engine NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 1429 of 1767

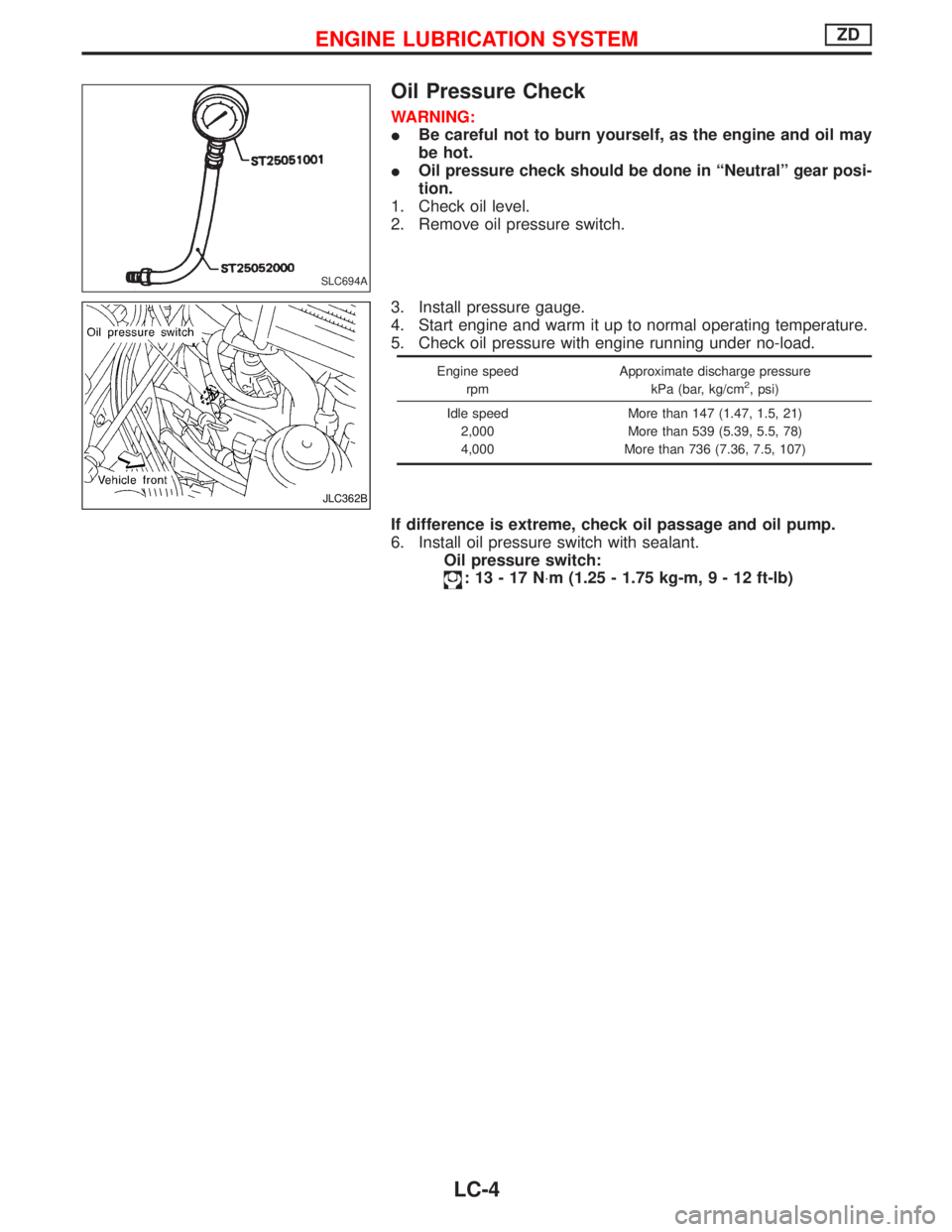

Oil Pressure Check

WARNING:

IBe careful not to burn yourself, as the engine and oil may

be hot.

IOil pressure check should be done in ªNeutralº gear posi-

tion.

1. Check oil level.

2. Remove oil pressure switch.

3. Install pressure gauge.

4. Start engine and warm it up to normal operating temperature.

5. Check oil pressure with engine running under no-load.

Engine speed

rpmApproximate discharge pressure

kPa (bar, kg/cm2, psi)

Idle speed

2,000

4,000More than 147 (1.47, 1.5, 21)

More than 539 (5.39, 5.5, 78)

More than 736 (7.36, 7.5, 107)

If difference is extreme, check oil passage and oil pump.

6. Install oil pressure switch with sealant.

Oil pressure switch:

:13-17N×m (1.25 - 1.75 kg-m,9-12ft-lb)

