general NISSAN TERRANO 2002 Service Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 438 of 1767

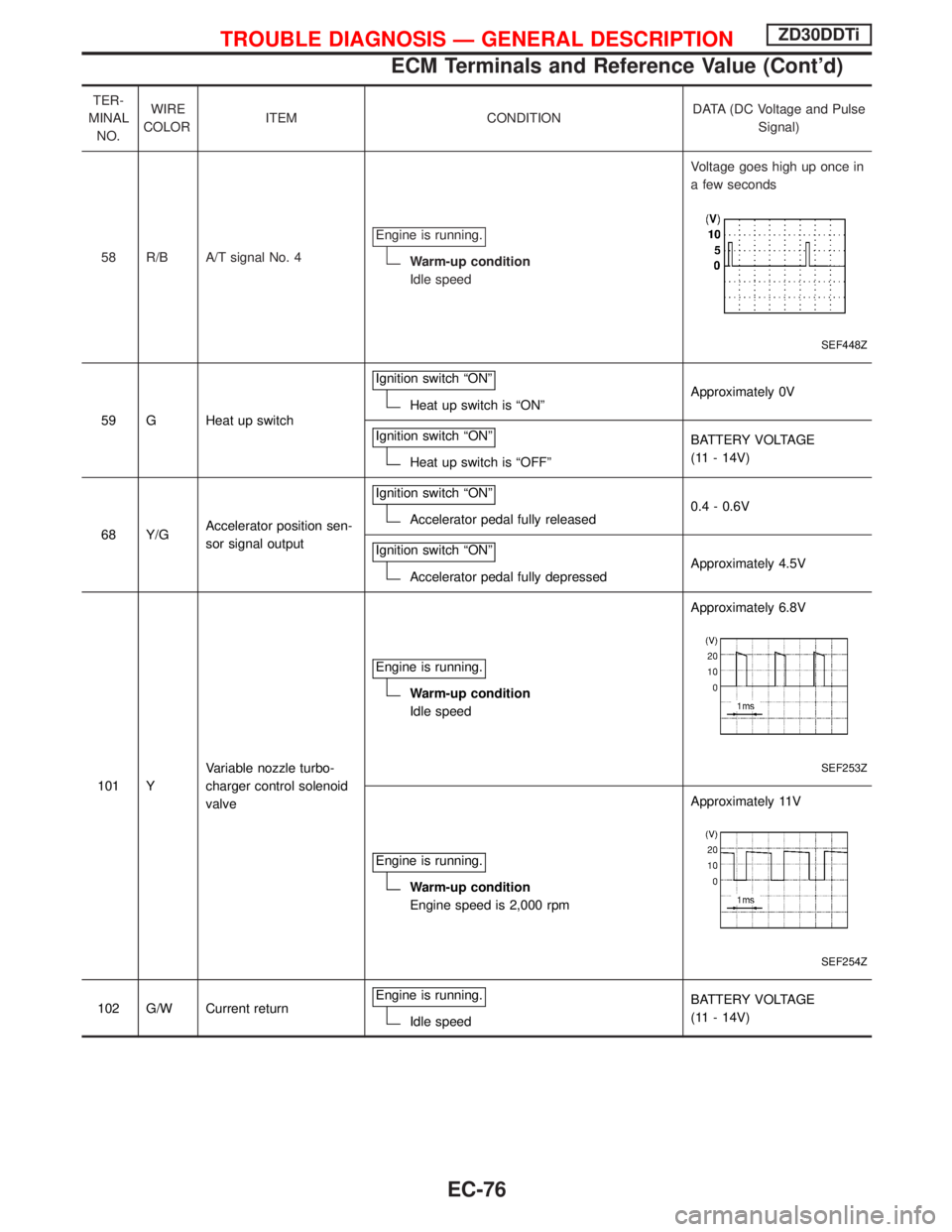

TER-

MINAL

NO.WIRE

COLORITEM CONDITIONDATA (DC Voltage and Pulse

Signal)

58 R/B A/T signal No. 4Engine is running.

Warm-up condition

Idle speedVoltage goes high up once in

a few seconds

SEF448Z

59 G Heat up switchIgnition switch ªONºHeat up switch is ªONºApproximately 0V

Ignition switch ªONº

Heat up switch is ªOFFºBATTERY VOLTAGE

(11 - 14V)

68 Y/GAccelerator position sen-

sor signal outputIgnition switch ªONº

Accelerator pedal fully released0.4 - 0.6V

Ignition switch ªONº

Accelerator pedal fully depressedApproximately 4.5V

101 YVariable nozzle turbo-

charger control solenoid

valveEngine is running.

Warm-up condition

Idle speedApproximately 6.8V

SEF253Z

Engine is running.

Warm-up condition

Engine speed is 2,000 rpmApproximately 11V

SEF254Z

102 G/W Current returnEngine is running.Idle speedBATTERY VOLTAGE

(11 - 14V)

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONZD30DDTi

ECM Terminals and Reference Value (Cont'd)

