general NISSAN TERRANO 2002 Service Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 1420 of 1767

Clutch pedal .............................................CL-3, 4, 5

Clutch release mechanism ...............................CL-9

Coil spring (rear) ......................................RA-14, 16

Collision diagnosis..........................................RS-57

Combination lamp, front, removal and

installation .....................................................BT-6

Combination lamp, rear, removal and

installation .....................................................BT-8

Combination meter (needle type) ...................EL-70

Combination meter removal and instal-

lation - See Instrument panel......................BT-16

Combination switch...................................EL-23, 24

Component Location (manual A/C) ..................HA-7

Compression pressure ...................................EM-10

Compressor clutch removal and

installation ...................................................HA-24

Compressor mounting ....................................HA-21

Connecting rod...............................................EM-73

Connecting rod bearing clearance.................EM-77

Connecting rod bushing clearance ................EM-73

Console box - See Instrument panel ..............BT-16

CONSULT for ABS .........................................BR-58

CONSULT for engine .............................EC-39, 327

CONSULT-II general information.....................GI-26

Control lever (M/T) .........................................MT-13

Control lever (Transfer) .....................................TF-8

Control sleeve position sensor .....................EC-414

Control valve (A/T) ........................................AT-113

COOL/F - Wiring diagram ............................EC-112

Coolant mixture ratio ...................MA-17, 20, 22, 31

Coolant replacement ...............MA-5, 17, 20, 22, 31

Cooling circuit (engine)...............................LC-9, 27

Cooling fan ...............................................LC-15, 33

Cooling fan control .......................................EC-109

Cooling fan relay ..........................................EC-426

Corrosion protection..........................................BT-5

Counter gear (M/T) .........................................MT-11

Counter gear (Transfer) ............................TF-10, 20

Cowl top ..........................................................BT-21

Cowl top cover ................................................BT-21

Crankcase emission control system -

See positive crankcase ventilation .....EC-23, 312

Crankcase ventilation system - See

Positive crankcase ventilation ............EC-23, 312

Crankshaft ......................................................EM-76

Crankshaft position sensor (TDC) .......EC-145, 385

Cylinder block ................................................EM-66

Cylinder head .................................................EM-52

D

Data link connector ................................EC-39, 327

Daytime light system ..........................EL-29, 30, 31

DEF - Wiring diagram ...................................EL-107

Defroster door control rod adjustment ...........HA-62

Diagnosis sensor unit .....................................RS-11

Diagnostic trouble code (DTC) for OBD

system ................................................EC-33, 321

Differential carrier assembly ....................PD-29, 53Differential carrier disassembly..........PD-18, 38, 40