SLC694A

JLC362B

ENGINE LUBRICATION SYSTEMZD

LC-4

Page 1430 of 1767

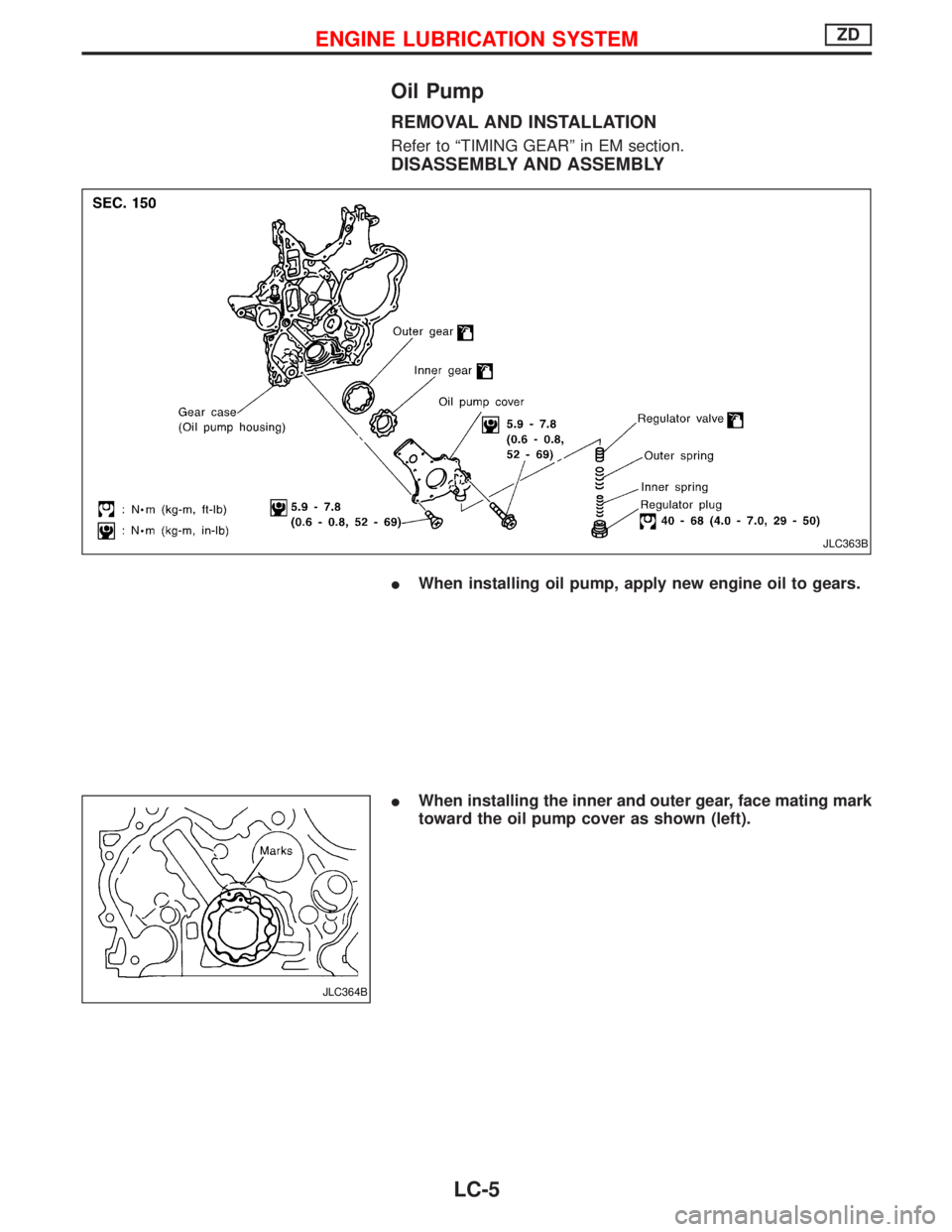

Oil Pump

REMOVAL AND INSTALLATION

Refer to ªTIMING GEARº in EM section.

DISASSEMBLY AND ASSEMBLY

IWhen installing oil pump, apply new engine oil to gears.

IWhen installing the inner and outer gear, face mating mark

toward the oil pump cover as shown (left).