EC-76

Page 439 of 1767

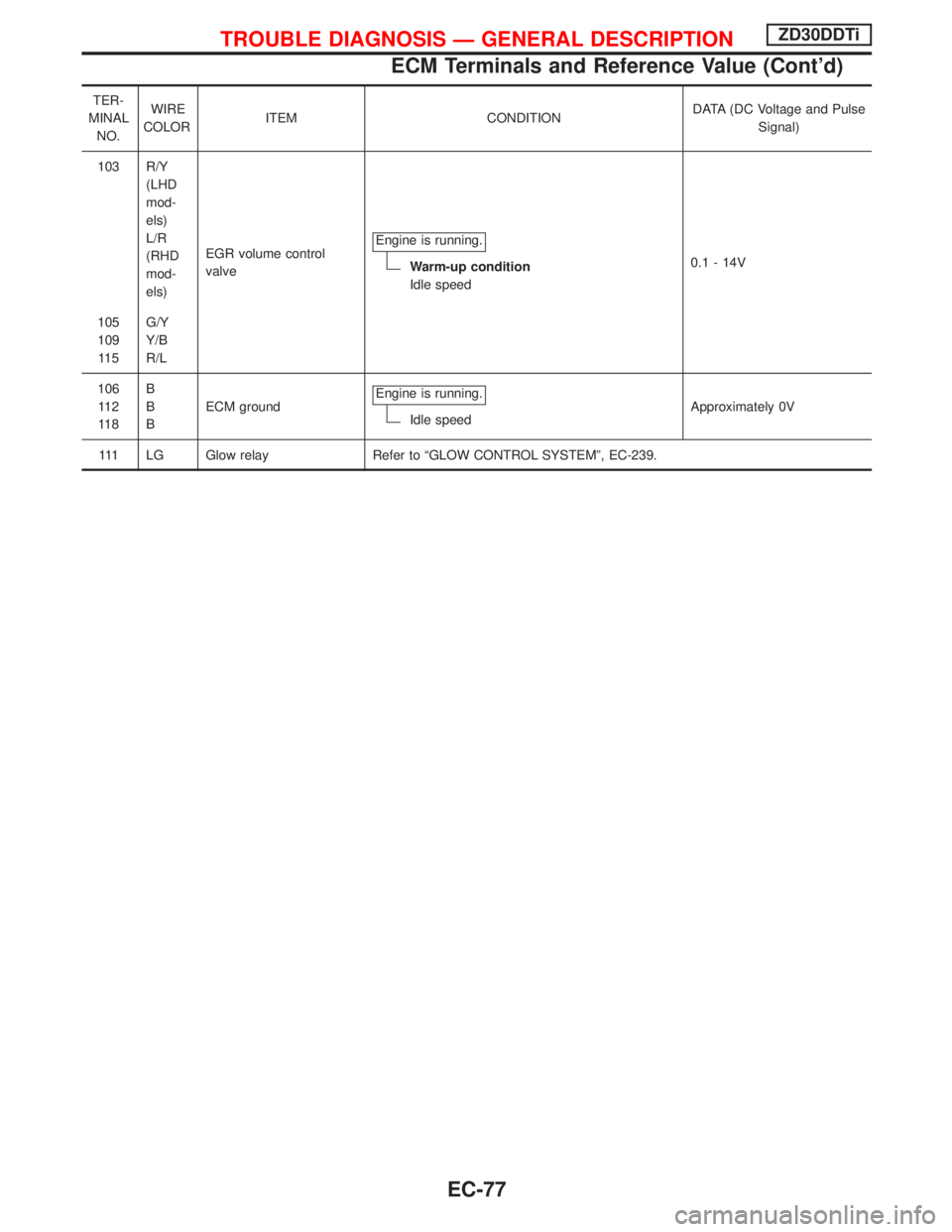

TER-

MINAL

NO.WIRE

COLORITEM CONDITIONDATA (DC Voltage and Pulse

Signal)

103 R/Y

(LHD

mod-

els)

L/R

(RHD

mod-

els)EGR volume control

valveEngine is running.

Warm-up condition

Idle speed0.1 - 14V

105

109

11 5G/Y

Y/B

R/L

106

11 2

11 8B

B

BECM groundEngine is running.

Idle speedApproximately 0V

111 LG Glow relay Refer to ªGLOW CONTROL SYSTEMº, EC-239.

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONZD30DDTi

ECM Terminals and Reference Value (Cont'd)

EC-77

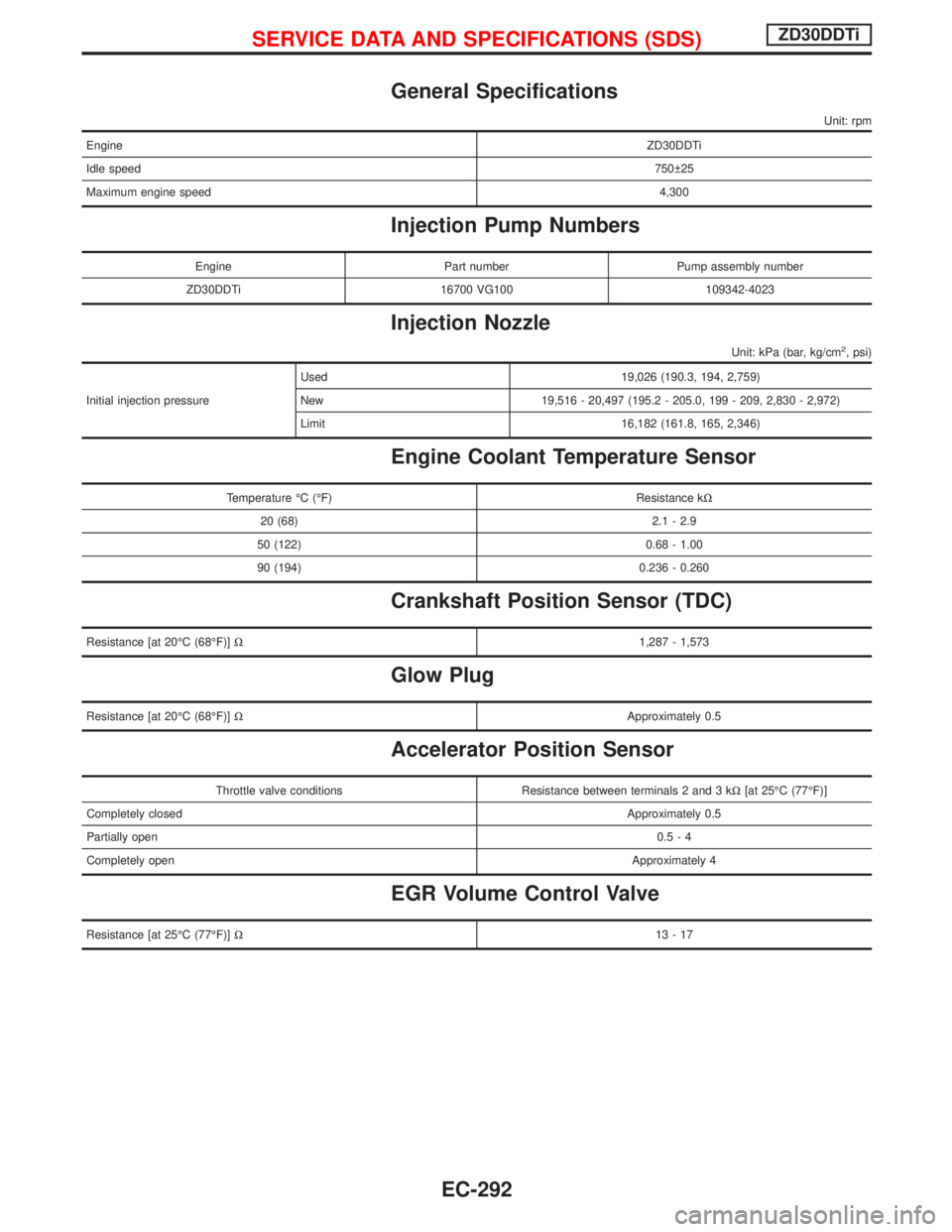

Page 654 of 1767

General Specifications

Unit: rpm

EngineZD30DDTi

Idle speed750 25

Maximum engine speed4,300

Injection Pump Numbers

Engine Part number Pump assembly number

ZD30DDTi 16700 VG100 109342-4023

Injection Nozzle

Unit: kPa (bar, kg/cm2, psi)