Differential gear oil replacement .......MA-36, 38, 39

Dimensions ......................................................GI-31

D/LOCK - Wiring diagram .............................EL-140

Door glass .......................................................BT-10

Door lock .........................................................BT-10

Door mirror ......................................................BT-48

Door trim .........................................................BT-19

Door, front .......................................................BT-10

Door, rear ........................................................BT-12

Drive belt inspection ................................MA-20, 28

Drive chain (Transfer) .....................................TF-10

Drive pinion diff. inspection ......................PD-20, 42

Drive pinion height ...................................PD-21, 49

Drive plate runout ..........................................EM-94

Drive shaft ........................................................MA-5

Drive shaft (front)..................................FA-4, 12, 22

Driver air bag..................................................RS-14

Dropping resistor (A/T)....................................AT-86

Dual pressure switch..................................HA-9, 61

E

ECM input/output signal .........................EC-69, 346

ECM relay ......................................EC-80, 209, 353

ECMRLY - Wiring diagram ...........................EC-210

ECTS - Wiring diagram ..................................EC-96

EGR control (EGRC) - solenoid valve .........EC-431

EGR control valve ........................................EC-439

EGR volume control valve ...........................EC-222

EGVC/V - Wiring diagram ............................EC-225

Electrical unit ................................................Foldout

Electronic fuel injection pump ......................EC-318

Engine compartment .......................................BT-50

Engine control circuit diagram ...............EC-16, 302

Engine control component parts

location ...............................................EC-12, 300

Engine control module (ECM) ......EC-69, 121, 200,

202, 213, 346,

407, 444

Engine control system diagram and

chart....................................................EC-17, 303

Engine coolant temperature sensor

(ECTS)................................................EC-95, 361

Engine oil filter replacement..........MA-5, 20, 21, 30

Engine oil precautions .......................................GI-6

Engine oil replacement ......................MA-20, 21, 29

Engine removal ..............................................EM-63

Engine room - See Engine

compartment ...............................................BT-50

Engine serial number ......................................GI-30

Exhaust manifold ...........................................EM-18

Exhaust system ..........................................FE-4, 10

Exhaust system inspection ............................MA-36

Extension tube diff. ..................................PD-19, 28

Exterior ............................................................BT-21

Exterior lamp.............................................EL-45, 60

ALPHABETICAL INDEX

IDX-3

Page 1423 of 1767

Pre-delivery inspection.....................................MA-3

Priming pump .................................................EC-50

Propeller shaft ............................................PD-5, 57

Propeller shaft greasing...........................MA-36, 38

Propeller shaft inspection ........................MA-36, 38

Propeller shaft on vehicle service ....................PD-6

Pump communication line (Electronic

Fuel Injection Pump) ................................EC-175

Pump control module (Electronic Fuel

Injection Pump).........................................EC-189

R

Radiator ....................................................LC-14, 32

Rear axle................................................RA-4, 6, 12

Rear bumper .....................................................BT-8

Rear case (Transfer)...................................TF-9, 24

Rear combination lamp removal and

installation .....................................................BT-8

Rear door ........................................................BT-12

Rear door trim...........................................BT-18, 19

Rear drum brake ............................................BR-31

Rear fog lamp .................................................EL-54

Rear side window .....................................BT-21, 43

Rear suspension ........................................RA-4, 12

Rear window defogger..................EL-107, 109, 110

Refrigerant connection precaution ...................HA-4

Refrigerant general precaution.........................HA-3

Refrigerant lines .............................................HA-17

Refrigeration cycle............................................HA-9

REMOTE - Wiring diagram ...........................EL-122

Removal and installation (A/T) ......................AT-116

Removal and installation (Transfer) ..................TF-7

Reverse clutch ..............................................AT-151

Reverse idler shaft (M/T)................................MT-11

Reverse main gear (M/T) ...............................MT-11

Revolution sensor (A/T) ..........................AT-50, 114

R/FOG - Wiring diagram .................................EL-54

Ring gear diff. inspection .........................PD-20, 42

Rocker cover ..................................................EM-20

Roof trim .........................................................BT-20

Rotor disc (front) .............................................FA-18

S

Screw jack .......................................................GI-32

Seal - See Exterior .........................................BT-21

Seat belt inspection .................................MA-36, 45

Seat belt pre-tensioner.................................RS-2, 9

Seat belt pre-tensioner disposal ....................RS-20

Seat belt, front ..................................................RS-4

Seat, front .......................................................BT-34

Seat, second (2nd) .........................................BT-37

Seat, third (3rd) ...............................................BT-39

Second (2nd) seat ..........................................BT-37

Self-diagnostic results ............................EC-35, 324

Shift control (Transfer) ..............................TF-11, 24Shift control components