JLC363B

JLC364B

ENGINE LUBRICATION SYSTEMZD

LC-5

Page 1431 of 1767

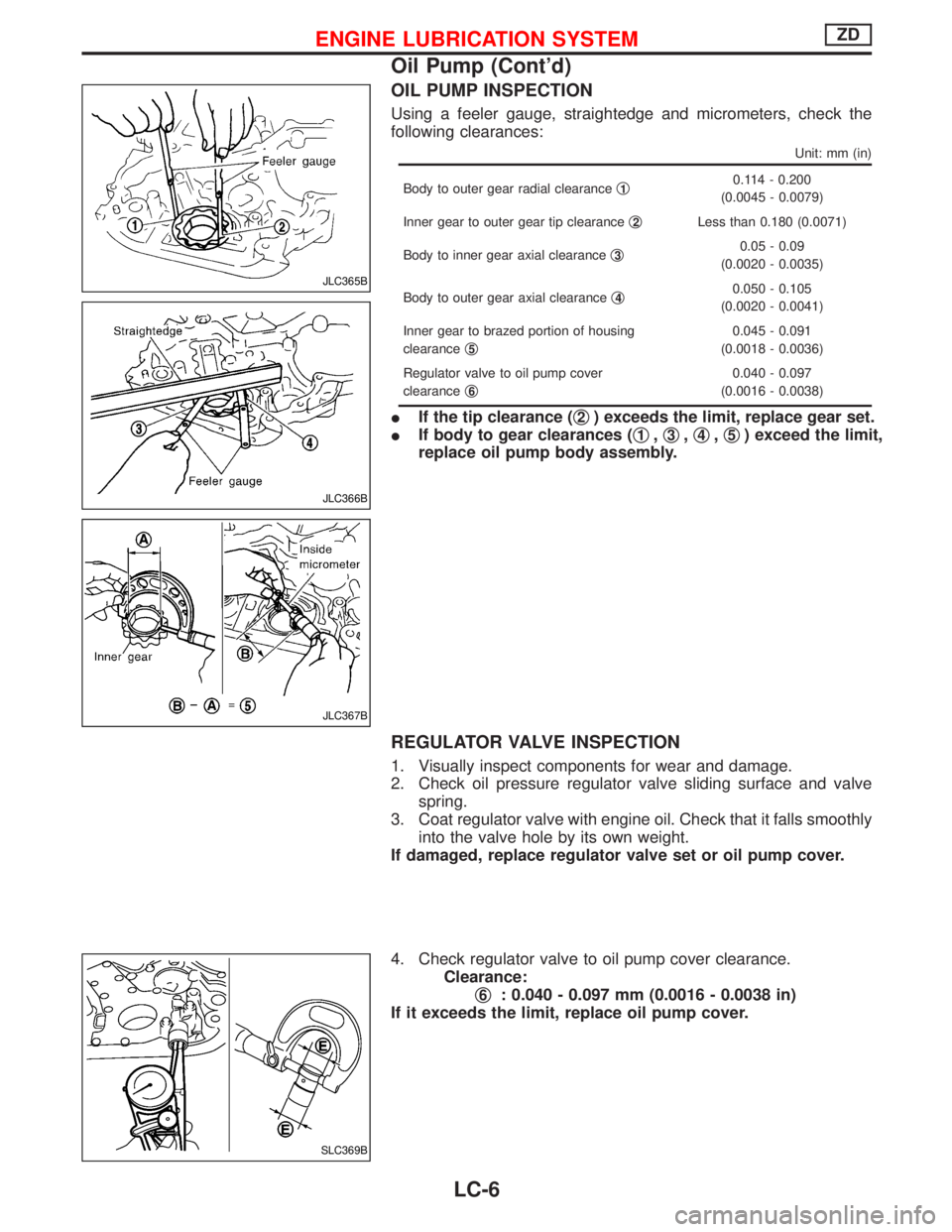

OIL PUMP INSPECTION

Using a feeler gauge, straightedge and micrometers, check the

following clearances:

Unit: mm (in)

Body to outer gear radial clearanceq10.114 - 0.200

(0.0045 - 0.0079)

Inner gear to outer gear tip clearanceq

2Less than 0.180 (0.0071)

Body to inner gear axial clearanceq

30.05 - 0.09

(0.0020 - 0.0035)

Body to outer gear axial clearanceq

40.050 - 0.105

(0.0020 - 0.0041)

Inner gear to brazed portion of housing

clearanceq

5

0.045 - 0.091

(0.0018 - 0.0036)

Regulator valve to oil pump cover

clearanceq

6

0.040 - 0.097

(0.0016 - 0.0038)

IIf the tip clearance (q2) exceeds the limit, replace gear set.

IIf body to gear clearances (q

1,q3,q4,q5) exceed the limit,

replace oil pump body assembly.

REGULATOR VALVE INSPECTION