Initial injection pressureUsed 19,026 (190.3, 194, 2,759)

New 19,516 - 20,497 (195.2 - 205.0, 199 - 209, 2,830 - 2,972)

Limit 16,182 (161.8, 165, 2,346)

Engine Coolant Temperature Sensor

Temperature ÉC (ÉF) Resistance kW

20 (68) 2.1 - 2.9

50 (122) 0.68 - 1.00

90 (194) 0.236 - 0.260

Crankshaft Position Sensor (TDC)

Resistance [at 20ÉC (68ÉF)]W1,287 - 1,573

Glow Plug

Resistance [at 20ÉC (68ÉF)]WApproximately 0.5

Accelerator Position Sensor

Throttle valve conditions Resistance between terminals 2 and 3 kW[at 25ÉC (77ÉF)]

Completely closedApproximately 0.5

Partially open0.5-4

Completely openApproximately 4

EGR Volume Control Valve

Resistance [at 25ÉC (77ÉF)]W13-17

SERVICE DATA AND SPECIFICATIONS (SDS)ZD30DDTi

EC-292

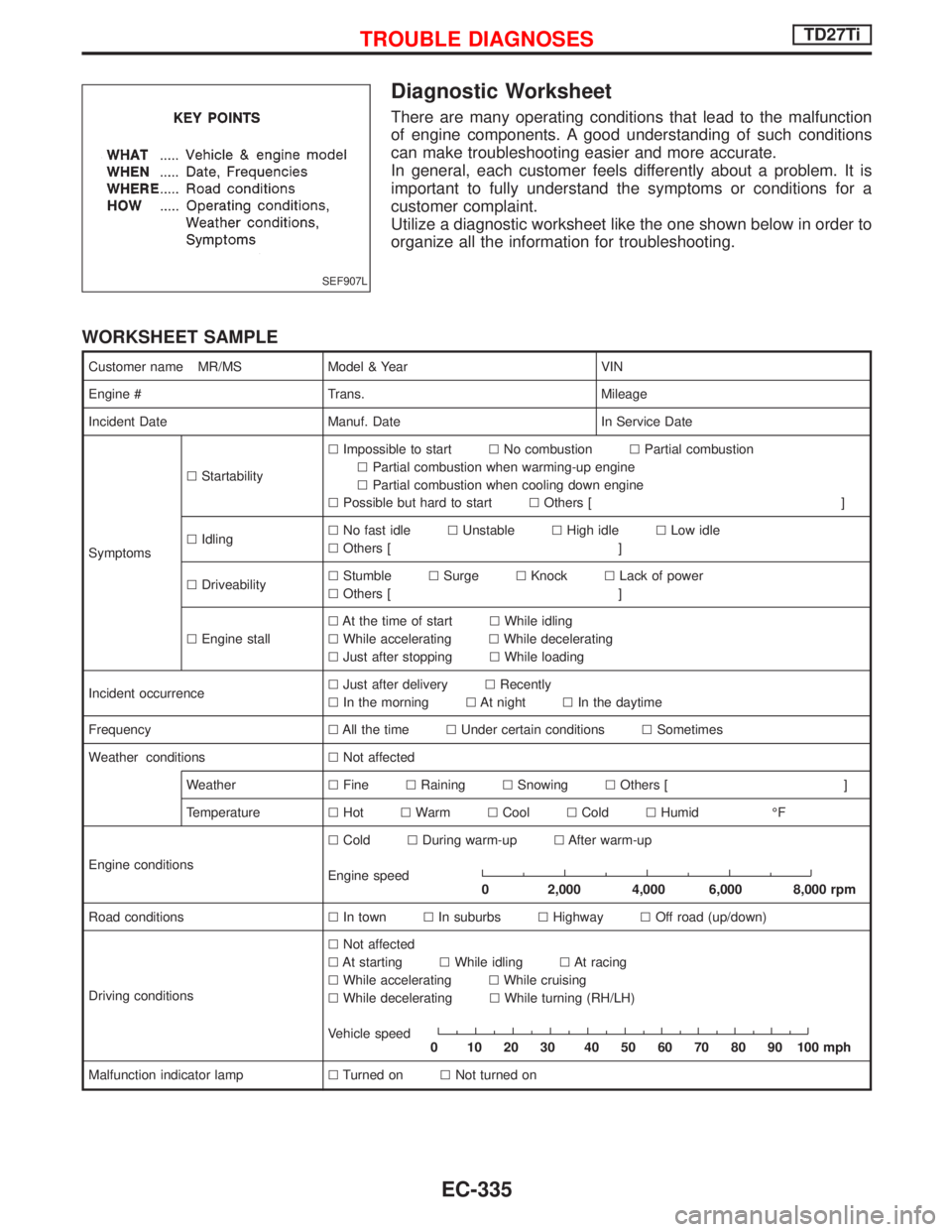

Page 697 of 1767

Diagnostic Worksheet

There are many operating conditions that lead to the malfunction

of engine components. A good understanding of such conditions

can make troubleshooting easier and more accurate.

In general, each customer feels differently about a problem. It is

important to fully understand the symptoms or conditions for a

customer complaint.

Utilize a diagnostic worksheet like the one shown below in order to

organize all the information for troubleshooting.

WORKSHEET SAMPLE

Customer name MR/MS Model & Year VIN

Engine # Trans. Mileage

Incident Date Manuf. Date In Service Date

SymptomslStartabilitylImpossible to startlNo combustionlPartial combustion

lPartial combustion when warming-up engine

lPartial combustion when cooling down engine

lPossible but hard to startlOthers [ ]

lIdlinglNo fast idlelUnstablelHigh idlelLow idle

lOthers [ ]

lDriveabilitylStumblelSurgelKnocklLack of power

lOthers [ ]

lEngine stalllAt the time of startlWhile idling

lWhile acceleratinglWhile decelerating

lJust after stoppinglWhile loading

Incident occurrencelJust after deliverylRecently

lIn the morninglAt nightlIn the daytime

FrequencylAll the timelUnder certain conditionslSometimes

Weather conditionslNot affected

WeatherlFinelRaininglSnowinglOthers [ ]

TemperaturelHotlWarmlCoollColdlHumid ÉF

Engine conditionslColdlDuring warm-uplAfter warm-up

Engine speed

0 2,000 4,000 6,000 8,000 rpm

Road conditionslIn townlIn suburbslHighwaylOff road (up/down)

Driving conditionslNot affected

lAt startinglWhile idlinglAt racing

lWhile acceleratinglWhile cruising

lWhile deceleratinglWhile turning (RH/LH)