(M/T) ............................MT-13, 14, 15, 21, 23, 31

Shift fork (M/T) ...............................................MT-13

Shift schedule................................................AT-196

Shift solenoid valve A (A/T).............................AT-63

Shift solenoid valve B (A/T) ............................AT-66

Shock absorber (front) ....................................FA-30

Shock absorber (rear) ..............................RA-14, 16

Side air bag ....................................................RS-18

Side air bag (satellite) sensor ........................RS-13

Side bearing preload diff. ...............................PD-24

Side trim....................................................BT-18, 21

Side window - See Rear side window ............BT-21

S/LOCK - Wiring diagram .............................EL-150

SMJ (super multiple junction) .......................Foldout

Speedometer...................................................EL-72

Spill valve .....................................................EC-182

Spiral cable.....................................................RS-14

SROOF - Wiring diagram .............................EL-130

SRS - See Supplemental Restraint

System ..........................................................RS-6

SRS - Wiring diagram ....................................RS-32

SRS Trouble diagnoses .................................RS-26

S/SIG - Wiring diagram ................................EC-248

Stabilizer bar (front) ....................................FA-4, 33

Stabilizer bar (rear) ..................................RA-15, 16

Stall test (A/T) .........................................AT-27, 196

Standardized relay ............................................EL-4

START - Wiring diagram ................................SC-14

Start signal ...................................................EC-248

Starter .............................................................SC-17

Starting system...............................................SC-13

Steering gear and linkage inspection ......MA-36, 43

Steering gear oil level ..............................MA-36, 44

Steering gear, linkage and transfer

gear inspection ..............................MA-36, 43, 44

Steering linkage ........................................ST-17, 22

Steering switch................................................EL-25

Steering wheel and column ........................ST-8, 22

Steering wheel play ..........................................ST-4

Steering wheel turning force .............................ST-6

Stop lamp ........................................................EL-48

Stop lamp switch ..................................EC-204, 403

STOP/L - Wiring diagram................................EL-48

Striking rod (M/T) ...........................................MT-13

Sub-gear (M/T) ...............................................MT-11

Sun roof, electric ...........................................EL-130

Sunroof............................................................BT-40

Super lock ............................EL-145, 146, 148, 158

Supplemental Restraint System .......................RS-6

Swirl control valve control solenoid

valve .........................................................EC-263

SWL/V - Wiring diagram ..............................EC-265

Symptom matrix chart ............................EC-56, 340

T

Tachometer .....................................................EL-72

Tail lamp ..........................................................EL-45

ALPHABETICAL INDEX

IDX-6

Page 1460 of 1767

MAINTENANCE

SECTION

MA

CONTENTS

PRE-DELIVERY INSPECTION ITEMS............................3

GENERAL MAINTENANCE............................................4

PERIODIC MAINTENANCE............................................5

Maintenance Schedule for Diesel Engine Models

(annual mileage < 30,000 km/year) ............................5

Maintenance Schedule for Diesel Engine Models

(annual mileage > 30,000 km/year) ............................8

Maintenance Under Severe Driving Conditions

(annual mileage < 30,000 km/year) .......................... 11

Maintenance Under Severe Driving Conditions

(annual mileage > 30,000 km/year) ..........................14

RECOMMENDED FLUIDS AND LUBRICANTS...........17

Fluids and Lubricants ................................................17

SAE Viscosity Number ..............................................18

Engine Coolant Mixture Ratio....................................19

TD

ENGINE MAINTENANCE..............................................20

Retightening Manifold Bolts and Nuts .......................20

Adjusting Intake and Exhaust Valve Clearance ........20

Drive Belt Inspection..................................................20

Changing Engine Oil..................................................21

Changing Oil Filter .....................................................21

Changing Engine Coolant..........................................22

Checking Cooling System .........................................23

Checking and Replacing fuel filter and Draining

Water .........................................................................23

Cleaning and Replacing Air Cleaner Filter (Dry

paper type).................................................................24

Checking Injection Nozzle .........................................25

Checking Idle Speed .................................................26

ZD

ENGINE MAINTENANCE..............................................28

Checking Tightening Torque ......................................28

Adjusting Intake and Exhaust Valve Clearance ........28

Checking Drive Belt ...................................................28

Removal .....................................................................29Installation ..................................................................29

Changing Engine Oil..................................................29

Changing Engine Oil Filter ........................................30

Changing Engine Coolant..........................................31

Checking Cooling System .........................................32

Checking and Replacing Fuel Filter and Draining

Water .........................................................................33