1. Visually inspect components for wear and damage.

2. Check oil pressure regulator valve sliding surface and valve

spring.

3. Coat regulator valve with engine oil. Check that it falls smoothly

into the valve hole by its own weight.

If damaged, replace regulator valve set or oil pump cover.

4. Check regulator valve to oil pump cover clearance.

Clearance:

q

6: 0.040 - 0.097 mm (0.0016 - 0.0038 in)

If it exceeds the limit, replace oil pump cover.

JLC365B

JLC366B

JLC367B

SLC369B

ENGINE LUBRICATION SYSTEMZD

Oil Pump (Cont'd)

LC-6

Page 1432 of 1767

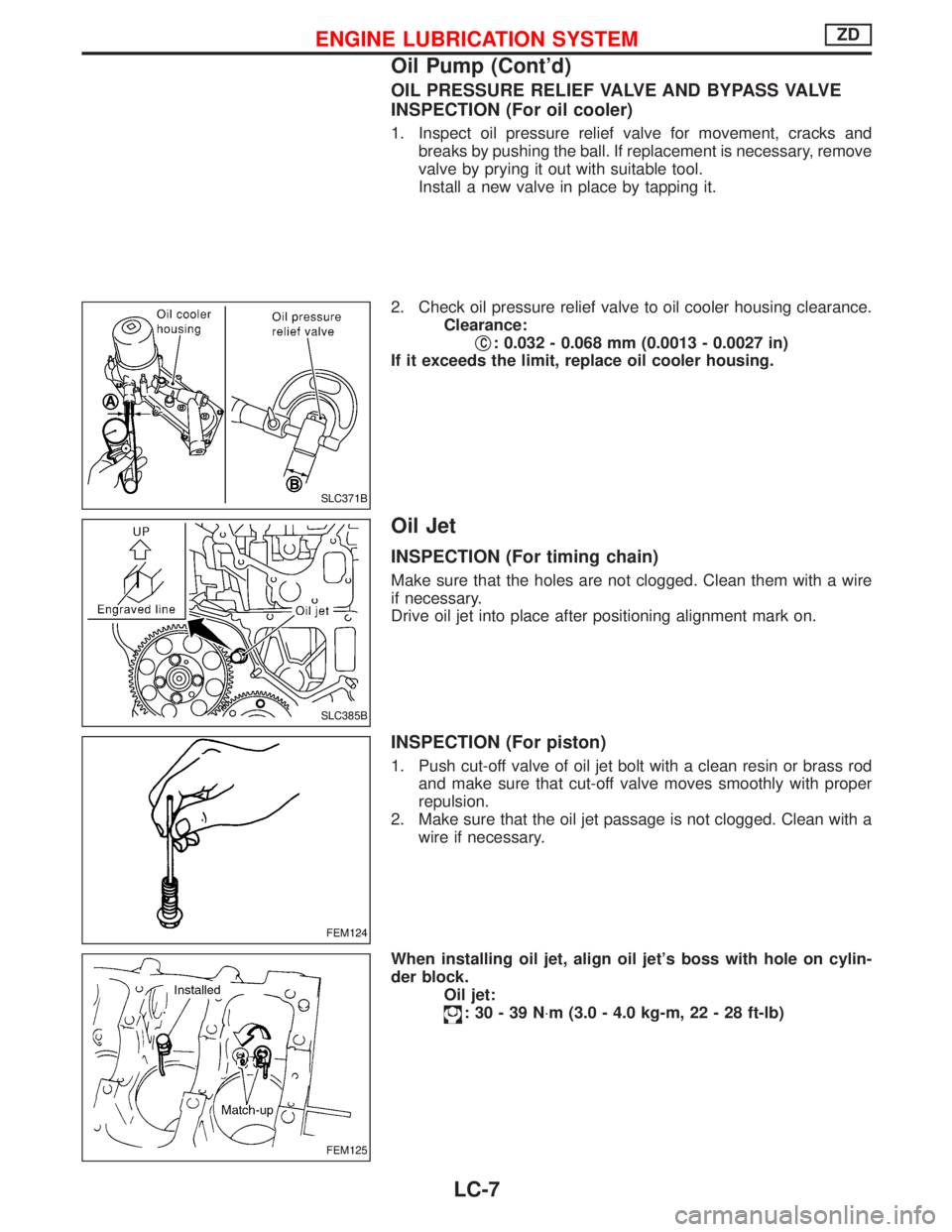

OIL PRESSURE RELIEF VALVE AND BYPASS VALVE

INSPECTION (For oil cooler)

1. Inspect oil pressure relief valve for movement, cracks and

breaks by pushing the ball. If replacement is necessary, remove

valve by prying it out with suitable tool.