Vehicle speed

0 102030 405060708090100mph

Malfunction indicator lamplTurned onlNot turned on

SEF907L

TROUBLE DIAGNOSESTD27Ti

EC-335

Page 727 of 1767

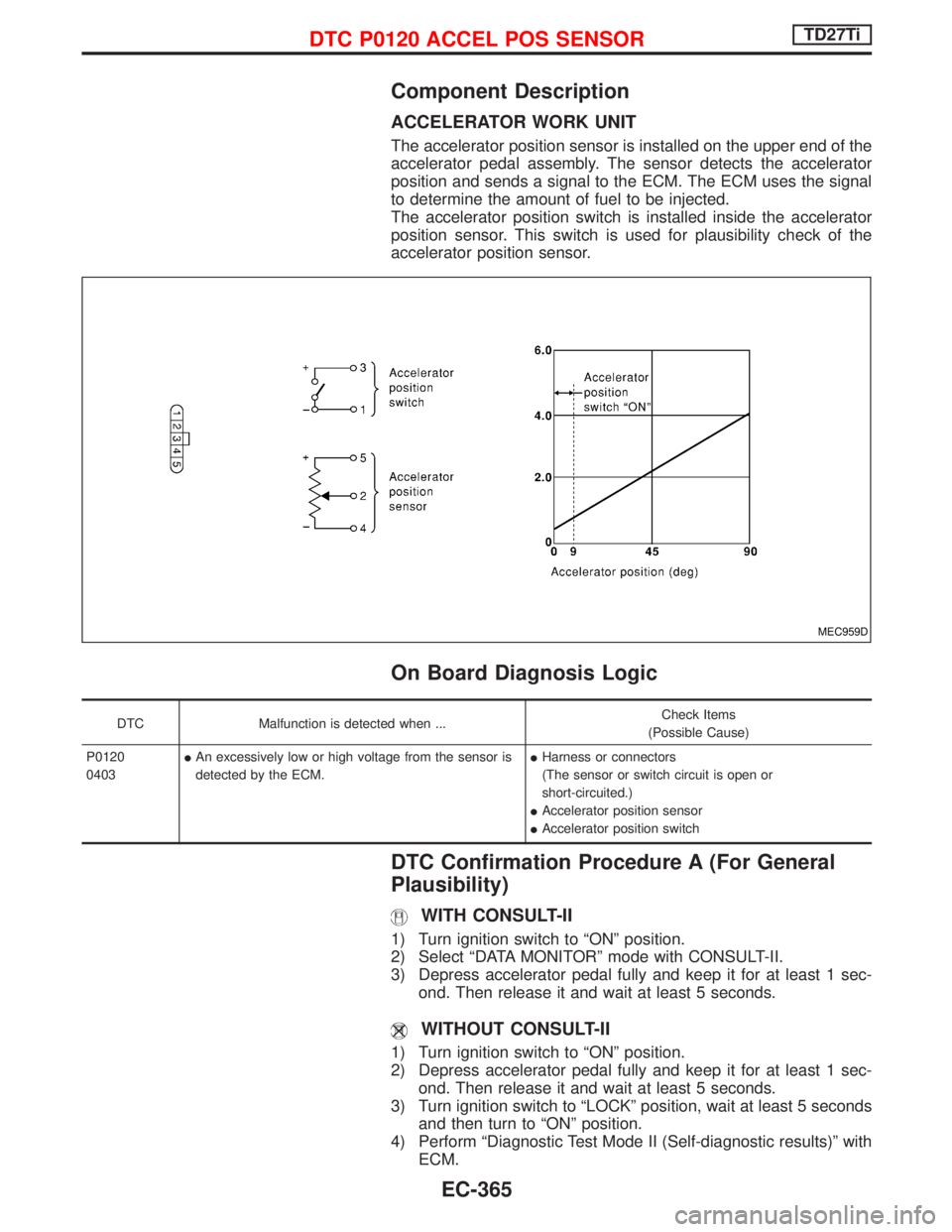

Component Description

ACCELERATOR WORK UNIT

The accelerator position sensor is installed on the upper end of the

accelerator pedal assembly. The sensor detects the accelerator

position and sends a signal to the ECM. The ECM uses the signal

to determine the amount of fuel to be injected.

The accelerator position switch is installed inside the accelerator

position sensor. This switch is used for plausibility check of the

accelerator position sensor.

On Board Diagnosis Logic

DTC Malfunction is detected when ...Check Items

(Possible Cause)

P0120

0403IAn excessively low or high voltage from the sensor is

detected by the ECM.IHarness or connectors

(The sensor or switch circuit is open or

short-circuited.)

IAccelerator position sensor

IAccelerator position switch

DTC Confirmation Procedure A (For General

Plausibility)

WITH CONSULT-II

1) Turn ignition switch to ªONº position.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Depress accelerator pedal fully and keep it for at least 1 sec-

ond. Then release it and wait at least 5 seconds.

WITHOUT CONSULT-II

1) Turn ignition switch to ªONº position.

2) Depress accelerator pedal fully and keep it for at least 1 sec-

ond. Then release it and wait at least 5 seconds.

3) Turn ignition switch to ªLOCKº position, wait at least 5 seconds

and then turn to ªONº position.

4) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with

ECM.

