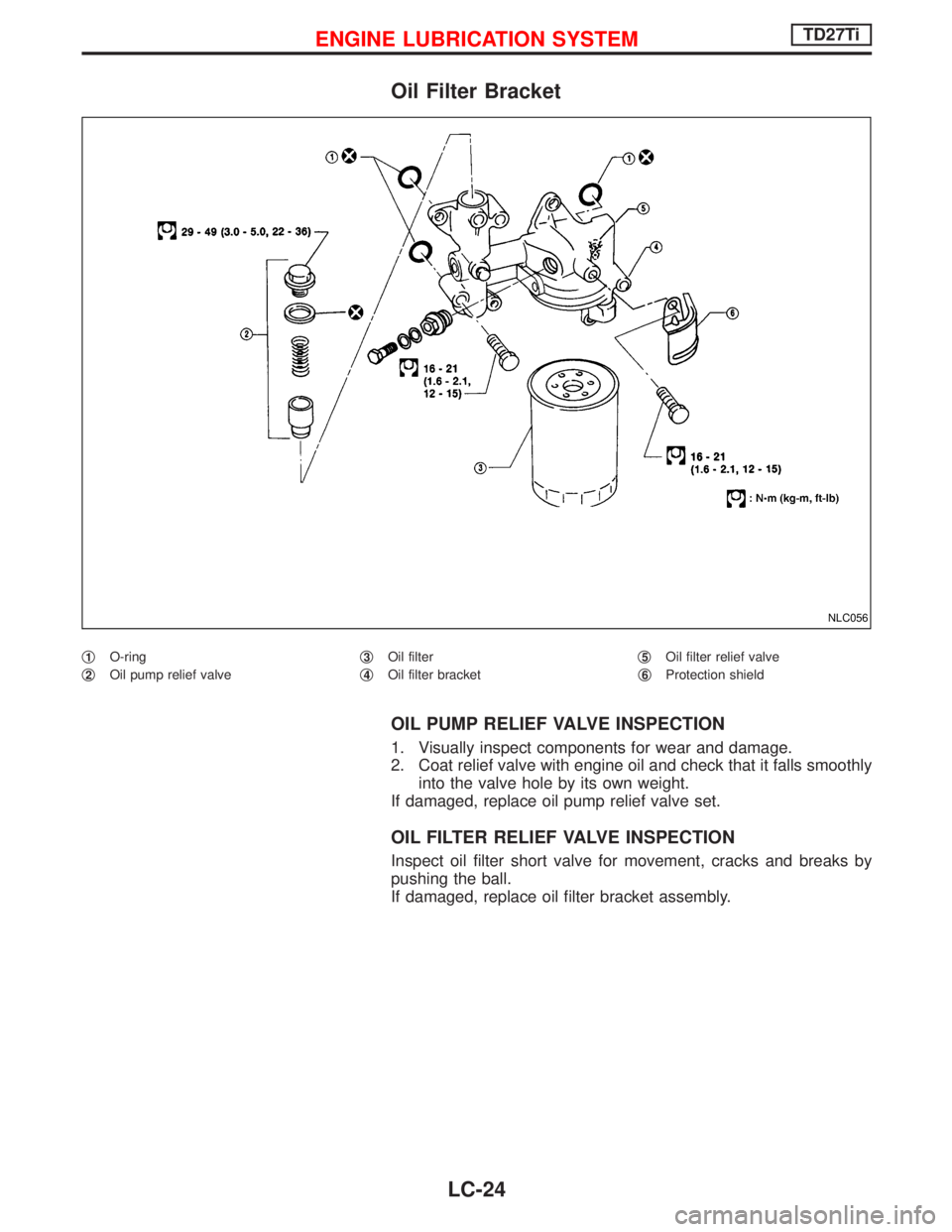

Oil Filter Bracket

q1O-ring

q

2Oil pump relief valveq

3Oil filter

q

4Oil filter bracketq

5Oil filter relief valve

q

6Protection shield

OIL PUMP RELIEF VALVE INSPECTION

1. Visually inspect components for wear and damage.

2. Coat relief valve with engine oil and check that it falls smoothly

into the valve hole by its own weight.

If damaged, replace oil pump relief valve set.

OIL FILTER RELIEF VALVE INSPECTION

Inspect oil filter short valve for movement, cracks and breaks by

pushing the ball.

If damaged, replace oil filter bracket assembly.

NLC056

ENGINE LUBRICATION SYSTEMTD27Ti

LC-24