Install a new valve in place by tapping it.

2. Check oil pressure relief valve to oil cooler housing clearance.

Clearance:

q

C: 0.032 - 0.068 mm (0.0013 - 0.0027 in)

If it exceeds the limit, replace oil cooler housing.

Oil Jet

INSPECTION (For timing chain)

Make sure that the holes are not clogged. Clean them with a wire

if necessary.

Drive oil jet into place after positioning alignment mark on.

INSPECTION (For piston)

1. Push cut-off valve of oil jet bolt with a clean resin or brass rod

and make sure that cut-off valve moves smoothly with proper

repulsion.

2. Make sure that the oil jet passage is not clogged. Clean with a

wire if necessary.

When installing oil jet, align oil jet's boss with hole on cylin-

der block.

Oil jet:

:30-39N×m (3.0 - 4.0 kg-m, 22 - 28 ft-lb)

SLC371B

SLC385B

FEM124

FEM125

ENGINE LUBRICATION SYSTEMZD

Oil Pump (Cont'd)

LC-7

Page 1433 of 1767

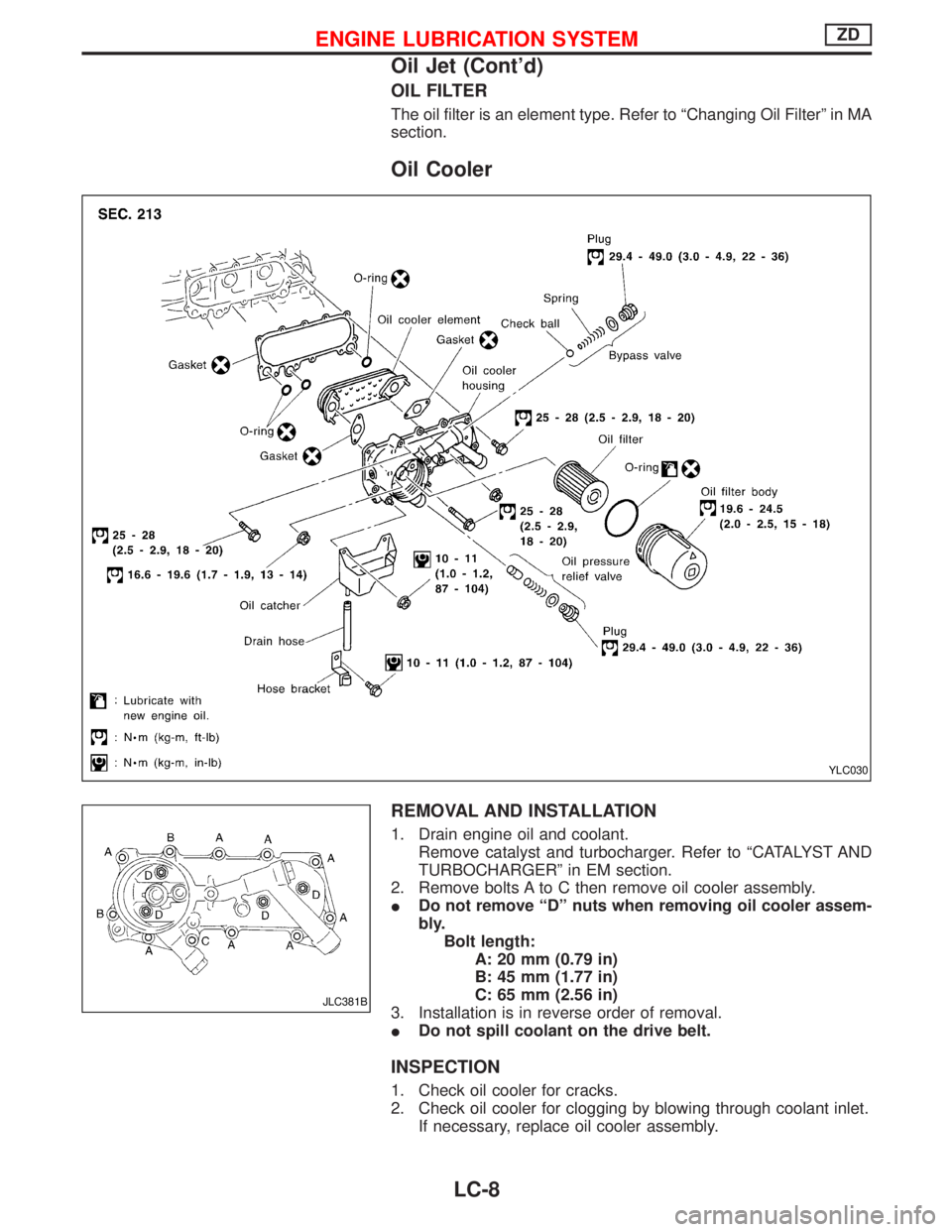

OIL FILTER

The oil filter is an element type. Refer to ªChanging Oil Filterº in MA

section.

Oil Cooler

REMOVAL AND INSTALLATION

1. Drain engine oil and coolant.

Remove catalyst and turbocharger. Refer to ªCATALYST AND

TURBOCHARGERº in EM section.