MEC959D

DTC P0120 ACCEL POS SENSORTD27Ti

EC-365

Page 815 of 1767

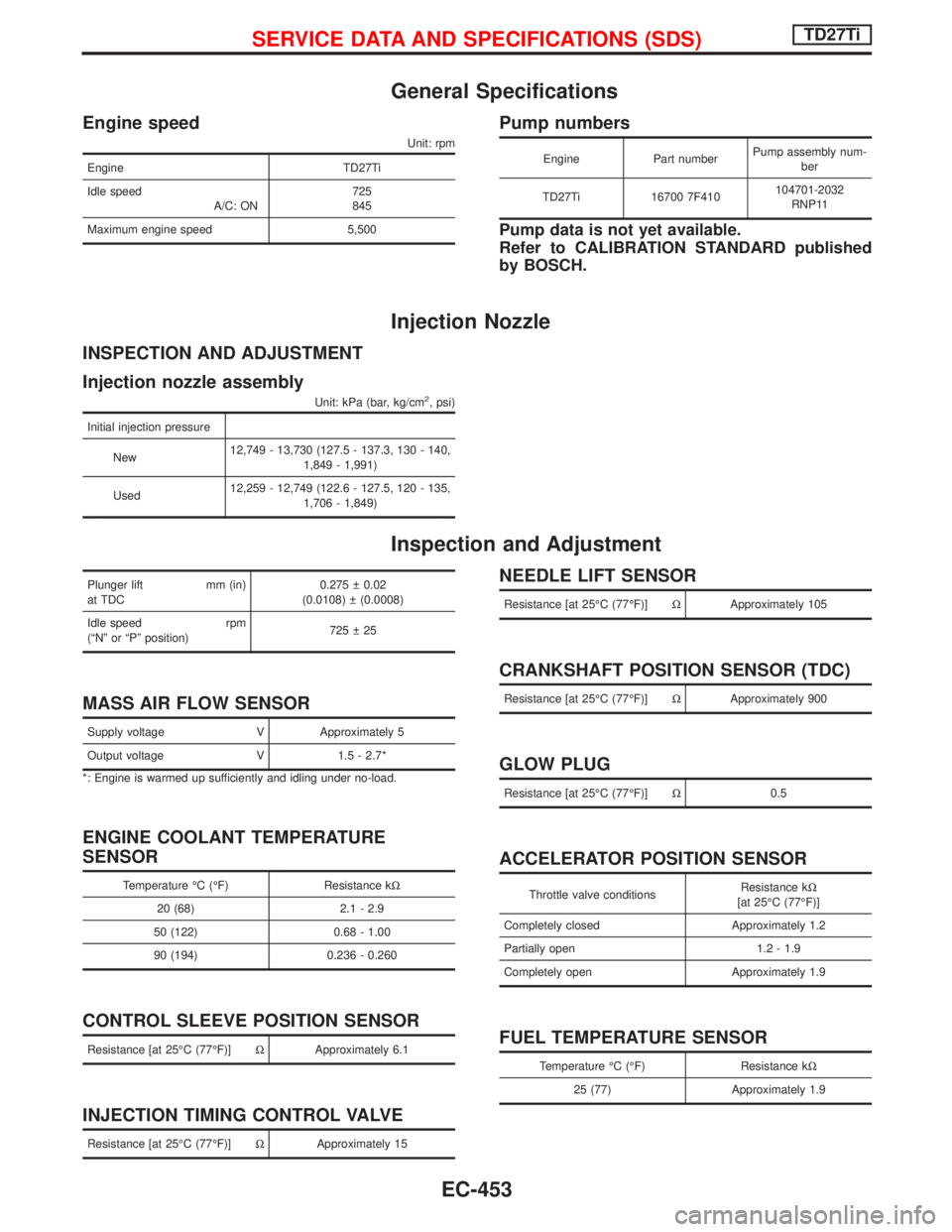

General Specifications

Engine speed

Unit: rpm

Engine TD27Ti

Idle speed

A/C: ON725

845

Maximum engine speed 5,500

Pump numbers

Engine Part numberPump assembly num-

ber

TD27Ti 16700 7F410104701-2032

RNP11

Pump data is not yet available.

Refer to CALIBRATION STANDARD published

by BOSCH.

Injection Nozzle

INSPECTION AND ADJUSTMENT

Injection nozzle assembly

Unit: kPa (bar, kg/cm2, psi)

Initial injection pressure

New12,749 - 13,730 (127.5 - 137.3, 130 - 140,

1,849 - 1,991)

Used12,259 - 12,749 (122.6 - 127.5, 120 - 135,

1,706 - 1,849)

Inspection and Adjustment

Plunger lift mm (in)

at TDC0.275 0.02

(0.0108) (0.0008)

Idle speed rpm

(ªNº or ªPº position)725 25

MASS AIR FLOW SENSOR

Supply voltage V Approximately 5

Output voltage V 1.5 - 2.7*

*: Engine is warmed up sufficiently and idling under no-load.

ENGINE COOLANT TEMPERATURE

SENSOR

Temperature ÉC (ÉF) Resistance kW

20 (68) 2.1 - 2.9

50 (122) 0.68 - 1.00

90 (194) 0.236 - 0.260

CONTROL SLEEVE POSITION SENSOR

Resistance [at 25ÉC (77ÉF)]WApproximately 6.1

INJECTION TIMING CONTROL VALVE

Resistance [at 25ÉC (77ÉF)]WApproximately 15

NEEDLE LIFT SENSOR

Resistance [at 25ÉC (77ÉF)]WApproximately 105

CRANKSHAFT POSITION SENSOR (TDC)

Resistance [at 25ÉC (77ÉF)]WApproximately 900

GLOW PLUG

Resistance [at 25ÉC (77ÉF)]W0.5

ACCELERATOR POSITION SENSOR

Throttle valve conditionsResistance kW

[at 25ÉC (77ÉF)]