Checking Fuel Lines ..................................................34

Cleaning and Replacing Air Cleaner Filter ................35

CHASSIS AND BODY MAINTENANCE.......................36

Checking Exhaust System.........................................36

Checking Clutch Operation........................................36

Checking Clutch Fluid Level and Leaks ....................36

Checking Clutch System ...........................................36

Checking M/T Oil .......................................................36

Changing M/T Oil.......................................................37

Checking Water Entry ................................................37

Checking Transfer Oil ................................................37

Changing Transfer Oil................................................38

Checking Propeller Shaft ...........................................38

Checking Differential Gear Oil ...................................38

Changing Differential Gear Oil ..................................39

Checking Front Wheel Bearing Grease ....................39

Repacking Front Wheel Bearing Grease ..................39

Checking Free-running Hub Grease .........................40

Checking Brake Fluid Level and Leaks.....................40

Checking Brake System ............................................40

Checking Brake Booster, Vacuum Hoses,

Connections and Check Valve ..................................40

Checking Disc Brake .................................................40

Checking Drum Brake ...............................................41

Checking Foot Brake Pedal Operation......................42

Checking Parking Brake ............................................42

Changing Brake Fluid ................................................43

Balancing Wheels ......................................................43

Tire Rotation ..............................................................43

Checking Steering Gear and Linkage .......................43

Checking Fluid Level and Leaks (Power steering) ...44

Page 1463 of 1767

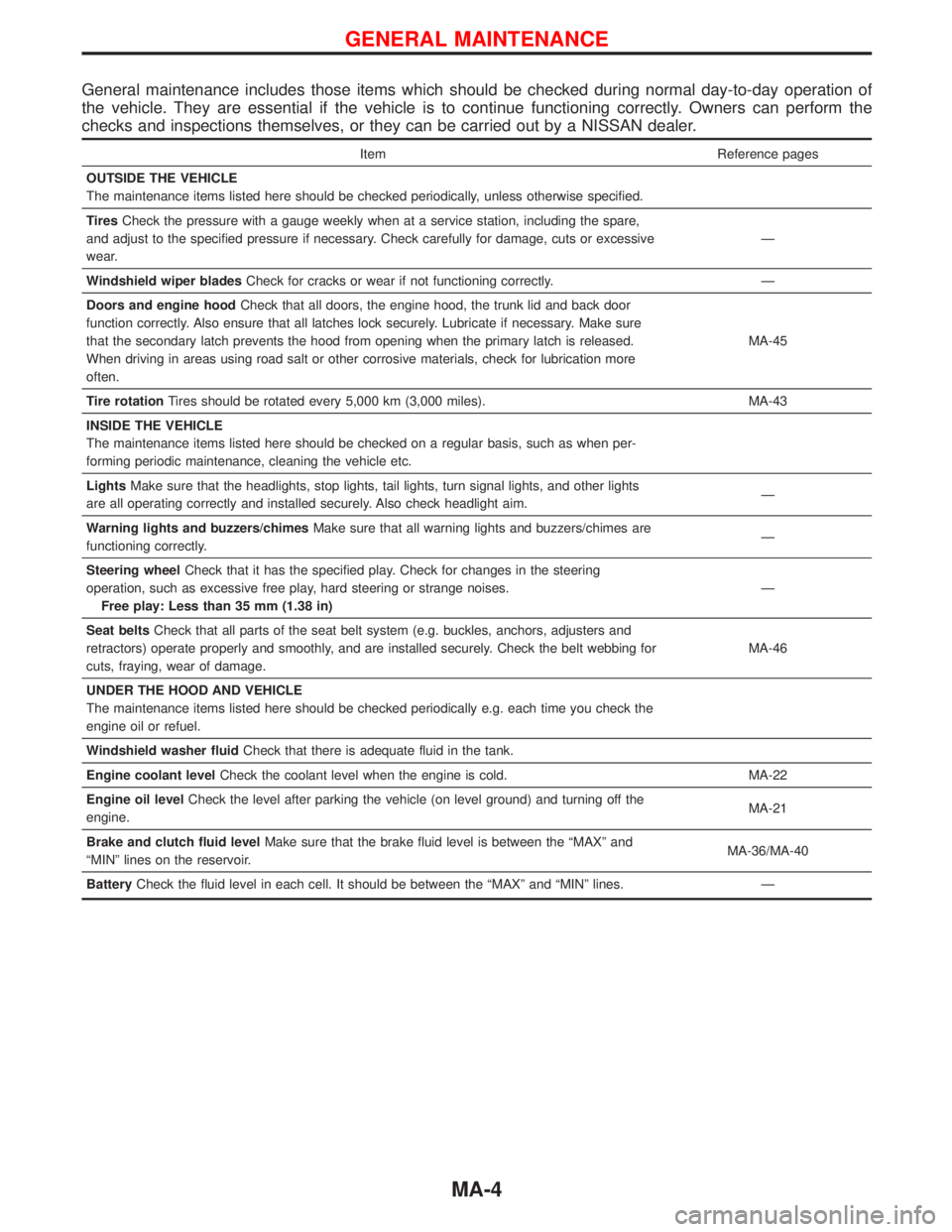

General maintenance includes those items which should be checked during normal day-to-day operation of

the vehicle. They are essential if the vehicle is to continue functioning correctly. Owners can perform the

checks and inspections themselves, or they can be carried out by a NISSAN dealer.

Item Reference pages

OUTSIDE THE VEHICLE

The maintenance items listed here should be checked periodically, unless otherwise specified.

TiresCheck the pressure with a gauge weekly when at a service station, including the spare,

and adjust to the specified pressure if necessary. Check carefully for damage, cuts or excessive

wear.Ð

Windshield wiper bladesCheck for cracks or wear if not functioning correctly. Ð

Doors and engine hoodCheck that all doors, the engine hood, the trunk lid and back door

function correctly. Also ensure that all latches lock securely. Lubricate if necessary. Make sure

that the secondary latch prevents the hood from opening when the primary latch is released.

When driving in areas using road salt or other corrosive materials, check for lubrication more

often.MA-45

Tire rotationTires should be rotated every 5,000 km (3,000 miles). MA-43

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when per-

forming periodic maintenance, cleaning the vehicle etc.

LightsMake sure that the headlights, stop lights, tail lights, turn signal lights, and other lights

are all operating correctly and installed securely. Also check headlight aim.Ð

Warning lights and buzzers/chimesMake sure that all warning lights and buzzers/chimes are

functioning correctly.Ð

Steering wheelCheck that it has the specified play. Check for changes in the steering

operation, such as excessive free play, hard steering or strange noises.

Free play: Less than 35 mm (1.38 in)Ð

Seat beltsCheck that all parts of the seat belt system (e.g. buckles, anchors, adjusters and

retractors) operate properly and smoothly, and are installed securely. Check the belt webbing for

cuts, fraying, wear of damage.MA-46

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically e.g. each time you check the

engine oil or refuel.

Windshield washer fluidCheck that there is adequate fluid in the tank.

Engine coolant levelCheck the coolant level when the engine is cold. MA-22

Engine oil levelCheck the level after parking the vehicle (on level ground) and turning off the

engine.MA-21

Brake and clutch fluid levelMake sure that the brake fluid level is between the ªMAXº and

ªMINº lines on the reservoir.MA-36/MA-40

BatteryCheck the fluid level in each cell. It should be between the ªMAXº and ªMINº lines. Ð

GENERAL MAINTENANCE

MA-4

Page 1510 of 1767

MANUAL TRANSMISSION

SECTION

MT

CONTENTS

PREPARATION................................................................2

Special Service Tools ..................................................2

Commercial Service Tools ...........................................4

TRANSMISSION FS5R30A.............................................5

Replacing the Rear Oil Seal ........................................5

FS5R30A

ON-VEHICLE SERVICE..................................................6

Check of Position Switches .........................................6

REMOVAL AND INSTALLATION....................................7

Removal .......................................................................7

Installation ....................................................................8

MAJOR OVERHAUL.....................................................10

Case Components .....................................................10

Gear Components ..................................................... 11

Shift Control Components .........................................13DISASSEMBLY..............................................................14