2. Remove bolts A to C then remove oil cooler assembly.

IDo not remove ªDº nuts when removing oil cooler assem-

bly.

Bolt length:

A: 20 mm (0.79 in)

B: 45 mm (1.77 in)

C: 65 mm (2.56 in)

3. Installation is in reverse order of removal.

IDo not spill coolant on the drive belt.

INSPECTION

1. Check oil cooler for cracks.

2. Check oil cooler for clogging by blowing through coolant inlet.

If necessary, replace oil cooler assembly.

YLC030

JLC381B

ENGINE LUBRICATION SYSTEMZD

Oil Jet (Cont'd)

LC-8

Page 1434 of 1767

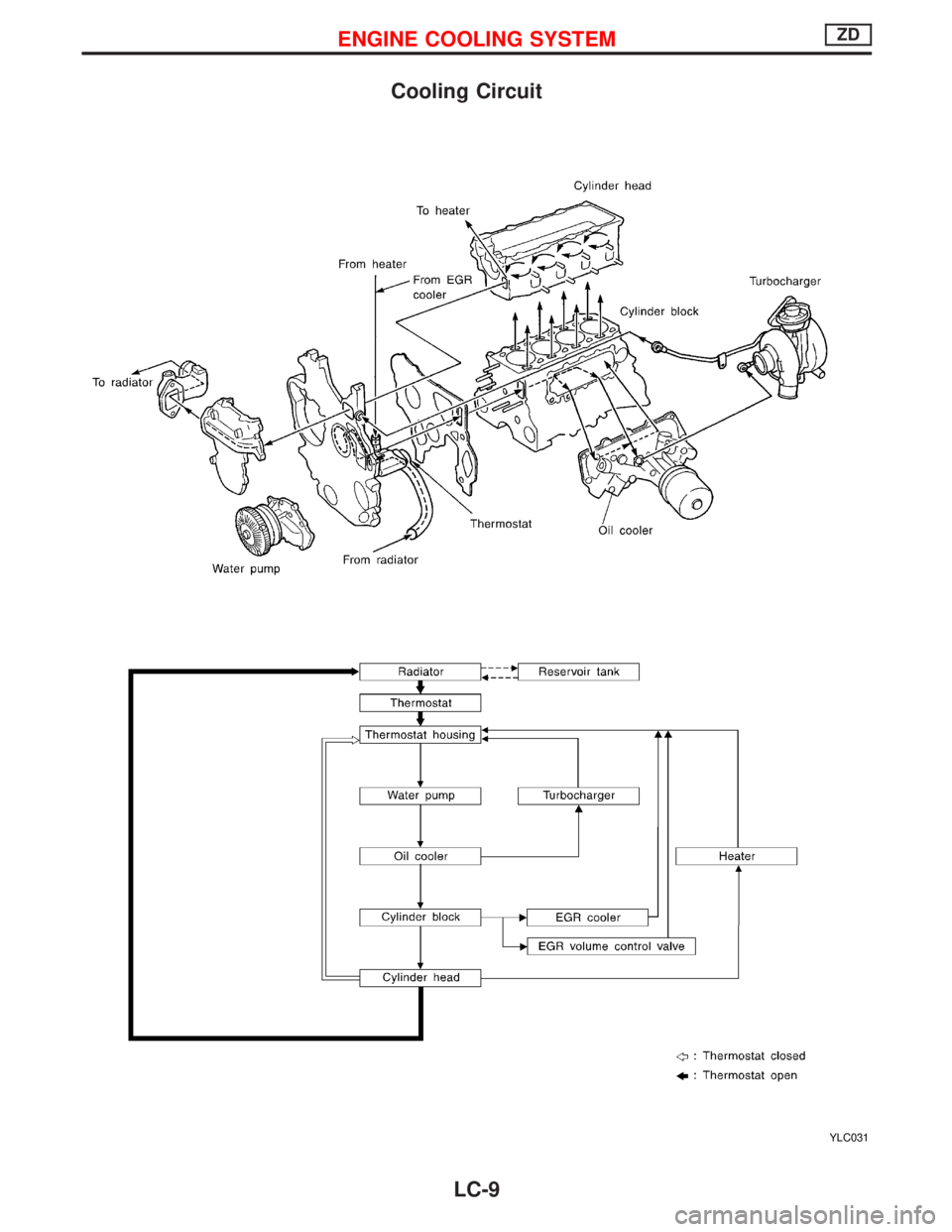

Cooling Circuit

YLC031

ENGINE COOLING SYSTEMZD

LC-9

Page 1435 of 1767

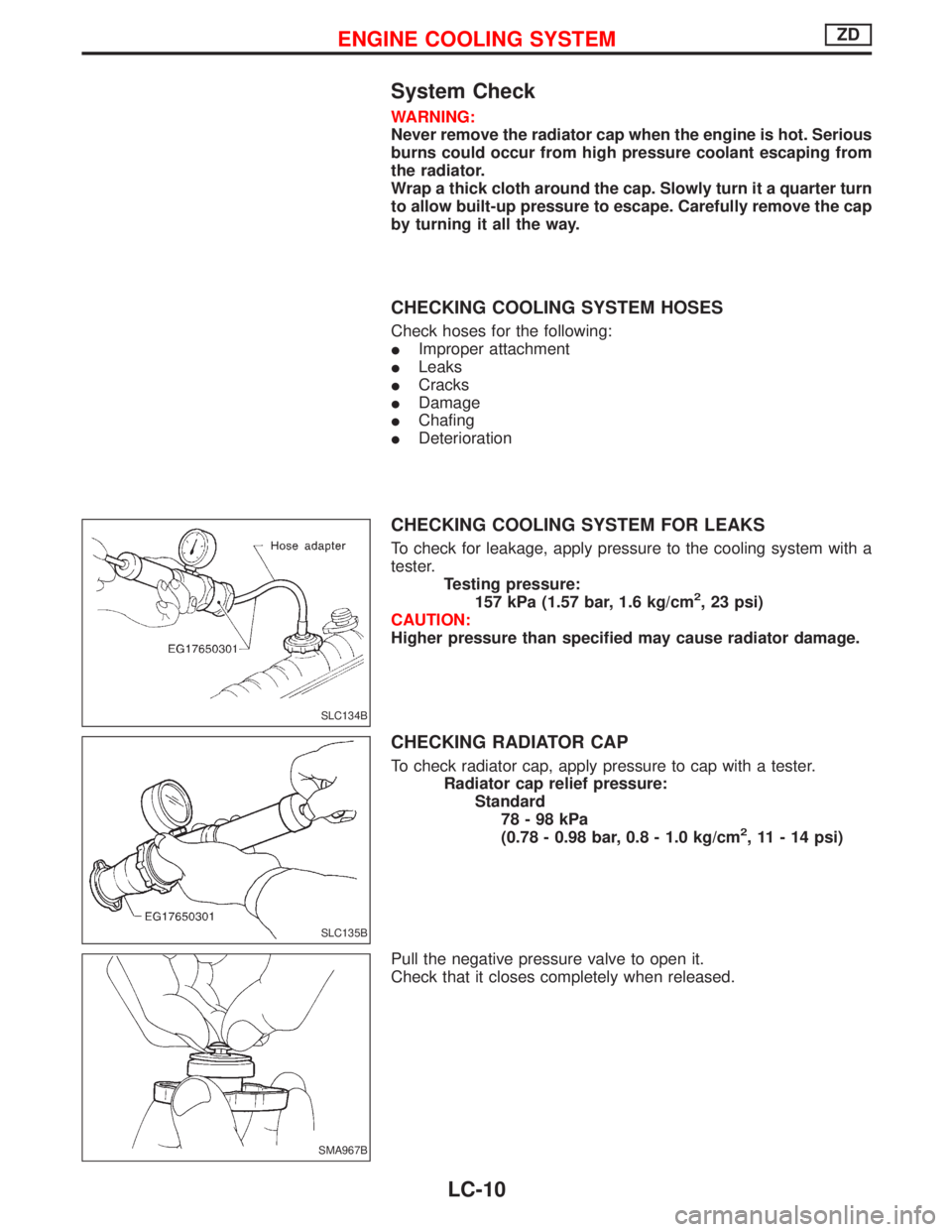

System Check

WARNING:

Never remove the radiator cap when the engine is hot. Serious

burns could occur from high pressure coolant escaping from

the radiator.

Wrap a thick cloth around the cap. Slowly turn it a quarter turn

to allow built-up pressure to escape. Carefully remove the cap

by turning it all the way.

CHECKING COOLING SYSTEM HOSES

Check hoses for the following:

IImproper attachment

ILeaks

ICracks

IDamage

IChafing

IDeterioration

CHECKING COOLING SYSTEM FOR LEAKS

To check for leakage, apply pressure to the cooling system with a

tester.

Testing pressure:

157 kPa (1.57 bar, 1.6 kg/cm

2, 23 psi)

CAUTION:

Higher pressure than specified may cause radiator damage.

CHECKING RADIATOR CAP

To check radiator cap, apply pressure to cap with a tester.

Radiator cap relief pressure:

Standard

78-98kPa

(0.78 - 0.98 bar, 0.8 - 1.0 kg/cm

2, 11 - 14 psi)

Pull the negative pressure valve to open it.

Check that it closes completely when released.