Completely closed Approximately 1.2

Partially open 1.2 - 1.9

Completely open Approximately 1.9

FUEL TEMPERATURE SENSOR

Temperature ÉC (ÉF) Resistance kW

25 (77) Approximately 1.9

SERVICE DATA AND SPECIFICATIONS (SDS)TD27Ti

EC-453

Page 1109 of 1767

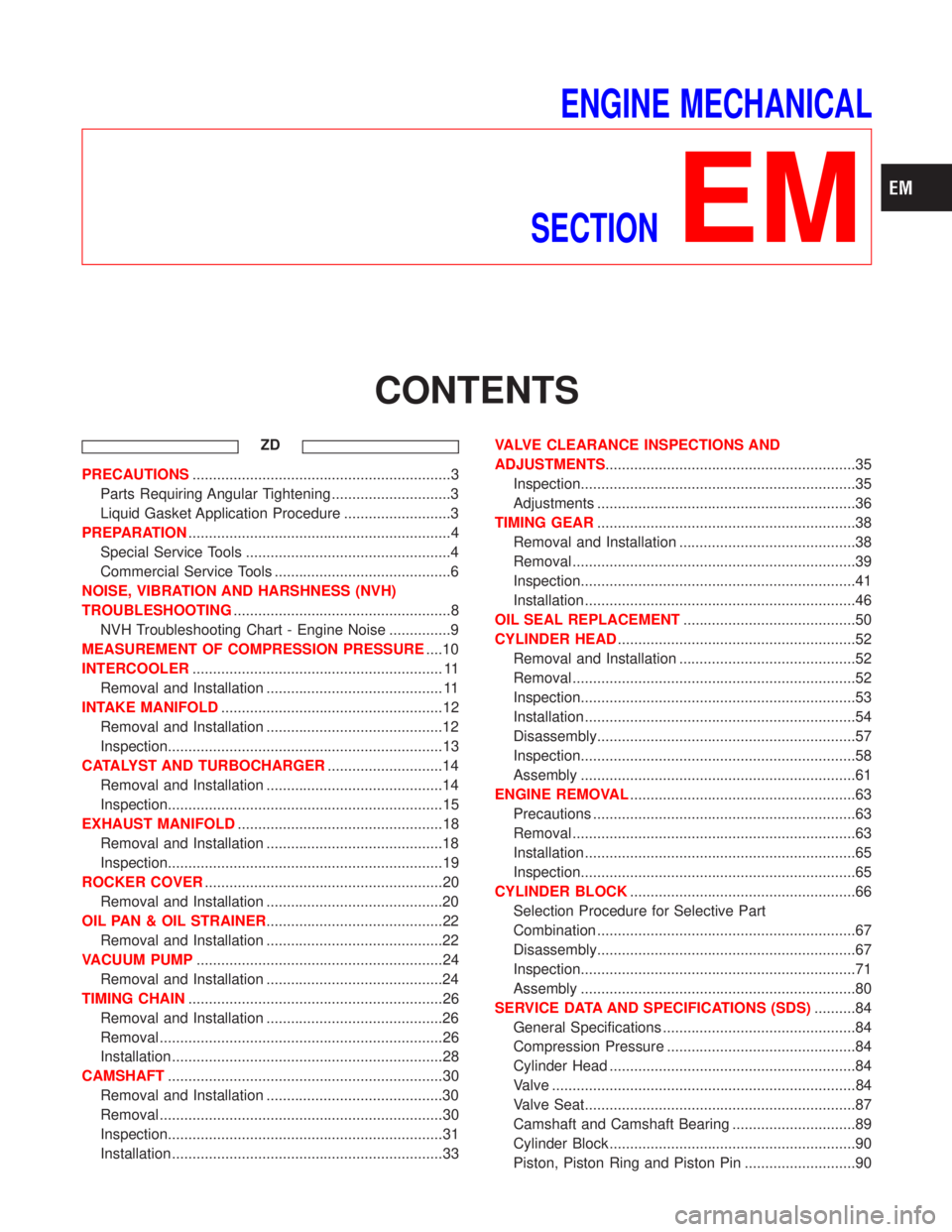

ENGINE MECHANICAL

SECTION

EM

CONTENTS

ZD

PRECAUTIONS...............................................................3

Parts Requiring Angular Tightening .............................3

Liquid Gasket Application Procedure ..........................3

PREPARATION................................................................4

Special Service Tools ..................................................4

Commercial Service Tools ...........................................6

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING.....................................................8

NVH Troubleshooting Chart - Engine Noise ...............9

MEASUREMENT OF COMPRESSION PRESSURE....10

INTERCOOLER............................................................. 11

Removal and Installation ........................................... 11

INTAKE MANIFOLD......................................................12

Removal and Installation ...........................................12

Inspection...................................................................13

CATALYST AND TURBOCHARGER............................14

Removal and Installation ...........................................14

Inspection...................................................................15

EXHAUST MANIFOLD..................................................18

Removal and Installation ...........................................18

Inspection...................................................................19

ROCKER COVER..........................................................20

Removal and Installation ...........................................20

OIL PAN & OIL STRAINER...........................................22

Removal and Installation ...........................................22

VACUUM PUMP............................................................24

Removal and Installation ...........................................24

TIMING CHAIN..............................................................26

Removal and Installation ...........................................26

Removal .....................................................................26

Installation ..................................................................28

CAMSHAFT...................................................................30

Removal and Installation ...........................................30

Removal .....................................................................30

Inspection...................................................................31

Installation ..................................................................33VALVE CLEARANCE INSPECTIONS AND

ADJUSTMENTS.............................................................35

Inspection...................................................................35

Adjustments ...............................................................36

TIMING GEAR...............................................................38

Removal and Installation ...........................................38

Removal .....................................................................39

Inspection...................................................................41

Installation ..................................................................46

OIL SEAL REPLACEMENT..........................................50

CYLINDER HEAD..........................................................52

Removal and Installation ...........................................52

Removal .....................................................................52

Inspection...................................................................53

Installation ..................................................................54

Disassembly...............................................................57

Inspection...................................................................58

Assembly ...................................................................61

ENGINE REMOVAL.......................................................63

Precautions ................................................................63

Removal .....................................................................63

Installation ..................................................................65

Inspection...................................................................65

CYLINDER BLOCK.......................................................66

Selection Procedure for Selective Part

Combination ...............................................................67

Disassembly...............................................................67

Inspection...................................................................71

Assembly ...................................................................80

SERVICE DATA AND SPECIFICATIONS (SDS)..........84

General Specifications ...............................................84

Compression Pressure ..............................................84

Cylinder Head ............................................................84

Valve ..........................................................................84