Case Components .....................................................14

Shift Control Components .........................................15

Gear Components .....................................................16

INSPECTION..................................................................21

Shift Control Components .........................................21

Gear Components .....................................................21

ASSEMBLY....................................................................23

Gear Components .....................................................23

Shift Control Components .........................................31

Case Components .....................................................32

SERVICE DATA AND SPECIFICATIONS (SDS)..........34

General Specifications ...............................................34

Inspection and Adjustment ........................................35

Page 1543 of 1767

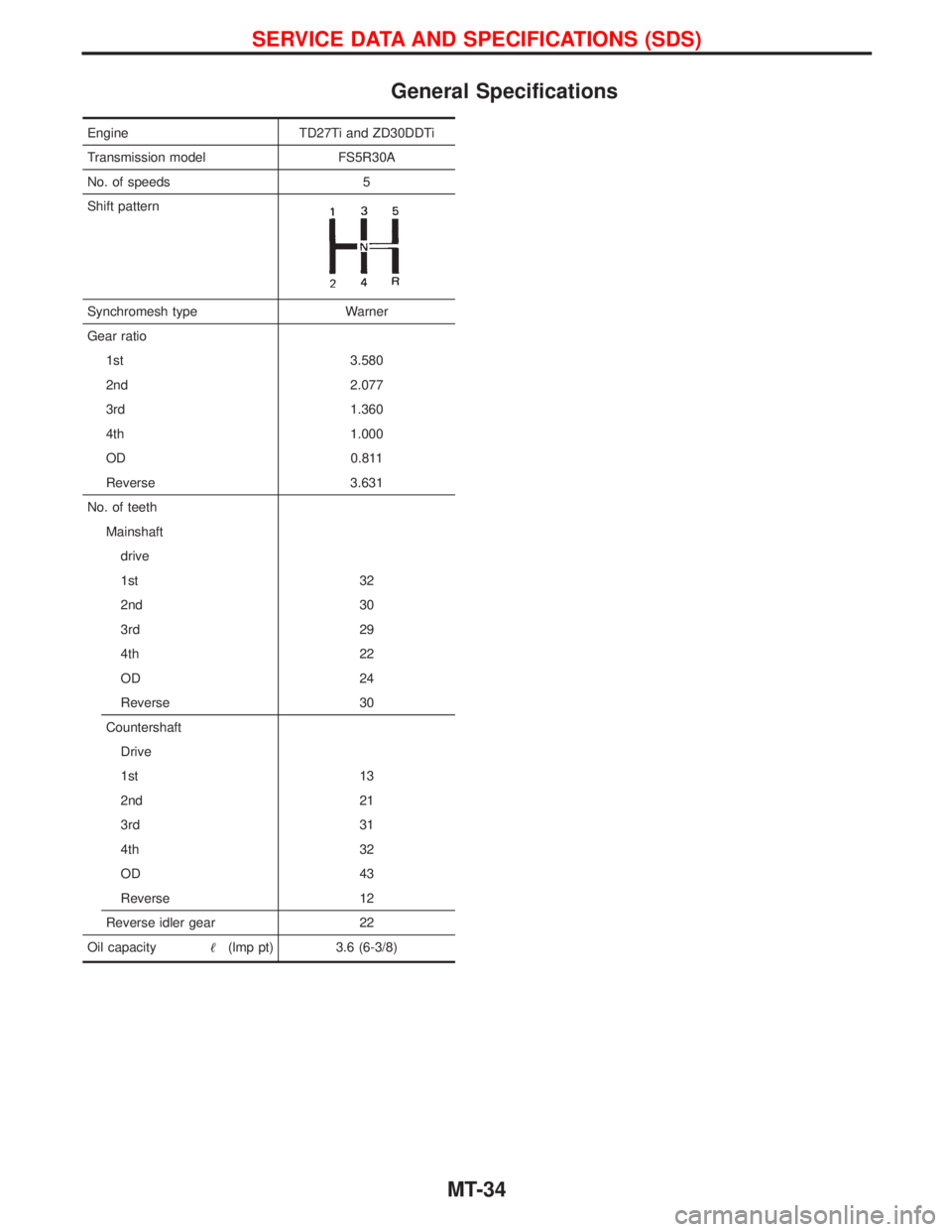

General Specifications

Engine TD27Ti and ZD30DDTi

Transmission model FS5R30A

No. of speeds 5

Shift pattern

Synchromesh type Warner

Gear ratio

1st 3.580

2nd 2.077

3rd 1.360

4th 1.000

OD 0.811

Reverse 3.631

No. of teeth

Mainshaft

drive

1st 32

2nd 30

3rd 29

4th 22

OD 24

Reverse 30

Countershaft

Drive

1st 13

2nd 21

3rd 31

4th 32

OD 43

Reverse 12

Reverse idler gear 22

Oil capacity(lmp pt) 3.6 (6-3/8)

SERVICE DATA AND SPECIFICATIONS (SDS)