SLC134B

SLC135B

SMA967B

ENGINE COOLING SYSTEMZD

LC-10

Page 1436 of 1767

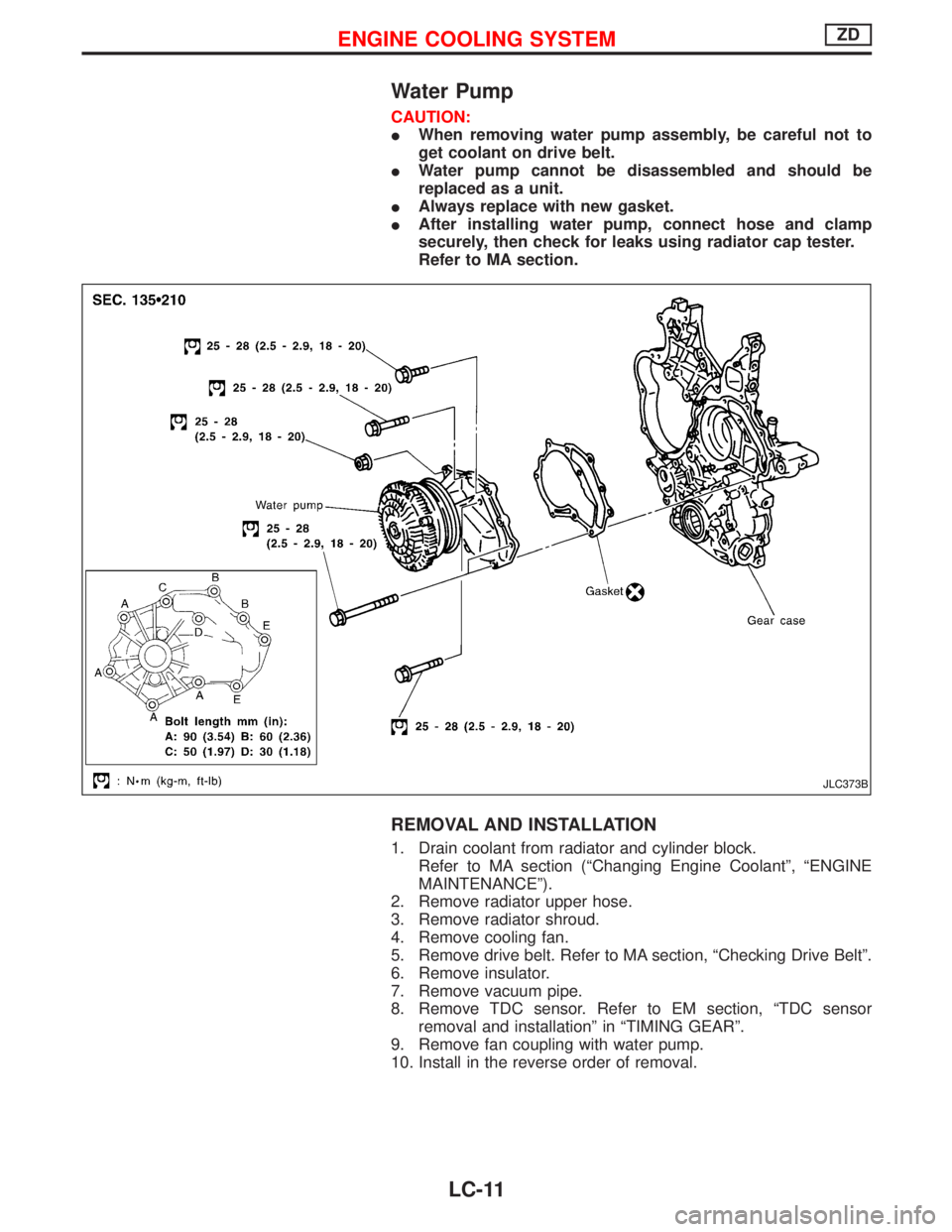

Water Pump

CAUTION:

IWhen removing water pump assembly, be careful not to

get coolant on drive belt.

IWater pump cannot be disassembled and should be

replaced as a unit.

IAlways replace with new gasket.

IAfter installing water pump, connect hose and clamp

securely, then check for leaks using radiator cap tester.

Refer to MA section.

REMOVAL AND INSTALLATION

1. Drain coolant from radiator and cylinder block.

Refer to MA section (ªChanging Engine Coolantº, ªENGINE

MAINTENANCEº).

2. Remove radiator upper hose.

3. Remove radiator shroud.

4. Remove cooling fan.

5. Remove drive belt. Refer to MA section, ªChecking Drive Beltº.

6. Remove insulator.

7. Remove vacuum pipe.

8. Remove TDC sensor. Refer to EM section, ªTDC sensor

removal and installationº in ªTIMING GEARº.

9. Remove fan coupling with water pump.

10. Install in the reverse order of removal.

JLC373B

ENGINE COOLING SYSTEMZD

LC-11

Page 1437 of 1767

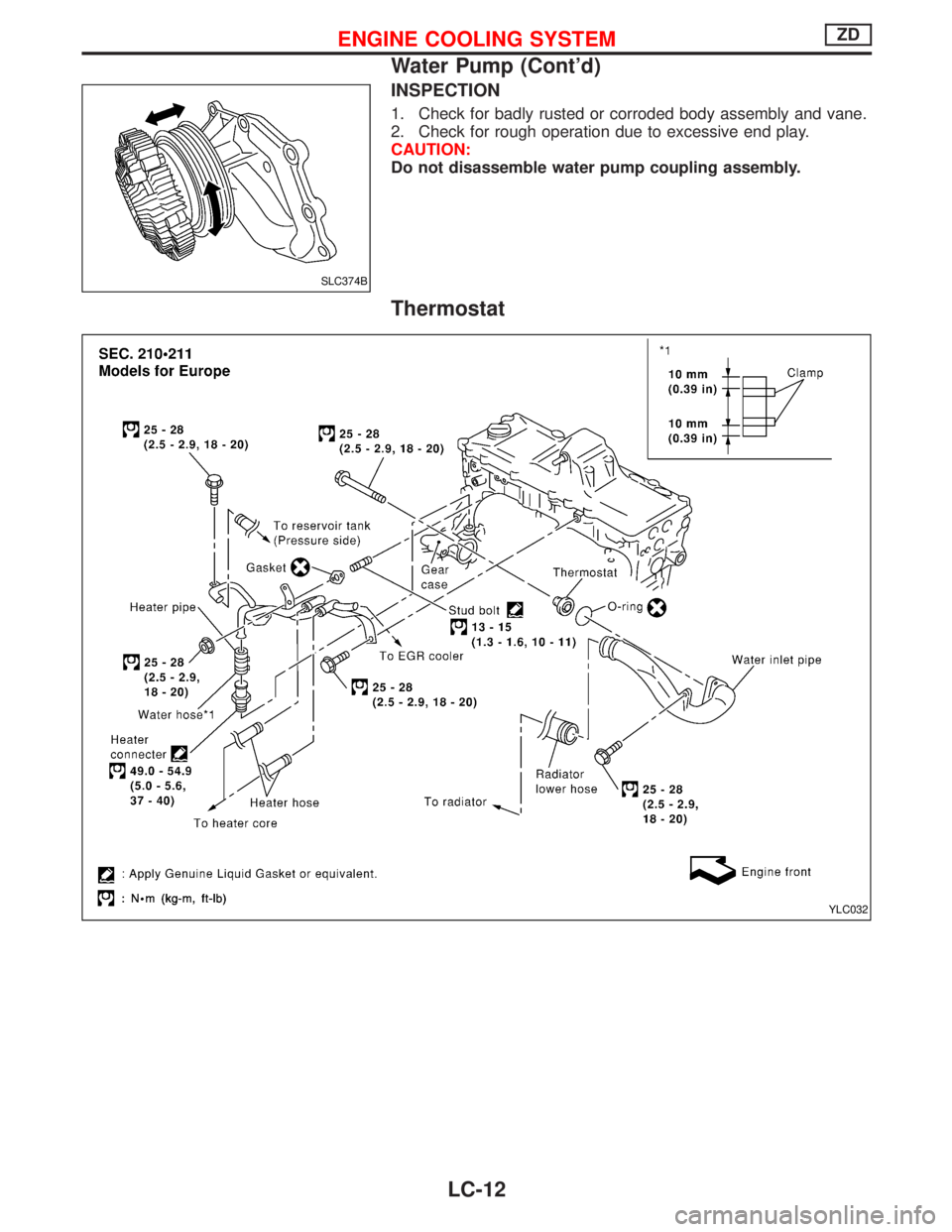

INSPECTION

1. Check for badly rusted or corroded body assembly and vane.

2. Check for rough operation due to excessive end play.

CAUTION:

Do not disassemble water pump coupling assembly.