Valve Seat..................................................................87

Camshaft and Camshaft Bearing ..............................89

Cylinder Block ............................................................90

Piston, Piston Ring and Piston Pin ...........................90

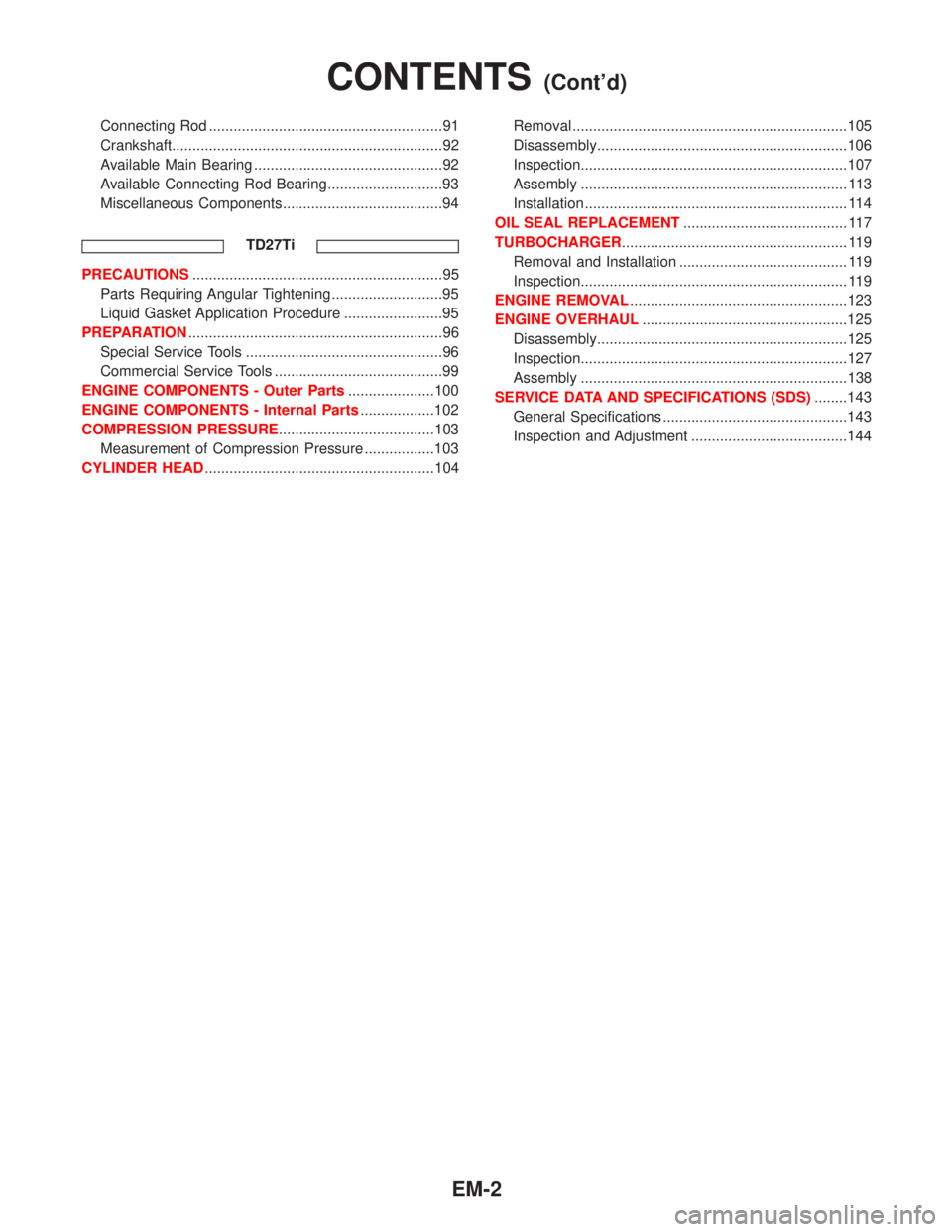

Page 1110 of 1767

Connecting Rod .........................................................91

Crankshaft..................................................................92

Available Main Bearing ..............................................92

Available Connecting Rod Bearing............................93

Miscellaneous Components.......................................94

TD27Ti

PRECAUTIONS.............................................................95

Parts Requiring Angular Tightening ...........................95

Liquid Gasket Application Procedure ........................95

PREPARATION..............................................................96

Special Service Tools ................................................96

Commercial Service Tools .........................................99

ENGINE COMPONENTS - Outer Parts.....................100

ENGINE COMPONENTS - Internal Parts..................102

COMPRESSION PRESSURE......................................103

Measurement of Compression Pressure .................103

CYLINDER HEAD........................................................104Removal ...................................................................105

Disassembly.............................................................106

Inspection.................................................................107

Assembly ................................................................. 113

Installation ................................................................ 114

OIL SEAL REPLACEMENT........................................ 117

TURBOCHARGER....................................................... 119

Removal and Installation ......................................... 119

Inspection................................................................. 119

ENGINE REMOVAL.....................................................123

ENGINE OVERHAUL..................................................125

Disassembly.............................................................125

Inspection.................................................................127

Assembly .................................................................138

SERVICE DATA AND SPECIFICATIONS (SDS)........143

General Specifications .............................................143

Inspection and Adjustment ......................................144

CONTENTS(Cont'd)

EM-2

Page 1125 of 1767

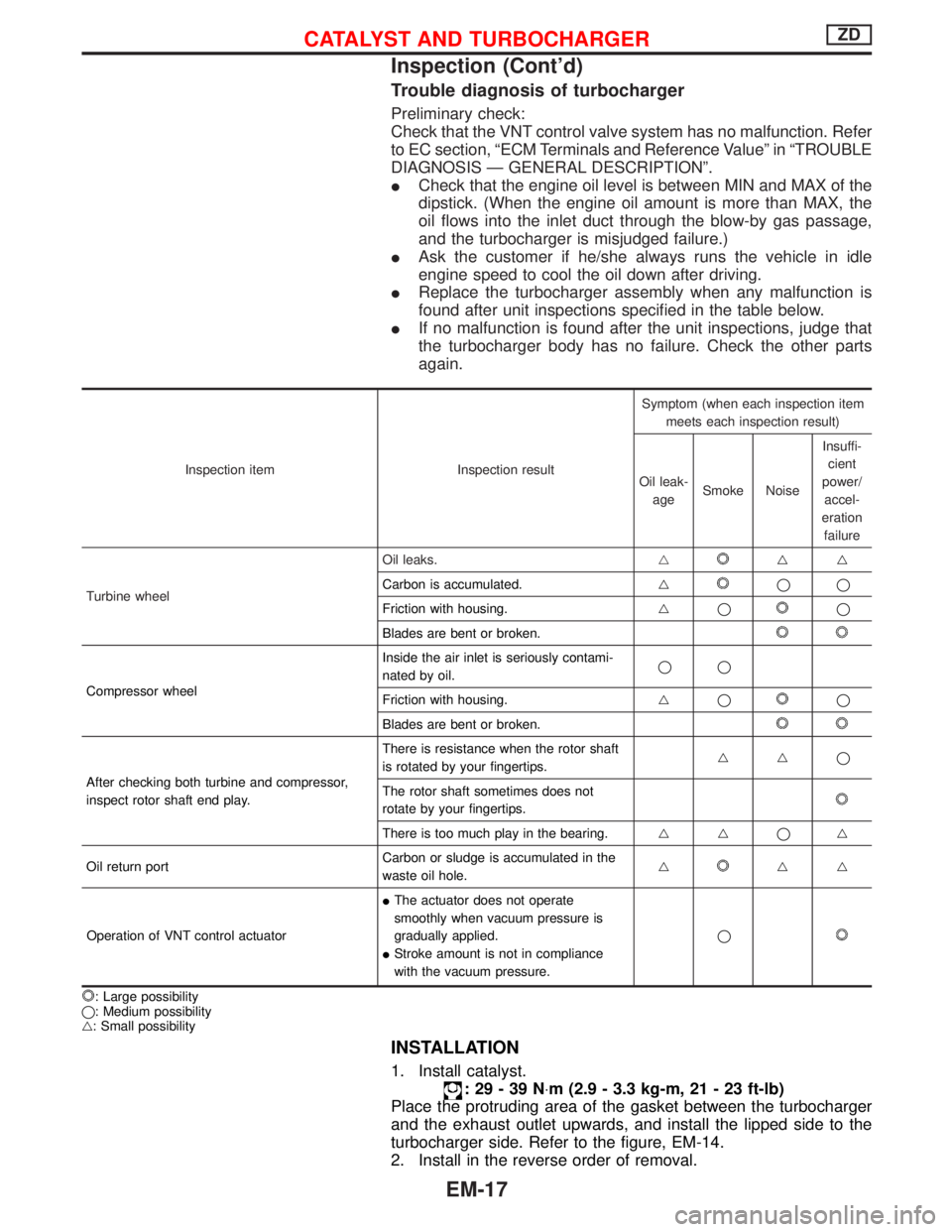

Trouble diagnosis of turbocharger

Preliminary check:

Check that the VNT control valve system has no malfunction. Refer

to EC section, ªECM Terminals and Reference Valueº in ªTROUBLE

DIAGNOSIS Ð GENERAL DESCRIPTIONº.