MT-34

Page 1602 of 1767

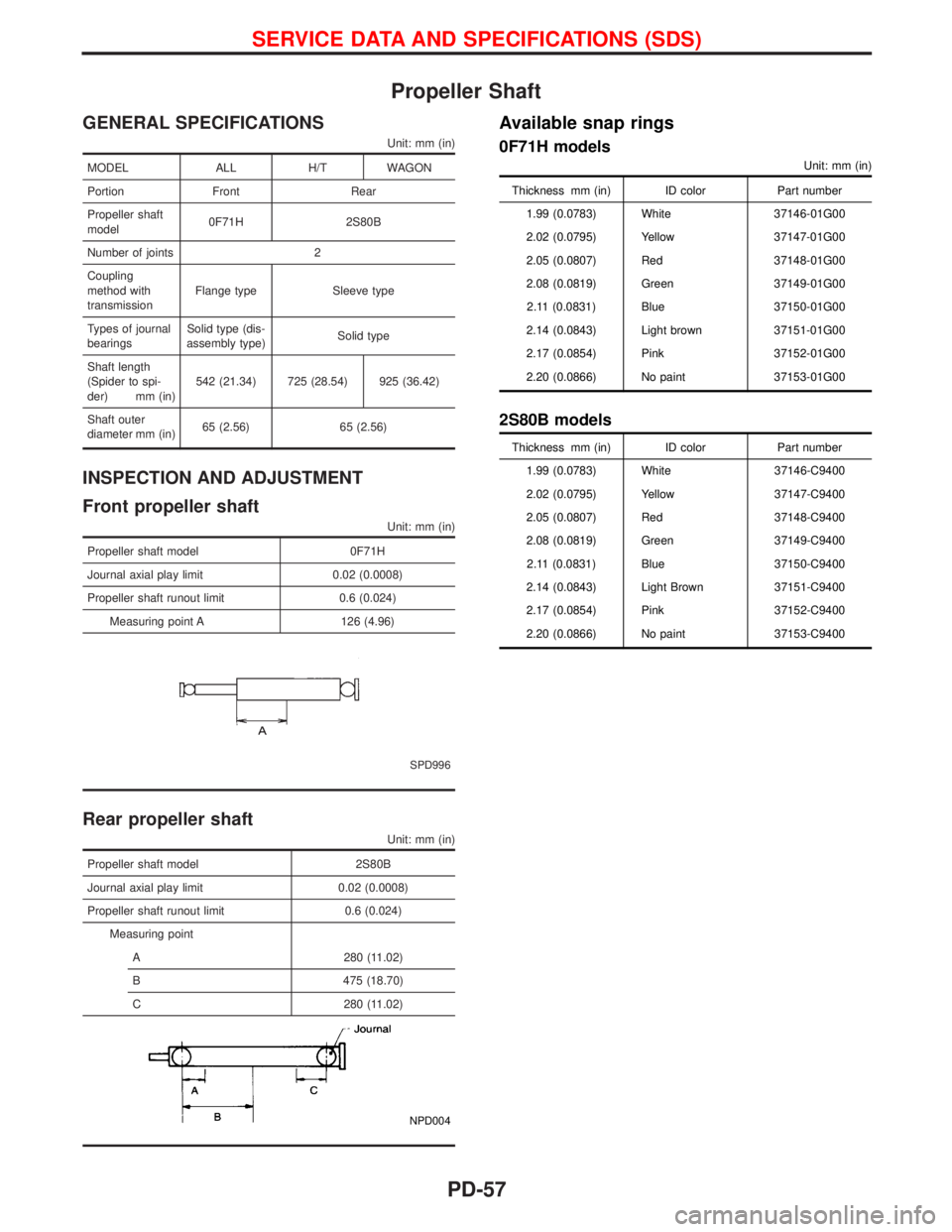

Propeller Shaft

GENERAL SPECIFICATIONS

Unit: mm (in)

MODEL ALL H/T WAGON

Portion Front Rear

Propeller shaft

model0F71H 2S80B

Number of joints 2

Coupling

method with

transmissionFlange type Sleeve type

Types of journal

bearingsSolid type (dis-

assembly type)Solid type

Shaft length

(Spider to spi-

der) mm (in)542 (21.34) 725 (28.54) 925 (36.42)

Shaft outer

diameter mm (in)65 (2.56) 65 (2.56)

INSPECTION AND ADJUSTMENT

Front propeller shaft

Unit: mm (in)

Propeller shaft model 0F71H

Journal axial play limit 0.02 (0.0008)

Propeller shaft runout limit 0.6 (0.024)

Measuring point A 126 (4.96)

SPD996

Rear propeller shaft

Unit: mm (in)

Propeller shaft model 2S80B

Journal axial play limit 0.02 (0.0008)

Propeller shaft runout limit 0.6 (0.024)

Measuring point

A 280 (11.02)

B 475 (18.70)

C 280 (11.02)

NPD004

Available snap rings

0F71H models

Unit: mm (in)

Thickness mm (in) ID color Part number

1.99 (0.0783) White 37146-01G00

2.02 (0.0795) Yellow 37147-01G00

2.05 (0.0807) Red 37148-01G00

2.08 (0.0819) Green 37149-01G00

2.11 (0.0831) Blue 37150-01G00

2.14 (0.0843) Light brown 37151-01G00

2.17 (0.0854) Pink 37152-01G00

2.20 (0.0866) No paint 37153-01G00

2S80B models

Thickness mm (in) ID color Part number

1.99 (0.0783) White 37146-C9400

2.02 (0.0795) Yellow 37147-C9400

2.05 (0.0807) Red 37148-C9400

2.08 (0.0819) Green 37149-C9400

2.11 (0.0831) Blue 37150-C9400

2.14 (0.0843) Light Brown 37151-C9400

2.17 (0.0854) Pink 37152-C9400

2.20 (0.0866) No paint 37153-C9400

SERVICE DATA AND SPECIFICATIONS (SDS)