Thermostat

SLC374B

YLC032

ENGINE COOLING SYSTEMZD

Water Pump (Cont'd)

LC-12

Page 1438 of 1767

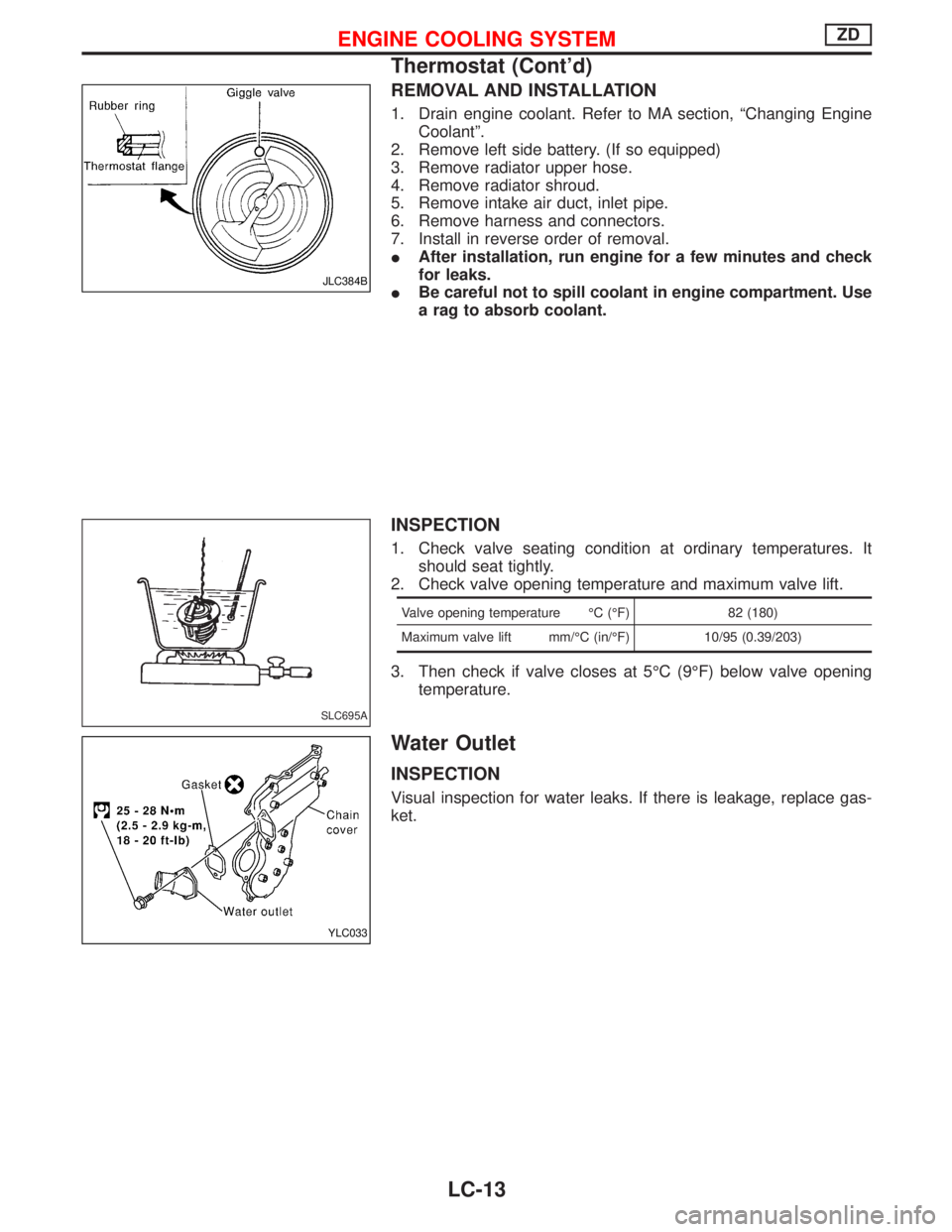

REMOVAL AND INSTALLATION

1. Drain engine coolant. Refer to MA section, ªChanging Engine

Coolantº.

2. Remove left side battery. (If so equipped)

3. Remove radiator upper hose.

4. Remove radiator shroud.

5. Remove intake air duct, inlet pipe.

6. Remove harness and connectors.

7. Install in reverse order of removal.

IAfter installation, run engine for a few minutes and check

for leaks.

IBe careful not to spill coolant in engine compartment. Use

a rag to absorb coolant.

INSPECTION

1. Check valve seating condition at ordinary temperatures. It

should seat tightly.

2. Check valve opening temperature and maximum valve lift.

Valve opening temperature ÉC (ÉF) 82 (180)

Maximum valve lift mm/ÉC (in/ÉF) 10/95 (0.39/203)

3. Then check if valve closes at 5ÉC (9ÉF) below valve opening

temperature.

Water Outlet

INSPECTION

Visual inspection for water leaks. If there is leakage, replace gas-

ket.

JLC384B

SLC695A

YLC033

ENGINE COOLING SYSTEMZD

Thermostat (Cont'd)

LC-13