ICheck that the engine oil level is between MIN and MAX of the

dipstick. (When the engine oil amount is more than MAX, the

oil flows into the inlet duct through the blow-by gas passage,

and the turbocharger is misjudged failure.)

IAsk the customer if he/she always runs the vehicle in idle

engine speed to cool the oil down after driving.

IReplace the turbocharger assembly when any malfunction is

found after unit inspections specified in the table below.

IIf no malfunction is found after the unit inspections, judge that

the turbocharger body has no failure. Check the other parts

again.

Inspection item Inspection resultSymptom (when each inspection item

meets each inspection result)

Oil leak-

ageSmoke NoiseInsuffi-

cient

power/

accel-

eration

failure

Turbine wheelOil leaks.g

gg

Carbon is accumulated.g

qq

Friction with housing.gq

q

Blades are bent or broken.

Compressor wheelInside the air inlet is seriously contami-

nated by oil.qq

Friction with housing.gqq

Blades are bent or broken.

After checking both turbine and compressor,

inspect rotor shaft end play.There is resistance when the rotor shaft

is rotated by your fingertips.ggq

The rotor shaft sometimes does not

rotate by your fingertips.

There is too much play in the bearing.ggqg

Oil return portCarbon or sludge is accumulated in the

waste oil hole.g

gg

Operation of VNT control actuatorIThe actuator does not operate

smoothly when vacuum pressure is

gradually applied.

IStroke amount is not in compliance

with the vacuum pressure.q

: Large possibility

q: Medium possibility

g: Small possibility

INSTALLATION

1. Install catalyst.

:29-39N×m (2.9 - 3.3 kg-m, 21 - 23 ft-lb)

Place the protruding area of the gasket between the turbocharger

and the exhaust outlet upwards, and install the lipped side to the

turbocharger side. Refer to the figure, EM-14.

2. Install in the reverse order of removal.

CATALYST AND TURBOCHARGERZD

Inspection (Cont'd)

EM-17

Page 1192 of 1767

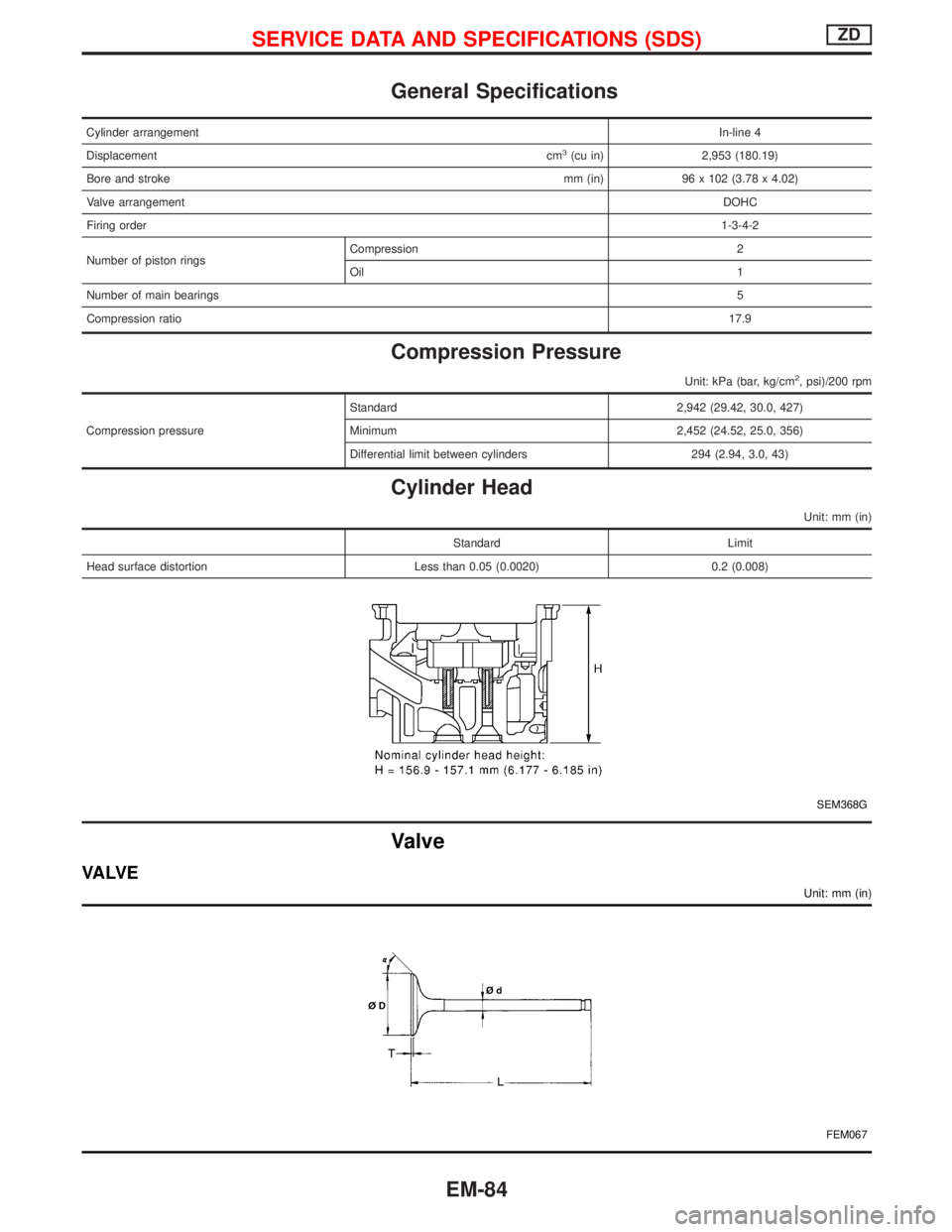

General Specifications

Cylinder arrangementIn-line 4

Displacementcm

3(cu in) 2,953 (180.19)

Bore and strokemm (in) 96 x 102 (3.78 x 4.02)

Valve arrangementDOHC

Firing order1-3-4-2

Number of piston ringsCompression 2

Oil1

Number of main bearings5

Compression ratio17.9

Compression Pressure

Unit: kPa (bar, kg/cm2, psi)/200 rpm

Compression pressureStandard 2,942 (29.42, 30.0, 427)

Minimum 2,452 (24.52, 25.0, 356)

Differential limit between cylinders 294 (2.94, 3.0, 43)

Cylinder Head

Unit: mm (in)

Standard Limit

Head surface distortion Less than 0.05 (0.0020) 0.2 (0.008)

SEM368G

Valve

VA LV E

Unit: mm (in)

FEM067

SERVICE DATA AND SPECIFICATIONS (SDS)ZD

EM-84