PD-57

Page 1603 of 1767

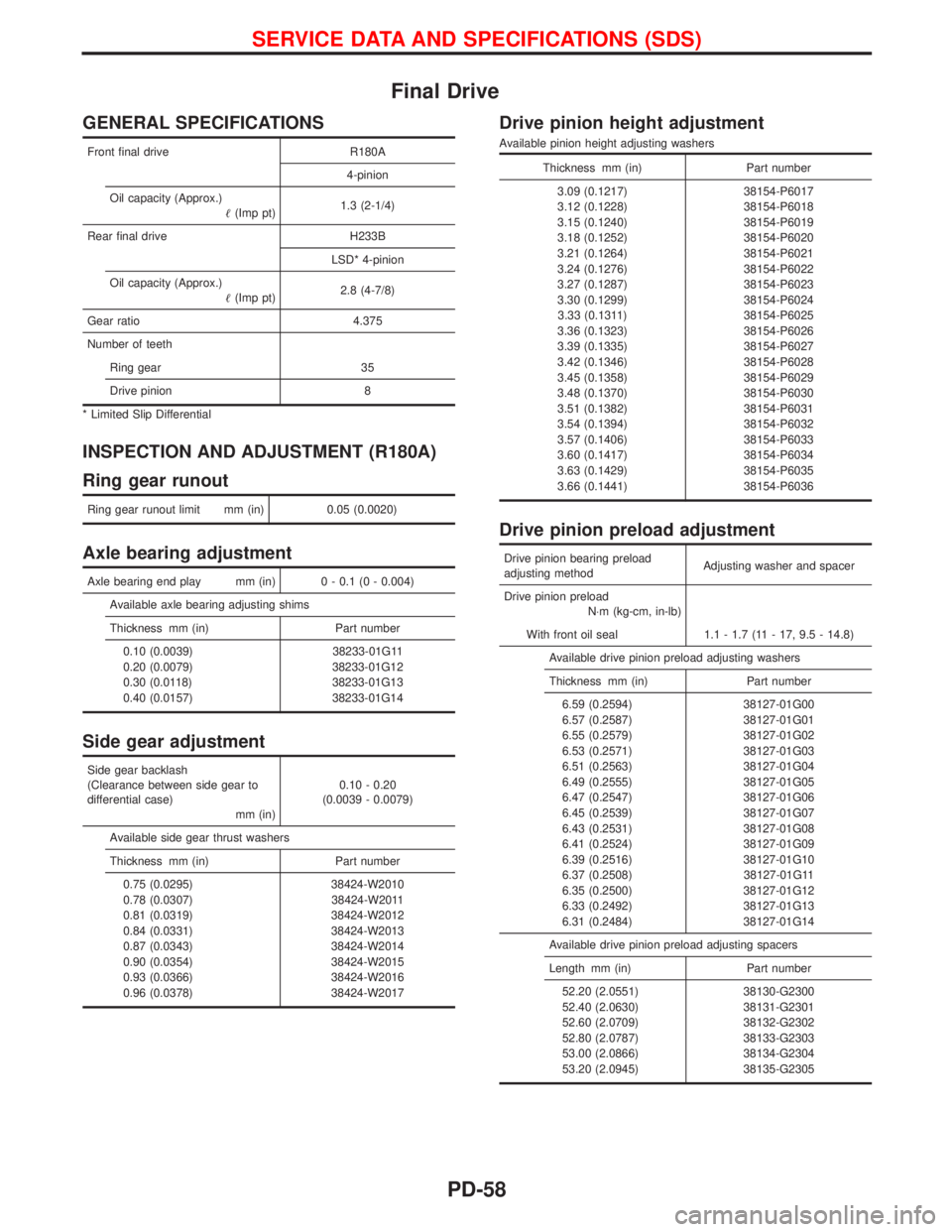

Final Drive

GENERAL SPECIFICATIONS

Front final drive R180A

4-pinion

Oil capacity (Approx.)

(Imp pt)1.3 (2-1/4)

Rear final drive H233B

LSD* 4-pinion

Oil capacity (Approx.)

(Imp pt)2.8 (4-7/8)

Gear ratio 4.375

Number of teeth

Ring gear 35

Drive pinion 8

* Limited Slip Differential

INSPECTION AND ADJUSTMENT (R180A)

Ring gear runout

Ring gear runout limit mm (in) 0.05 (0.0020)

Axle bearing adjustment

Axle bearing end play mm (in) 0 - 0.1 (0 - 0.004)

Available axle bearing adjusting shims

Thickness mm (in) Part number

0.10 (0.0039) 38233-01G11

0.20 (0.0079) 38233-01G12

0.30 (0.0118) 38233-01G13

0.40 (0.0157) 38233-01G14

Side gear adjustment

Side gear backlash

(Clearance between side gear to

differential case)

mm (in)0.10 - 0.20

(0.0039 - 0.0079)

Available side gear thrust washers

Thickness mm (in) Part number

0.75 (0.0295) 38424-W2010

0.78 (0.0307) 38424-W2011

0.81 (0.0319) 38424-W2012

0.84 (0.0331) 38424-W2013

0.87 (0.0343) 38424-W2014

0.90 (0.0354) 38424-W2015

0.93 (0.0366) 38424-W2016

0.96 (0.0378) 38424-W2017

Drive pinion height adjustment

Available pinion height adjusting washers

Thickness mm (in) Part number

3.09 (0.1217) 38154-P6017

3.12 (0.1228) 38154-P6018

3.15 (0.1240) 38154-P6019

3.18 (0.1252) 38154-P6020

3.21 (0.1264) 38154-P6021

3.24 (0.1276) 38154-P6022

3.27 (0.1287) 38154-P6023

3.30 (0.1299) 38154-P6024

3.33 (0.1311) 38154-P6025

3.36 (0.1323) 38154-P6026

3.39 (0.1335) 38154-P6027

3.42 (0.1346) 38154-P6028

3.45 (0.1358) 38154-P6029

3.48 (0.1370) 38154-P6030

3.51 (0.1382) 38154-P6031

3.54 (0.1394) 38154-P6032

3.57 (0.1406) 38154-P6033

3.60 (0.1417) 38154-P6034

3.63 (0.1429) 38154-P6035

3.66 (0.1441) 38154-P6036

Drive pinion preload adjustment

Drive pinion bearing preload

adjusting methodAdjusting washer and spacer

Drive pinion preload

N×m (kg-cm, in-lb)

With front oil seal 1.1 - 1.7 (11 - 17, 9.5 - 14.8)

Available drive pinion preload adjusting washers

Thickness mm (in) Part number

6.59 (0.2594) 38127-01G00

6.57 (0.2587) 38127-01G01

6.55 (0.2579) 38127-01G02

6.53 (0.2571) 38127-01G03

6.51 (0.2563) 38127-01G04

6.49 (0.2555) 38127-01G05

6.47 (0.2547) 38127-01G06

6.45 (0.2539) 38127-01G07

6.43 (0.2531) 38127-01G08

6.41 (0.2524) 38127-01G09

6.39 (0.2516) 38127-01G10

6.37 (0.2508) 38127-01G11

6.35 (0.2500) 38127-01G12

6.33 (0.2492) 38127-01G13

6.31 (0.2484) 38127-01G14

Available drive pinion preload adjusting spacers

Length mm (in) Part number

52.20 (2.0551) 38130-G2300

52.40 (2.0630) 38131-G2301

52.60 (2.0709) 38132-G2302

52.80 (2.0787) 38133-G2303

53.00 (2.0866) 38134-G2304

53.20 (2.0945) 38135-G2305

SERVICE DATA AND SPECIFICATIONS (SDS)

PD-58

Page 1606 of 1767

REAR AXLE &

REAR SUSPENSION

SECTION

RA

CONTENTS

PRECAUTIONS AND PREPARATION............................2

Precautions ..................................................................2

Preparation ..................................................................2

REAR AXLE AND REAR SUSPENSION........................4

CHECK AND ADJUSTMENT..........................................5

Rear Axle and Rear Suspension Parts .......................5

Rear Wheel Bearing ....................................................5

REAR AXLE.....................................................................6

Components.................................................................6

Removal .......................................................................7

Inspection.....................................................................8Installation ....................................................................9

REAR AXLE AND REAR SUSPENSION......................12

Removal and Installation ...........................................12

REAR SUSPENSION.....................................................13

Components...............................................................13

Coil Spring Shock Absorber ......................................14

Upper Link, Lower Link and Panhard Rod ................14

Stabilizer Bar .............................................................15

SERVICE DATA AND SPECIFICATIONS (SDS)..........16

General Specifications ...............................................16

Inspection and Adjustment ........................................16

Page 1621 of 1767

General Specifications

COIL SPRING AND SHOCK ABSORBER

Model Hardtop Wagon

Coil spring

Wire diameter mm (in) 13.0 (0.512) 13.5 (0.531)

Free length mm (in) 400 (15.75) 417 (16.42)

Spring constant

N/mm (kg/mm, lb/in)25.5 (2.6, 146) 29 (3.0, 168)

Shock absorber

Shock absorber type Non-adjustable (hydraulic)

Maximum length mm (in) 586 (23.07) 596 (23.46)

Minimum length mm (in) 350 (13.78) 356 (14.02)

Damping force

[at 0.3 m (1.0 ft)/sec.]

N (kg, lb)

Expansion990 - 1,330

(101 - 136,

223 - 229)1,169 - 1,563

(119 - 159,

223 - 351)

Compression346 - 524

(35.3 - 53.4,

77.8 - 117.8)301 - 461

(30.7 - 47.0,

67.7 - 103.6)

RA260

STABILIZER BAR

Model Hardtop Wagon

Diameter mm (in) 23 (0.91) 24 (0.94)

Spring constant

N/mm (kg/mm, lb/in)24.5 (2.5, 140) 29.0 (3.0, 166)

Inspection and Adjustment

WHEEL BEARING

Total end play mm (in) 0 (0)

SERVICE DATA AND SPECIFICATIONS (SDS)

RA-16